FORD CAPRI 1974 Repair Manual

Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 51 of 205

\.

50 C hapter 1 Engine

51 T llp pcts -removat

Remove the 1

5 2 Crnnksh

4 Wilhdraw Ih~ Wood'uH key hom the end of th(! CllInk5hah and pl,lC,(! " w'lh Ihe pulley. til(! holl alld its washer 5 The C'.1nk~h;)h p"lIey m;oy he ICliloved wilh Ihe eno,,,e III Ihe C:\I. hilt ,I 'S IIIsl tU!Ccss;o,y 10 ,emove Ihe ',ld'illO' :lI1d thc rh'vehelts

53 Flyw heel -remov[ll

P,even llhe flywhcel hum 101m",!) by FHlHllln\J Ihe lin!) !lcal ;ollain~1 ;In imp.ovised SIOI). 2 On nlodels willi nl;lnu:ol 1I;o"$""S5'01i. Icmove Ihe Clulch plessure 1)1;lle and disc :os described in Ch:op!Cr 5. 3 Rele.lse Ihe s,~ bolts secu.in!1 Ihe flywheel 10 Ihe CllInksh;oll .lnd lefl\OVC I,ve of Ihenl.

4 Whilc supporling Ihe tJywheel III pl;ll':e .• emove Ihc Sixlh hoi' ,'11d Iolt Ihe lIywheel otl c;o,elully. so 111:01 Ihe m;lllllg su.lilccs of flywheel [lild c.;onksh;oit ;o.e 1101 dllm,'ged

5 4 Sump -removal

W"h lhe '''1(1'''') oul fli the e,". CII~"'C Ihal Ihe sump has 1o('CIl d,amvd ;ond then lilln the engll1C ()VCI so tl1011 Ihe sump's U l)I)ClmOSI F" wOOr1CII bloc"s tn Slll)lmrl tim en!l'ne 'n Ih,s POSIIiOIl . 2 Remove 11m h()IIS seCUlln( J the oil Sump 10 Ihe CI.1nkColSe o1nd rClllOVO Ihe SUll1p_ 11 the sump IS stuck 10 the c r;ollkcasc . II should be reh;lIsctl hy 1"'SII1\1 olle SIde wllh 11 sClcw drover. 3 To !Cn,ovtl .Ile sump wllh Ihc CIIU"HJ Hl tloe eM. 11151 IcnlUVC Ihe

d'l)S llck :ond d'SCOIlII(!Ct Ihe hatlery 4 Remove Ihe luur holts ;ond lou. Ch,)S ;ond dCI.leh Ihe OIl splash

shIeld.

5 Pl;oce a Con'"lIlcr 01 at lellst 6lttre (106 JlIllI) cal,,-.elly heneath Ihe SUml). remove Ihe d,ain pl\l(l ;ond d,aln Iha sump. Reflilhe d.am plull and (11)hlen II 10 Ihe 10lqUO wrench seilIng gtven In the SIXlClflC;JIIons G Del:och the engme fubl)CI mounllngs, by lemovlng the" nuts an(1 w:oshe!s. 7 Romove the ciampinI) bolt hom the tal) ;oml bOIlOI11 endS 01 the Steellll!.) intellnediate sh(lil. rush Ihe lap end 0 1 Ihe shlilt upwollds unlll Ihe lowcr ell(1 Clin be dlsenga\led 8 PI

55 FrOllt cover -removlll

If Ihe engHle IS In the CM. II wllllnSI he necessaly 10 dlsc()nneC lthe l!allefY. drll'" 11m coolll1\) sys tem ;ond lel110lle Iho radiillor. 2 loosen the alternalol mounllrlg bOilS. SWlrlg the aitemalor downwilids .0w:Olds the cyltnder block and lemove Ihe drive belt

3 Remove the bolt Irom the cenlro of Ihe cooling Ian .. nd pull (

Ian and clutch assembly. 4 Remove Ihc boil an d wilsher from Ihe centre of the cran pulley .. nd I hen use ., claw puller 10 drilw Ihe I)ulley ofllhe sha nOI anempllO lelle, Ihe pulley ott. t)Ccause Ihis may .esull in dllm. t he Irani covcr.

5 Rcmove the si~ bolts secuung Ihe sump 1 0 Ihe honl cover an, t he cleven bolts securing Ihe I ront cover 10 the Cylllldcl block . G lIlt Ihe cover ott ;ond remove Ihe g;oskel.

5 6 Tillling gears -relllov;ol

1 Remove the honl cover 10 e xpose Ihe IImlnu ueo1/S 2 Removc Ihe bolt and washer sccu"I1IJ Ihe fat!Je gear I,

cn,nsIl1'll t. IhCIi pull.he geill ol! and Icmovc tho Woodllll! key. 3 Dlllw the ileal hOI11 Ihe cr;onk!;h:oh am! remove Ihe Wood'utl

57 Carllshaft -r erllov;ol

The camsh:olt nwy be rCUlovfld wllh the cll!JlIle 1<1 Ihe car •• lollowlng p!Cpol.aloIY wo,k IS co1med out. 2 0,,,,,. Ihe cootong syStelll nnd .emove Ihe .ad,mOl 3 Dlsconneci the ballery. 1 Remove Iho sp.1lk pili!! IC.1ds 1,om Ihe spalk 11lugs. 5 D,s':Ol

eCI the le;ods I,ull' Ihe :l lt'!11\.110r. remove Ihc allelllalo·

l i S (hivebell. G Undo "nd rem ovC tho screws S()CIIIII1U Ihe .0dcl covers and It Ihe rocke. covels and Iheir ilaskcls 7 Sincken lhe nulS secullnu the rocker ~"ns unlollhe locke' arm, he swung aside . 8 Remove the pushrods. idenlllylllg each one as .. IS lemoved. so 1 Ciln be rell1l ed in Ihe same position 9 Remove the cylmde. heads,

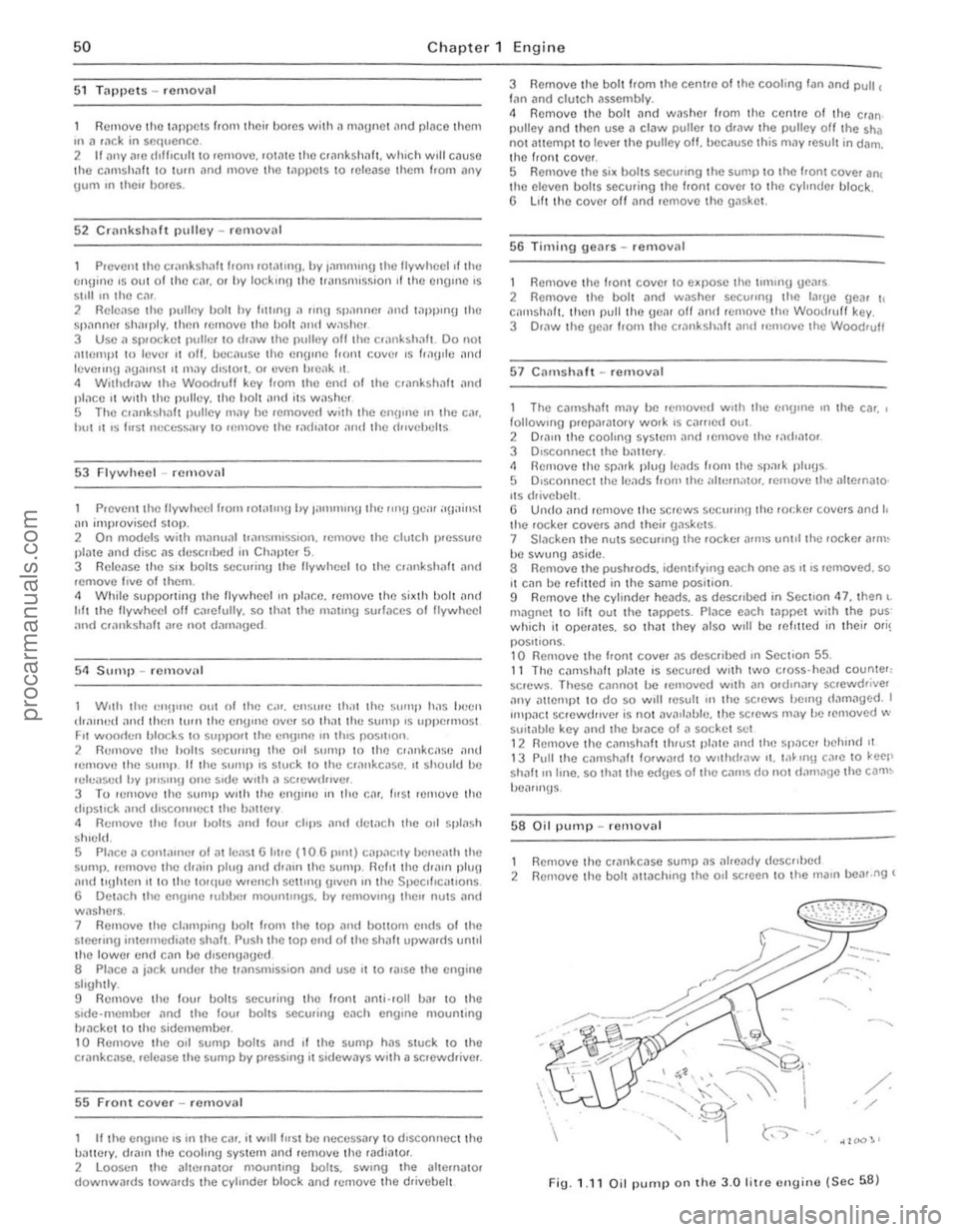

58 O il pump -r e m oval

Remove Ihe crill1kc:ose sump as ;olleady dcsc"hed 1 2 Remove Ihe boll aUJchmg the 011 scrcen 10 the Illalll 00111.119 (

/ /

Fig. 1.11 Oil pump o n tho 3.0 f itre efluill(l (Se c 58)

F

procarmanuals.com

Page 52 of 205

t

,

l . ,

)

f

)

-• the twO boilS sccurong Ihe 0,1 pump 10 the crankcase and 3 R emov

',.,' . the pump assembly nnd ,ts (roves la I-wllh

drilw

59 P istons, c o nnecting rods and bCilr ings -removal

1/ lhe crankcase sump and the cylinder hC

~ssemblv Ollt of the top of thu cyhnder . 6 W,thdrllw Ihe assemhly frorn the cyhntler ,lIld ptace Ihe hCillrnO C,IP

~ck on the connecllrt{J 10(1. 1 If Ihe be.:uinos rue l>CrllO ",newetl. lelnove the uld 1)("""'!15 hy ),,1I1n9 Ihem lound unlrl Ihe nOl ch on Ihe !J(,,,,rnO ~h.,tl rs tlrsenH<10cd

f rom Ihe lecess on Ihe l)e,1r1"U Se,llrnn 'lIlll Ihen hft the IJofI<1rrtlH oul If tho beJrin{Js <11e lemovell ,,,,d the S,lnm ones ,l.e 1":111111 nsctl a!F"n. illS viMlthat Ihey ale .elillcd III Ihe s.lmc scahnH a ... Ihe Olle I.om whIch

thf.'Y WC.C lemoveli.

60 Crankshaft reM oil seal - rellloll,,1

To !emove Ihe 011 sei\1 wllh Ihe ell!J",e In Ihe ca,. Iusl remove Ihe U

(Sec 60)

~ Crank sh aft llnd main

henri nUs -re rnov.r1

, Relnovc" 2 n Ie CIIIl"I" 1'011 Ihe car . 'J, 3 n emovc the ClelC h HSSI~olhly 011 Illllllual transm,ss,on madels ·1 ernove lir", , , ,

L'

·

.... yw lI.le ;lIld Ihe leal 01 sual cal"er. "/-·H. $'i;:.

5 1

Sld e d own. chock It sccu

CilP S all .111(1 lay 1111:111 out'" order NOlll Ihm Ih" c~nlle 111:1111 hcn"ng f.':IP has Ihrll~1 wa~hcfs M;l,k Ihetr POSIIIOIIS hili",,,

62 Ellgiflo Carl\l)Ollelll~ -e~iHllil\1ltiol1 far we"r

nc:lm 10 Soctll)" I 1

63 noct.e r arillS -examination ;ond nmovalion

llll) siuds 011 whIch Ihe locke, arm~ p,vot arc a pless 101 Into the cyhllder he,1I1. ,111(1 II .1 51'<1'0101 cdUO IS Inld aCfOSS all s'x. II cnn be seell whelhtlf ;"'y h,ll1e 1>f:\Jull II) pull oul. II Ihl5 IS Ihu case. Ihe stud w,1I have 10 h e I..,1ll0vt:d. Ihe hole re,lllll!'\! 0111 ,IIId ,Ill overSlie Stud hllll(1 2 Check Ihal Iht.: Itucuds on the sluds a,e!ll Uood conti'IIOI1 anll that ~ \IJ'(juc 01 nllc.1S1 59 N", (

Silil dl:lrCIUIlI. hi a locknul to Ihe mlluslef 3 EX;IIWlln 1hll Illeke. <1111l~ ;IIH) IUit;IUIlI snalS 10' S'~lns 1.11 rrdH'nU. 1.1< I:XCtJSS we,ll 1111 Ih'l Ilc;o,'nu $IIII"I:<.'S II Cllher p.lll shows excessIve W"'II. 1".111 Ihe ,",.k.)! ;",n a"ti ti,e 1\lle'IliH sent '''u~1 IlIl .enowcd If When I;hcr:klll\l lilt"! rI)C~,)lS ;UIIlS. 'C"IOVI) Ih,;", one .11 a l"no \0 ,,"mlll(llo: allY POS).Ihllrly 01 ,urllS ,Iud seals Ilct:lJn l,tlH ullerchan\)cti. or Ilelll(l 1.,!I1Il:d III Ihe W'OIl(j ~IIIrI

GIf Tappets ,HId pushra()s -elWlllin alion ;lIld renoviltian

ncle. 10 Sm;trr)ll I 3

65 CamslHlIt ,\lid ca!l1sh':llt bC(H inos -c~arl\il\"tion and

renovation

UlllhHSI~C camshaft beaflflf)S ;1fC ayml.,tJle. so II IS poss,hlo \0 SOlly,IUIl , I waul c amsh31t by rCtJtlIl(lrnO Ihe 10uII1als. II the call1s . or skew gllar. atll wOln stOllllocallll y. Of arc d':II11.10,,(I. a ncw call1Sh.1h

IllUSt be I'lled and thc tJcallngs should Ihen also be renewed. 2 WOlll or dalllaUed c;m,sha1t bearings can be replaced by ncw ones. hullh,s re'lullt;:s spI)Clal tOOls and should llc om,usted 10 il FOld dC<1lel. 0 ' 10 (1 wa.kshol) wh,ch undertakes carnshafl reclalnl'nu

G G Cylinder horus _ eXHl11irHltio n and re nov(ltion

Reier

til S(:Cllon 1 G

67 P is tons and t)isto n rillUs -ellamilwlioll ,lIld renov(ltion

R e

lcf 10 Sectlo" 11.

procarmanuals.com

Page 53 of 205

, ,

52 Chapter 1 Engin e

68 Connecting rods and gudgeon pins -Il~nmination a nd renovation

Refer 10 Sccuo n 18.

69 Cr,lIlkshnft -e~(lrl1in

70 Mail' and biu·end heafinUs -olwillinmion and H)!1ovation

Ilelo,r to Seo.:lIOIl 20

71 TilninU oellrs -e~i1miniltion find renOVlltio n

Re f

el to Sec t,on 21.

72 Flywhee l/ d riveplale -Okamitliltiotl lind ronovtttion

Inspf:CI lhu ffywhf)l)I 0 ' ([ttvl'pl,,": fOI (!;U";'\lC ilnd 1:I".1I:k Ih;'1 Ihe ""!I H".u docs uol have .IIlY \)Iok"n o. l);Idly wOtn teeth. :1 On ''''''''';11 I'''"''''US~IO'' mnd"b ,I IS pOSSII.Il) 10 'CHew the I"'!l \]C,II .'S Ilesl:

[xallutle Ihl} v,tlves 101 IlIls "lid !l,ooves lind the valve SIems to. e~c,'SslV') we,l' III d'~loIIIOII' 2 Ek,""l1ltJ Ihe v,oIVil hf)"d 10' SI!.!"S 01 hu",u,U of the vOllvo seillS lind ch .. !ck Ihe ht 01 Ihl) villves III Iho v,llve UUldes . 10 SCl) II Ihe villve uu,des il,e WO!ll

3 We"" valve U",dcs c;'" be r l),lIned O\It lind vlIlves w'th overs.~e Siems lilted II iI v

S To 1,1P the valves. In tt s u ction Iype gnmlonu 1001 to Ihe villvc hettd. smeil' a lu tle COil.se c;ubo.unllulll urmdmu pOIste on to I he sealing I~c e 01 Ihe vnlve ond inserllhe valve 11110 the cyJonder he"d. Rub Ihe stern of the v al ve gundlng 1001 hetween the palms 0 1 the hands. so Ihal Ihe valve,s ,otllle(l hHckwards 1I11d lo.wa.ds When II IS lelt lhOlI culling has

ceased. loft Ihe villvc. rotate It th.ough 90·, lowe. 1 and fepCill the u"n(llnu o.:.e.atlon . • e dlslllbulill9 the g"nd,ng pas!O on Ihe seal if necessilry. Conlinue Ihe process unlll a mllll gwy bOlnd IS pfoduced OIloun d the complete pe"phclY of hoth the vlllvc and t he valve seil l G RepoiJl Ihe opcrilllO" US" 'U fine o""d,nU I).Jsle. 10 ohtil'"

IInlsh. then clean lJoth Ihe valvcs and Ille v alve seals 10 ,emove IIU \llIces 01 u"ndlno pash:! 7 II 'I IS convenl,,1lI 10 liIke Ihe eyhndc. he

When Ihe cyllnde. heilds (li e removed. eilhe. in Ihe Course ovelhJul Of for inspection 01 bows 0. villve condllion when the e IS in Ihe CM . il IS nO'''1

Ihe eiliite. dilys 01 10nU stroke low .eVYlnO en!)lIles tJUllllodern enUil fuels ilnd Itrb"canlS C,1use less cOIIOOn deposils OInyway and any. b ehind lend merely 10 cause h O I .SpO IS.

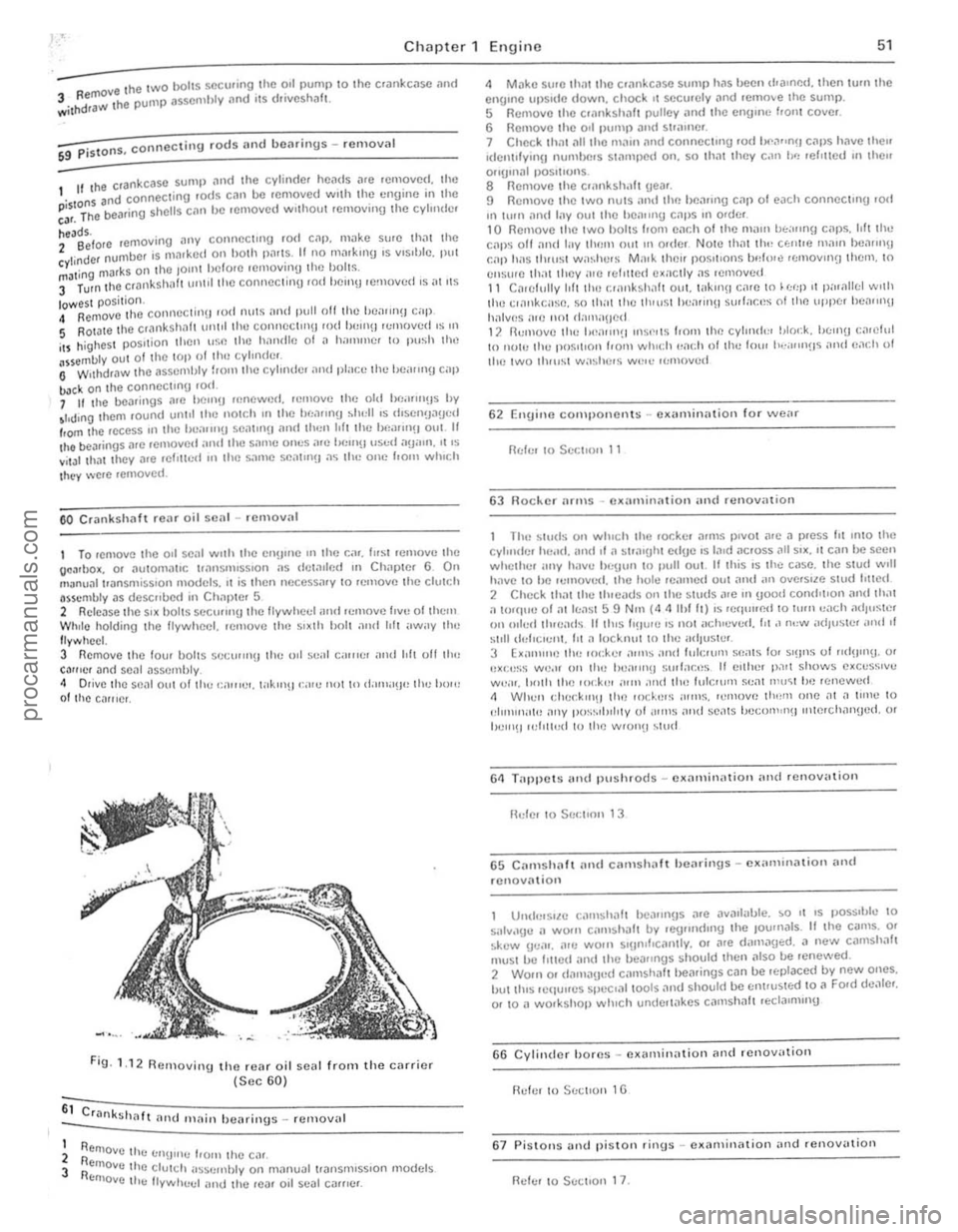

75 Oil PU"',) -disnwntlino. eknmin"liOil ,,"d reOlssembly

The Oil pump mm"Itt;"S a I)ressure 0 1 ilbout 2 8 kgl/cm' (3 Ihf/in') lInd unless Ihere is ,1 sIo",IIcanl (hop In 001 P'(lSsuro willel ,)loved to he due 10 the Pllln,). rillhn. Ih;", 10 wo", heil'm!)s. 11 IS be .

t o le"ve Ihe 011 pump und'S hilhed. 2 To d'smanlle Ihe pump. fll:.1 ,emove II hOln the en!l'ne ns desc,,1 III SUClion 58 3 Remove Ihe IWO bolts seCulII1!J Ihe en d cover 10 the body 1 'emove the covel ilnd 1he .ehel v;" ve "sscmhly. Ihen Ihe Iwo P"

fOIOI assembly.

" Remove ,he IWO bolts lind ,,,ke Ihe p,ck·up w he lind SCIl' lIssembly oft Ihe pump housin!1 S Wilsh all lhe pilrlS In petlo'. usc iI hlllsh 10 cleol" Ihe Inside 01 1 pump ho usinu ilnd lhe p.cssu,.., .elle' vil've eh'!lnbel. ilnd milke 5' Ihilt ,111 p,tltlClcs 01 dill ilnd mewl n,e ,emoved Allow the pttrlS 10'~ n;IIUf,lllyor blow them d.y G Check Ihe Illslde ollho Puml) houSII'9. Ihe OilIer .;w:e ilnd Ihe 101 101 dilfllilUe and e~cesSIve weill 7 E~ll'''Ule the I111lling su.lace 01 lhe I)Ump cove. 101 we,lr It Ihe CO' IS sco,ed. o rooved. a. shows ilny s'g ns o f wea •. a new covef must I hlled 8 W,lh the ,otor assembly filted in the hOuSing. place a straighl·ed!. over Ihe end 0 1 the housing

Page 54 of 205

" ....

Chapter 1 Engin e 53

-----------------~--~--------------~

@

I

2 5 -

6-

3

7

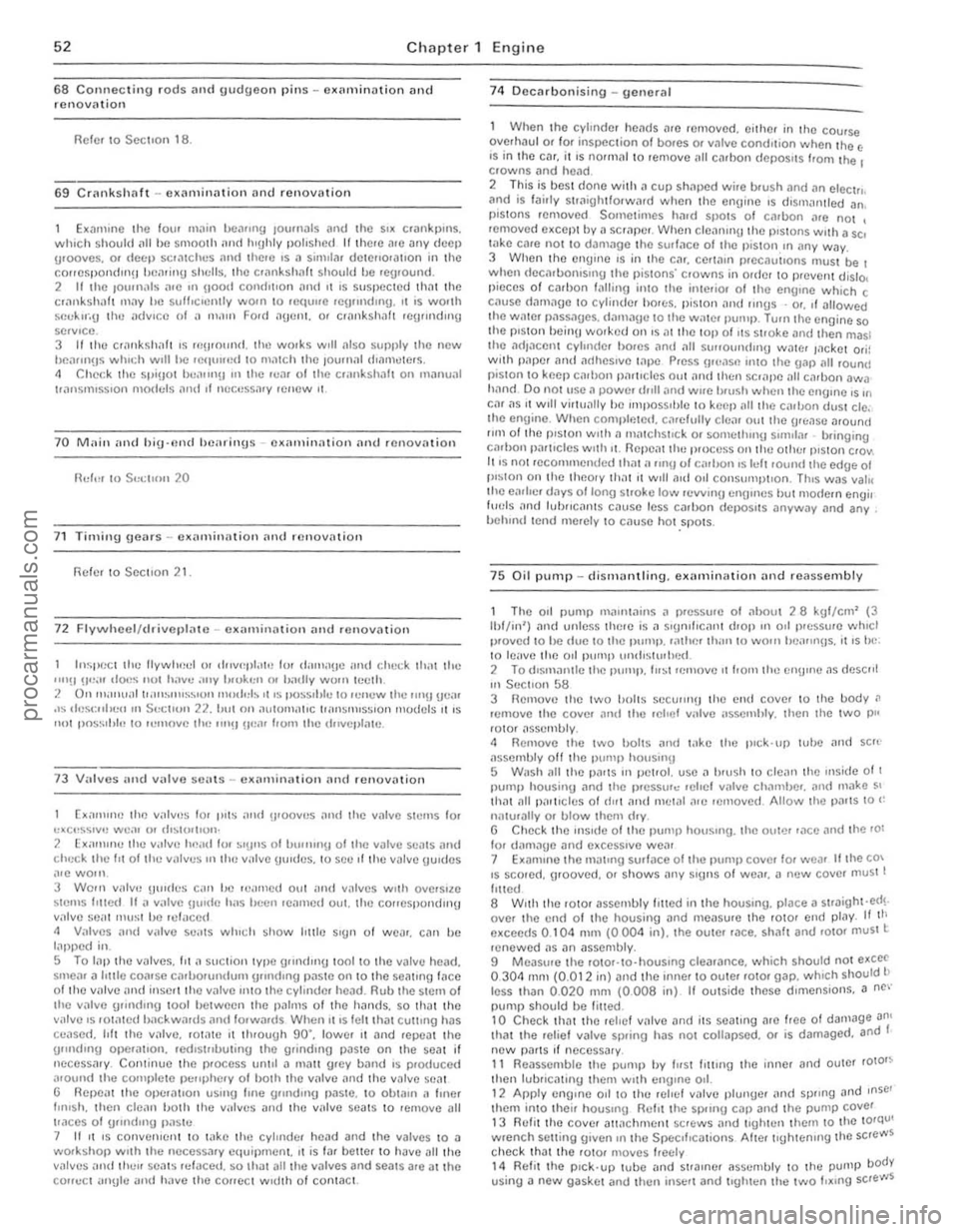

Fig .1 14 E . ngine IlibriC

) _ d tron sys te m _ description

T he lub, . _ ~ng Jl re,)l'on syslen , IS villually lhe same as lhat for the 2_8 hire $IJP~le rJrJese"hf'd III Section 2<1. except Ih

,

l..j

Fig. 1 .1 3 Ex ploded view of the oil pump (Sec 75)

I 2 3 4 5

Piclc-Ojl (ul)(; i/ml SC/C~'{) G,1$icCI Clips Pump body O"II~f fOlvf 6 ImlL'1 rOl{lr 7 Elld COIIL'r 8 ScM 9 Swing 10 Rc/iL" v,llllc 1)luIl9 ~" II Clip 12 SlI.lf(

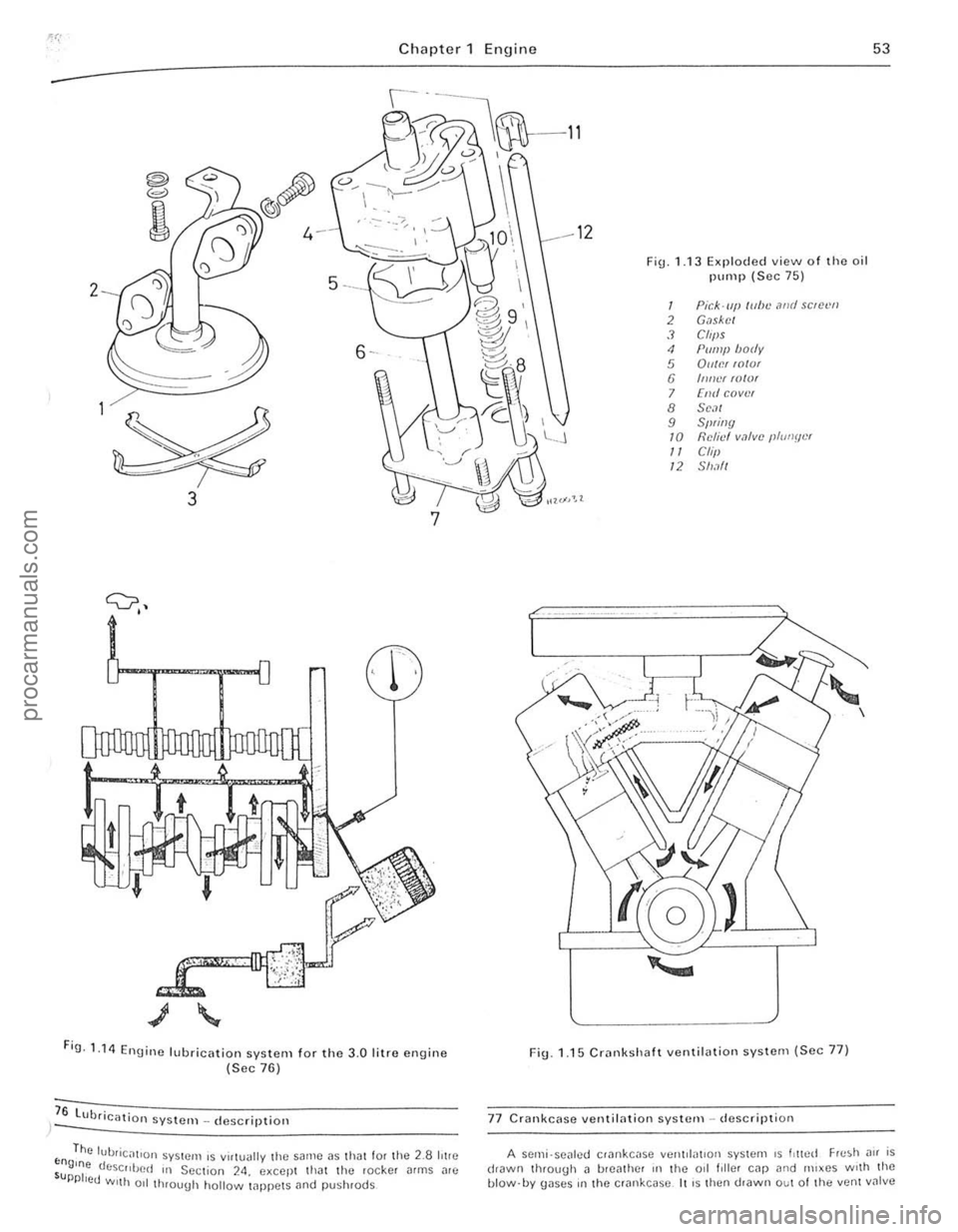

Fig . 1.1 5 Cr

CrankC

procarmanuals.com

Page 55 of 205

) 54 Chapter 1 Engine

,n the "Oill hand ror;ke. covc. ~nd mlO Ihl) en!IHlC Ih'ouUh .111 .1(1,1pl0' bene,.!!> the (.1,hl"l)ll01 The sys\cm '!nSlI.ct; 11\.11 !lIlhurnl lIilSCS ille .ChunNt to Ihe enU'"e fOI fUllher (:orlllJ\'~I'OIl

78 Engine reassernbly - gcner

79 C,lInsllllll -re';II'I1I)

SI"h, Illc SpM.,<1 "",th li S ChitrllfCI1'" "ml [""I onin Ill" r:;HlI:.hall ;oml ,, the kr,y 2 LlIb",':"I" lh" c"m~h,111 lo",.,als w,lh <:Ill)"") nd ,llld ~I,d" Ihe ' ·.IIlI~hah "' hOln\h" hOIl!. 1.II-IItH C;UI~ 10 ~""P ,1 ~1',IO!lhl. SO ,I', nvt III rl.mlil!1" II", /:.III1,h,,11 I)","'IIO~ 3 rr! th., (.l", ~h"h 11""~1 ,)1",,, wuhou! ;, !1.'~"('1 fIt lI,e two (,(lInl\I:!,,,nk hr',lei rr,!,'"lll'!! serews ;1I,d 11\lhl"" III"",

80 Cranksh .. ft reblti,,!!

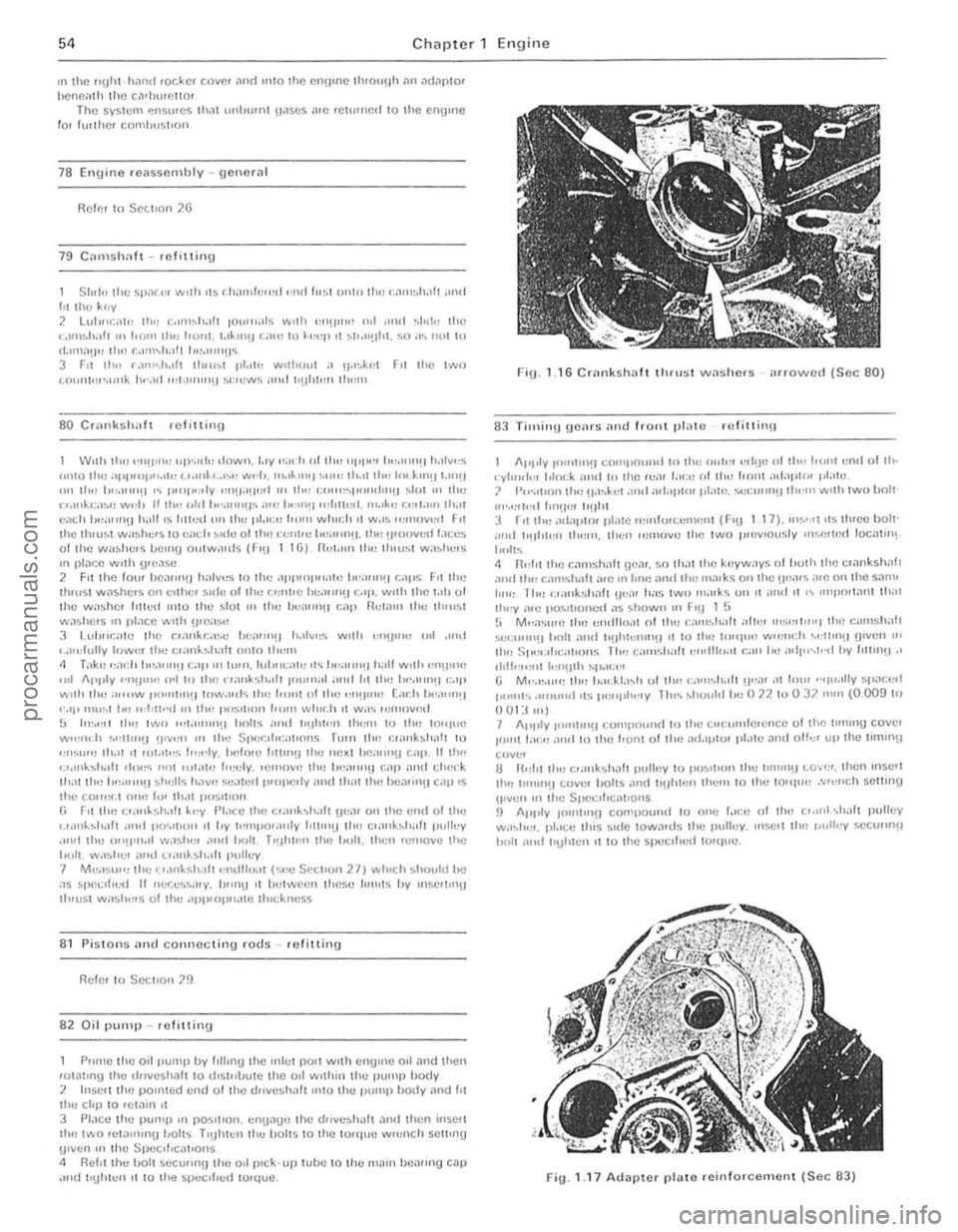

~V'lh lilt: "II\IIIH' "p',ul" ,low". I. 'v ";I, h "I II", "1'1"'11"',""'0 h.,I,,",s ''''10 Ih" "1'1""1''''''1: u.",ll .• '~" wI·h. 111,'''''''1 ~,,,,, Ih." Ih" 1<" ""'!II.IIIO 0" II", I""""'!I '~P"'I""IV ""!!,,!!,,,I '" ,II" ':C"":~I"""h"!I ~I{)I '" II,,: 1; • • u'"c;I~" WI'!> Illh., "Id I""""'!I~ .,," I"""!I ",!tW:Il. ItI.lk" .;",1.111,,10:01 e.lch I .. """,!! hill! IS '''Iud • III III.., 1'1.,, ;11 h"ll wh";h,, W.IS ",mo"..,d Fn Iht:: Ih'u~1 w.lsh".s 10 <1;lcl. ~,,11l 01 11", CI:'II • .., I...,a''''!I. Ih" 0''''''''''([ l;lI;"s 01 Ihe wa~I'e.s IJelll!! Oulw;!lds (1"11 1 16) n"I.""II,c II"tI~1 w.l~I""s 11 1)lar.r. w,lh UH}.1SC 2 FII Ihe low ll anO "!1 halv",s 10 the app,op""h: I>";'''''!I ,;nps 1"1 Ihl1 IllIuSI wM,h.."s on ellll(!' S,dCl "r Ihe <""'"11 I>e;"'I1!l ':"1', Wllh Iho 1.," 01 Ihe w" she. Iitied "1i0 Ihe slOI It' IluI be''''''!1 <;;'1' Rel

RclC' 10 $CCI'O" ;:t!)

82 Oil pump -refillin U

P"lTle

Ihe oilllUlllp L>V 1IIIol1g Ihe IlIlel 1101l wnh Cl1g,"e 0,1 and Ihen flJlat,ng Iho dllvcshilh 10 d,sl"L>ule Ihe 011 wllh," the I'lI"'P hodv 2 Inselllhp. pOll1led end ollhe dliveshMI "'to Ihe PWIlP hodv and III Ihe clop 10 .etain II 3 Place Ih o pUIliP U1 I)051110n . cngnU!! Ihe d""e~h;JII and Iheo inseH Ihe ' .... 0 llitallung IJolls r'\lhlet1ll1.., holts to thC lo.que w'lInch SCII,ng

\I,,,(:n III Ihc SpClcol,c,lIIons < Rell lihu boll SClCU.IIlU Ihe 0,1 pick up luhe 10 IhCl ",nln I)C;UU1U cap ",,(I "U"l"" II 10 Ihe ~j}ec"H,d 10'ljue. F

ig. 1

.16 Cr.1J1 kshilft Ihru st wash ers ~ ;orrowed (Sec 80)

83 T illl i,,!! !I ClH'S illid I rOll 1 pla to rclillill!!

Apply 1""'III'!1 1:1>"'1","11<1 In Ih " (11,1,,1 ""!I" nllh" 1"'''1 "n,loI Ih. <,yin""" hl(1{.k ;"HI l

1o"lh < no:l,1 the e:"nlsl1.1 lt ge".. Sf> Ih.ll Iho kP.VW.1VS "I I>ulh Ihl} CI.lnkshall ill1Illlol: e:.1t11sh"'1 "H) In lone ;11111 Ih,: ",,,,ks on Ihe tW,lIS .1,Q on 11m Silllll

I",,, II", <.I:'l1ksllo1ft \1";11 hilS IWO "';IIks Oil 'I alII I " " mipOIWnl Ih;n 111"V iIIe l'OSI\loncd as ~hown ,,' f.U I!; [) M""~,,,e Ir." I:lldllo.1l 01 II", <:.1I1l~hall ;,ft,,, '"~"'IIIIII Ihe t:alllsh;oIl "''''''''''!I hull ami lI\1hl"IIIlI\1 , 10 Iho: 111"1'''' wII,I1I:h ~I:H"'!I U,,,e,, III 1111, SI'"",I,,;;llll)lIS 11", cillll:;h:.11 1;"dllu"l e:"" I", ;111",'01"01 lIy f,ItIl'lI .'

Ilelf'·I,".1 1''''lIlh ~I'.".'·I G M""~,,,e'II": 1"".ll.l~h ul II,,, 1:O",,,h.111 !I",,, ill 1"lIl ··'IIl.,lly ~1'.1(:",1 PIII"i'. .",,,,,,,1 "s I""'I"""V lh.~ ~hull"ll", 0 7.2 In 0 32 """ (000910 001:l "I) 7 AIII,IV 1"'''h''!1 (:O"'P(111,,<1 II! Ihe cII(:uII11r:"",ce ollhe 1",uIIU CO"..,, 101111 I.",,~ .IIHI It) l hl) 100111 01 Ille ;"I.'pIO' pl.'le JI,d oil." up Ihe 1I1l11r'>{'

co"el 8 1l,,1'1 Ih" ",,"'kshall j)l11l!:V to pO~'I'IHI Ih.., IIIIIIII!} '.0"'1<. rhcll mSCIl III" 1""'''11 CO"", hOlls alld t'H"I"" Ih..,111 10 Ihll 10'<1"(: .·"~IIe:h Sr:l1Illg

11''' 1)'' UI Ihe SI'I1t:o/'C;l\'OllS

9 Apply ,0"lIuIII C0111llOll11d In 01111 f.,.:c 01 Ihl! e:,.,,,1 ~11i,11 llullllV w;o~I"", pl.lcc Ihls s,de 10w",US 111(; I'tlilev . ItISC.I Ihl! pull,;V SCCUH"!I holl ,,"(1 ilUhlCIl II 10 Ihc SP':Cllll1d tOlqllC

Fi

U.1 .17 Adap te r plato reinlo lcclllcnt (Sec 83)

procarmanuals.com

Page 56 of 205

7

Chapter 1 Engine

Fig . 1.1 8 R ear oil sen I ilnd ildaptcr pliltc (Sec 84)

84 Renr oil se;1i ,,,,(I lIywheel - rc fitti"u

1 I'll the ()n!J"I(~ .r,," ,,(1"1'10' pla1<:1 and s(:clIre ,I wllh 'I S IIv(: holls. 2 Smenr en\J1ne (ld OlltO the CI,mkshah '''". Smear 0,1 on the lip 01 the sea l tlnd pos(( lon tlon ';".11 on th e cran hha ll. 3 Align the seil l c;""er holos wllh Ihose 011 the cylrnd(:, hlock . Insell the loul bolts and 11!lhlCll Ihem 10 the SpeCifIed 10lqUfl 4 F it the flywher.:l . or dllveplalc on au lOlllallC lwnsrnis sion Illodels.

InSerll h e six holl S ;",d u\llole rllhem 10 Ihe 10 lque w rench sell"'U Uiven in lhe Speclllcm'olls

8 5 Sump -rciiuill!)

En~",,, lh;ol Ill" ru,rI "'!) ',u.l,u :e s 01 hoth IllI.! Slimp a"d t h e c(,1nkcilsc ,lie cl ea" ,mol IIi,1I n", '.""I",!) SlIrJ ,u;e 01 the Sli mp IS not d'S lo lte d. 2 Apply IO" ,I,,,!! c"'''pollnd 1 0 the pOUltS wllel(~ Ihe l"llllll) cover ablilS lhu ,;yir r"lr" 1,Io ck .lIId where Ihe rea' 001 $u,,1 carr.(:r "dIOIllS II 3 Pln ce tloo \J,,~k"l '" fJo~.t.on, lIt tlo" SlIm l} ,'Ild IIlS(). 1 lhe r0Io1111il1l)

bolts ImUO I tl!lhl 4 PrO!lres~lvely 1I!llIt,," llw sump holt s 011 opposIte I'ilr ts lIllt,1 all 0 1

t

hem ,H" il l tl", ~ 1"":lllI"d IOlllUU , 5 FII ,1 now w;,~h", 10 Ihe ~Ul1lp II"'UI pili!) , IIlscrl lhe dl,lIll pllll) and

t ,uhlen ,t

8 6 Cylinder h e"ds re;rssernbly

L~y the cylrnd" r h",.\! on .IS s Ide. luhrrcnt e cvcry valve Uu ide with eng;l1(! oil. ,lilt! ,"~,,"t the valves 11110 the \Ju, dc Irom whIch lh ey wele remov(:d 2 To ,WOld d

lhero.s dilnlJC' oltl1<.: ~I""IU rcW""C' dillllil\)IIlU tllC villve SHlm 011 sen l

G Ahcr "lsert")!J tit" ~pllt collets. r eleilSo the spllny compressor (111(1

rcmove II 7 C hcc k th"t lh..: ~pl'l cull":IS hilve seilled properly and t

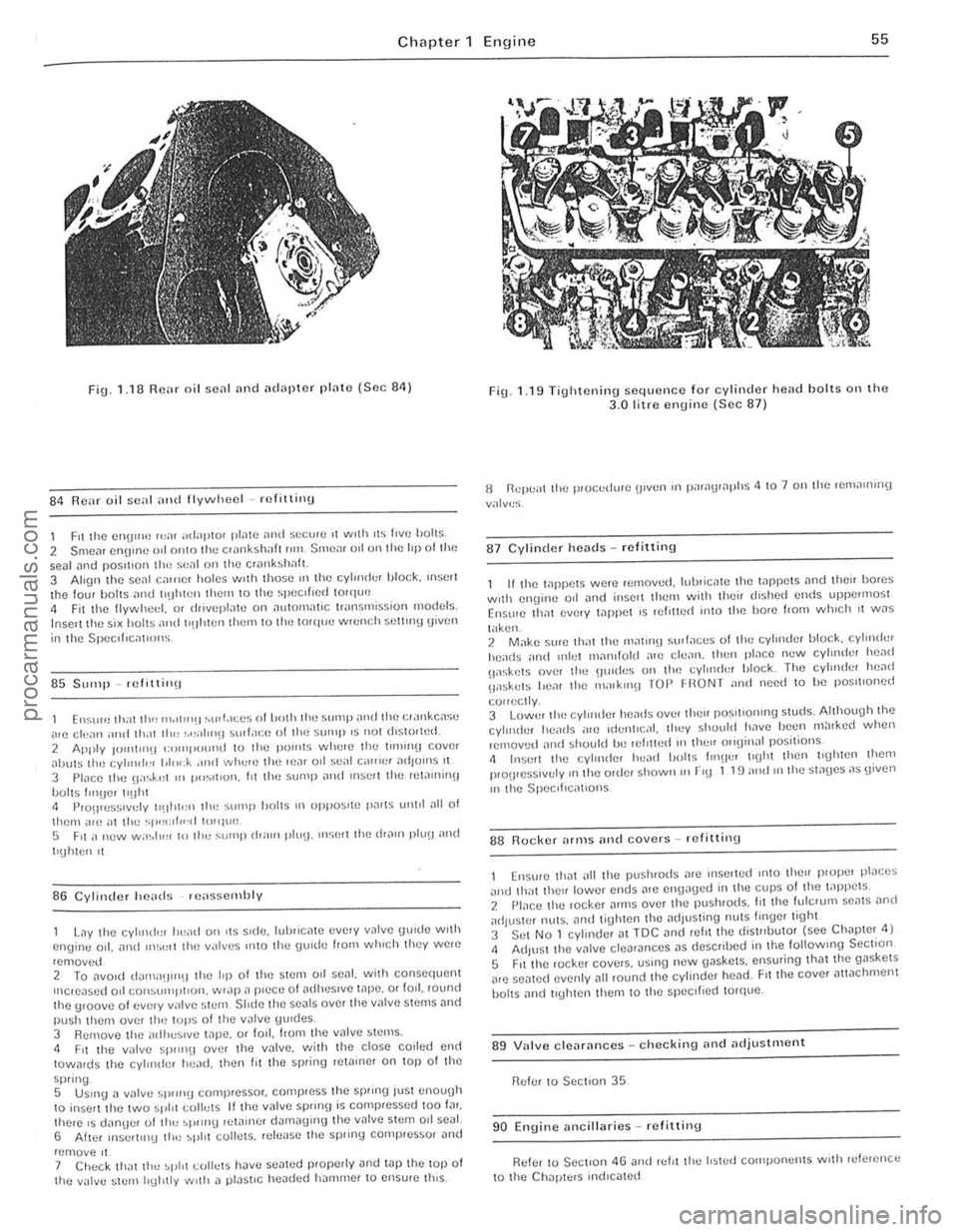

Fi g. 1.1 9 Tightening sequenc e for cylinde r head bolts on the 3.0 litre enuine (Sec 8 7)

a Repe"l liln pruccdwn orven III p;ua!Jrnphs 1 to 7 o n the (CmJlnlllU

v,llv"s

87 Cylinder heads - re fitt;nu

11 the tappels w ere rcmoved. luiJricnle lhe lilppets nnd I heu hores wnh enoine orl nnd insor t thOlll wilh lhc;, d Ished cnds uppermost Ensule lha l every tappet ,s rclltlcd Into lhe hore hom whIch II wns

t nkcl1

2 Mak e sure tha t Ihe rna t"'!1 surlaccs o f lhe cylinder block. cyl lndor henrJs ;Uld 1111,,1 Ill,lIlIlold ;lIe de;"l. then plnce new cyhndcr head \Ja~kets ove, the Wildes un thn cylrmh" block. Tho cyirnder head \I,,~k ~IS beilr thO malkln\! TOP f:nON T ilnd nced to h e pOSII,oned

cOII(:ct ly .

3 Low ul Ille cyl ""lcr he,1ds ov"r the" posl tlonrngst u(!s, Although t he cyhlld\~r headS ,"0 Id entlc;,I, they should h,lVe been Illtlrke d when remuved ilnd should be lehllUd III thcrr ()IIUinal positions t1 Inse rt the cyirndcf 11I)"d boilS f"'!I(:r t.!Jh l then tIghten lhelll prUglC SSlv(: ty OIl the olde, shown III r,U I l!J and III llle stnucs",s U iven

m the SpcelirC;lt'OnS

88 Rocker arms and cover

s -refiUing

Ensure Ihm "II Ihe puslllOlls ,lie ,nselwd I!ltO the" p'llpor placos ;II1

)olt S nntl lighten them t o the spec ,f led torque.

89 Valve clearnnees -checking nnd adjustment

R eier

to SeC!lon 3 5

90 Engine ancillaries -refitting

R eier 10 Sec tIon 46 and ref, t lhe I. ste d componenlS w,th refercnce

to th e Chaptels ind,cilte(f

procarmanuals.com

Page 57 of 205

56 Chapter 1 Engine

91 Engine -refilting

Rcf'tlIng the engine is a rCllcrsnl alth e removJI procedure given In Section 44. bUI in addrhon note the following 1)O;I1IS:

(,,) Ugh/I)' 9(0"50 Ihe ycar/)QIC ;npu{ Sh,ll{ (m,lI/v.,1 transmission) (b) Check tlMllhe dlileh fc/c,He .7Im is cOIf(!clly loentcd (m,lllu,)1 (fiJn$miSS;OIl) (e) Adiusl (he clutch cClbfll ,15 (/(!sCllbcri ill Clwp/fN 5 (m,mu,,1 flilMmission) (d) BelOfc COfl/weliny the engine /0 {I!(! ,W{omMIC {MOSl/tllSion check 111M /he /O((/lle con vet/or is fully 01l9,19N/ wilh lite /f,lfI smiSSI()II pump by reh'/(!IICa to CIWp/Of 6 (e) Refll' file ,)II/QIII,llie ("'''lllltHiOIl WillI 1141/11 ,15 dcsCfI/)t'd III Ch,lpWI 6 (/) Ad/usllhe lellsioll 01 the IJowor steeling IIlIfIIll MId .11/emMa. !lnvalid/(s) ,15 d(!scfI/)ml in Ch,?pICIS 10 i/lld 2 f(!SpcC/lv(!/y (!I) Fill Ihc cooJillfl sys/cm (el,.l/'/C' 2) ,md /lOW,!' Slcc/IIIY

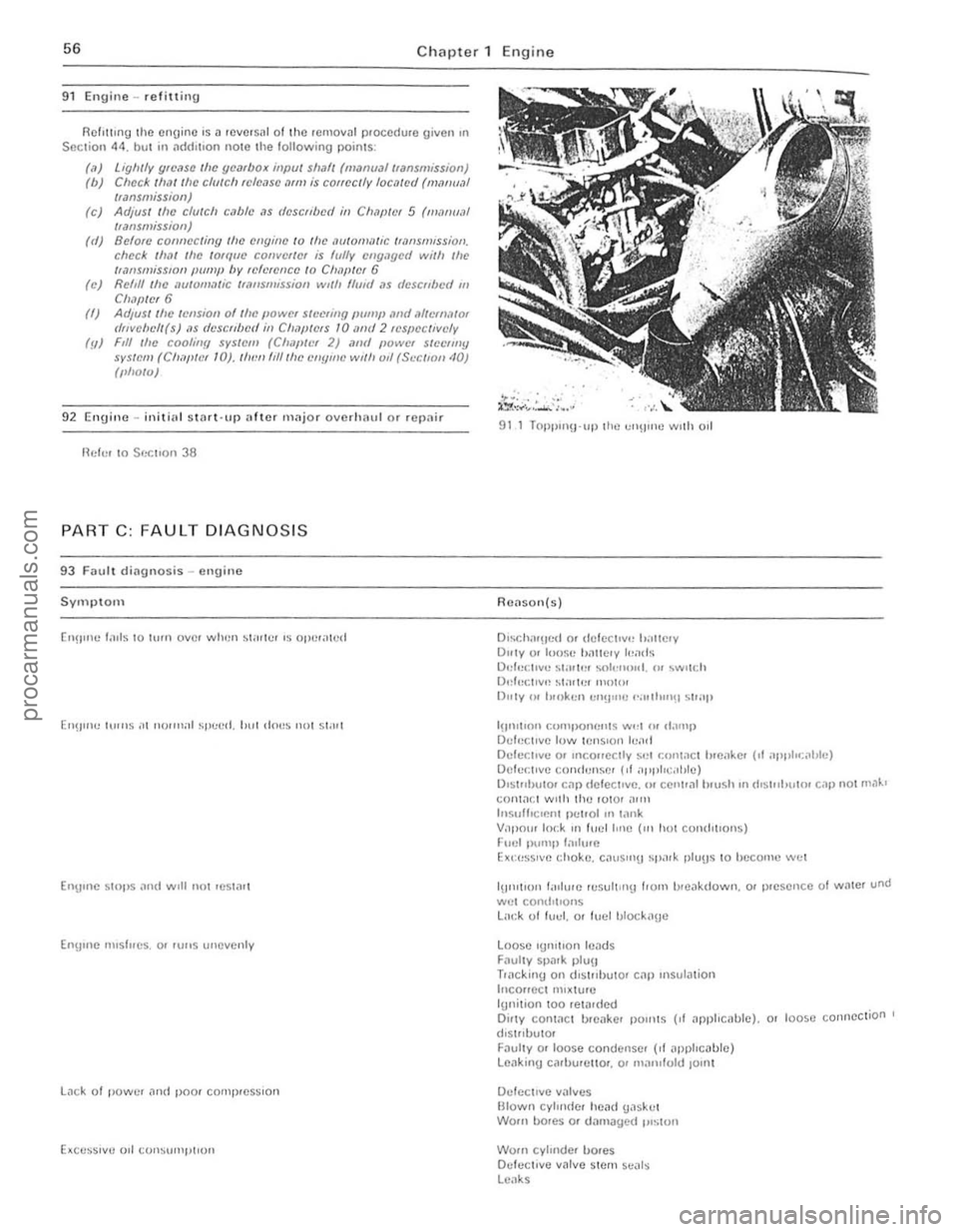

SVS/l:tII (ella,'/Cf 10), 1111:11 fIIlllle mlylllc Willi od (SeC/lOll ti~) ("ho/Q)

92 E n £line -initial start-u p after major overlwul or re pair

Hel",

10 Sect Ion 38

PART C, FAULT D IAGNOSIS

93 Faull diagnosis -engine

Sympto m

(n!Jlne f.111s to tllm OVCI whim ~t;llt", IS Opc,;) lcd

Enll"n) lUIIIS ill no.",al ~pced. hili dous not 51,IIt

E"u'ne SlOp s ilnd Will not 'estill t

Enll'Ile

.",slucs, O. lUll S unevenly

L~ck of powc. illlt! poo, comp.esslo ll

91 1 T OPPln! 1 lIl) tile ""'II"") wIth od

ReilSOn(S)

DI~ch.1'Hed 01 delec tlv" 1o:,lle.y

Dilly 01 lI)os" lI.11tc.y le.,ds

O"f '!I:llve sl; IIt", soL"",,,, I. ,II SW'II: " Odl'ctlvl' s lillte. "UIIOf

Dilly 0 ' III"ken e"!I"IC "'''1111''11 SIt;IP

1\I1'"111 ':Ol1lpOlu",ts Will (If ,1;""1) DefectIve low te nSIOIi le"d Detective o. InCOllec,ly :,,, 1 ,:"III"C I h,e;oke. (,I "PI.I,,:a"fe)

Oe f"ctlve condense. (If '11'lllIo,;.,"lc) O'st"hulor cal) defec tIve. or celltral h,ush HI (irs l,,"uto ' cap Ilot m,,~, COfltilf.t w'th th e .otor a"n Ifls.ulhc,em petrol "' tilllk V.1pOOf Iud '11 luel hlle (," hut cOl1{lIuolls)

Fuet pump I:uhlfe E~O:Hs51ve c hoke, caus,,,u spillk pluUs 10 hccolllt) wet

IU"I1I(HI 1,,,IUle result Ill!.! 110111 b.cakdown. or prescncc o t w;'1ler \,Inti w(: 1 cOnthllOIlS l:n:k 1.11 tud. at luel IJlock, l!Je

loose 19111tlon Icads F(luIIV s J)n. k 1)Iuli T'(1ckin£l on d,slllbuto. cnjl IIlsuliltion

InCOIICCll11lxtu'e 'Ullilion 100 telilldcd Dilly con[,lCI blcakc. POlll1S (,I ajlplPcablc). or loose connection'

D"lectlve v.,lves Blown cyIP"de . head £lasket

WOlll bo.es OJ dilm ilye

Page 58 of 205

,. Chapter 2 Cooling system

Cont ents

AntIfreeze mixture Cool ing system -draining, Cooling system -filhng Coo ling system -flushing " D,ivcbcllS -femoy~1 and refilling Expansion lank -removal and reflllmg F;)n hub be,Hing (3 .0 lit re eng ine) -renewal . Fault diagnosis -cooling system

Sp(lcifiCiltions

System type

Thermostat

Opening lempel

M'ninlllnl IhennO SWI Havel _

Orivebelt tension

O()lleCI,on JlHOwily between pulleys (longeSI run)

Prossure cnp setting

3 0 lure engines -._ .. ,. "._ 2 8 hire engin es _

System capncit y

30 htle eng ines .. , .... 2 8 lille engines

Ioorque Wrench settings "lIe fHlgil)( :s

'" ~JI~;·;~~;~'·." _ ... , .. " , e"noSl~t 110[151119

G 3 5 4 10

" 12 15

Gene',,' description RmhalOr -.ellloy;,I, inspection, clCilning imd refllting RO\ J\inc rn

1 7 2 13 8 11 9

P,cssu"scd. With beil ·drlven pump ,1"d larl (VISCOUS (hive type on 1.1u:, moduls). IhcrrnoSWI ... nd expansion \,lflk on I"W' Illodels

85 to 9S ·C (185 to 208'F) 79 to 83" C ( 1 74 to lSl'F)

9910 10TC (21010 2Hi"F)

9 T C (207'F) 7.0 nun (028 Ill)

100nll)1 (0.4 in)

091 klll/enl' ( 12 .9 Ibljin') 0 .8510 1.10 klli /elll' (12110 15.6 Ibf!m')

931111e (16.4 pinl) 8.71111e (15 3 p inl)

No.

710 10 710 10 161020

81011 17 10 20 9 to 13 810 11 20 to 25 201025

Ibf ft

5 to ., 5 to ., 12 10 15

6 108 13 to 15

7 10 1 0 6108 151018 1510 18

procarmanuals.com

Page 59 of 205

,

I ;

I

i

, . I

)

58 Chapter 2 Cooling system

Goneral descriptio n

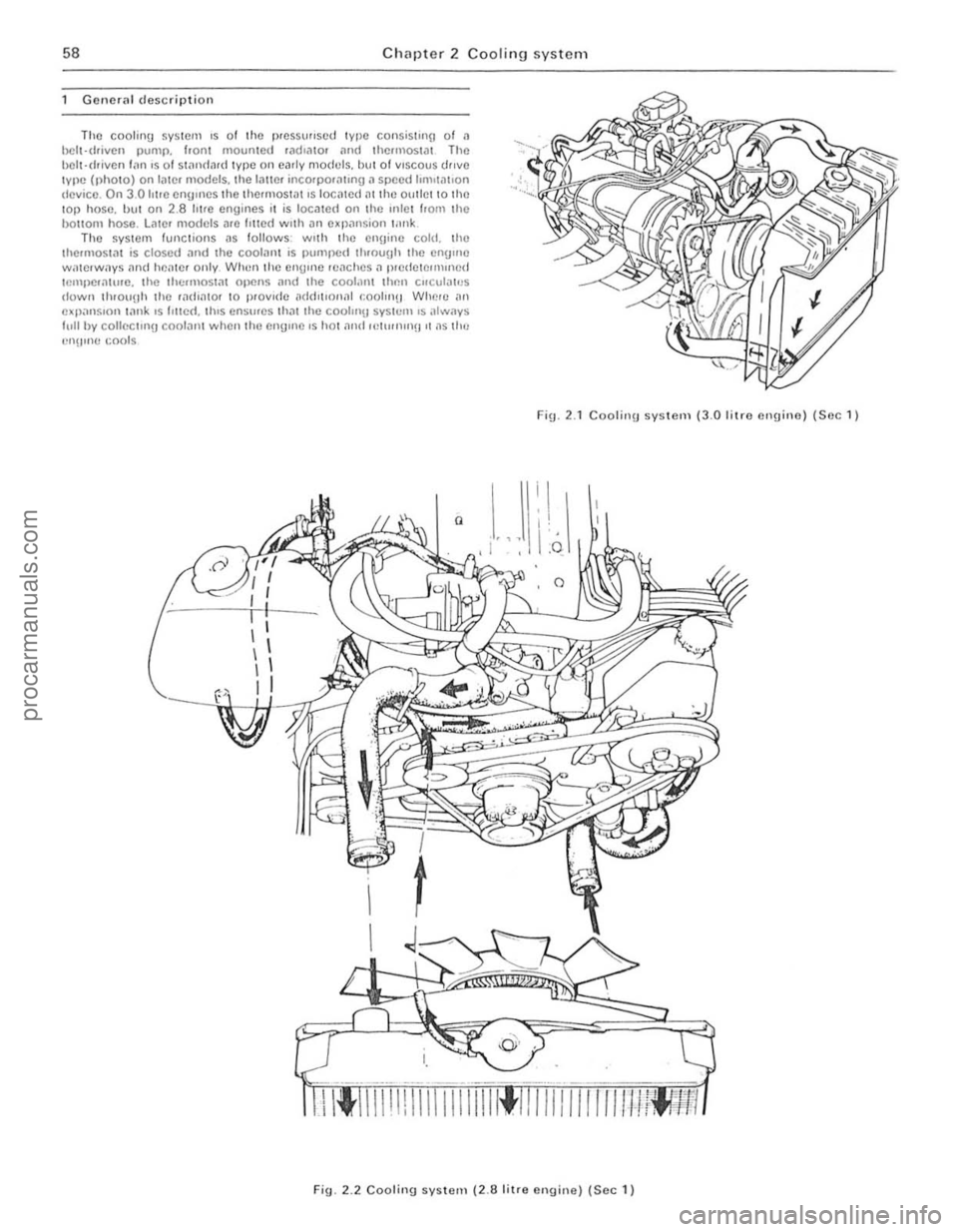

Tho coo1inU sys tem IS of tile flfCSSll"sc d type consiSling of 11 helt·driven pump. h0l11 mourllc d .ild,ator and thermOSI"! Th e hClt·rhrvcn 1,111 IS of SI;mf!ard type on carly models, bllt of VISCOUS drive IYlle ( l) holO) on lalC I models. the lallci jllCOrPO'ilUllg iI speed 1I0)'I<1110n (I(!vkc, On 3.0 hue cnOllles t he IhcollOSlill IS IOCillcd (I( tho,'! 011 tiel to tl lC tOp hose. but on 2.8 htre engines i, is localcd on the 11110 1 hom 1ho baliom hose . Lmc. models

Fin. 2 .1 Coolinu systelll (3.0 lilro cngine) (Soc 1 )

Fig. 2 .2 Cooling syslcm (2.8 litre engine) (Soc 1 )

procarmanuals.com

Page 60 of 205

)

'tz

Chapter 2 Cooting system 59

1 I VISCOUS (IPlVC I,m coupling (I,~mpc,alu,e sensitIve 1VIle shown) 2.5 Tuppill\l -lIplhc COlllilll1 h,vel in the c~J)alls,on \;lI\k 27 Checkin U the drive-belt IClls,on (28 hire CIlUulC)

2 Routino Illaintcnanco

Altho ,n1C, ... "ls SPOC""]!! utlhe Rouhnc M .. "UcnanCf! SOChOr! on Ihe 110111 01 the m;uu,a1 c;lrIy oul the lol1oWl!ljl p.occduoes

Check cnoling syslcm lor /c,1k.~ 1 In spe cl Iht! coolin!! sysh),l) hose s 'llcludlll!) the ,adIOiIO' :,"<1 Iwate. hoses for damage. detcriOlllll0n i1nd sccullly If Ihelt) is I'Irly IOulle;1I'01] of swelling 01 p

COf/ec t tension If .equir e d .

9 Run the enuine f o r severlll minutes Ihen rec hec k t he lension.

Renew,1/Jtilreeze 10 O.am i1nd flush Ihe CO(lhng System as descrlhed in Sections 3 and 4 . 11 F,II the coollllg system With Ihe correct solullon of watel and amlf,ccle as desc"hed in SeClions 5 and 6 .

3

Cooling sysl e m -drai"inU

If pOSSIble. ensu,e thilt the engine IS cold belo.t! d.al"i"lJ Ihe cool ant. 10 aVOid the fisk of scalding.

2 Remove Ihe .adlatOf or expanSIon tank IIlIe. cap. If the eflUlnc IS hot. Ih ls must be done vl;lry caul,ously, because a sudden release 0 1

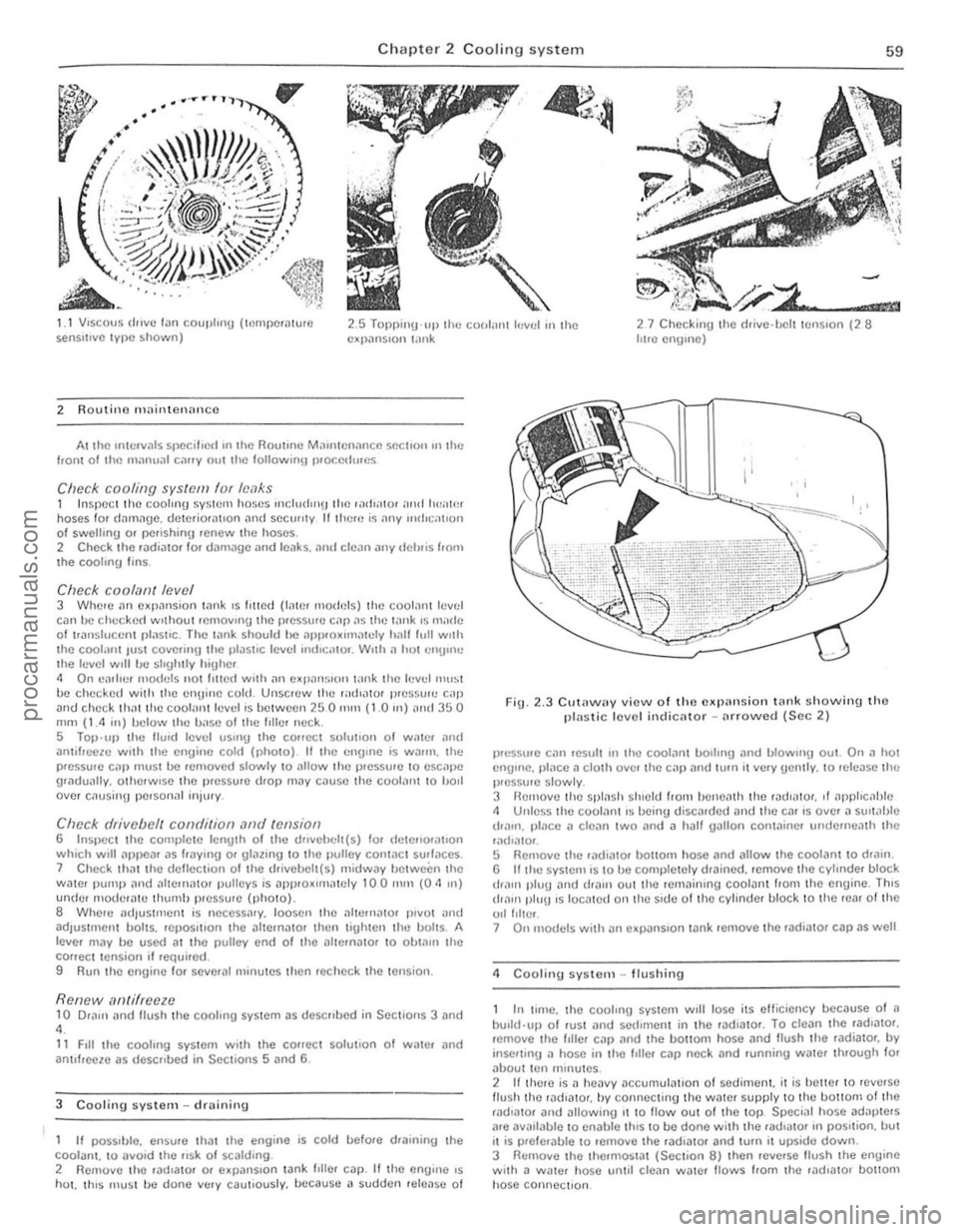

Fig. 2.3 Clltawa y view o f Iho expan sio n tlln k showin g tho plastic lovel indicator -tH rowed (Sec 2)

P'".'·S5U'0 CilIl ,esull II. the cool(lnl !.>oIling i1nd blOWing Oul. On ,1 hot enUlIle. plilce iI cluth ove, the caf} and lurn il ve. y uently. '0 release tim p,ess\lIe slowly. 3 flel110ve the SplilSh shield frOI11 b enomh the ra(II;IIOf. of i1pplrcilble

" Unless !he coolilnt IS beinu discarded and thc ca. 's over (I slilt illJle

d'illl1. ,,'"ce a deiln IWO i1nd a half gallon Conl;1ine. underneath the ,adlaIOl. !) Rel110ve the radlatOl bOllom hose lind allow the coo'al11 10 drili" . 6 If the SyStel1'IS to be completely d,ained. rcmove the cyhnde. block d.;1I1' pluU and draIn oul Iho .emainlng coolant hom tho engine . ThiS d'illf' plug IS locilted all the s,de of the cyl inder block to Ihe rear of the oiliolicr. 7 On 1I10deis wilh all eXJ}ilnSlon tank 'emove the rad.alO' cap as well

4 Cooling systom -ftushing

In IUlIe. !he cooling syStel11 Will lose ils efficiency because o f a bu,ld'lIp 01 .uSI and sedunen t in the radiator. To clean the .adliltol. .emove thc IllIer Cill) i1nd 'he bOllom hose ilnd !lush Ihe radialo" by inse.llng a hose in Iho f,lle. car> neck i1nd funninu Wille. th.ough fOf about tr.m I11mules . 2 If Ihere is a Ilea vy aCCUmuliltlOn 01 sediment. it is betler to .eve.se

flu sh Ihe .adl~tor. by connecting the water supply 10 Ih o boltom of the rilclmof alld allowinu II 10 flow oul of the tOIl. Speclnl hose adapters arc avai lable to enahle thIS to be done w ith the rild.ator In I)OSllion. but It is p,efe.able '0 removc the lad,ato. and tum il upside down.

3 Remove t he thernlos,a, (Section 8) then .eve.se lIush Ihe engine wi,h a W1l1e. hose u n lll clean waler flows from the .ndlat Of bottom h ose connectIon.

procarmanuals.com