DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

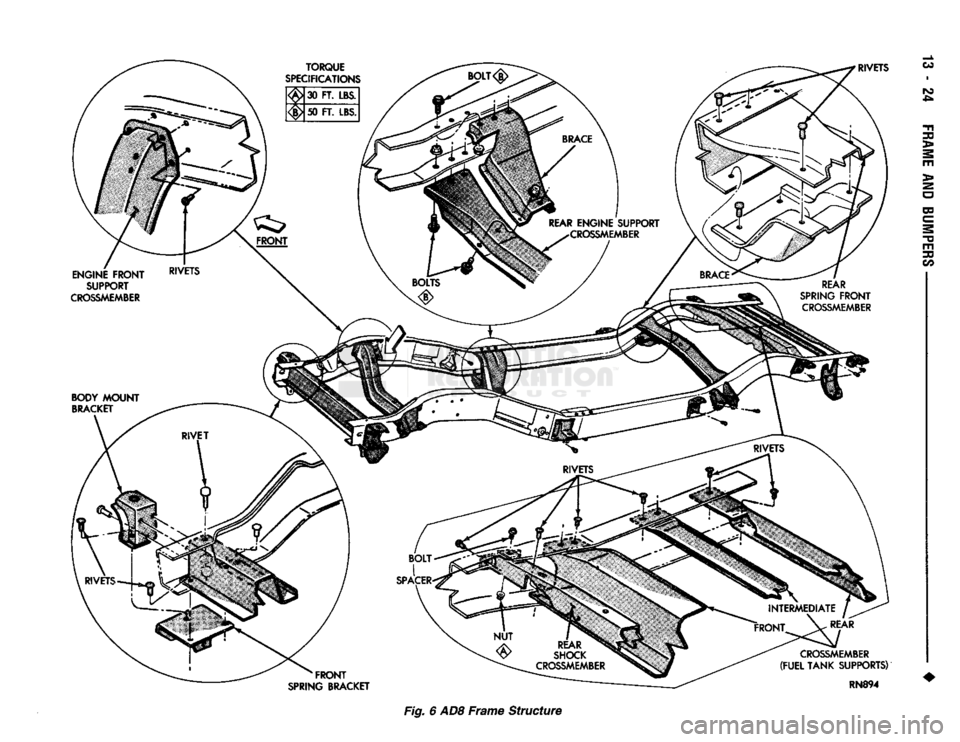

Page 811 of 1502

Page 812 of 1502

FRAME

AND

BUMPERS

13 - 25

FUNCTION

The frame is the foundation and the structural cen

ter of the vehicle. The primary function of a frame is

to provide support and attachment locations: • For all the chassis/drivetrain components

• For the cab/body

• For the vehicle payload While limiting deflections and twisting of the

frame members. The frame maintains the correct relationship and

alignment of the powertrain. This relationship and

alignment ensures normal operation of the attached

units.

CONSTRUCTION MATERIAL High-strength, carbon steel with a minimum yield

strength of 32,000 psi is used to construct frame side

rails.

A frame made of 32,000 psi minimum yield

strength steel has, in reality, a range of 32,000 to

44,000 psi yield strength.

For 4WD vehicle applications, the frame side rails

reinforcements are constructed of the same high- strength, carbon steel as the side rails.

BENDING RESISTANCE A frame reacts to its load and the road surface de

viations by deflecting and twisting. The primary de

flecting frame members are the side rails. Resistance

to frame twist is provided by the crossmembers.

FRAME

INSPECTION/MEASUREMENTS

INSPECTION Inspect the frame members for visible damage and

metal deformations. Inspect all riveted, bolted and

welded connections for looseness and/or missing hardware. All damaged areas must be repaired and/or the

frame members replaced, as necessary.

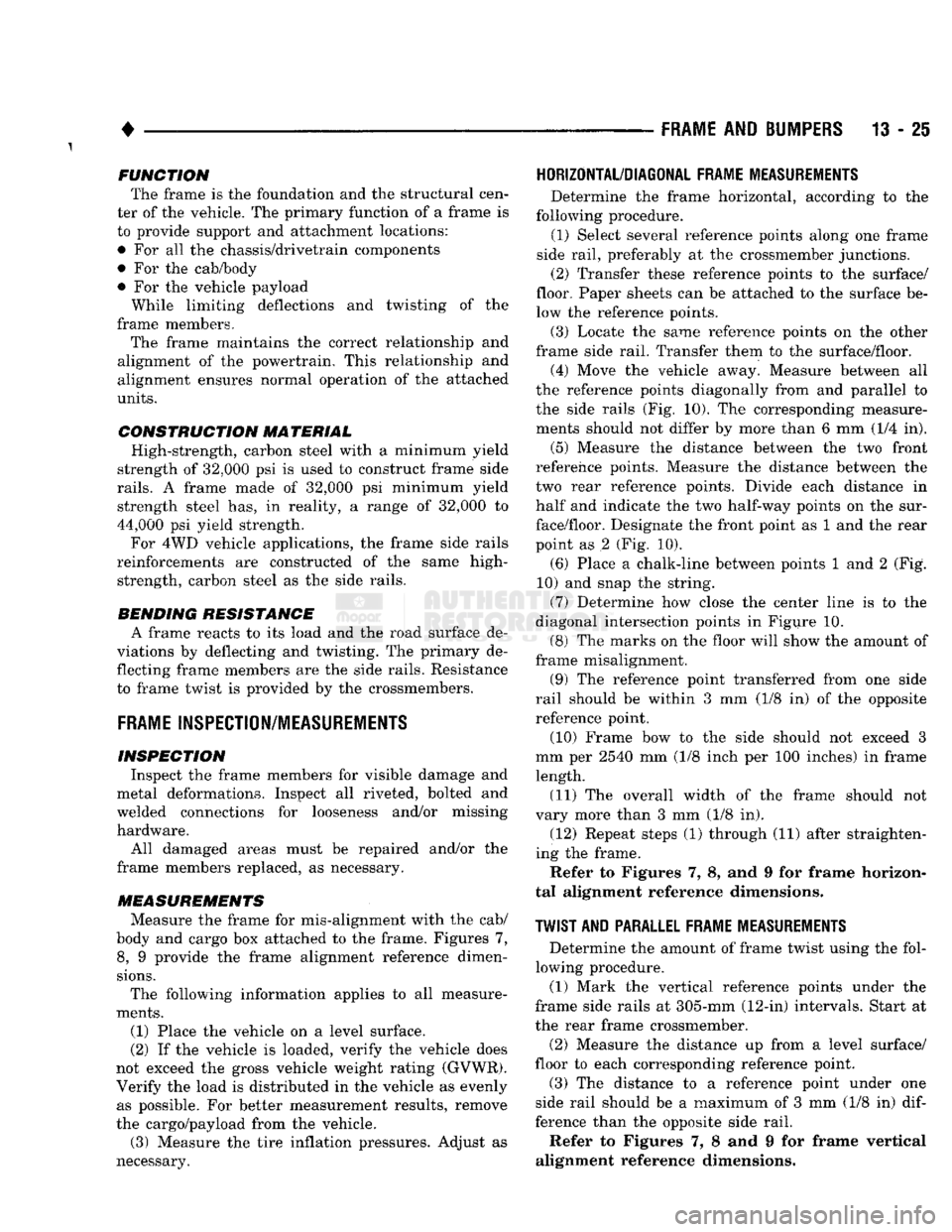

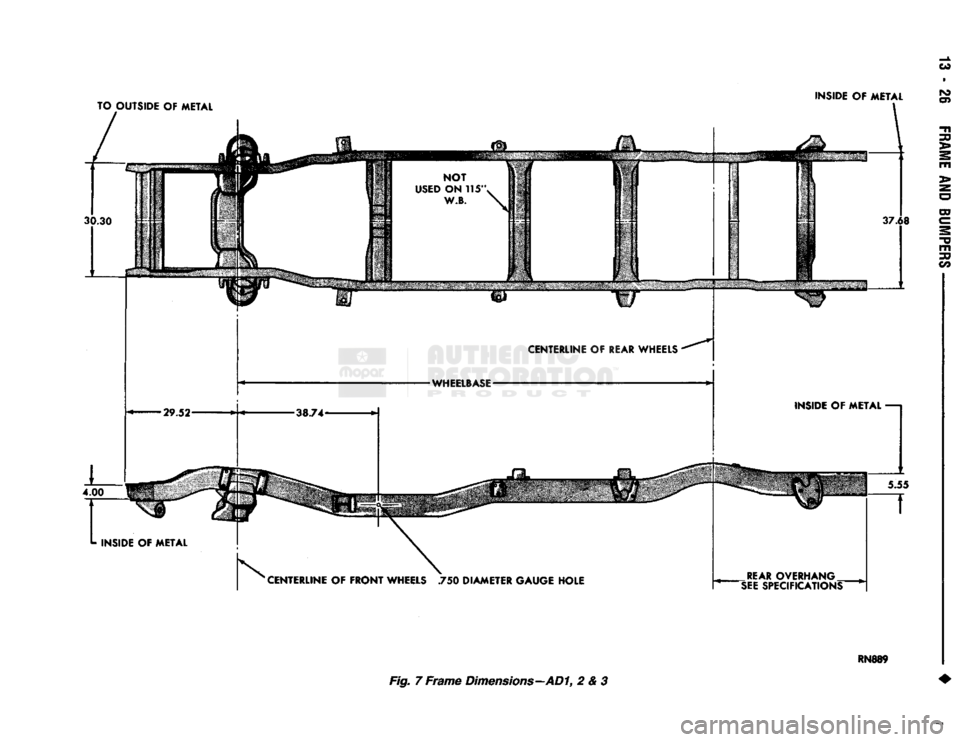

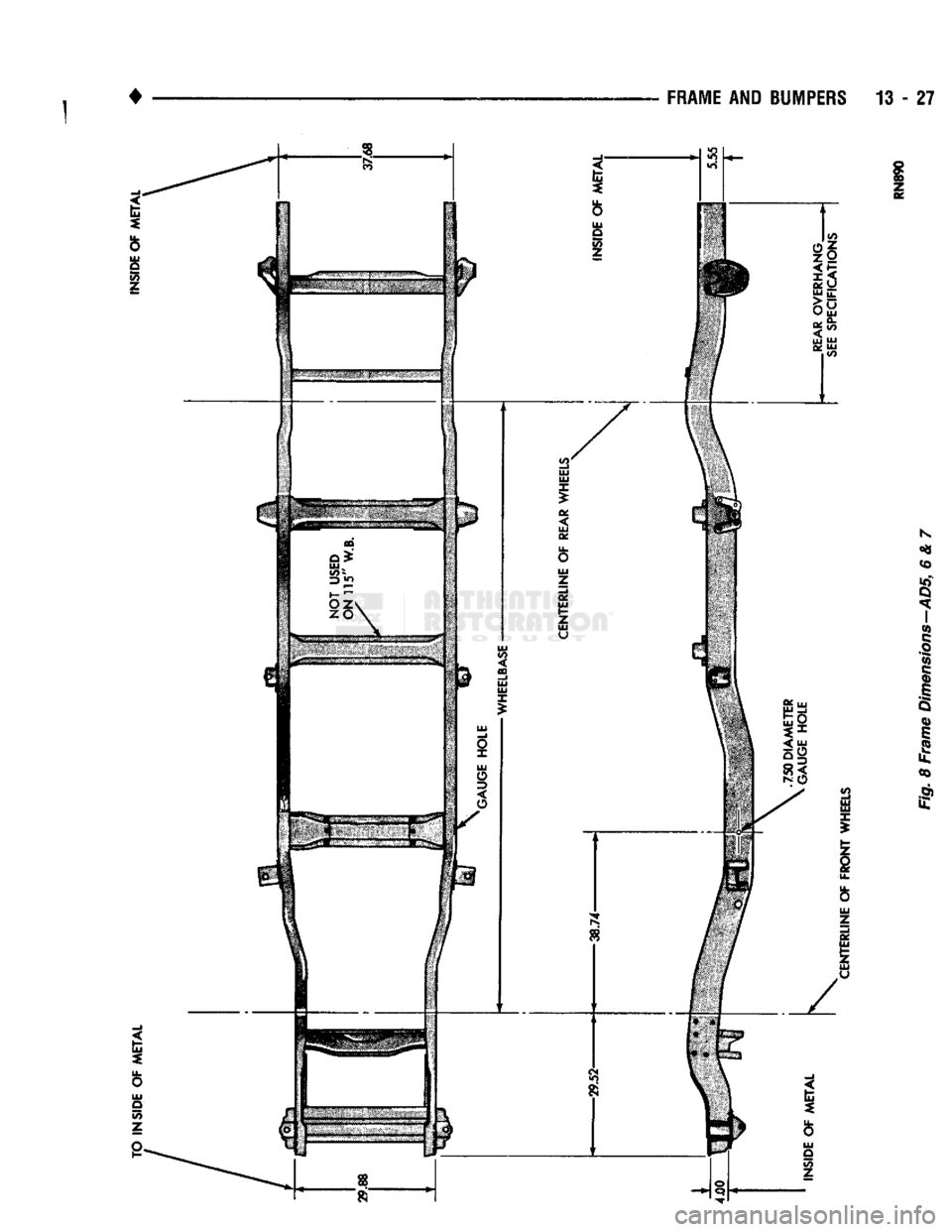

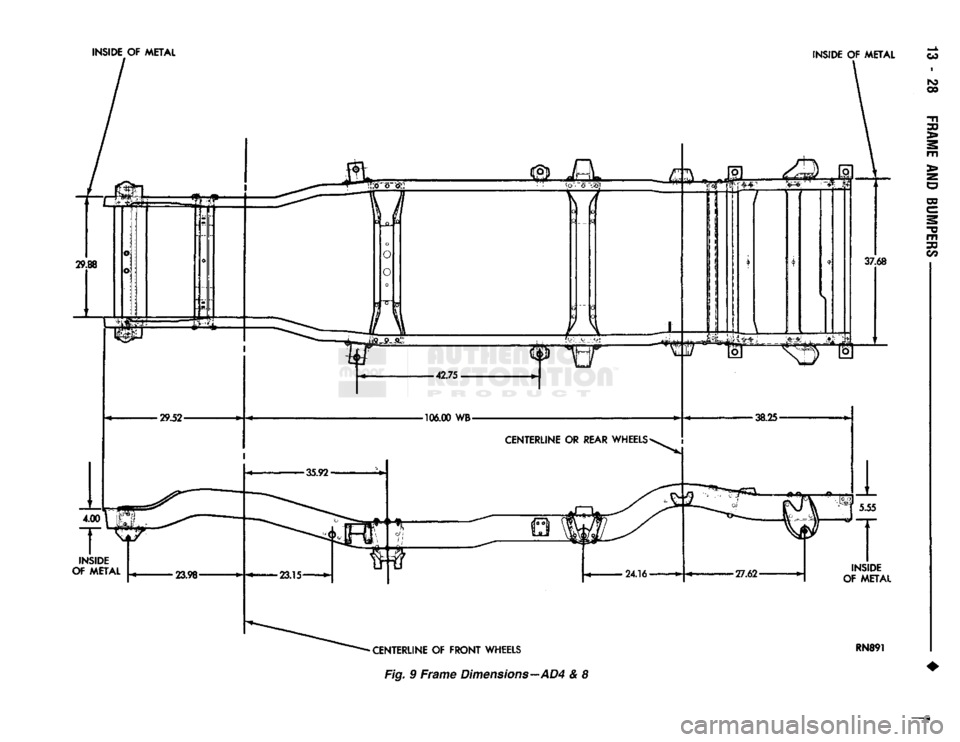

MEASUREMENTS Measure the frame for mis-alignment with the cab/

body and cargo box attached to the frame. Figures 7, 8, 9 provide the frame alignment reference dimen

sions.

The following information applies to all measure

ments.

(1) Place the vehicle on a level surface.

(2) If the vehicle is loaded, verify the vehicle does

not exceed the gross vehicle weight rating (GVWR).

Verify the load is distributed in the vehicle as evenly as possible. For better measurement results, remove

the cargo/payload from the vehicle.

(3) Measure the tire inflation pressures. Adjust as

necessary.

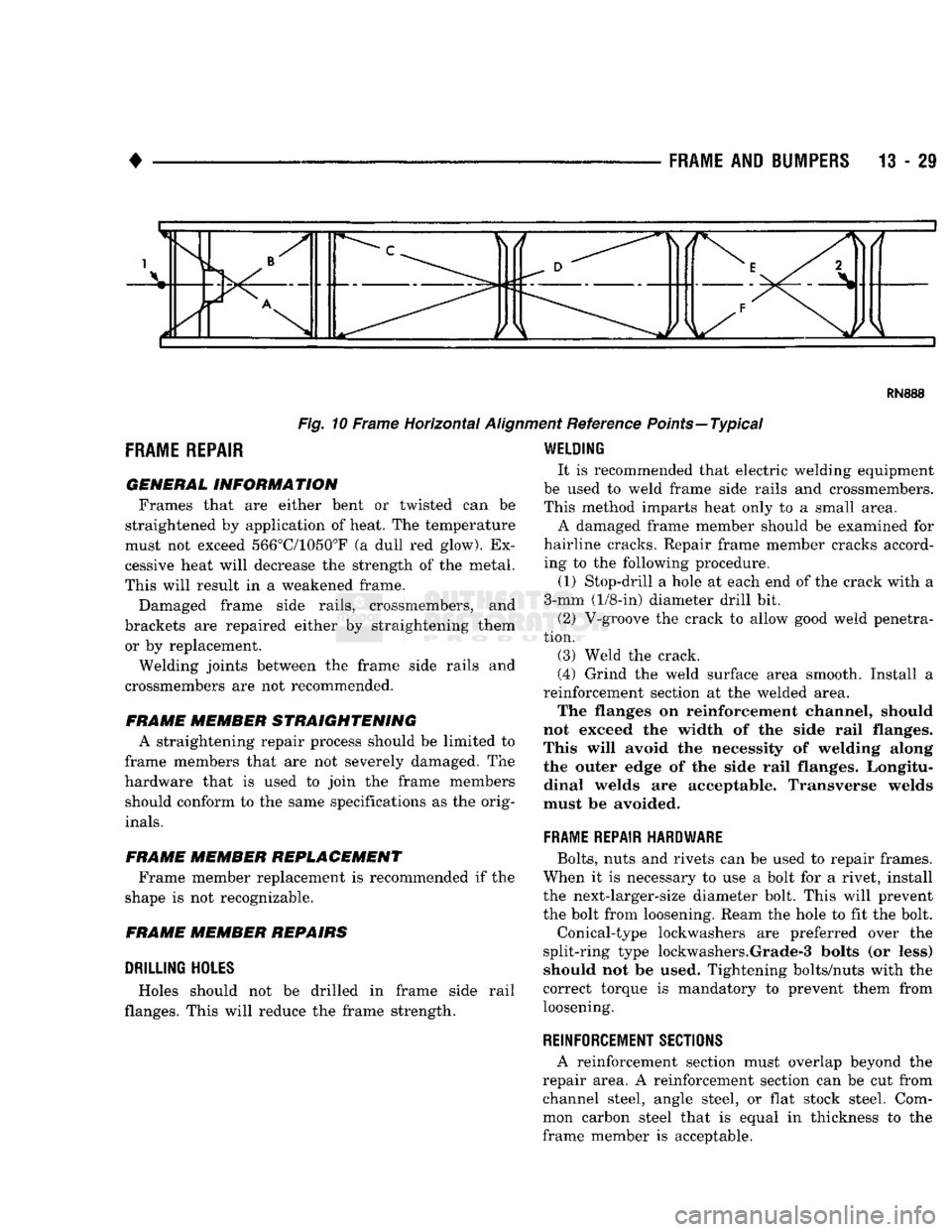

HORIZONTAL/DIAGONAL

FRAME MEASUREMENTS

Determine the frame horizontal, according to the

following procedure.

(1) Select several reference points along one frame

side rail, preferably at the crossmember junctions.

(2) Transfer these reference points to the surface/

floor. Paper sheets can be attached to the surface be low the reference points.

(3) Locate the same reference points on the other

frame side rail. Transfer them to the surface/floor.

(4) Move the vehicle away. Measure between all

the reference points diagonally from and parallel to

the side rails (Fig. 10). The corresponding measure ments should not differ by more than 6 mm (1/4 in).

(5)

Measure the distance between the two front

reference points. Measure the distance between the

two rear reference points. Divide each distance in

half and indicate the two half-way points on the sur

face/floor. Designate the front point as 1 and the rear

point as 2 (Fig. 10).

(6) Place a chalk-line between points 1 and 2 (Fig.

10) and snap the string.

(7) Determine how close the center line is to the

diagonal intersection points in Figure 10.

(8) The marks on the floor will show the amount of

frame misalignment.

(9) The reference point transferred from one side

rail should be within 3 mm (1/8 in) of the opposite

reference point.

(10) Frame bow to the side should not exceed 3

mm per 2540 mm (1/8 inch per 100 inches) in frame

length.

(11) The overall width of the frame should not

vary more than 3 mm (1/8 in). (12) Repeat steps (1) through (11) after straighten

ing the frame.

Refer to Figures 7, 8, and 9 for frame horizon

tal alignment reference dimensions.

TWIST

AND PARALLEL FRAME MEASUREMENTS

Determine the amount of frame twist using the fol

lowing procedure.

(1) Mark the vertical reference points under the

frame side rails at 305-mm (12-in) intervals. Start at

the rear frame crossmember.

(2) Measure the distance up from a level surface/

floor to each corresponding reference point. (3) The distance to a reference point under one

side rail should be a maximum of 3 mm (1/8 in)

dif

ference than the opposite side rail.

Refer to Figures 7, 8 and 9 for frame vertical

alignment reference dimensions.

Page 813 of 1502

TO OUTSIDE

OF

METAL

INSIDE

OF

METAL

37.68

CENTERLINE

OF

FRONT

WHEELS

750

DIAMETER GAUGE HOLE 5.55

REAR

OVERHANG

'SEE

SPECIFICATIONS"

Fig. 7

Frame

Dimensions—AD1, 2 & 3

mm

Page 814 of 1502

•

FRAME

AND BUMPERS 13 - 27

Page 815 of 1502

Page 816 of 1502

RN888

Fig.

10 Frame Horizontal

Aligi

FRAME

REPAIR

GENERAL

INFORMATION

Frames that are either bent or twisted can be

straightened by application of heat, The temperature

must not exceed 566°C/1050°F (a dull red glow). Ex

cessive heat will decrease the strength of the metal.

This will result in a weakened frame.

Damaged frame side rails, crossmembers, and

brackets are repaired either by straightening them or by replacement.

Welding joints between the frame side rails and

crossmembers are not recommended.

FRAME MEMBER

STRAIGHTENING

A straightening repair process should be limited to

frame members that are not severely damaged. The

hardware that is used to join the frame members should conform to the same specifications as the orig

inals.

FRAME MEMBER

REPLACEMENT Frame member replacement is recommended if the

shape is not recognizable.

FRAME

MEMBER REPAIRS

DRILLING

HOLES

Holes should not be drilled in frame side rail

flanges. This will reduce the frame strength. ent Reference Points—Typical

WELDING

It is recommended that electric welding equipment

be used to weld frame side rails and crossmembers. This method imparts heat only to a small area.

A damaged frame member should be examined for

hairline cracks. Repair frame member cracks accord ing to the following procedure.

(1) Stop-drill a hole at each end of the crack with a

3-mm (1/8-in) diameter drill bit.

(2) V-groove the crack to allow good weld penetra

tion. (3) Weld the crack.

(4) Grind the weld surface area smooth. Install a

reinforcement section at the welded area. The flanges on reinforcement channel, should

not exceed the width of the side rail flanges.

This will avoid the necessity of welding along

the outer edge of the side rail flanges. Longitu dinal welds are acceptable. Transverse welds

must be avoided.

FRAME REPAIR HARDWARE

Bolts,

nuts and rivets can be used to repair frames.

When it is necessary to use a bolt for a rivet, install

the next-larger-size diameter bolt. This will prevent

the bolt from loosening. Ream the hole to fit the bolt.

Conical-type lockwashers are preferred over the

split-ring type lockwashers.Grade-3 bolts (or less) should not be used. Tightening bolts/nuts with the

correct torque is mandatory to prevent them from

loosening.

REINFORCEMENT SECTIONS

A reinforcement section must overlap beyond the

repair area. A reinforcement section can be cut from channel steel, angle steel, or flat stock steel. Com

mon carbon steel that is equal in thickness to the

frame member is acceptable.

Page 817 of 1502

13

- 30 FRAME AND BUMPERS

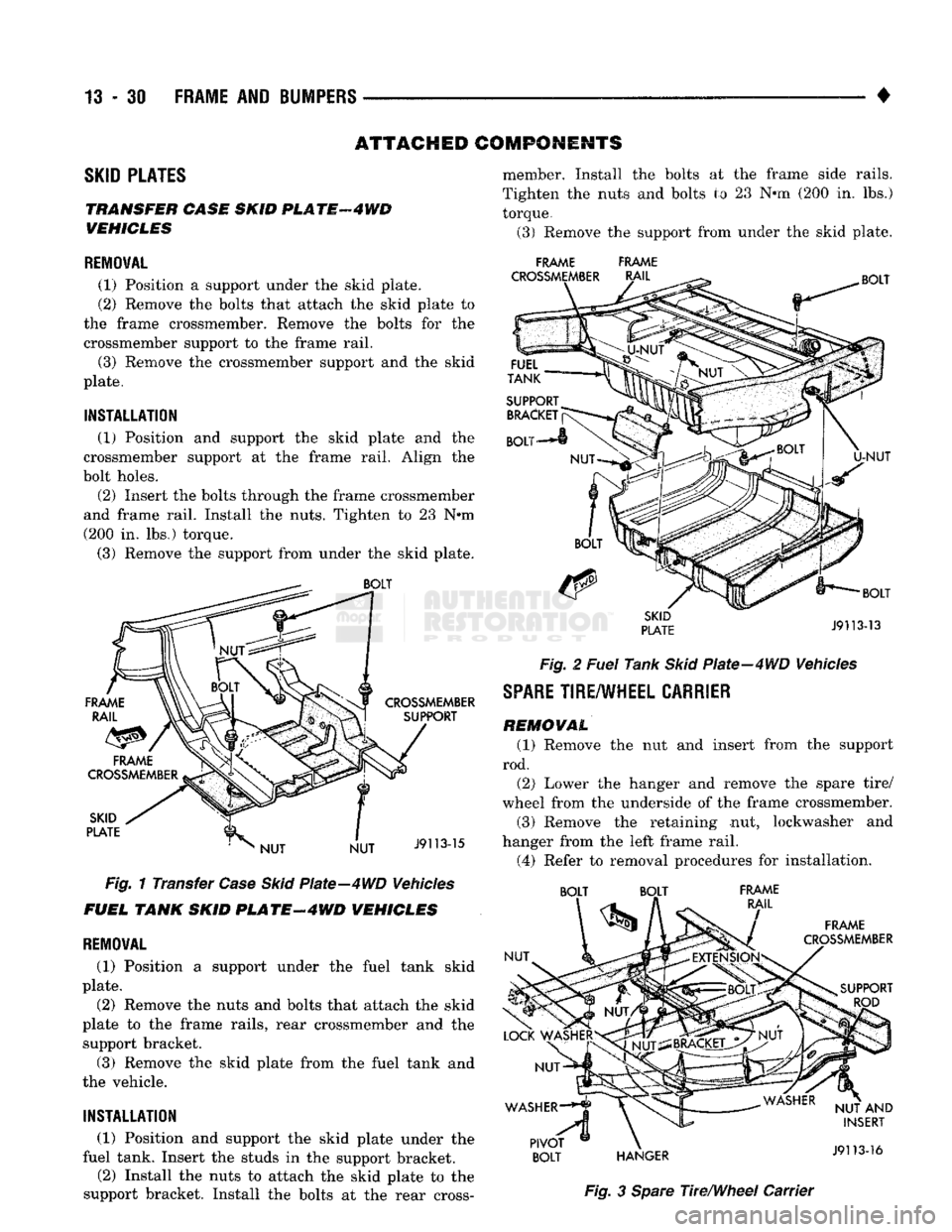

ATTACHED COMPONENTS

SKID

PLATES

TRANSFER CASE SKID

PL

ATF

4 WD

VEHICLES

REMOVAL

(1) Position

a

support under

the

skid plate.

(2) Remove

the

bolts that attach

the

skid plate

to

the frame crossmember. Remove

the

bolts

for the

crossmember support

to the

frame rail.

(3) Remove

the

crossmember support

and the

skid

plate.

INSTALLATION

(1) Position

and

support

the

skid plate

and the

crossmember support

at the

frame rail. Align

the

bolt holes.

(2) Insert

the

bolts through

the

frame crossmember

and frame rail. Install

the

nuts. Tighten

to 23 N*m

(200

in. lbs.)

torque.

(3) Remove

the

support from under

the

skid plate.

Fig.

1

Transfer

Case Skid

Plate—4WD Vehicles

FUEL TANK SKID

PLATE-4WD

VEHICLES

REMOVAL

(1) Position

a

support under

the

fuel tank skid

plate.

(2) Remove

the

nuts

and

bolts that attach

the

skid

plate

to the

frame rails, rear crossmember

and the

support bracket.

(3) Remove

the

skid plate from

the

fuel tank

and

the vehicle.

INSTALLATION

(1) Position

and

support

the

skid plate under

the

fuel tank. Insert

the

studs

in the

support bracket.

(2) Install

the

nuts

to

attach

the

skid plate

to the

support bracket. Install

the

bolts

at the

rear cross- member. Install

the

bolts

at the

frame side rails.

Tighten

the

nuts

and

bolts

to 23 N*m (200 in. lbs.)

torque.

(3) Remove

the

support from under

the

skid plate.

FRAME FRAME

Fig.

2

Fuel

Tank

Skid

Plate-4WD Vehicles

SPARE

TIRE/WHEEL

CARRIER

REMOVAL

(1) Remove

the nut and

insert from

the

support

rod. (2) Lower

the

hanger

and

remove

the

spare tire/

wheel from

the

underside

of the

frame crossmember.

(3) Remove

the

retaining

nut,

lockwasher

and

hanger from

the

left frame rail.

(4) Refer

to

removal procedures

for

installation. BOLT BOLT FRAME

Fig.

3

Spare

The/Wheel Carrier

Page 818 of 1502

1

•

FRAME

AND

BUMPERS

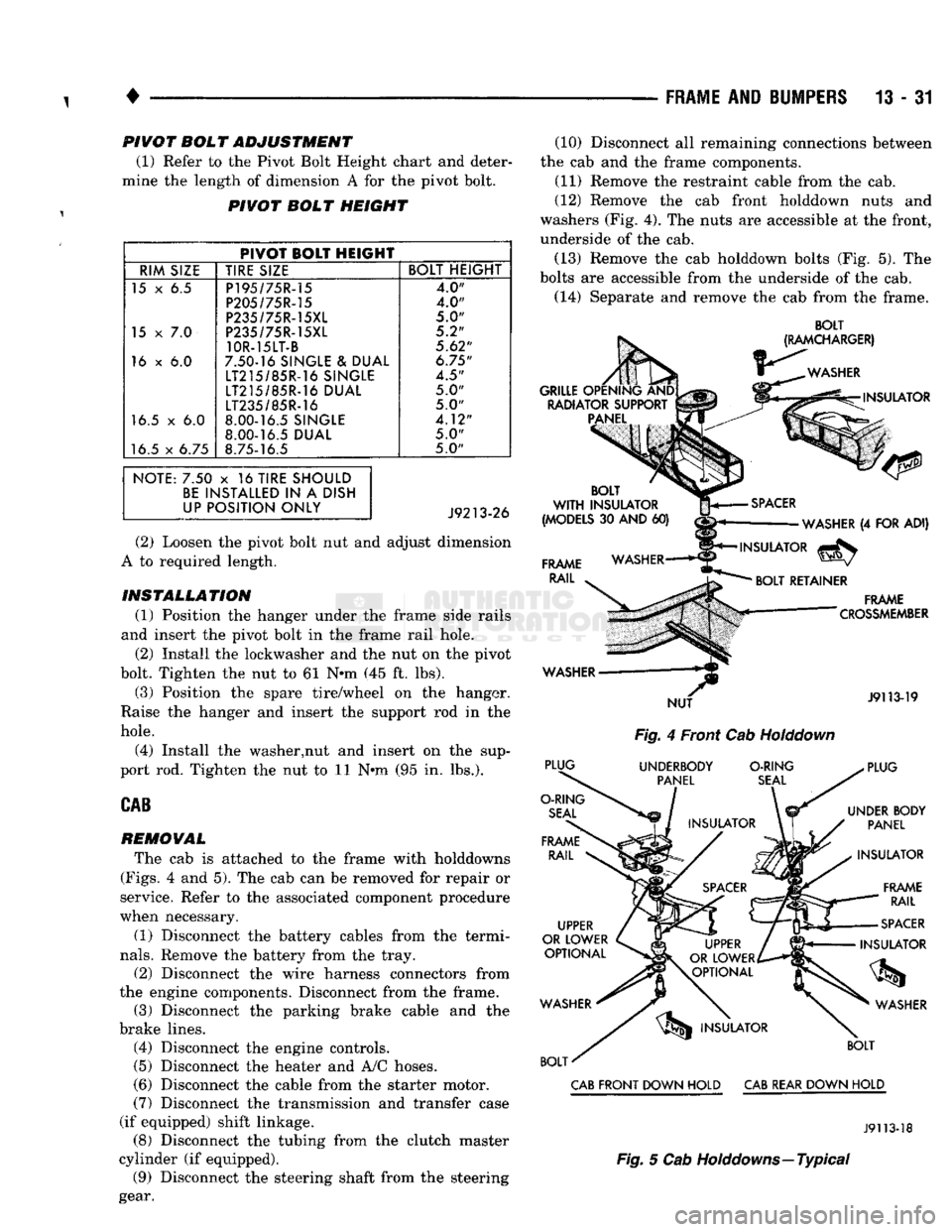

13 - 31 PIVOT BOL T ADJUSTMENT

(1) Refer to the Pivot Bolt Height chart and deter

mine the length of dimension A for the pivot bolt.

PIVOT BOLT HEIGHT

PIVOT BOLT HEIGHT

RIM SIZE TIRE SIZE BOLT HEIGHT

15 x 6.5 P195/75R-15

4.0"

P205/75R-15 4.0"

P235/75R-15XL

5.0"

15

x 7.0

P235/75R-15XL 5.2"

10R-15LT-B

5.62"

16 x 6.0 7.50-16 SINGLE & DUAL

6.75"

LT215/85R-16 SINGLE

4.5"

LT215/85R-16 DUAL 5.0"

LT235/85R-16

5.0"

16.5 x 6.0 8.00-16.5 SINGLE

4.12"

8.00-16.5 DUAL

5.0"

16.5 x 6.75 8.75-16.5 5.0"

NOTE: 7.50 x 16 TIRE SHOULD BE INSTALLED IN A DISH

UP POSITION ONLY

(2) Loosen the pivot bolt nut and adjust dimension

A to required length.

INSTALLATION (1) Position the hanger under the frame side rails

and insert the pivot bolt in the frame rail hole. (2) Install the lockwasher and the nut on the pivot

bolt. Tighten the nut to 61 N*m (45 ft. lbs).

(3) Position the spare tire/wheel on the hanger.

Raise the hanger and insert the support rod in the

hole.

(4) Install the washer,nut and insert on the sup

port rod. Tighten the nut to 11 Nnn (95 in. lbs.).

CAB

REMOVAL

The cab is attached to the frame with holddowns

(Figs.

4 and 5). The cab can be removed for repair or

service. Refer to the associated component procedure

when necessary.

(1) Disconnect the battery cables from the termi

nals.

Remove the battery from the tray.

(2) Disconnect the wire harness connectors from

the engine components. Disconnect from the frame. (3) Disconnect the parking brake cable and the

brake lines. (4) Disconnect the engine controls.

(5)

Disconnect the heater and A/C hoses.

(6) Disconnect the cable from the starter motor.

(7)

Disconnect the transmission and transfer case

(if equipped) shift linkage. (8) Disconnect the tubing from the clutch master

cylinder (if equipped). (9) Disconnect the steering shaft from the steering

gear. (10) Disconnect all remaining connections between

the cab and the frame components. (11) Remove the restraint cable from the cab.

(12) Remove the cab front holddown nuts and

washers (Fig. 4). The nuts are accessible at the front,

underside of the cab.

(13) Remove the cab holddown bolts (Fig. 5). The

bolts are accessible from the underside of the cab.

(14) Separate and remove the cab from the frame.

BOLT

Fig.

4 Front Cab

Holddown

CAB

FRONT DOWN HOLD

CAB

REAR DOWN HOLD

J9113-18

Fig.

5 Cab Holddowns—Typical

Page 819 of 1502

13

- 32

FRAME

AND

BUMPERS

• r INSTALLATION

(1) Verify the insulators and spacers are positioned

on the frame holddown brackets (Figs. 4 and 5). (2) Position the cab on the frame.

(3) Install the cab holddown nuts and bolts (Figs. 4

and 5). Tighten the nuts to 68 N-m (50 ft. lbs.)

torque. Tighten the bolts to 81 Nnn (60 ft. lbs.)

torque. (4) Position the restraint cable ends on the cab

rear seat belt anchor bolts. Install the retaining nuts.

Tighten the nuts to 45 N-m. (33 ft. lbs.) torque.

(5) Connect the steering shaft to the steering gear.

(6) Connect the tubing to the clutch master cylin

der (if equipped).

(7) Connect the transmission and transfer case (if

equipped) shift linkage. (8) Connect the cable to the starter motor.

(9) Connect the heater and A/C hoses.

(10) Connect the engine controls.

(11) Connect the parking brake cable and the

brake lines.

(12) Connect the wire harness connectors to the

engine components and to the frame. (13) Connect all remaining items between the cab

and the frame components. (14) Install the battery in the tray. Connect the ca

bles to the terminals. (15) Inspect the installation of the cab on the

frame and verify that:

• All connecting hardware is tightened

• All fluids and lubricants are full

• All electrical, engine, drivetrain and chassis com

ponents are operational.

CARGO

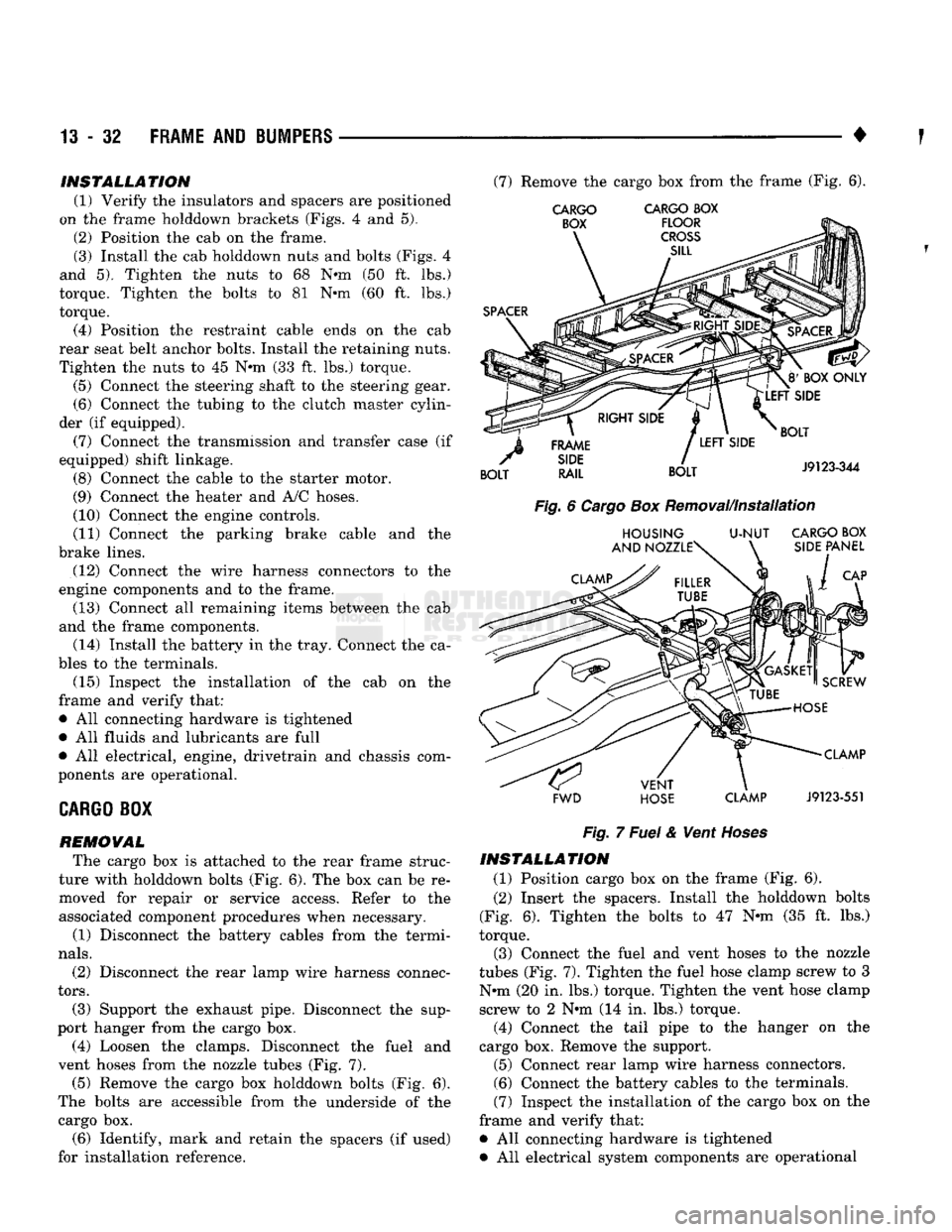

BOX REMOVAL The cargo box is attached to the rear frame struc

ture with holddown bolts (Fig. 6). The box can be re moved for repair or service access. Refer to the

associated component procedures when necessary.

(1) Disconnect the battery cables from the termi

nals.

(2) Disconnect the rear lamp wire harness connec

tors.

(3) Support the exhaust pipe. Disconnect the sup

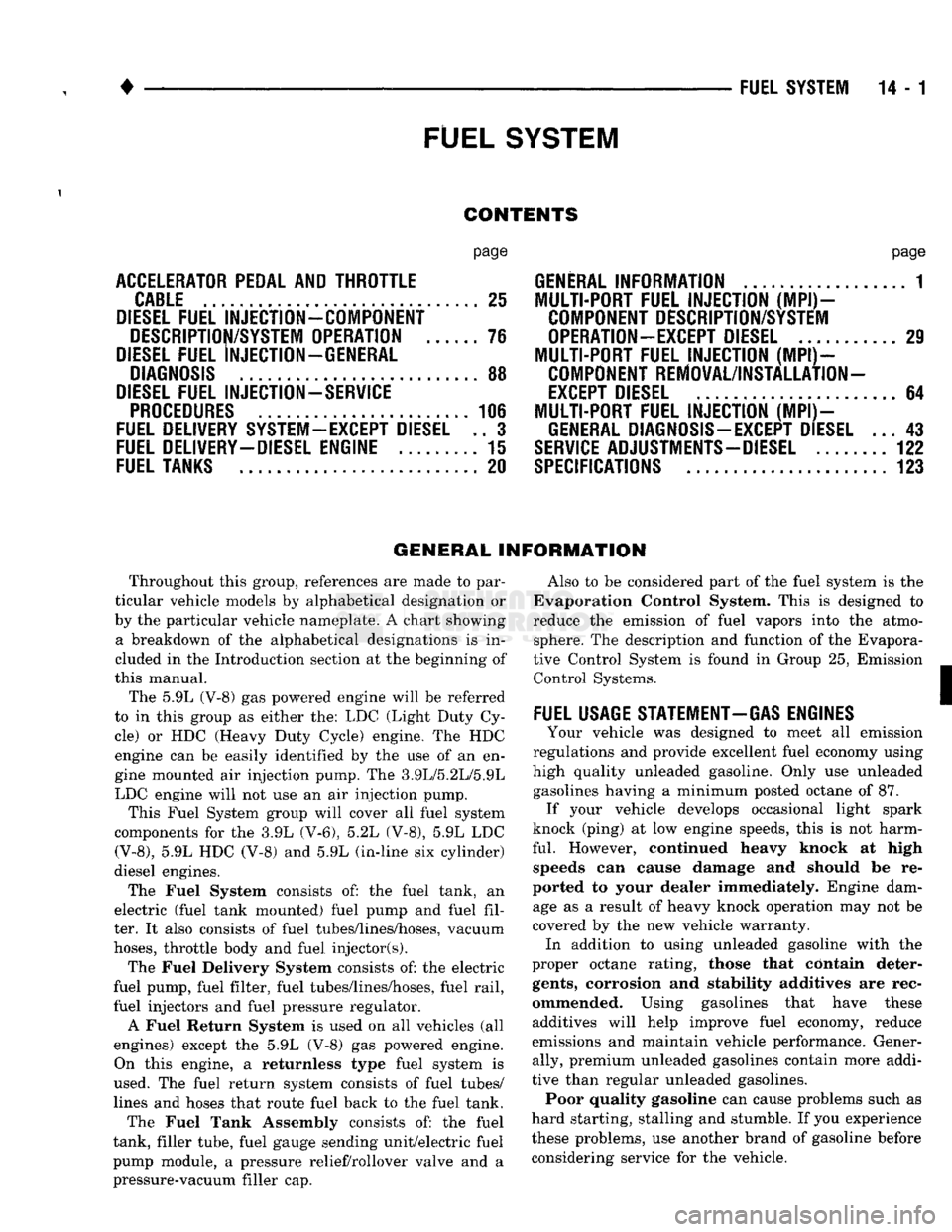

port hanger from the cargo box. (4) Loosen the clamps. Disconnect the fuel and

vent hoses from the nozzle tubes (Fig. 7). (5) Remove the cargo box holddown bolts (Fig. 6).

The bolts are accessible from the underside of the cargo box. (6) Identify, mark and retain the spacers (if used)

for installation reference. (7) Remove the cargo box from the frame (Fig. 6).

CARGO CARGO

BOX

FWD HOSE CLAMP

J9123-551

Fig.

7

Fuel

& Vent

Hoses

INSTALLATION

(1) Position cargo box on the frame (Fig. 6).

(2) Insert the spacers. Install the holddown bolts

(Fig. 6). Tighten the bolts to 47 Nnn (35 ft. lbs.)

torque.

(3) Connect the fuel and vent hoses to the nozzle

tubes (Fig. 7). Tighten the fuel hose clamp screw to 3

Nnn (20 in. lbs.) torque. Tighten the vent hose clamp screw to 2 Nnn (14 in. lbs.) torque.

(4) Connect the tail pipe to the hanger on the

cargo box. Remove the support. (5) Connect rear lamp wire harness connectors.

(6) Connect the battery cables to the terminals.

(7) Inspect the installation of the cargo box on the

frame and verify that:

• All connecting hardware is tightened • All electrical system components are operational

Page 820 of 1502

•

FUEL

SYSTEM

14 - 1

FUEL

SYSTEM

page

ACCELERATOR

PEDAL

AND THROTTLE

CABLE

................ 25

DIESEL

FUEL

INJECTION-COMPONENT

DESCRIPTION/SYSTEM

OPERATION

76

DIESEL

FUEL

INJECTION-GENERAL

DIAGNOSIS

88

DIESEL

FUEL

INJECTION-SERVICE

PROCEDURES

....................... 106

FUEL

DELIVERY

SYSTEM-EXCEPT

DIESEL

.. 3

FUEL

DELIVERY-DIESEL

ENGINE

15

FUEL

TANKS

.... 20

page

GENERAL

INFORMATION 1

MULTI-PORT

FUEL

INJECTION (MPI)-

COMPONENT

DESCRIPTION/SYSTEM

OPERATION-EXCEPT

DIESEL

29

MULTI-PORT

FUEL

INJECTION (MPI)-

COMPONENT

REMOVAL/INSTALLATION-

EXCEPT

DIESEL

64

MULTI-PORT

FUEL

INJECTION (MPI)-

GENERAL

DIAGNOSIS-EXCEPT

DIESEL

...43

SERVICE

ADJUSTMENTS-DIESEL

122

SPECIFICATIONS

123

GENERAL INFORMATION

Throughout this group, references are made to par

ticular vehicle models by alphabetical designation or

by the particular vehicle nameplate. A chart showing a breakdown of the alphabetical designations is in

cluded in the Introduction section at the beginning of

this manual.

The 5.9L (V-8) gas powered engine will be referred

to in this group as either the: LDC (Light Duty Cy cle) or HDC (Heavy Duty Cycle) engine. The HDC engine can be easily identified by the use of an en

gine mounted air injection pump. The 3.9L/5.2L/5.9L

LDC engine will not use an air injection pump.

This Fuel System group will cover all fuel system

components for the 3.9L (V-6), 5.2L (V-8), 5.9L LDC

(V-8),

5.9L HDC (V-8) and 5.9L (in-line six cylinder)

diesel engines.

The Fuel System consists of: the fuel tank, an

electric (fuel tank mounted) fuel pump and fuel fil

ter. It also consists of fuel tubes/lines/hoses, vacuum

hoses,

throttle body and fuel injector(s).

The Fuel Delivery System consists of: the electric

fuel pump, fuel filter, fuel tubes/lines/hoses, fuel rail,

fuel injectors and fuel pressure regulator.

A Fuel Return System is used on all vehicles (all

engines) except the 5.9L (V-8) gas powered engine. On this engine, a returnless type fuel system is

used. The fuel return system consists of fuel tubes/

lines and hoses that route fuel back to the fuel tank.

The Fuel Tank Assembly consists of: the fuel

tank, filler tube, fuel gauge sending unit/electric fuel

pump module, a pressure relief/rollover valve and a

pressure-vacuum filler cap. Also to be considered part of the fuel system is the

Evaporation Control System. This is designed to

reduce the emission of fuel vapors into the atmo sphere. The description and function of the Evapora

tive Control System is found in Group 25, Emission Control Systems.

FUEL

USAGE

STATEMENT-GAS

ENGINES

Your vehicle was designed to meet all emission

regulations and provide excellent fuel economy using

high quality unleaded gasoline. Only use unleaded gasolines having a minimum posted octane of 87. If your vehicle develops occasional light spark

knock (ping) at low engine speeds, this is not harm

ful.

However, continued heavy knock at high speeds can cause damage and should be re

ported to your dealer immediately. Engine dam age as a result of heavy knock operation may not be

covered by the new vehicle warranty. In addition to using unleaded gasoline with the

proper octane rating, those that contain deter

gents,

corrosion and stability additives are rec

ommended. Using gasolines that have these additives will help improve fuel economy, reduce

emissions and maintain vehicle performance. Gener ally, premium unleaded gasolines contain more addi

tive than regular unleaded gasolines. Poor quality gasoline can cause problems such as

hard starting, stalling and stumble. If you experience

these problems, use another brand of gasoline before considering service for the vehicle.