sensor FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 726 of 1226

303-01 B-I 04 Engine - 2.OL Duratec-HE (M14) 303-01 B-I 04

ASSEMBLY

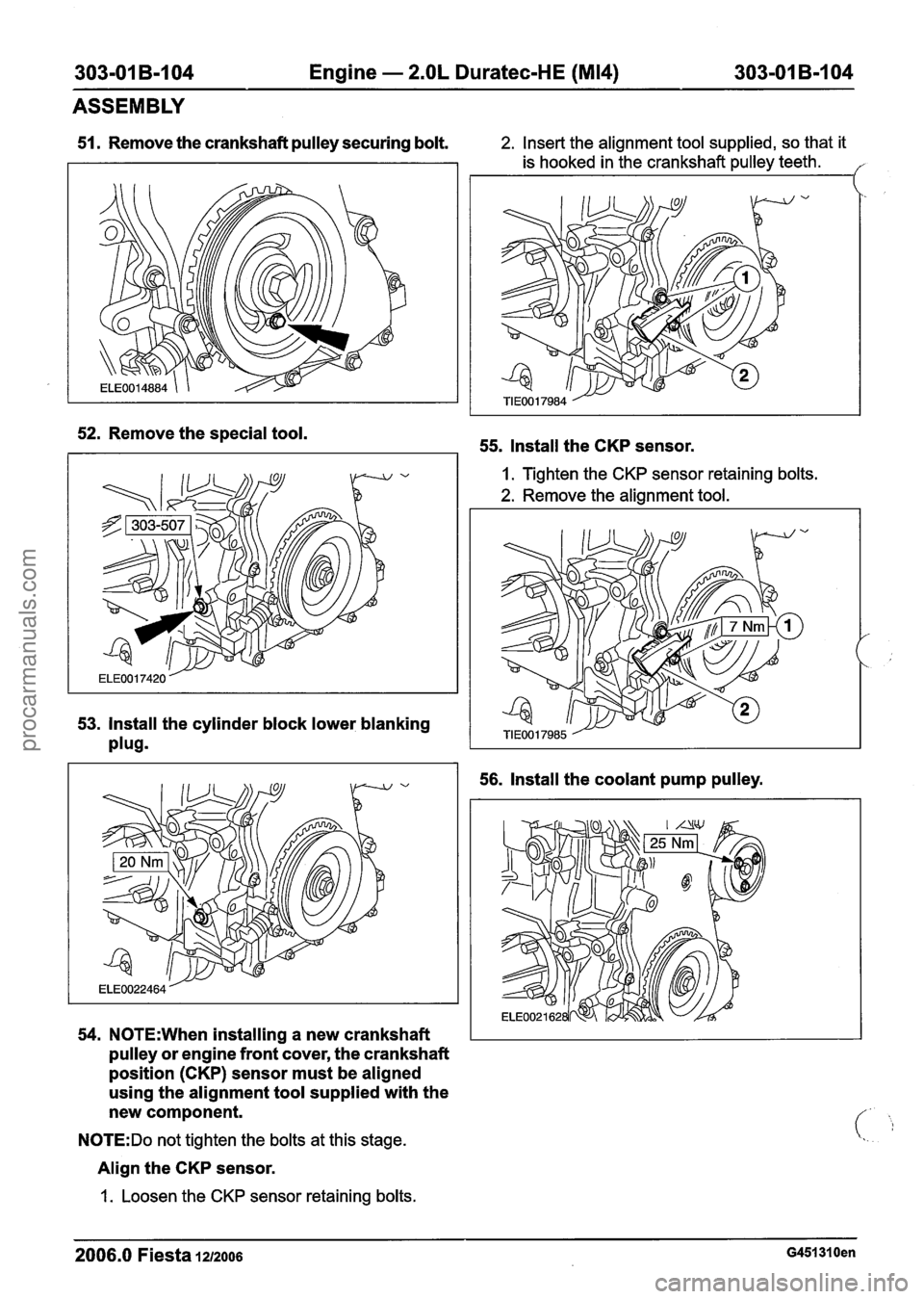

51. Remove the crankshaft pulley securing bolt. 2. Insert the alignment tool supplied, so that it

is hooked in the crankshaft pulley teeth.

I

52. Remove the special tool.

53. Install the cylinder block lower blanking

plug9

54. N0TE:When installing a new crankshaft

pulley or engine front cover, the crankshaft

position

(CKP) sensor must be aligned

using the alignment tool supplied with the

new component.

N0TE:Do not tighten the bolts at this stage.

Align the CKP sensor.

1.

Loosen the CKP sensor retaining bolts.

55. Install the CKP sensor.

I. Tighten the CKP sensor retaining bolts.

2. Remove the alignment tool.

56. Install the coolant pump pulley.

2006.0 Fiesta 1212006 G451310en

procarmanuals.com

Page 729 of 1226

303-01 B-107 Engine - 2.OL Duratec-HE (M14) 303-01 B-107

ASSEMBLY

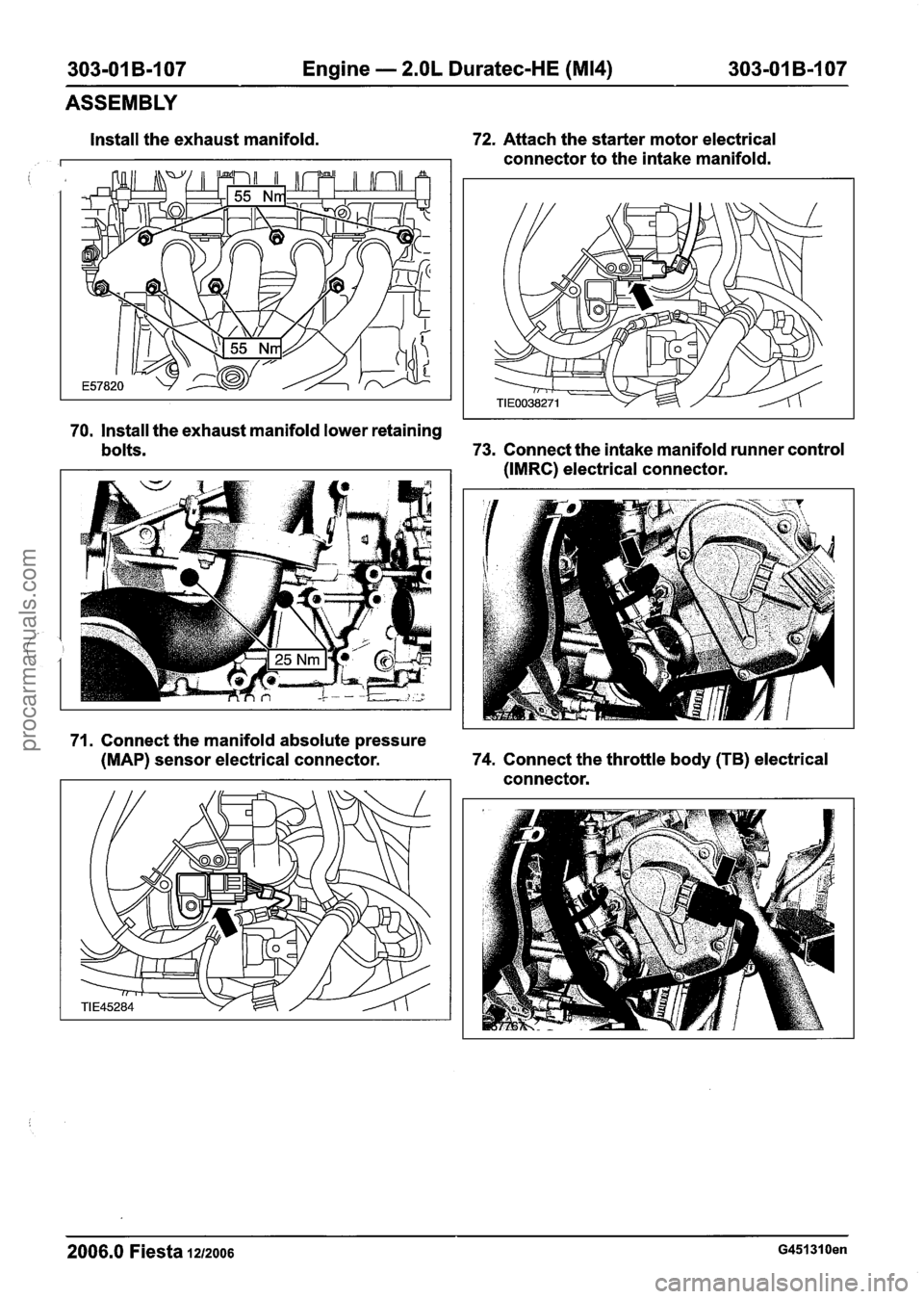

Install the exhaust manifold.

i

72. Attach the starter motor electrical

connector to the intake manifold.

70, Install the exhaust manifold lower retaining

bolts.

73. Connect the intake manifold runner control

(IMRC) electrical connector.

71. Connect the manifold absolute pressure

(MAP) sensor electrical connector. 74.

Connect the throttle body

(TB) electrical

connector.

2006.0 Fiesta 1212006 G451310en

procarmanuals.com

Page 730 of 1226

303-01 B-I08 Engine - 2.OL Duratec-HE (M14) 303-01 B-108

ASSEMBLY

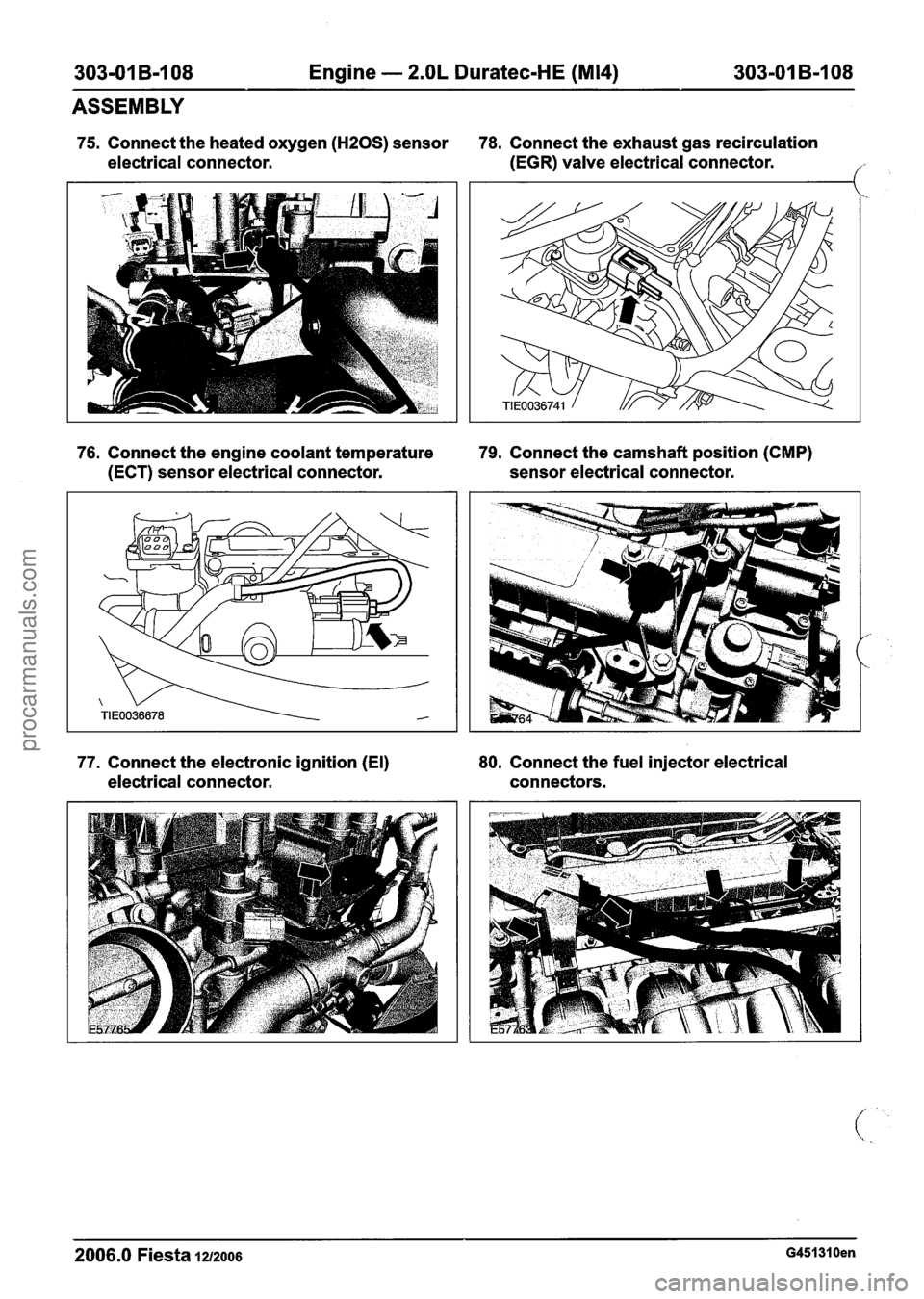

75. Connect the heated oxygen (HZOS) sensor 78. Connect the exhaust gas recirculation

electrical connector. (EGR)

valve electrical connector.

('

76. Connect the engine coolant temperature 79. Connect the camshaft position (CMP)

(ECT) sensor electrical connector. sensor electrical connector.

77. Connect the electronic ignition (El) 80.

Connect the fuel injector electrical

electrical connector. connectors.

2006.0 Fiesta 1212006 G451310en

procarmanuals.com

Page 731 of 1226

303-01 B-I 09 Engine - 2.OL Duratec-HE (M14) 303-01 B-109

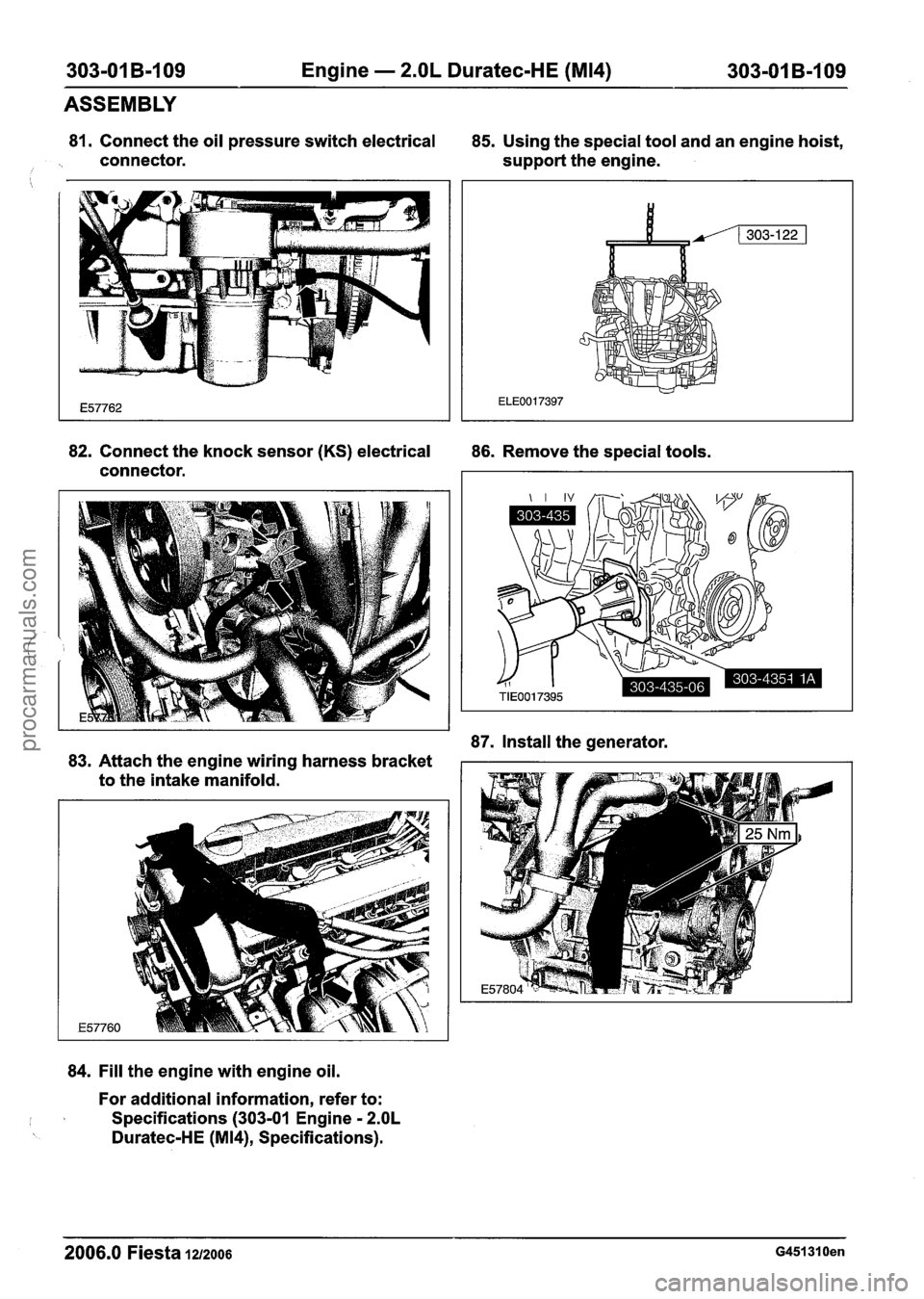

81. Connect the oil pressure switch electrical

85. Using the special tool and an engine hoist,

connector. support the engine.

i

ASSEMBLY

82. Connect the knock sensor (KS) electrical

86. Remove the special tools.

connector.

87. Install the generator.

83. Attach the engine wiring harness bracket

to the intake manifold.

84. Fill the engine with engine oil.

For additional information, refer to:

I I Specifications (303-01 Engine - 2.OL

Duratec-HE (M14), Specifications).

2006.0 Fiesta 1z/zoo6 G451310en

procarmanuals.com

Page 732 of 1226

303-01 B-I 10 Engine - 2.OL Duratec-HE (M14) 303101 B-110

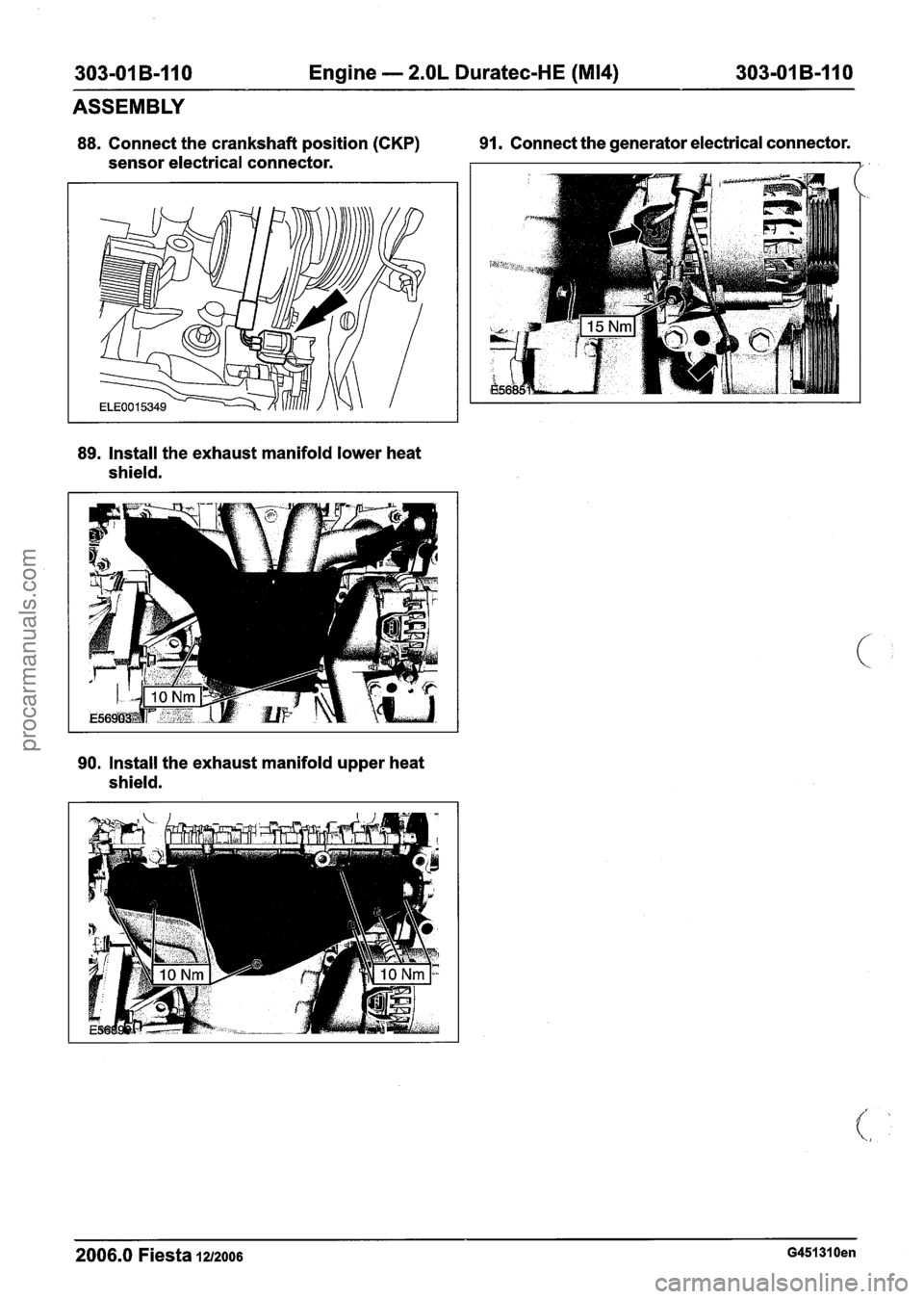

ASSEMBLY

88. Connect the crankshaft position (CKP) 91. Connect

the generator electrical connector.

sensor electrical connector.

89. Install the exhaust manifold lower heat

shield.

90. Install the exhaust manifold upper heat

shield.

2006.0 Fiesta 1212006 G451310en

procarmanuals.com

Page 740 of 1226

303-01 B-I 18 Engine - 2.OL Duratec-HE (M14) 303-01 B-118

INSTALLATION

44. Attach the power steering high-pressure 47.

Connect the catalyst monitor sensor

line retaining bracket to the transaxle. electrical

connector.

//

45. Install the engine wiring harness bracket. 48.

Connect the power steering pump switch

electrical connector.

46. Connect the engine wiring harness

electrical connector.

49. Install the battery tray support bracket.

2006.0 Fiesta 1212006 G451291 en

procarmanuals.com

Page 749 of 1226

Enaine Cooling - 1.3L Duratec-8V

(~ocah)ll.25L ~Cratec-1 6~ (Sigma)ll.4L

303-03A-7 Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma) 303-03A-7

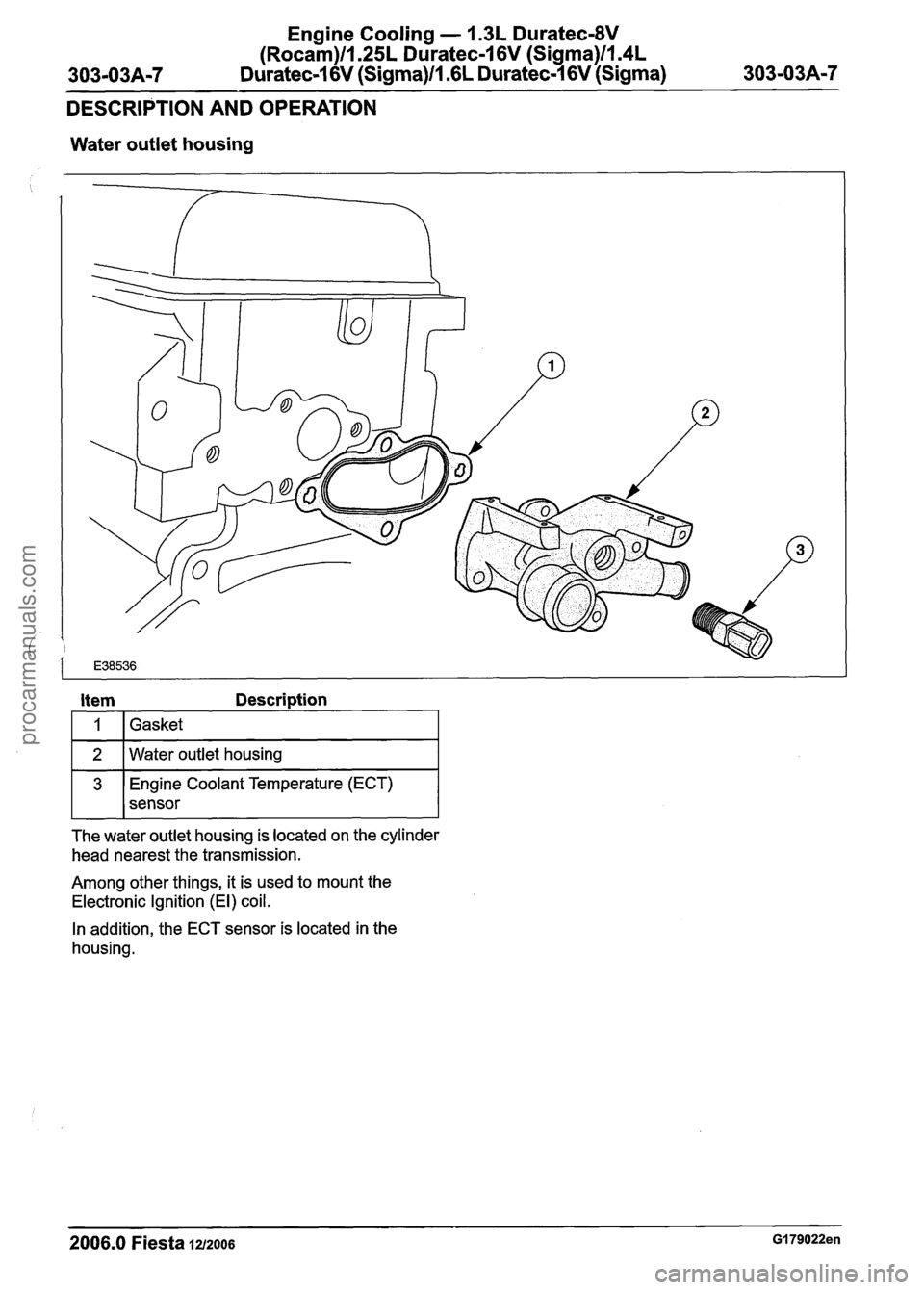

DESCRIPTION AND OPERATION

Water outlet housing

Coolant Temperature (ECT)

sensor

Item Description

The water outlet housing is located on the cylinder

head nearest the transmission.

1

2

Among other things, it is used to mount the

Electronic Ignition (El) coil.

Gasket

Water outlet housing

In addition, the ECT sensor is located in the

housing.

2006.0 Fiesta 1212006 GI 79022en

procarmanuals.com

Page 750 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

303-03A-8 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-8

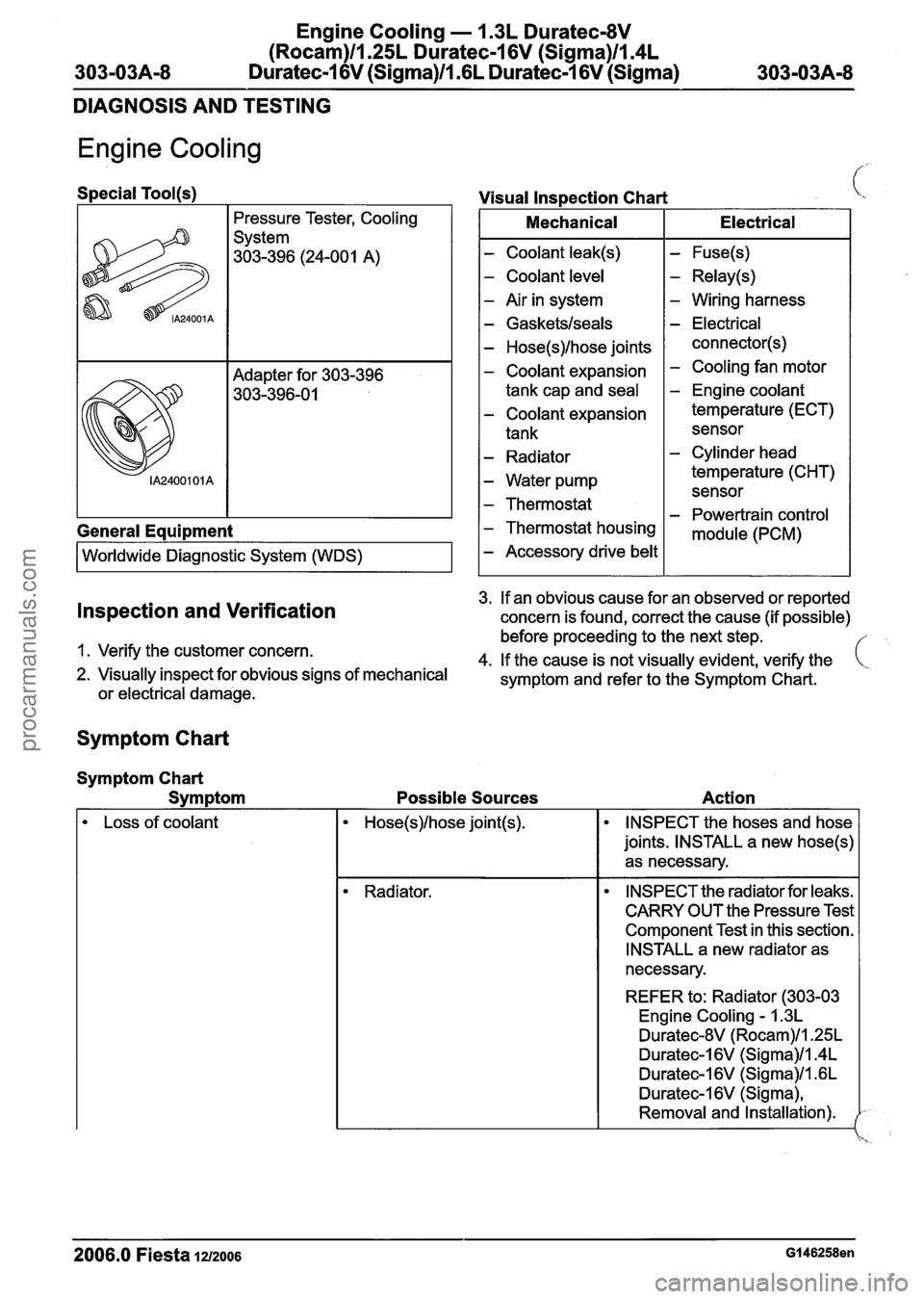

DIAGNOSIS AND TESTING

Engine Cooling

Special Tool(~)

Pressure Tester,

Cooling

System

303-396 (24-001 A)

General

Equipment

I Worldwide Diagnostic System (WDS) I

Visual Inspection Chart i,

I Mechanical I Electrical I

- Coolant leak(s)

- Coolant level

- Air in system

- Gasketslseals

- Hose(s)lhose joints

- Coolant expansion

tank cap and

seal

- Coolant expansion

tank

- Radiator

- Water pump

- Thermostat

- Thermostat housing

- Accessory drive belt

- Fuse(s)

- Relay(s)

- Wiring harness

- Electrical

connector(s)

- Cooling fan motor

- Engine coolant

temperature (ECT)

sensor

- Cylinder head

temperature (CHT) sensor

- Powertrain control

module (PCM)

3.

If an obvious cause for an observed or reported Inspection and Verification concern is found, correct the cause (if possible)

before proceeding to the next step.

1. Verify the customer concern.

4.

If the cause is not visually evident, verify the ( 2. Visually inspect for obvious signs of mechanical

symptom and refer to the Symptom Chart.

or

electrical damage.

Symptom Chart

Symptom Chart

Svm

ptom Possible Sources Action

Loss of

coolant INSPECT the hoses and hose

joints. INSTALL a new

hose(s)

as necessary.

Radiator. INSPECT the radiator for leaks.

CARRY OUT the Pressure Test

Component Test in this section.

INSTALL a new radiator as

necessary.

REFER to: Radiator (303-03 Engine

Cooling - 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-1 6V (Sigma)1ln4L

Duratec-1 6V (Sigma)ll .6L

Duratec-I 6V (Sigma),

Removal and Installation).

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 757 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)llI25L Duratec-1 6V (Sigma)llI4L

303-03A-I 5 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-0344-15

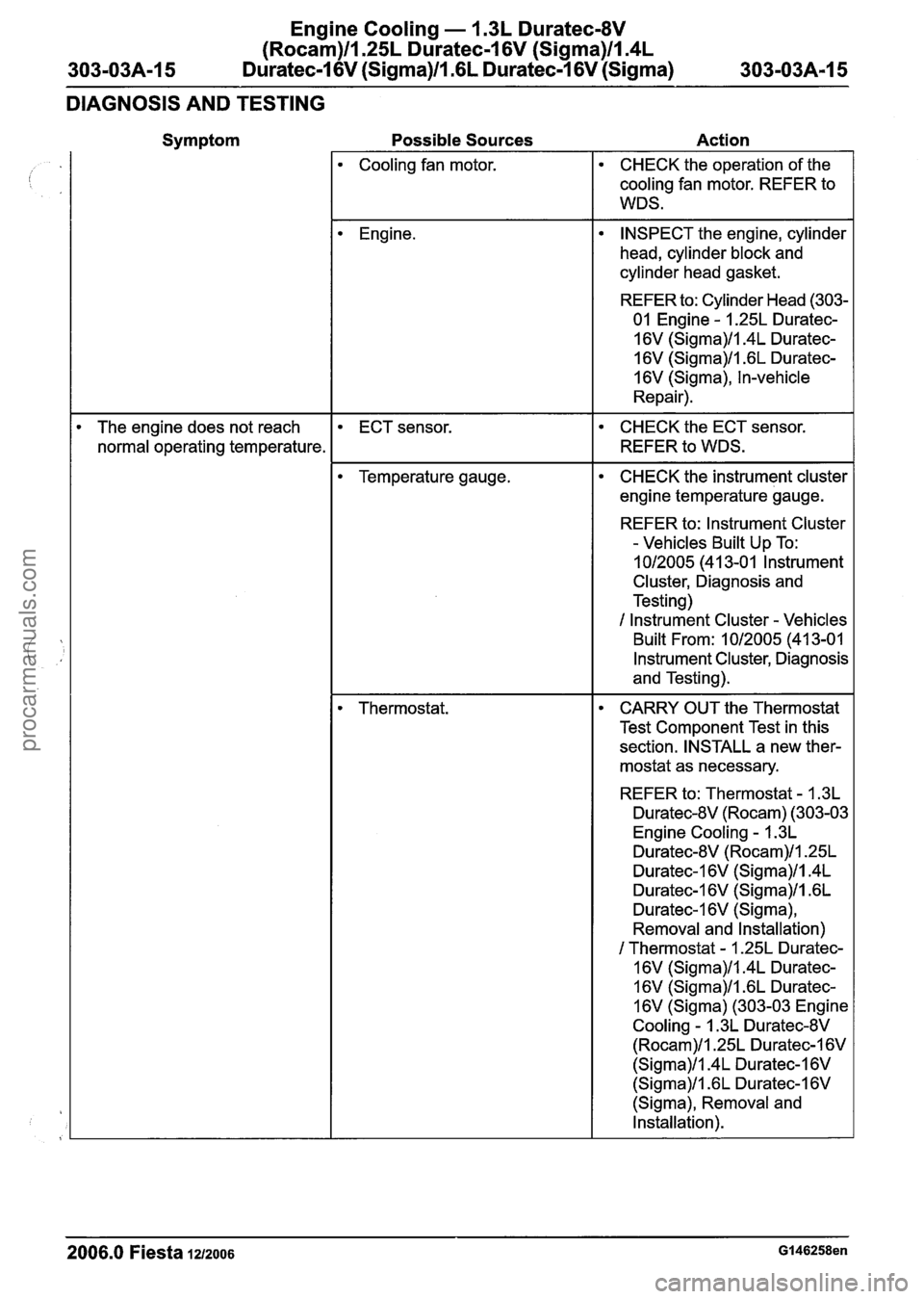

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

Cooling fan motor. CHECK the operation of the

cooling fan motor. REFER to

WDS.

Engine. INSPECT

the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to: Cylinder Head (303-

01 Engine - 1.25L Duratec-

16V (Sigma)/l.4L Duratec-

16V (Sigma)/l.GL Duratec-

16V (Sigma), In-vehicle

Repair).

, The engine does not reach

normal operating temperature. ECT sensor. CHECK the ECT sensor.

I REFER to WDS.

Temperature gauge. CHECK

the instrument cluster

engine temperature gauge.

REFER to: lnstrument Cluster

- Vehicles Built Up To:

1012005 (41 3-01 lnstrument

Cluster, Diagnosis and

Testing)

I lnstrument Cluster - Vehicles

Built From:

1012005 (41 3-01

lnstrument Cluster, Diagnosis

and Testing).

Thermostat. CARRY OUT the Thermostat

Test Component Test in this

section. INSTALL a new ther-

mostat as necessary.

REFER to: Thermostat

- I .3L

Duratec-8V

(Rocam) (303-03

Engine Cooling

- 1.3L

Duratec-8V (Rocam)ll.25L

Duratec-16V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L

Duratec-16V (Sigma),

Removal and Installation)

I Thermostat - 1.25L Duratec-

16V (Sigma)/l.4L Duratec-

16V (Sigma)ll .6L Duratec-

16V (Sigma) (303-03 Engine

Cooling

- 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)/l .6L Duratec-I 6V

(Sigma), Removal and

Installation).

2006.0 Fiesta 1212oo6 GI 46258en

procarmanuals.com

Page 758 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-I 6V (Sigma)ll.4L

303-03A-16 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-16

DIAGNOSIS AND TESTING

Component Tests

Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2.

Install the special tools to the coolant expansion

tank.

3. Pressurize the system to the

coolant expansion

tank cap

release pressure.

REFER to: Specifications (303-03 Engine

Cooling - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma),

Specifications).

4. Observe the

cooling system pressure tester

gauge reading for

approximately two minutes.

The pressure

should not drop during this time.

If the system holds pressure, proceed to step

6.

If the system does not hold pressure, check

it

thoroughly for coolant leaks.

5. Check the engine for coolant leaks. Drain the

cooling system, repair any coolant leaks found

and

fill and bleed the cooling system as

necessary.

REFER to:

Cooling System Draining, Filling and

Bleeding - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma) (303-03

Engine

Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V

(Sigma), General Procedures).

Clean the radiator thoroughly before leak testing

it, to prevent contamination of the water in the test

tank. Leak test the radiator in

clean water with 138(

kpa (20 psi) air pressure. Check it thoroughly for

air

leaks. INSTALL a new radiator if necessary.

REFER to: Radiator (303-03 Engine

Cooling - 1.3L

Duratec-8V (Rocam)/l.25L Duratec-I 6V

(Sigma)/l.4L Duratec-I 6V (Sigma)ll .6L

Duratec-I 6V (Sigma), Removal and Installation).

Coolant Expansion Tank Cap Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2. Use water to clean the area of the rubber seal

and pressure relief valve. Install the pressure

tester and adapter and immerse the

coolant

expansion tank cap in water .

N0TE:lf the plunger of the pump is depressed too

quickly, an erroneous pressure reading will result. l-

3. Slowly depress the plunger of the pressure test

pump until the pressure gauge reading stops

increasing, and note the highest pressure

reading obtained.

4.

Release pressure by turning the pressure relief

screw counterclockwise. Tighten the pressure

relief screw and repeat step 3 at least twice to

make sure the pressure test reading is

repeatable and within acceptable gauge reading

limits of the coolant expansion tank cap.

5.

If the pressure test gauge readings are not

within the

acceptable gauge reading limits,

INSTALL a new coolant expansion tank cap.

6. Recheck the system by repeating steps 3 and

4 at least twice.

Thermostat Test

Radiator Leak Test, Removed From Vehicle

A CAUTI0N:Radiator internal pressure must

not exceed

130 kpa (20 psi) or damage may

result.

1. Connect the WDS to the data link connector

(DLC).

2. Using the WDS

datalogger function, SELECT

the

following sensors (as applicable to the

application):

IAT - intake air temperature (IAT) sensor

ECT

- engine coolant temperature (ECT) sensort

CHT - cylinder head temperature (CHT) sensori

LOAD - engine load

VSS - vehicle speed sensor (VSS)

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com