DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: fuel fill door release, maintenance, clock, park assist, instrument cluster, lumbar support, washer fluid

Page 2551 of 5267

INPUT SHAFT

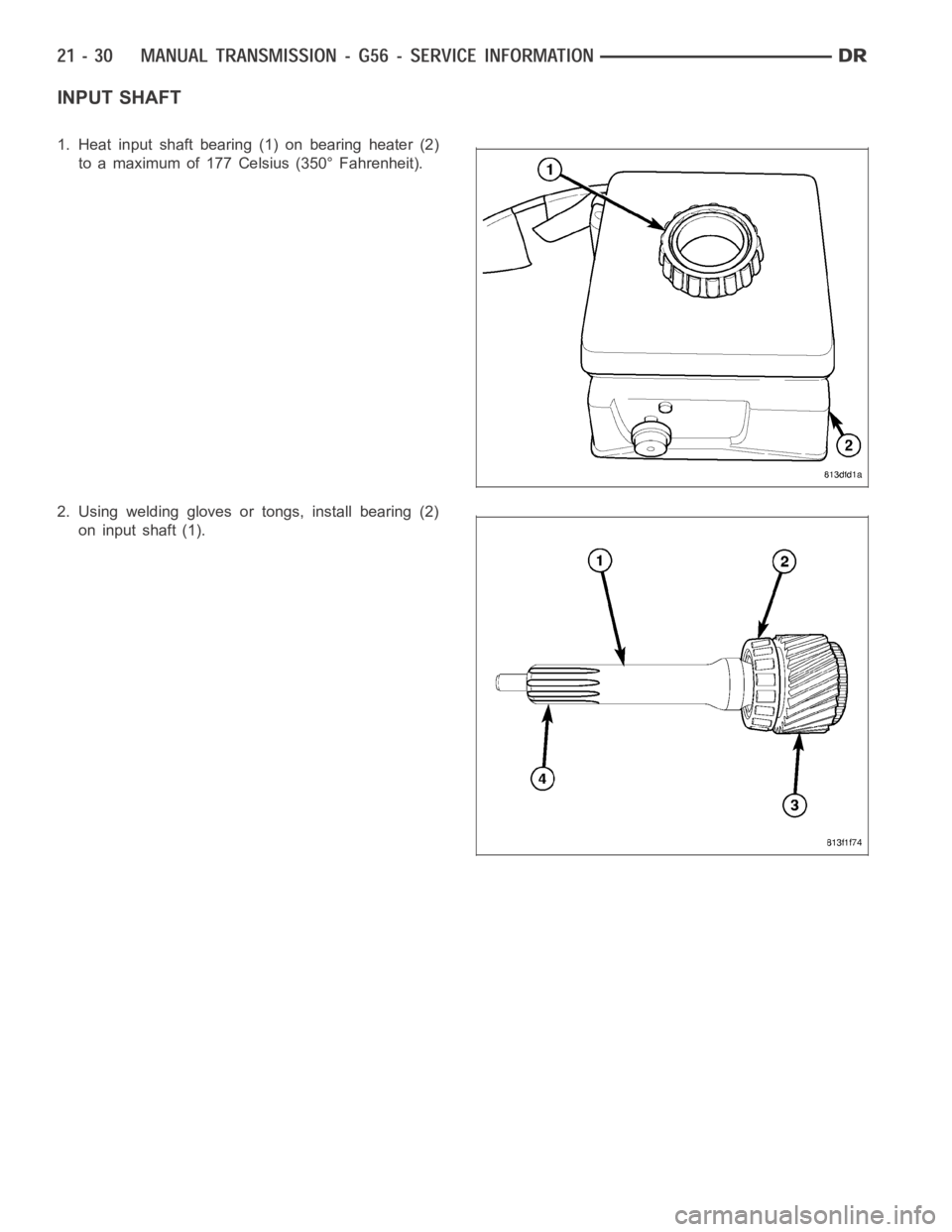

1. Heat input shaft bearing (1) on bearing heater (2)

to a maximum of 177 Celsius (350° Fahrenheit).

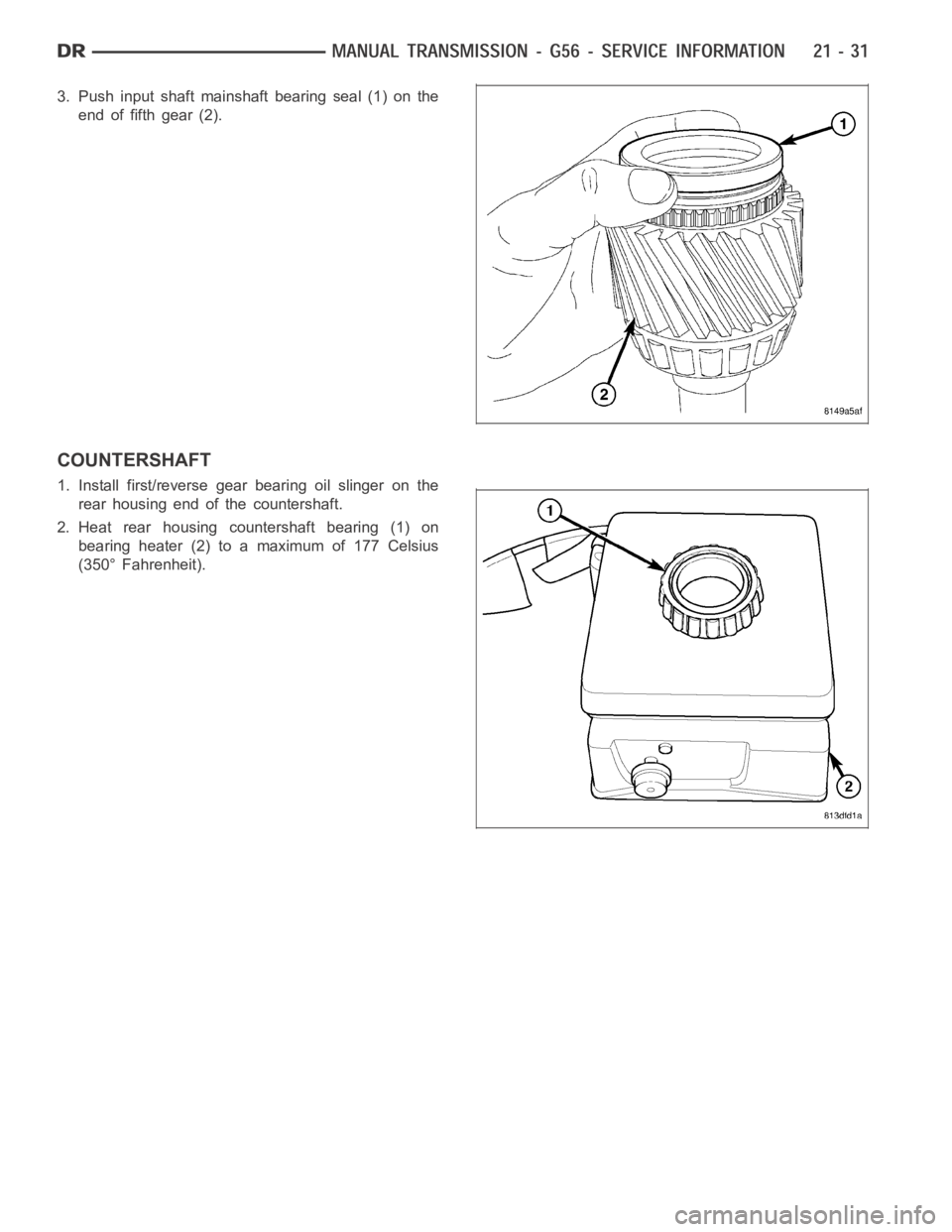

2. Using welding gloves or tongs, install bearing (2)

on input shaft (1).

Page 2552 of 5267

3. Push input shaft mainshaft bearing seal (1) on the

end of fifth gear (2).

COUNTERSHAFT

1. Install first/reverse gear bearing oil slinger on the

rear housing end of the countershaft.

2. Heat rear housing countershaft bearing (1) on

bearing heater (2) to a maximum of 177 Celsius

(350° Fahrenheit).

Page 2553 of 5267

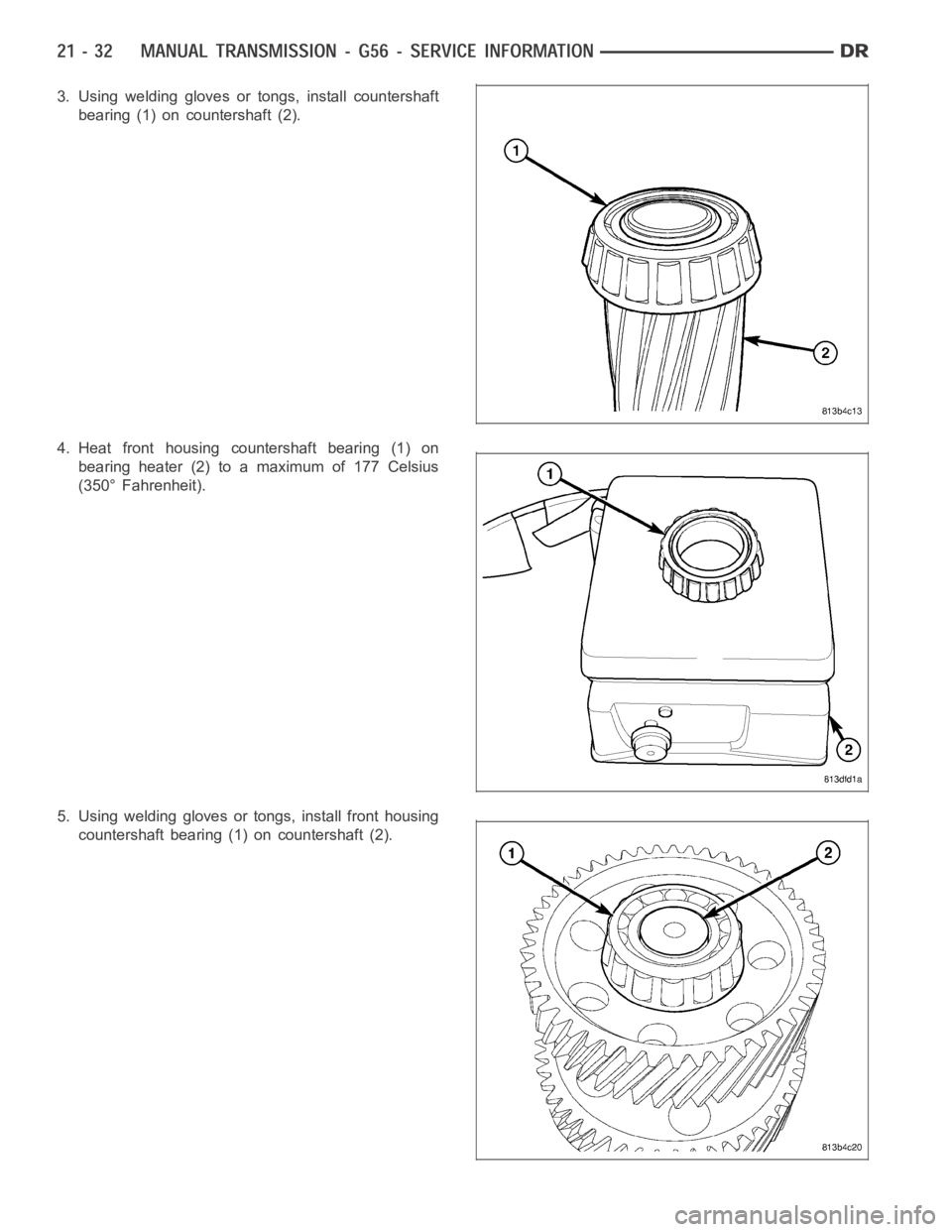

3. Using welding gloves or tongs, install countershaft

bearing (1) on countershaft (2).

4. Heat front housing countershaft bearing (1) on

bearing heater (2) to a maximum of 177 Celsius

(350° Fahrenheit).

5. Using welding gloves or tongs, install front housing

countershaft bearing (1) on countershaft (2).

Page 2554 of 5267

MAINSHAFT

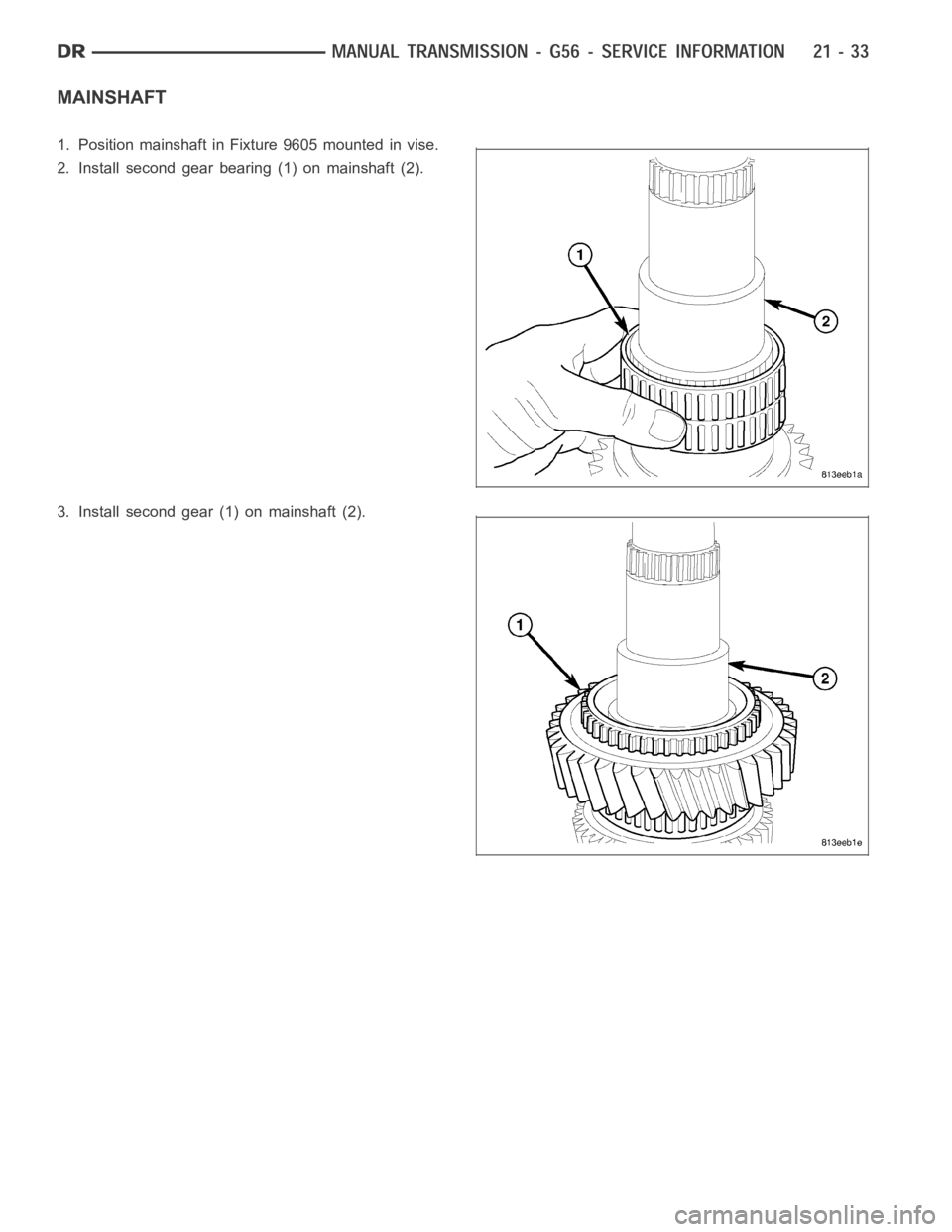

1. Position mainshaft in Fixture 9605 mounted in vise.

2. Install second gear bearing (1) on mainshaft (2).

3. Install second gear (1) on mainshaft (2).

Page 2555 of 5267

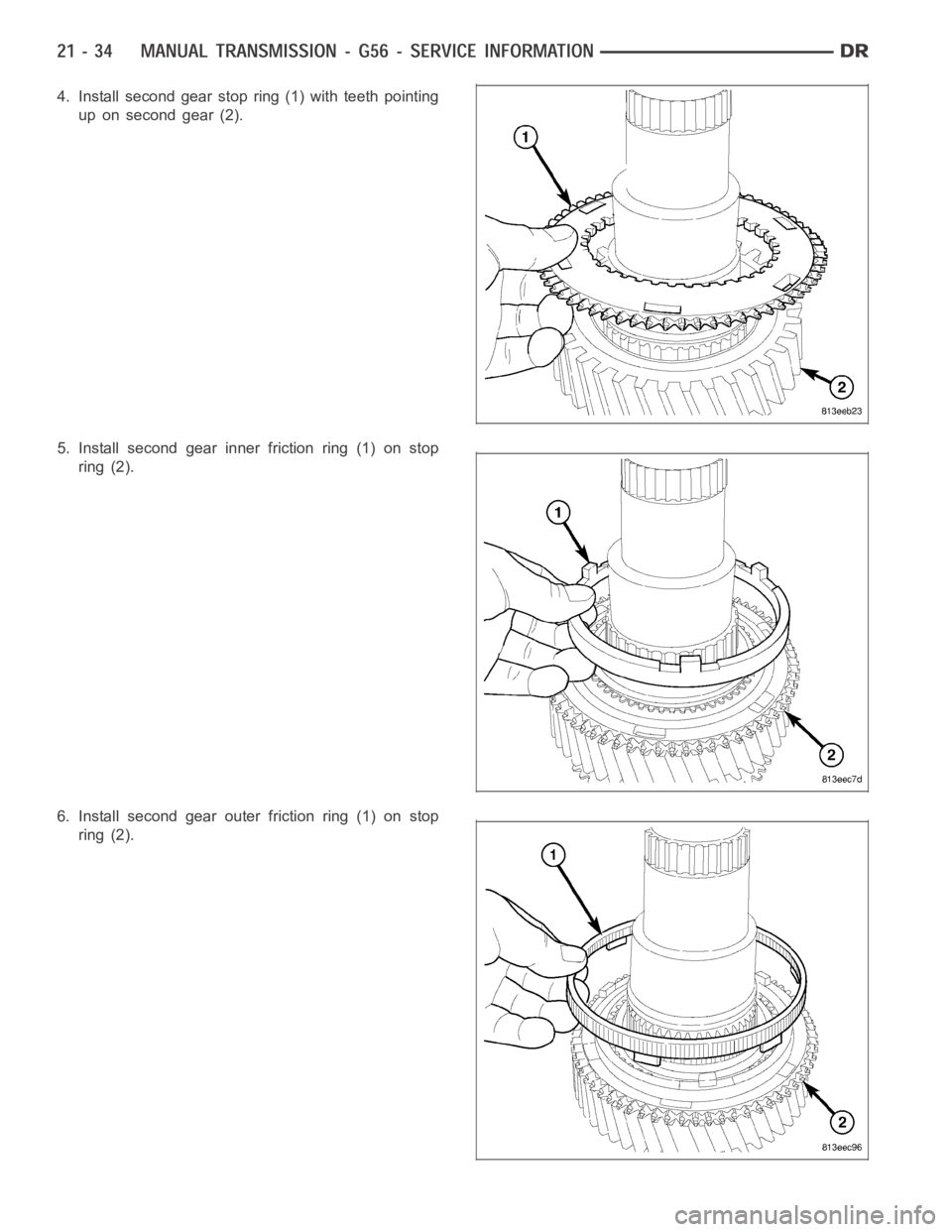

4. Install second gear stop ring (1) with teeth pointing

up on second gear (2).

5. Install second gear inner friction ring (1) on stop

ring (2).

6. Install second gear outer friction ring (1) on stop

ring (2).

Page 2556 of 5267

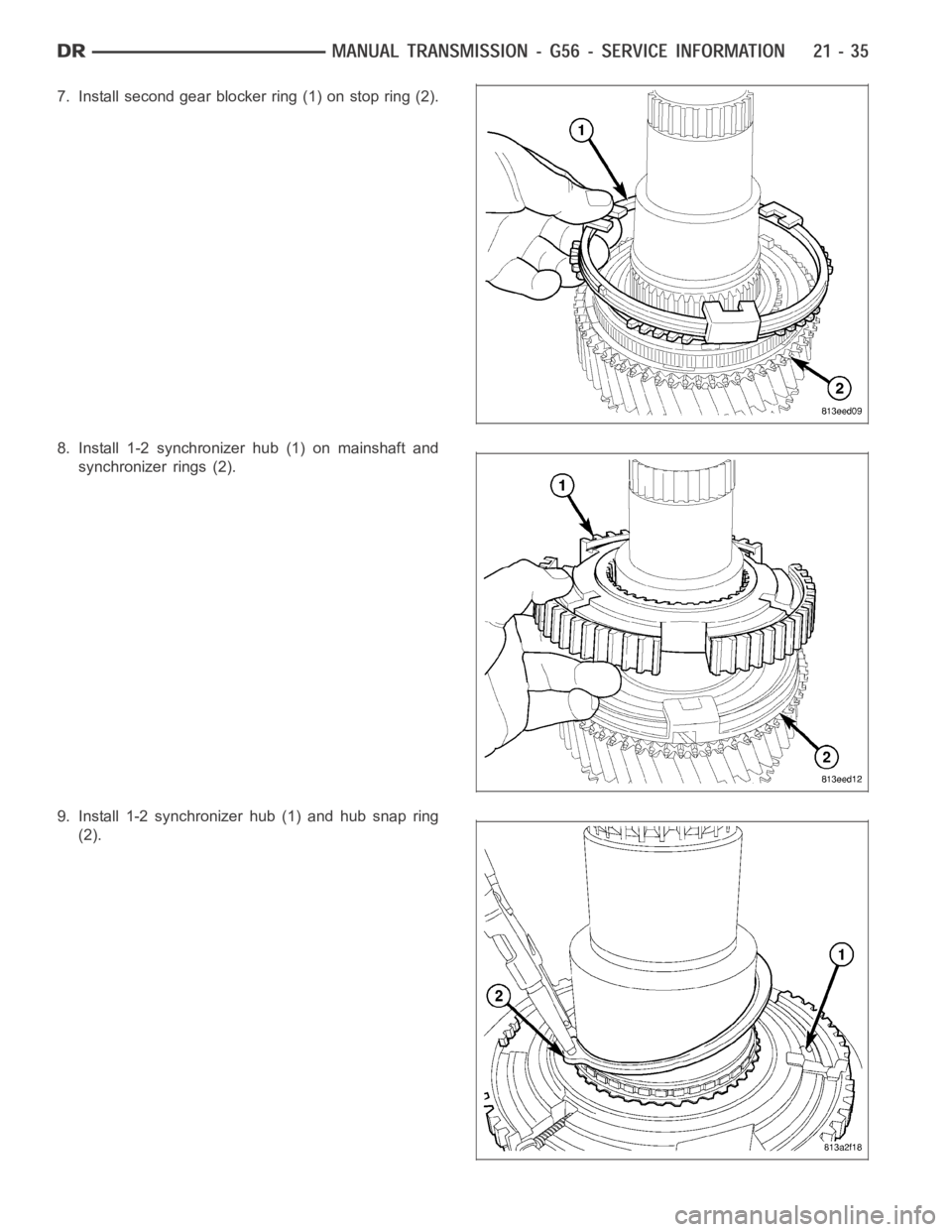

7. Install second gear blocker ring (1) on stop ring (2).

8. Install 1-2 synchronizer hub (1) on mainshaft and

synchronizer rings (2).

9. Install 1-2 synchronizer hub (1) and hub snap ring

(2).

Page 2557 of 5267

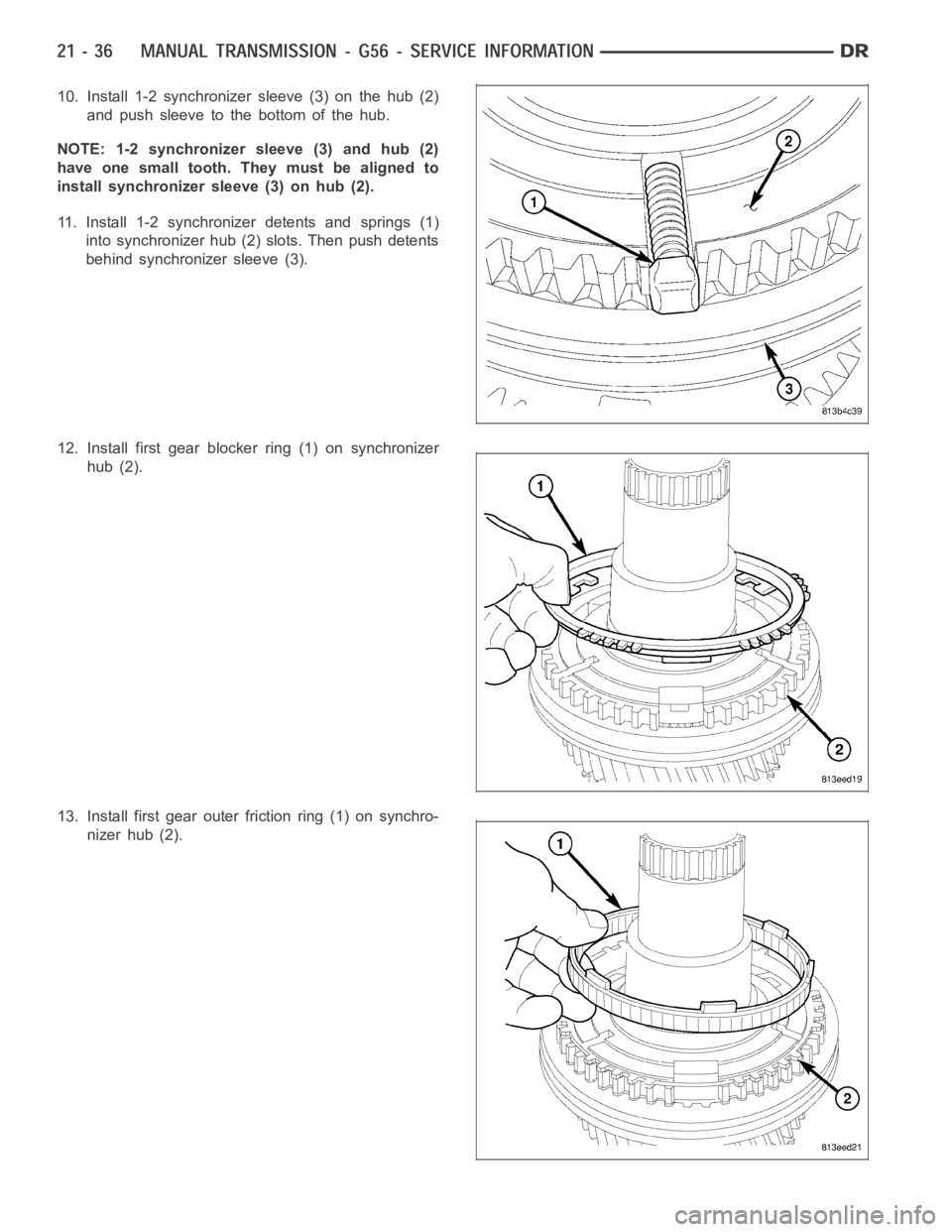

10. Install 1-2 synchronizer sleeve (3) on the hub (2)

and push sleeve to the bottom of the hub.

NOTE: 1-2 synchronizer sleeve (3) and hub (2)

have one small tooth. They must be aligned to

install synchronizer sleeve (3) on hub (2).

11. Install 1-2 synchronizer detents and springs (1)

into synchronizer hub (2) slots. Then push detents

behind synchronizer sleeve (3).

12. Install first gear blocker ring (1) on synchronizer

hub (2).

13. Install first gear outer friction ring (1) on synchro-

nizer hub (2).

Page 2558 of 5267

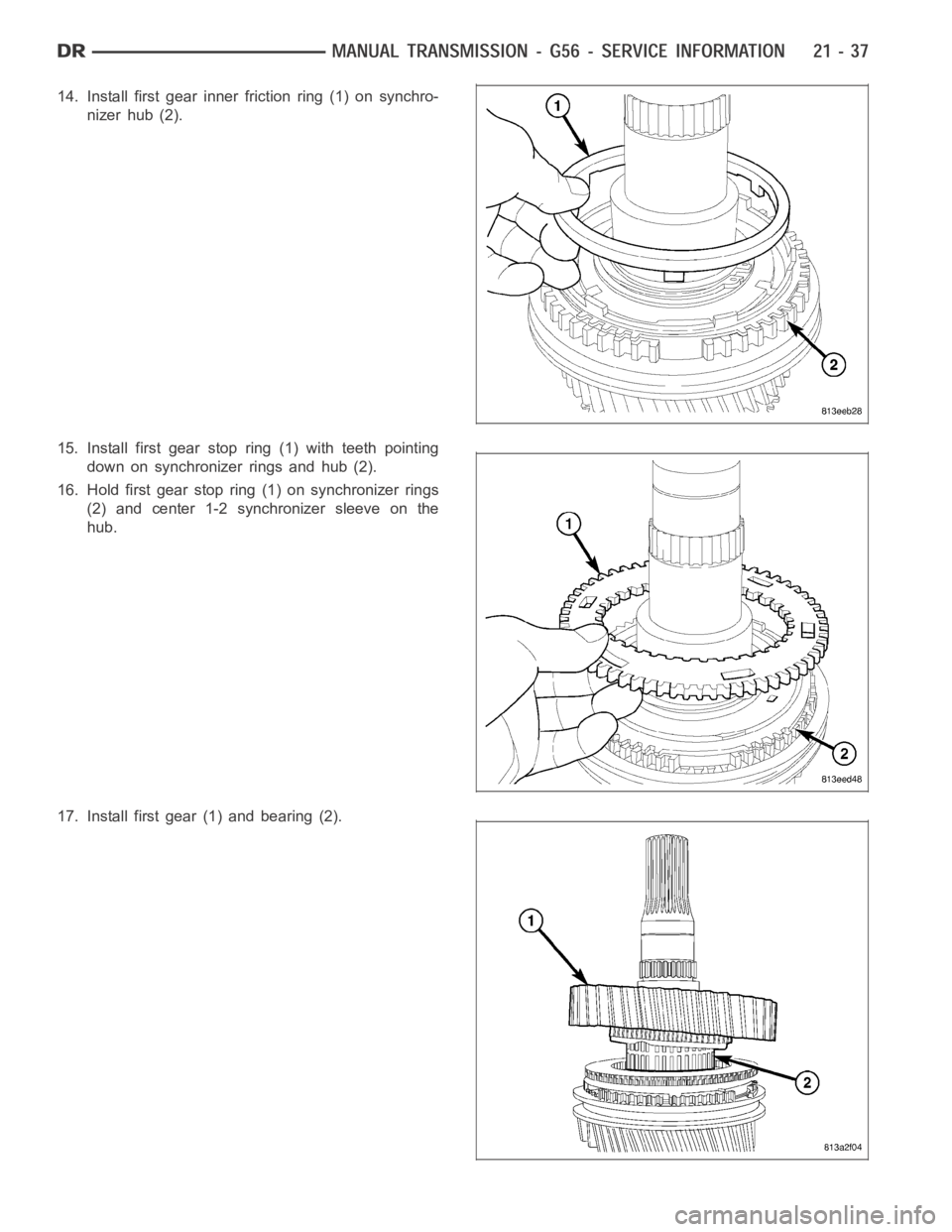

14. Install first gear inner friction ring (1) on synchro-

nizer hub (2).

15. Install first gear stop ring (1) with teeth pointing

down on synchronizer rings and hub (2).

16. Hold first gear stop ring (1) on synchronizer rings

(2) and center 1-2 synchronizer sleeve on the

hub.

17. Install first gear (1) and bearing (2).

Page 2559 of 5267

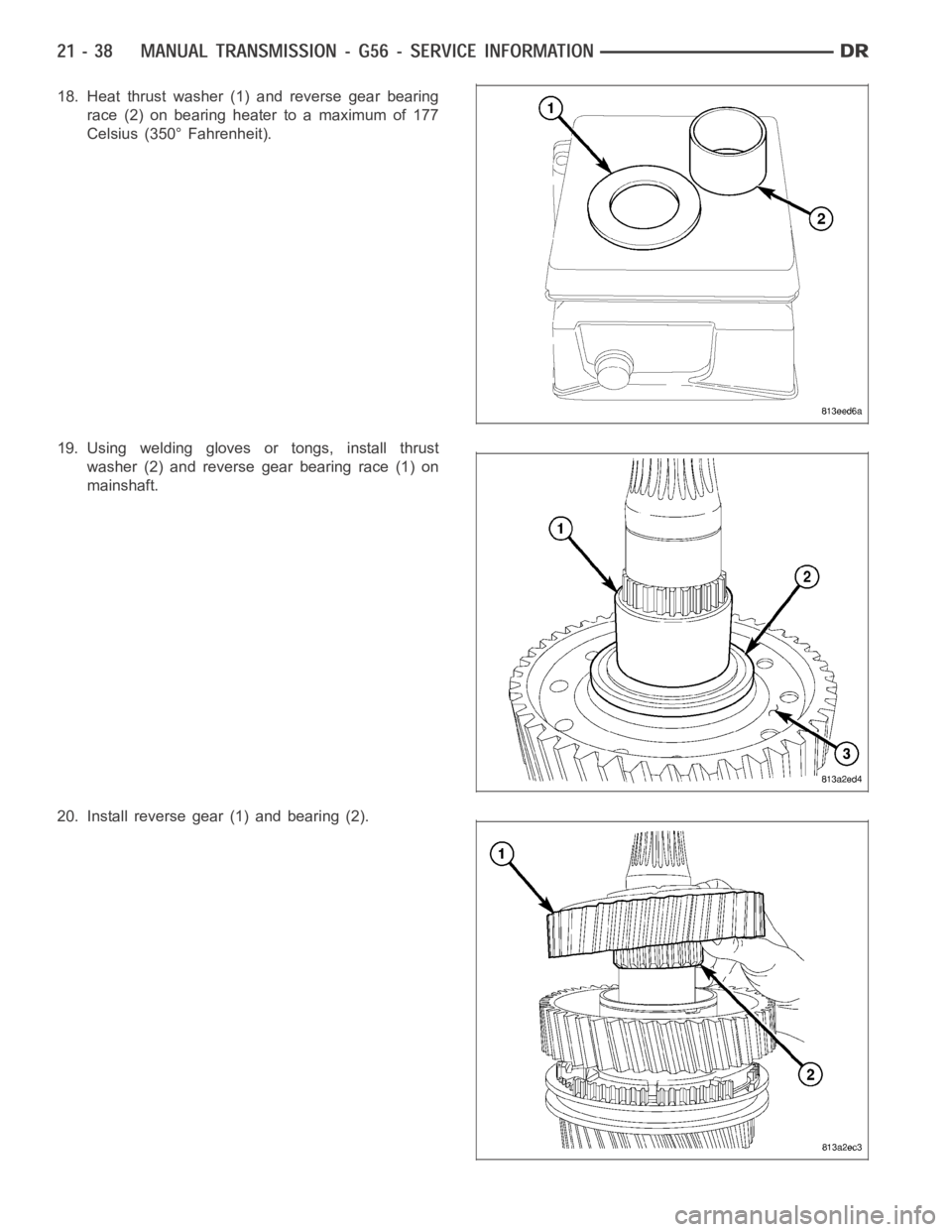

18. Heat thrust washer (1) and reverse gear bearing

race (2) on bearing heater to a maximum of 177

Celsius (350° Fahrenheit).

19. Using welding gloves or tongs, install thrust

washer (2) and reverse gear bearing race (1) on

mainshaft.

20. Install reverse gear (1) and bearing (2).

Page 2560 of 5267

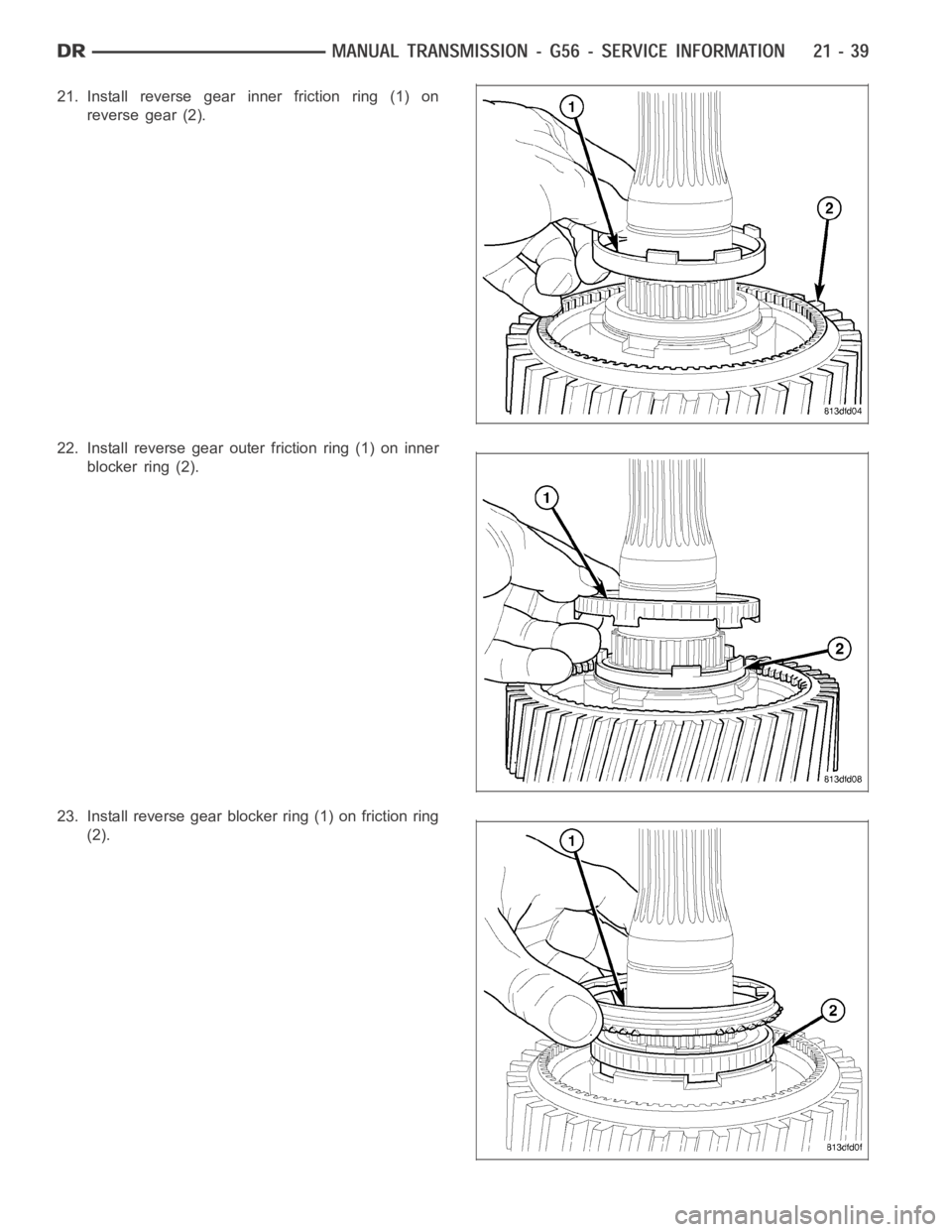

21. Install reverse gear inner friction ring (1) on

reverse gear (2).

22. Install reverse gear outer friction ring (1) on inner

blocker ring (2).

23. Install reverse gear blocker ring (1) on friction ring

(2).

Trending: flat tire, oil dipstick, fuel pump, cooling, diagram, oil filter, load capacity