FIAT BARCHETTA 2003 1.G Owners Manual

Manufacturer: FIAT, Model Year: 2003, Model line: BARCHETTA, Model: FIAT BARCHETTA 2003 1.GPages: 170, PDF Size: 3.55 MB

Page 131 of 170

130

BODYWORK

PROTECTING THE CAR

FROM ATMOSPHERIC

AGENTS

The main causes of rust are:

– atmospheric pollution

– salt and humidity in the atmosphere

(seaside or very hot and humid areas)

– environmental conditions that are

specific to the season.

In addition, the abrasiveness of dust

in the atmosphere and sand carried by

the wind as well as mud and stones

kicked up by other vehicles must not

be underestimated.

For your Fiat barchetta, Fiat has used

leading-edge technological solutions to

effectively protect the body from rust.These are the main ones:

– Painting systems and products that

make the car particularly resistant to

rust and scratching.

– The use of zinc-plated (or pre-

treated) sheet steel which is highly re-

sistant to rust.

– The spraying of the underbody, en-

gine compartment, inside the wheel-

arches and other parts with wax-based

products with a high protective ca-

pacity.

– Spraying plastic-coating materials

for protecting the most exposed

points: under the door, inside the

wings, the edges etc.

– The use of “open” box sections to

prevent condensation and water from

building up and rusting the inside of

the parts.

MANUAL CLIMATE

CONTROL SYSTEM

(where fitted)

During the winter, the climate con-

trol system must be turned on at least

once a month for about ten minutes.

Have the system checked at a Fiat

Dealershipbefore the summer.

The system uses R134a

refrigerating liquid. If it

accidentally leaks it will

not damage the environment.

Under no circumstances should

R12 fluid be used. Besides being

incompatible with the system's

components, it contains chloro-

fluorocarbides (CFC).

Page 132 of 170

131

BODY AND UNDERBODY

GUARANTEE

The Fiat barchetta is covered guar-

antee against any original structural or

body part being holed by rust. Refer

to the “Warranty Booklet” for the

general conditions of this guarantee.

TIPS FOR KEEPING THE

BODY IN GOOD CONDITION

Paintwork

The paintwork is not only to make

your car look attractive but also to

protect the steel.

If your car is scuffed or scratched

deeply you are therefore recom-

mended to touch up the paintwork as

necessary to prevent rust from form-

ing.

Only use genuine products when

touching up the paintwork (see the

“Technical Specifications” chapter).To wash the car properly:

1) Soak the body using a low pres-

sure jet of water.

2) Wipe a sponge with a slightly

soapy solution over the body, fre-

quently rinsing the sponge.

3)Rinse well with water and dry

with a jet of air or a chamois leather.

When drying the car, be careful to

get at those parts which are not so

easily seen e.g. the door frames, bon-

net and around the headlights where

water can most readily collect. You

are advised not to take the car into a

closed area immediately but to leave

it out in the open so any water left can

evaporate more easily.

Do not wash the car after it has been

parked in the sun or while the bon-

net is hot: it could take the shine off

the paint. Ordinary maintenance of the paint-

work consists in washing it. The fre-

quency you should do this depends on

the conditions and the environment

the car is driven in. For example, if you

drive in areas with a high level of air

pollution or on roads sprinkled with

road salt, it is a good idea to wash the

car more often.

Detergents pollute wa-

ter. For this reason, the

car must be washed in an

area equipped for the collection

and purification of the liquids

used while washing.

Page 133 of 170

132

Windows

Use specific window cleaners to

clean the windows. Use very clean

cloths to avoid scratching the glass or

damaging its transparency.

Engine compartment

At the end of each winter season,

carefully clean the engine compart-

ment. Have this done at a garage.Detergents pollute wa-

ter. The car must there-

fore be washed in an area

equipped for the collection and

purification of the liquids used

while washing.

IMPORTANTThe car should be

washed while the engine is cold and

with the ignition key at STOP. After

washing the car, make sure that the

various protections (e.g. rubber boots

and various guards) have not been re-

moved or damaged. Outside plastic parts must be cleaned

following the usual car washing pro-

cedure.

Avoid parking your car under trees;

the resinous substances that often

drop will dull the paintwork and in-

crease the possibility of corrosion.

IMPORTANT Bird droppings must

be washed off immediately and with

great care as their acid is particularly

aggressive.

Page 134 of 170

133

HOOD

Normal maintenance of the hood

consists in washing it.

Dust the hood off before washing it.

Dirt must be removed using an ap-

propriate cleaning compound; then

rinse thoroughly using a low pressure

hose.

INTERIORS

From time to time, check that wa-

ter has not collected under the mats

(from dripping shoes, umbrellas etc.)

which could cause the steel to rust.

You are advised to wash

the hood by hand. When

washing a car in an auto-

matic car wash, the rotating

brushes exert a strong pressure

on the surface of the hood that

could damage it and scratch the

rear window. In addition, the

cleaning compounds and addi-

tives could have a negative effect

and spoil the hood's appearance.IMPORTANT Do not use petrol,

stain removers, benzol, paint thinners

or solvents to remove dirt marks; on-

ly use products designed for the pur-

pose. If the marks still will not come

out, see a Fiat Dealership.

REAR WINDOW

This window can be replaced; con-

tact a Fiat Dealershipto have this

done.

When cleaning the rear window be

particularly careful to avoid scratches

or scuffs that could spoil its appear-

ance.

Never use flammable prod-

ucts (petroleum ether or

petrol) to clean the inside of the

car. Electrostatic charges generat-

ed by rubbing while cleaning could

cause fires.

WARNING

Page 135 of 170

134

If the stain does not come out, use

a special cleaning compound being par-

ticularly careful to follow the instruc-

tions for use.

IMPORTANTNever use alcohol

or alcohol-base products.

PLASTIC PARTS INSIDE

THE CAR

Use special products designed not to

alter the appearance of the compo-

nents.

IMPORTANT Do not use alcohol

or petrol for cleaning the glass of the

instrument panel. CLEANING THE SEATS AND

FABRIC UPHOLSTERY

– Remove the dust with a soft brush

or a vacuum cleaner.

– Rub the seats with a rag moistened

in a solution of water and neutral de-

tergent.

CLEANING LEATHER SEATS

– Remove the dry dirt with a buck-

skin or very slightly moist cloth with-

out exerting too much pressure.

– Remove liquid or grease stains with

a dry absorbent cloth without rubbing.

Then wipe with a buckskin or soft

cloth moistened with water and neu-

tral soap.

Do not keep aerosol cans in

the car. There is the risk

they might explode. Aerosol cans

must never be exposed to a tem-

perature above 50°C. The temper-

ature inside the car might go well

beyond that figure if the car is ex-

posed to the sun.

WARNING

Page 136 of 170

135

TECHNICAL SPECIFICATIONS

Motor and engineering enthusiasts as well as those

“in the trade” will probably start reading from this point

in the manual. This, in fact, is where a section jam-

packed with facts, figures, formulae, measurements and

tables begins. In a sense it is the Fiat barchetta’s iden-

tity card. A document that introduces the car and ex-

plains in technical jargon all the features that go together

to make the Fiat barchetta a model designed to give you

superlative driving satisfaction.IDENTIFICATION DATA ................................................ 136

ENGINE CODE - BODY VERSION .............................. 137

ENGINE ................................................................................. 137

TRANSMISSION ................................................................. 139

BRAKES ................................................................................. 139

SUSPENSIONS .................................................................... 140

STEERING ............................................................................. 140

WHEEL GEOMETRY ......................................................... 140

PERFORMANCE ................................................................. 140

WHEELS ................................................................................ 141

DIMENSIONS ...................................................................... 142

WEIGHTS ............................................................................. 143

CAPACITIES ........................................................................ 144

FLUIDS AND LUBRICANTS ........................................... 145

FUEL CONSUMPTION .................................................... 147

CO

2EMISSIONS ................................................................. 147

TYRES PRESSURE ............................................................... 148

Page 137 of 170

136

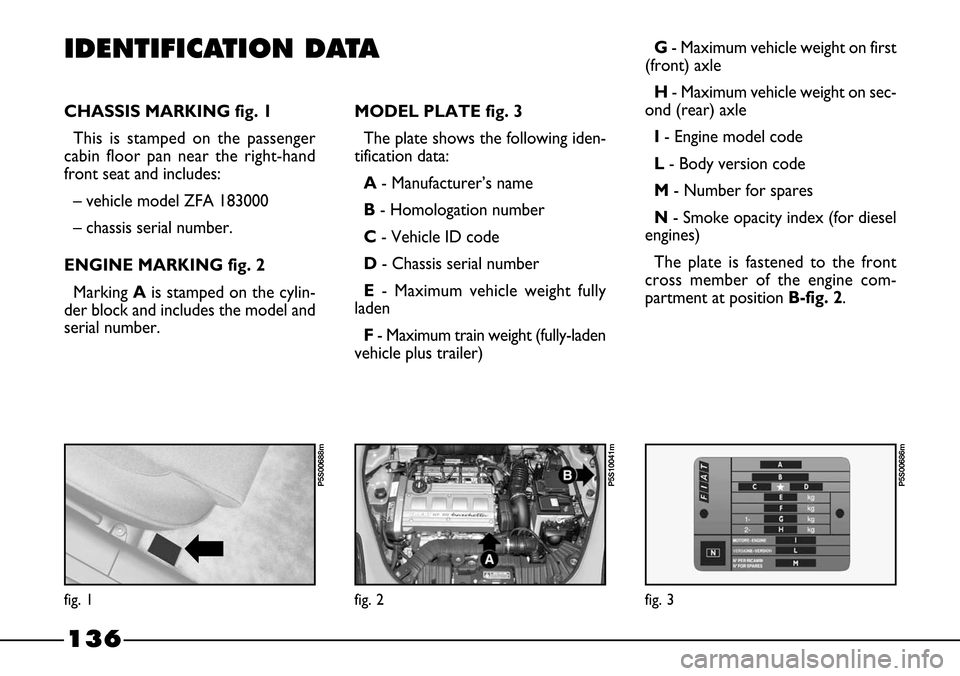

IDENTIFICATION DATA

MODEL PLATE fig. 3

The plate shows the following iden-

tification data:

A- Manufacturer’s name

B- Homologation number

C- Vehicle ID code

D- Chassis serial number

E- Maximum vehicle weight fully

laden

F- Maximum train weight (fully-laden

vehicle plus trailer)

fig. 2

P5S10041m

fig. 3

P5S00686m

fig. 1

P5S00688m

G- Maximum vehicle weight on first

(front) axle

H- Maximum vehicle weight on sec-

ond (rear) axle

I - Engine model code

L- Body version code

M- Number for spares

N- Smoke opacity index (for diesel

engines)

The plate is fastened to the front

cross member of the engine com-

partment at position B-fig. 2. CHASSIS MARKING fig. 1

This is stamped on the passenger

cabin floor pan near the right-hand

front seat and includes:

– vehicle model ZFA 183000

– chassis serial number.

ENGINE MARKING fig. 2

Marking Ais stamped on the cylin-

der block and includes the model and

serial number.

Page 138 of 170

ENGINE CODE - BODY VERSION

137

Engine type code Body version code

188A6.000 183SB1AA 01

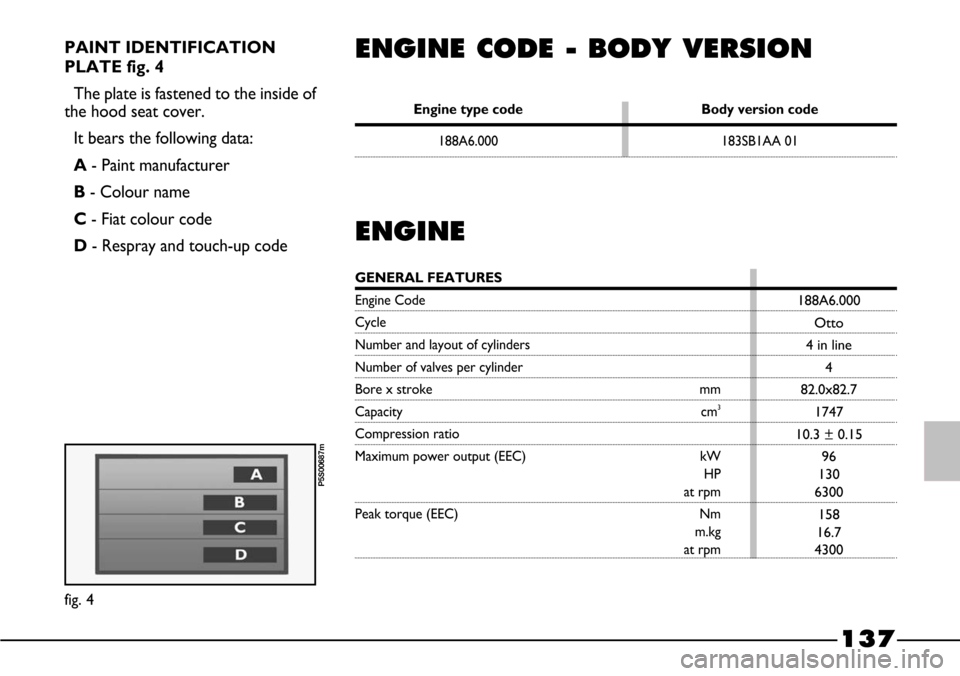

PAINT IDENTIFICATION

PLATE fig. 4

The plate is fastened to the inside of

the hood seat cover.

It bears the following data:

A- Paint manufacturer

B- Colour name

C- Fiat colour code

D- Respray and touch-up code

fig. 4

P5S00687m

ENGINE

GENERAL FEATURES

Engine Code

Cycle

Number and layout of cylinders

Number of valves per cylinder

Bore x stroke mm

Capacity cm3

Compression ratio

Maximum power output (EEC) kW

HP

at rpm

Peak torque (EEC) Nm

m.kg

at rpm

188A6.000

Otto

4 in line

4

82.0x82.7

1747

10.3 ± 0.15

96

130

6300

158

16.7

4300

Page 139 of 170

138

FUEL SUPPLY/IGNITION

Integrated electronic injection and ig-

nition system: a single electronic con-

trol unit controls both functions. It

processes both the time the injection

lasts (for fuel metering) and the igni-

tion’s advance angle.

Type: Sequential in phase Multipoint

Air cleaner: dry-type with paper fil-

ter element; thermostatically con-

trolled intake.

Petrol pump: in-tank.

Injection pressure: 3 bar

Method of measuring the amount of

aspirated air by directly measuring the

maximum rate of flow with a hot wire

air flow meter.

“Closed loop” petrol metering (in-

formation about combustion provid-

ed by the Lambda sensor).Firing order: 1-3-4-2

Spark plugs:

– Champion RC10YCC

– NGK BKR6EZLUBRICATION

Forced-fed with gear pump with

pressure relief valve incorporated.

Oil purification by means of full-flow-

cartridge filter.

COOLING

Cooling system with radiator, cen-

trifugal pump and expansion tank.

“Controlled” by-pass type thermo-

stat on the secondary circuit for the

recirculation of water from the engine

to the radiator.

Electric fan for radiator cooling with

thermostatically-controlled on/off

switch on the radiator.

Modifications or repairs to

the fuel feed system that

are not carried out properly or do

not take the system’s technical

specifications into account can

cause malfunctions with the risk of

fire.

WARNING

Page 140 of 170

139

TRANSMISSION

CLUTCH

Self-adjusting with no pedal free trav-

el.

GEARBOX

Five forward speeds and reverse with

synchromesh for forward gear en-

gagement. SERVICE AND EMERGENCY

BRAKES

Front: disc, floating calliper type with

a master cylinder for each wheel.

Rear: disc type with floating calliper.

Cross-over hydraulic circuit control.

8" vacuum servo brakes.

Four-channel, four-sensor ABS sys-

tem (where fitted).

Automatic take up of clearance due

to friction lining wear.

Electronic brake corrector (EBD sys-

tem).

HANDBRAKE

Controlled by a lever working me-

chanically on the rear brake callipers.

BRAKES

Water, ice and salt sprin-

kled on the roads can de-

posit on the brake discs and reduce

the effectiveness braking the first

time they are used.

WARNING

Be careful when fitting

spoilers, alloy rims and af-

ter-market wheel caps: they could

reduce ventilation and effectiveness

in the event of abrupt and repeat-

ed braking or when driving down hill

for a long time.

WARNING