DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 831 of 1502

14

- 12

FUEL

SYSTEM

•

PULL TAB

RETAINER TAB RETAINER TAB BENT

IN ORIGINAL UPRIGHT DOWN

FOR

POSITION REMOVAL

J9114-168

Fig.

23 Retainer Tabs

MANUAL DISASSEMBLY WARNING:

RELEASE

FUEL

SYSTEM PRESSURE

BEFORE

DISCONNECTING

A

QUICK-CONNECT FIT

TING.

REFER

TO THE

FUEL

PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from the battery,

(2) Perform the Fuel Pressure Release Procedure.

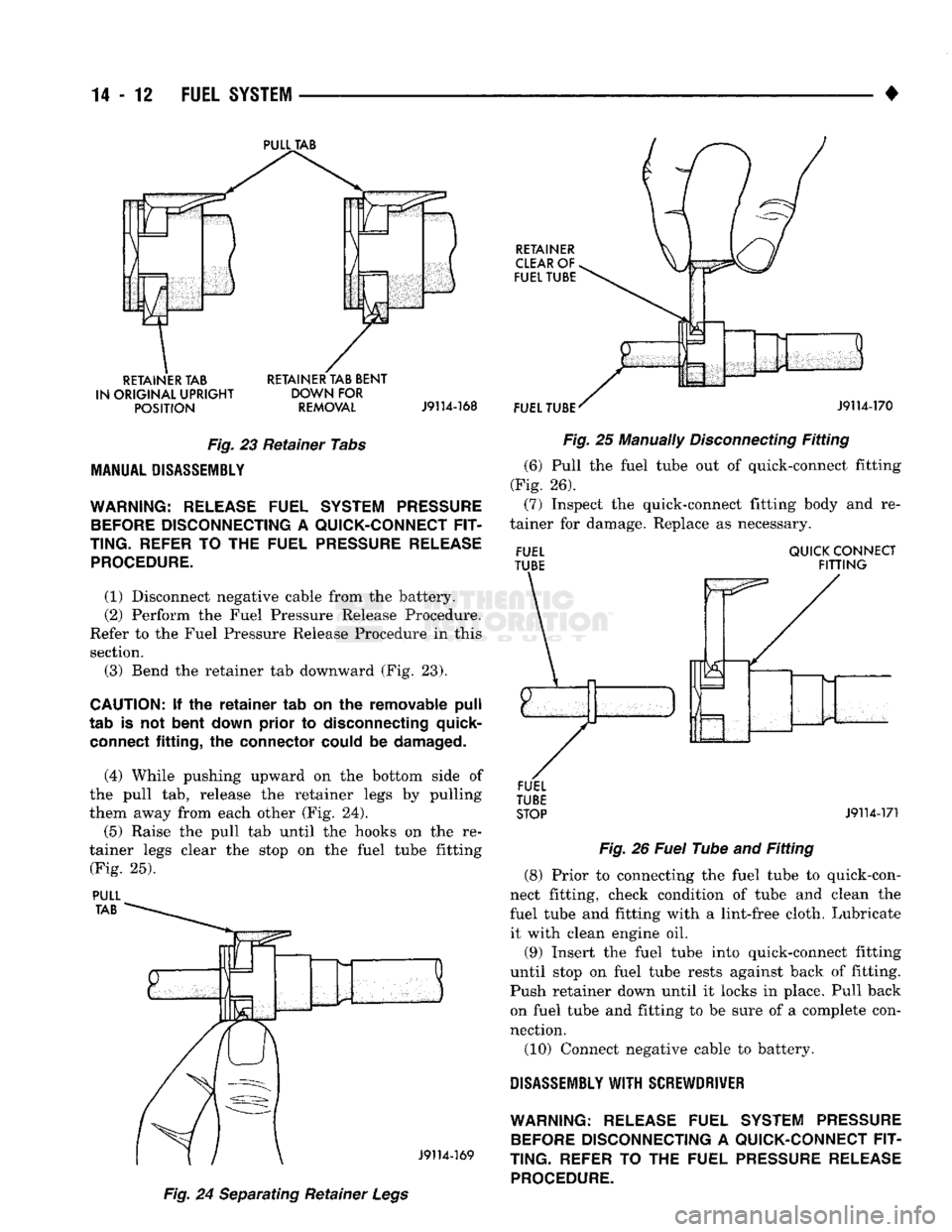

Refer to the Fuel Pressure Release Procedure in this section. (3) Bend the retainer tab downward (Fig. 23).

CAUTION:

If the

retainer

tab on the removable

pull

tab is not

bent

down

prior

to disconnecting quick- connect

fitting,

the connector could be

damaged.

(4) While pushing upward on the bottom side of

the pull tab, release the retainer legs by pulling

them away from each other (Fig. 24).

(5) Raise the pull tab until the hooks on the re

tainer legs clear the stop on the fuel tube fitting (Fig. 25).

PULL Fig.

24 Separating Retainer

Legs Fig.

25 Manually

Disconnecting

Fitting

(6) Pull the fuel tube out of quick-connect fitting

(Fig. 26). (7) Inspect the quick-connect fitting body and re

tainer for damage. Replace as necessary.

FUEL QUICK CONNECT

TUBE

FITTING

STOP

J9114-171

Fig.

26

Fuel

Tube and

Fitting

(8) Prior to connecting the fuel tube to quick-con

nect fitting, check condition of tube and clean the

fuel tube and fitting with a lint-free cloth. Lubricate

it with clean engine oil.

(9) Insert the fuel tube into quick-connect fitting

until stop on fuel tube rests against back of fitting. Push retainer down until it locks in place. Pull back

on fuel tube and fitting to be sure of a complete con

nection.

(10) Connect negative cable to battery.

DISASSEMBLY

WITH

SCREWDRIVER WARNING:

RELEASE

FUEL

SYSTEM PRESSURE

BEFORE

DISCONNECTING

A

QUICK-CONNECT FIT

TING.

REFER

TO THE

FUEL

PRESSURE RELEASE

PROCEDURE.

Page 832 of 1502

•

FUEL

SYSTEM

14 - 13 (1) Disconnect negative cable from the battery.

(2) Perform the Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this section.

(3) Bend the retainer tab downward.

CAUTION:

If the

retainer

tab on the

removable

pull

tab

is not

bent

down

prior

to

disconnecting

the

quick-connect

fitting,

the

connector

could

be

dam

aged.

(4) Insert screwdriver tip between connector body

and retainer pull tab (Fig. 27).

RETAINER

SCREWDRIVER

J9114-172

J9114-181

Fig.

29

Disconnecting

Fitting

(9) Prior to connecting fuel tube to quick-connect

fitting, check condition of tube and clean the fuel

tube and fitting with a lint-free cloth. Lubricate it

with clean engine oil.

(10) Insert fuel tube into quick-connect fitting un

til stop on fuel tube rests against back of fitting.

Push retainer down until it locks in place. Pull back on fuel tube and fitting to be sure of a complete con

nection.

(11) Connect negative cable to battery.

PLASTIC RING TYPE FITTING

Fig.

27

Disassembly

with

Screwdriver

(5) Turn screwdriver 90 degrees to lift retainer up

(Fig. 28).

RETAINER

PULL

TAB

SCREWDRIVER

J9114-173

Fig.

28

Releasing

Retainer

(6) Raise the pull tab until the hooks on the re

tainer legs clear the stop on the fuel tube fitting

(Fig. 29). (7) Pull fuel tube out of quick-connect fitting.

(8) Inspect fitting body and retainer for damage.

Replace as necessary.

WARNING:

RELEASE

FUEL

SYSTEM PRESSURE

BEFORE

DISCONNECTING

A

QUICK-CONNECT FIT

TING.

REFER

TO THE

FUEL

PRESSURE RELEASE PROCEDURE.

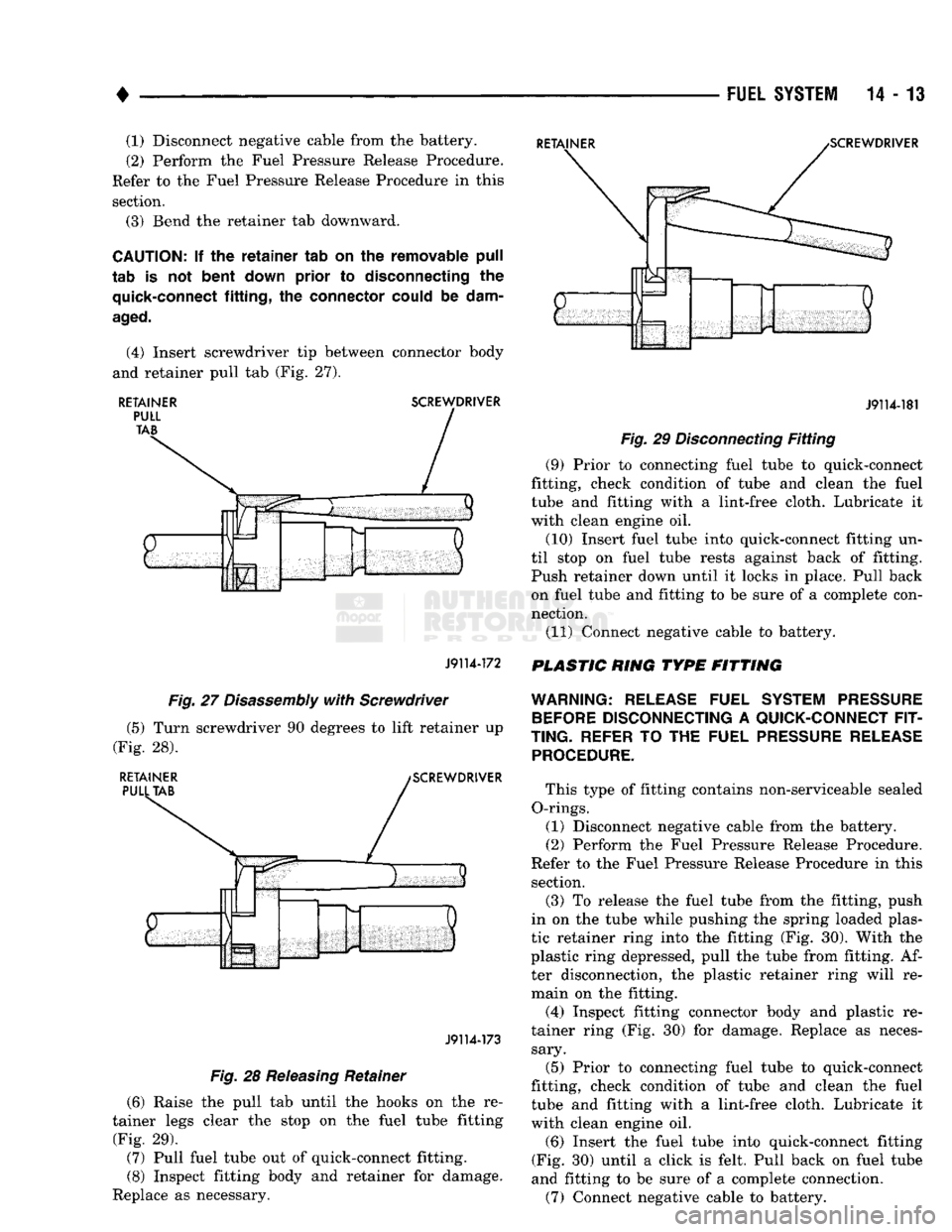

This type of fitting contains non-serviceable sealed

O-rings. (1) Disconnect negative cable from the battery.

(2) Perform the Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this section. (3) To release the fuel tube from the fitting, push

in on the tube while pushing the spring loaded plas

tic retainer ring into the fitting (Fig. 30). With the

plastic ring depressed, pull the tube from fitting. Af ter disconnection, the plastic retainer ring will re

main on the fitting.

(4) Inspect fitting connector body and plastic re

tainer ring (Fig. 30) for damage. Replace as neces sary.

(5) Prior to connecting fuel tube to quick-connect

fitting, check condition of tube and clean the fuel

tube and fitting with a lint-free cloth. Lubricate it

with clean engine oil.

(6) Insert the fuel tube into quick-connect fitting

(Fig. 30) until a click is felt. Pull back on fuel tube

and fitting to be sure of a complete connection.

(7) Connect negative cable to battery.

Page 833 of 1502

14 - 14

FUEL

SYSTEM

FUEL TUBE

REMOVAL

QUICK CONNECT

FITTING

PUSH

INSTALLATION

^ PUSH

»-

/

PLASTIC

RETAINER

J93U-100

Fig.

30 Plastic

Ring

Type Fitting

•PUSH

Page 834 of 1502

FUEL

DELIVERY—DIESEL

ENGINE

INDEX

page

Fuel Gauge Sending Unit Module

15

General Information

15

Manual

Shut Down Lever

. . 17

page

Mechanical

Lift

Pump

15

Quick

Connect Fittings—Except

Chassis

Fuel Tubes

17

GENERAL

INFORMATION

The fuel system of the 5.9L turbo-diesel engine

consists of the:

• Fuel tank • Low and high pressure fuel supply lines

• Mechanical lift pump

• Fuel/water separator filter

• Fuel heater

• Fuel injection pump • Fuel injectors

• Fuel return lines For information regarding fuel requirements of the

5.9L turbo diesel engine, refer to the Fuel Require

ments—Diesel Engines paragraph at the front of this group.

MECHANICAL

LIFT

PUMP

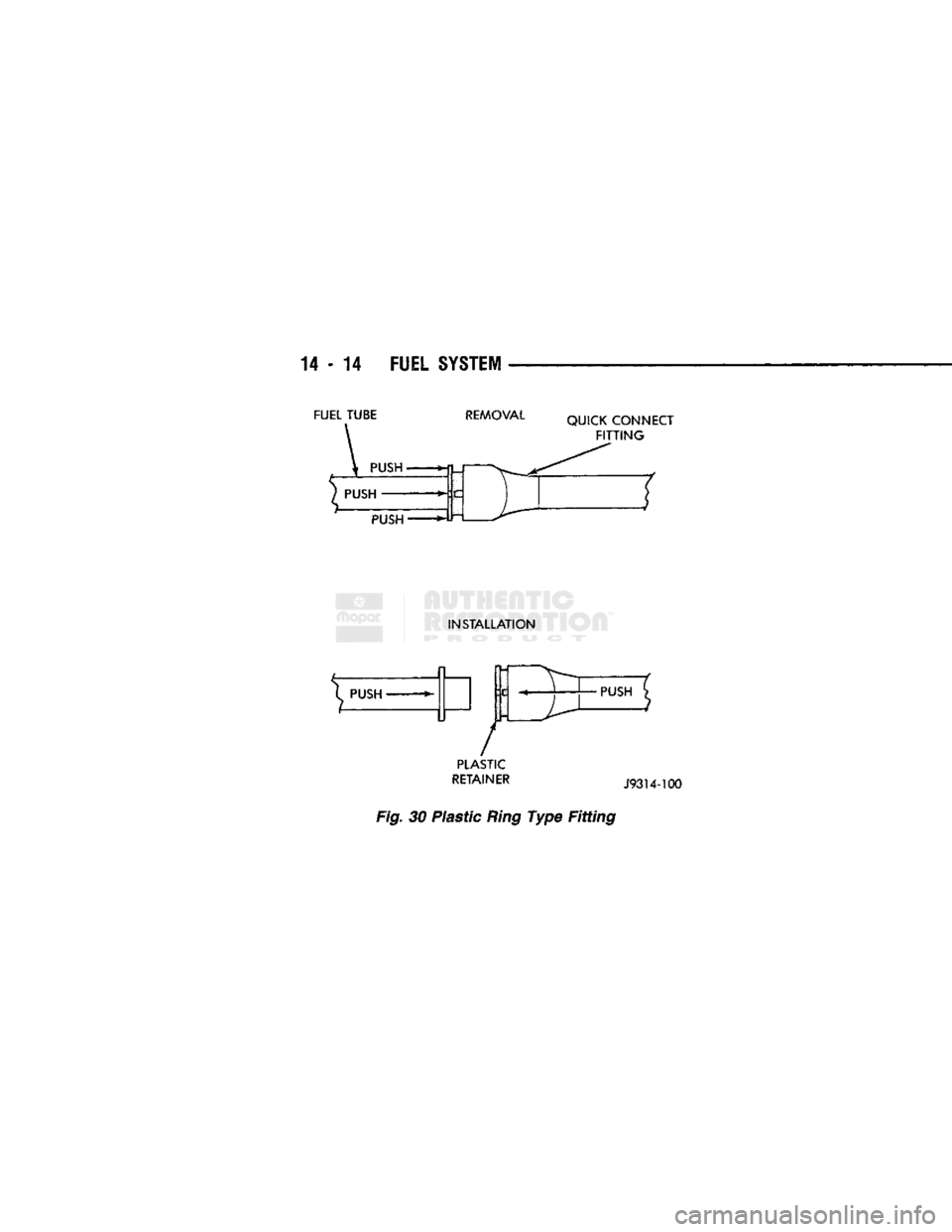

The mechanical lift pump is located on the left side

of the engine cylinder block. The lift pump is driven

by an eccentric on the camshaft that actuates a spring loaded lever in the pump (Fig. 1). The lever is

connected to the pump diaphragm. When the eccen

tric on the camshaft pushes the lever upward, the le ver in turn pulls the diaphragm to its extended

position. Fuel is drawn into the pump chamber

through the inlet check valve. When the pump gath ers more fuel in the fuel chamber than the engine

can consume, the outlet check valve is held closed.

The fuel gathered in lift pump chamber prevents the diaphragm from relaxing. The lever will continue to

move up and down on the shaft connecting it to the

diaphragm. However, the lever is prevented from op

erating the diaphragm until the check valve again

opens to expel fuel from the pump chamber. This pro cess continues as long as the engine is running.

Minimum lift pump output pressure is 21 Kpa (3

psi).

Lift pump output volume is 0.75 liters (0.70 U.S. quarts) per 30 seconds of engine cranking. The lift pump housing has a weep hole at the bot

tom of the casing (Fig. 1). If the diaphragm ruptures,

fuel will exit out of the weep hole and the pump

must be replaced. The lift pump is not serviceable and must be replaced as a complete assembly.

CAUTION:

Do not

operate

the

engine

if the

fuel

supply

line

has a

restriction

of

more than

95 MM Hg

(3.75

in Hg).

Fig.

1

Lift

Pump

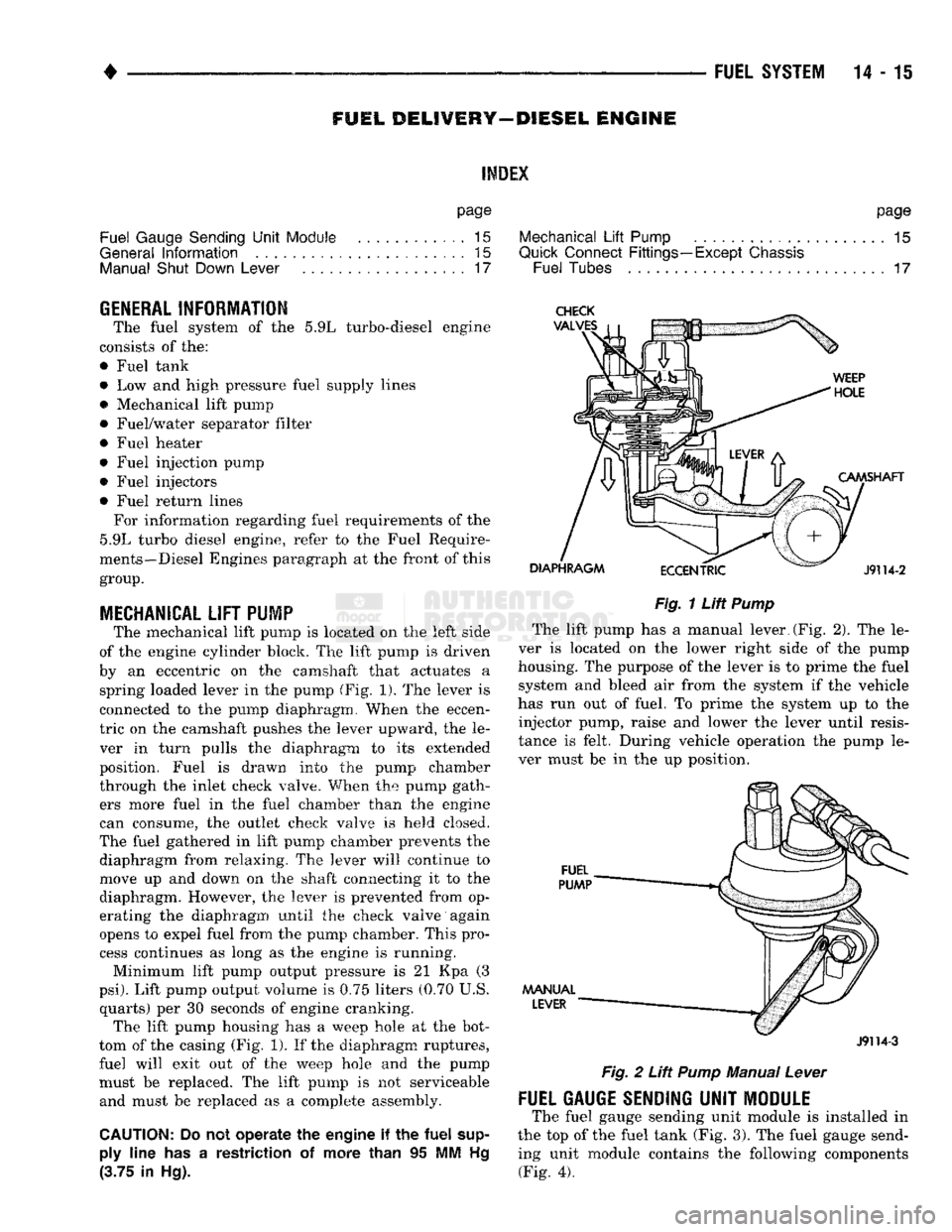

The lift pump has a manual lever.(Fig. 2). The le

ver is located on the lower right side of the pump

housing. The purpose of the lever is to prime the fuel system and bleed air from the system if the vehicle

has run out of fuel. To prime the system up to the injector pump, raise and lower the lever until resis

tance is felt. During vehicle operation the pump le

ver must be in the up position.

J9114-3

Fig.

2

Lift

Pump

Manual

Lever

FUEL GAUGE SENDING

UNIT

MODULE

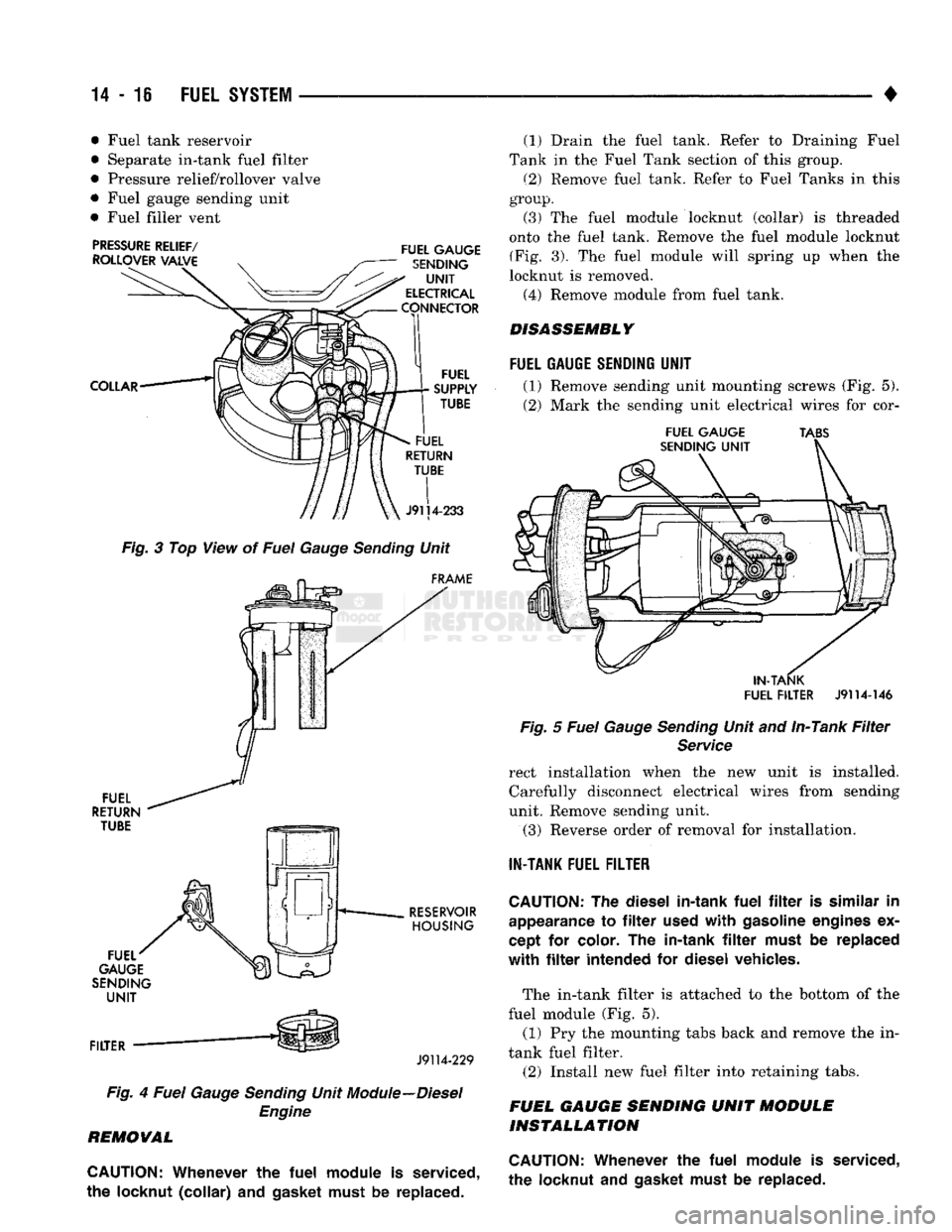

The fuel gauge sending unit module is installed in

the top of the fuel tank (Fig. 3). The fuel gauge send ing unit module contains the following components (Fig. 4).

Page 835 of 1502

14-16 FUEL SYSTEM

• • Fuel tank reservoir

• Separate in-tank fuel filter

• Pressure relief/rollover valve

• Fuel gauge sending unit

• Fuel filler vent

Fig. 3 Top View of Fuel Gauge Sending Unit

J9114-229

Fig. 4 Fuel Gauge Sending Unit Module--Diesel Engine

REMOVAL

CAUTION:

Whenever

the

fuel

module

is

serviced,

the

locknut

(collar)

and

gasket must

be

replaced. (1)

Drain the fuel tank. Eefer to Draining Fuel

Tank in the Fuel Tank section of this group.

(2) Remove fuel tank. Refer to Fuel Tanks in this

group.

(3)

The fuel module locknut (collar) is threaded

onto the fuel tank. Remove the fuel module locknut (Fig. 3). The fuel module will spring up when the

locknut is removed. (4) Remove module from fuel tank.

DISASSEMBLY

FUEL

GAUGE SENDING

UNIT

(1) Remove sending unit mounting screws (Fig. 5).

(2) Mark the sending unit electrical wires for cor-

FUEL

GAUGE TABS

IN-TANK

FUEL FILTER

J9114-146

Fig. 5 Fuel Gauge Sending Unit and In-Tank Filter Service

rect installation when the new unit is installed. Carefully disconnect electrical wires from sending

unit. Remove sending unit.

(3)

Reverse order of removal for installation.

IN-TANK

FUEL FILTER

CAUTION:

The

diesel in-tank

fuel

filter is

similar

in

appearance

to filter

used

with

gasoline engines

ex

cept

for

color.

The

in-tank

filter

must

be

replaced

with

filter

intended

for

diesel vehicles.

The in-tank filter is attached to the bottom of the

fuel module (Fig. 5). (1) Pry the mounting tabs back and remove the in-

tank fuel filter. (2) Install new fuel filter into retaining tabs.

FUEL GAUGE SENDING UNIT MODULE INSTALLATION

CAUTION:

Whenever

the

fuel

module

is

serviced,

the locknut

and

gasket must

be

replaced.

Page 836 of 1502

•

FUEL SYSTEM

14-17

(1) Using

a new

gasket, position fuel module into

opening

in

fuel tank.

(2) Position

new

locknut over

top of

fuel module.

(3) Tighten locknut. (4) Install fuel tank. Refer

to

Fuel Tank Installa

tion

in

this section.

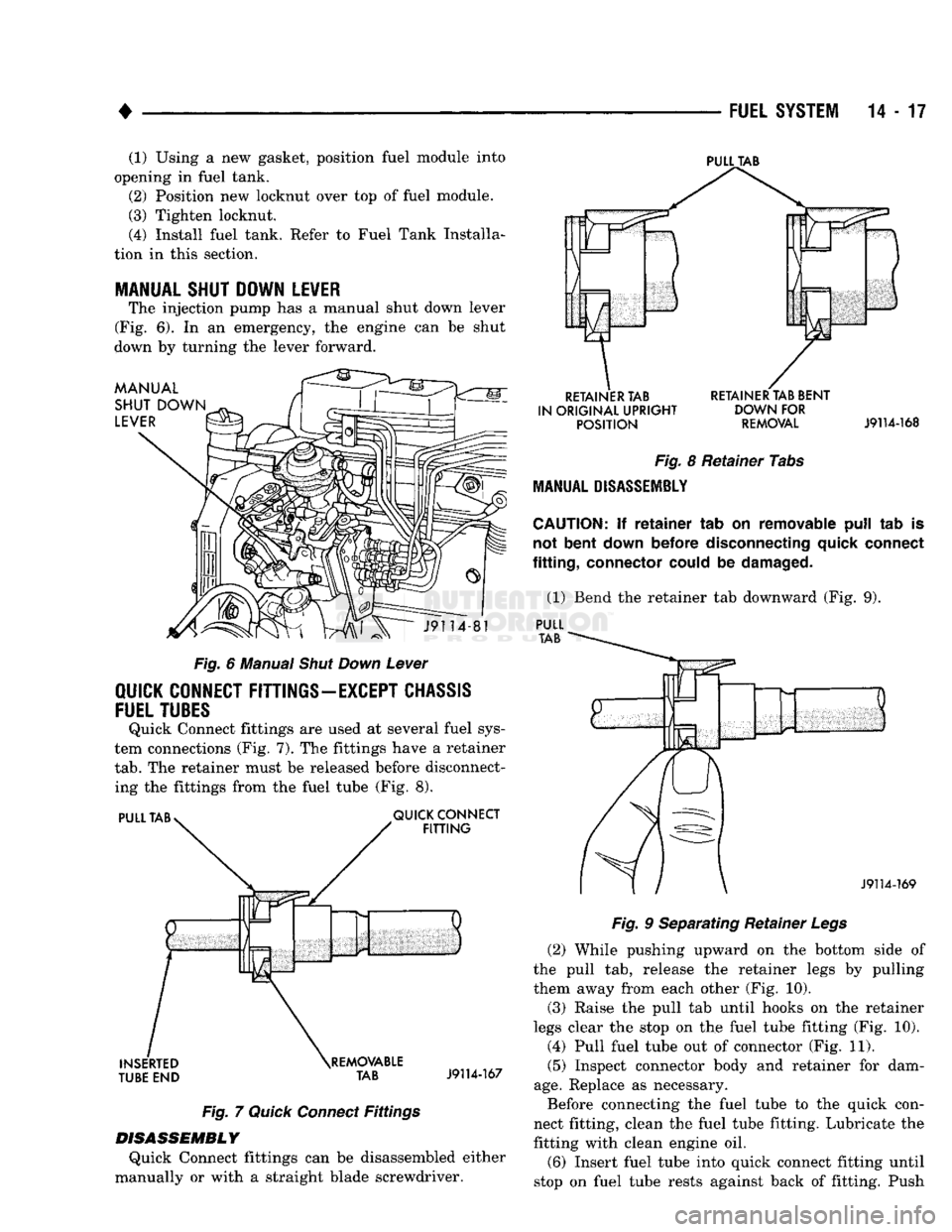

MANUAL SHUT

DOWN

LE¥ER

The injection pump

has a

manual shut down lever

(Fig.

6). In an

emergency,

the

engine

can be

shut

down

by

turning

the

lever forward.

Fig.

6

Manual

Shut

Down

Lever

QUICK CONNECT

FITTINGS-EXCEPT

CHASSIS

FUEL TUBES

Quick Connect fittings

are

used

at

several fuel sys

tem connections

(Fig. 7). The

fittings have

a

retainer

tab.

The

retainer must

be

released before disconnect

ing

the

fittings from

the

fuel tube

(Fig. 8).

Fig.

7

Quick

Connect

Fittings

DISASSEMBLY

Quick Connect fittings

can be

disassembled either

manually

or

with

a

straight blade screwdriver.

PULL

TAB

RETAINER

TAB

RETAINER

TAB

BENT

IN

ORIGINAL

UPRIGHT DOWN FOR

POSITION

REMOVAL

J9114-168

Fig.

8

Retainer Tabs

MANUAL

DISASSEMBLY

CAUTION:

If

retainer

tab on

removable

pull

tab is

not

bent

down

before

disconnecting quick connect

fitting,

connector could

be

damaged.

(1) Bend

the

retainer

tab

downward

(Fig. 9).

PULL

Fig.

9

Separating Retainer

Legs

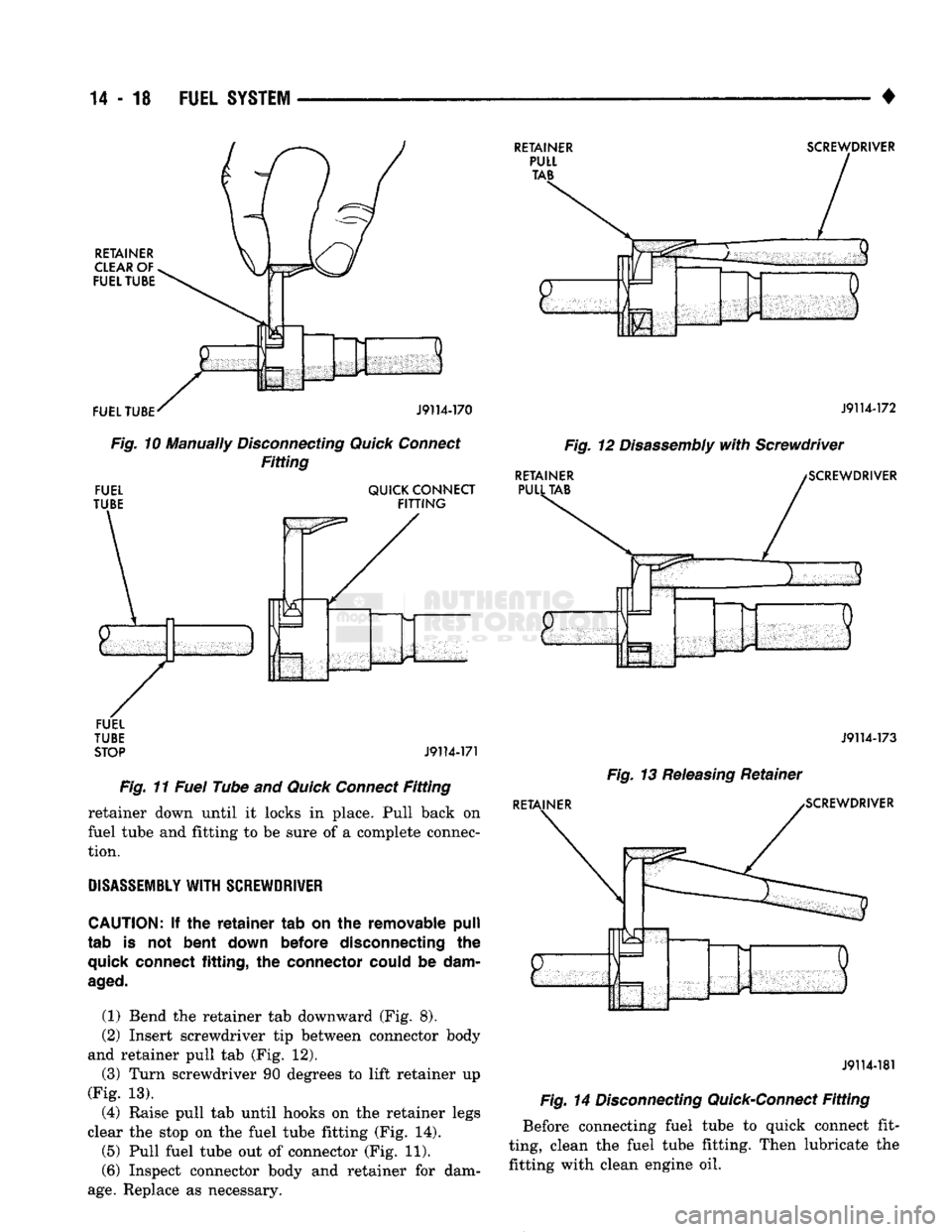

(2) While pushing upward

on the

bottom side

of

the pull

tab,

release

the

retainer legs

by

pulling

them away from each other

(Fig. 10).

(3) Raise

the

pull

tab

until hooks

on the

retainer

legs clear

the

stop

on the

fuel tube fitting

(Fig. 10).

(4) Pull fuel tube

out of

connector

(Fig. 11).

(5) Inspect connector body

and

retainer

for

dam

age.

Replace

as

necessary.

Before connecting

the

fuel tube

to the

quick con

nect fitting, clean

the

fuel tube fitting. Lubricate

the

fitting with clean engine

oil.

(6) Insert fuel tube into quick connect fitting until

stop

on

fuel tube rests against back

of

fitting. Push

Page 837 of 1502

14

- 18

FUEL

SYSTEM

•

RETAINER

CLEAR

OF

FUEL TUBE FUEL TUBE

RETAINER

PULL TAB

SCREWDRIVER

ff

t

iiiilil

J9114-170

Fig.

10 Manually

Disconnecting

Quick

Connect

Fitting

FUEL

TUBE QUICK CONNECT

FITTING

RETAINER

PULL TAB

J9114-172

Fig.

12

Disassembly

with

Screwdriver

SCREWDRIVER

FUEL

TUBE STOP

J9114-171

Fig.

11

Fuel

Tube and

Quick

Connect

Fitting

retainer down until it locks in place. Pull back on

fuel tube and fitting to be sure of a complete connec

tion.

DISASSEMBLY

WITH

SCREWDRIVER

CAUTION:

If the

retainer

tab on the removable

pull

tab is not

bent

down

before

disconnecting the

quick

connect

fitting,

the

connector could

be

dam

aged.

(1) Bend the retainer tab downward (Fig. 8).

(2) Insert screwdriver tip between connector body

and retainer pull tab (Fig. 12).

(3) Turn screwdriver 90 degrees to lift retainer up

(Fig. 13).

(4) Raise pull tab until hooks on the retainer legs

clear the stop on the fuel tube fitting (Fig. 14). (5) Pull fuel tube out of connector (Fig. 11).

(6) Inspect connector body and retainer for dam

age.

Replace as necessary.

J9114-173

Fig.

13

Releasing

Retainer

RETAINER ^SCREWDRIVER

J9114-181

Fig.

14

Disconnecting

Quick-Connect

Fitting

Before connecting fuel tube to quick connect fit

ting, clean the fuel tube fitting. Then lubricate the fitting with clean engine oil.

Page 838 of 1502

•

FUEL

SYSTEM

14 - 19 (7) Insert fuel tube into quick connect fitting until

stop on fuel tube rests against back of fitting. Push

retainer down until it locks in place. Pull back on

fuel tube and fitting to be sure of a complete connec

tion.

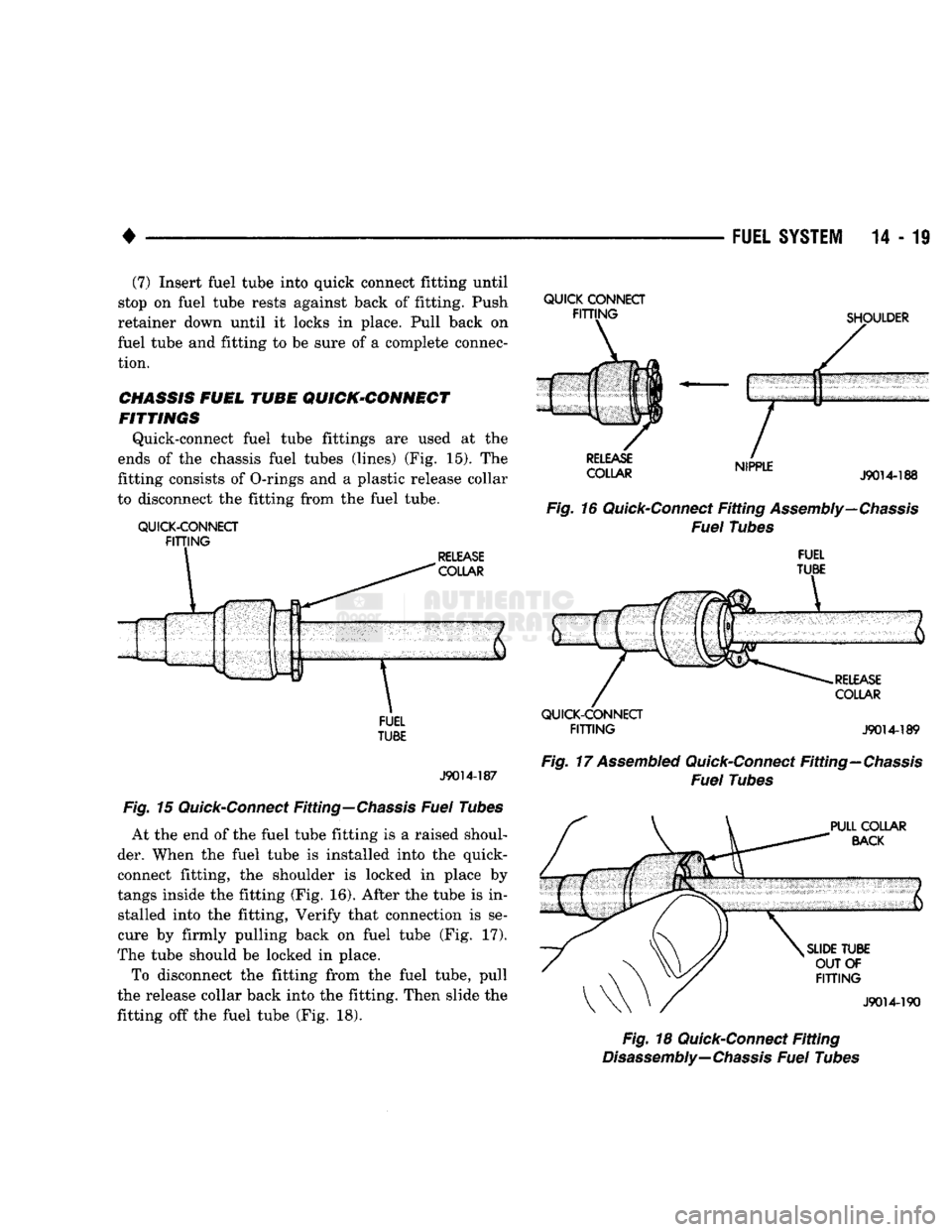

CHASSIS

FUEL

TUBE

QUICK-CONNECT

FITTINGS

Quick-connect fuel tube fittings are used at the

ends of the chassis fuel tubes (lines) (Fig. 15). The

fitting consists of O-rings and a plastic release collar

to disconnect the fitting from the fuel tube.

QUICK-CONNECT

FITTING

FUEL

J9014-187

Fig.

15

Quick-Connect

Fitting—Chassis

Fuel

Tubes

At the end of the fuel tube fitting is a raised shoul

der. When the fuel tube is installed into the quick-

connect fitting, the shoulder is locked in place by

tangs inside the fitting (Fig. 16). After the tube is in stalled into the fitting, Verify that connection is se

cure by firmly pulling back on fuel tube (Fig. 17).

The tube should be locked in place.

To disconnect the fitting from the fuel tube, pull

the release collar back into the fitting. Then slide the

fitting off the fuel tube (Fig. 18).

QUICK

CONNECT

COLLAR

,wrLC

J9014-188

Fig.

16

Quick-Connect

Fitting

Assembly—Chassis

Fuel

Tubes

FUEL

TUBE

QUICK-CONNECT

FITTING

J9014-189

Fig.

17

Assembled

Quick-Connect

Fitting—Chassis

Fuel

Tubes

Fig.

18

Quick-Connect

Fitting

Disassembly—

Chassis

Fuel

Tubes

Page 839 of 1502

14-20 FUEL

SYSTEM

•

FUEL

TANKS

INDEX

page

Fuel Gauge Sending

Unit

24

Fuel Pump

22

Fuel Reservoir

23

Fuel Tank

Filler

Tube

Cap 20

Fuel Tank Pressure Relief/Rollover Valve

...... 24

GENERAL

INFORMATION

All Dodge Trucks pass a full 360 degree rollover with

out fuel leakage. To accomplish this, fuel and vapor

flow controls are required for all fuel tank connections. All models have a pressure relief/rollover valve

mounted in the top of the fuel tank. On vehicles equipped with a return line from fuel pump to fuel

tank, a one-way check valve is used to provide required

protection. In addition to the valve, improved flow con trol is used in the fuel pump. Fuel flow is controlled if

pump is subjected to higher than normal pressure dur ing rollover. For the same reason, a fuel tank filler tube

cap (gas cap) with higher pressure setting is used to

control fuel flow on vehicles with side fill. An evaporation control system is used to reduce

emissions of fuel vapors into atmosphere by evapora

tion and to reduce unburned hydrocarbons emitted

by vehicle engine. When fuel evaporates from fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister. The are temporarily held in the

canister. When the engine is running, the vapors are

drawn into intake manifold. Refer to Group 25,

Emission Control System for additional information. Inspect all hose connections to make sure they are

secure and not leaking. Hoses should be replaced im

mediately if there is any evidence of degradation

that could result in failure. Avoid contact with clamps or other components

that cause abrasions or scuffing. Be sure that the

rubber hoses are properly routed to prevent pinching and to avoid heat sources.

The hoses used on fuel injected vehicles are of a

special construction due to higher fuel pressures in

volved in system. If hoses need replacement, only use

hoses marked EFM/EFI.

The hose clamps used on fuel injected vehicles have

a special rolled edge construction. This prevents the

edge of the clamp from cutting into the hose. Only

these rolled edge type clamps may be used on this system. Other clamps may cut into the hoses. This

could cause high pressure fuel leaks.

NO-LEAD FUEL TANK FILLER TUBE

All catalyst equipped vehicles have a special fuel

tank filler tube. The fuel filler opening is smaller in

page

Fuel Tank Skid

Plate

. 20

Fuel Tanks

21

General

Information

20

Heat Shields

21

No-Lead

Fuel Tank

Filler

Tube

20

diameter than those used for non-catalyst vehicles to

permit entry of only the smaller no-lead fuel nozzles.

A deflector is installed in the fuel filler opening. The

deflector is opened by the no-lead fuel nozzle. The fuel filler tube on these models has a one-way

ball check valve. The valve is designed to prevent

fuel back splash which may occur while filling the tank. A label is attached to instrument panel under fuel

gauge that reads UNLEADED FUEL ONLY as a re

minder to driver. A similar label is located near fuel

tank filler.

FUEL TANK FILLER TUBE

CAP The loss of any fuel or vapor out of filler neck is

prevented by the use of a pressure-vacuum fuel tank

filler tube cap. Relief valves inside cap will release only under significant pressure of 6.58 to 8.44 kPa (1.95 to 2.5 psi). The vacuum release for all gas caps

is between .97 and 2.0 kPa (.14 and .29 psi). This cap

must be replaced by a similar unit if replacement is necessary. This is in order for the system to remain

effective.

CAUTION:

Remove

fuel

tank

filler

tube

cap

before

servicing

any

fuel

system component. This

is

done

to help

relieve

tank pressure.

FUEL

TANK

CAPACITIES

TANK:

LITERS

GALLONS

Standard

83.0

22

Optional 114

30

Ramcharger 120.9 34

Nominal

refill

capacities are

shown.

A variation may be observed

from vehicle to vehicle due to manufacturing tolerances and

refill

procedures.

J9014-182

FUEL TANK SKID PLATE

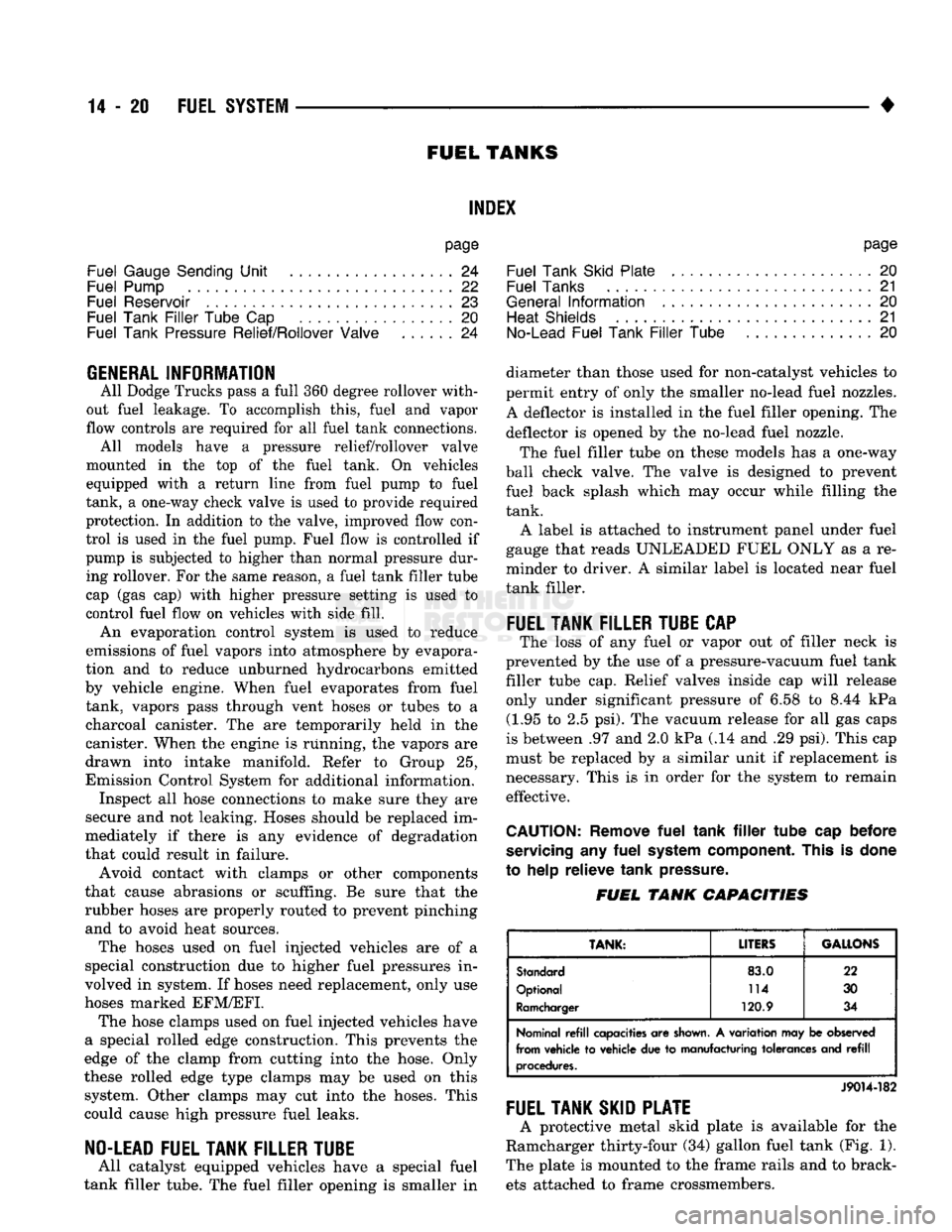

A protective metal skid plate is available for the

Ramcharger thirty-four (34) gallon fuel tank (Fig. 1).

The plate is mounted to the frame rails and to brack ets attached to frame crossmembers.

Page 840 of 1502

•

FUEL

SYSTEM

14-21

FRAME

RAIL

SKID

PLATE

RN869

Fig.

1

Fuel

Tank

Skid

Plate

HEAT

SHIELDS

The sheet metal heat shields must be removed

when servicing fuel tank, fuel tubes/lines or vapor

vent line. It is very important that these heat shields be reinstalled after service. They are used

to protect lines and tank from heat of exhaust sys

tem. See Group 11 in this manual for proper instal lation.

FUEL

TANKS

DRAINING

FUEL

TANK

(1) Remove fuel tank filler tube cap to release fuel

tank pressure. (2) Perform Fuel System Pressure Release proce

dure as described in this group.

(3) Raise vehicle on hoist.

(4) Drain fuel into an approved portable holding

tank or a properly labeled gasoline safety container.

• If fuel pump operates, fuel can be drained through

fuel supply hose. The DRB II scan tool can be used to operate the electric fuel pump (gas engines only).

• If pump does not operate, but fuel level in fuel

tank is below fuel filler hose, fuel can be siphoned

through fuel filler hose. The hose will have to be dis connected from filler neck.

• If fuel tank is full and fuel pump does not operate,

drain fuel from filler neck. Support fuel tank with a

transmission jack. Loosen fuel tank mounting straps with passenger side fuel strap loosened slightly more

than driver side strap. Lower the tank slightly. Loosen the filler neck-to-filler hose clamp. Slide

clamp back on hose. Wrap shop towels around fuel

filler hose to absorb any spilled fuel. Disconnect filler

hose from filler neck. Drain fuel tank through filler

hose.

REMOVAL-MID-FRAME

MOUNTED

TANKS

(1) Drain fuel tank. Refer to Draining Fuel Tank

in this group. (2) Disconnect negative battery cable at battery.

(3) Remove fuel tank filler tube cap.

(4) Pump all fuel from fuel tank into an approved

portable holding tank. If this equipment is not avail

able,

disconnect fuel tube (line) and drain tank dry

into a properly identified Gasoline safety container.

Refer to Draining Fuel Tank.

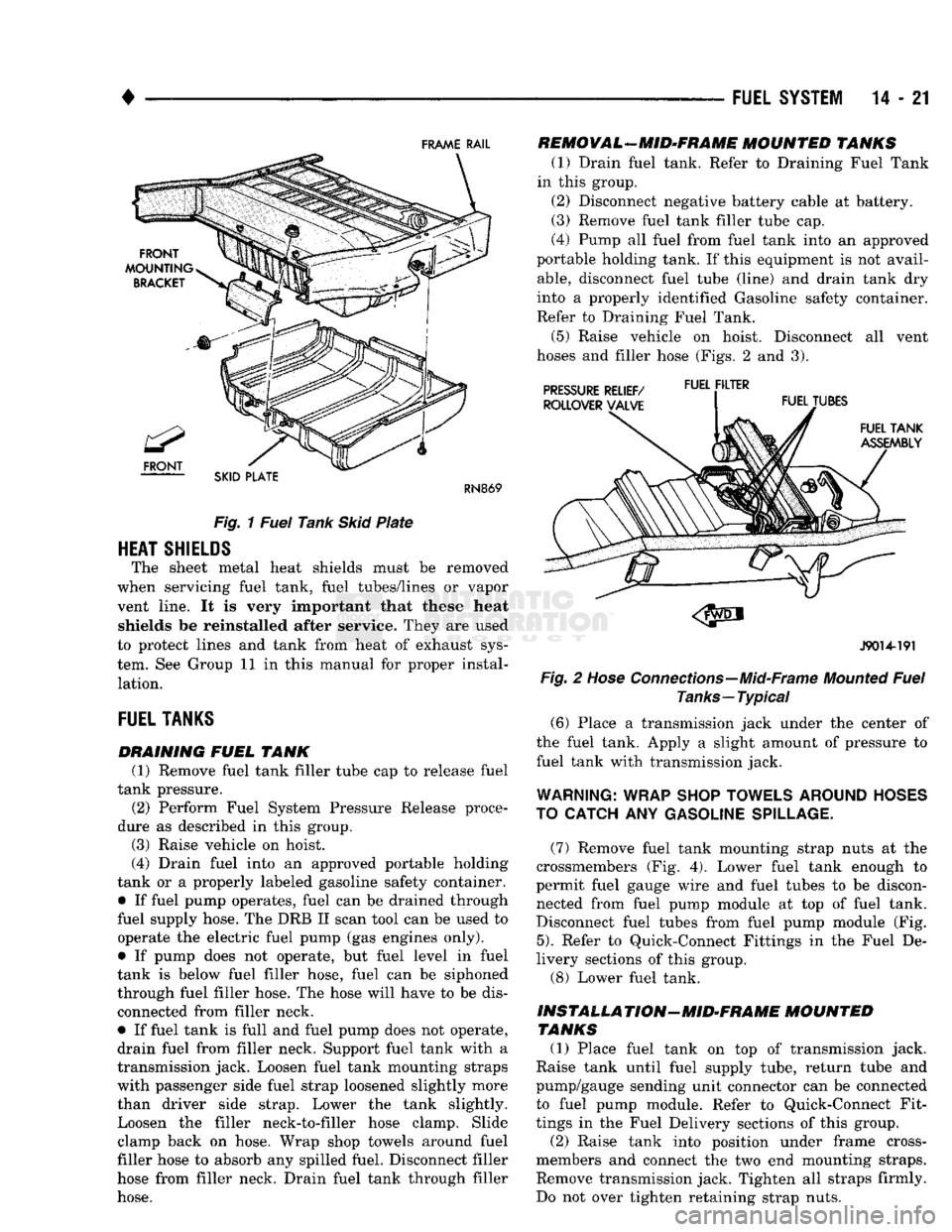

(5) Raise vehicle on hoist. Disconnect all vent

hoses and filler hose (Figs. 2 and 3).

PRESSURE

RELIEF/

FUEL F,LTER

J9014-191

Fig.

2

Hose

Connections—Mid-Frame

Mounted

Fuel

Tanks—Typical (6) Place a transmission jack under the center of

the fuel tank. Apply a slight amount of pressure to fuel tank with transmission jack.

WARNING:

WRAP

SHOP

TOWELS

AROUND

HOSES

TO

CATCH

ANY

GASOLINE

SPILLAGE.

(7) Remove fuel tank mounting strap nuts at the

crossmembers (Fig. 4). Lower fuel tank enough to

permit fuel gauge wire and fuel tubes to be discon nected from fuel pump module at top of fuel tank.

Disconnect fuel tubes from fuel pump module (Fig.

5).

Refer to Quick-Connect Fittings in the Fuel De

livery sections of this group.

(8) Lower fuel tank.

INSTALLA

TION—MID-FRAME

MOUNTED

TANKS (1) Place fuel tank on top of transmission jack.

Raise tank until fuel supply tube, return tube and

pump/gauge sending unit connector can be connected to fuel pump module. Refer to Quick-Connect Fit

tings in the Fuel Delivery sections of this group.

(2) Raise tank into position under frame cross-

members and connect the two end mounting straps.

Remove transmission jack. Tighten all straps firmly.

Do not over tighten retaining strap nuts.