torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3372 of 5267

Some suspected converter housing fluid leaks may not be leaks at all. They may only be the result of residual fluid

in the converter housing, or excess fluid spilled during factory fill or fill after repair. Converter housing leaks have

several potential sources. Through careful observation, a leak source can be identified before removing the trans-

mission for repair. Torque converter seal leaks tend to move along the drive hub and onto the rear of the converter.

Pump cover seal leaks tend to run down the cover and the inside surface of thebellhousing.

Some leaks, or suspected leaks, may be particularly difficult to locate. If necessary, a Mopar

approved dye should

be used to locate and confirm a leak.

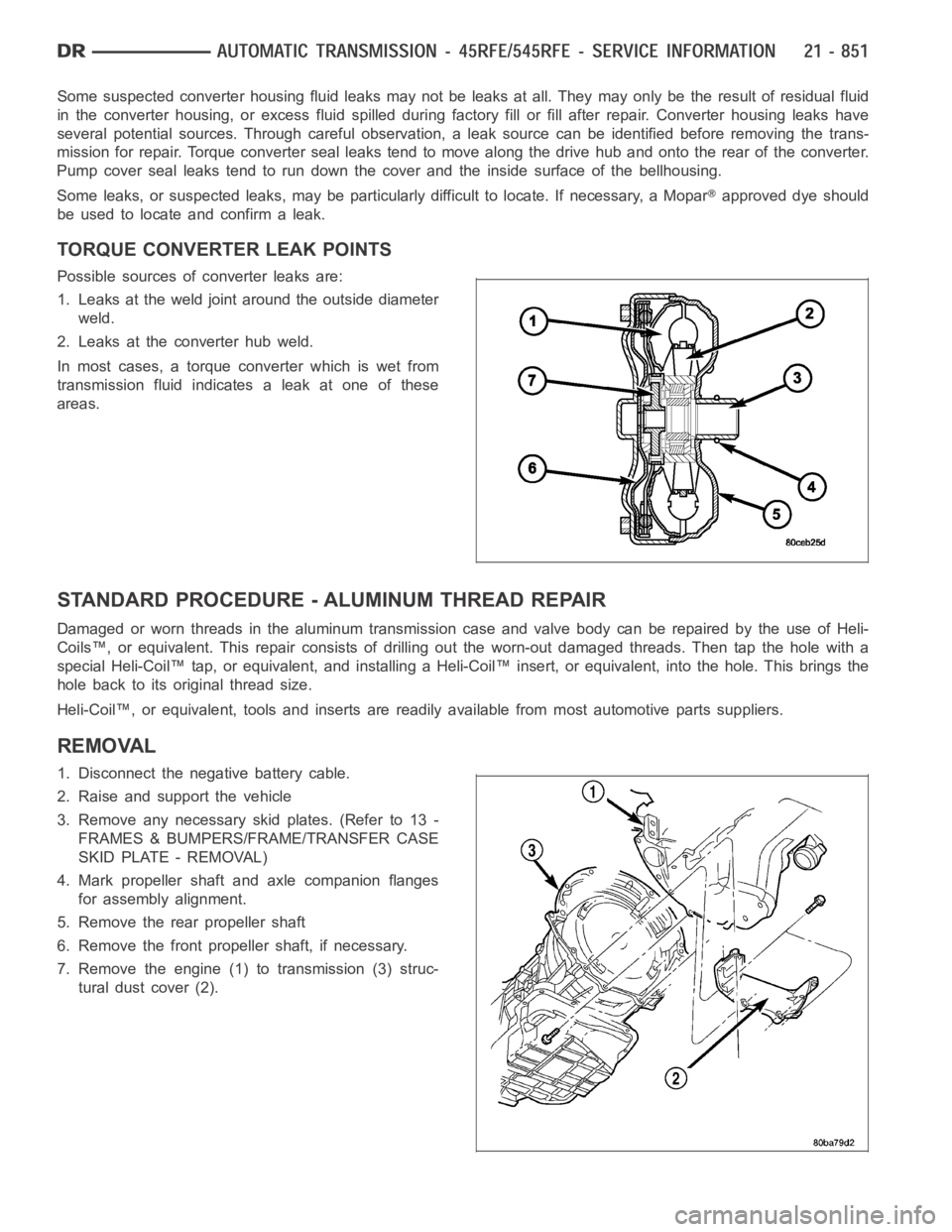

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

1. Leaks at the weld joint around the outside diameter

weld.

2. Leaks at the converter hub weld.

In most cases, a torque converter which is wet from

transmission fluid indicates a leak at one of these

areas.

STANDARD PROCEDURE - ALUMINUM THREAD REPAIR

DamagedorwornthreadsinthealuminumtransmissioncaseandvalvebodycanberepairedbytheuseofHeli-

Coils™, or equivalent. This repair consists of drilling out the worn-out damaged threads. Then tap the hole with a

special Heli-Coil™ tap, or equivalent, and installing a Heli-Coil™ insert, or equivalent, into the hole. This brings the

hole back to its original thread size.

Heli-Coil™, or equivalent, tools and inserts are readily available from most automotive parts suppliers.

REMOVAL

1. Disconnect the negative battery cable.

2. Raise and support the vehicle

3. Remove any necessary skid plates. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

4. Mark propeller shaft and axle companion flanges

for assembly alignment.

5. Remove the rear propeller shaft

6. Remove the front propeller shaft, if necessary.

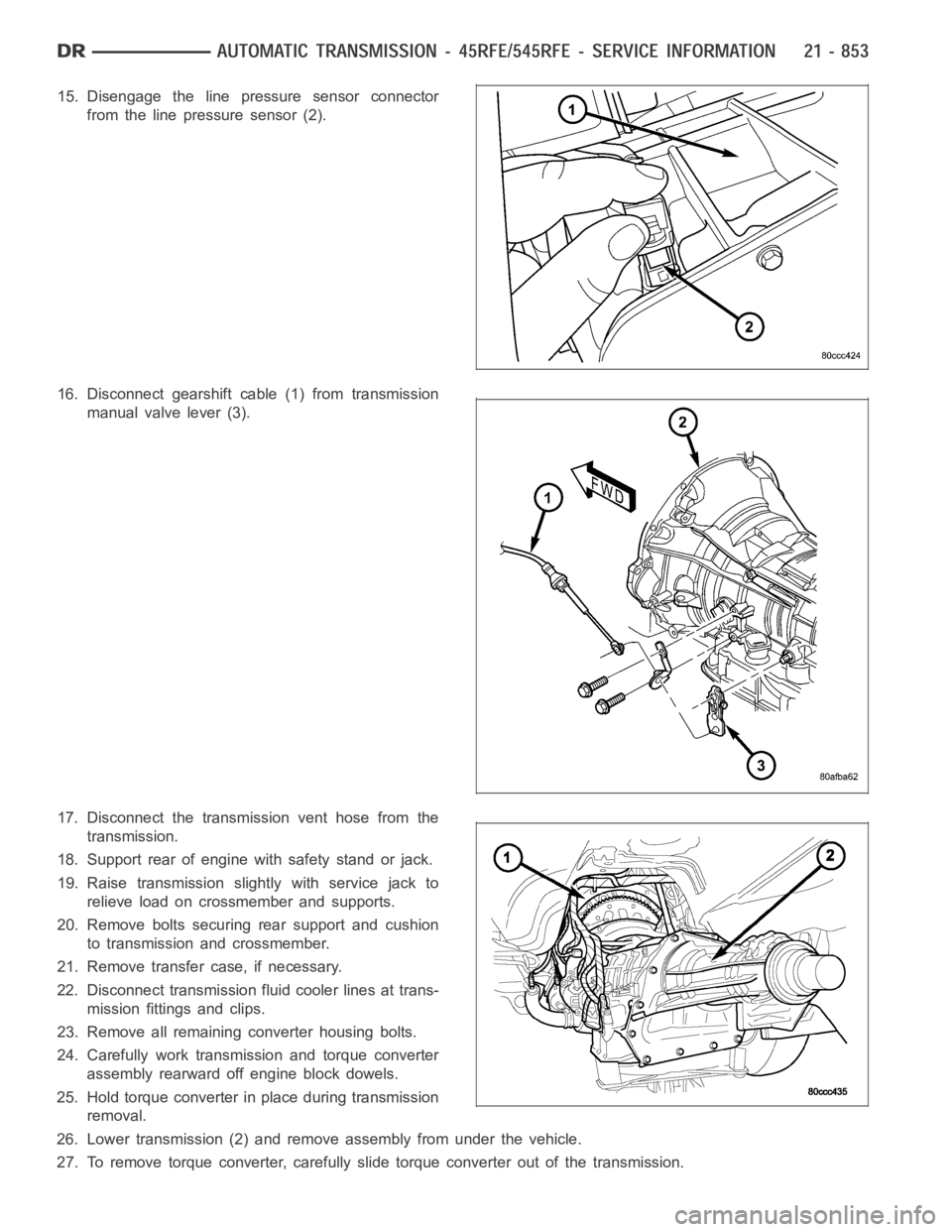

7. Remove the engine (1) to transmission (3) struc-

tural dust cover (2).

Page 3374 of 5267

15. Disengage the line pressure sensor connector

from the line pressure sensor (2).

16. Disconnect gearshift cable (1) from transmission

manual valve lever (3).

17. Disconnect the transmission vent hose from the

transmission.

18. Support rear of engine with safety stand or jack.

19. Raise transmission slightly with service jack to

relieve load on crossmember and supports.

20. Remove bolts securing rear support and cushion

to transmission and crossmember.

21. Remove transfer case, if necessary.

22. Disconnect transmission fluid cooler lines at trans-

mission fittings and clips.

23. Remove all remaining converter housing bolts.

24. Carefully work transmission and torque converter

assembly rearward off engine block dowels.

25. Hold torque converter in place during transmission

removal.

26. Lower transmission (2) and remove assembly from under the vehicle.

27. To remove torque converter, carefully slide torque converter out of the transmission.

Page 3375 of 5267

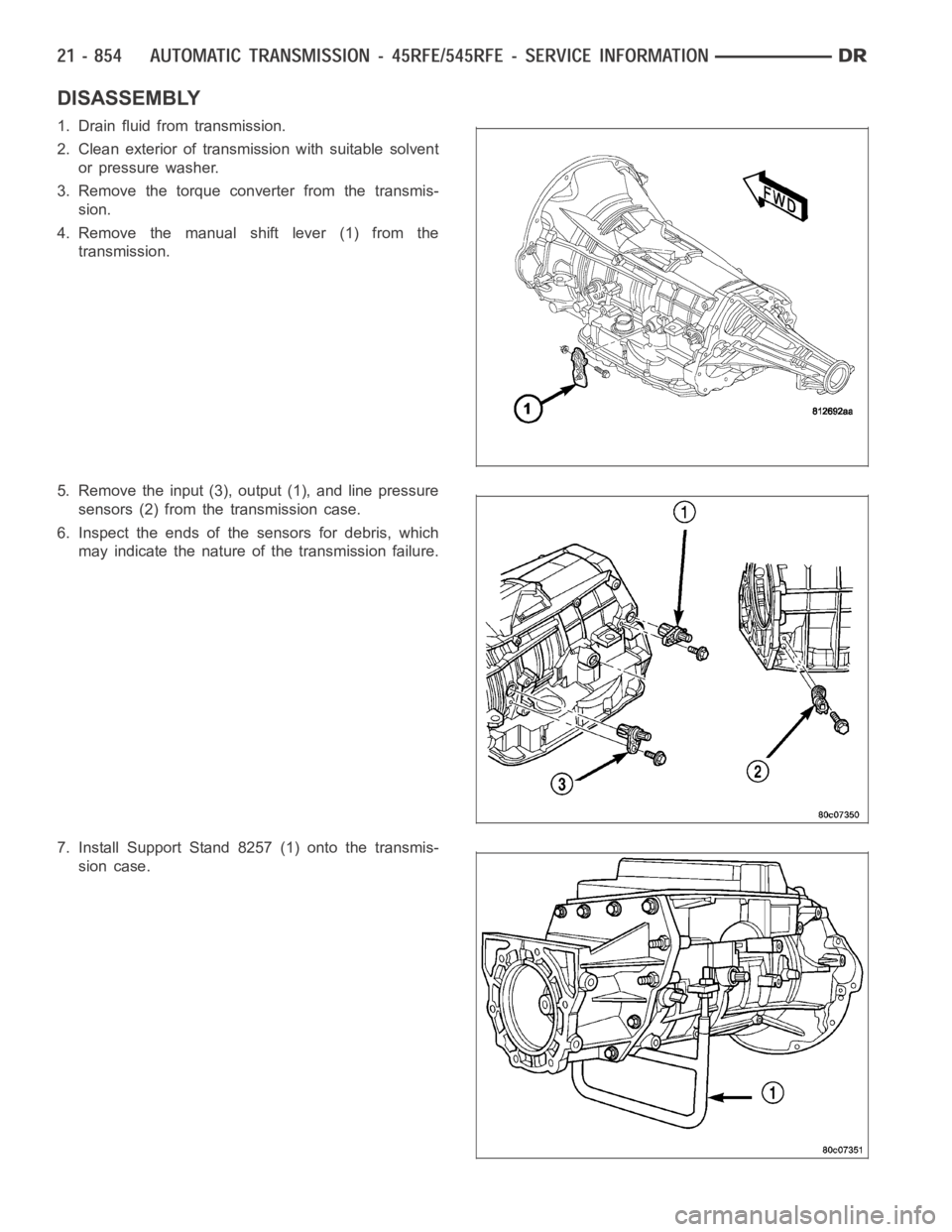

DISASSEMBLY

1. Drain fluid from transmission.

2. Clean exterior of transmission with suitable solvent

or pressure washer.

3. Remove the torque converter from the transmis-

sion.

4. Remove the manual shift lever (1) from the

transmission.

5. Remove the input (3), output (1), and line pressure

sensors (2) from the transmission case.

6. Inspect the ends of the sensors for debris, which

may indicate the nature of the transmission failure.

7. Install Support Stand 8257 (1) onto the transmis-

sion case.

Page 3382 of 5267

NOTE: Do not use shop towels or rags to dry the case (or any other transmission component) unless they

aremadefromlint-freematerials.Lintwillsticktocasesurfacesandtransmission components and circu-

late throughout the transmission after assembly. A sufficient quantity of lint can block fluid passages and

interfere with valve body operation.

INSPECTION

Inspect the case for cracks, porous spots, worn bores, or damaged threads.Damaged threads can be repaired with

Helicoil

thread inserts. However, the case will have to be replaced if it exhibits any type of damage or wear.

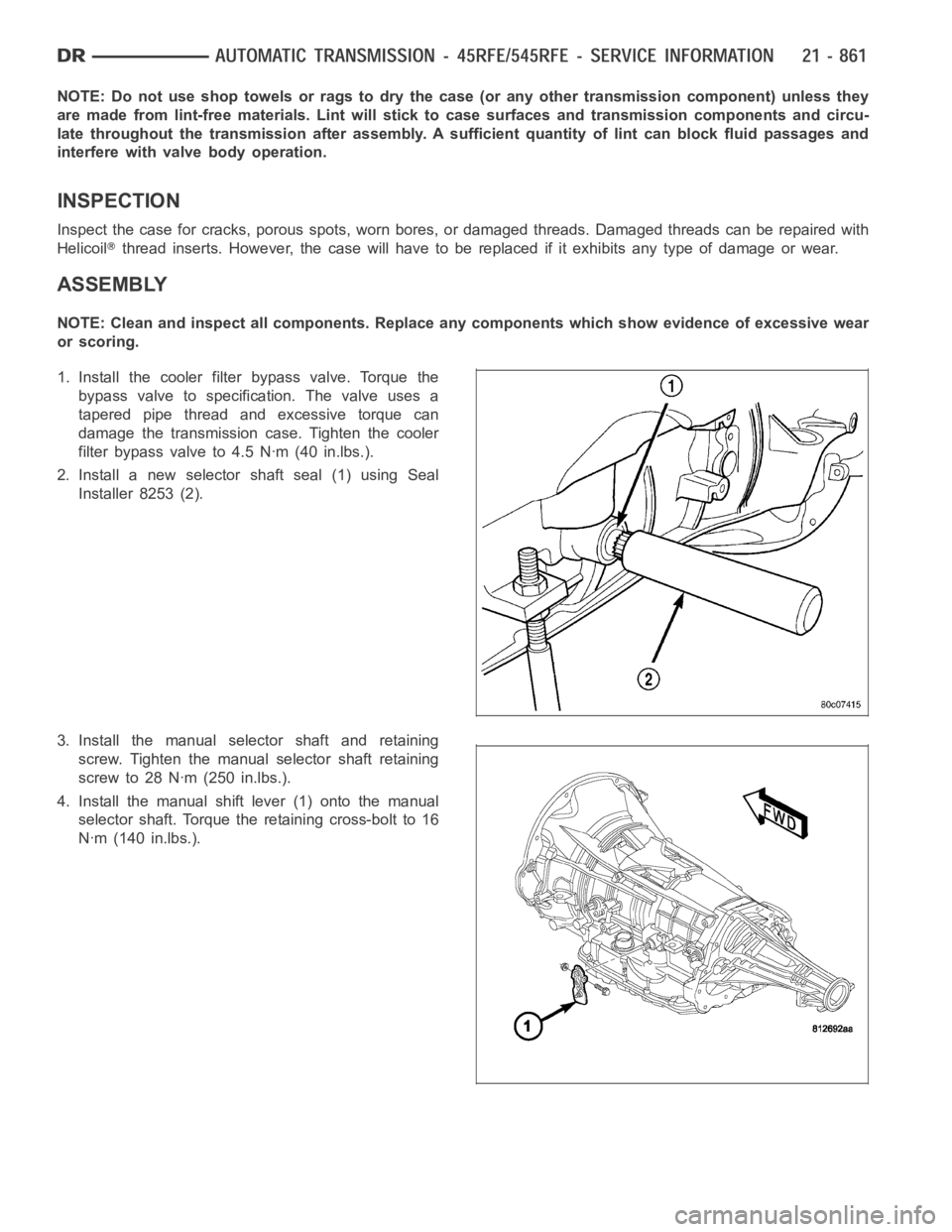

ASSEMBLY

NOTE: Clean and inspect all components. Replace any components which showevidence of excessive wear

or scoring.

1. Install the cooler filter bypass valve. Torque the

bypass valve to specification. The valve uses a

tapered pipe thread and excessive torque can

damage the transmission case. Tighten the cooler

filter bypass valve to 4.5 Nꞏm (40 in.lbs.).

2. Install a new selector shaft seal (1) using Seal

Installer 8253 (2).

3. Install the manual selector shaft and retaining

screw. Tighten the manual selector shaft retaining

screw to 28 Nꞏm (250 in.lbs.).

4. Install the manual shift lever (1) onto the manual

selector shaft. Torque the retaining cross-bolt to 16

Nꞏm (140 in.lbs.).

Page 3389 of 5267

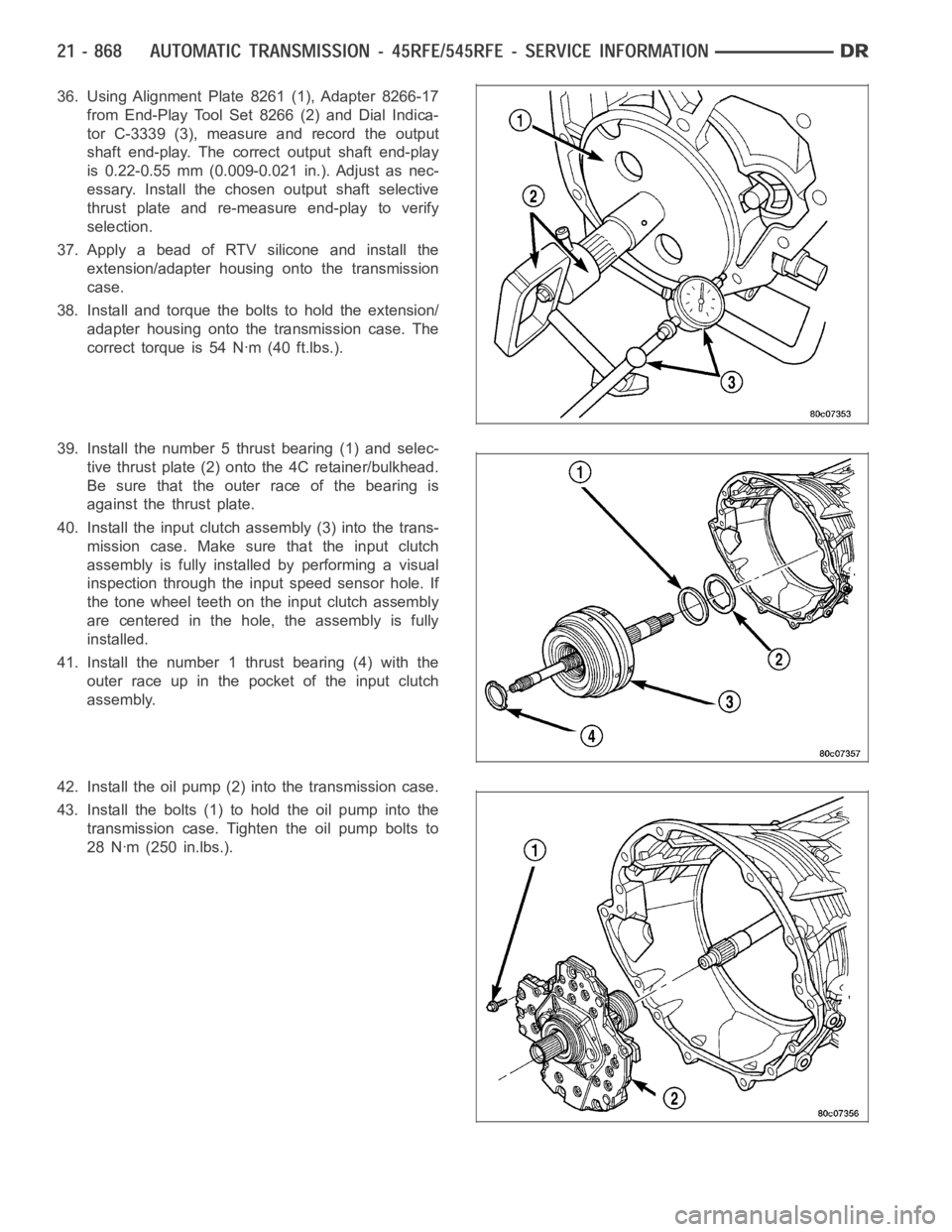

36. Using Alignment Plate 8261 (1), Adapter 8266-17

from End-Play Tool Set 8266 (2) and Dial Indica-

tor C-3339 (3), measure and record the output

shaft end-play. The correct output shaft end-play

is 0.22-0.55 mm (0.009-0.021 in.). Adjust as nec-

essary. Install the chosen output shaft selective

thrust plate and re-measure end-play to verify

selection.

37. Apply a bead of RTV silicone and install the

extension/adapter housing onto the transmission

case.

38. Install and torque the bolts to hold the extension/

adapter housing onto the transmission case. The

correct torque is 54 Nꞏm (40 ft.lbs.).

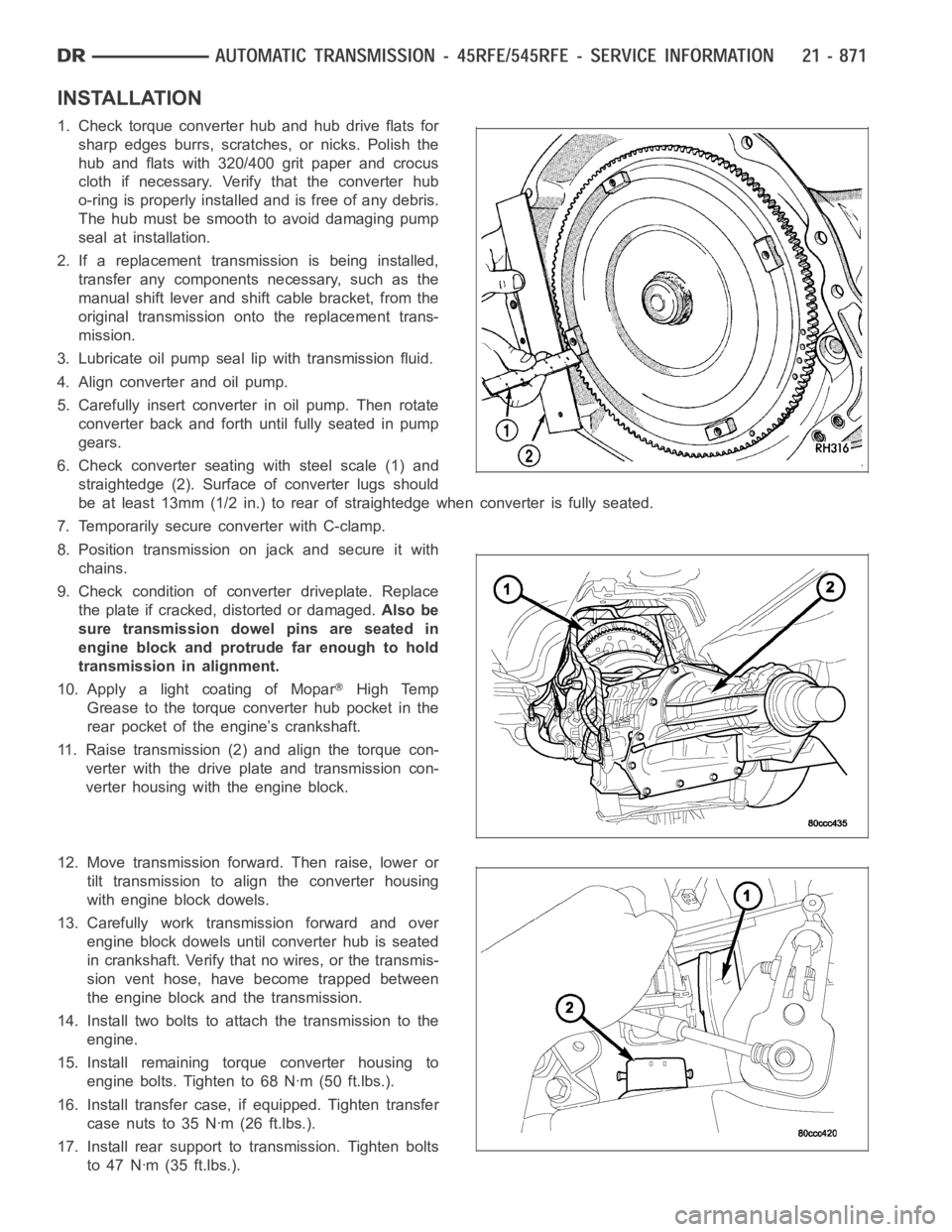

39. Install the number 5 thrust bearing (1) and selec-

tive thrust plate (2) onto the 4C retainer/bulkhead.

Be sure that the outer race of the bearing is

against the thrust plate.

40. Install the input clutch assembly (3) into the trans-

mission case. Make sure that the input clutch

assembly is fully installedbyperformingavisual

inspection through the input speed sensor hole. If

the tone wheel teeth on the input clutch assembly

are centered in the hole, the assembly is fully

installed.

41. Install the number 1 thrust bearing (4) with the

outer race up in the pocket of the input clutch

assembly.

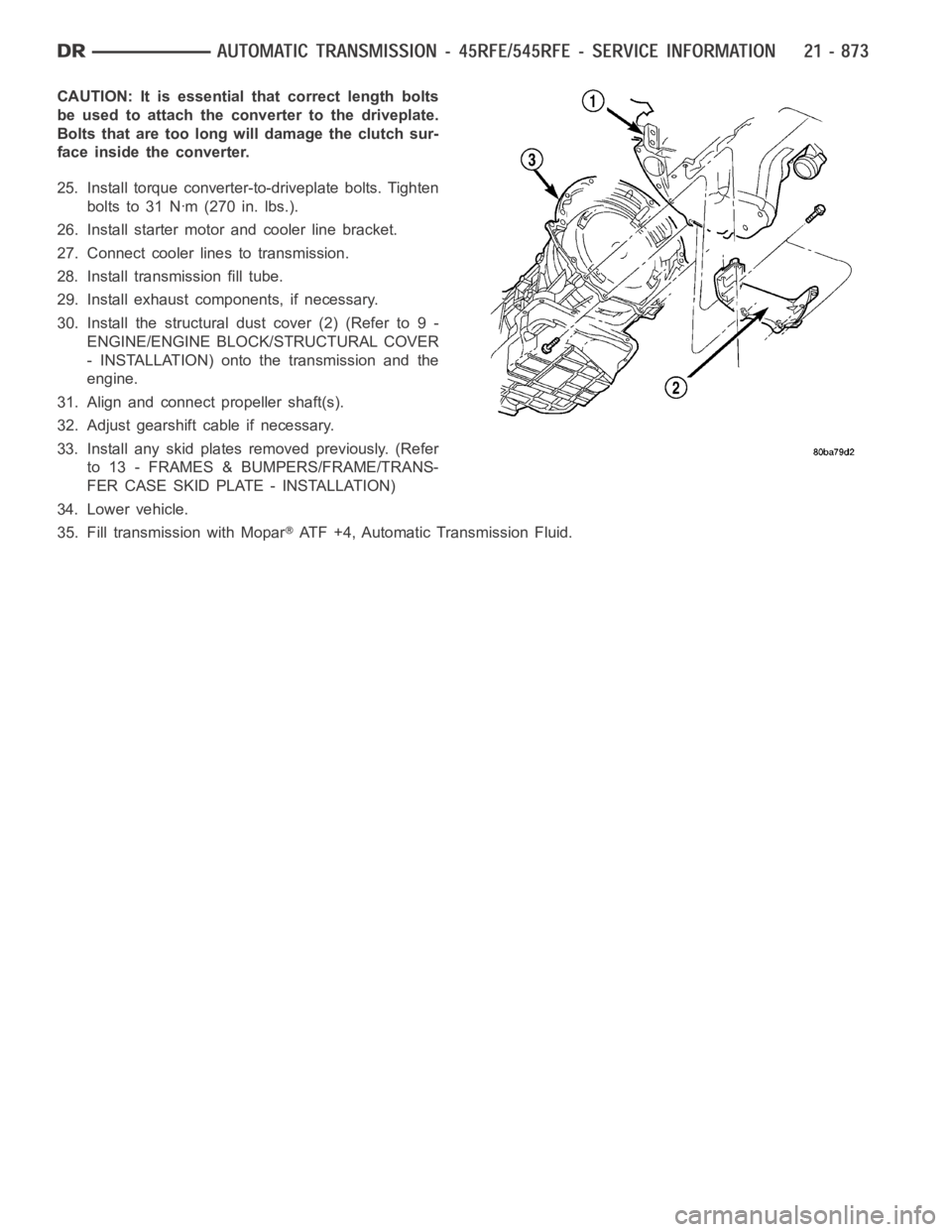

42. Install the oil pump (2) into the transmission case.

43. Install the bolts (1) to hold the oil pump into the

transmission case. Tighten the oil pump bolts to

28 Nꞏm (250 in.lbs.).

Page 3392 of 5267

INSTALLATION

1. Check torque converter hub and hub drive flats for

sharp edges burrs, scratches, or nicks. Polish the

hub and flats with 320/400 grit paper and crocus

cloth if necessary. Verify that the converter hub

o-ring is properly installed and is free of any debris.

The hub must be smooth to avoid damaging pump

seal at installation.

2. If a replacement transmission is being installed,

transfer any components necessary, such as the

manual shift lever and shift cable bracket, from the

original transmission onto the replacement trans-

mission.

3. Lubricate oil pump seal lip with transmission fluid.

4. Align converter and oil pump.

5. Carefully insert converter in oil pump. Then rotate

converter back and forth until fully seated in pump

gears.

6. Check converter seating with steel scale (1) and

straightedge (2). Surface of converter lugs should

be at least 13mm (1/2 in.) to rear of straightedge when converter is fully seated.

7. Temporarily secure converter with C-clamp.

8. Position transmission on jack and secure it with

chains.

9. Check condition of converter driveplate. Replace

the plate if cracked, distorted or damaged.Also be

sure transmission dowel pins are seated in

engine block and protrude far enough to hold

transmission in alignment.

10. Apply a light coating of Mopar

High Temp

Grease to the torque converter hub pocket in the

rear pocket of the engine’s crankshaft.

11. Raise transmission (2) and align the torque con-

verter with the drive plate and transmission con-

verter housing with the engine block.

12. Move transmission forward. Then raise, lower or

tilt transmission to align the converter housing

with engine block dowels.

13. Carefully work transmission forward and over

engine block dowels until converter hub is seated

in crankshaft. Verify that no wires, or the transmis-

sion vent hose, have become trapped between

theengineblockandthetransmission.

14. Install two bolts to attach the transmission to the

engine.

15. Install remaining torque converter housing to

engine bolts. Tighten to 68 Nꞏm (50 ft.lbs.).

16. Install transfer case, if equipped. Tighten transfer

case nuts to 35 Nꞏm (26 ft.lbs.).

17. Install rear support to transmission. Tighten bolts

to 47 Nꞏm (35 ft.lbs.).

Page 3394 of 5267

CAUTION: It is essential that correct length bolts

be used to attach the converter to the driveplate.

Bolts that are too long will damage the clutch sur-

face inside the converter.

25. Install torque converter-to-driveplate bolts. Tighten

boltsto31Nꞏm(270in.lbs.).

26. Install starter motor and cooler line bracket.

27. Connect cooler lines to transmission.

28. Install transmission fill tube.

29. Install exhaust components, if necessary.

30. Install the structural dust cover (2) (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER

- INSTALLATION) onto the transmission and the

engine.

31. Align and connect propeller shaft(s).

32. Adjust gearshift cable if necessary.

33. Install any skid plates removed previously. (Refer

to 13 - FRAMES & BUMPERS/FRAME/TRANS-

FER CASE SKID PLATE - INSTALLATION)

34. Lower vehicle.

35. Fill transmission with Mopar

ATF +4, Automatic Transmission Fluid.

Page 3417 of 5267

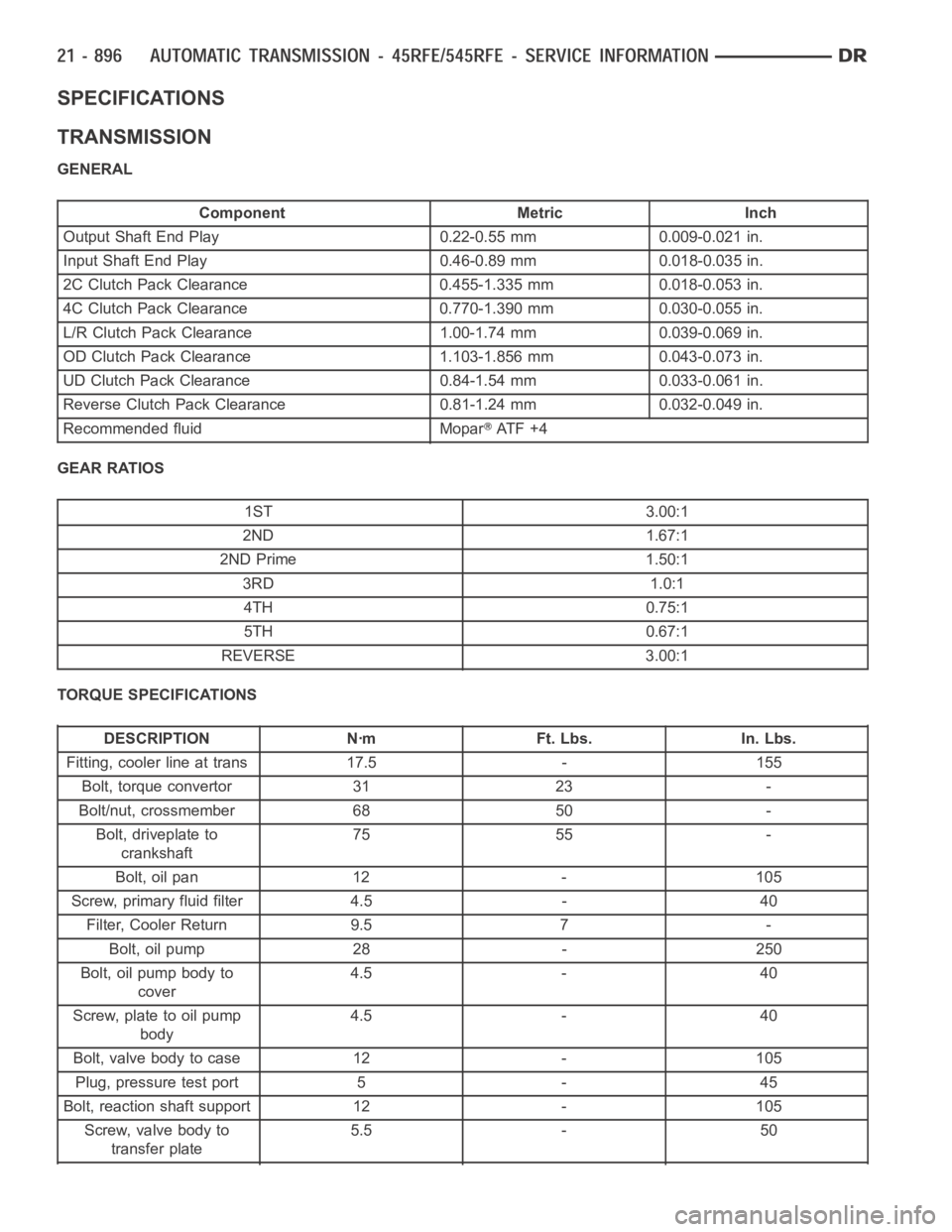

SPECIFICATIONS

TRANSMISSION

GENERAL

Component Metric Inch

Output Shaft End Play 0.22-0.55 mm 0.009-0.021 in.

Input Shaft End Play 0.46-0.89 mm 0.018-0.035 in.

2C Clutch Pack Clearance 0.455-1.335 mm 0.018-0.053 in.

4C Clutch Pack Clearance 0.770-1.390 mm 0.030-0.055 in.

L/R Clutch Pack Clearance 1.00-1.74 mm 0.039-0.069 in.

OD Clutch Pack Clearance 1.103-1.856 mm 0.043-0.073 in.

UD Clutch Pack Clearance 0.84-1.54 mm 0.033-0.061 in.

Reverse Clutch Pack Clearance 0.81-1.24 mm 0.032-0.049 in.

Recommended fluid Mopar

AT F + 4

GEAR RATIOS

1ST 3.00:1

2ND 1.67:1

2ND Prime 1.50:1

3RD 1.0:1

4TH 0.75:1

5TH 0.67:1

REVERSE 3.00:1

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Fitting, cooler line at trans 17.5 - 155

Bolt, torque convertor 31 23 -

Bolt/nut, crossmember 68 50 -

Bolt, driveplate to

crankshaft75 55 -

Bolt, oil pan 12 - 105

Screw, primary fluid filter 4.5 - 40

Filter, Cooler Return 9.5 7 -

Bolt, oil pump 28 - 250

Bolt, oil pump body to

cover4.5 - 40

Screw, plate to oil pump

body4.5 - 40

Bolt, valve body to case 12 - 105

Plug, pressure test port 5 - 45

Bolt, reaction shaft support 12 - 105

Screw, valve body to

transfer plate5.5 - 50

Page 3430 of 5267

FLUID AND FILTER

DIAGNOSIS AND TESTING

EFFECTS OF INCORRECT FLUID LEVEL

Alowfluidlevelallowsthepumptotakeinairalongwiththefluid.Airinthe fluid will cause fluid pressures to be

low and develop slower than normal. If the transmission is overfilled, thegears churn the fluid into foam. This aer-

ates the fluid and causing the same conditions occurring with a low level. In either case, air bubbles cause fluid

overheating, oxidation, and varnish buildup which interferes with valveand clutch operation. Foaming also causes

fluid expansion which can result in fluid overflow from the transmission vent or fill tube. Fluid overflow can easily be

mistaken for a leak if inspection is not careful.

CAUSES OF BURNT FLUID

Burnt, discolored fluid is a result of overheating which has three primarycauses.

1. Internal clutch slippage, usually caused by low line pressure, inadequate clutch apply pressure, or clutch seal

failure.

2. A result of restricted fluid flow through the main and/or auxiliary cooler. This condition is usually the result of a

faulty or improperly installed drainback valve, a damaged oil cooler, or severe restrictions in the coolers and lines

caused by debris or kinked lines.

3. Heavy duty operation with a vehicle not properly equipped for this type of operation. Trailer towing or similar high

load operation will overheat the transmission fluid if the vehicle is improperly equipped. Such vehicles should

have an auxiliary transmission fluid cooler, a heavy duty cooling system,and the engine/axle ratio combination

needed to handle heavy loads.

FLUID CONTAMINATION

Transmission fluid contamination is generally a result of:

adding incorrect fluid

failure to clean dipstick and fill tube when checking level

engine coolant entering the fluid

internal failure that generates debris

overheat that generates sludge (fluid breakdown)

failure to replace contaminated converter after repair

The use of non-recommended fluids can result in transmission failure. Theusual results are erratic shifts, slippage,

abnormal wear and eventual failure due to fluid breakdown and sludge formation. Avoid this condition by using rec-

ommended fluids only.

The dipstick cap and fill tube should be wiped clean before checking fluid level. Dirt, grease and other foreign mate-

rial on the cap and tube could fall into the tube if not removed beforehand. Take the time to wipe the cap and tube

clean before withdrawing the dipstick.

Engine coolant in the transmission fluid is generally caused by a cooler malfunction. The only remedy is to replace

the radiator as the cooler in the radiator is not a serviceable part. If coolant has circulated through the transmission,

an overhaul is necessary.

The torque converter should also be replaced whenever a failure generatessludge and debris. This is necessary

because normal converter flushing procedures will not remove all contaminants.

STANDARD PROCEDURE

FLUID LEVEL CHECK

Low fluid level can cause a variety of conditions because it allows the pumpto take in air along with the fluid. As

in any hydraulic system, air bubbles make the fluid spongy, therefore, pressures will be low and build up slowly.

Improper filling can also raise the fluid level too high. When the transmssion has too much fluid, the geartrain

churns up foam and cause the same conditions which occur with a low fluid level.

Page 3431 of 5267

In either case, air bubbles can cause overheating and/or fluid oxidation,and varnishing. This can interfere with nor-

mal valve, clutch, and accumulator operation. Foaming can also result in fluid escaping from the transmission vent

where it may be mistaken for a leak.

After the fluid has been checked, seat the dipstick fully to seal out water and dirt.

The transmission has a dipstick to check oil level. It is located on the right side of the engine. Be sure to wipe all

dirt from dipstick handle before removing.

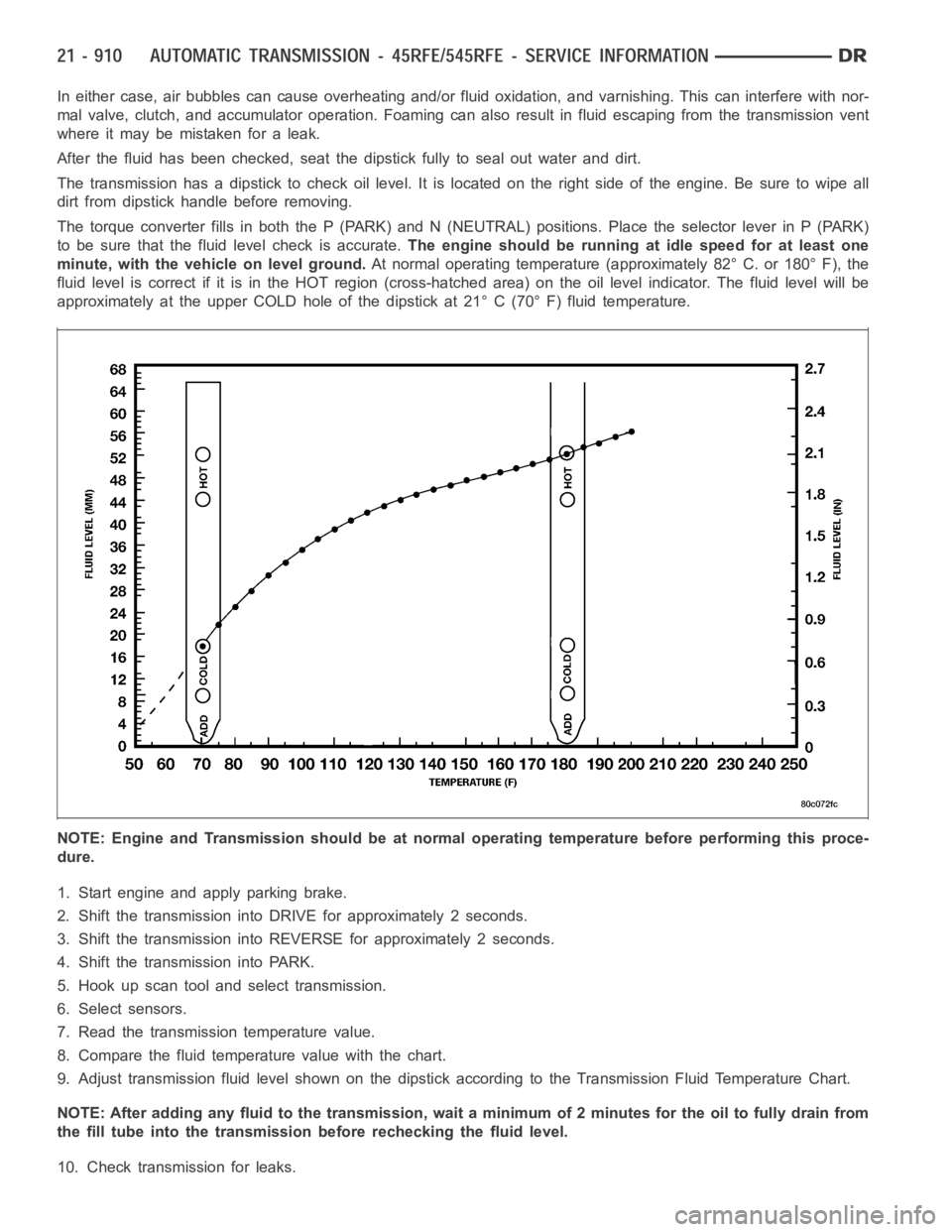

The torque converter fills in both the P(PARK) and N (NEUTRAL) positions. Place the selector lever in P (PARK)

to be sure that the fluid level check is accurate.The engine should be running at idle speed for at least one

minute, with the vehicle on level ground.At normal operating temperature (approximately 82° C. or 180° F), the

fluid level is correct if it is in the HOT region (cross-hatched area) on theoil level indicator. The fluid level will be

approximately at the upper COLD hole of the dipstick at 21° C (70° F) fluid temperature.

NOTE: Engine and Transmission should be at normal operating temperature before performing this proce-

dure.

1. Start engine and apply parking brake.

2. Shift the transmission into DRIVE for approximately 2 seconds.

3. Shift the transmission into REVERSE for approximately 2 seconds.

4. Shift the transmission into PARK.

5. Hook up scan tool andselect transmission.

6. Select sensors.

7. Read the transmission temperature value.

8. Compare the fluid temperature value with the chart.

9. Adjust transmission fluid level shown on the dipstick according to the Transmission Fluid Temperature Chart.

NOTE: After adding any fluid to the transmission, wait a minimum of 2 minutes for the oil to fully drain from

the fill tube into the transmission before rechecking the fluid level.

10. Check transmission for leaks.