DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 841 of 1502

14

- 22

FUEL SYSTEM

•

CLAMP (2)

VIEW

IN

DIRECTION OF

ARROW

Z

CLAMP

(20

INCH-POUNDS)

RB1362A

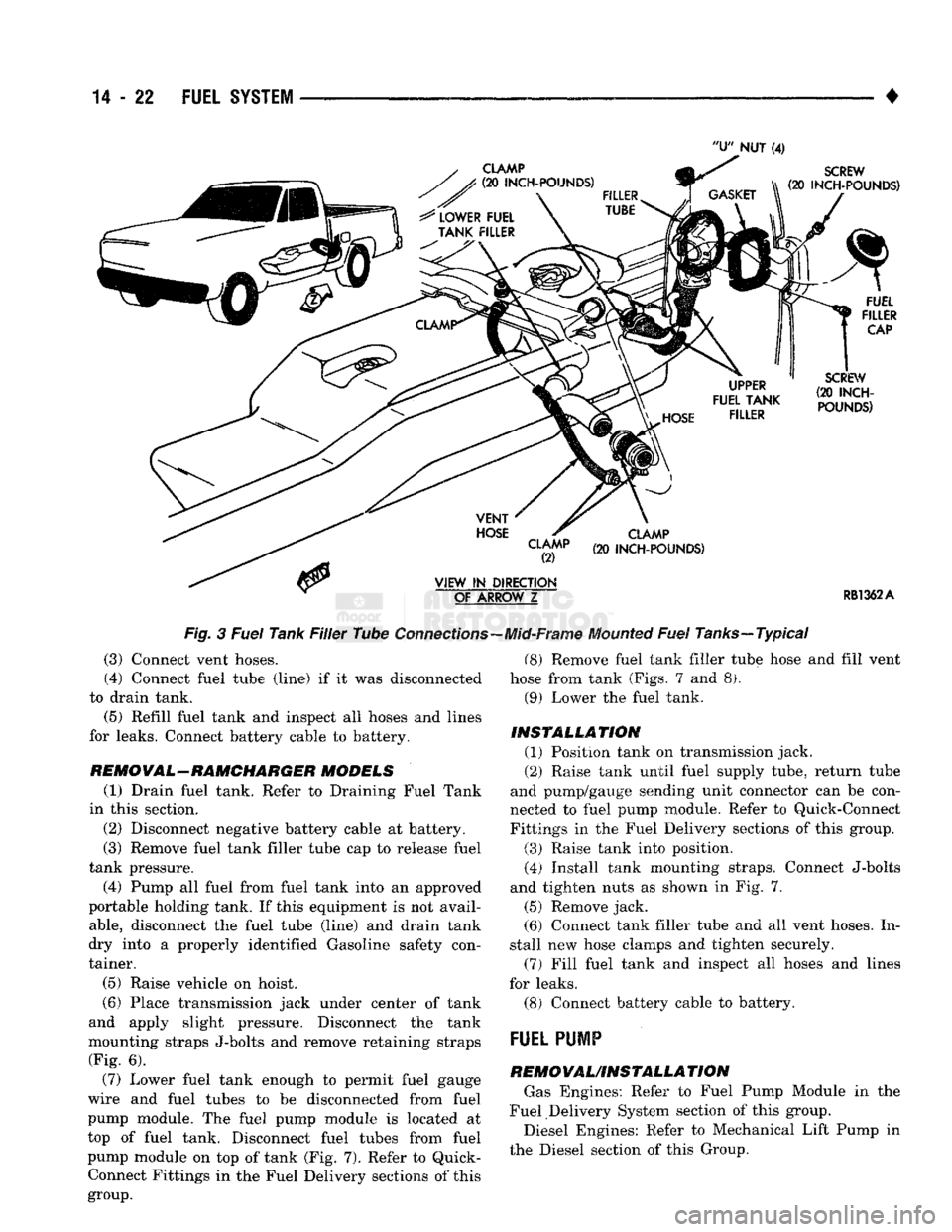

Fig. 3 Fuel Tank Filler Tube

Connections-

(3) Connect vent hoses.

(4) Connect fuel tube (line) if it was disconnected

to drain tank. (5) Refill fuel tank and inspect all hoses and lines

for leaks. Connect battery cable to battery.

RE MO VA L—RAMCHARGER MODELS (1) Drain fuel tank. Refer to Draining Fuel Tank

in this section. (2) Disconnect negative battery cable at battery.

(3) Remove fuel tank filler tube cap to release fuel

tank pressure. (4) Pump all fuel from fuel tank into an approved

portable holding tank. If this equipment is not avail

able,

disconnect the fuel tube (line) and drain tank

dry into a properly identified Gasoline safety con

tainer.

(5) Raise vehicle on hoist.

(6) Place transmission jack under center of tank

and apply slight pressure. Disconnect the tank

mounting straps J-bolts and remove retaining straps (Fig. 6).

(7) Lower fuel tank enough to permit fuel gauge

wire and fuel tubes to be disconnected from fuel

pump module. The fuel pump module is located at

top of fuel tank. Disconnect fuel tubes from fuel

pump module on top of tank (Fig. 7). Refer to Quick- Connect Fittings in the Fuel Delivery sections of this

group. -Mid-Frame

Mounted

Fuel

Tanks—Typical

(8) Remove fuel tank filler tube hose and fill vent

hose from tank (Figs. 7 and 8). (9) Lower the fuel tank.

INSTALLATION (1) Position tank on transmission jack.

(2) Raise tank until fuel supply tube, return tube

and pump/gauge sending unit connector can be con

nected to fuel pump module. Refer to Quick-Connect Fittings in the Fuel Delivery sections of this group.

(3) Raise tank into position. (4) Install tank mounting straps. Connect J-bolts

and tighten nuts as shown in Fig. 7.

(5) Remove jack. (6) Connect tank filler tube and all vent hoses. In

stall new hose clamps and tighten securely. (7) Fill fuel tank and inspect all hoses and lines

for leaks. (8) Connect battery cable to battery.

FUEL PUMP

REMOVAL/INSTALLA TION Gas Engines: Refer to Fuel Pump Module in the

Fuel Delivery System section of this group. Diesel Engines: Refer to Mechanical Lift Pump in

the Diesel section of this Group.

Page 842 of 1502

•

FUEL SYSTEM

14 - 23

USED

WITH

7-INCH

RAIL TIGHTENING TORQUE

A

30 FT

LBS

(41 N-m)

B

TIGHTEN

TO

SECURE TANK

C

100 IN

LBS

(11 N-m)

REAR

STRAP

VIEW

IN

CIRCLE

Z (30 GAL

TANK)

PRESSURE

RELIEF/

ROLLOVER

VALVE

LOCKNUT Fig.

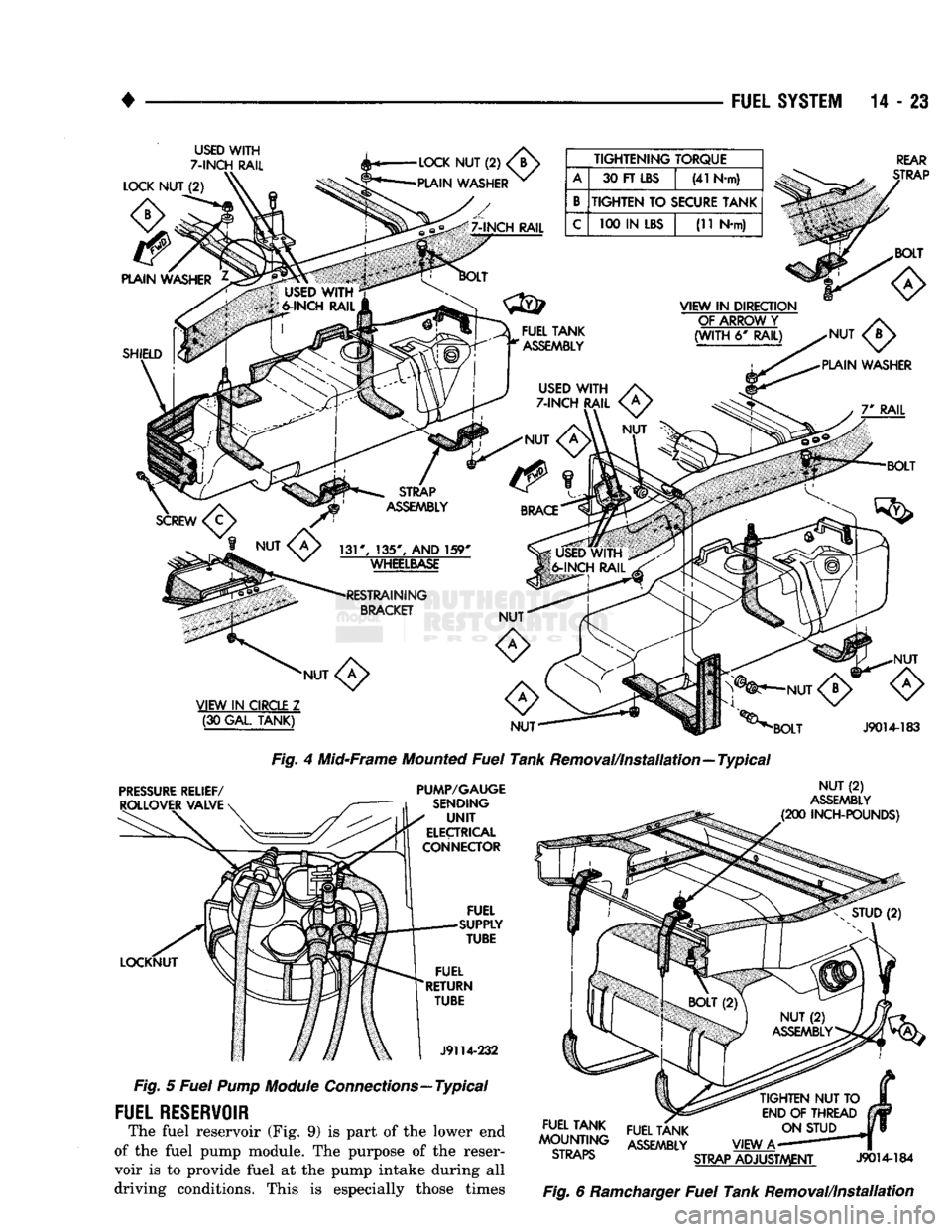

4 Mid-Frame Mounted

Fuel

Tank Removal/Installation—Typical

PUMP/GAUGE

SENDING

UNIT

ELECTRICAL

CONNECTOR FUEL

SUPPLY

TUBE

FUEL

RETURN TUBE

J9114-232

J9014-183

NUT

(2)

ASSEMBLY

(200

INCH-POUNDS)

Fig.

5

Fuel Pump

Module Connections—Typical

FUEL

RESERVOIR

The fuel reservoir (Fig. 9) is part of the lower end

of the fuel pump module. The purpose of the reser

voir is to provide fuel at the pump intake during all

driving conditions. This is especially those times

TIGHTEN

NUT TO

END

OF

THREAD ON STUD

VIEW

A-

STRAP

ADJUSTMENT

J9014-184

Fig.

6 Ramcharger

Fuel

Tank Removal/Installation

FUEL TANK

^OUNTWG ASSEMBLY

ol

KAP5>

Page 843 of 1502

14

- 24

FUEL

SYSTEM

•

FUEL

TUBES

TO FILLER

NECK

J9014-185

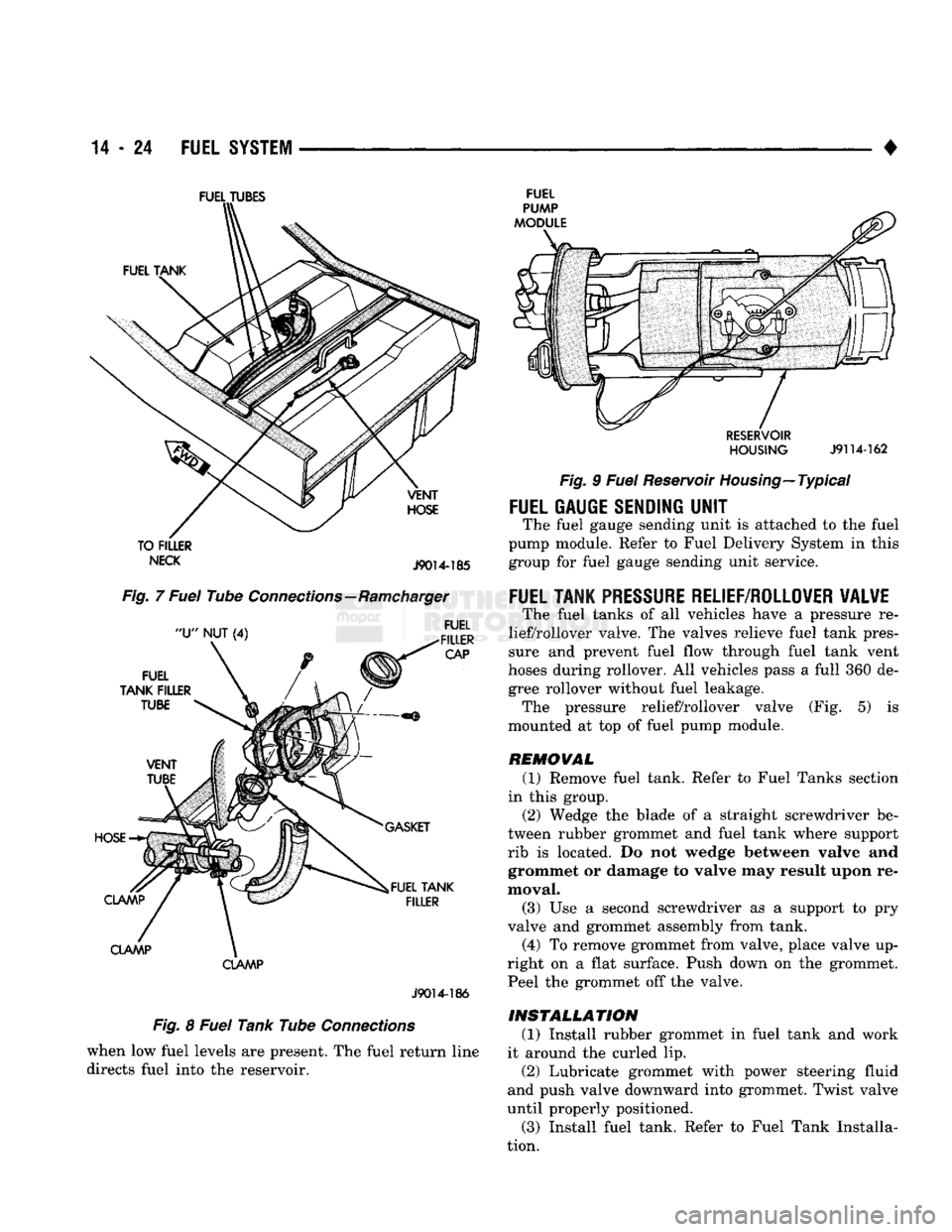

Fig. 7 Fuel Tube Connections—Ramcharger

CLAMP

J9014-186

Fig. 8 Fuel Tank Tube Connections when low fuel levels are present. The fuel return line

directs fuel into the reservoir.

FUEL

HOUSING

J9114-162

Fig. 9 Fuel Reservoir Housing—Typical

FUEL

GAUGE SENDING

UNIT

The fuel gauge sending unit is attached to the fuel

pump module. Refer to Fuel Delivery System in this

group for fuel gauge sending unit service.

FUEL TANK

PRESSURE

RELIEF/ROLLOVER VALVE

The fuel tanks of all vehicles have a pressure re

lief/rollover valve. The valves relieve fuel tank pres

sure and prevent fuel flow through fuel tank vent

hoses during rollover. All vehicles pass a full 360 de gree rollover without fuel leakage. The pressure relief/rollover valve (Fig. 5) is

mounted at top of fuel pump module.

REMOVAL (1) Remove fuel tank. Refer to Fuel Tanks section

in this group. (2) Wedge the blade of a straight screwdriver be

tween rubber grommet and fuel tank where support

rib is located. Do not wedge between valve and grommet or damage to valve may result upon re

moval.

(3) Use a second screwdriver as a support to pry

valve and grommet assembly from tank. (4) To remove grommet from valve, place valve up

right on a flat surface. Push down on the grommet. Peel the grommet off the valve.

INSTALLATION

(1) Install rubber grommet in fuel tank and work

it around the curled lip. (2) Lubricate grommet with power steering fluid

and push valve downward into grommet. Twist valve

until properly positioned.

(3) Install fuel tank. Refer to Fuel Tank Installa

tion.

Page 844 of 1502

FUEL

SYSTEM 14-25

ACCELERATOR PEDAL AND THROTTLE CABLE

INDEX

page

Accelerator Pedal

........................

25

General

Information

25

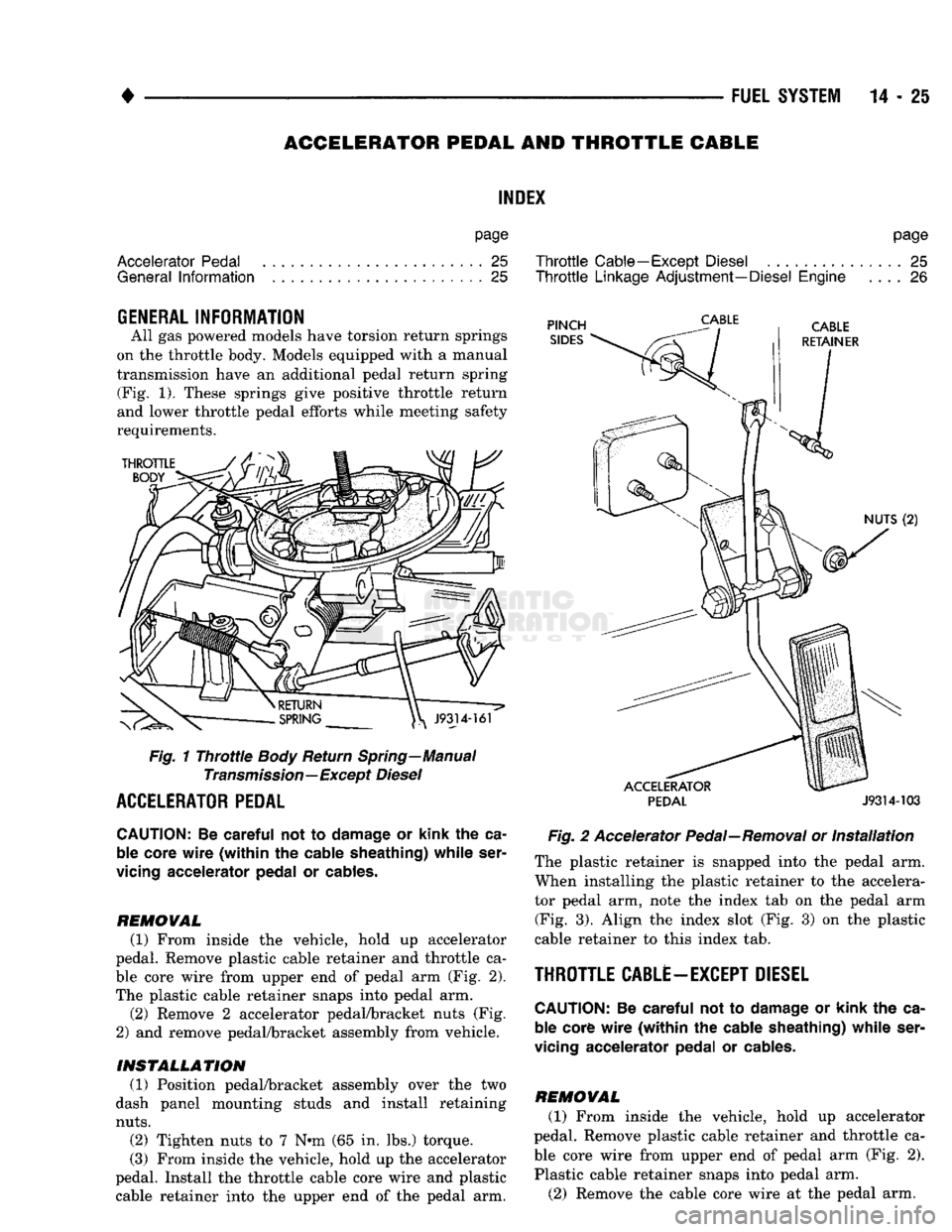

GENERAL

INFORMATION

All

gas

powered models have torsion return springs

on

the

throttle body. Models equipped with

a

manual

transmission have

an

additional pedal return spring (Fig.

1).

These springs give positive throttle return

and lower throttle pedal efforts while meeting safety

requirements.

Fig.

1

Throttle

Body

Return

Spring—Manual

Transmission—Except

Diesel

ACCELERATOR

PEDAL

CAUTION:

Be

careful

not

to

damage

or

kink

the

ca

ble core

wire

(within

the

cable sheathing) while ser

vicing

accelerator

pedal

or

cables.

REMOVAL (1)

From inside

the

vehicle, hold

up

accelerator

pedal. Remove plastic cable retainer

and

throttle

ca

ble core wire from upper

end of

pedal

arm (Fig. 2).

The plastic cable retainer snaps into pedal

arm.

(2)

Remove

2

accelerator pedal/bracket nuts

(Fig.

2)

and

remove pedal/bracket assembly from vehicle.

INSTALLATION (1)

Position pedal/bracket assembly over

the two

dash panel mounting studs

and

install retaining

nuts.

(2)

Tighten nuts

to 7 N*m

(65

in. lbs.)

torque.

(3) From inside

the

vehicle, hold

up the

accelerator

pedal. Install

the

throttle cable core wire

and

plastic cable retainer into

the

upper

end of the

pedal

arm.

page

Throttle

Cable—Except Diesel

...............

25

Throttle

Linkage Adjustment—Diesel Engine

.... 26

PINCH

SIDES

PEDAL

J9314-103

Fig.

2

Accelerator Pedal—Removal

or

Installation

The plastic retainer

is

snapped into

the

pedal

arm.

When installing

the

plastic retainer

to the

accelera

tor pedal

arm,

note

the

index

tab on the

pedal

arm

(Fig.

3).

Align

the

index slot

(Fig. 3) on the

plastic

cable retainer

to

this index

tab.

THROTTLE CABLE-EXCEPT DIESEL

CAUTION:

Be

careful

not

to

damage

or

kink

the

ca

ble core

wire

(within

the

cable sheathing) while ser

vicing

accelerator

pedal

or

cables.

REMOVAL (1)

From inside

the

vehicle, hold

up

accelerator

pedal. Remove plastic cable retainer

and

throttle

ca

ble core wire from upper

end of

pedal

arm (Fig. 2).

Plastic cable retainer snaps into pedal

arm.

(2)

Remove

the

cable core wire

at the

pedal

arm.

Page 845 of 1502

14

- 26

FUEL

SYSTEM

•

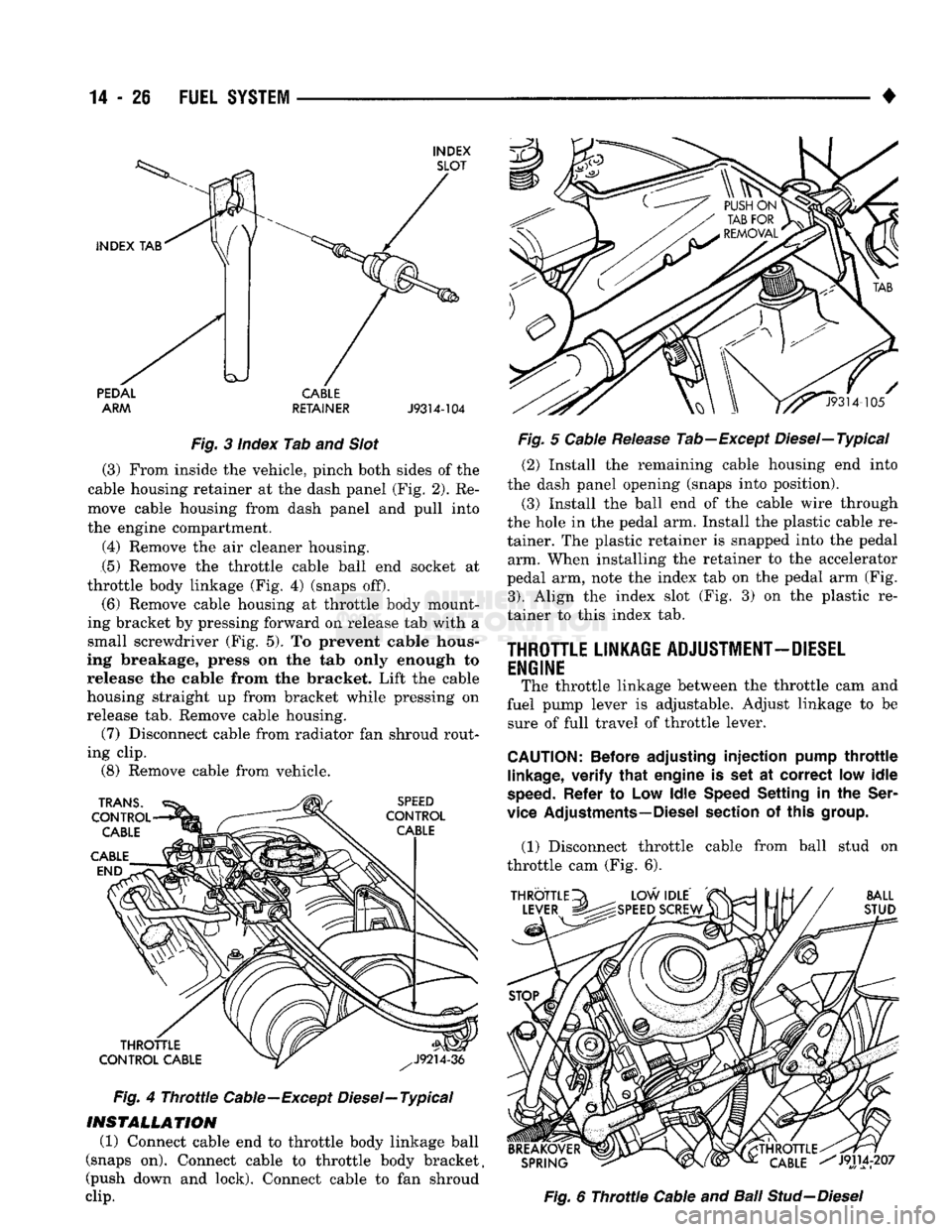

INDEX SLOT

INDEX

TAB PEDAL

ARM CABLE

RETAINER

J9314-104

Fig.

3 Index Tab and

Slot

(3) From inside the vehicle, pinch both sides of the

cable housing retainer at the dash panel (Fig. 2). Re

move cable housing from dash panel and pull into

the engine compartment.

(4) Remove the air cleaner housing. (5) Remove the throttle cable ball end socket at

throttle body linkage (Fig. 4) (snaps off).

(6) Remove cable housing at throttle body mount

ing bracket by pressing forward on release tab with a

small screwdriver (Fig. 5). To prevent cable hous

ing breakage, press on the tab only enough to release the cable from the bracket. Lift the cable

housing straight up from bracket while pressing on

release tab. Remove cable housing. (7) Disconnect cable from radiator fan shroud rout

ing clip. (8) Remove cable from vehicle.

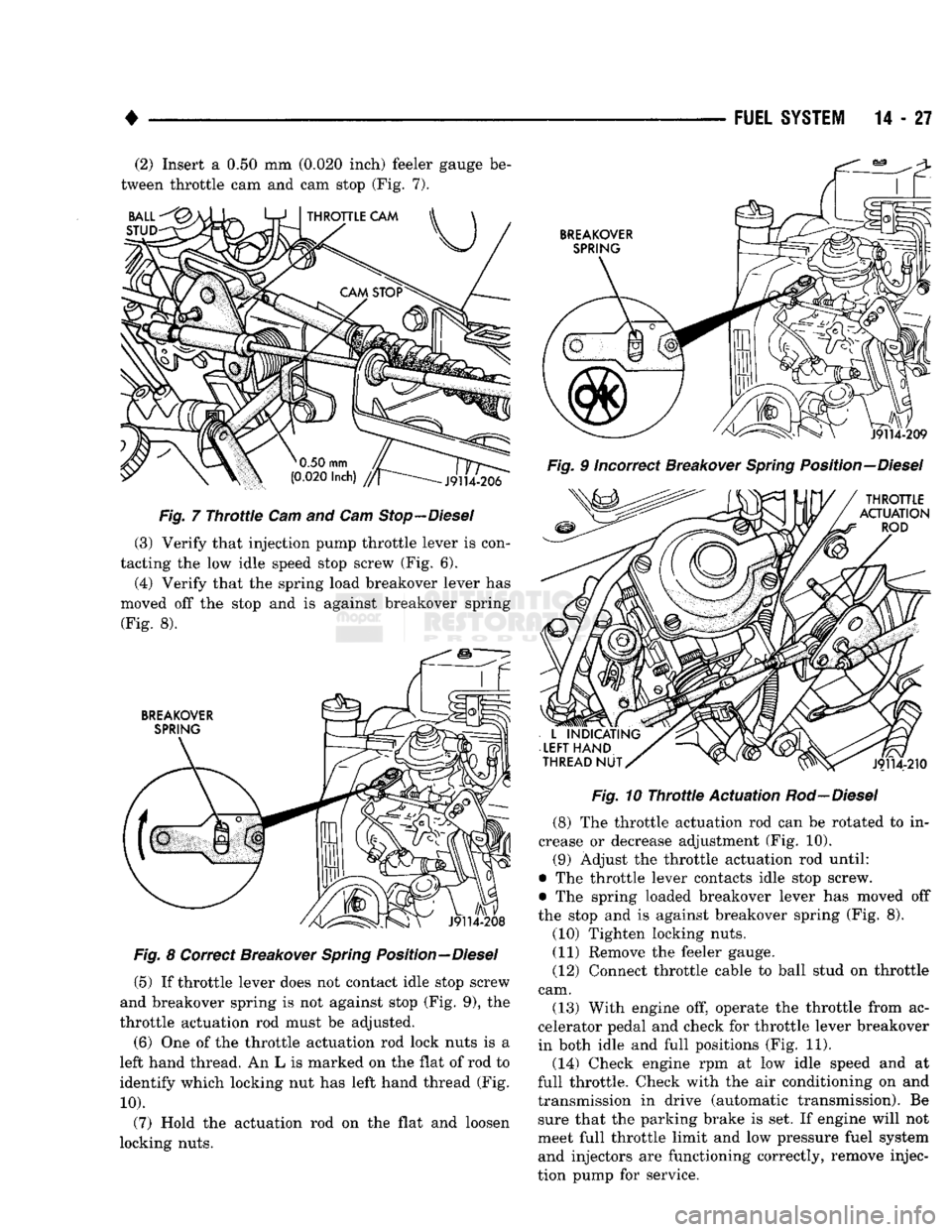

TRANS.

CONTROL CABLE

CABLE END SPEED

CONTROL CABLE

THROTTLE

CONTROL CABLE

Fig.

4

Throttle

Cable—Except Diesel—Typical

INSTALLATION

(1) Connect cable end to throttle body linkage ball

(snaps on). Connect cable to throttle body bracket,

(push down and lock). Connect cable to fan shroud

clip.

^^J9314-105

Fig.

5 Cable

Release

Tab—Except Diesel—Typical (2) Install the remaining cable housing end into

the dash panel opening (snaps into position).

(3) Install the ball end of the cable wire through

the hole in the pedal arm. Install the plastic cable re

tainer. The plastic retainer is snapped into the pedal arm. When installing the retainer to the accelerator

pedal arm, note the index tab on the pedal arm (Fig.

3).

Align the index slot (Fig. 3) on the plastic re

tainer to this index tab.

THROTTLE LINKAGE ADJUSTMENT-DIESEL

ENGINE The throttle linkage between the throttle cam and

fuel pump lever is adjustable. Adjust linkage to be sure of full travel of throttle lever.

CAUTION:

Before adjusting

injection

pump

throttle

linkage,

verify

that

engine

is set at

correct

low

idle

speed.

Refer

to Low

Idle

Speed Setting

in the

Ser

vice Adjustments—Diesel section

of

this group.

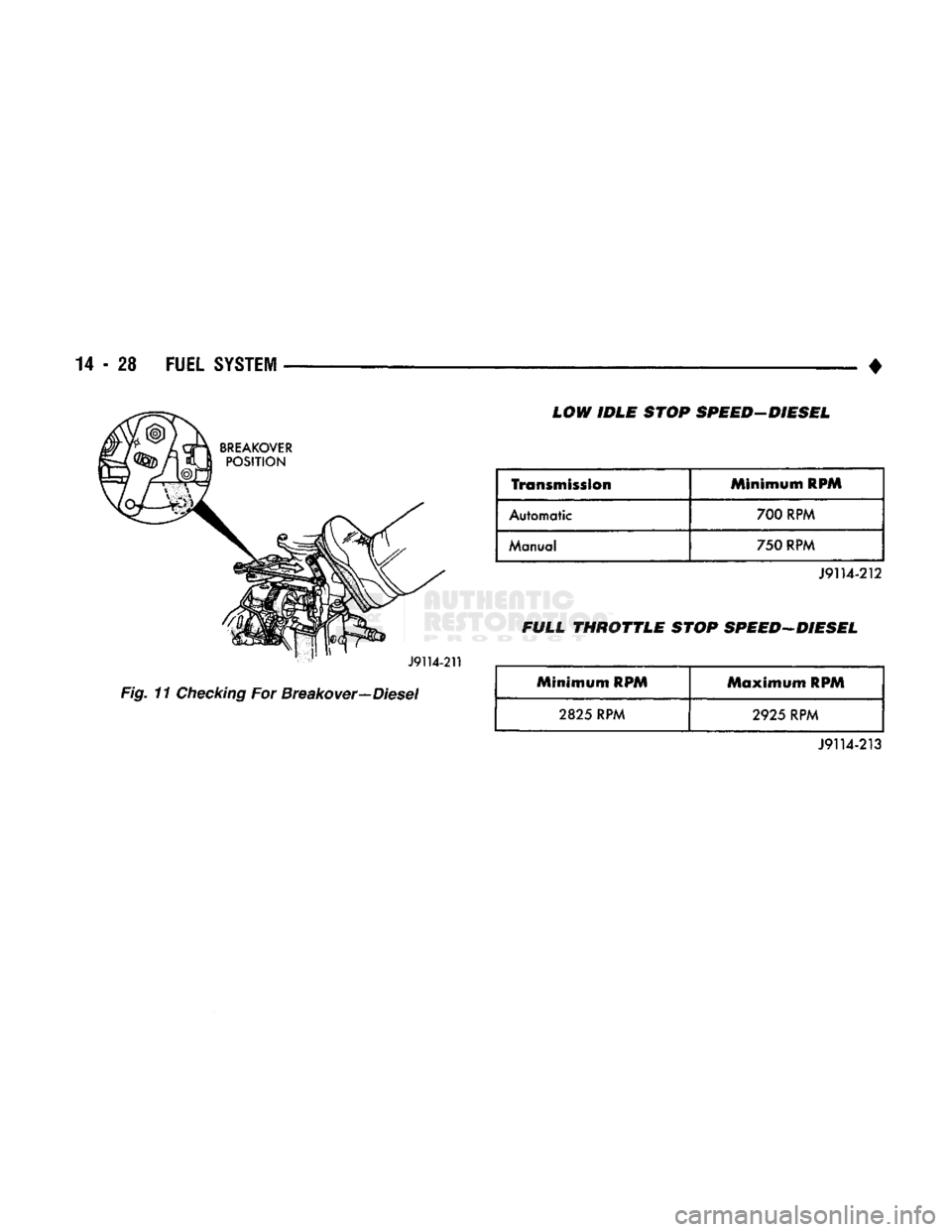

(1) Disconnect throttle cable from ball stud on

throttle cam (Fig. 6).

THROTTLE

LEVER BALL

STUD

BREAKOVER SPRING

THROTTLE.

CABLE

^J9114r207

Fig.

6

Throttle

Cable and Bali

Stud-Diesel

Page 846 of 1502

•

FUEL

SYSTEM

14 - 27 (2) Insert a 0.50 mm (0.020 inch) feeler gauge be

tween throttle cam and cam stop (Fig. 7). BALL

STUD

J9114-206

Fig.

7

Throttle

Cam and Cam

Stop—Diesel

(3) Verify that injection pump throttle lever is con

tacting the low idle speed stop screw (Fig. 6). (4) Verify that the spring load breakover lever has

moved off the stop and is against breakover spring (Fig. 8).

BREAKOVER SPRING

J9114-208

Fig.

8 Correct Breakover

Spring

Position—Diesel

(5) If throttle lever does not contact idle stop screw

and breakover spring is not against stop (Fig. 9), the

throttle actuation rod must be adjusted.

(6) One of the throttle actuation rod lock nuts is a

left hand thread. An L is marked on the flat of rod to

identify which locking nut has left hand thread (Fig.

10).

(7) Hold the actuation rod on the flat and loosen

locking nuts. '

BREAKOVER

SPRING

J9114-209

Fig.

9 Incorrect Breakover

Spring

Position—Diesel

THROTTLE

ACTUATION

ROD

L

INDICATING

LEFT

HAND

THREAD

NUT

J9114-210

Fig.

10

Throttle

Actuation

Rod—Diesel

(8) The throttle actuation rod can be rotated to in

crease or decrease adjustment (Fig. 10). (9) Adjust the throttle actuation rod until:

• The throttle lever contacts idle stop screw.

• The spring loaded breakover lever has moved off

the stop and is against breakover spring (Fig. 8).

(10) Tighten locking nuts. (11) Remove the feeler gauge.

(12) Connect throttle cable to ball stud on throttle

cam.

(13) With engine off, operate the throttle from ac

celerator pedal and check for throttle lever breakover

in both idle and full positions (Fig. 11).

(14) Check engine rpm at low idle speed and at

full throttle. Check with the air conditioning on and

transmission in drive (automatic transmission). Be sure that the parking brake is set. If engine will not

meet full throttle limit and low pressure fuel system and injectors are functioning correctly, remove injec

tion pump for service.

Page 847 of 1502

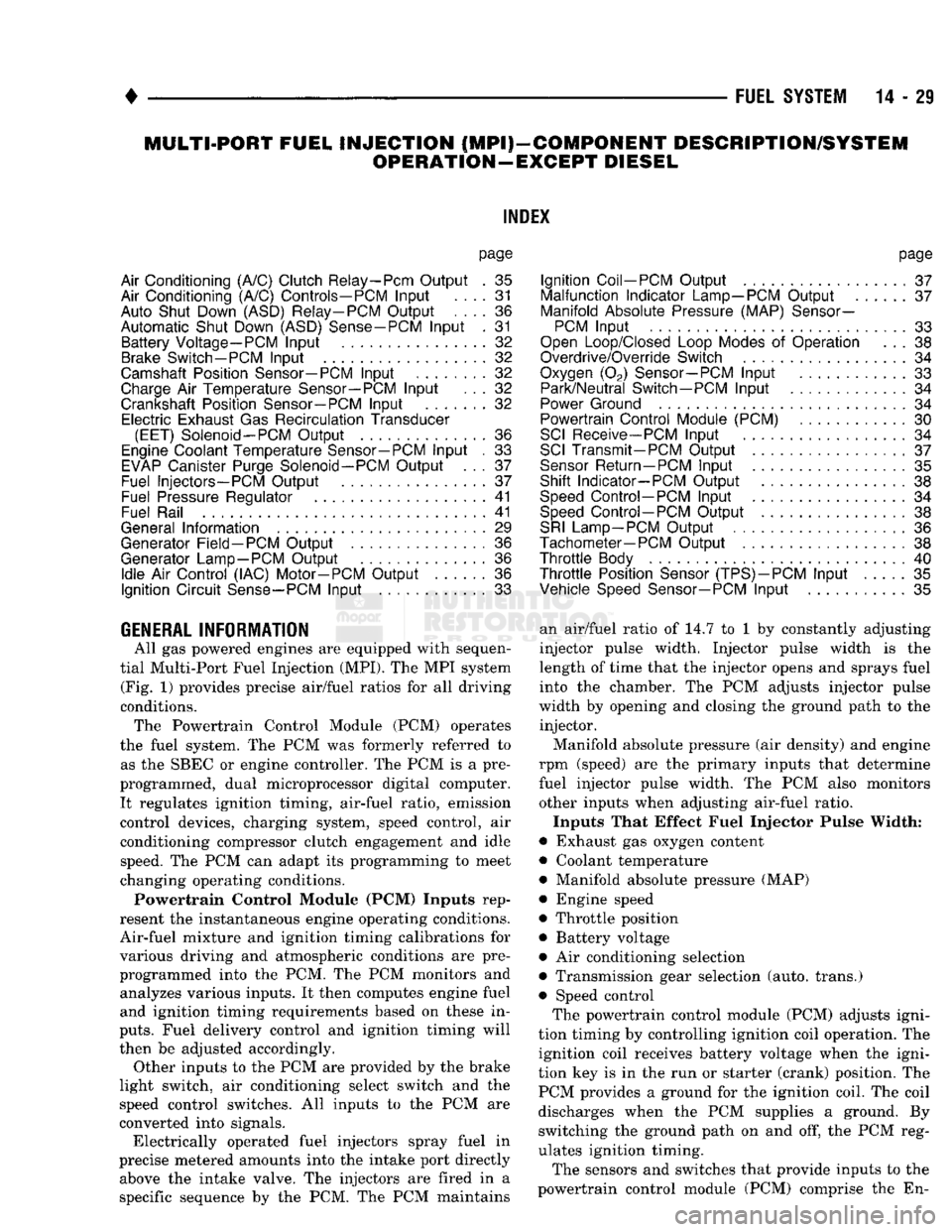

Fig.

11

Checking

For Breakover—Diesel LOW IDLE STOP SPEED-DIESEL

Transmission

Minimum

RPM

Automatic 700 RPM

Manual 750 RPM

J9114-212

FULL

THROTTLE

STOP SPEED-DIESEL

Minimum RPM

Maximum

RPM

2825 RPM 2925 RPM

J9114-213

Page 848 of 1502

•

FUEL

SYSTEM

14-29

MULTI-PORT

FUEL

INJECTION

(MPI)-COMPONENT DESCRIPTION/SYSTEM

OPERATION-EXCEPT DIESEL

INDEX

page

Air

Conditioning (A/C) Clutch

Relay-Pern

Output

. 35

Air

Conditioning (A/C)

Controls—PCM

Input

.... 31

Auto

Shut

Down

(ASD)

Relay-PCM

Output

. ... 36

Automatic

Shut

Down

(ASD)

Sense-PCM

Input

. 31

Battery

Voltage-PCM

Input

32

Brake

Switch-PCM

Input

32

Camshaft

Position

Sensor—PCM

Input

32

Charge

Air

Temperature

Sensor—PCM

Input

. . . 32

Crankshaft

Position

Sensor-PCM

Input

.......

32

Electric

Exhaust

Gas Recirculation Transducer

(EET)

Solenoid-PCM

Output

...

.......

36

Engine

Coolant Temperature

Sensor—PCM

Input

. 33

EVAP

Canister

Purge

Solenoid—PCM

Output

. . . 37

Fuel

Injectors-PCM Output

37

Fuel

Pressure

Regulator

41

Fuel

Rail

41

General

Information

.......................

29

Generator

Field-PCM

Output

36

Generator

Lamp-PCM

Output

36

Idle

Air

Control

(IAC)

Motor-PCM

Output

......

36

Ignition

Circuit

Sense—PCM

Input

33

GENERAL

INFORMATION

All

gas

powered engines

are

equipped with sequen

tial Multi-Port Fuel Injection (MPI).

The MPI

system (Fig.

1)

provides precise air/fuel ratios

for all

driving

conditions. The Powertrain Control Module

(PCM)

operates

the fuel system.

The PCM was

formerly referred

to

as

the

SBEC

or

engine controller.

The PCM is a

pre

programmed, dual microprocessor digital computer. It regulates ignition timing, air-fuel ratio, emission

control devices, charging system, speed control,

air

conditioning compressor clutch engagement

and

idle speed.

The PCM can

adapt

its

programming

to

meet

changing operating conditions.

Powertrain Control Module (PCM) Inputs rep

resent

the

instantaneous engine operating conditions.

Air-fuel mixture

and

ignition timing calibrations

for

various driving

and

atmospheric conditions

are

pre

programmed into

the PCM. The PCM

monitors

and

analyzes various inputs.

It

then computes engine fuel

and ignition timing requirements based

on

these

in

puts.

Fuel delivery control

and

ignition timing will

then

be

adjusted accordingly. Other inputs

to the

PCM

are

provided

by the

brake

light switch,

air

conditioning select switch

and the

speed control switches.

All

inputs

to the PCM are

converted into signals. Electrically operated fuel injectors spray fuel

in

precise metered amounts into

the

intake port directly above

the

intake valve.

The

injectors

are

fired

in a

specific sequence

by the PCM. The PCM

maintains

page

Ignition

Coil-PCM

Output

37

Malfunction Indicator

Lamp—PCM

Output

37

Manifold

Absolute

Pressure

(MAP)

Sensor-

PCM

Input

33

Open

Loop/Closed

Loop

Modes

of

Operation

. . . 38

Overdrive/Override

Switch

34

Oxygen

(02)

Sensor—PCM

Input

33

Park/Neutral

Switch—PCM

Input

34

Power

Ground

34

Powertrain Control Module

(PCM)

30

SCI

Receive-PCM

Input

. 34

SCI

Transmit-PCM

Output

37

Sensor

Return

—PCM

Input

35

Shift Indicator-PCM Output

38

Speed

Control-PCM

Input

34

Speed

Control-PCM

Output

38

SRI

Lamp-PCM

Output

36

Tachometer—PCM

Output

38

Throttle

Body

40

Throttle

Position

Sensor

(TPS)-PCM

Input

35

Vehicle

Speed

Sensor-PCM

Input

35

an air/fuel ratio

of 14.7 to 1 by

constantly adjusting

injector pulse width. Injector pulse width

is the

length

of

time that

the

injector opens

and

sprays fuel into

the

chamber.

The PCM

adjusts injector pulse

width

by

opening

and

closing

the

ground path

to the

injector.

Manifold absolute pressure

(air

density)

and

engine

rpm (speed)

are the

primary inputs that determine

fuel injector pulse width.

The PCM

also monitors

other inputs when adjusting air-fuel ratio.

Inputs That Effect Fuel Injector Pulse Width:

• Exhaust

gas

oxygen content

• Coolant temperature

• Manifold absolute pressure (MAP)

• Engine speed

• Throttle position

• Battery voltage •

Air

conditioning selection

• Transmission gear selection (auto, trans.)

• Speed control The powertrain control module (PCM) adjusts igni

tion timing

by

controlling ignition coil operation.

The

ignition coil receives battery voltage when

the

igni

tion

key is in the run or

starter (crank) position.

The

PCM provides

a

ground

for the

ignition coil.

The

coil

discharges when

the PCM

supplies

a

ground.

By

switching

the

ground path

on and off, the PCM

reg

ulates ignition timing.

The sensors

and

switches that provide inputs

to the

powertrain control module

(PCM)

comprise

the En-

Page 849 of 1502

14

- 30

FUEL

SYSTEM

INPUTS

OUTPUTS

POWERTRAIN

CONTROL

MODULE

DRB

II

SCAN

TOOL

SPEED

CONTROL

BRAKE

SWITCH

A/C

LOW

PRESSURE

CUTOFF

SWITCH VEHICLE

SPEED

SENSOR PARK/NEUTRAL

SWITCH TORQUE CONVERTER

CLUTCH SOLENOID

MALFUNCTION

INDICATOR

LAMP

m

HEATED

i

*OXYGEN SENSOR ENGINE

COOLANT

yy

BATTERY

TEMPERATURE

SENSOR

MAP SENSOR

i—r

CHARGE

AIR

TEMPERATURE

SENSOR

AIR CHARGE

TEMPERATURE

SENSOR

DISTRIBUTOR

WITH

CAMSHAFT

r

POSITION

SENSOR

(|

TACHOMETER

A/C

CLUTCH RELAY

AUTO

SHUTDOWN

RELAY OVERDRIVE

SOLENOID

IDLE AIR

CONTROL MOTOR

SPEED

CONTROL

SHIFT

INDICATOR

LAMP

EMISSION

CONTROL SOLENOIDS

IGNITION

COIL

OVERDRIVE

OVERRIDE SWITCH

ASD

SENSE

FUEL

INJECTORS

PARK

THROTTLE

SOLENOID

GENERATOR CRANKSHAFT

POSITION FUEL

PUMP

RELAY

J9314-117

Fig.

1 Multi-Port

Fuel

Injection

Components—Except

Diesel

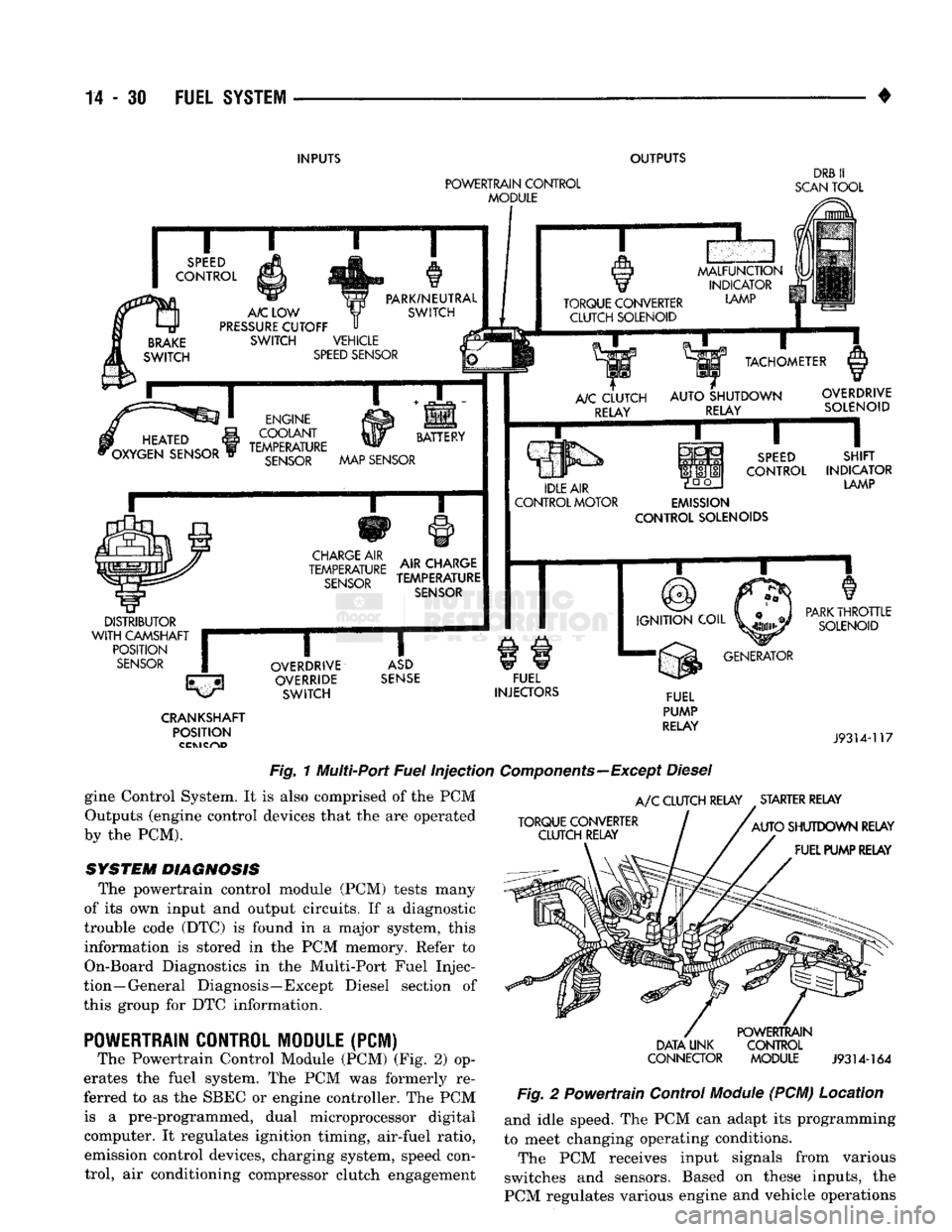

gine Control System. It is also comprised of the PCM Outputs (engine control devices that the are operated

by the PCM).

SYSTEM DIAGNOSIS

The powertrain control module (PCM) tests many

of its own input and output circuits. If a diagnostic

trouble code (DTC) is found in a major system, this information is stored in the PCM memory. Refer to

On-Board Diagnostics in the Multi-Port Fuel Injec

tion—General Diagnosis—Except Diesel section of

this group for DTC information.

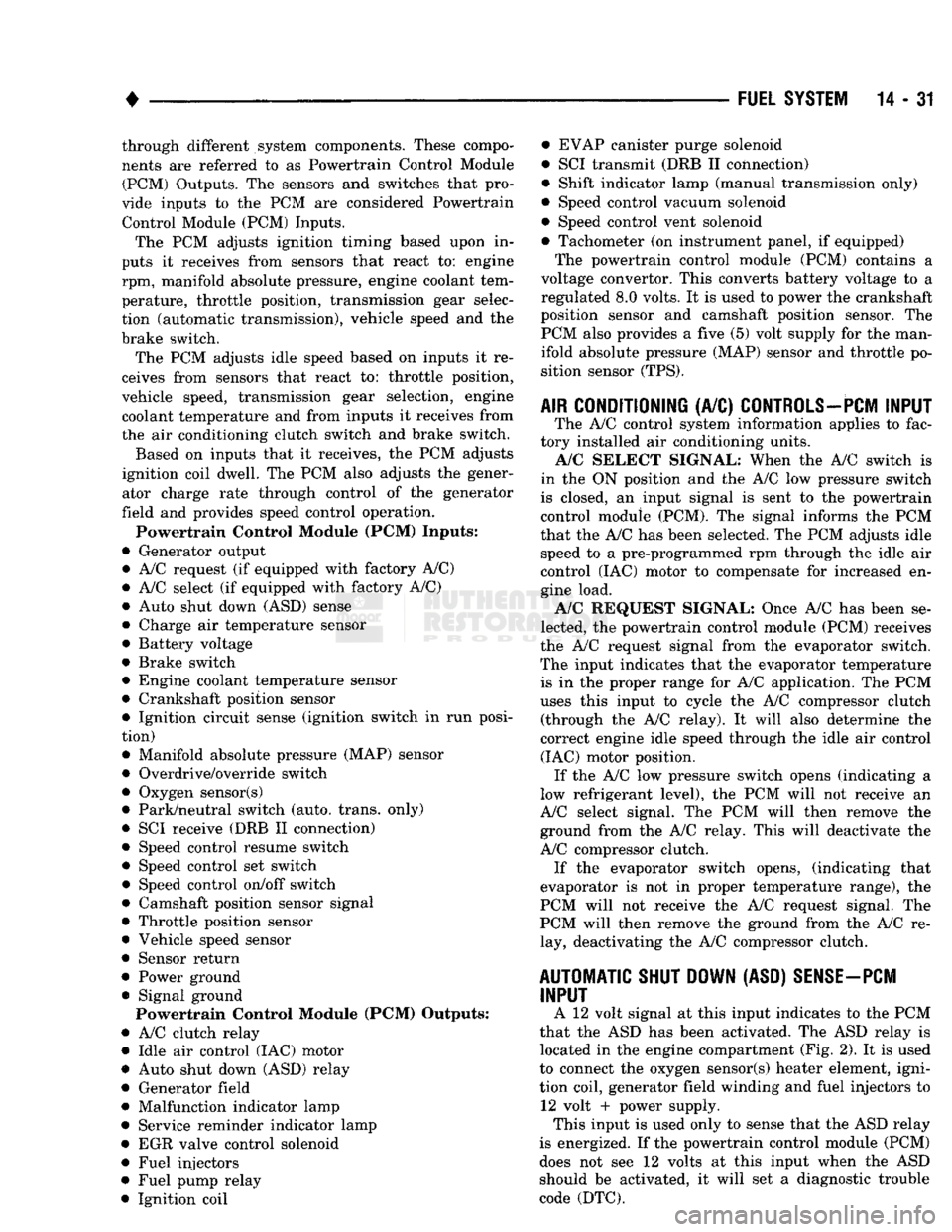

POWERTRAIN

CONTROL MODULE (PCM)

The Powertrain Control Module (PCM) (Fig. 2) op

erates the fuel system. The PCM was formerly re

ferred to as the SBEC or engine controller. The PCM is a pre-programmed, dual microprocessor digital computer. It regulates ignition timing, air-fuel ratio, emission control devices, charging system, speed control, air conditioning compressor clutch engagement

A/C

CLUTCH RELAY STARTER RELAY

TORQUE CONVERTER CLUTCH RELAY

AUTO

SHUTDOWN RELAY

FUEL PUMP RELAY

DATA UNK

CONNECTOR

POWERTRAIN

CONTROL MODULE

J9314-164

Fig.

2 Powertrain Control

Module

(PCM) Location and idle speed. The PCM can adapt its programming

to meet changing operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

Page 850 of 1502

•

FUEL SYSTEM

14-31 through different system components. These compo

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro

vide inputs to the PCM are considered Powertrain Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon in

puts it receives from sensors that react to: engine rpm, manifold absolute pressure, engine coolant tem

perature, throttle position, transmission gear selec

tion (automatic transmission), vehicle speed and the

brake switch.

The PCM adjusts idle speed based on inputs it re

ceives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener

ator charge rate through control of the generator

field and provides speed control operation.

Powertrain Control Module (PCM) Inputs:

• Generator output • A/C request (if equipped with factory A/C)

• A/C select (if equipped with factory A/C)

• Auto shut down (ASD) sense

• Charge air temperature sensor

• Battery voltage

• Brake switch

• Engine coolant temperature sensor

• Crankshaft position sensor • Ignition circuit sense (ignition switch in run posi

tion)

• Manifold absolute pressure (MAP) sensor

• Overdrive/override switch

• Oxygen sensor(s)

• Park/neutral switch (auto, trans, only)

• SCI receive (DRB II connection) • Speed control resume switch

• Speed control set switch • Speed control on/off switch

• Camshaft position sensor signal

• Throttle position sensor

• Vehicle speed sensor

• Sensor return

• Power ground

• Signal ground Powertrain Control Module (PCM) Outputs:

• A/C clutch relay

• Idle air control (IAC) motor

• Auto shut down (ASD) relay

• Generator field

• Malfunction indicator lamp

• Service reminder indicator lamp

• EGR valve control solenoid • Fuel injectors

• Fuel pump relay

• Ignition coil • EVAP canister purge solenoid

• SCI transmit (DRB II connection)

• Shift indicator lamp (manual transmission only)

• Speed control vacuum solenoid

• Speed control vent solenoid

• Tachometer (on instrument panel, if equipped) The powertrain control module (PCM) contains a

voltage convertor. This converts battery voltage to a

regulated 8.0 volts. It is used to power the crankshaft

position sensor and camshaft position sensor. The

PCM also provides a five (5) volt supply for the man ifold absolute pressure (MAP) sensor and throttle po

sition sensor (TPS).

AIR

CONDITIONING

(A/C)

CONTROLS-PCM

INPUT

The A/C control system information applies to fac

tory installed air conditioning units. A/C SELECT SIGNAL: When the A/C switch is

in the ON position and the A/C low pressure switch

is closed, an input signal is sent to the powertrain

control module (PCM). The signal informs the PCM

that the A/C has been selected. The PCM adjusts idle speed to a pre-programmed rpm through the idle air

control (IAC) motor to compensate for increased en

gine load. A/C REQUEST SIGNAL: Once A/C has been se

lected, the powertrain control module (PCM) receives

the A/C request signal from the evaporator switch.

The input indicates that the evaporator temperature is in the proper range for A/C application. The PCM

uses this input to cycle the A/C compressor clutch (through the A/C relay). It will also determine the

correct engine idle speed through the idle air control (IAC) motor position. If the A/C low pressure switch opens (indicating a

low refrigerant level), the PCM will not receive an

A/C select signal. The PCM will then remove the ground from the A/C relay. This will deactivate the

A/C compressor clutch. If the evaporator switch opens, (indicating that

evaporator is not in proper temperature range), the

PCM will not receive the A/C request signal. The

PCM will then remove the ground from the A/C re lay, deactivating the A/C compressor clutch.

AUTOMATIC SHUT DOWN

(ASD)

SENSE-PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The ASD relay is located in the engine compartment (Fig. 2). It is used

to connect the oxygen sensor(s) heater element, igni

tion coil, generator field winding and fuel injectors to 12 volt + power supply. This input is used only to sense that the ASD relay

is energized. If the powertrain control module (PCM)

does not see 12 volts at this input when the ASD

should be activated, it will set a diagnostic trouble

code (DTC).