DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 771 of 5267

For a complete wiring diagramRefer to Section 8W.

When Monitored:

With engine running.

Set Condition:

Low voltage detected at the APPS supply circuit or low voltage detected at the APPS 1 5–volt supply.

Possible Causes

(F855) APPS 5-VOLT SUPPLY OPEN

APPS HIGH RESISTANCE

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO (K922) RETURN CIRCUIT

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO BATTERY NEGATIVE

ECM

INTERMITTENT CONDITION

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO OTHER CIRCUITS

APPS

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

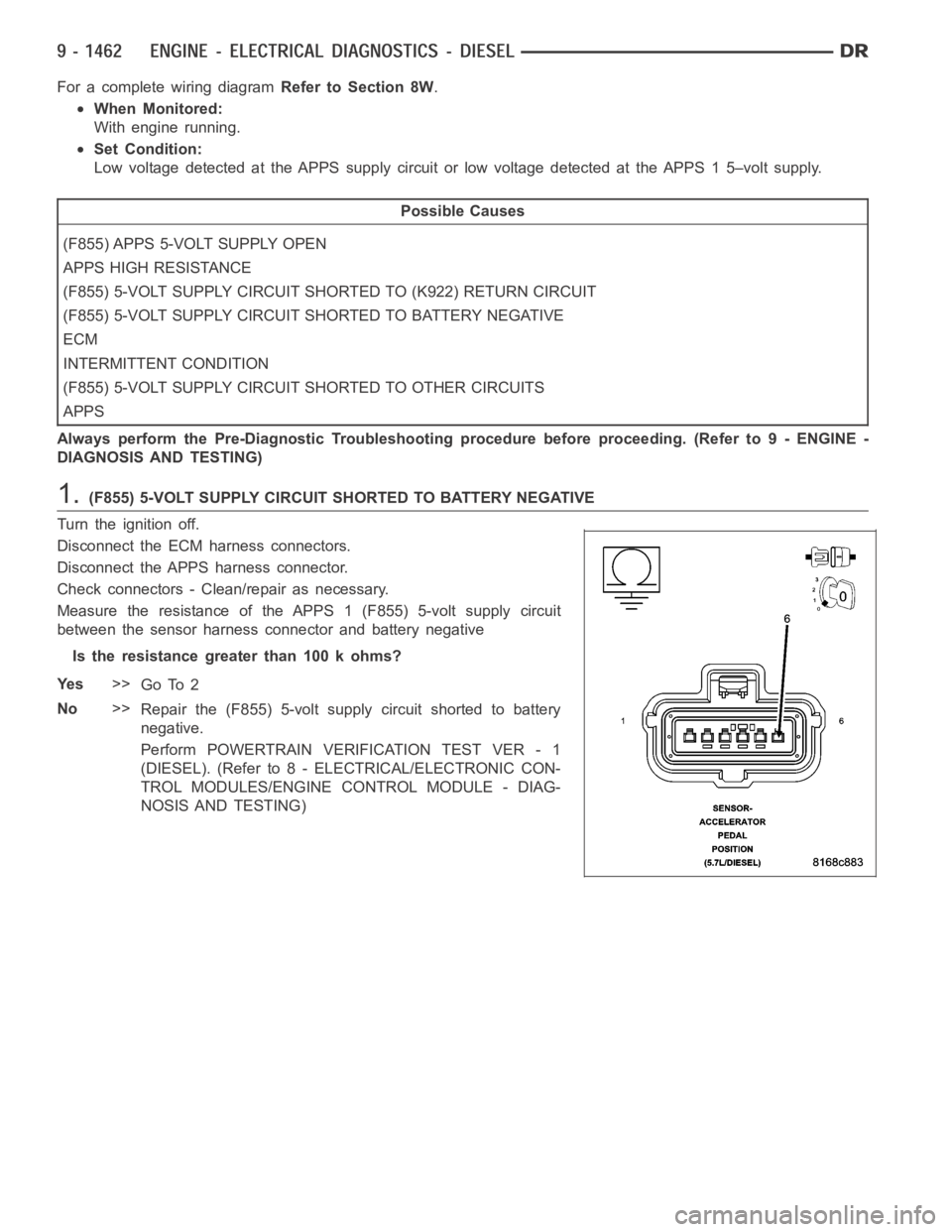

1.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO BATTERY NEGATIVE

Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the APPS harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance of the APPS1 (F855) 5-volt supply circuit

between the sensor harness connector and battery negative

Is the resistance greater than 100 k ohms?

Ye s>>

Go To 2

No>>

Repair the (F855) 5-volt supply circuit shorted to battery

negative.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 772 of 5267

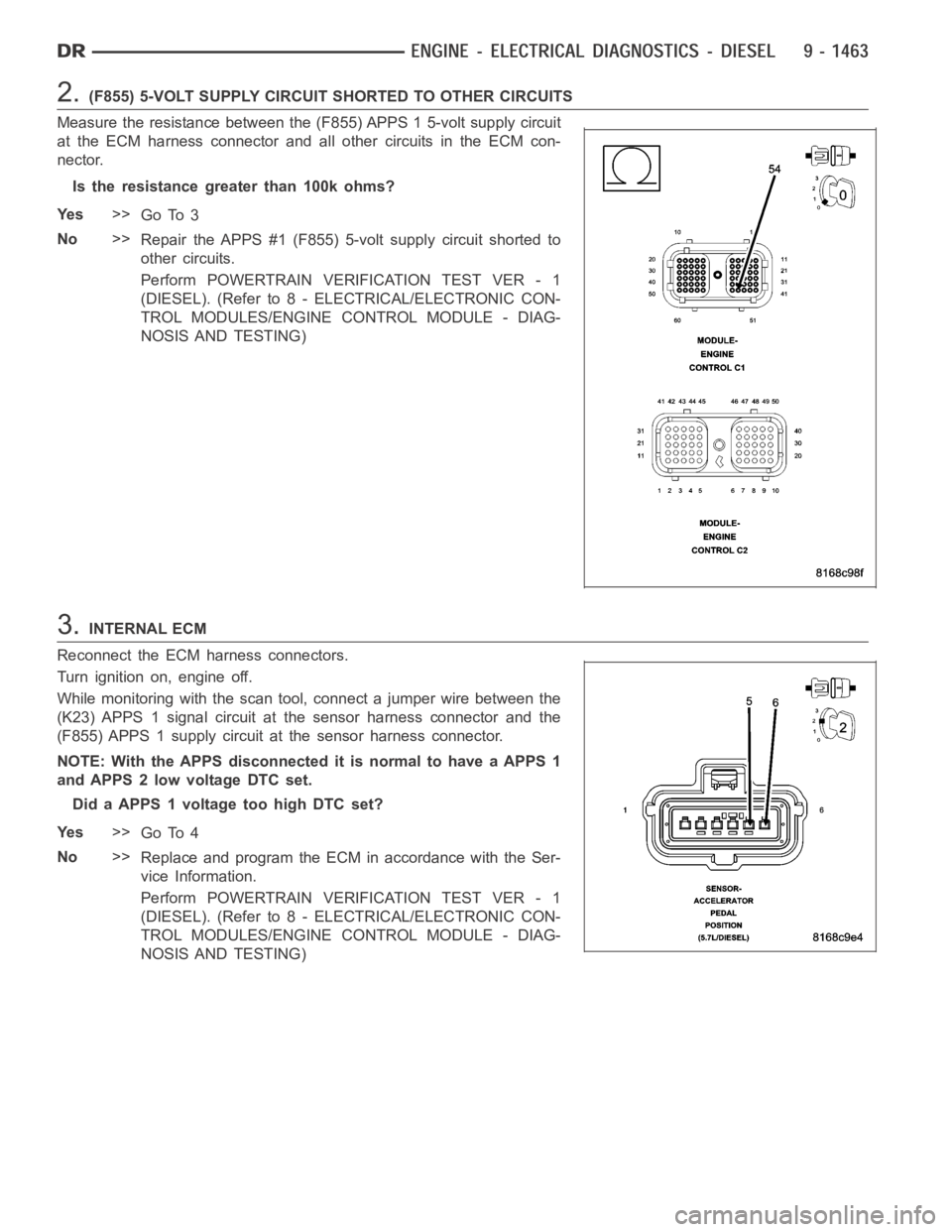

2.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO OTHER CIRCUITS

Measure the resistancebetween the (F855) APPS 1 5-volt supply circuit

at the ECM harness connector and all other circuits in the ECM con-

nector.

Is the resistance greater than 100k ohms?

Ye s>>

Go To 3

No>>

Repair the APPS #1 (F855) 5-volt supply circuit shorted to

other circuits.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

3.INTERNAL ECM

Reconnect the ECM harness connectors.

Turn ignition on, engine off.

While monitoring with the scan tool, connect a jumper wire between the

(K23) APPS 1 signal circuit at the sensor harness connector and the

(F855) APPS 1 supply circuit at the sensor harness connector.

NOTE: With the APPS disconnected it is normal to have a APPS 1

and APPS 2 low voltage DTC set.

Did a APPS 1 voltage too high DTC set?

Ye s>>

Go To 4

No>>

Replace and program the ECM in accordance with the Ser-

vice Information.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 773 of 5267

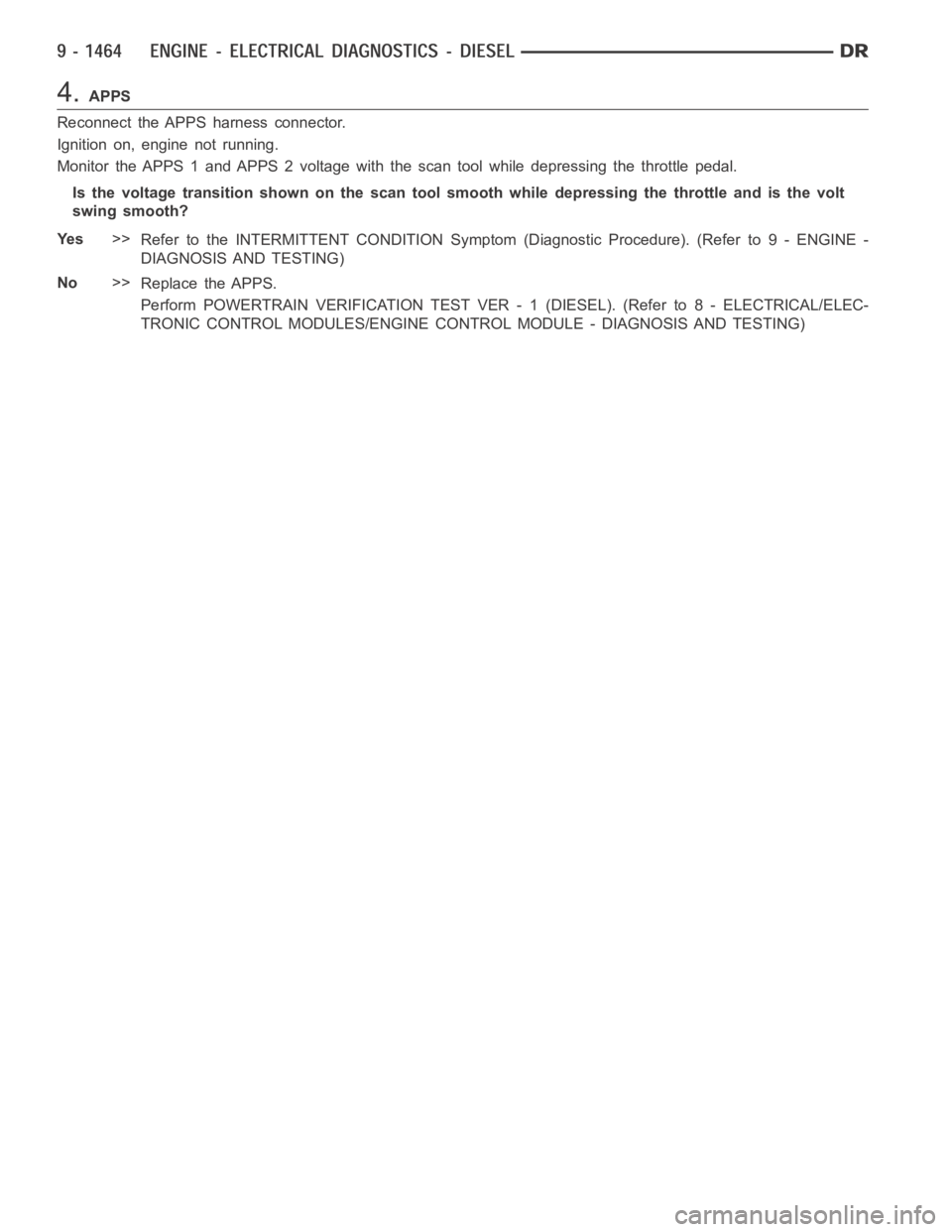

4.APPS

Reconnect the APPS harness connector.

Ignition on, engine not running.

Monitor the APPS 1 and APPS 2 voltage with the scan tool while depressing thethrottle pedal.

Is the voltage transition shown on the scan tool smooth while depressing thethrottleandisthevolt

swing smooth?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diagnostic Procedure). (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

No>>

Replace the APPS.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 774 of 5267

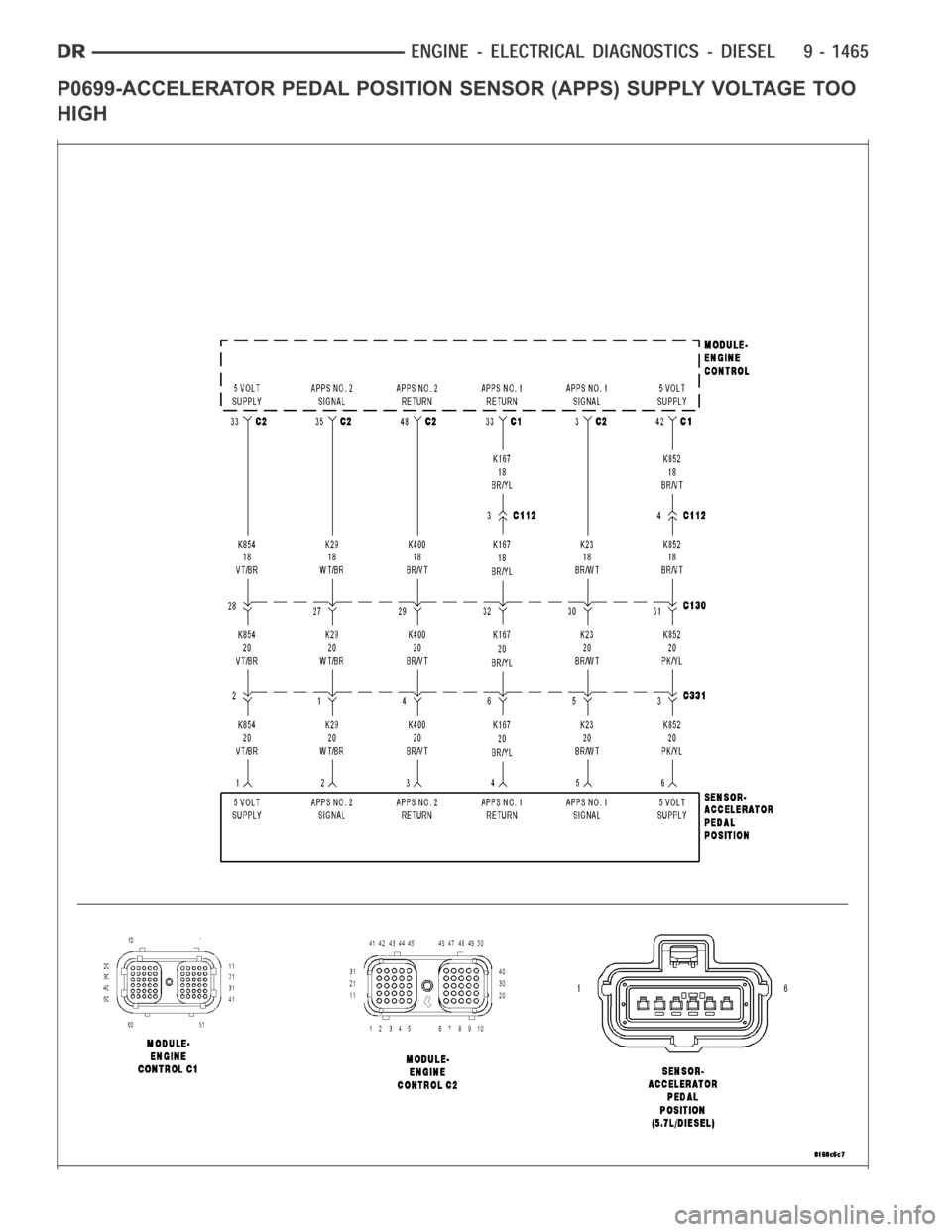

P0699-ACCELERATOR PEDAL POSITION SENSOR (APPS) SUPPLY VOLTAGE TOO

HIGH

Page 775 of 5267

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Whileengineisrunning.

Set Condition:

High voltage detected at the APPS supply circuit.

Possible Causes

(F855) 5-VOLT SUPPLY OPEN

(F855) 5-VOLT SUPPLY SHORT TO VOLTAGE

ECM

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

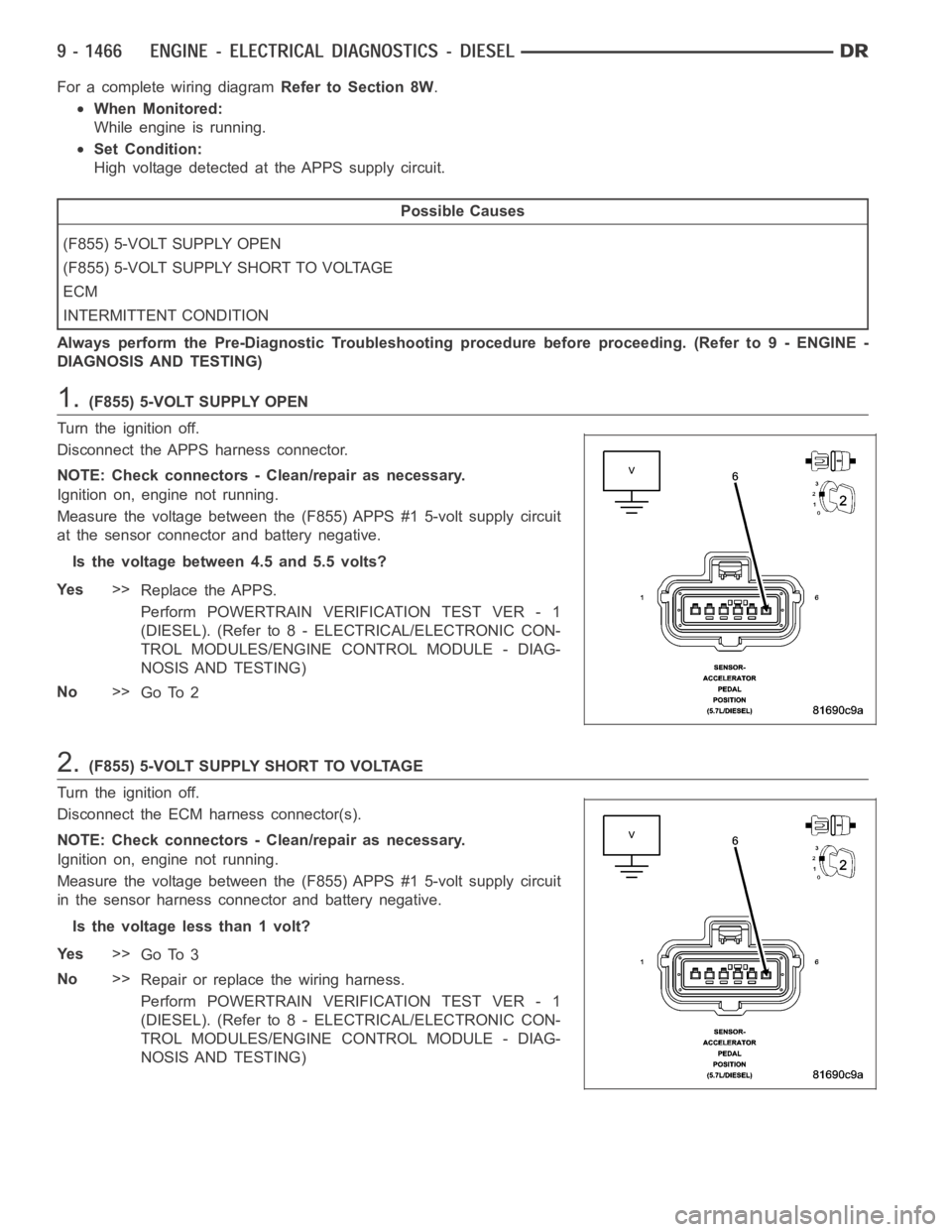

1.(F855) 5-VOLT SUPPLY OPEN

Turn the ignition off.

Disconnect the APPS harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Measure the voltage between the (F855) APPS #1 5-volt supply circuit

at the sensor connector and battery negative.

Is the voltage between 4.5 and 5.5 volts?

Ye s>>

Replace the APPS.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 2

2.(F855) 5-VOLT SUPPLY SHORT TO VOLTAGE

Turn the ignition off.

Disconnect the ECM harness connector(s).

NOTE: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Measure the voltage between the (F855) APPS #1 5-volt supply circuit

in the sensor harness connector and battery negative.

Is the voltage less than 1 volt?

Ye s>>

Go To 3

No>>

Repair or replace the wiring harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 776 of 5267

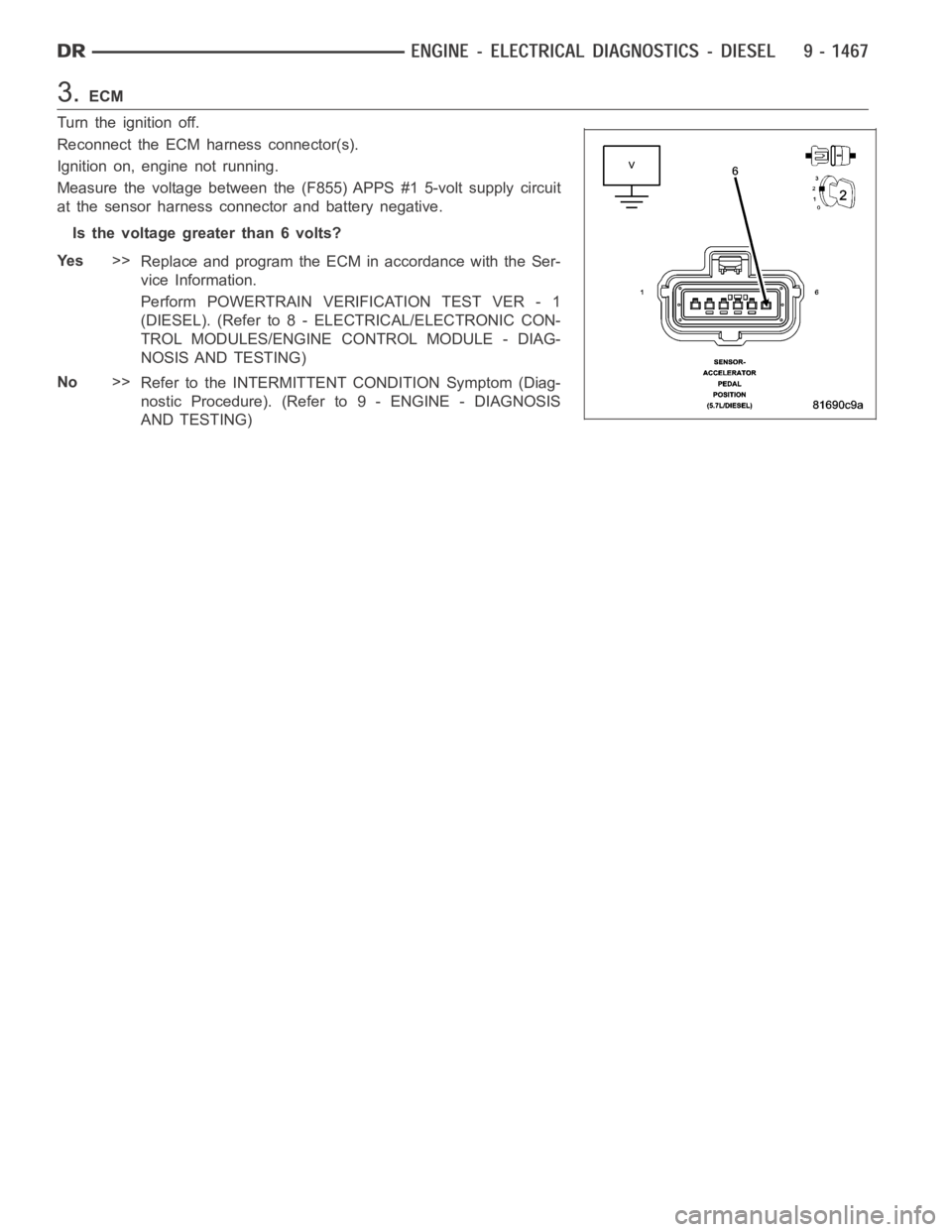

3.ECM

Turn the ignition off.

Reconnect the ECM harness connector(s).

Ignition on, engine not running.

Measure the voltage between the (F855) APPS #1 5-volt supply circuit

at the sensor harness connector and battery negative.

Is the voltage greater than 6 volts?

Ye s>>

Replace and program the ECM in accordance with the Ser-

vice Information.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Refer to the INTERMITTENT CONDITION Symptom (Diag-

nostic Procedure). (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)

Page 777 of 5267

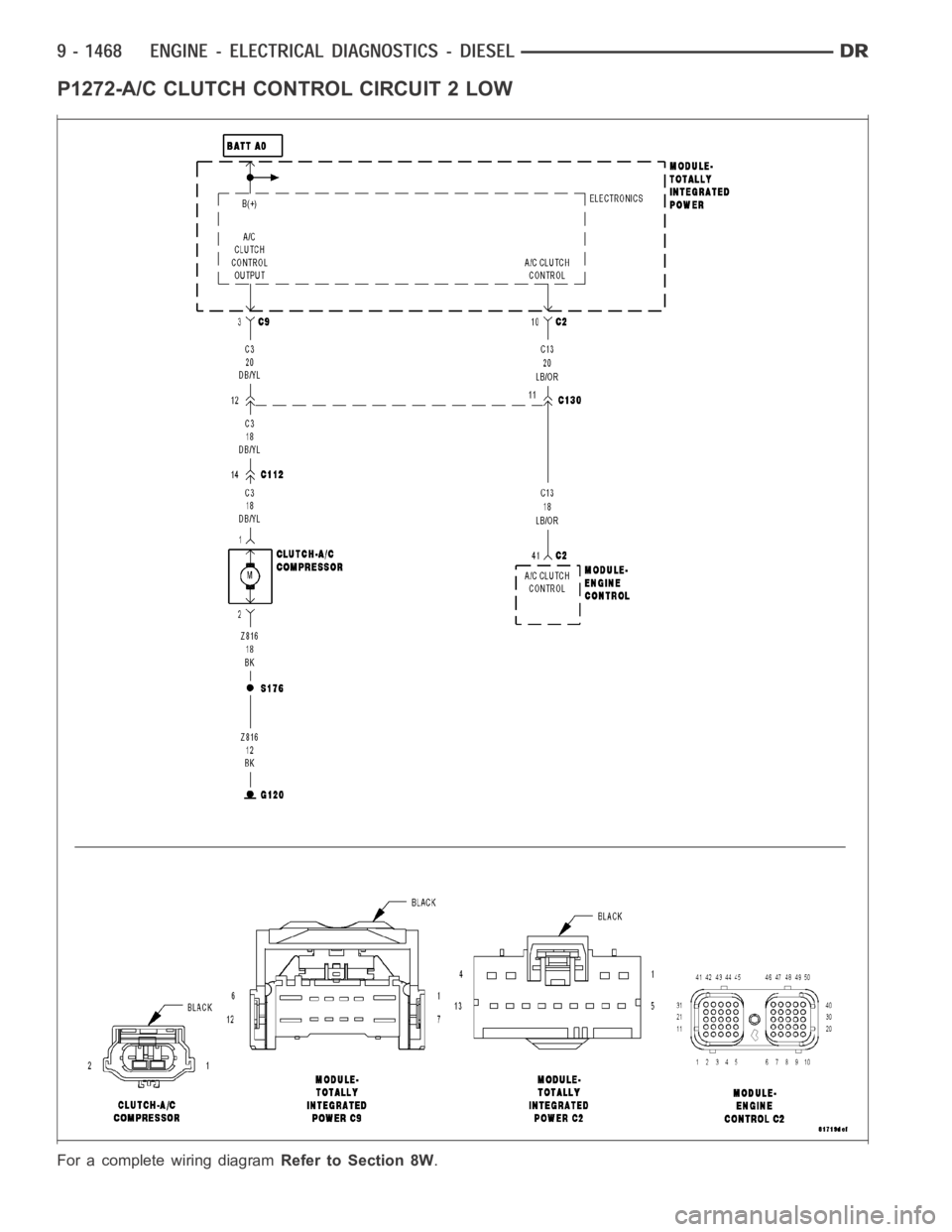

P1272-A/C CLUTCH CONTROL CIRCUIT 2 LOW

For a complete wiring diagramRefer to Section 8W.

Page 778 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10 volts. A/C Switch on.

Set Condition:

A shorted condition is detected in the A/C clutch relay control circuit. One Trip Fault. Three good trips to turn

off the MIL.

Possible Causes

(C3) A/C COMPRESSOR CLUTCH CONTROL CIRCUIT SHORTED TO GROUND

A/C COMPRESSOR CLUTCH

TIPM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.A/C COMPRESSOR CLUTCH OPERATION

Ignition on, engine not running.

With a scan tool under the PCM Actuators, actuate the A/C Clutch.

Is the A/C Clutch actuating?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

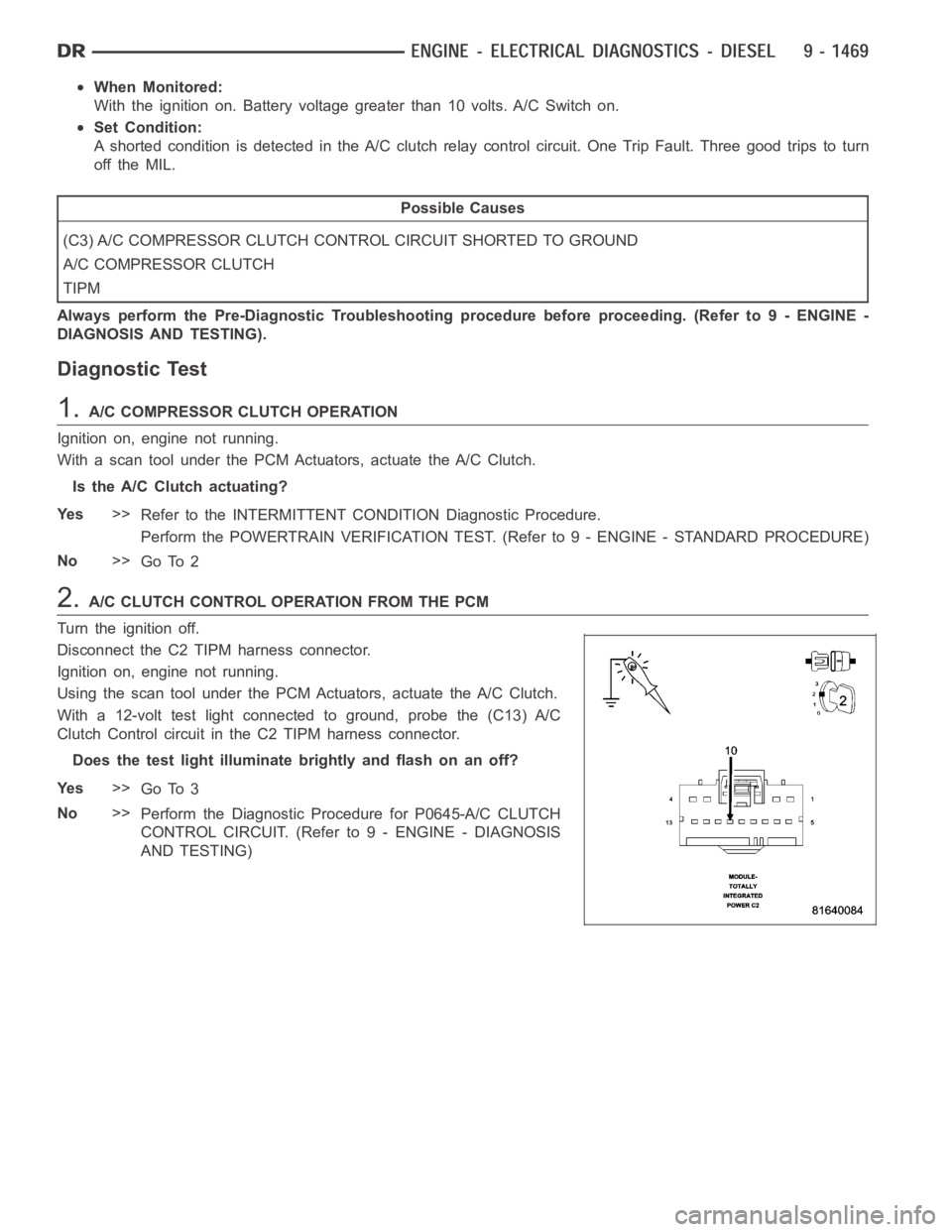

2.A/C CLUTCH CONTROL OPERATION FROM THE PCM

Turn the ignition off.

Disconnect the C2 TIPM harness connector.

Ignition on, engine not running.

Using the scan tool under the PCM Actuators, actuate the A/C Clutch.

With a 12-volt test light connected to ground, probe the (C13) A/C

Clutch Control circuit in the C2 TIPM harness connector.

Does the test light illuminate brightly and flash on an off?

Ye s>>

Go To 3

No>>

Perform the Diagnostic Procedure for P0645-A/C CLUTCH

CONTROL CIRCUIT. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)

Page 779 of 5267

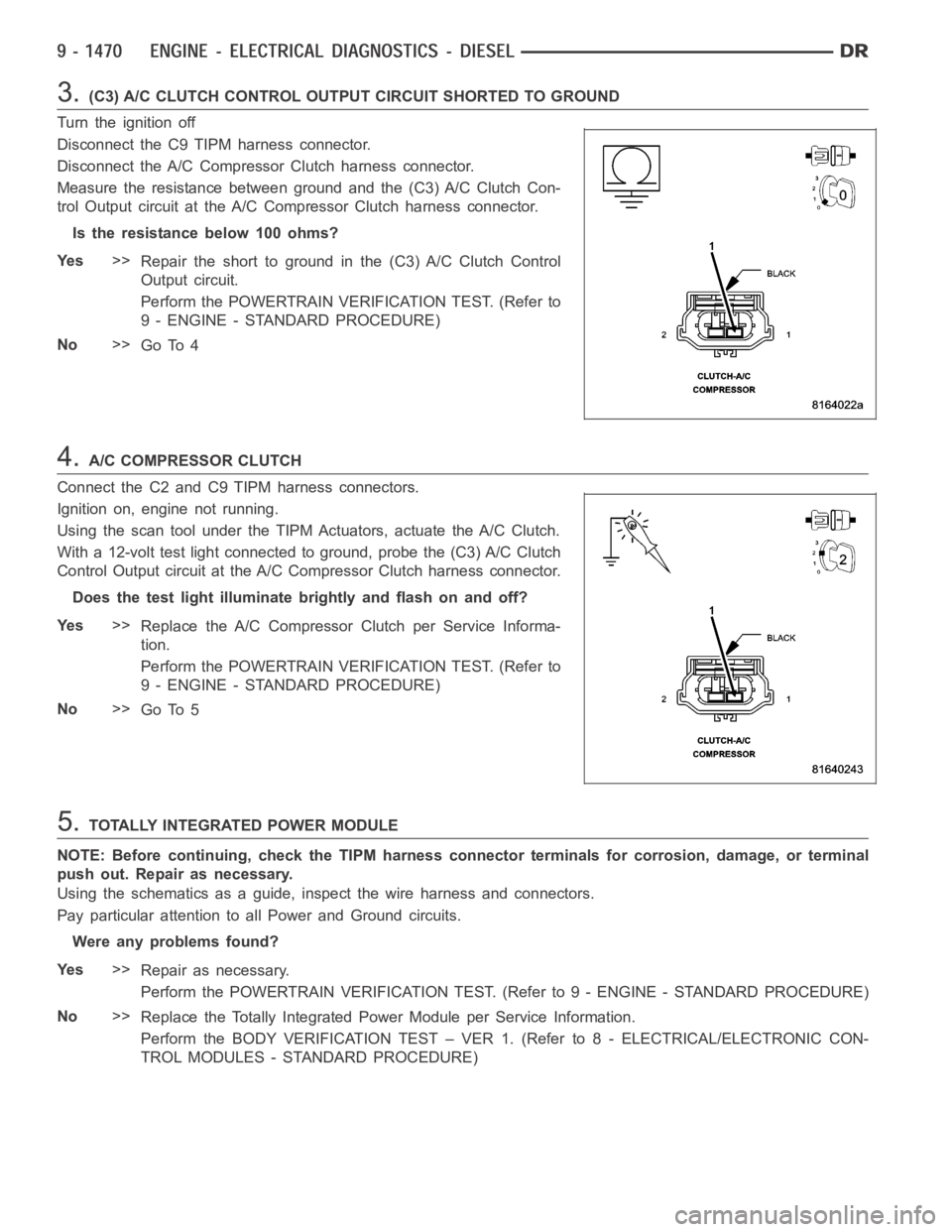

3.(C3) A/C CLUTCH CONTROL OUTPUT CIRCUIT SHORTED TO GROUND

Turn the ignition off

Disconnect the C9 TIPM harness connector.

Disconnect the A/C Compressor Clutch harness connector.

Measure the resistance between ground and the (C3) A/C Clutch Con-

trol Output circuit at the A/C Compressor Clutch harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (C3) A/C Clutch Control

Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.A/C COMPRESSOR CLUTCH

Connect the C2 and C9 TIPM harness connectors.

Ignition on, engine not running.

Using the scan tool under the TIPM Actuators, actuate the A/C Clutch.

With a 12-volt test light connected to ground, probe the (C3) A/C Clutch

Control Output circuit at the A/C Compressor Clutch harness connector.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Replace the A/C Compressor Clutch per Service Informa-

tion.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES - STANDARD PROCEDURE)

Page 780 of 5267

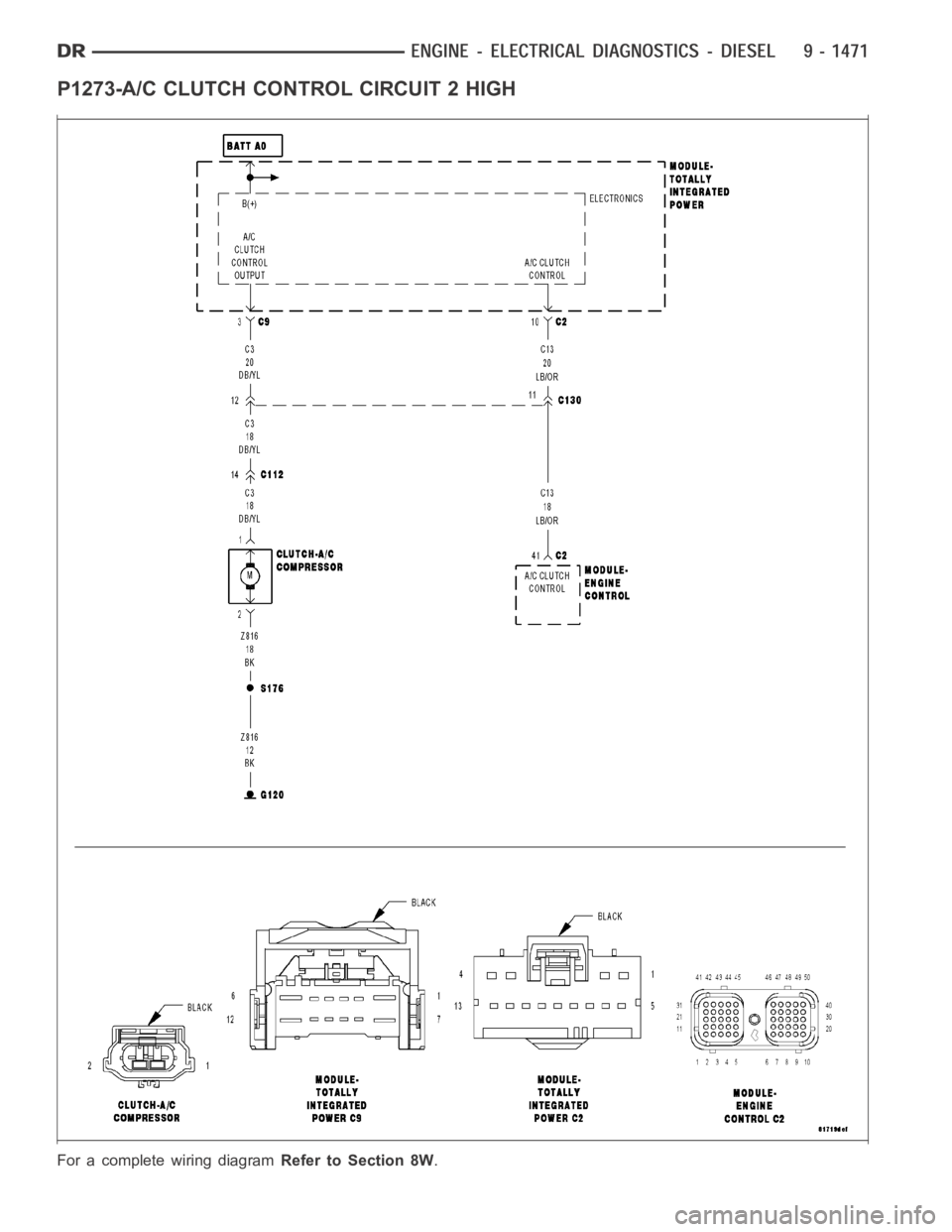

P1273-A/C CLUTCH CONTROL CIRCUIT 2 HIGH

For a complete wiring diagramRefer to Section 8W.