DODGE TOWN AND COUNTRY 2001 Service Manual

Manufacturer: DODGE, Model Year: 2001, Model line: TOWN AND COUNTRY, Model: DODGE TOWN AND COUNTRY 2001Pages: 2321, PDF Size: 68.09 MB

Page 1701 of 2321

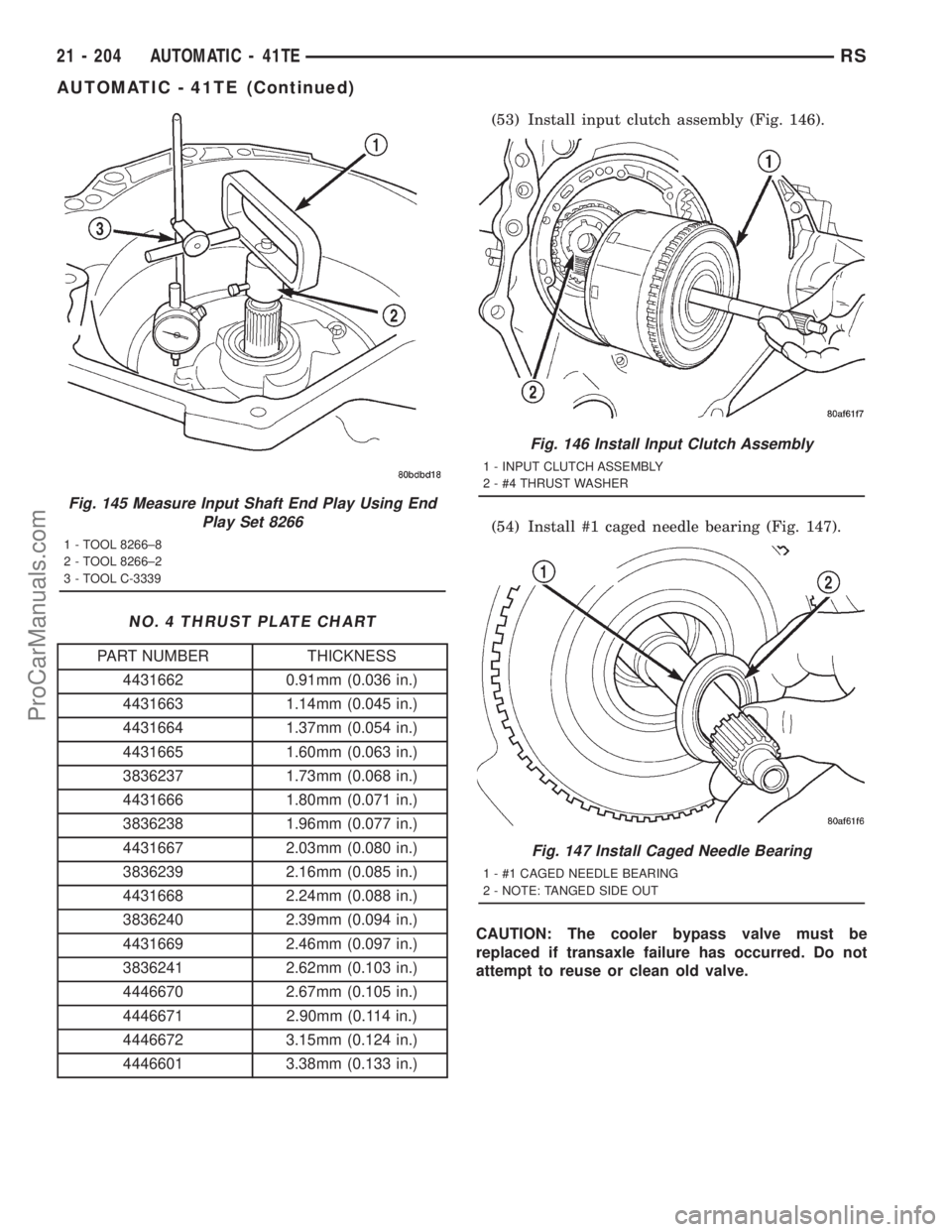

NO. 4 THRUST PLATE CHART

PART NUMBER THICKNESS

4431662 0.91mm (0.036 in.)

4431663 1.14mm (0.045 in.)

4431664 1.37mm (0.054 in.)

4431665 1.60mm (0.063 in.)

3836237 1.73mm (0.068 in.)

4431666 1.80mm (0.071 in.)

3836238 1.96mm (0.077 in.)

4431667 2.03mm (0.080 in.)

3836239 2.16mm (0.085 in.)

4431668 2.24mm (0.088 in.)

3836240 2.39mm (0.094 in.)

4431669 2.46mm (0.097 in.)

3836241 2.62mm (0.103 in.)

4446670 2.67mm (0.105 in.)

4446671 2.90mm (0.114 in.)

4446672 3.15mm (0.124 in.)

4446601 3.38mm (0.133 in.)(53) Install input clutch assembly (Fig. 146).

(54) Install #1 caged needle bearing (Fig. 147).

CAUTION: The cooler bypass valve must be

replaced if transaxle failure has occurred. Do not

attempt to reuse or clean old valve.

Fig. 145 Measure Input Shaft End Play Using End

Play Set 8266

1 - TOOL 8266±8

2 - TOOL 8266±2

3 - TOOL C-3339

Fig. 146 Install Input Clutch Assembly

1 - INPUT CLUTCH ASSEMBLY

2 - #4 THRUST WASHER

Fig. 147 Install Caged Needle Bearing

1 - #1 CAGED NEEDLE BEARING

2 - NOTE: TANGED SIDE OUT

21 - 204 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1702 of 2321

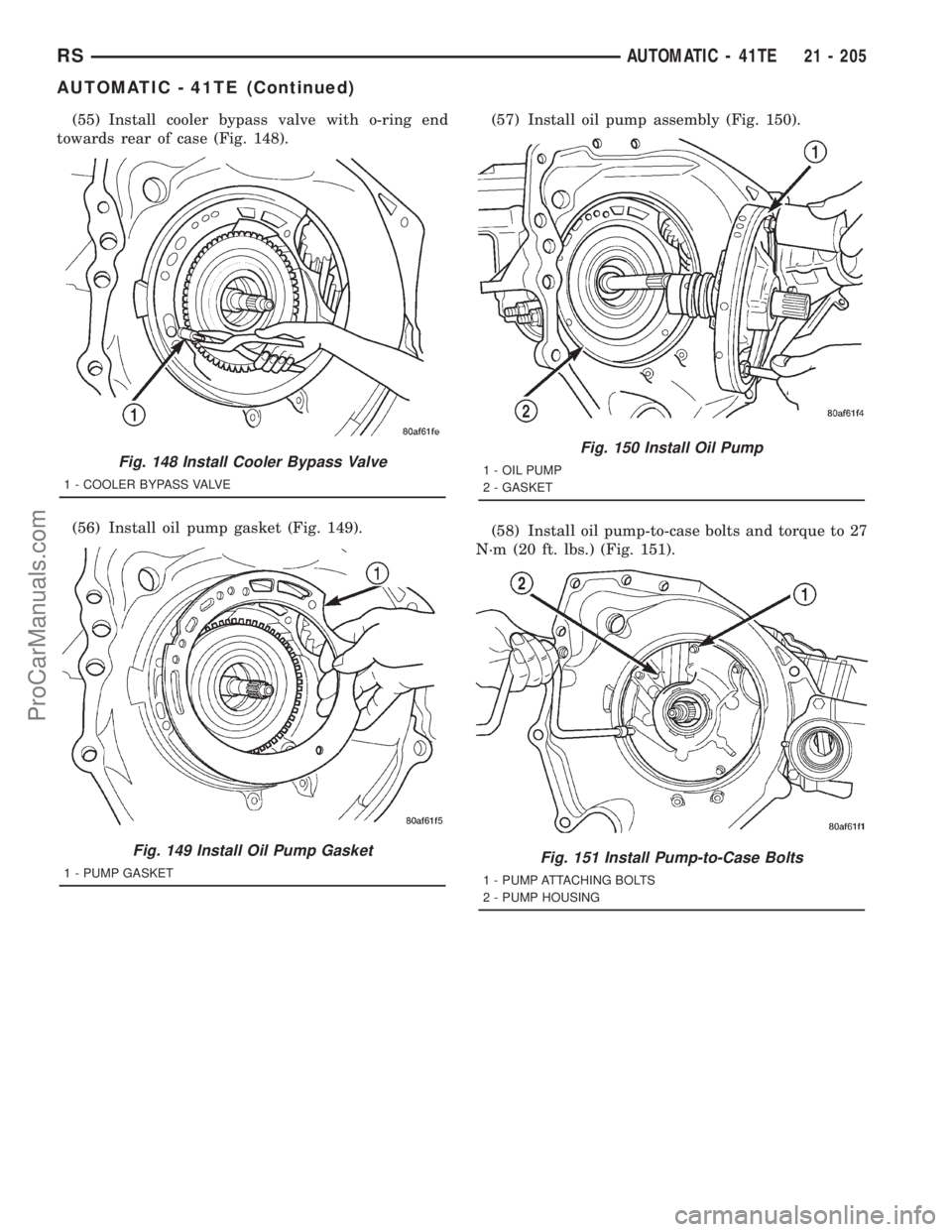

(55) Install cooler bypass valve with o-ring end

towards rear of case (Fig. 148).

(56) Install oil pump gasket (Fig. 149).(57) Install oil pump assembly (Fig. 150).

(58) Install oil pump-to-case bolts and torque to 27

N´m (20 ft. lbs.) (Fig. 151).

Fig. 148 Install Cooler Bypass Valve

1 - COOLER BYPASS VALVE

Fig. 149 Install Oil Pump Gasket

1 - PUMP GASKET

Fig. 150 Install Oil Pump

1 - OIL PUMP

2 - GASKET

Fig. 151 Install Pump-to-Case Bolts

1 - PUMP ATTACHING BOLTS

2 - PUMP HOUSING

RSAUTOMATIC - 41TE21 - 205

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1703 of 2321

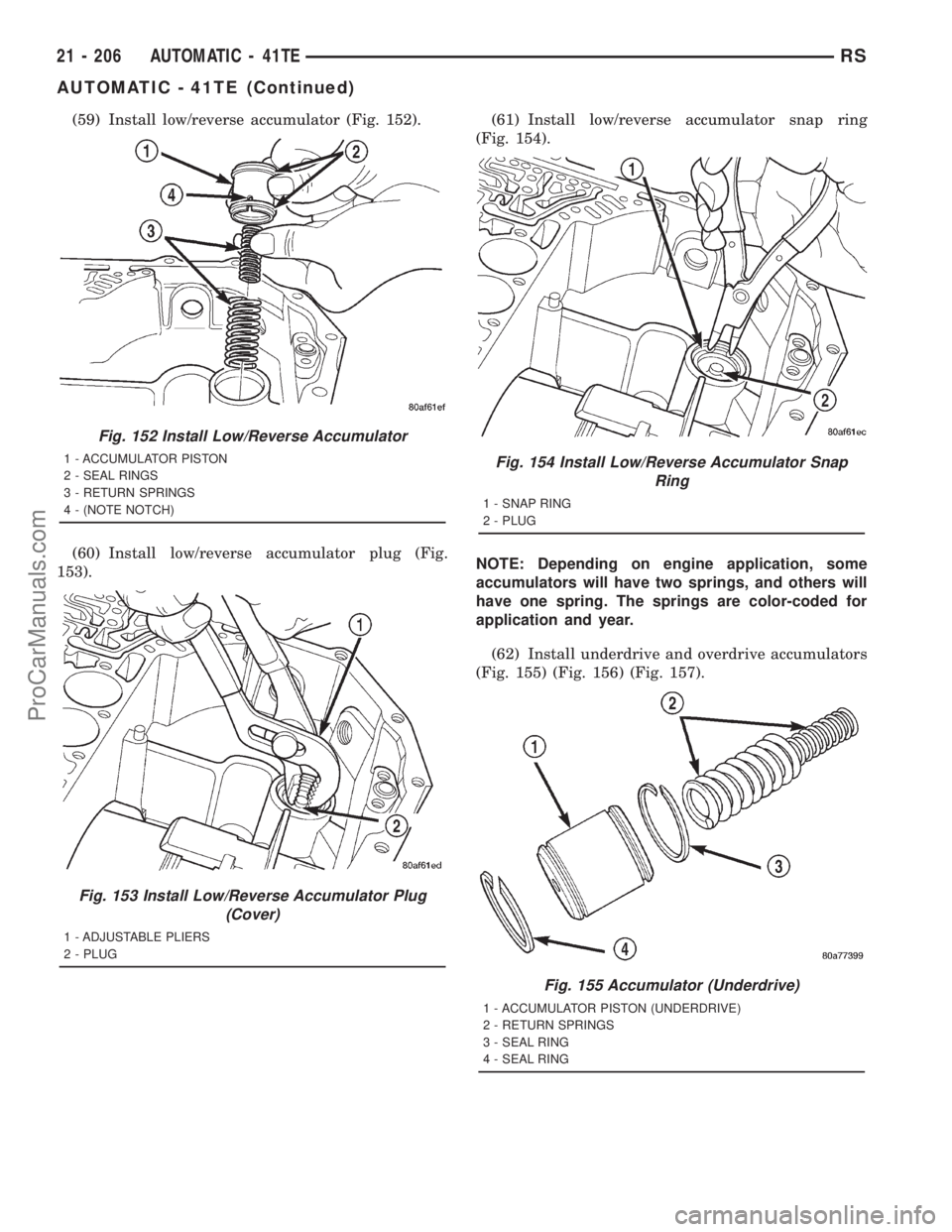

(59) Install low/reverse accumulator (Fig. 152).

(60) Install low/reverse accumulator plug (Fig.

153).(61) Install low/reverse accumulator snap ring

(Fig. 154).

NOTE: Depending on engine application, some

accumulators will have two springs, and others will

have one spring. The springs are color-coded for

application and year.

(62) Install underdrive and overdrive accumulators

(Fig. 155) (Fig. 156) (Fig. 157).

Fig. 152 Install Low/Reverse Accumulator

1 - ACCUMULATOR PISTON

2 - SEAL RINGS

3 - RETURN SPRINGS

4 - (NOTE NOTCH)

Fig. 153 Install Low/Reverse Accumulator Plug

(Cover)

1 - ADJUSTABLE PLIERS

2 - PLUG

Fig. 154 Install Low/Reverse Accumulator Snap

Ring

1 - SNAP RING

2 - PLUG

Fig. 155 Accumulator (Underdrive)

1 - ACCUMULATOR PISTON (UNDERDRIVE)

2 - RETURN SPRINGS

3 - SEAL RING

4 - SEAL RING

21 - 206 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1704 of 2321

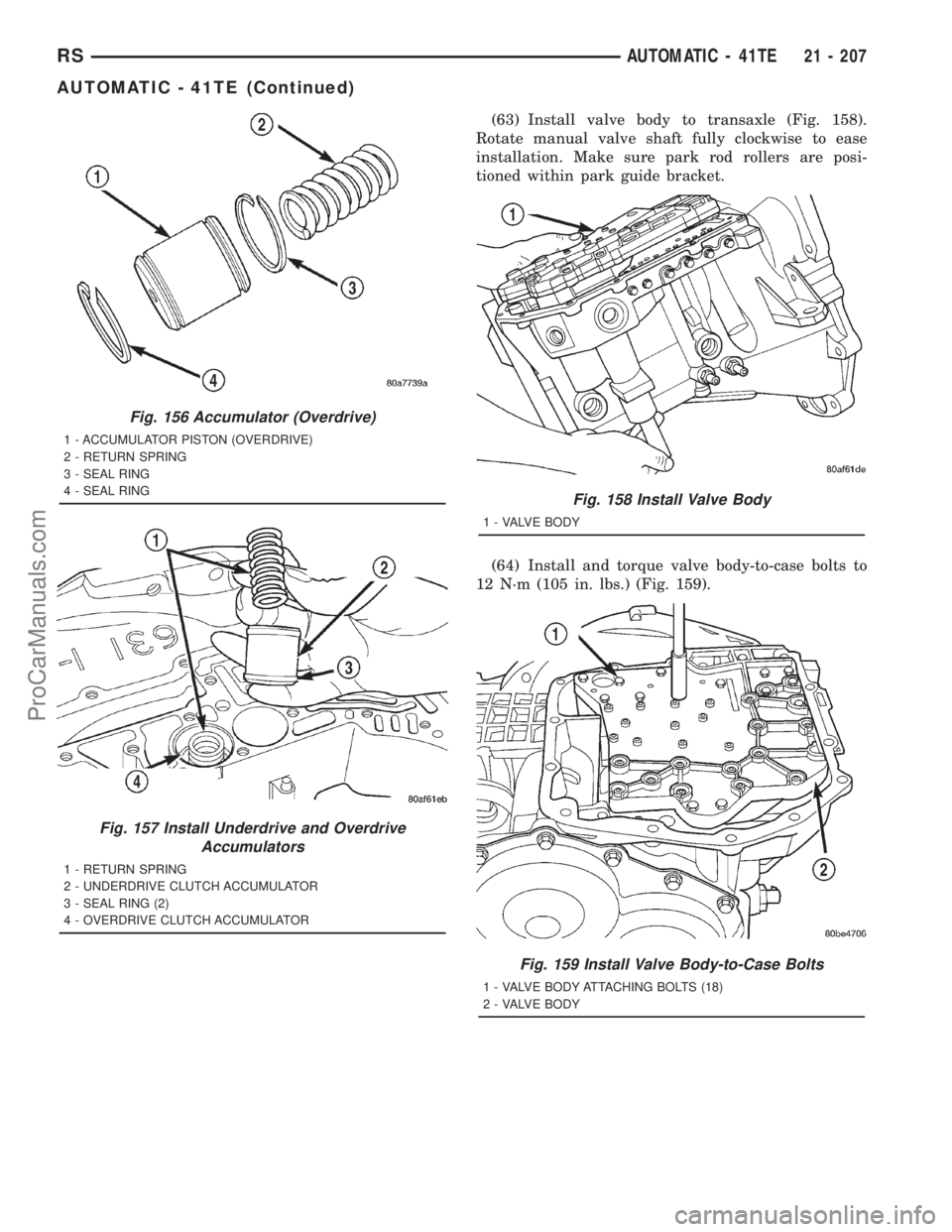

(63) Install valve body to transaxle (Fig. 158).

Rotate manual valve shaft fully clockwise to ease

installation. Make sure park rod rollers are posi-

tioned within park guide bracket.

(64) Install and torque valve body-to-case bolts to

12 N´m (105 in. lbs.) (Fig. 159).

Fig. 156 Accumulator (Overdrive)

1 - ACCUMULATOR PISTON (OVERDRIVE)

2 - RETURN SPRING

3 - SEAL RING

4 - SEAL RING

Fig. 157 Install Underdrive and Overdrive

Accumulators

1 - RETURN SPRING

2 - UNDERDRIVE CLUTCH ACCUMULATOR

3 - SEAL RING (2)

4 - OVERDRIVE CLUTCH ACCUMULATOR

Fig. 158 Install Valve Body

1 - VALVE BODY

Fig. 159 Install Valve Body-to-Case Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

RSAUTOMATIC - 41TE21 - 207

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1705 of 2321

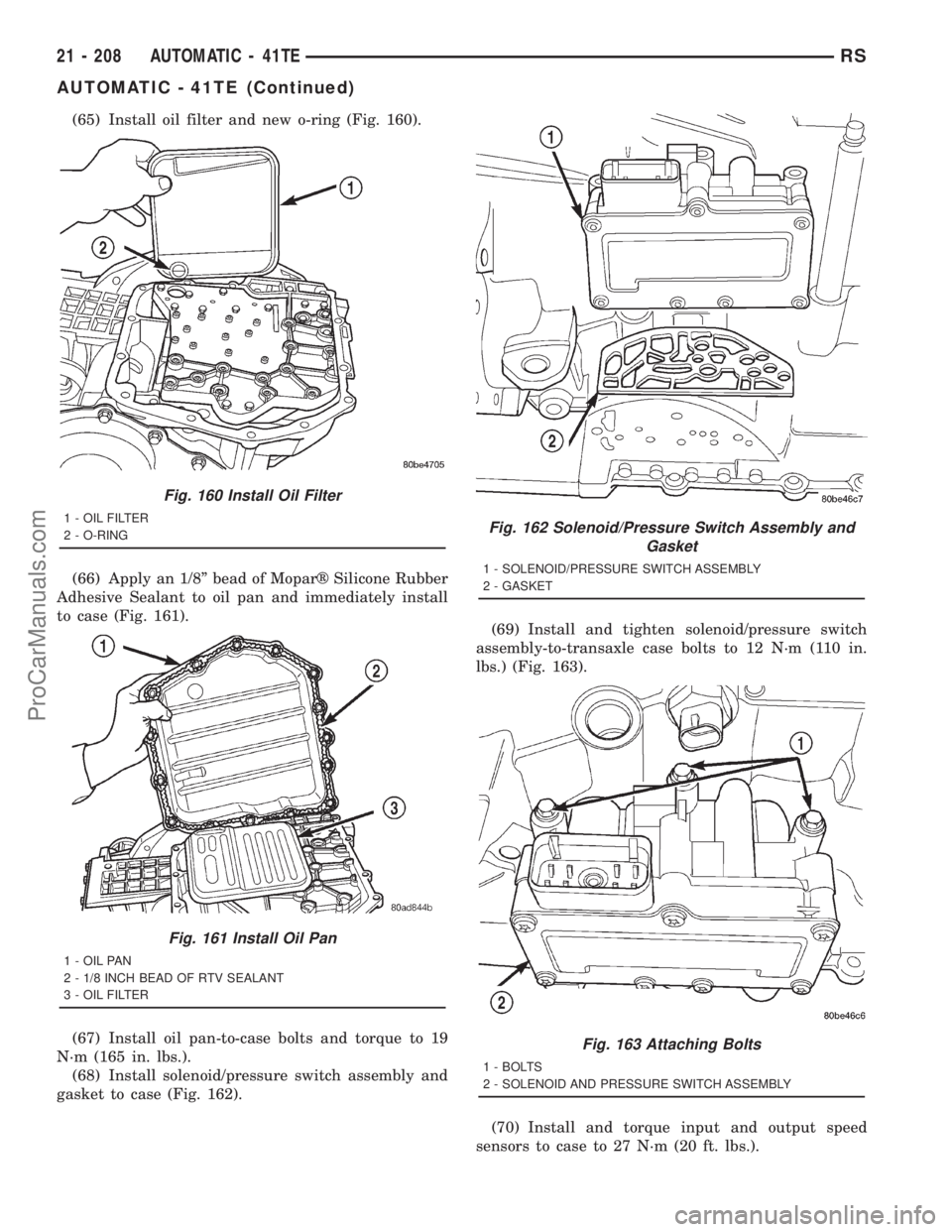

(65) Install oil filter and new o-ring (Fig. 160).

(66) Apply an 1/8º bead of Moparž Silicone Rubber

Adhesive Sealant to oil pan and immediately install

to case (Fig. 161).

(67) Install oil pan-to-case bolts and torque to 19

N´m (165 in. lbs.).

(68) Install solenoid/pressure switch assembly and

gasket to case (Fig. 162).(69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 163).

(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

Fig. 160 Install Oil Filter

1 - OIL FILTER

2 - O-RING

Fig. 161 Install Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

Fig. 162 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 163 Attaching Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

21 - 208 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1706 of 2321

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perfrom the TCM Quick Learn proce-

dure. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

NOTE: If torque converter assembly has been

replaced, it is necessary to reset the TCC Break-In

Strategy. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

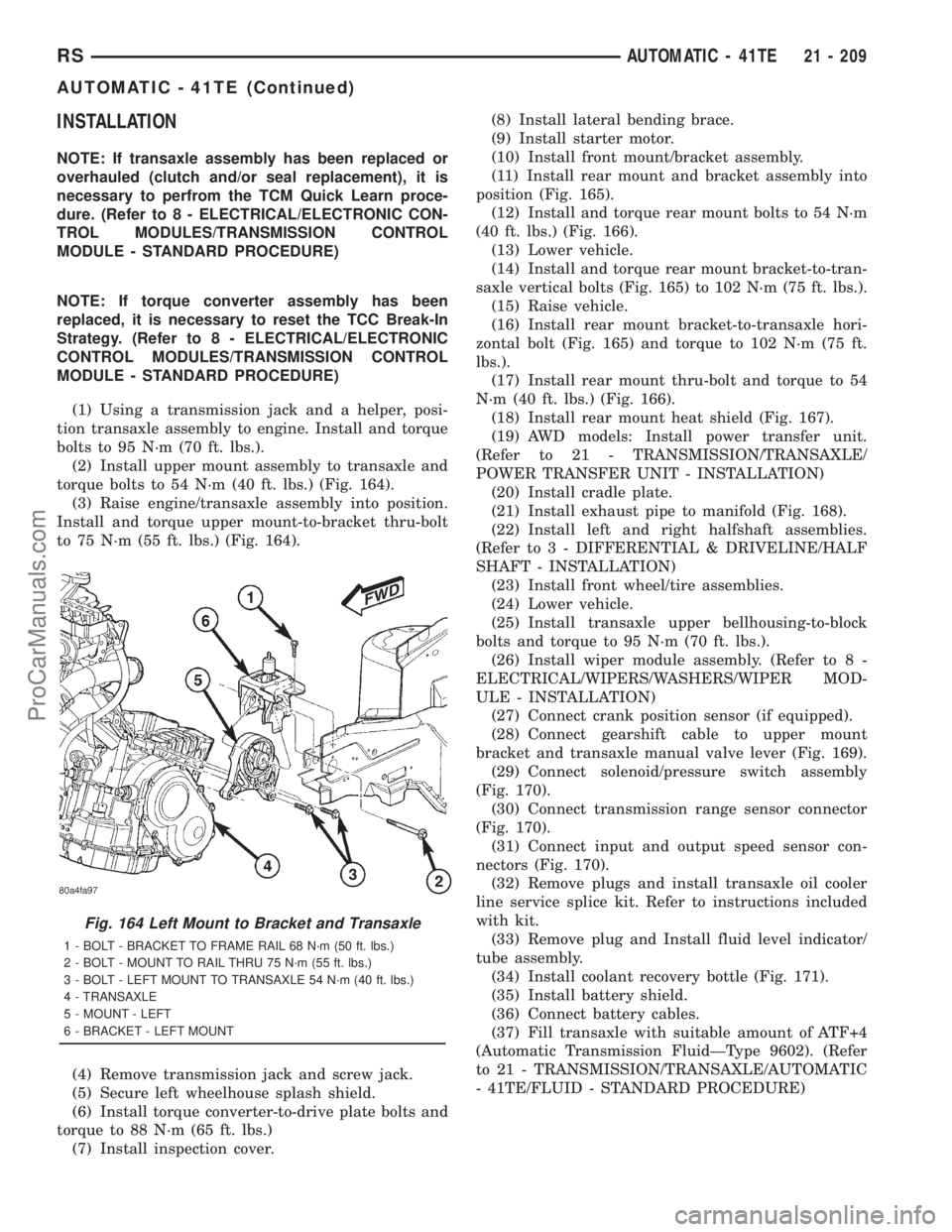

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bolts to 95 N´m (70 ft. lbs.).

(2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 164).

(3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 164).

(4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.)

(7) Install inspection cover.(8) Install lateral bending brace.

(9) Install starter motor.

(10) Install front mount/bracket assembly.

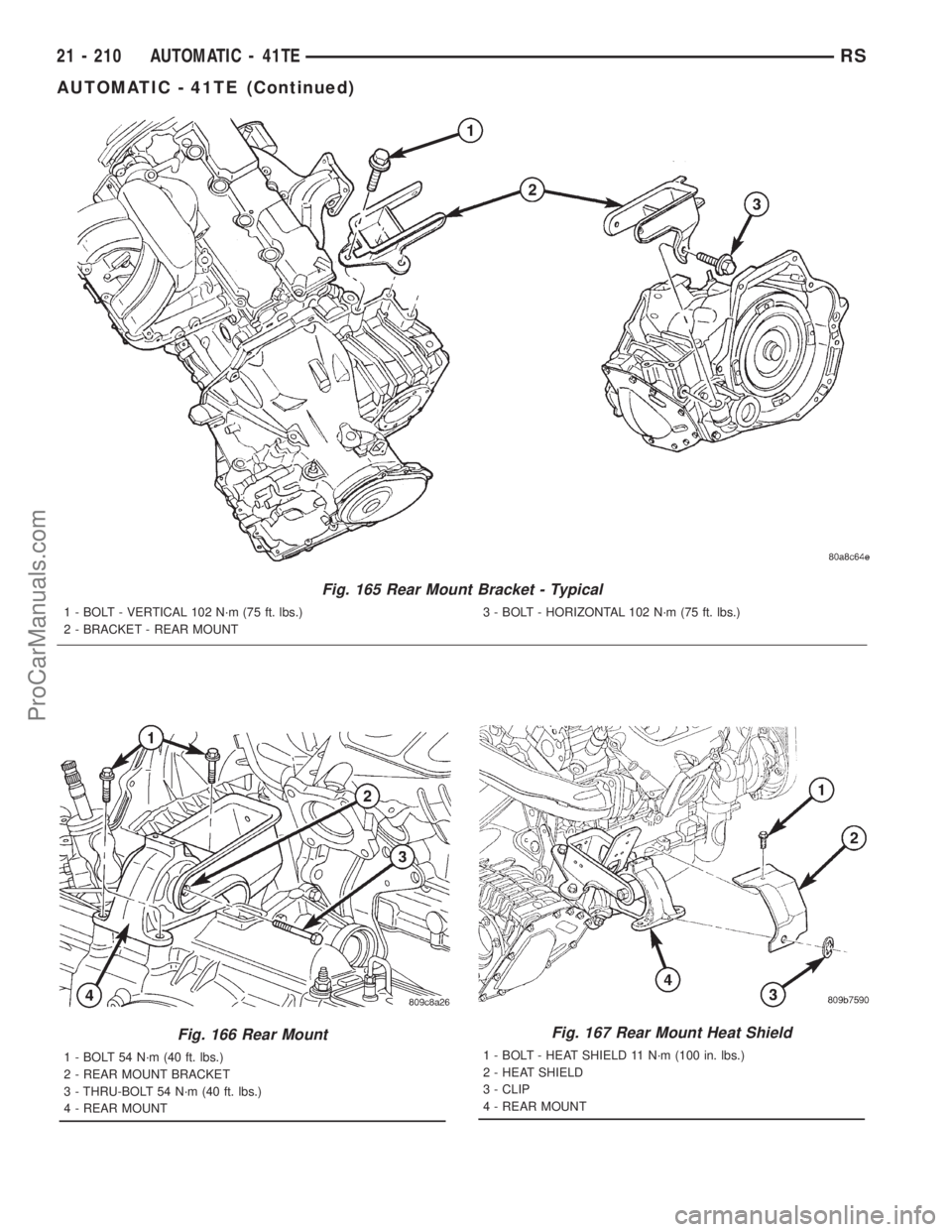

(11) Install rear mount and bracket assembly into

position (Fig. 165).

(12) Install and torque rear mount bolts to 54 N´m

(40 ft. lbs.) (Fig. 166).

(13) Lower vehicle.

(14) Install and torque rear mount bracket-to-tran-

saxle vertical bolts (Fig. 165) to 102 N´m (75 ft. lbs.).

(15) Raise vehicle.

(16) Install rear mount bracket-to-transaxle hori-

zontal bolt (Fig. 165) and torque to 102 N´m (75 ft.

lbs.).

(17) Install rear mount thru-bolt and torque to 54

N´m (40 ft. lbs.) (Fig. 166).

(18) Install rear mount heat shield (Fig. 167).

(19) AWD models: Install power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - INSTALLATION)

(20) Install cradle plate.

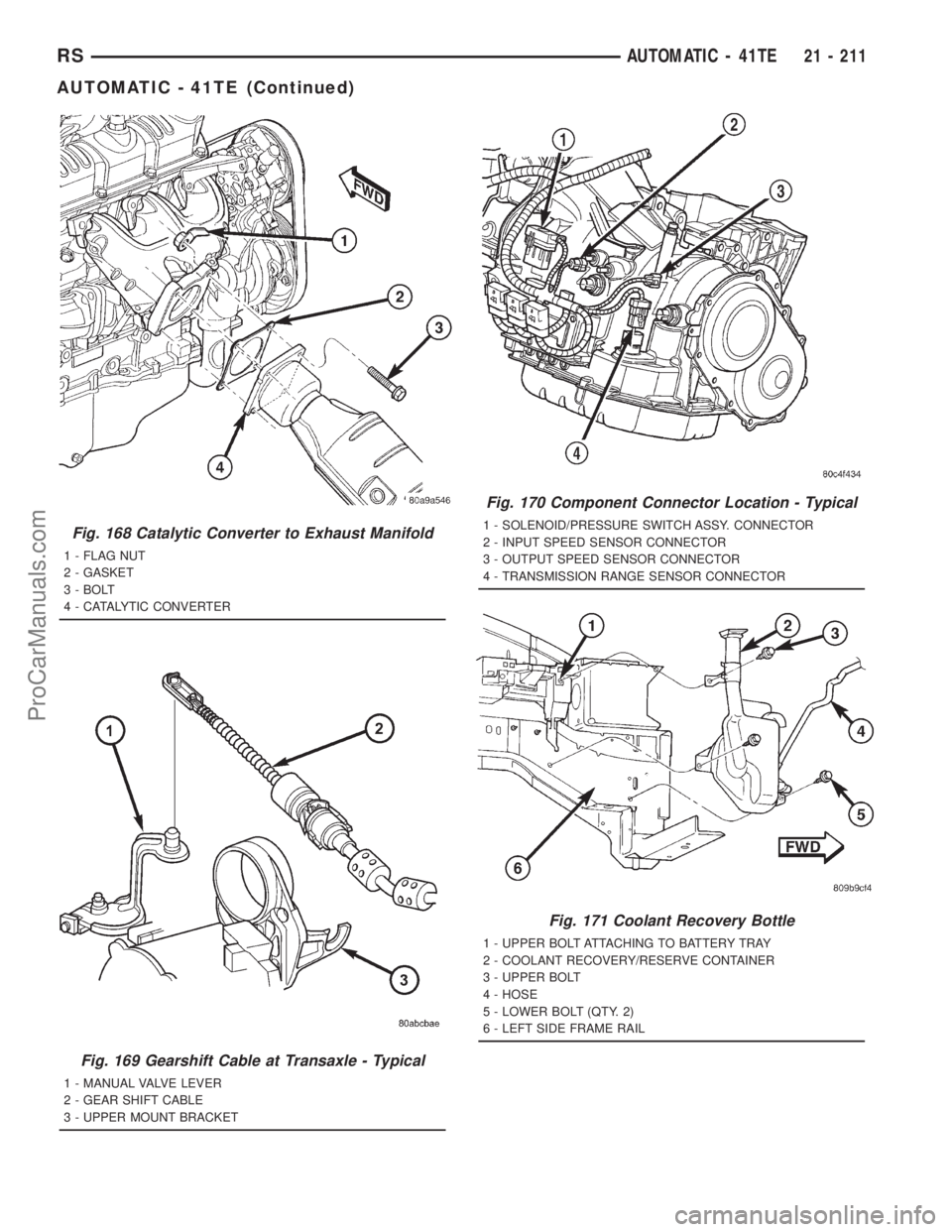

(21) Install exhaust pipe to manifold (Fig. 168).

(22) Install left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - INSTALLATION)

(23) Install front wheel/tire assemblies.

(24) Lower vehicle.

(25) Install transaxle upper bellhousing-to-block

bolts and torque to 95 N´m (70 ft. lbs.).

(26) Install wiper module assembly. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION)

(27) Connect crank position sensor (if equipped).

(28) Connect gearshift cable to upper mount

bracket and transaxle manual valve lever (Fig. 169).

(29) Connect solenoid/pressure switch assembly

(Fig. 170).

(30) Connect transmission range sensor connector

(Fig. 170).

(31) Connect input and output speed sensor con-

nectors (Fig. 170).

(32) Remove plugs and install transaxle oil cooler

line service splice kit. Refer to instructions included

with kit.

(33) Remove plug and Install fluid level indicator/

tube assembly.

(34) Install coolant recovery bottle (Fig. 171).

(35) Install battery shield.

(36) Connect battery cables.

(37) Fill transaxle with suitable amount of ATF+4

(Automatic Transmission FluidÐType 9602). (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE/FLUID - STANDARD PROCEDURE)

Fig. 164 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

RSAUTOMATIC - 41TE21 - 209

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1707 of 2321

Fig. 165 Rear Mount Bracket - Typical

1 - BOLT - VERTICAL 102 N´m (75 ft. lbs.)

2 - BRACKET - REAR MOUNT3 - BOLT - HORIZONTAL 102 N´m (75 ft. lbs.)

Fig. 166 Rear Mount

1 - BOLT 54 N´m (40 ft. lbs.)

2 - REAR MOUNT BRACKET

3 - THRU-BOLT 54 N´m (40 ft. lbs.)

4 - REAR MOUNT

Fig. 167 Rear Mount Heat Shield

1 - BOLT - HEAT SHIELD 11 N´m (100 in. lbs.)

2 - HEAT SHIELD

3 - CLIP

4 - REAR MOUNT

21 - 210 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1708 of 2321

Fig. 168 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

Fig. 169 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

Fig. 170 Component Connector Location - Typical

1 - SOLENOID/PRESSURE SWITCH ASSY. CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 171 Coolant Recovery Bottle

1 - UPPER BOLT ATTACHING TO BATTERY TRAY

2 - COOLANT RECOVERY/RESERVE CONTAINER

3 - UPPER BOLT

4 - HOSE

5 - LOWER BOLT (QTY. 2)

6 - LEFT SIDE FRAME RAIL

RSAUTOMATIC - 41TE21 - 211

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1709 of 2321

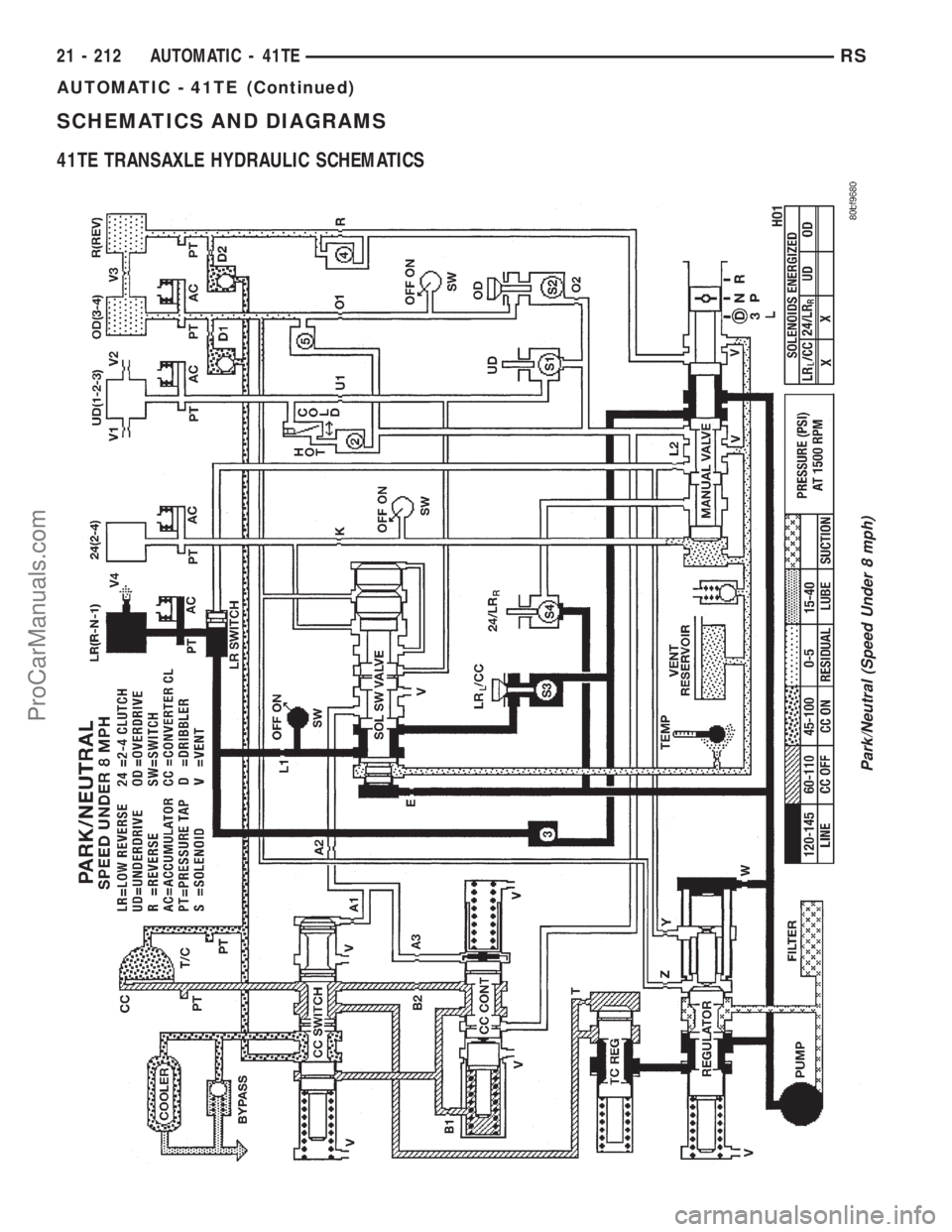

SCHEMATICS AND DIAGRAMS

41TE TRANSAXLE HYDRAULIC SCHEMATICS

Park/Neutral (Speed Under 8 mph)

21 - 212 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

ProCarManuals.com

Page 1710 of 2321

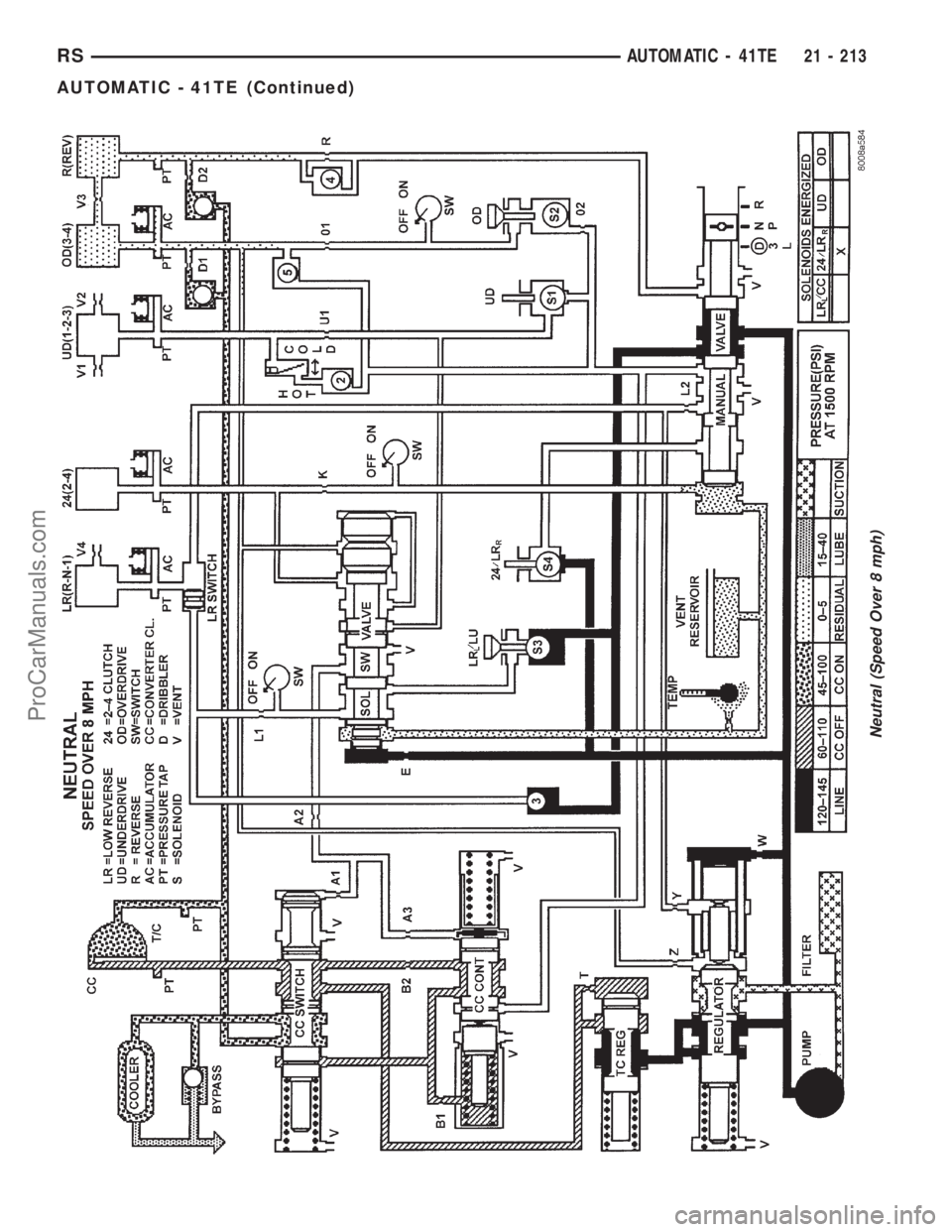

Neutral (Speed Over 8 mph)

RSAUTOMATIC - 41TE21 - 213

AUTOMATIC - 41TE (Continued)

ProCarManuals.com