FORD FIESTA 1989 Service Owners Manual

Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 91 of 296

necessary for reassembly of the engine are at

hand. In addition to all normal tools and

materials, jointing and thread locking

compound will be needed during engine

reassembly. For general-purpose applications,

it is recommended that Loctite 275 setting

sealer or Hylomar PL32M non-setting sealer

be used for joints where required, and

Loctite 270 for stud and bolt thread-locking.

For specific applications on Zetec engines,

Hylosil 102 for the cylinder block/crankcase-

to-sump/oil pump/oil seal carrier joints, and

Loctite 518 for the camshaft right-hand

bearing caps should be used. These are

recommended by, and obtained from, Ford

dealers. In all other cases, provided the

relevant mating surfaces are clean and flat,

new gaskets will be sufficient to ensure joints

are oil-tight. Do notuse any kind of silicone-

based sealant on any part of the fuel system or

inlet manifold, and neveruse exhaust sealants

upstream of the catalytic converter.

2 In order to save time and avoid problems,

engine reassembly can be carried out in the

following order (as applicable).

a) Engine ventilation cap (CVH and PTE engines).

b) Tappets and camshaft (HCS engines).

c) Crankshaft and main bearings.

d) Pistons and connecting rods.

e) Oil pump.

f) Sump.

g) Flywheel/driveplate.

h) Cylinder head.

i) Timing sprockets and chain/belt.

j) Engine external components.

3 Ensure that everything is clean prior to

reassembly. As mentioned previously, dirt and

metal particles can quickly destroy bearings

and result in major engine damage. Use clean

engine oil to lubricate during reassembly.

16 Piston rings - refitting

2

1Before installing new piston rings, check

the end gaps. Lay out each piston set with a

piston/connecting rod assembly, and keep them together as a matched set from now on.

2

Insert the top compression ring into the first

cylinder, and square it up with the cylinder

walls by pushing it in with the top of the

piston. The ring should be near the bottom of

the cylinder, at the lower limit of ring travel.

3 To measure the end gap, slip feeler gauges

between the ends of the ring, until a gauge

equal to the gap width is found. The feeler

gauge should slide between the ring ends

with a slight amount of drag. Compare the

measurement to the value given in the

Specifications in this Chapter; if the gap is

larger or smaller than specified, double-check to make sure you have the correct rings

before proceeding. If you are assessing the

condition of used rings, have the cylinder

bores checked and measured by a Ford

dealer or similar engine reconditioning

specialist, so that you can be sure of exactly

which component is worn, and seek advice as

to the best course of action to take.

4 If the end gap is still too small, it must be

opened up by careful filing of the ring ends

using a fine file. If it is too large, this is not as

serious, unless the specified limit is exceeded,

in which case very careful checking is

required of the dimensions of all components,

as well as of the new parts.

5 Repeat the procedure for each ring that will

be installed in the first cylinder, and for each

ring in the remaining cylinders. Remember to

keep rings, pistons and cylinders matched up.

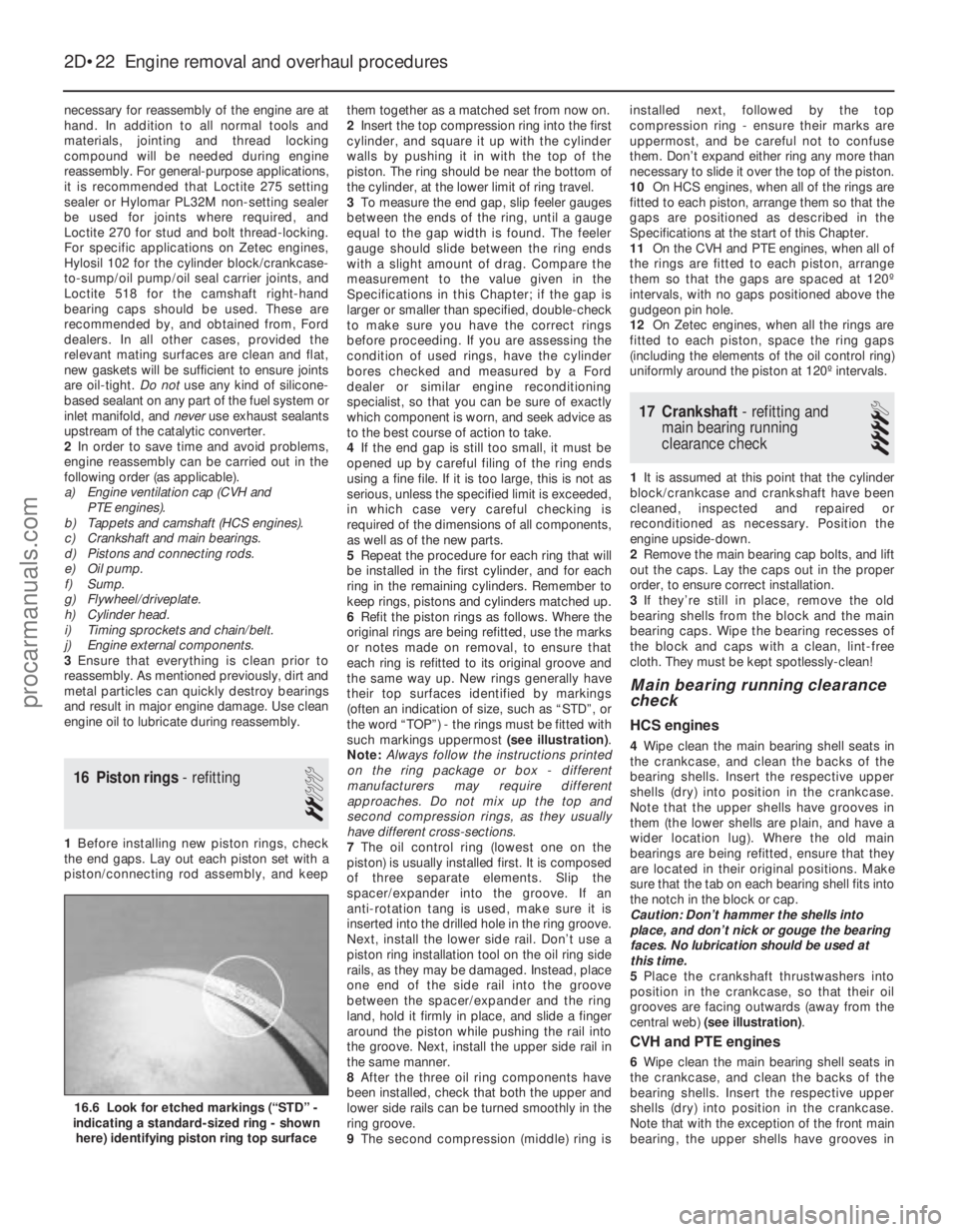

6 Refit the piston rings as follows. Where the

original rings are being refitted, use the marks

or notes made on removal, to ensure that

each ring is refitted to its original groove and

the same way up. New rings generally have

their top surfaces identified by markings

(often an indication of size, such as “STD”, or

the word “TOP”) - the rings must be fitted with

such markings uppermost (see illustration) .

Note: Always follow the instructions printed

on the ring package or box - different

manufacturers may require different

approaches. Do not mix up the top and

second compression rings, as they usually

have different cross-sections.

7 The oil control ring (lowest one on the

piston) is usually installed first. It is composed

of three separate elements. Slip the

spacer/expander into the groove. If an

anti- rotation tang is used, make sure it is

inserted into the drilled hole in the ring groove.

Next, install the lower side rail. Don’t use a

piston ring installation tool on the oil ring side

rails, as they may be damaged. Instead, place

one end of the side rail into the groove

between the spacer/expander and the ring

land, hold it firmly in place, and slide a finger

around the piston while pushing the rail into

the groove. Next, install the upper side rail in

the same manner.

8 After the three oil ring components have

been installed, check that both the upper and

lower side rails can be turned smoothly in the

ring groove.

9 The second compression (middle) ring is installed next, followed by the top

compression ring - ensure their marks are

uppermost, and be careful not to confuse

them. Don’t expand either ring any more than

necessary to slide it over the top of the piston.

10

On HCS engines, when all of the rings are

fitted to each piston, arrange them so that the

gaps are positioned as described in the

Specifications at the start of this Chapter.

11 On the CVH and PTE engines, when all of

the rings are fitted to each piston, arrange

them so that the gaps are spaced at 120º

intervals, with no gaps positioned above the

gudgeon pin hole.

12 On Zetec engines, when all the rings are

fitted to each piston, space the ring gaps

(including the elements of the oil control ring)

uniformly around the piston at 120º intervals.

17 Crankshaft - refitting and

main bearing running

clearance check

4

1 It is assumed at this point that the cylinder

block/crankcase and crankshaft have been

cleaned, inspected and repaired or

reconditioned as necessary. Position the

engine upside-down.

2 Remove the main bearing cap bolts, and lift

out the caps. Lay the caps out in the proper

order, to ensure correct installation.

3 If they’re still in place, remove the old

bearing shells from the block and the main

bearing caps. Wipe the bearing recesses of

the block and caps with a clean, lint-free

cloth. They must be kept spotlessly-clean!

Main bearing running clearance

check

HCS engines

4 Wipe clean the main bearing shell seats in

the crankcase, and clean the backs of the

bearing shells. Insert the respective upper

shells (dry) into position in the crankcase.

Note that the upper shells have grooves in

them (the lower shells are plain, and have a

wider location lug). Where the old main

bearings are being refitted, ensure that they

are located in their original positions. Make

sure that the tab on each bearing shell fits into

the notch in the block or cap.

Caution: Don’t hammer the shells into

place, and don’t nick or gouge the bearing

faces. No lubrication should be used at

this time.

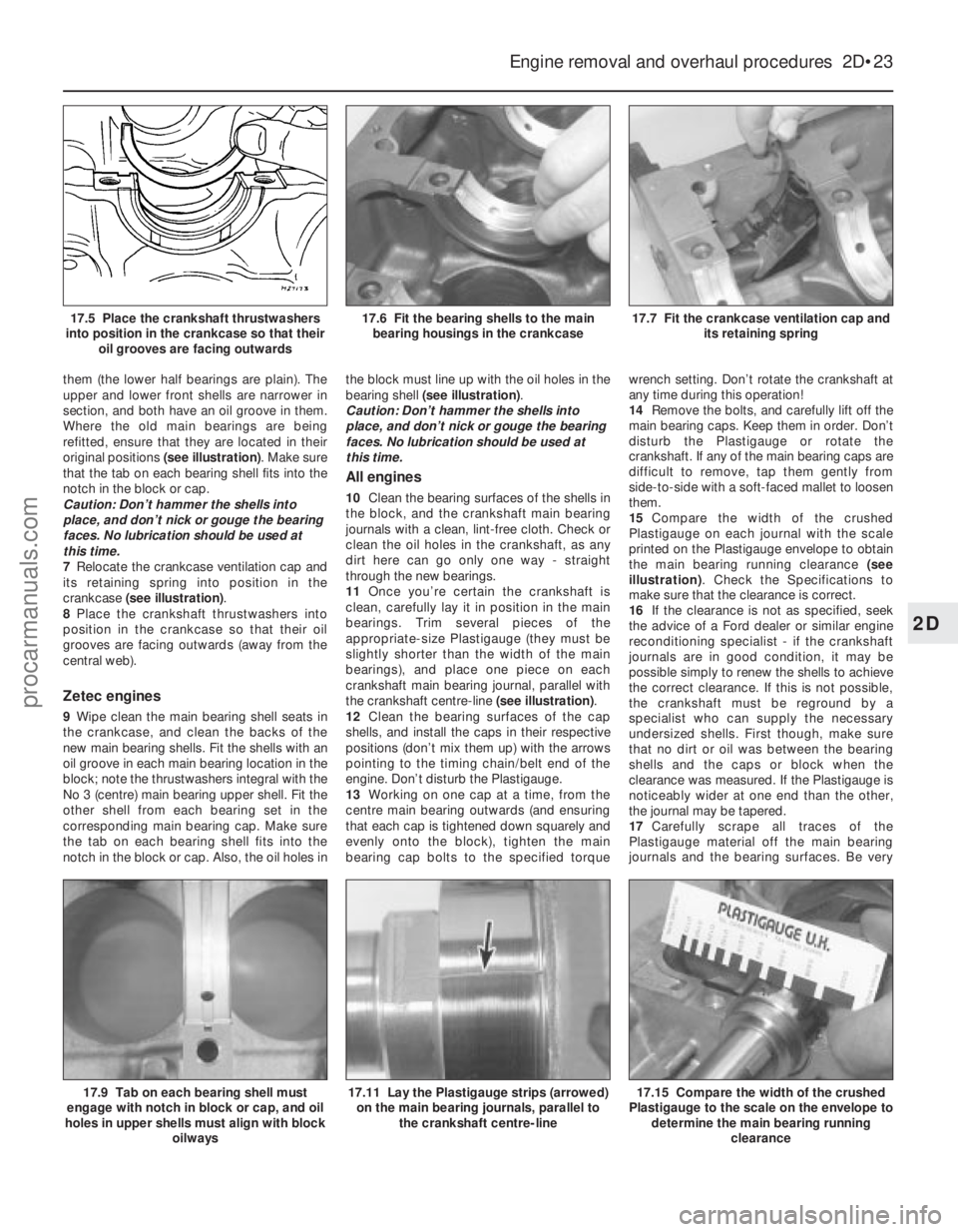

5 Place the crankshaft thrustwashers into

position in the crankcase, so that their oil

grooves are facing outwards (away from the

central web) (see illustration) .

CVH and PTE engines

6Wipe clean the main bearing shell seats in

the crankcase, and clean the backs of the

bearing shells. Insert the respective upper

shells (dry) into position in the crankcase.

Note that with the exception of the front main

bearing, the upper shells have grooves in

2D•22 Engine removal and overhaul procedures

16.6 Look for etched markings (“STD” -

indicating a standard-sized ring - shown

here) identifying piston ring top surface

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 92 of 296

them (the lower half bearings are plain). The

upper and lower front shells are narrower in

section, and both have an oil groove in them.

Where the old main bearings are being

refitted, ensure that they are located in their

original positions (see illustration). Make sure

that the tab on each bearing shell fits into the

notch in the block or cap.

Caution: Don’t hammer the shells into

place, and don’t nick or gouge the bearing

faces. No lubrication should be used at

this time.

7 Relocate the crankcase ventilation cap and

its retaining spring into position in the

crankcase (see illustration) .

8 Place the crankshaft thrustwashers into

position in the crankcase so that their oil

grooves are facing outwards (away from the

central web).

Zetec engines

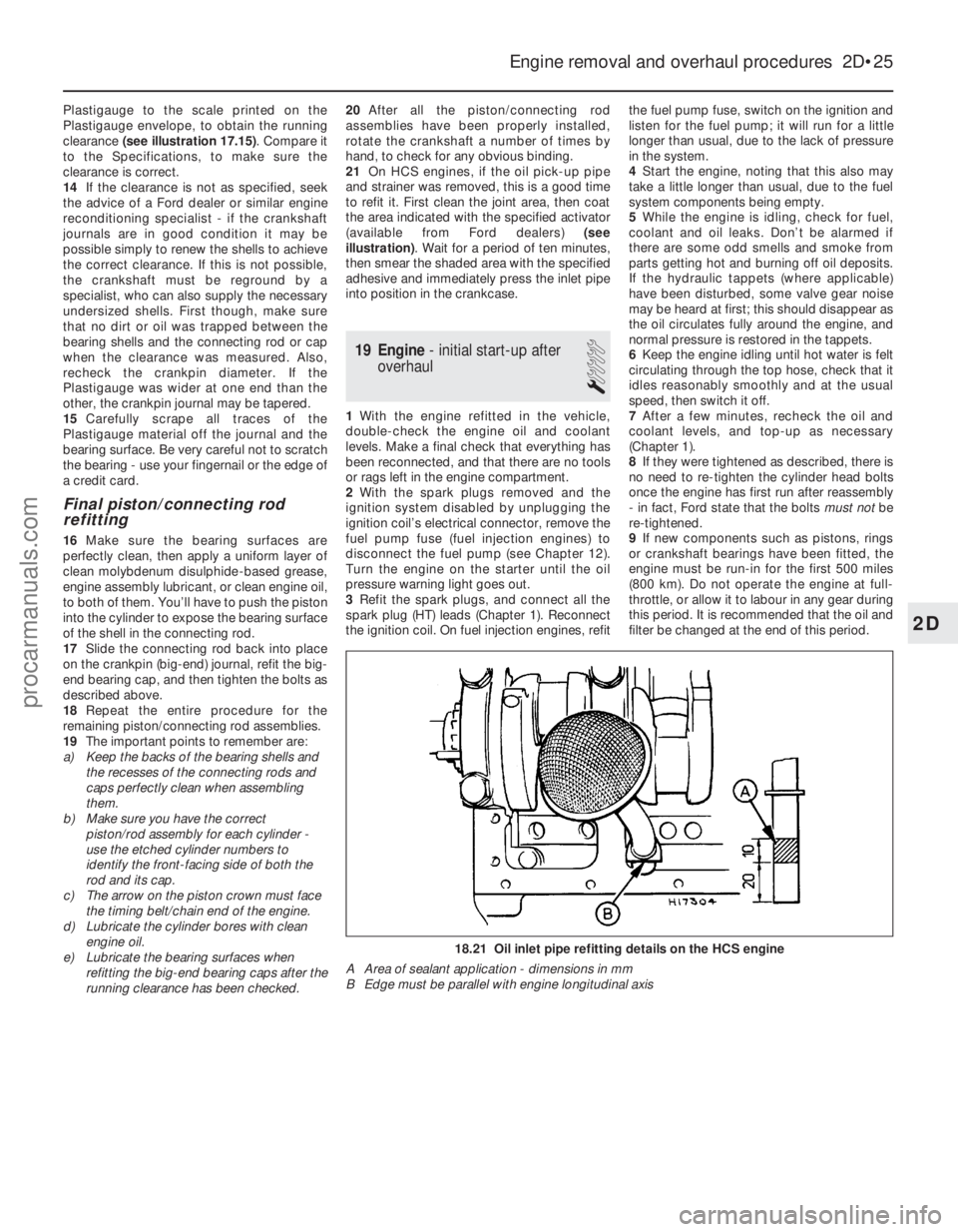

9 Wipe clean the main bearing shell seats in

the crankcase, and clean the backs of the

new main bearing shells. Fit the shells with an

oil groove in each main bearing location in the

block; note the thrustwashers integral with the

No 3 (centre) main bearing upper shell. Fit the

other shell from each bearing set in the

corresponding main bearing cap. Make sure

the tab on each bearing shell fits into the

notch in the block or cap. Also, the oil holes in the block must line up with the oil holes in the

bearing shell

(see illustration) .

Caution: Don’t hammer the shells into

place, and don’t nick or gouge the bearing

faces. No lubrication should be used at

this time.

All engines

10 Clean the bearing surfaces of the shells in

the block, and the crankshaft main bearing

journals with a clean, lint-free cloth. Check or

clean the oil holes in the crankshaft, as any

dirt here can go only one way - straight

through the new bearings.

11 Once you’re certain the crankshaft is

clean, carefully lay it in position in the main

bearings. Trim several pieces of the

appropriate-size Plastigauge (they must be

slightly shorter than the width of the main

bearings), and place one piece on each

crankshaft main bearing journal, parallel with

the crankshaft centre-line (see illustration).

12 Clean the bearing surfaces of the cap

shells, and install the caps in their respective

positions (don’t mix them up) with the arrows

pointing to the timing chain/belt end of the

engine. Don’t disturb the Plastigauge.

13 Working on one cap at a time, from the

centre main bearing outwards (and ensuring

that each cap is tightened down squarely and

evenly onto the block), tighten the main

bearing cap bolts to the specified torque wrench setting. Don’t rotate the crankshaft at

any time during this operation!

14

Remove the bolts, and carefully lift off the

main bearing caps. Keep them in order. Don’t

disturb the Plastigauge or rotate the

crankshaft. If any of the main bearing caps are

difficult to remove, tap them gently from

side-to-side with a soft-faced mallet to loosen

them.

15 Compare the width of the crushed

Plastigauge on each journal with the scale

printed on the Plastigauge envelope to obtain

the main bearing running clearance (see

illustration) . Check the Specifications to

make sure that the clearance is correct.

16 If the clearance is not as specified, seek

the advice of a Ford dealer or similar engine

reconditioning specialist - if the crankshaft

journals are in good condition, it may be

possible simply to renew the shells to achieve

the correct clearance. If this is not possible,

the crankshaft must be reground by a

specialist who can supply the necessary

undersized shells. First though, make sure

that no dirt or oil was between the bearing

shells and the caps or block when the

clearance was measured. If the Plastigauge is

noticeably wider at one end than the other,

the journal may be tapered.

17 Carefully scrape all traces of the

Plastigauge material off the main bearing

journals and the bearing surfaces. Be very

Engine removal and overhaul procedures 2D•23

17.7 Fit the crankcase ventilation cap and its retaining spring17.6 Fit the bearing shells to the mainbearing housings in the crankcase

17.15 Compare the width of the crushed

Plastigauge to the scale on the envelope to determine the main bearing running

clearance17.11 Lay the Plastigauge strips (arrowed)on the main bearing journals, parallel to the crankshaft centre-line17.9 Tab on each bearing shell must

engage with notch in block or cap, and oil

holes in upper shells must align with block

oilways

2D

1595Ford Fiesta Remake

17.5 Place the crankshaft thrustwashers

into position in the crankcase so that their oil grooves are facing outwardsprocarmanuals.com

http://vnx.su

Page 93 of 296

careful not to scratch the bearing - use your

fingernail or the edge of a credit card.

Final crankshaft refitting

18Carefully lift the crankshaft out of the

engine. Clean the bearing surfaces of the

shells in the block, then apply a thin, uniform

layer of clean molybdenum disulphide- based

grease, engine assembly lubricant, or clean

engine oil to each surface. Coat the

thrustwasher surfaces as well.

19 Lubricate the crankshaft oil seal journals

with molybdenum disulphide-based grease,

engine assembly lubricant, or clean engine oil.

20 Make sure the crankshaft journals are

clean, then lay the crankshaft back in place in

the block (see illustration) . Clean the bearing

surfaces of the shells in the caps, then

lubricate them. Install the caps in their

respective positions, with the arrows pointing

to the timing belt/chain end of the engine.

21 Working on one cap at a time, from the

centre main bearing outwards (and ensuring

that each cap is tightened down squarely and

evenly onto the block), tighten the main

bearing cap bolts to the specified torque

wrench setting.

22 Rotate the crankshaft a number of times

by hand, to check for any obvious binding.

23 Check the crankshaft endfloat (see Sec-

tion 12). It should be correct if the crankshaft

thrust faces aren’t worn or damaged.

24 Refit the crankshaft left-hand oil seal

carrier, and install a new seal (see Part A, B

or C of this Chapter according to engine type).

18 Piston/connecting rod

assemblies - refitting and big-end

bearing running clearance check

4

Note: On HCS engines, new big-end bearing

cap retaining bolts will be required for

reassembly.

1 Before refitting the piston/connecting rod

assemblies, the cylinder bores must be

perfectly clean, the top edge of each cylinder

must be chamfered, and the crankshaft must

be in place.

2 Remove the big-end bearing cap from No 1

cylinder connecting rod (refer to the marks

noted or made on removal). Remove the

original bearing shells, and wipe the bearing

recesses of the connecting rod and cap with a

clean, lint-free cloth. They must be kept

spotlessly-clean!

Big-end bearing running

clearance check

3 Clean the back of the new upper bearing

shell, fit it to the connecting rod, then fit the

other shell of the bearing set to the big-end

bearing cap. Make sure that the tab on each

shell fits into the notch in the rod or cap

recess (see illustration) .

Caution: Don’t hammer the shells into

place, and don’t nick or gouge the bearing

face. Don’t lubricate the bearing at this

time.

4 It’s critically important that all mating

surfaces of the bearing components are

perfectly clean and oil-free when they’re

assembled.

5 Position the piston ring gaps as described

in Section 16, lubricate the piston and rings

with clean engine oil, and attach a piston ring

compressor to the piston. Leave the skirt

protruding about a quarter-inch, to guide the

piston into the cylinder bore. The rings must

be compressed until they’re flush with the

piston.

6 Rotate the crankshaft until No 1 crankpin

(big-end) journal is at BDC (Bottom Dead

Centre), and apply a coat of engine oil to the

cylinder walls.

7 Arrange the No 1 piston/connecting rod

assembly so that the arrow on the piston crown points to the timing belt/chain end of

the engine. Gently insert the assembly into the

No 1 cylinder bore, and rest the bottom edge

of the ring compressor on the engine block.

8

Tap the top edge of the ring compressor to

make sure it’s contacting the block around its

entire circumference.

9 Gently tap on the top of the piston with the

end of a wooden hammer handle (see

illustration) , while guiding the connecting

rod’s big-end onto the crankpin. The piston

rings may try to pop out of the ring

compressor just before entering the cylinder

bore, so keep some pressure on the ring

compressor. Work slowly, and if any

resistance is felt as the piston enters the

cylinder, stop immediately. Find out what’s

binding, and fix it before proceeding. Do not,

for any reason, force the piston into the

cylinder - you might break a ring and/or the

piston.

10 To check the big-end bearing running

clearance, cut a piece of the appropriate-size

Plastigauge slightly shorter than the width of

the connecting rod bearing, and lay it in place

on the No 1 crankpin (big-end) journal, parallel

with the crankshaft centre-line (see

illustration 17.11).

11 Clean the connecting rod-to-cap mating

surfaces, and refit the big-end bearing cap.

Tighten the cap bolts evenly - on the HCS and

Zetec engines, first use a torque wrench to

tighten the bolts to the Stage 1 torque setting,

then use an ordinary socket extension bar and

an angle gauge to tighten the bolts further

through the Stage 2 angle (see illustration).

On the CVH and PTE engines, tighten the

bolts progressively to the specified torque;

further angle-tightening is not required on

these engines. Use a thin-wall socket, to

avoid erroneous torque readings that can

result if the socket is wedged between the

cap and nut. If the socket tends to wedge

itself between the nut and the cap, lift up on it

slightly until it no longer contacts the cap.

Don’t rotate the crankshaft at any time during

this operation!

12 Unscrew the bolts and detach the cap,

being very careful not to disturb the

Plastigauge.

13 Compare the width of the crushed

2D•24 Engine removal and overhaul procedures

18.11 Angle-tightening the big-end bolts

using the correct tool18.9 The piston can be driven gently into

the cylinder bore with the end of a wooden

or plastic hammer handle18.3 Tab on each big-end bearing shell

must engage with notch in connecting rod

or cap

17.20 Refit the crankshaft after checkingbearing clearances

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 94 of 296

Plastigauge to the scale printed on the

Plastigauge envelope, to obtain the running

clearance (see illustration 17.15) . Compare it

to the Specifications, to make sure the

clearance is correct.

14 If the clearance is not as specified, seek

the advice of a Ford dealer or similar engine

reconditioning specialist - if the crankshaft

journals are in good condition it may be

possible simply to renew the shells to achieve

the correct clearance. If this is not possible,

the crankshaft must be reground by a

specialist, who can also supply the necessary

undersized shells. First though, make sure

that no dirt or oil was trapped between the

bearing shells and the connecting rod or cap

when the clearance was measured. Also,

recheck the crankpin diameter. If the

Plastigauge was wider at one end than the

other, the crankpin journal may be tapered.

15 Carefully scrape all traces of the

Plastigauge material off the journal and the

bearing surface. Be very careful not to scratch

the bearing - use your fingernail or the edge of a credit card.

Final piston/connecting rod

refitting

16 Make sure the bearing surfaces are

perfectly clean, then apply a uniform layer of

clean molybdenum disulphide-based grease,

engine assembly lubricant, or clean engine oil,

to both of them. You’ll have to push the piston

into the cylinder to expose the bearing surface

of the shell in the connecting rod.

17 Slide the connecting rod back into place

on the crankpin (big-end) journal, refit the big-

end bearing cap, and then tighten the bolts as

described above.

18 Repeat the entire procedure for the

remaining piston/connecting rod assemblies.

19 The important points to remember are:

a) Keep the backs of the bearing shells and the recesses of the connecting rods and

caps perfectly clean when assembling

them.

b) Make sure you have the correct

piston/rod assembly for each cylinder -

use the etched cylinder numbers to

identify the front-facing side of both the

rod and its cap.

c) The arrow on the piston crown must face the timing belt/chain end of the engine.

d) Lubricate the cylinder bores with clean

engine oil.

e) Lubricate the bearing surfaces when refitting the big-end bearing caps after the

running clearance has been checked. 20

After all the piston/connecting rod

assemblies have been properly installed,

rotate the crankshaft a number of times by

hand, to check for any obvious binding.

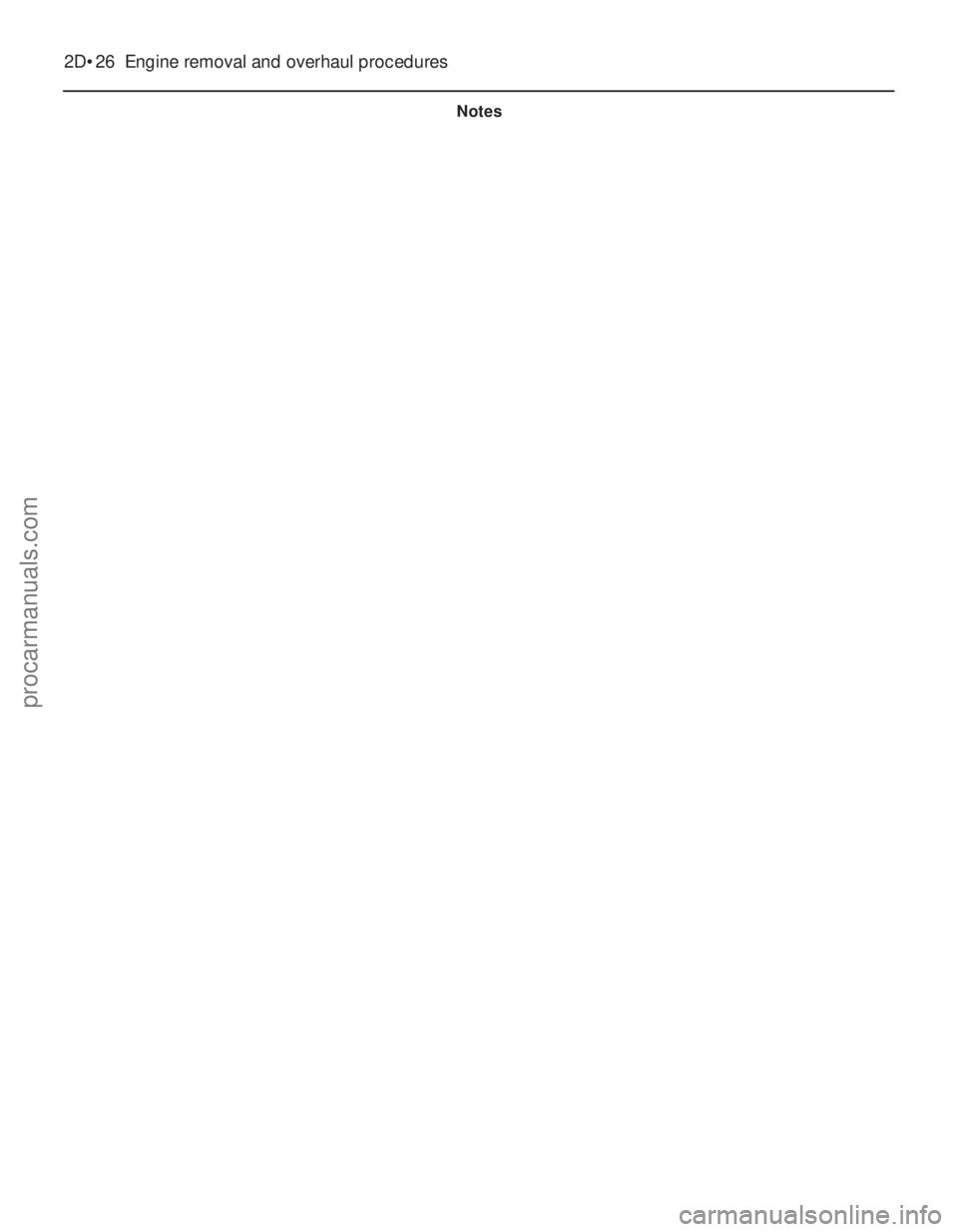

21 On HCS engines, if the oil pick-up pipe

and strainer was removed, this is a good time

to refit it. First clean the joint area, then coat

the area indicated with the specified activator

(available from Ford dealers) (see

illustration) . Wait for a period of ten minutes,

then smear the shaded area with the specified

adhesive and immediately press the inlet pipe

into position in the crankcase.

19 Engine - initial start-up after

overhaul

1

1 With the engine refitted in the vehicle,

double-check the engine oil and coolant

levels. Make a final check that everything has

been reconnected, and that there are no tools

or rags left in the engine compartment.

2 With the spark plugs removed and the

ignition system disabled by unplugging the

ignition coil’s electrical connector, remove the

fuel pump fuse (fuel injection engines) to

disconnect the fuel pump (see Chapter 12).

Turn the engine on the starter until the oil

pressure warning light goes out.

3 Refit the spark plugs, and connect all the

spark plug (HT) leads (Chapter 1). Reconnect

the ignition coil. On fuel injection engines, refit the fuel pump fuse, switch on the ignition and

listen for the fuel pump; it will run for a little

longer than usual, due to the lack of pressure

in the system.

4

Start the engine, noting that this also may

take a little longer than usual, due to the fuel

system components being empty.

5 While the engine is idling, check for fuel,

coolant and oil leaks. Don’t be alarmed if

there are some odd smells and smoke from

parts getting hot and burning off oil deposits.

If the hydraulic tappets (where applicable)

have been disturbed, some valve gear noise

may be heard at first; this should disappear as

the oil circulates fully around the engine, and

normal pressure is restored in the tappets.

6 Keep the engine idling until hot water is felt

circulating through the top hose, check that it

idles reasonably smoothly and at the usual

speed, then switch it off.

7 After a few minutes, recheck the oil and

coolant levels, and top-up as necessary

(Chapter 1).

8 If they were tightened as described, there is

no need to re-tighten the cylinder head bolts

once the engine has first run after reassembly

- in fact, Ford state that the bolts must notbe

re-tightened.

9 If new components such as pistons, rings

or crankshaft bearings have been fitted, the

engine must be run-in for the first 500 miles

(800 km). Do not operate the engine at full-

throttle, or allow it to labour in any gear during

this period. It is recommended that the oil and

filter be changed at the end of this period.

Engine removal and overhaul procedures 2D•25

18.21 Oil inlet pipe refitting details on the HCS engine

A Area of sealant application - dimensions in mm

B Edge must be parallel with engine longitudinal axis

2D

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 95 of 296

2D•26 Engine removal and overhaul procedures

1595Ford Fiesta Remake

Notes

procarmanuals.com

http://vnx.su

Page 96 of 296

3

1595Ford Fiesta Remake

Coolant

Mixture type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . See Chapter 1

Cooling system capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

See Chapter 1

System pressure

Pressure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . 1.2 bars - should hold this pressure for at least 10 seconds

Expansion tank filler cap

Pressure rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1.0 to 1.4 bars approximately - see cap for actual value

Thermostat

Starts to open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . 85ºC to 89ºC

Coolant temperature sensor

Resistance:At 0ºC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . 89 to 102 kilohms

At 20ºC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 35 to 40 kilohms

At 100ºC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 1.9 to 2.5 kilohms

At 120ºC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . 1.0 to 1.4 kilohms

Chapter 3

Cooling, heating and ventilation systems

Antifreeze - general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . .See Chapter 1

Coolant level check . . . . . . . . . . . . . . . . . . . . . . .See

“Weekly Checks”

Cooling system - draining . . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

Cooling system - filling . . . . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

Cooling system - flushing . . . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

Cooling system electrical switches and sensors - testing, removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 6

Cooling system hoses - disconnection and renewal . . . . . . . . . . . . 3

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . 1 Heater/ventilation components - removal and refitting . . . . . . . . . . . 11

Radiator and expansion tank - removal, inspection and refitting . . . 7

Radiator electric cooling fan assembly - testing, removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . 5

Thermostat - removal, testing and refitting . . . . . . . . . . . . . . . . . . . . 4

Underbonnet check for fluid leaks and hose condition . .See Chapter 1

Water pump (CVH and PTE engines) - removal and refitting . . . . . . 9

Water pump (HCS engines) - removal and refitting . . . . . . . . . . . . . 8

Water pump (Zetec engines) - removal and refitting . . . . . . . . . . . . . 10

3•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su

Page 97 of 296

Torque wrench settingsNmlbf ft

Thermostat housing to cylinder head: HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 17 to 21 13 to 16

CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 9 to 12 7 to 9

PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 9 7

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 17 to 21 13 to 16

Water outlet to thermostat housing (Zetec engines) . . . . . . . . . . . . . . . 9 to 12 7 to 9

Water pump pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 107.5

Water pump retaining bolts: HCS, CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 1813

Coolant temperature gauge sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4

Coolant temperature sensor: HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 2317

CVH engines: 1.4 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . 1914

1.6 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . 1511

PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 1511

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 1511

Radiator mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. 20 to 27 15 to 20

Radiator cooling fan shroud retaining bolt . . . . . . . . . . . . . . . . . . . . . . . 3 to 5 2 to 4

Radiator cooling fan motor to shroud nuts . . . . . . . . . . . . . . . . . . . . . . . 9 to 12 7 to 9

Automatic transmission fluid cooling pipe connections to radiator . . . . 17 to 21 13 to 16

3•2 Cooling, heating and ventilation systems

1595Ford Fiesta Remake

1 General information and

precautions

Engine cooling system

The cooling system is of the pressurised

type consisting of a belt-driven pump,

aluminium crossflow radiator, expansion tank,

electric cooling fan and a thermostat. The

system functions as follows. Cold coolant in

the bottom of the radiator passes through the

bottom hose to the water pump, where it is

pumped around the cylinder block and head

passages. After cooling the cylinder bores,

combustion surfaces and valve seats, the

coolant reaches the underside of the

thermostat, which is initially closed. The

coolant passes through the heater and

inlet manifold and is returned to the water

pump. When the engine is cold, the coolant

circulates through the cylinder block, cylinder

head, heater and inlet manifold. When the

coolant reaches a predetermined tempera-

ture, the thermostat opens, and the coolant

then passes through the top hose to

the radiator. As the coolant circulates

through the radiator, it is cooled by the inrush

of air when the car is in forward motion.

Airflow is supplemented by the action of the

electric cooling fan when necessary. Upon

reaching the bottom of the radiator, the

coolant is now cooled, and the cycle is

repeated. When the engine is at normal operating

temperature, the coolant expands, and some

of it is displaced into the expansion tank. This

coolant collects in the tank, and is returned to

the radiator when the system cools.

The electric cooling fan, mounted behind

the radiator, is controlled by a thermostatic switch. At a predetermined coolant

temperature, the switch contacts close, thus

actuating the fan.

Heating/ventilation system

The heating system consists of a blower fan

and heater matrix (radiator) located in the

heater unit, with hoses connecting the heater

matrix to the engine cooling system. Hot

engine coolant is circulated through the

heater matrix. Air is forced through the matrix

by the three-speed fan, dispersing the heat

into the vehicle interior. Fresh air enters the

vehicle through the grille slats between the

windscreen and the rear edge of the bonnet,

and passes through to the heater casing.

Depending on the position of the heater slide

controls, which actuate cable-controlled flap

valves within the heater casing, the air is

distributed, either heated or unheated, via the

ducting to outlet vents. The main outlet vents

in the facia are adjustable. The airflow passes

through the passenger compartment to exit at

the rear of the vehicle.

Precautions

Warning: DO NOT attempt to

remove the expansion tank filler

cap, or to disturb any part of the

cooling system, while it or the

engine is hot, as there is a very great risk

of scalding. If the expansion tank filler cap

must be removed before the engine and

radiator have fully cooled down (even

though this is not recommended) the

pressure in the cooling system must first

be released. Cover the cap with a thick

layer of cloth, to avoid scalding, and slowly

unscrew the filler cap until a hissing sound

can be heard. When the hissing has

stopped, showing that pressure is

released, slowly unscrew the filler cap

further until it can be removed; if more

hissing sounds are heard, wait until they have stopped before unscrewing the cap

completely. At all times, keep well away

from the filler opening.

Warning: Do not allow antifreeze

to come in contact with your

skin, or with the painted

surfaces of the vehicle. Rinse off

spills immediately with plenty of water.

Never leave antifreeze lying around in an

open container, or in a puddle in the

driveway or on the garage floor. Children

and pets are attracted by its sweet smell,

but antifreeze can be fatal if ingested. Warning: If the engine is hot, the

electric cooling fan may start

rotating even if the engine is not

running, so be careful to keep

hands, hair and loose clothing well clear

when working in the engine compartment.

2 Antifreeze -

general information

Note: Refer to the warnings given in Section 1

of this Chapter before proceeding. The cooling system should be filled with a

water/ethylene glycol-based antifreeze

solution, of a strength which will prevent

freezing down to at least -25ºC, or lower if the

local climate requires it. Antifreeze also

provides protection against corrosion, and

increases the coolant boiling point. The cooling system should be maintained

according to the schedule described in

Chapter 1. If antifreeze is used that is not to

Ford’s specification, old or contaminated

coolant mixtures are likely to cause damage,

and encourage the formation of corrosion and

scale in the system. Use distilled water with the

antifreeze, if available - if not, be sure to use

only soft water. Clean rainwater is suitable.

procarmanuals.com

http://vnx.su

Page 98 of 296

Before adding antifreeze, check all hoses

and hose connections, because antifreeze

tends to leak through very small openings.

Engines don’t normally consume coolant, so if

the level falls regularly, find the cause and

correct it. The exact mixture of antifreeze-to-water

which you should use depends on the relative

weather conditions. The mixture should

contain at least 40% antifreeze, but not more

than 70%. Consult the mixture ratio chart on

the antifreeze container before adding

coolant. Hydrometers are available at most

automotive accessory shops to test the

coolant. Use only good-quality ethylene-

glycol-based antifreeze which meets the

vehicle manufacturer’s specifications.

3 Cooling system hoses -

disconnection and renewal

1

Note: Refer to the warnings given in Section 1

of this Chapter before starting work.

1 If the checks described in Chapter 1 reveal

a faulty hose, it must be renewed as follows.

2 First drain the cooling system (see Chap-

ter 1); if the antifreeze is not due for renewal,

the drained coolant may be re-used, if it is

collected in a clean container.

3 To disconnect any hose, use a pair of pliers

to release the spring clamps (or a screwdriver

to slacken screw-type clamps), then move

them along the hose clear of the union.

Carefully work the hose off its stubs. The

hoses can be removed with relative ease

when new - on an older car, they may have

stuck.

4 If a hose proves stubborn, try to release it

by rotating it on its unions before attempting

to work it off. Gently prise the end of the hose

with a blunt instrument (such as a flat-bladed

screwdriver), but do not apply too much force,

and take care not to damage the pipe stubs or

hoses. Note in particular that the radiator hose

unions are fragile; do not use excessive force

when attempting to remove the hoses.

5 When refitting a hose, first slide the clamps

onto the hose, then work the hose onto its

unions. 6

Work each hose end fully onto its union,

then check that the hose is settled correctly

and is properly routed. Slide each clip along

the hose until it is behind the union flared end,

before tightening it securely.

7 Refill the system with coolant (see Chap-

ter 1).

8 Check carefully for leaks as soon as

possible after disturbing any part of the

cooling system.

4 Thermostat -

removal, testing and refitting

1

Note: Refer to the warnings given in Section 1

of this Chapter before starting work.

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Drain the cooling system (see Chapter 1).

3 Refer to the relevant Part of Chapter 4 and

remove the air cleaner or air inlet hoses,

according to engine type as necessary, to

gain access to the thermostat housing.

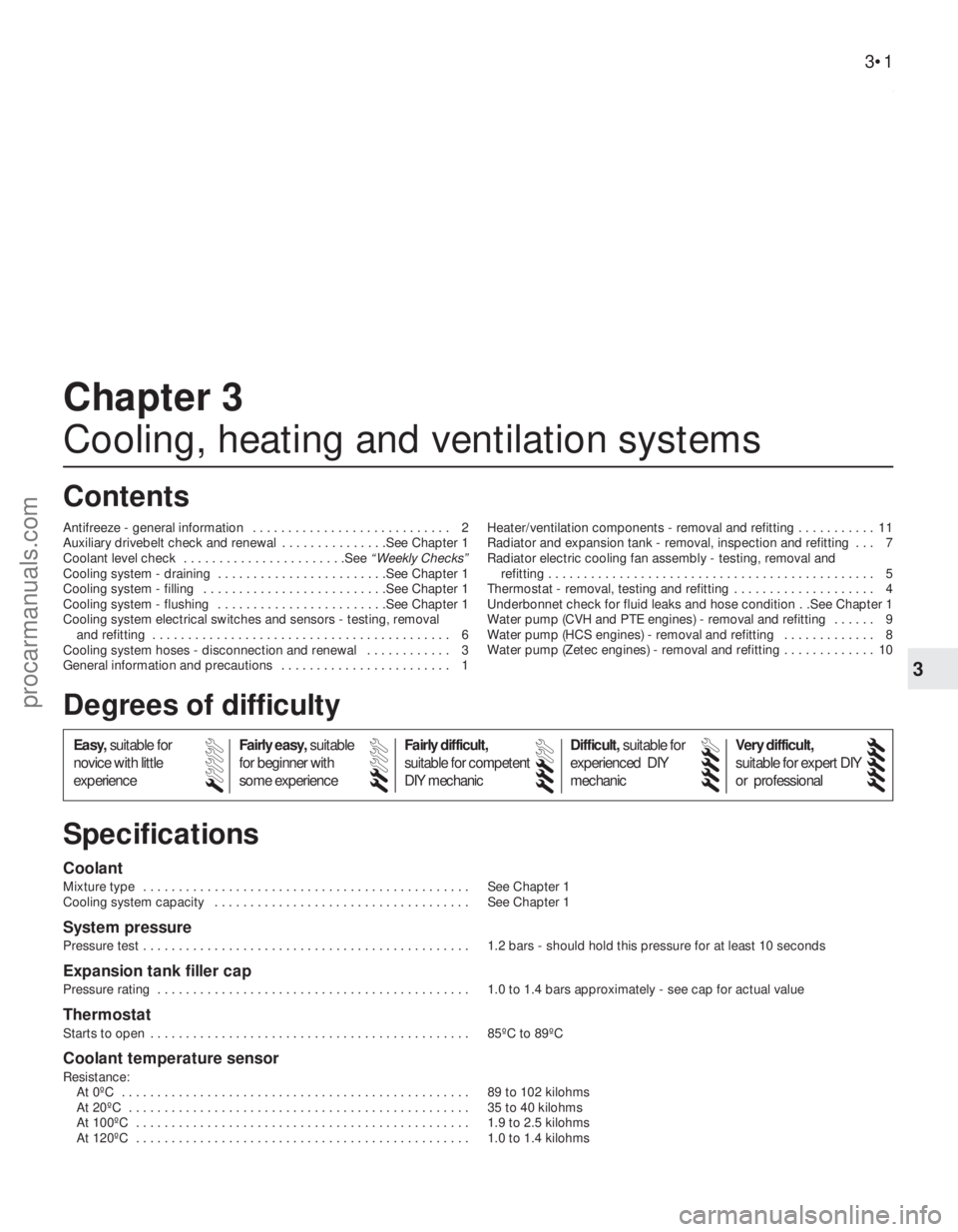

HCS, CVH and PTE engines

4 Loosen the clips, and disconnect the

radiator top hose, expansion tank hose and,

where applicable, the heater hose from the

thermostat housing (see illustrations).5

Disconnect the thermostatic switch wire

multi-plug from the thermostat housing.

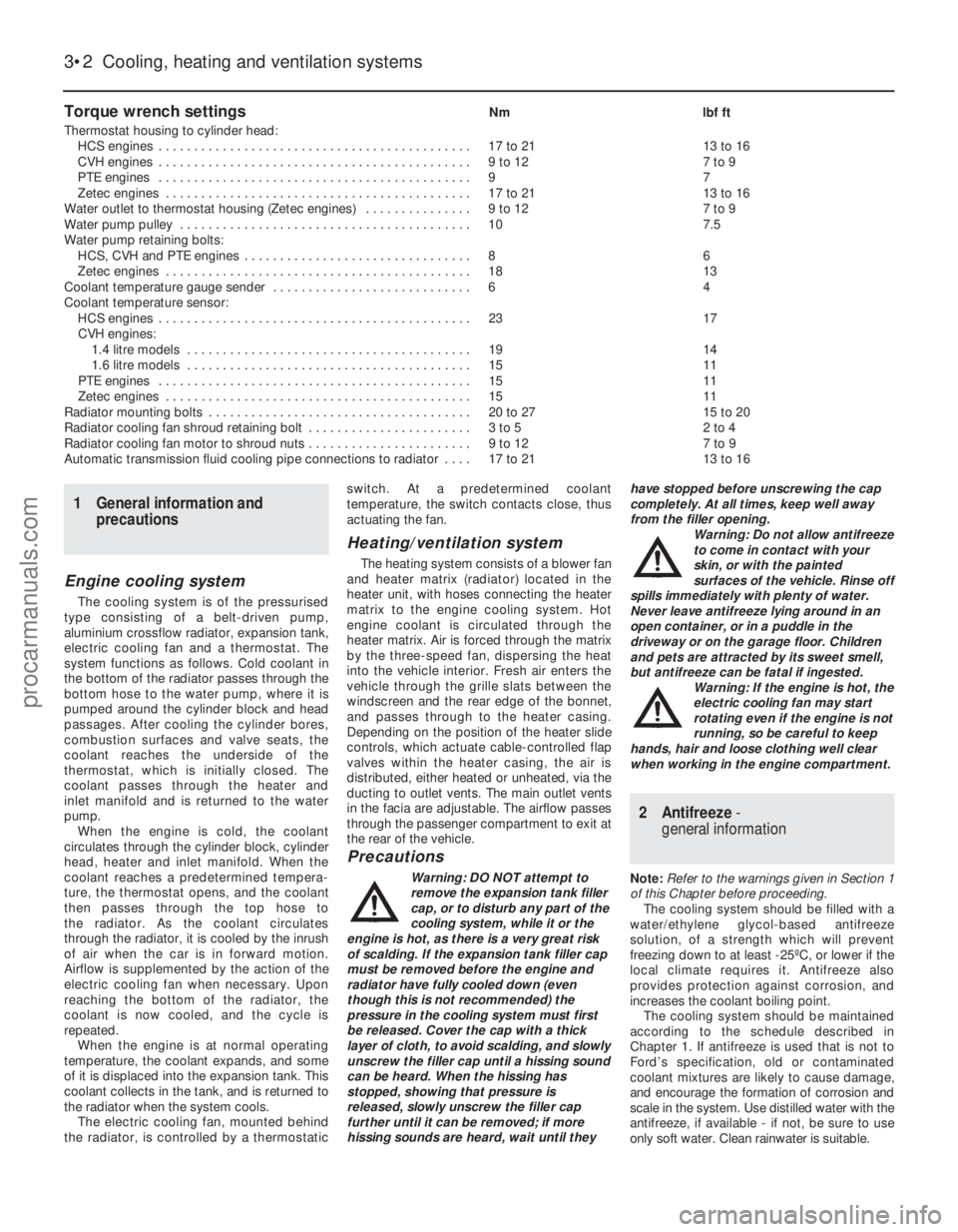

6 Unscrew the retaining bolts, and remove

the thermostat housing (see illustration).

7 Remove the gasket from the mating face of

the thermostat housing, then using suitable

pliers, compress the thermostat retaining clip

(where applicable) and remove it from the

housing. Extract the thermostat from

the housing (noting its direction of fitting) and

where applicable, remove the O-ring seal (see

illustrations) .

Zetec engines

8Disconnect the expansion tank hose and

Cooling, heating and ventilation systems 3•3

4.4b Disconnecting the expansion tank

top hose from the thermostat housing

(HCS engine). Radiator cooling fan thermal switch (arrowed)4.4a Thermostat housing hose

attachments on the CVH engine

4.7b Exploded view of thermostat and housing (CVH and PTE engines)

A Sealing ring C Retaining clip

B Thermostat

4.7a Removing the gasket and thermostat from an HCS engine4.6 Removing the thermostat housingfrom a CVH engine

3

1595Ford Fiesta Remake

If all else fails, cut the hose

with a sharp knife, then slit

it so that it can be peeled off

in two pieces. Although this

may prove expensive if the hose is

otherwise undamaged, it is preferable

to buying a new radiator.

If the hose is stiff, use a little

soapy water as a lubricant,

or soften the hose by

soaking it in hot water. Do

not use oil or grease, which may attack

the rubber.

procarmanuals.com

http://vnx.su

Page 99 of 296

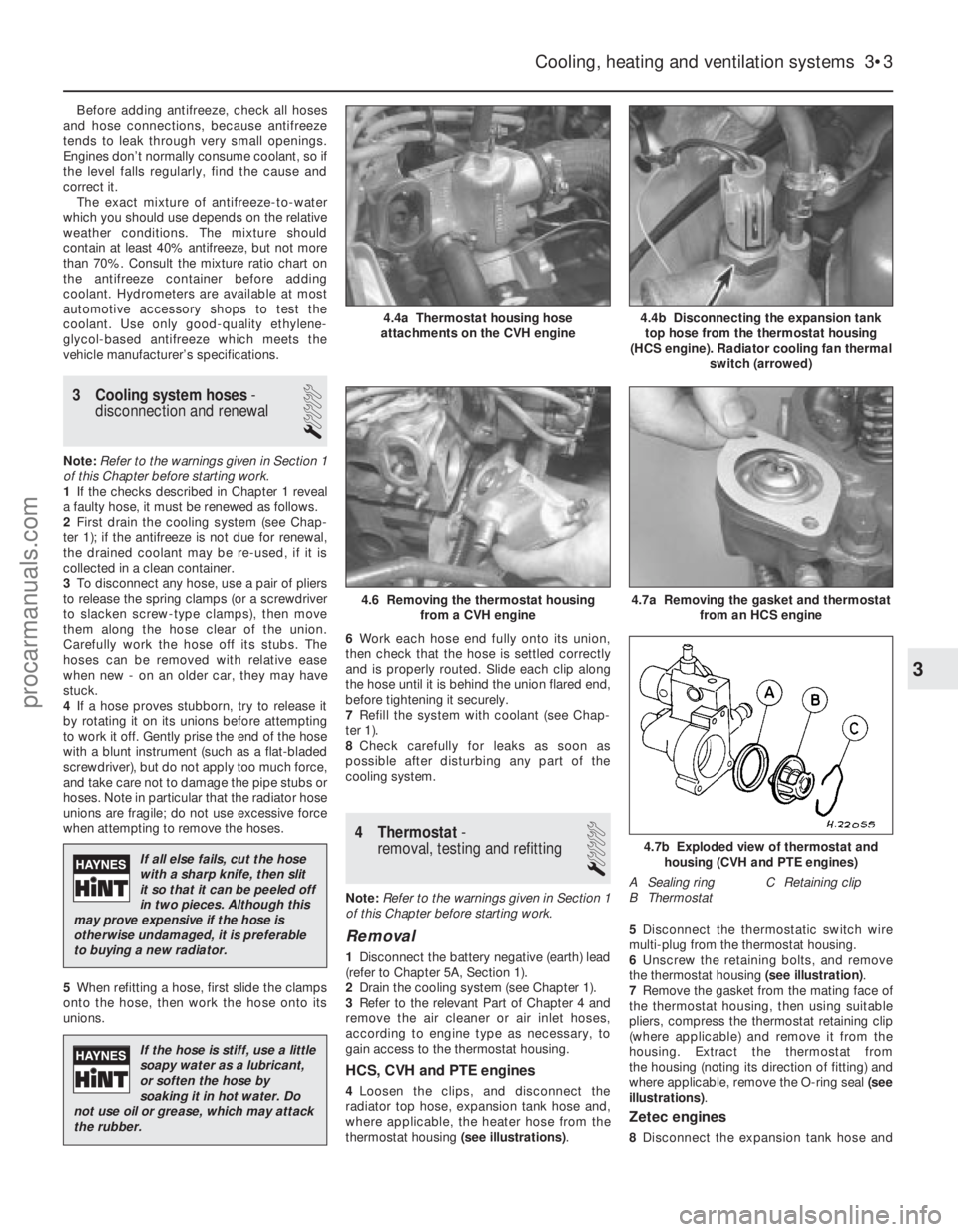

the radiator top hose from the thermostat

housing’s water outlet (see illustration).

9 Unscrew the retaining bolts, and remove

the water outlet from the thermostat housing.

10 Withdraw the thermostat from the housing

noting the position of the air bleed valve, and

how the thermostat is installed (which end is

facing outwards) (see illustration).

Testing

General check

11Before assuming the thermostat is to

blame for a cooling system problem, check

the coolant level, auxiliary drivebelt tension

and condition (see Chapter 1) and

temperature gauge operation.

12 If the engine seems to be taking a long

time to warm up (based on heater output or

temperature gauge operation), the thermostat

is probably stuck open. Renew the thermostat.

13 If the engine runs hot, use your hand to

check the temperature of the radiator top

hose. If the hose isn’t hot, but the engine is,

the thermostat is probably stuck closed,

preventing the coolant inside the engine from

escaping to the radiator - renew the

thermostat.

Caution: Don’t drive the vehicle without a

thermostat. The lack of a thermostat will

slow warm-up time. The engine

management system’s ECU will then stay

in warm-up mode for longer than

necessary, causing emissions and fuel

economy to suffer. 14

If the radiator top hose is hot, it means

that the coolant is flowing and the thermostat

is open. Consult the “Fault finding” section at

the end of this manual to assist in tracing

possible cooling system faults.

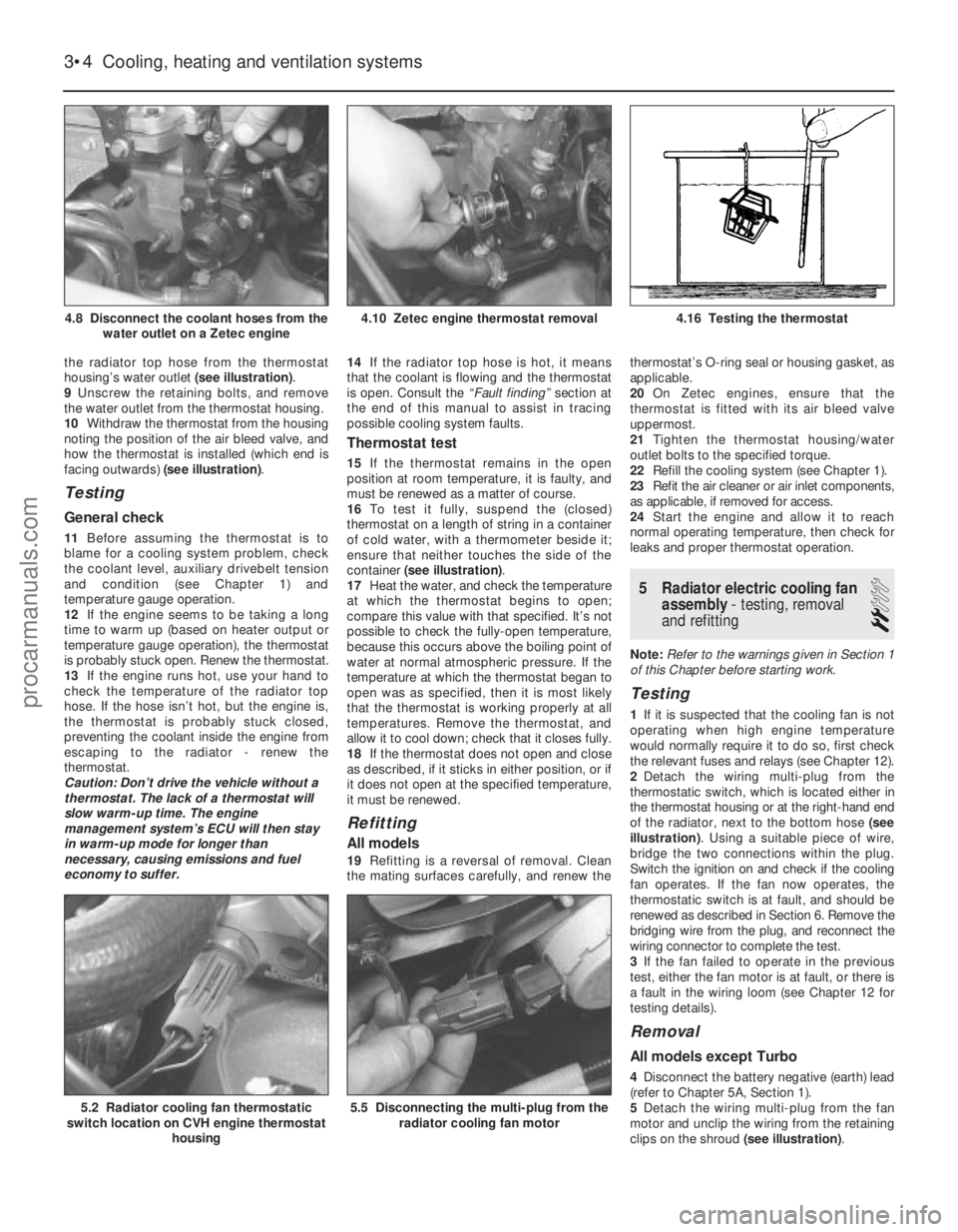

Thermostat test

15 If the thermostat remains in the open

position at room temperature, it is faulty, and

must be renewed as a matter of course.

16 To test it fully, suspend the (closed)

thermostat on a length of string in a container

of cold water, with a thermometer beside it;

ensure that neither touches the side of the

container (see illustration) .

17 Heat the water, and check the temperature

at which the thermostat begins to open;

compare this value with that specified. It’s not

possible to check the fully-open temperature,

because this occurs above the boiling point of

water at normal atmospheric pressure. If the

temperature at which the thermostat began to

open was as specified, then it is most likely

that the thermostat is working properly at all

temperatures. Remove the thermostat, and

allow it to cool down; check that it closes fully.

18 If the thermostat does not open and close

as described, if it sticks in either position, or if

it does not open at the specified temperature,

it must be renewed.

Refitting

All models

19 Refitting is a reversal of removal. Clean

the mating surfaces carefully, and renew the thermostat’s O-ring seal or housing gasket, as

applicable.

20

On Zetec engines, ensure that the

thermostat is fitted with its air bleed valve

uppermost.

21 Tighten the thermostat housing/water

outlet bolts to the specified torque.

22 Refill the cooling system (see Chapter 1).

23 Refit the air cleaner or air inlet components,

as applicable, if removed for access.

24 Start the engine and allow it to reach

normal operating temperature, then check for

leaks and proper thermostat operation.

5 Radiator electric cooling fan assembly - testing, removal

and refitting

2

Note: Refer to the warnings given in Section 1

of this Chapter before starting work.

Testing

1 If it is suspected that the cooling fan is not

operating when high engine temperature

would normally require it to do so, first check

the relevant fuses and relays (see Chapter 12).

2 Detach the wiring multi-plug from the

thermostatic switch, which is located either in

the thermostat housing or at the right-hand end

of the radiator, next to the bottom hose (see

illustration) . Using a suitable piece of wire,

bridge the two connections within the plug.

Switch the ignition on and check if the cooling

fan operates. If the fan now operates, the

thermostatic switch is at fault, and should be

renewed as described in Section 6. Remove the

bridging wire from the plug, and reconnect the

wiring connector to complete the test.

3 If the fan failed to operate in the previous

test, either the fan motor is at fault, or there is

a fault in the wiring loom (see Chapter 12 for

testing details).

Removal

All models except Turbo

4 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

5 Detach the wiring multi-plug from the fan

motor and unclip the wiring from the retaining

clips on the shroud (see illustration).

3•4 Cooling, heating and ventilation systems

5.5 Disconnecting the multi-plug from the

radiator cooling fan motor5.2 Radiator cooling fan thermostatic

switch location on CVH engine thermostat

housing

4.16 Testing the thermostat4.10 Zetec engine thermostat removal4.8 Disconnect the coolant hoses from thewater outlet on a Zetec engine

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 100 of 296

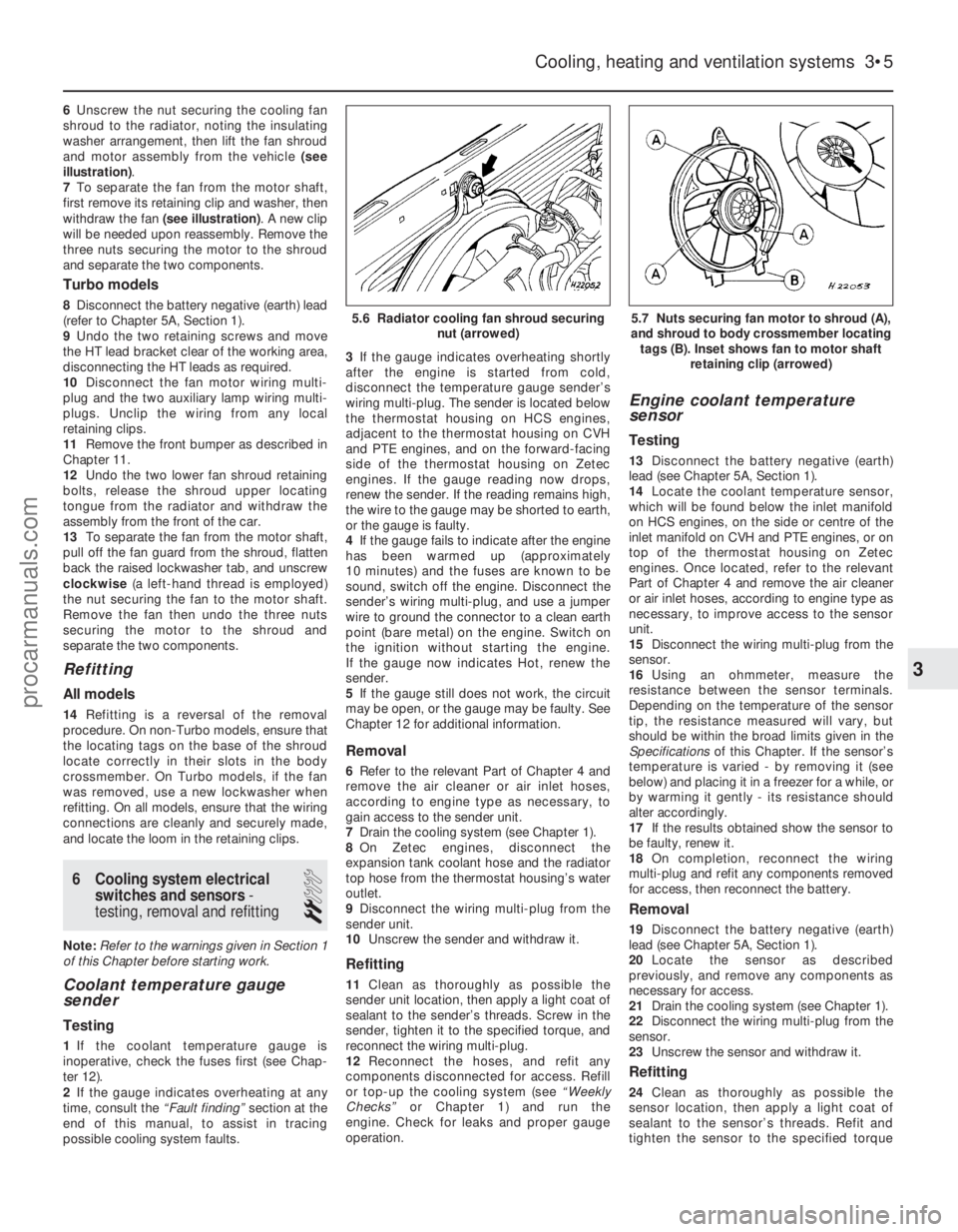

6Unscrew the nut securing the cooling fan

shroud to the radiator, noting the insulating

washer arrangement, then lift the fan shroud

and motor assembly from the vehicle (see

illustration) .

7 To separate the fan from the motor shaft,

first remove its retaining clip and washer, then

withdraw the fan (see illustration) . A new clip

will be needed upon reassembly. Remove the

three nuts securing the motor to the shroud

and separate the two components.

Turbo models

8 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

9 Undo the two retaining screws and move

the HT lead bracket clear of the working area,

disconnecting the HT leads as required.

10 Disconnect the fan motor wiring multi-

plug and the two auxiliary lamp wiring multi-

plugs. Unclip the wiring from any local

retaining clips.

11 Remove the front bumper as described in

Chapter 11.

12 Undo the two lower fan shroud retaining

bolts, release the shroud upper locating

tongue from the radiator and withdraw the

assembly from the front of the car.

13 To separate the fan from the motor shaft,

pull off the fan guard from the shroud, flatten

back the raised lockwasher tab, and unscrew

clockwise (a left-hand thread is employed)

the nut securing the fan to the motor shaft.

Remove the fan then undo the three nuts

securing the motor to the shroud and

separate the two components.

Refitting

All models

14 Refitting is a reversal of the removal

procedure. On non-Turbo models, ensure that

the locating tags on the base of the shroud

locate correctly in their slots in the body

crossmember. On Turbo models, if the fan

was removed, use a new lockwasher when

refitting. On all models, ensure that the wiring

connections are cleanly and securely made,

and locate the loom in the retaining clips.

6 Cooling system electrical switches and sensors -

testing, removal and refitting

2

Note: Refer to the warnings given in Section 1

of this Chapter before starting work.

Coolant temperature gauge

sender

Testing

1 If the coolant temperature gauge is

inoperative, check the fuses first (see Chap-

ter 12).

2 If the gauge indicates overheating at any

time, consult the “Fault finding” section at the

end of this manual, to assist in tracing

possible cooling system faults. 3

If the gauge indicates overheating shortly

after the engine is started from cold,

disconnect the temperature gauge sender’s

wiring multi-plug. The sender is located below

the thermostat housing on HCS engines,

adjacent to the thermostat housing on CVH

and PTE engines, and on the forward-facing

side of the thermostat housing on Zetec

engines. If the gauge reading now drops,

renew the sender. If the reading remains high,

the wire to the gauge may be shorted to earth,

or the gauge is faulty.

4 If the gauge fails to indicate after the engine

has been warmed up (approximately

10 minutes) and the fuses are known to be

sound, switch off the engine. Disconnect the

sender’s wiring multi-plug, and use a jumper

wire to ground the connector to a clean earth

point (bare metal) on the engine. Switch on

the ignition without starting the engine.

If the gauge now indicates Hot, renew the

sender.

5 If the gauge still does not work, the circuit

may be open, or the gauge may be faulty. See

Chapter 12 for additional information.

Removal

6 Refer to the relevant Part of Chapter 4 and

remove the air cleaner or air inlet hoses,

according to engine type as necessary, to

gain access to the sender unit.

7 Drain the cooling system (see Chapter 1).

8 On Zetec engines, disconnect the

expansion tank coolant hose and the radiator

top hose from the thermostat housing’s water

outlet.

9 Disconnect the wiring multi-plug from the

sender unit.

10 Unscrew the sender and withdraw it.

Refitting

11Clean as thoroughly as possible the

sender unit location, then apply a light coat of

sealant to the sender’s threads. Screw in the

sender, tighten it to the specified torque, and

reconnect the wiring multi-plug.

12 Reconnect the hoses, and refit any

components disconnected for access. Refill

or top-up the cooling system (see “Weekly

Checks” or Chapter 1) and run the

engine. Check for leaks and proper gauge

operation.

Engine coolant temperature

sensor

Testing

13 Disconnect the battery negative (earth)

lead (see Chapter 5A, Section 1).

14 Locate the coolant temperature sensor,

which will be found below the inlet manifold

on HCS engines, on the side or centre of the

inlet manifold on CVH and PTE engines, or on

top of the thermostat housing on Zetec

engines. Once located, refer to the relevant

Part of Chapter 4 and remove the air cleaner

or air inlet hoses, according to engine type as

necessary, to improve access to the sensor

unit.

15 Disconnect the wiring multi-plug from the

sensor.

16 Using an ohmmeter, measure the

resistance between the sensor terminals.

Depending on the temperature of the sensor

tip, the resistance measured will vary, but

should be within the broad limits given in the

Specifications of this Chapter. If the sensor’s

temperature is varied - by removing it (see

below) and placing it in a freezer for a while, or

by warming it gently - its resistance should

alter accordingly.

17 If the results obtained show the sensor to

be faulty, renew it.

18 On completion, reconnect the wiring

multi-plug and refit any components removed

for access, then reconnect the battery.

Removal

19 Disconnect the battery negative (earth)

lead (see Chapter 5A, Section 1).

20 Locate the sensor as described

previously, and remove any components as

necessary for access.

21 Drain the cooling system (see Chapter 1).

22 Disconnect the wiring multi-plug from the

sensor.

23 Unscrew the sensor and withdraw it.

Refitting

24Clean as thoroughly as possible the

sensor location, then apply a light coat of

sealant to the sensor’s threads. Refit and

tighten the sensor to the specified torque

Cooling, heating and ventilation systems 3•5

5.7 Nuts securing fan motor to shroud (A),

and shroud to body crossmember locating tags (B). Inset shows fan to motor shaft retaining clip (arrowed)5.6 Radiator cooling fan shroud securing nut (arrowed)

3

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su