cool FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 415 of 454

inspect and repair circuit between switch harness connector and fuse panel.

5.Check Kickdown Switch

Turn ignition off. Check continuity between kickdown switch terminals. Continuity should only exist with accelerator fully depressed. I

f

switch is functioning correctly, go to next step. Replace switch if it failed testing. Road test vehicle to verify repair.

6.Check Circuit Between Kickdown Switch & Kickdown Solenoid

Ensure ignition is off. Disconnect kickdown switch harness connector. Disconnect kickdown solenoid harness connector. Check

continuity of White/Black wire between switch harness connector and solenoid harness connector. If continuity does not exist, inspect

and repair open circuit as needed. If continuity exists, check continuity between White/Black wire terminal at solenoid harness

connector and ground. If continuity exists, inspect and repair short circuit as needed. If continuity does not exist, replace kickdown

solenoid.

VACUUM THROTTLE VALVE DIAPHRAGM (MODULATOR) TEST

1.Check System Integrity

Inspect all vacuum hoses and connections for leaks or damage. Disconnect vacuum hose at diaphragm connection and inspect for

leaking ATF. Repair as needed. Go to next step.

2.Check Vacuum At Modulator

Ensure ignition is off. Disconnect vacuum hose at modulator valve and connect vacuum gauge to hose. Start and run engine at idle.

Vacuum should be 15-22 In. Hg. If vacuum is not within specification, inspect and repair vacuum hose. If vacuum is within specification,

go to next step.

3.Check Modulator Valve Function

Turn ignition off. Remove modulator valve from transaxle. Connect hand-held vacuum pump to valve. Apply 16-20 In. Hg of vacuum.

Ensure vacuum is held by valve. Release vacuum and verify that valve moves freely. If valve is functioning correctly, go to next step.

Replace valve if it fails testing.

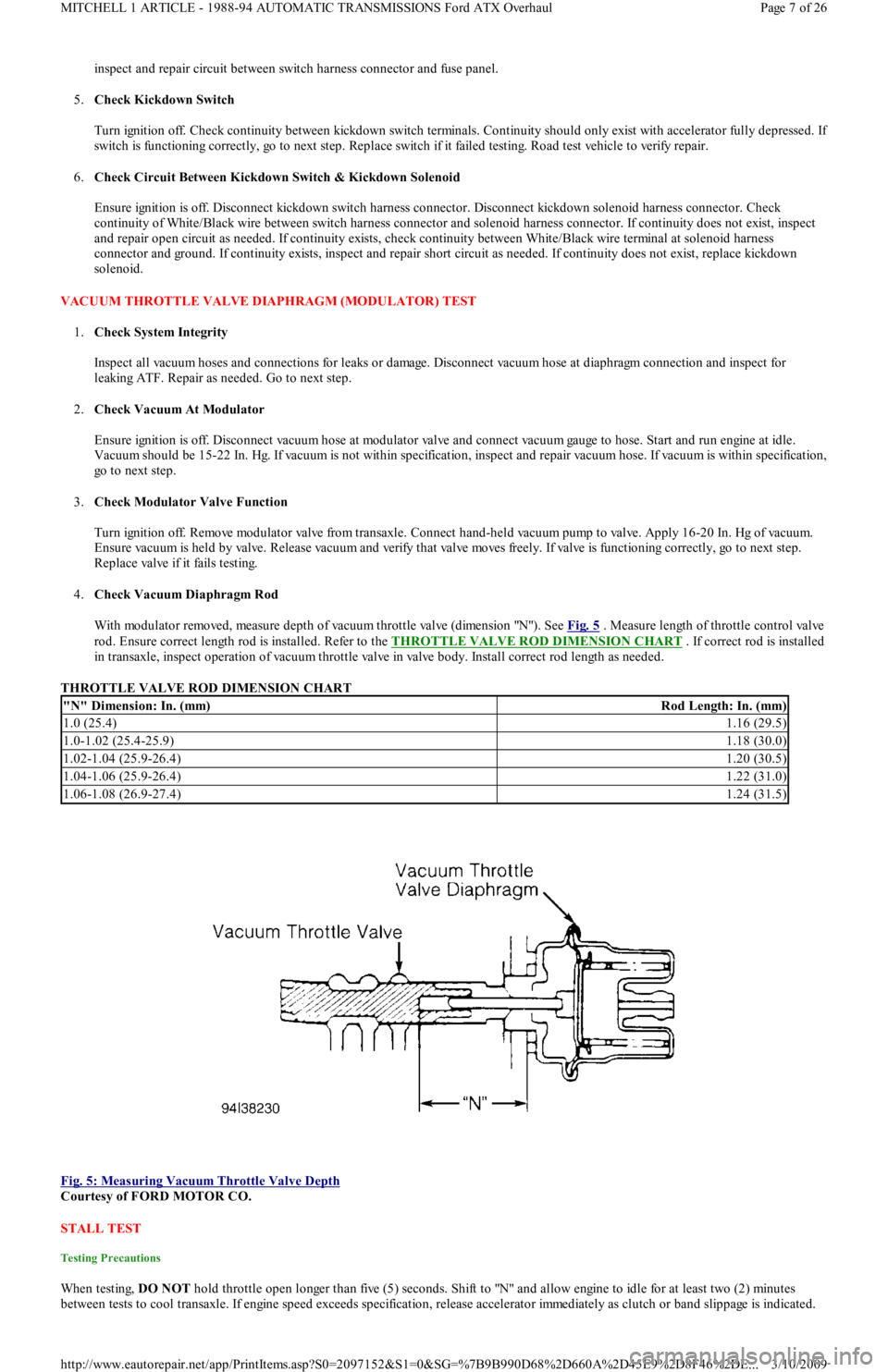

4.Check Vacuum Diaphragm Rod

With modulator removed, measure depth of vacuum throttle valve (dimension "N"). See Fig. 5

. Measure length of throttle control valve

rod. Ensure correct length rod is installed. Refer to the THROTTLE VALVE ROD DIMENSION CHART

. If correct rod is installed

in transaxle, inspect operation of vacuum throttle valve in valve body. Install correct rod length as needed.

THROTTLE VALVE ROD DIMENSION CHART

Fig. 5: Measuring Vacuum Throttle Valve Depth

Courtesy of FORD MOTOR CO.

STALL TEST

Testing Precautions

When testing, DO NOT hold throttle open longer than five (5) seconds. Shift to "N" and allow engine to idle for at least two (2) minutes

between tests to cool transaxle. If engine speed exceeds specification, release accelerator immediately as clutch or band slippage is indicated.

"N" Dimension: In. (mm)Rod Length: In. (mm)

1.0 (25.4)1.16 (29.5)

1.0-1.02 (25.4-25.9)1.18 (30.0)

1.02-1.04 (25.9-26.4)1.20 (30.5)

1.04-1.06 (25.9-26.4)1.22 (31.0)

1.06-1.08 (26.9-27.4)1.24 (31.5)

Page 7 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 417 of 454

CLUTCH & BAND APPLICATION

CLUTCH & BAND APPLICATION CHART

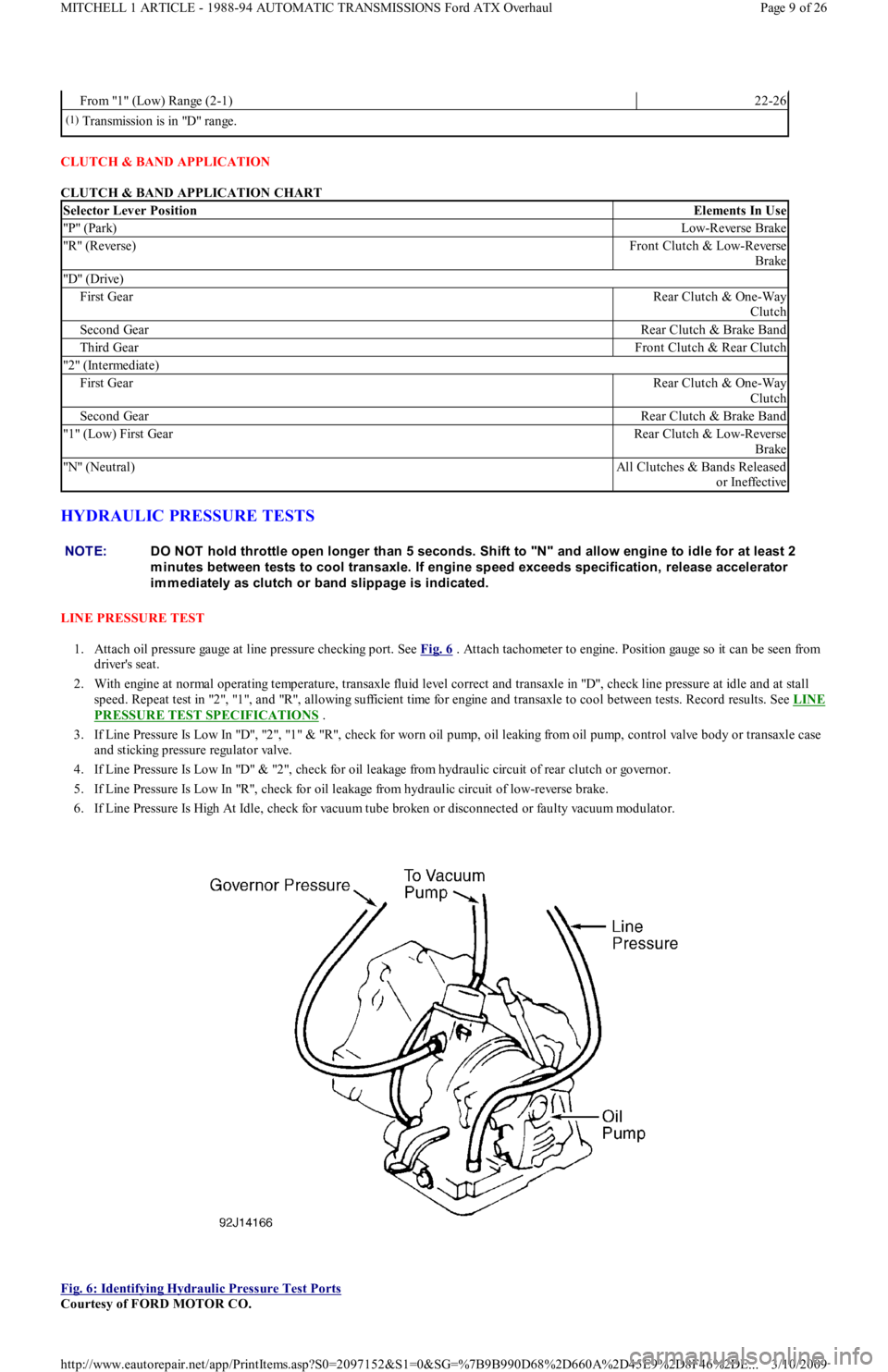

HYDRAULIC PRESSURE TESTS

LINE PRESSURE TEST

1. Attach oil pressure gauge at line pressure checking port. See Fig. 6

. Attach tachometer to engine. Position gauge so it can be seen from

driver's seat.

2. With engine at normal operating temperature, transaxle fluid level correct and transaxle in "D", check line pressure at idle and at stall

sp eed . Rep eat t est in "2 ", "1 ", an d "R", al l o win g su fficien t t ime for engine and transaxle to cool between tests. Record results. See LINE

PRESSURE TEST SPECIFICATIONS .

3 . If Lin e Pressu re Is Lo w In "D", "2 ", "1 " & "R", ch eck fo r worn oil pump, oil leaking from oil pump, control valve body or transaxle case

and sticking pressure regulator valve.

4. If Line Pressure Is Low In "D" & "2", check for oil leakage from hydraulic circuit of rear clutch or governor.

5. If Line Pressure Is Low In "R", check for oil leakage from hydraulic circuit of low-reverse brake.

6. If Line Pressure Is High At Idle, check for vacuum tube broken or disconnected or faulty vacuum modulator.

Fig. 6: Identifying Hydraulic Pressure Test Ports

Courtesy of FORD MOTOR CO.

From "1" (Low) Range (2-1)22-26

(1)Transmission is in "D" range.

Selector Lever PositionElements In Use

"P" (Park)Low-Reverse Brake

"R" (Reverse)Front Clutch & Low-Reverse

Brake

"D" (Drive)

First GearRear Clutch & One-Way

Clutch

Second GearRear Clutch & Brake Band

Third GearFront Clutch & Rear Clutch

"2" (Intermediate)

First GearRear Clutch & One-Way

Clutch

Second GearRear Clutch & Brake Band

"1" (Low) First GearRear Clutch & Low-Reverse

Brake

"N" (Neutral)All Clutches & Bands Released

o r In effect ive

NOTE:DO NOT hold throttle open longer than 5 seconds. Shift to "N" and allow engine to idle for at least 2

m inutes between tests to cool transaxle. If engine speed exceeds specification, release accelerator

im m ediately as clutch or band slippage is indicated.

Page 9 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...