ECU DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5070 of 5267

ACTUATOR-RECIRCULATION DOOR

DESCRIPTION

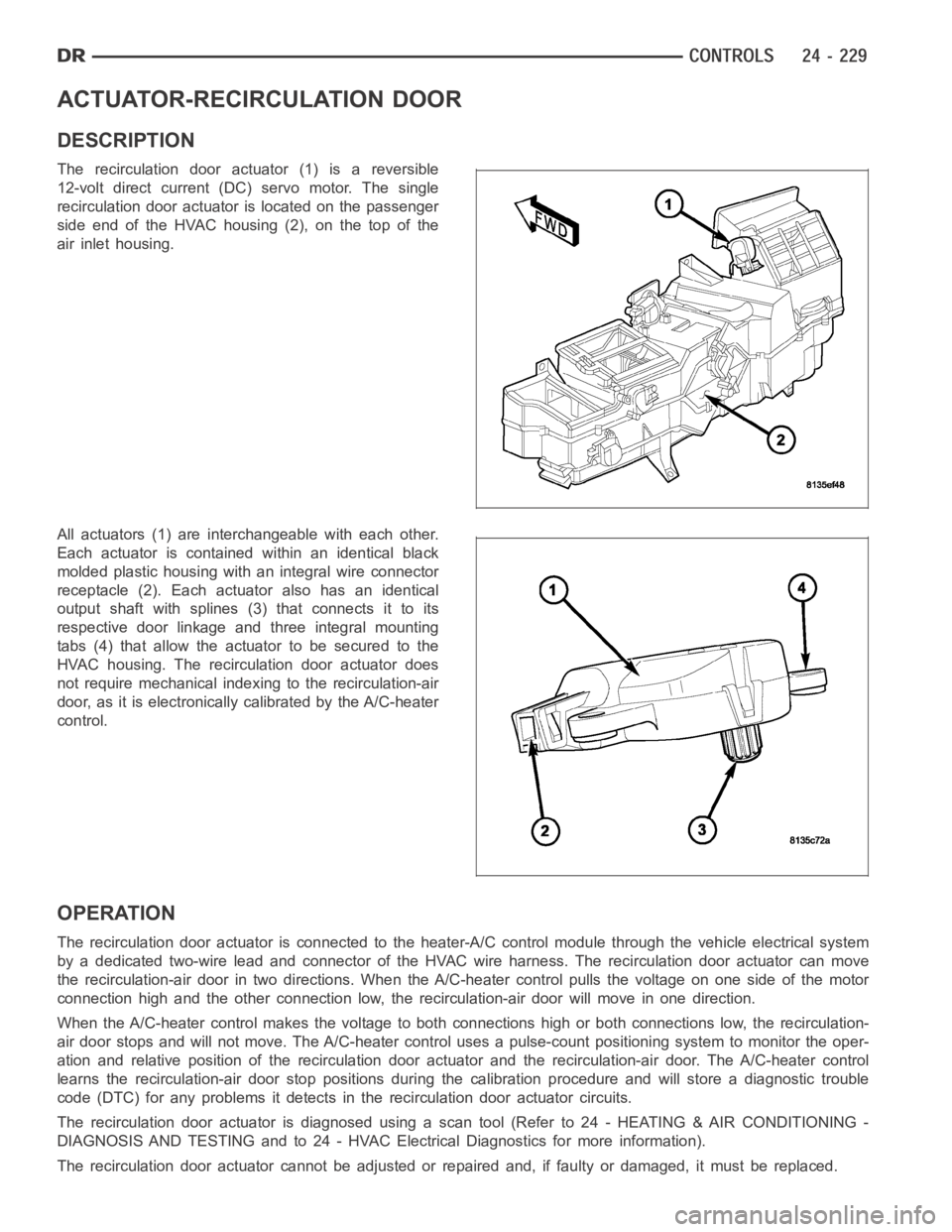

The recirculation door actuator (1) is a reversible

12-volt direct current (DC)servo motor. The single

recirculation door actuator is located on the passenger

side end of the HVAC housing (2), on the top of the

air inlet housing.

All actuators (1) are interchangeable with each other.

Each actuator is contained within an identical black

molded plastic housing with an integral wire connector

receptacle (2). Each actuator also has an identical

output shaft with splines (3) that connects it to its

respective door linkage and three integral mounting

tabs (4) that allow the actuator to be secured to the

HVAC housing. The recirculation door actuator does

not require mechanical indexing to the recirculation-air

door, as it is electronically calibrated by the A/C-heater

control.

OPERATION

The recirculation door actuator is connected to the heater-A/C control module through the vehicle electrical system

by a dedicated two-wire lead and connector of the HVAC wire harness. The recirculation door actuator can move

the recirculation-air door in two directions. When the A/C-heater control pulls the voltage on one side of the motor

connection high and the other connection low, the recirculation-air doorwill move in one direction.

When the A/C-heater control makes the voltage to both connections high or both connections low, the recirculation-

air door stops and will not move. The A/C-heater control uses a pulse-countpositioning system to monitor the oper-

ation and relative position of the recirculation door actuator and the recirculation-air door. The A/C-heater control

learns the recirculation-air door stop positions during the calibrationprocedure and will store a diagnostic trouble

code (DTC) for any problems it detects in the recirculation door actuator circuits.

The recirculation door actuator is diagnosed using a scan tool (Refer to 24- HEATING & AIR CONDITIONING -

DIAGNOSIS AND TESTING and to 24 - HVAC Electrical Diagnostics for more information).

The recirculation door actuator cannot be adjusted or repaired and, if faulty or damaged, it must be replaced.

Page 5071 of 5267

REMOVAL

WARNING: On vehicles equipped with airbags, disable the airbag system before attempting any steering

wheel, steering column, or instrument panel component diagnosis or service. Disconnect and isolate the

battery negative (ground) cable, then wait two minutes for the airbag system capacitor to discharge before

performing further diagnosis or service. This is the only sure way to disable the airbag system. Failure to

take the proper precautions could result in accidental airbag deploymentand possible personal injury or

death.

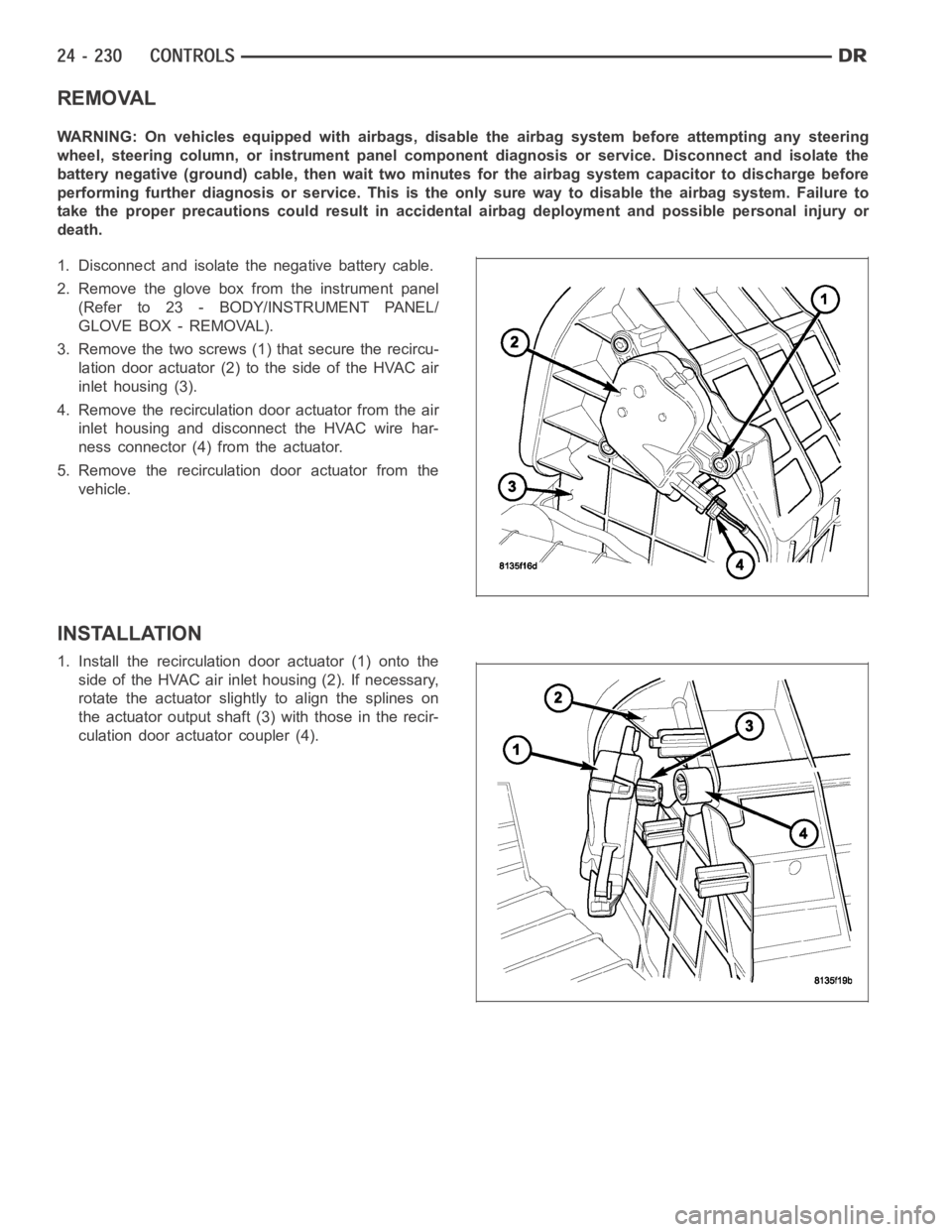

1. Disconnect and isolate the negative battery cable.

2. Remove the glove box from the instrument panel

(Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

3. Remove the two screws (1) that secure the recircu-

lation door actuator (2) to the side of the HVAC air

inlet housing (3).

4. Remove the recirculation door actuator from the air

inlet housing and disconnect the HVAC wire har-

ness connector (4) from the actuator.

5. Remove the recirculation door actuator from the

vehicle.

INSTALLATION

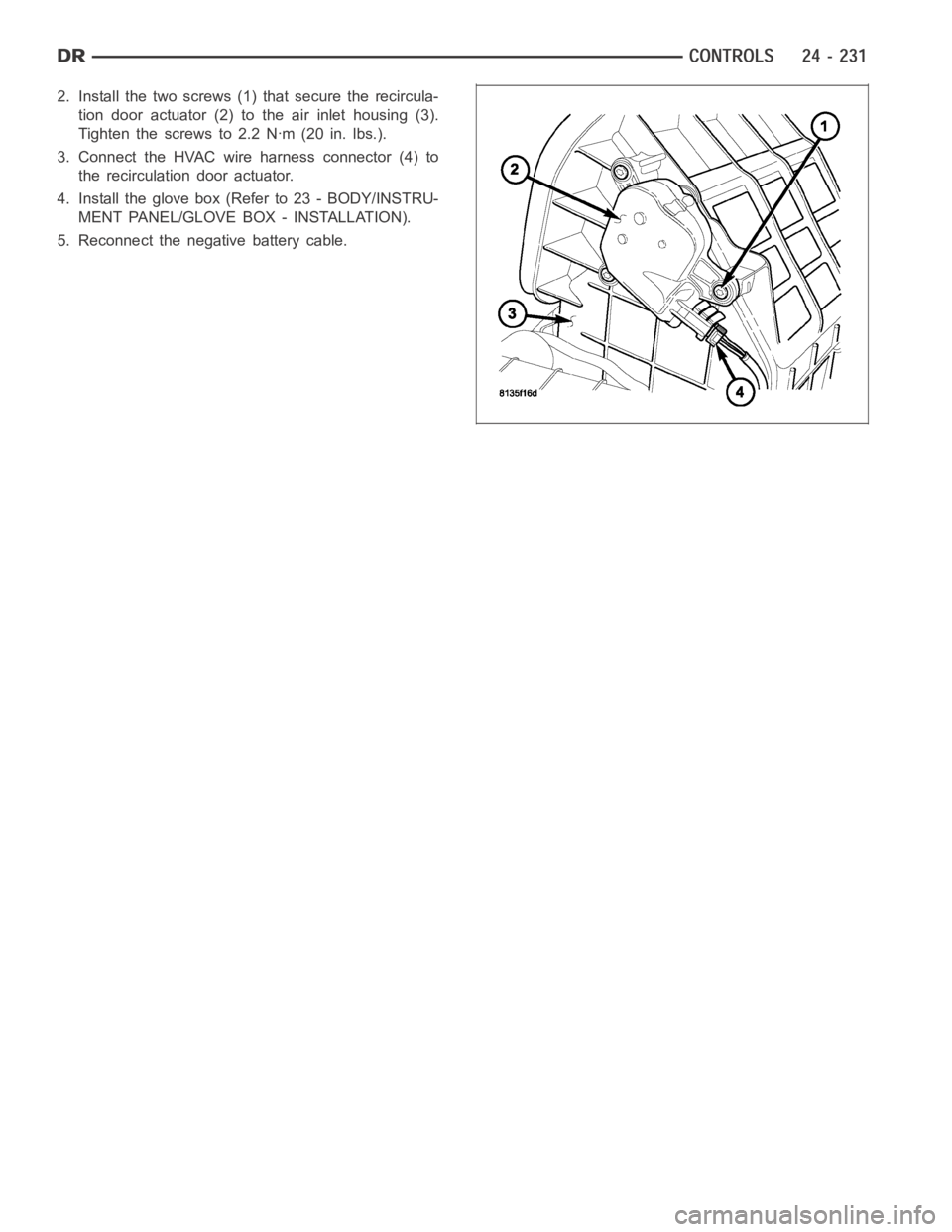

1. Install the recirculation door actuator (1) onto the

side of the HVAC air inlet housing (2). If necessary,

rotate the actuator slightly to align the splines on

the actuator output shaft (3) with those in the recir-

culation door actuator coupler (4).

Page 5072 of 5267

2. Install the two screws (1)that secure the recircula-

tion door actuator (2) to the air inlet housing (3).

Tighten the screws to 2.2 Nꞏm (20 in. lbs.).

3. Connect the HVAC wire harness connector (4) to

the recirculation door actuator.

4. Install the glove box (Refer to 23 - BODY/INSTRU-

MENT PANEL/GLOVE BOX - INSTALLATION).

5. Reconnect the negative battery cable.

Page 5073 of 5267

CLUTCH-A/C COMPRESSOR

DESCRIPTION

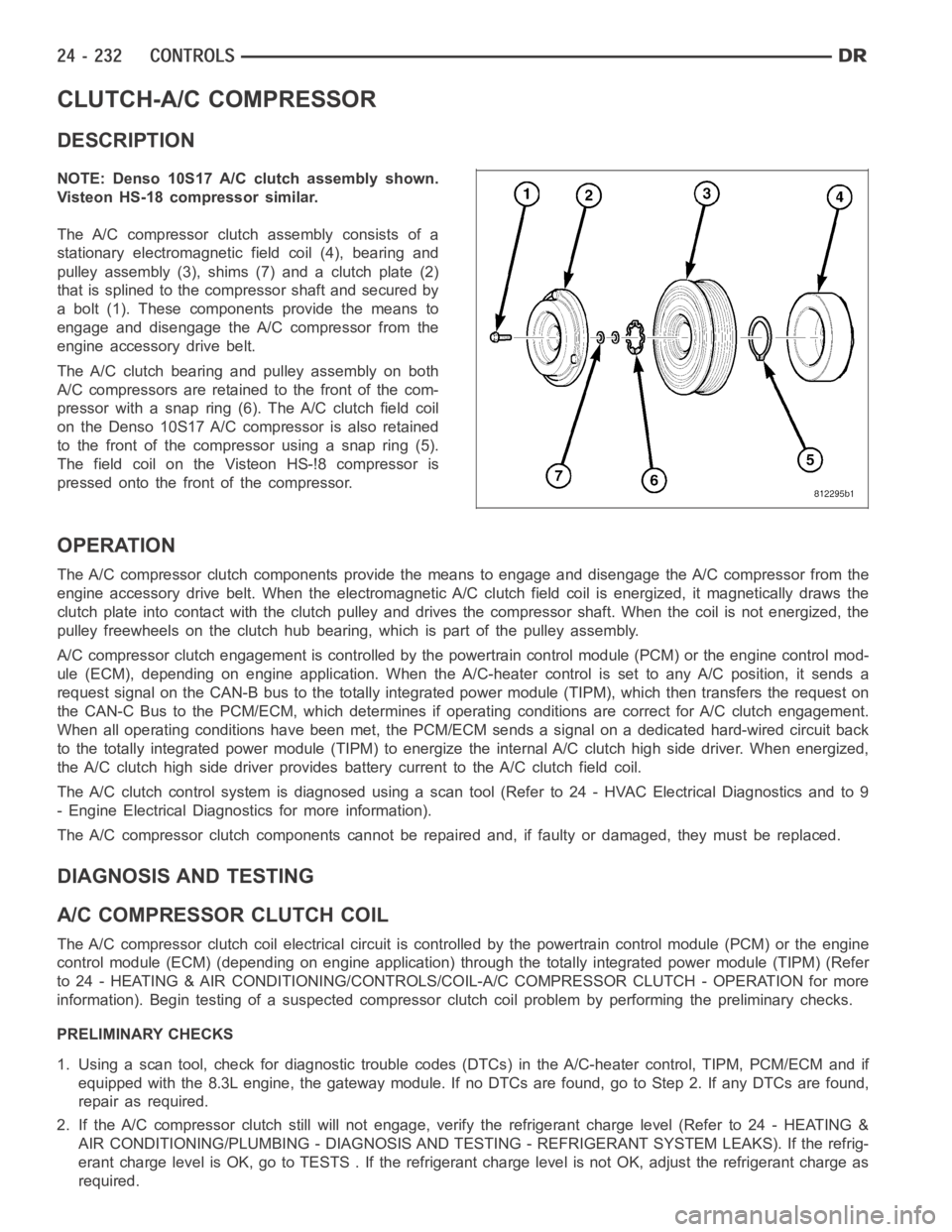

NOTE: Denso 10S17 A/C clutch assembly shown.

Visteon HS-18 compressor similar.

The A/C compressor clutch assembly consists of a

stationary electromagnetic field coil (4), bearing and

pulley assembly (3), shims (7) and a clutch plate (2)

that is splined to the compressor shaft and secured by

a bolt (1). These components provide the means to

engage and disengage the A/C compressor from the

engine accessory drive belt.

The A/C clutch bearing and pulley assembly on both

A/C compressors are retained to the front of the com-

pressor with a snap ring (6). The A/C clutch field coil

on the Denso 10S17 A/C compressor is also retained

to the front of the compressor using a snap ring (5).

The field coil on the Visteon HS-!8 compressor is

pressed onto the front of the compressor.

OPERATION

The A/C compressor clutch components provide the means to engage and disengage the A/C compressor from the

engine accessory drive belt. When the electromagnetic A/C clutch field coil is energized, it magnetically draws the

clutch plate into contact with the clutch pulley and drives the compressorshaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is part of the pulley assembly.

A/C compressor clutch engagement is controlled by the powertrain controlmodule (PCM) or the engine control mod-

ule (ECM), depending on engine application. When the A/C-heater control is set to any A/C position, it sends a

request signal on the CAN-B bus to the totally integrated power module (TIPM), which then transfers the request on

the CAN-C Bus to the PCM/ECM, which determines if operating conditions arecorrect for A/C clutch engagement.

When all operating conditions have been met, the PCM/ECM sends a signal on adedicated hard-wired circuit back

to the totally integrated power module (TIPM) to energize the internal A/Cclutch high side driver. When energized,

the A/C clutch high side driver provides battery current to the A/C clutch field coil.

The A/C clutch control system is diagnosed using a scan tool (Refer to 24 - HVAC Electrical Diagnostics and to 9

- Engine Electrical Diagnostics for more information).

The A/C compressor clutch components cannot be repaired and, if faulty or damaged, they must be replaced.

DIAGNOSIS AND TESTING

A/CCOMPRESSORCLUTCHCOIL

The A/C compressor clutch coil electrical circuit is controlled by the powertrain control module (PCM) or the engine

control module (ECM) (depending on engine application) through the totally integrated power module (TIPM) (Refer

to 24 - HEATING & AIR CONDITIONING/CONTROLS/COIL-A/C COMPRESSOR CLUTCH -OPERATION for more

information). Begin testing of a suspected compressor clutch coil problem by performing the preliminary checks.

PRELIMINARY CHECKS

1. Using a scan tool, check for diagnostic trouble codes (DTCs) in the A/C-heater control, TIPM, PCM/ECM and if

equipped with the 8.3L engine, the gateway module. If no DTCs are found, go to Step 2. If any DTCs are found,

repair as required.

2. If the A/C compressor clutch still will not engage, verify the refrigerant charge level (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - DIAGNOSIS AND TESTING - REFRIGERANT SYSTEM LEAKS). If the refrig-

erant charge level is OK, go to TESTS . If the refrigerant charge level is notOK, adjust the refrigerant charge as

required.

Page 5075 of 5267

REMOVAL

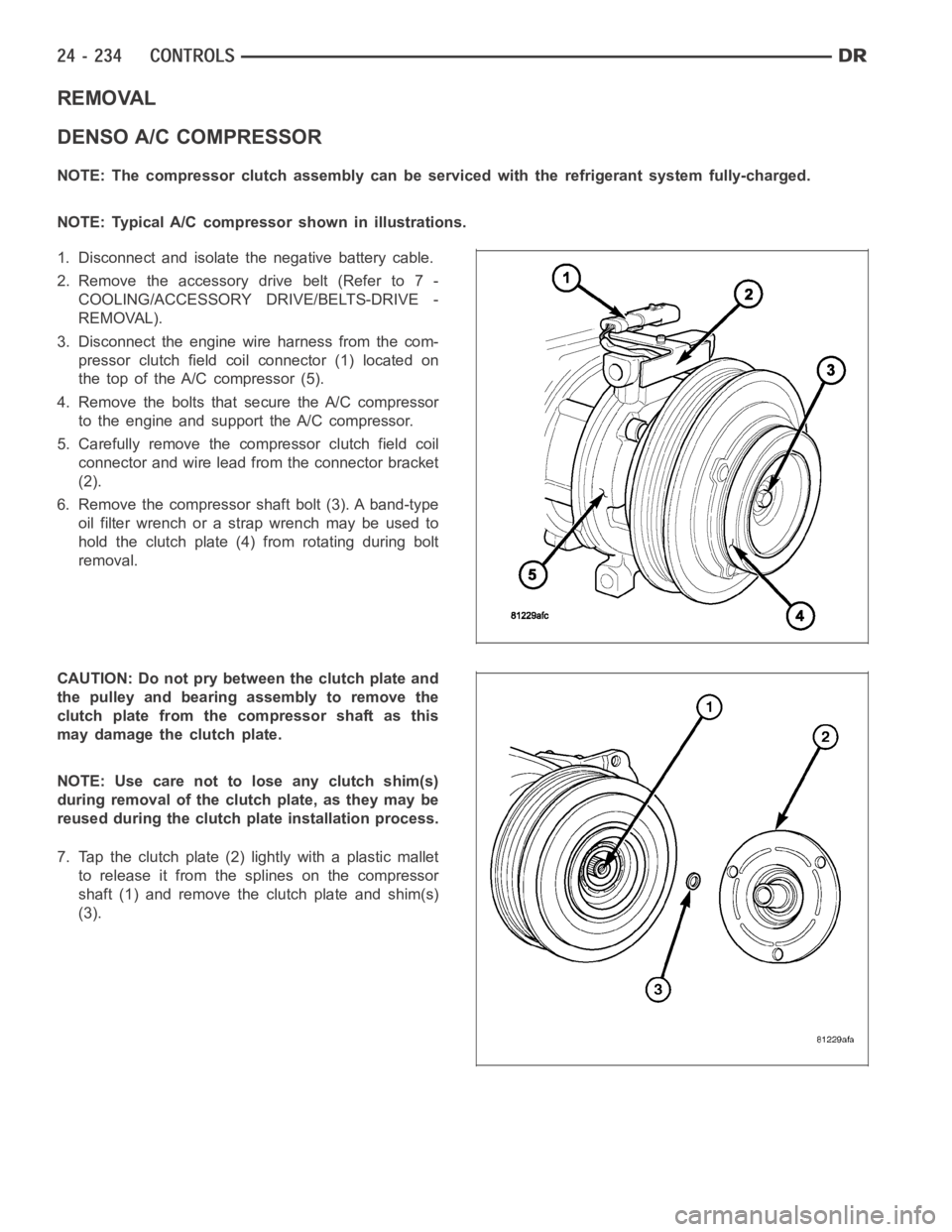

DENSO A/C COMPRESSOR

NOTE: The compressor clutch assembly can be serviced with the refrigerantsystem fully-charged.

NOTE: Typical A/C compressor shown in illustrations.

1. Disconnect and isolate the negative battery cable.

2. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

3. Disconnect the engine wire harness from the com-

pressor clutch field coilconnector (1) located on

the top of the A/C compressor (5).

4. Remove the bolts that secure the A/C compressor

to the engine and support the A/C compressor.

5. Carefully remove the compressor clutch field coil

connector and wire lead from the connector bracket

(2).

6. Remove the compressor shaft bolt (3). A band-type

oil filter wrench or a strap wrench may be used to

hold the clutch plate (4) from rotating during bolt

removal.

CAUTION: Do not pry between the clutch plate and

the pulley and bearing assembly to remove the

clutch plate from the compressor shaft as this

may damage the clutch plate.

NOTE: Use care not to lose any clutch shim(s)

during removal of the clutch plate, as they may be

reused during the clutch plate installation process.

7. Tap the clutch plate (2) lightly with a plastic mallet

to release it from the splines on the compressor

shaft (1) and remove the clutch plate and shim(s)

(3).

Page 5076 of 5267

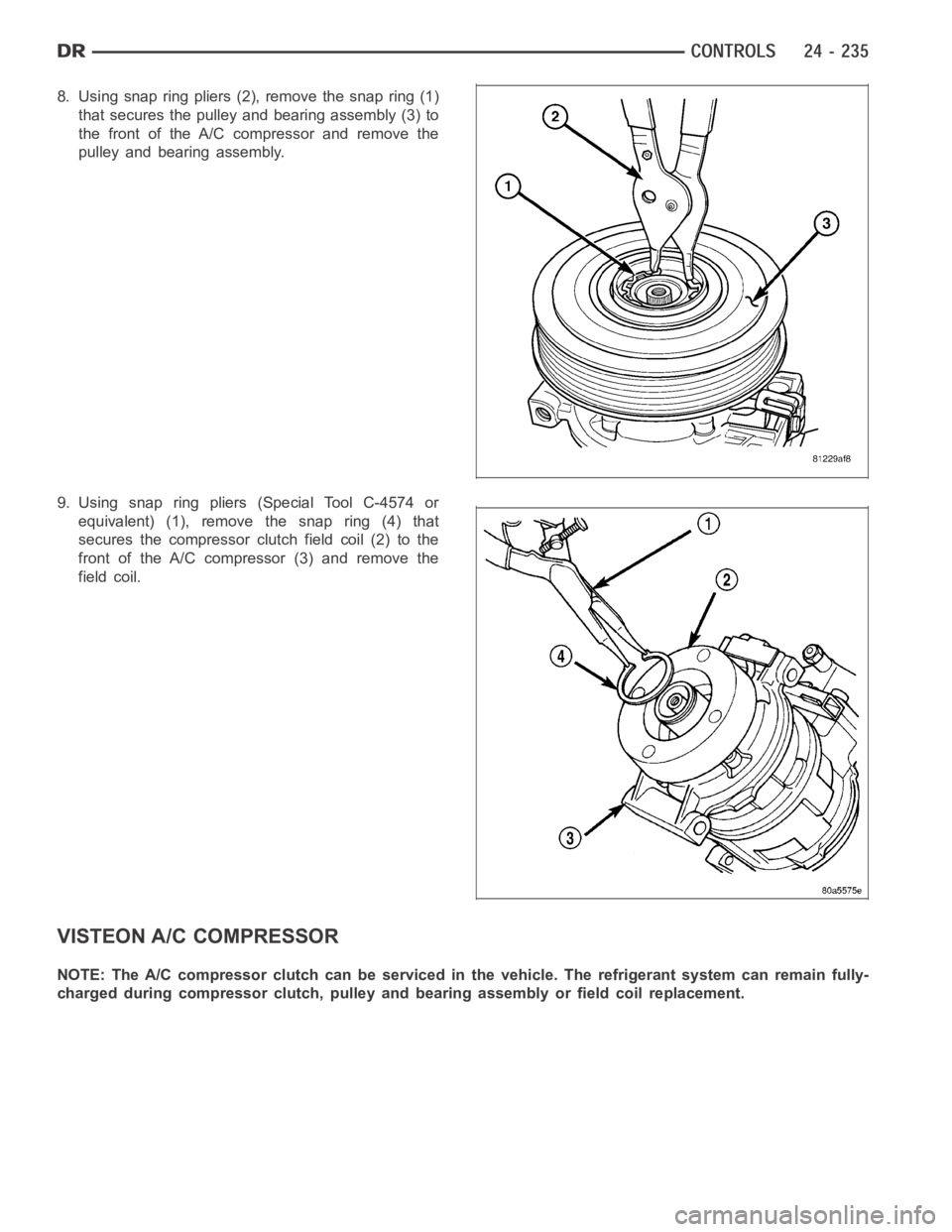

8. Using snap ring pliers (2), remove the snap ring (1)

that secures the pulley and bearing assembly (3) to

the front of the A/C compressor and remove the

pulley and bearing assembly.

9. Using snap ring pliers (Special Tool C-4574 or

equivalent) (1), remove the snap ring (4) that

secures the compressor clutch field coil (2) to the

front of the A/C compressor (3) and remove the

field coil.

VISTEON A/C COMPRESSOR

NOTE: The A/C compressor clutch can be serviced in the vehicle. The refrigerant system can remain fully-

charged during compressor clutch, pulley and bearing assembly or field coil replacement.

Page 5077 of 5267

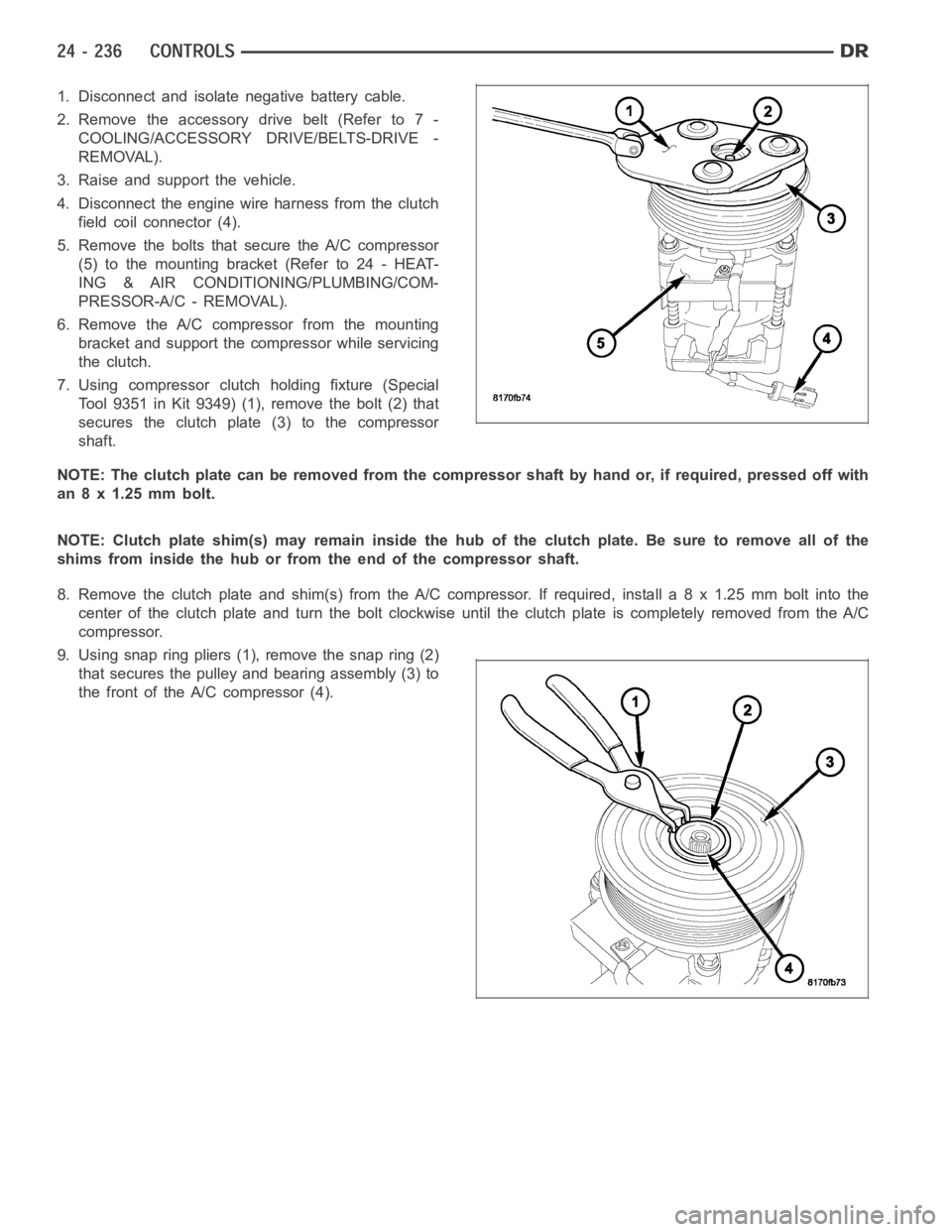

1. Disconnect and isolate negative battery cable.

2. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

3. Raise and support the vehicle.

4. Disconnect the engine wire harness from the clutch

field coil connector (4).

5. Remove the bolts that secure the A/C compressor

(5)tothemountingbracket(Referto24-HEAT-

ING & AIR CONDITIONING/PLUMBING/COM-

PRESSOR-A/C - REMOVAL).

6. Remove the A/C compressor from the mounting

bracket and support the compressor while servicing

the clutch.

7. Using compressor clutch holding fixture (Special

Tool 9351 in Kit 9349) (1), remove the bolt (2) that

secures the clutch plate (3) to the compressor

shaft.

NOTE: The clutch plate can be removed from the compressor shaft by hand or, if required, pressed off with

an 8 x 1.25 mm bolt.

NOTE: Clutch plate shim(s) may remain inside the hub of the clutch plate. Besure to remove all of the

shims from inside the hub or from the end of the compressor shaft.

8. Remove the clutch plate and shim(s) from the A/C compressor. If required, install a 8 x 1.25 mm bolt into the

centeroftheclutchplateandturntheboltclockwiseuntiltheclutchplate is completely removed from the A/C

compressor.

9. Using snap ring pliers (1), remove the snap ring (2)

that secures the pulley and bearing assembly (3) to

the front of the A/C compressor (4).

Page 5078 of 5267

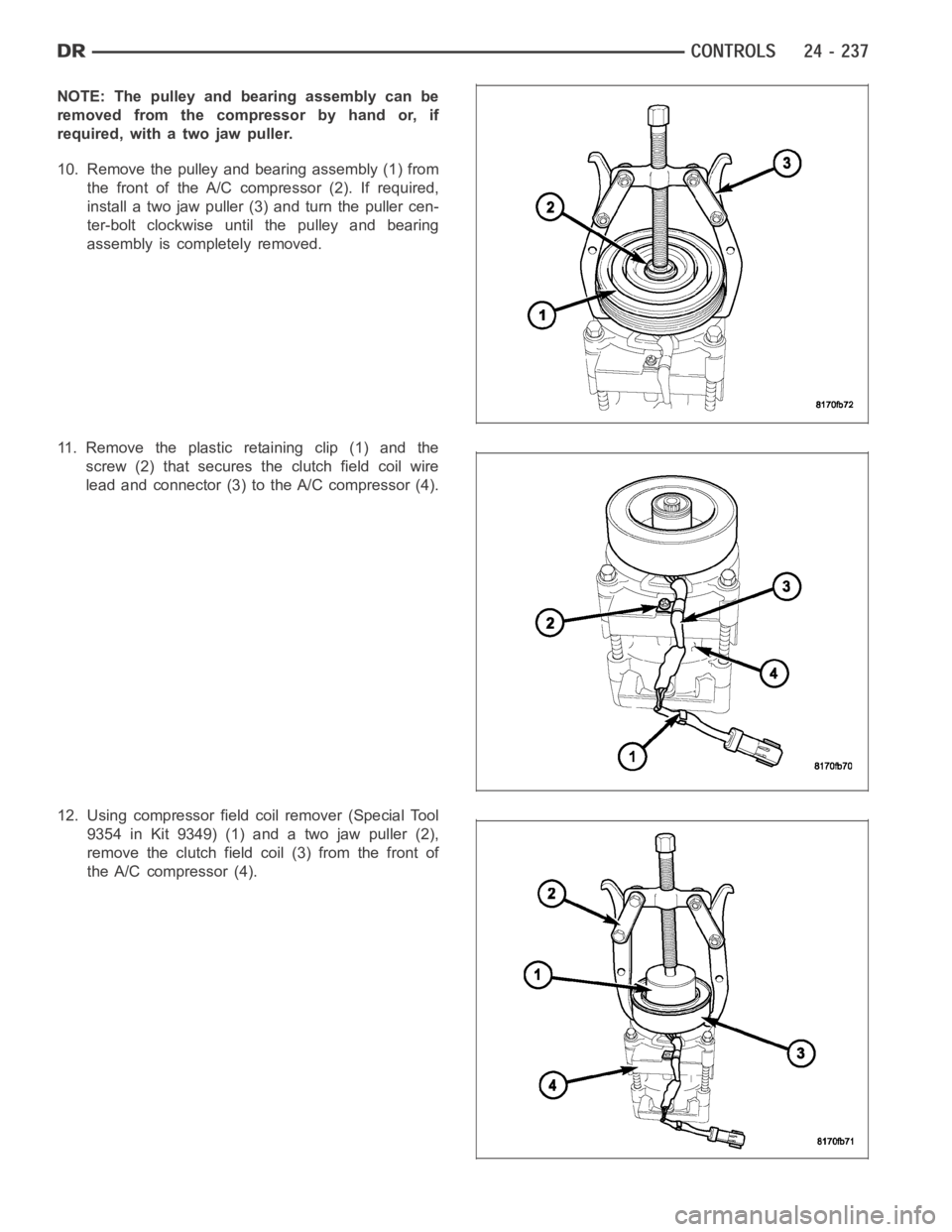

NOTE: The pulley and bearing assembly can be

removed from the compressor by hand or, if

required, with a two jaw puller.

10. Remove the pulley and bearing assembly (1) from

the front of the A/C compressor (2). If required,

install a two jaw puller (3) and turn the puller cen-

ter-bolt clockwise until the pulley and bearing

assembly is completely removed.

11. Remove the plastic retaining clip (1) and the

screw (2) that secures the clutch field coil wire

lead and connector (3) to the A/C compressor (4).

12. Using compressor field coil remover (Special Tool

9354 in Kit 9349) (1) and a two jaw puller (2),

remove the clutch field coil (3) from the front of

the A/C compressor (4).

Page 5079 of 5267

INSTALLATION

DENSO A/C COMPRESSOR

NOTE: Typical A/C compressor shown in illustrations.

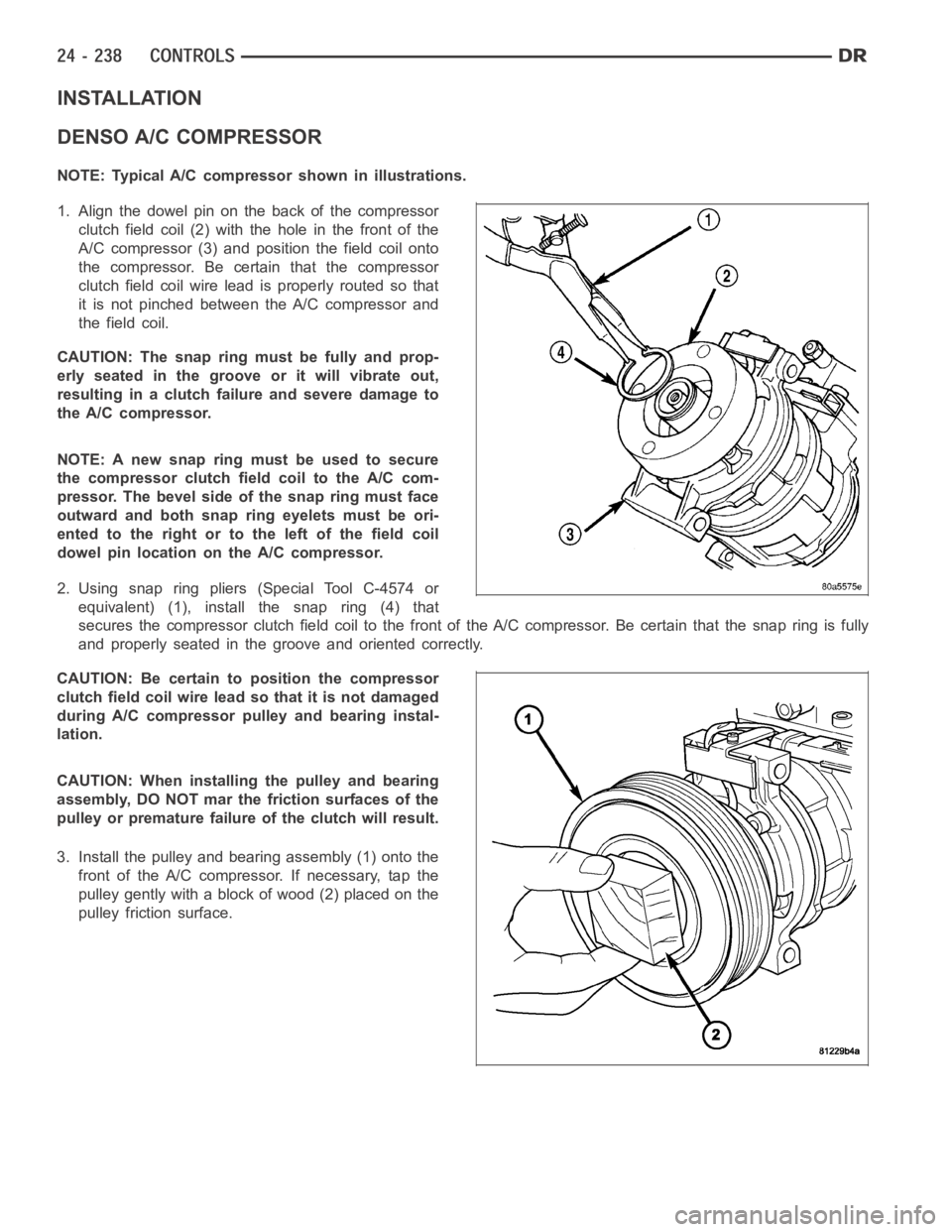

1. Align the dowel pin on the back of the compressor

clutch field coil (2) with the hole in the front of the

A/C compressor (3) and position the field coil onto

the compressor. Be certain that the compressor

clutch field coil wire lead is properly routed so that

it is not pinched between the A/C compressor and

the field coil.

CAUTION:Thesnapringmustbefullyandprop-

erly seated in the groove or it will vibrate out,

resulting in a clutch failure and severe damage to

the A/C compressor.

NOTE:Anewsnapringmustbeusedtosecure

the compressor clutch field coil to the A/C com-

pressor. The bevel side of the snap ring must face

outward and both snap ring eyelets must be ori-

ented to the right or to the left of the field coil

dowel pin location on the A/C compressor.

2. Using snap ring pliers (Special Tool C-4574 or

equivalent) (1), install the snap ring (4) that

secures the compressor clutch field coil to the front of the A/C compressor. Be certain that the snap ring is fully

and properly seated in the groove and oriented correctly.

CAUTION:Becertaintopositionthecompressor

clutch field coil wire lead so that it is not damaged

during A/C compressor pulley and bearing instal-

lation.

CAUTION: When installing the pulley and bearing

assembly, DO NOT mar the friction surfaces of the

pulley or premature failure of the clutch will result.

3. Install the pulley and bearing assembly (1) onto the

front of the A/C compressor. If necessary, tap the

pulley gently with a block of wood (2) placed on the

pulley friction surface.

Page 5080 of 5267

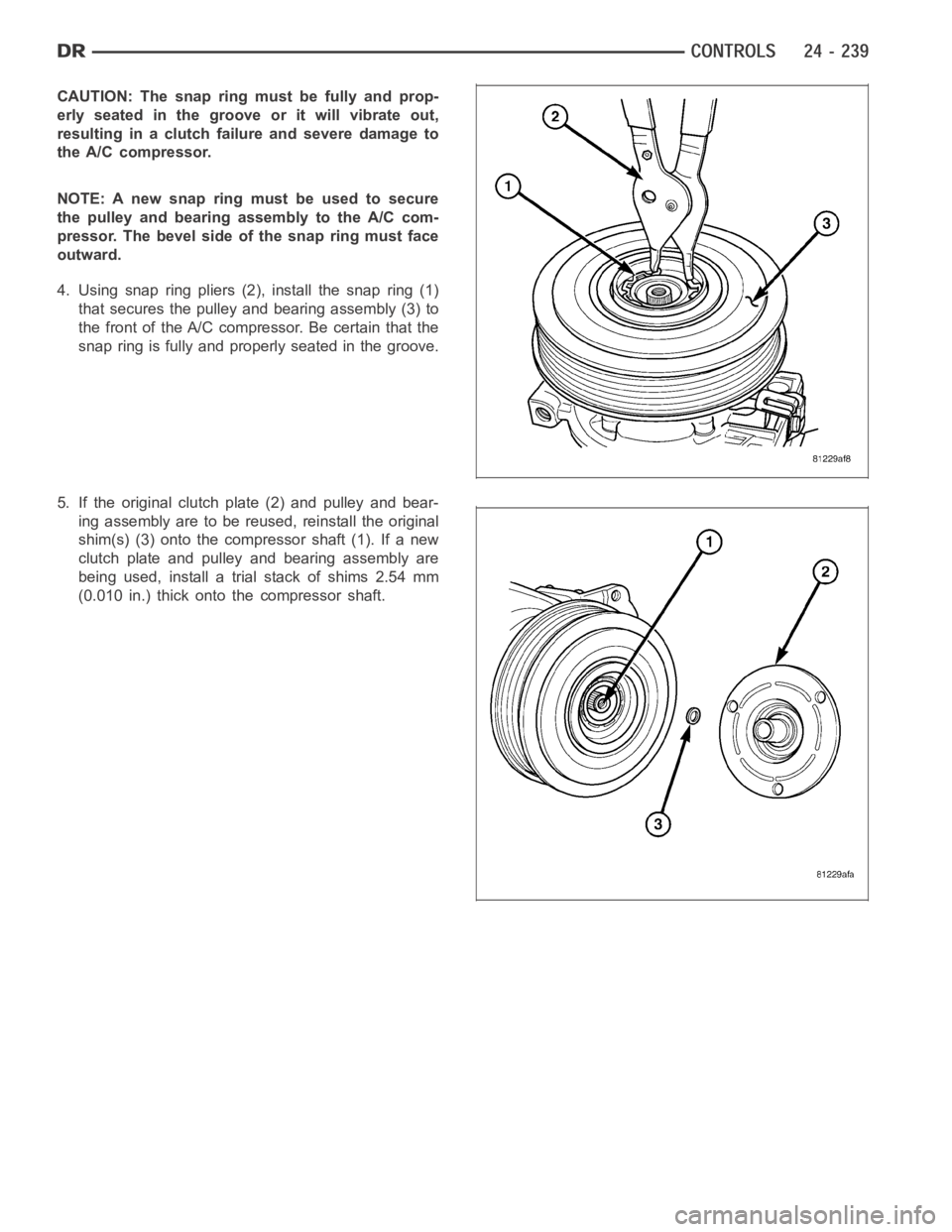

CAUTION:Thesnapringmustbefullyandprop-

erly seated in the groove or it will vibrate out,

resulting in a clutch failure and severe damage to

the A/C compressor.

NOTE:Anewsnapringmustbeusedtosecure

the pulley and bearing assembly to the A/C com-

pressor. The bevel side of the snap ring must face

outward.

4. Using snap ring pliers (2), install the snap ring (1)

that secures the pulley and bearing assembly (3) to

the front of the A/C compressor. Be certain that the

snap ring is fully and properly seated in the groove.

5. If the original clutch plate (2) and pulley and bear-

ing assembly are to be reused, reinstall the original

shim(s) (3) onto the compressor shaft (1). If a new

clutch plate and pulley and bearing assembly are

being used, install a trial stack of shims 2.54 mm

(0.010 in.) thick onto the compressor shaft.