DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 801 of 5267

5.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to all Power and Ground circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module in accordance with the Service Information.

Perform the BODY VERIFICATION TEST – VER 1. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 802 of 5267

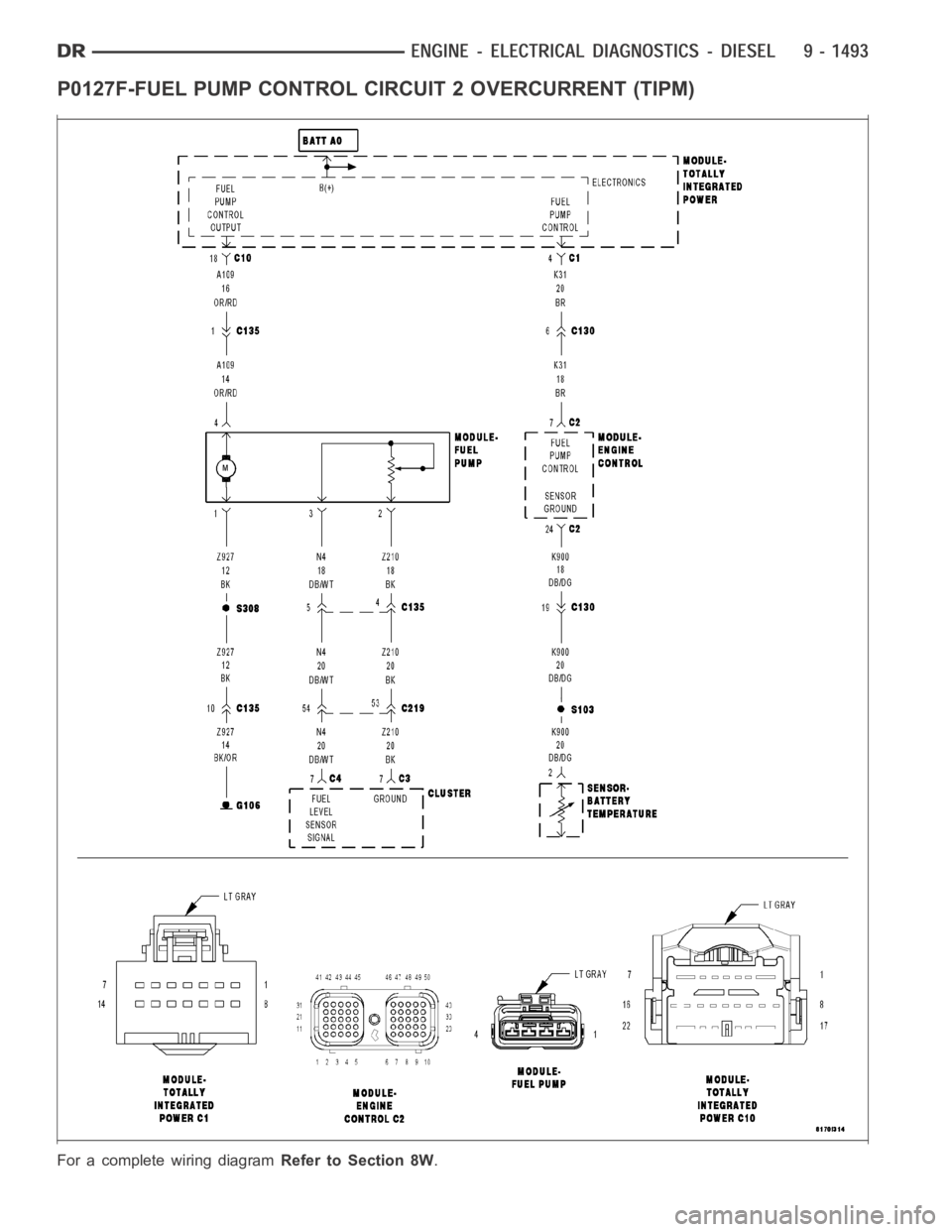

P0127F-FUEL PUMP CONTROL CIRCUIT 2 OVERCURRENT (TIPM)

For a complete wiring diagramRefer to Section 8W.

Page 803 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts. TIPM requesting Fuel Pump operation.

Set Condition:

An overcurrent condition is detected in the fuel pump control output circuit. One Trip Fault. Three good trips to

turn off the MIL.

Possible Causes

TERMINAL DAMAGE OR CORROSION

FUEL PUMP MOTOR GROUND HIGH RESISTANCE

(A109) FUEL PUMP CONTROL OUTPUT CIRCUIT HIGH RESISTANCE

FUEL PUMP MOTOR

TIPM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.FUEL PUMP OPERATION

Ignition on, engine not running.

With a scan tool in the TIPM Actuators, actuate the Fuel Pump.

Is the Fuel Pump operating?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.VISUAL AND PHYSICAL CONNECTOR AND TERMINAL INSPECTION

Turn the ignition off.

Disconnect the C10 TIPM harness connector.

Disconnect the Fuel Pump Module harness connector.

Inspect the terminal and connector condition. Check for signs of corrosion build up or damage the would compro-

mise the terminal to controller pin connector.

NOTE: Make sure that all in-line connectors are inspected for corrosion and/or damage.

Visually inspect the wiring harness. Look for any chafed, pierced, pinched or partially broken wires hidden in the

wire insulation.

Were any of the above conditions found?

Ye s>>

Repair or replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 804 of 5267

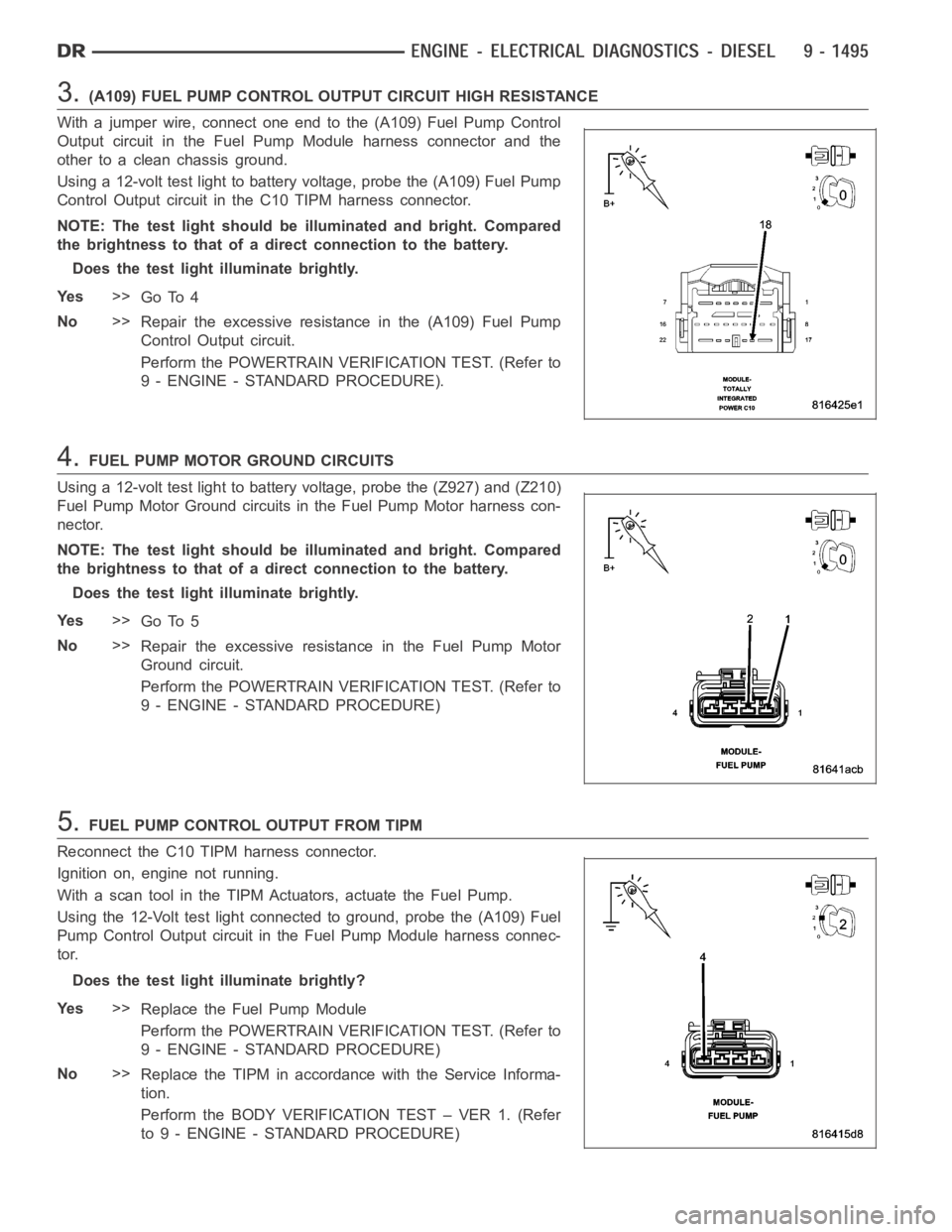

3.(A109) FUEL PUMP CONTROL OUTPUT CIRCUIT HIGH RESISTANCE

With a jumper wire, connect one end to the (A109) Fuel Pump Control

Output circuit in the Fuel Pump Module harness connector and the

other to a clean chassis ground.

Using a 12-volt test light to battery voltage, probe the (A109) Fuel Pump

Control Output circuit in the C10 TIPM harness connector.

NOTE: The test light should be illuminated and bright. Compared

the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly.

Ye s>>

Go To 4

No>>

Repair the excessive resistance in the (A109) Fuel Pump

Control Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE).

4.FUEL PUMP MOTOR GROUND CIRCUITS

Using a 12-volt test light to battery voltage, probe the (Z927) and (Z210)

Fuel Pump Motor Ground circuits in the Fuel Pump Motor harness con-

nector.

NOTE: The test light should be illuminated and bright. Compared

the brightness to that of a direct connection to the battery.

Does the test light illuminate brightly.

Ye s>>

Go To 5

No>>

Repair the excessive resistance in the Fuel Pump Motor

Ground circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

5.FUEL PUMP CONTROL OUTPUT FROM TIPM

Reconnect the C10 TIPM harness connector.

Ignition on, engine not running.

With a scan tool in the TIPM Actuators, actuate the Fuel Pump.

Using the 12-Volt test light connected to ground, probe the (A109) Fuel

Pump Control Output circuit in the Fuel Pump Module harness connec-

tor.

Does the test light illuminate brightly?

Ye s>>

Replace the Fuel Pump Module

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the TIPM in accordance with the Service Informa-

tion.

Perform the BODY VERIFICATION TEST – VER 1. (Refer

to 9 - ENGINE - STANDARD PROCEDURE)

Page 805 of 5267

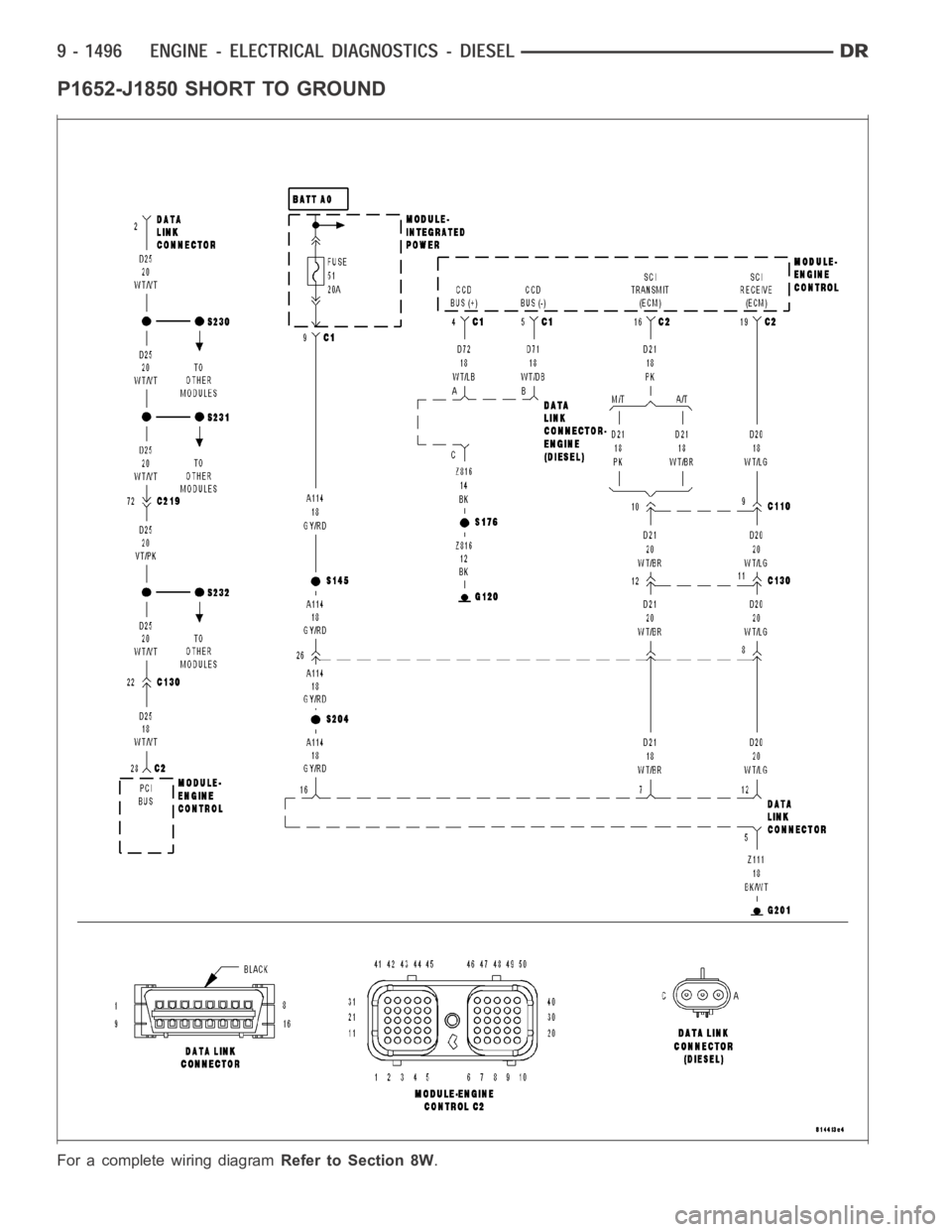

P1652-J1850 SHORT TO GROUND

For a complete wiring diagramRefer to Section 8W.

Page 806 of 5267

When Monitored:

While the ignition is on.

Set Condition:

The ECM detects a short to ground on the J1850.

Possible Causes

ECM

(D25) J1850 SHORTED

COMMUNICATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

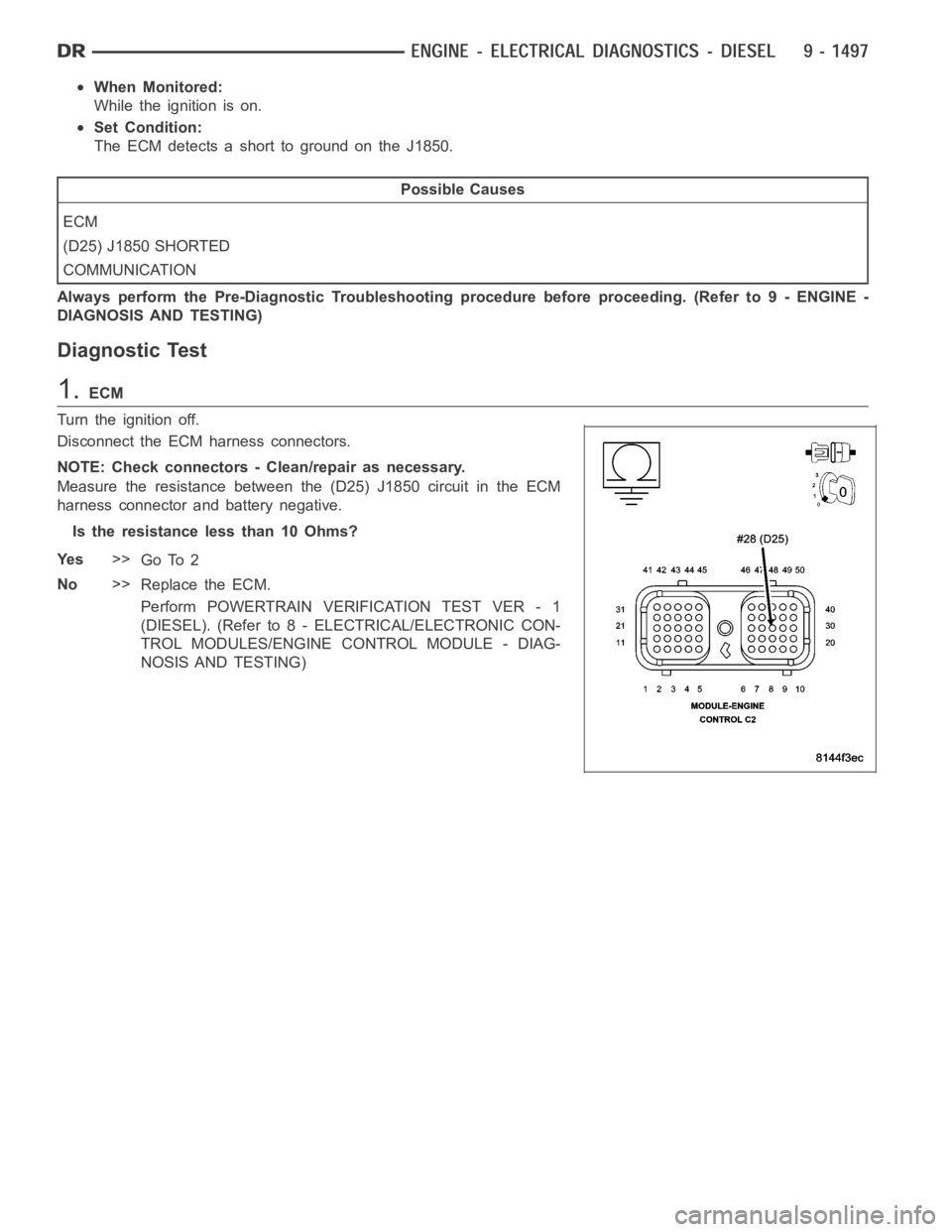

1.ECM

Turn the ignition off.

Disconnect the ECM harness connectors.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the (D25) J1850 circuit in the ECM

harness connector and battery negative.

Is the resistance less than 10 Ohms?

Ye s>>

Go To 2

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 807 of 5267

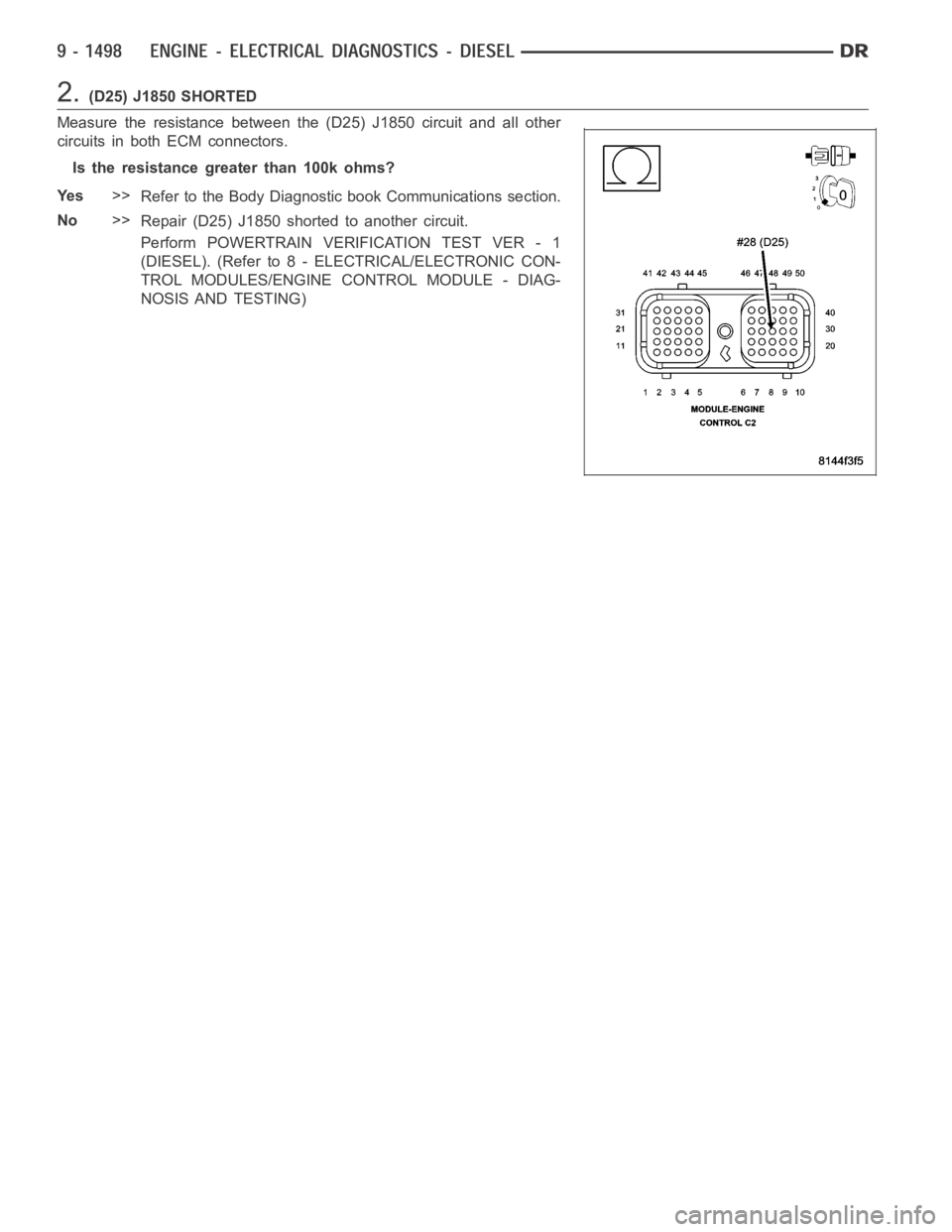

2.(D25) J1850 SHORTED

Measure the resistance between the (D25) J1850 circuit and all other

circuits in both ECM connectors.

Is the resistance greater than 100k ohms?

Ye s>>

Refer to the Body Diagnostic book Communications section.

No>>

Repair (D25) J1850 shorted to another circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 808 of 5267

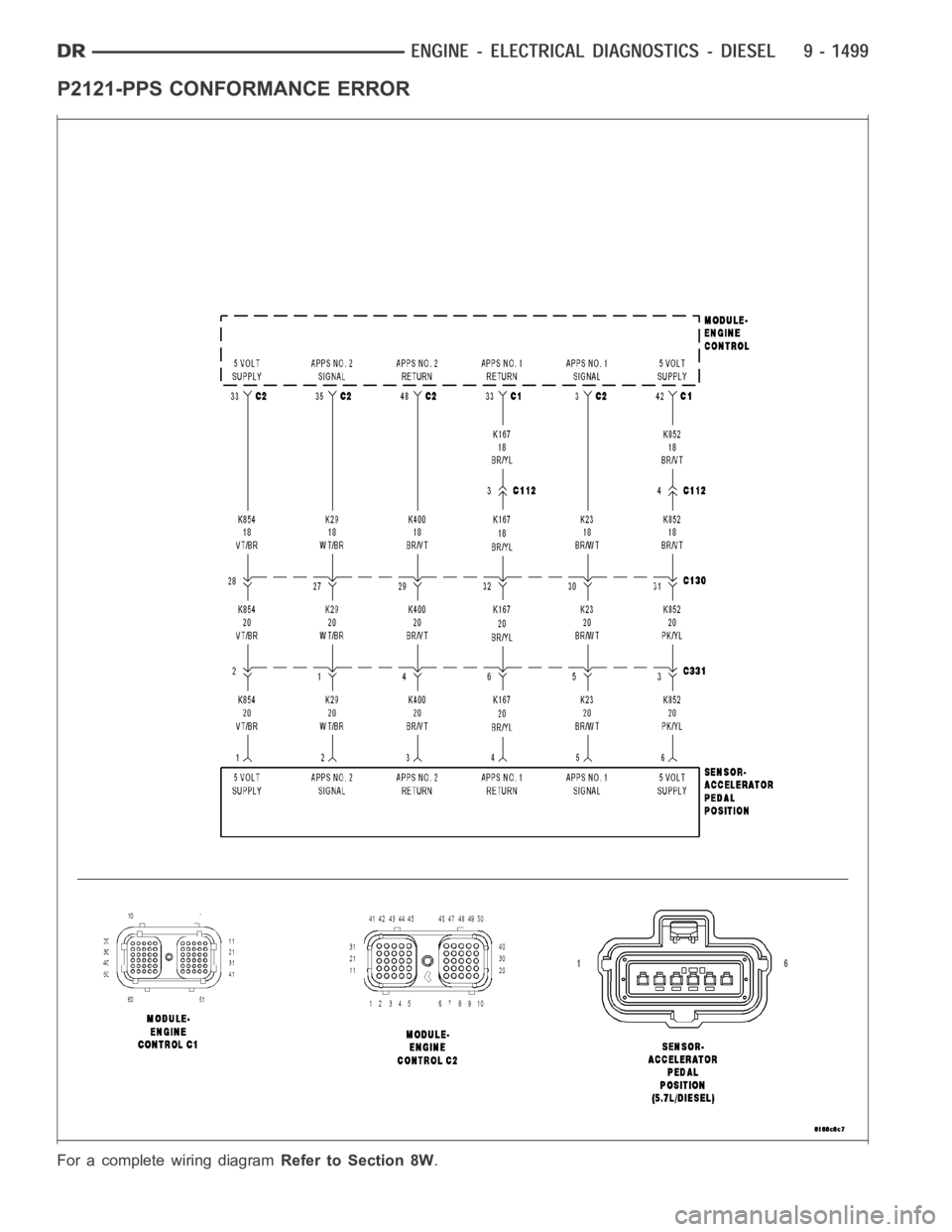

P2121-PPS CONFORMANCE ERROR

For a complete wiring diagramRefer to Section 8W.

Page 809 of 5267

When Monitored:

While the engine is running

Set Condition:

The ECM detected a conformance error between PPS 1 and PPS 2

Possible Causes

OTHER DTC’S

WIRING HARNESS OR CONNECTOR DAMAGED

APPS

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S PRESENT

Using the scan tool, check for any additional APPS fault codes

Do you have any additiona APPS faults?

Ye s>>

troubleshoot other DTC’s first, Go To 2

No>>

Go To 12

2.APPS HARNESS

Verify that the APPS is connected.

Inspect the harness and the APPS connector.

Are any pins damaged?

Ye s>>

Repair or replace the harness.

No>>

Go To 3

3.APPS

Monitor the APPS 1 and APPS 2 voltage with the scan tool while depressing theacceralator pedal.

Is the voltage transition shown on the scan tool smooth while depressing the acceralator pedal and is

the voltage from APPS 1 twice as much as the voltage from APPS 2?

Ye s>>

Go To 4

No>>

Replace the APPS.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 810 of 5267

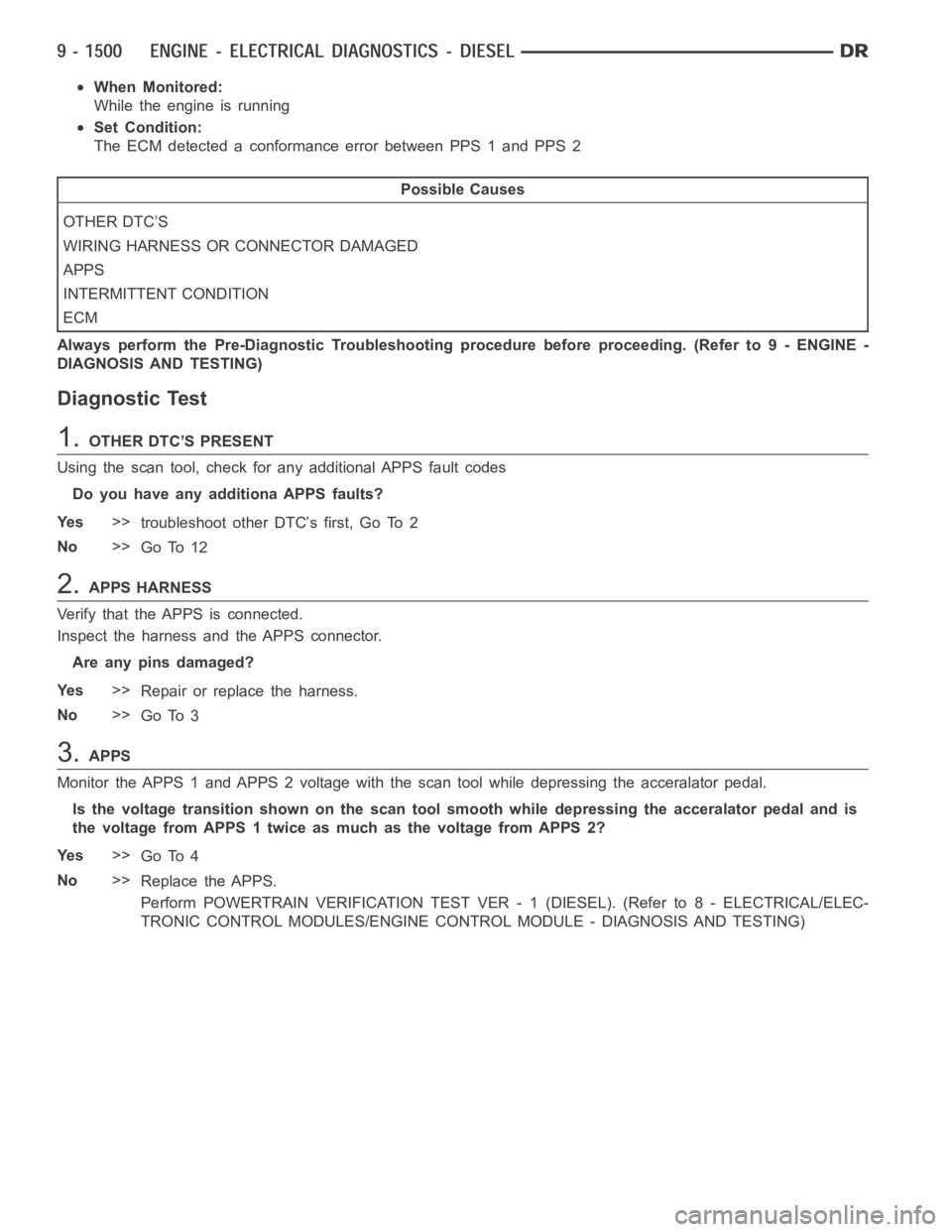

4.OPEN SIGNAL CIRCUIT

Disconnect the ECM connectors.

Disconnect the APPS connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the APPS 1 signal circuit between the APPS

sensor connector and the ECM connector.

Ye s>>

Go To 5

No>>

Repair or Replace the harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

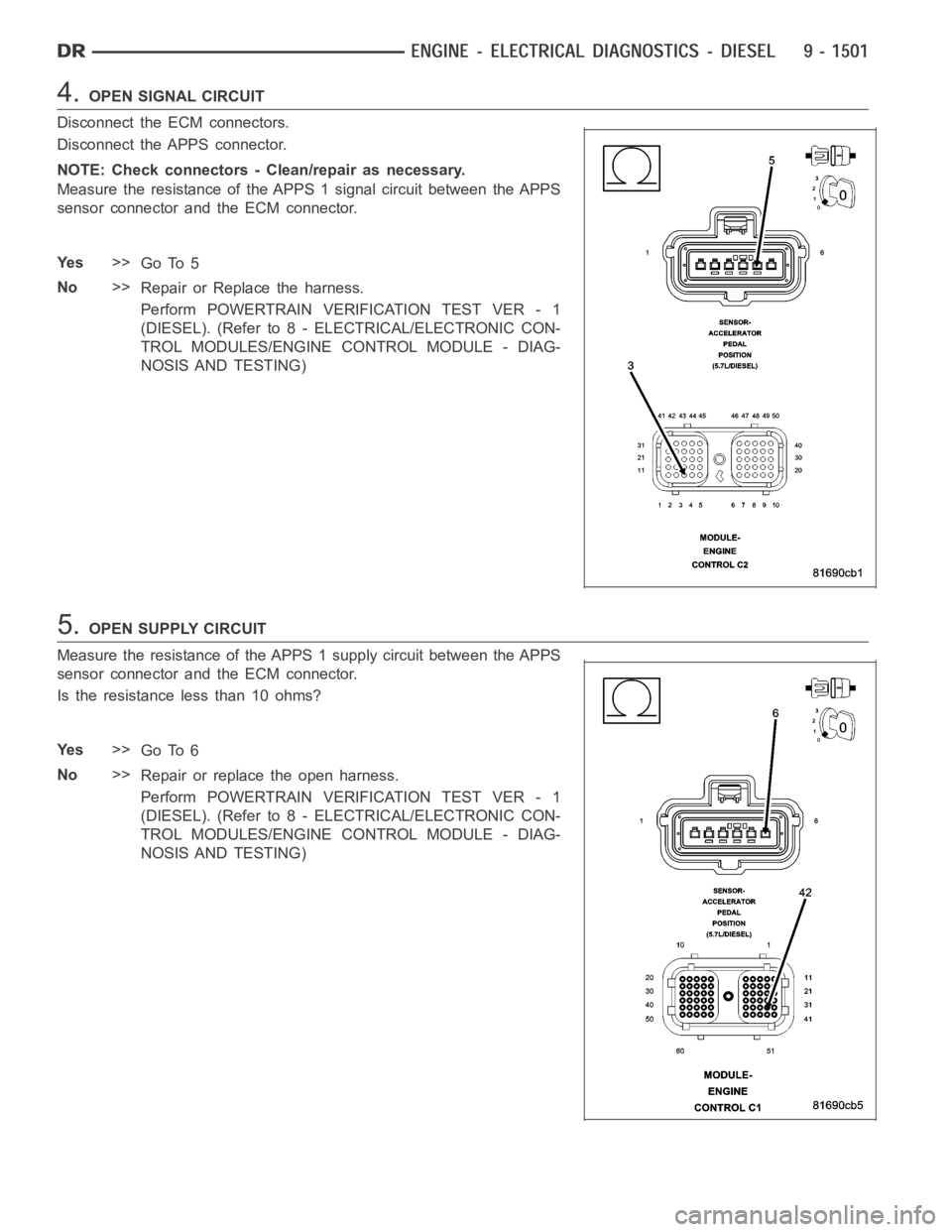

5.OPEN SUPPLY CIRCUIT

Measure the resistance of the APPS 1 supply circuit between the APPS

sensor connector and the ECM connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 6

No>>

Repair or replace the open harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)