FORD FIESTA 2007 Workshop Manual

Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 941 of 1226

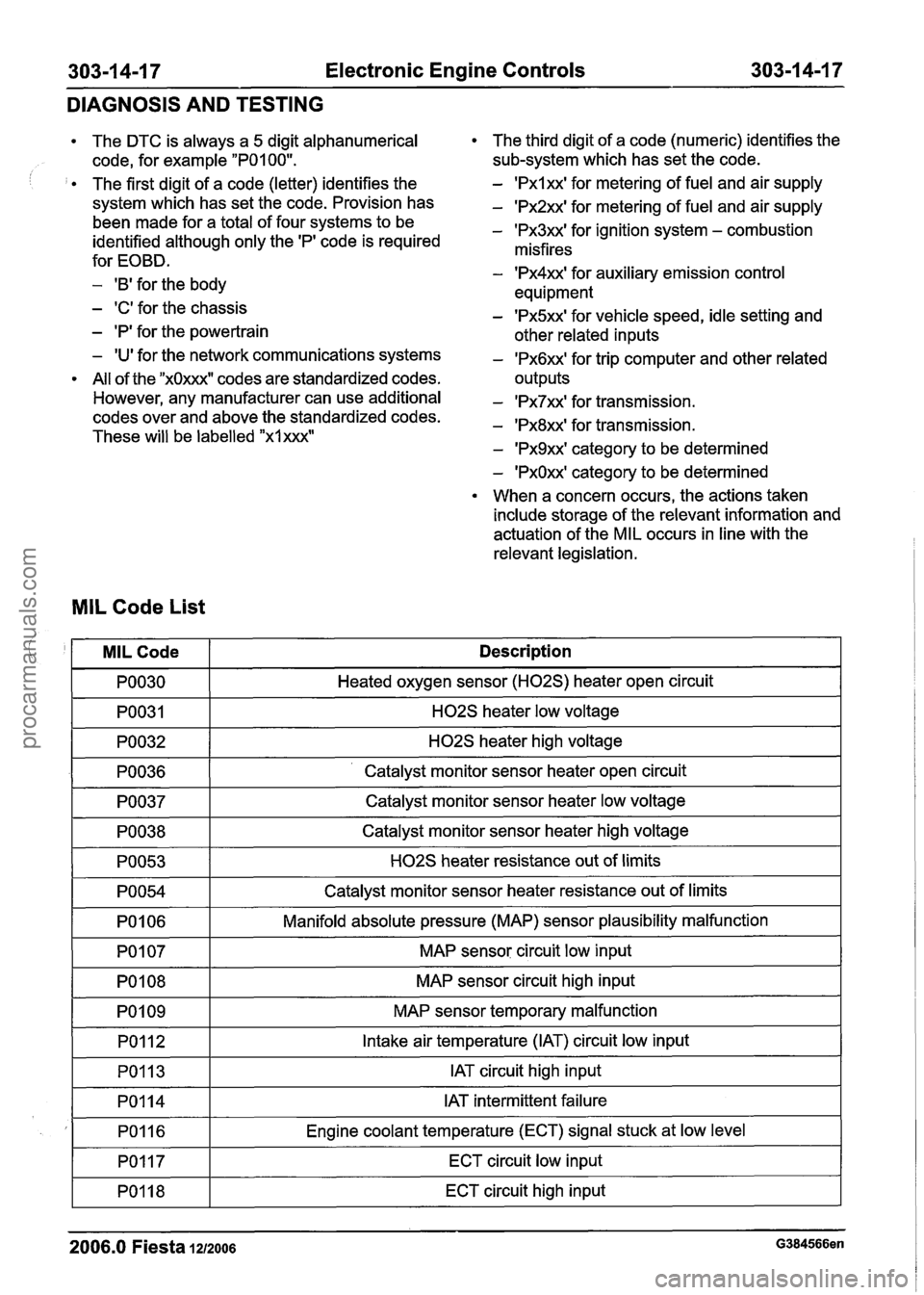

303-1 4-1 7 Electronic Engine Controls 303-1 4-1 7

DIAGNOSIS AND TESTING

The DTC is always a 5 digit alphanumerical

code, for example

"POI 00".

The first digit of a code (letter) identifies the

system which has set the code. Provision has

been made for a total of four systems to be

identified although only the

'PI code is required

for EOBD.

- 'B' for the body

- 'C' for the chassis

- 'P' for the powertrain

- 'U' for the network communications systems

All of the

"xOxxxW codes are standardized codes.

However, any manufacturer can use additional

codes over and above the standardized codes.

These will be labelled

"xlxxx"

The third digit of a code (numeric) identifies the

sub-system which has set the code.

- 'Pxlxx' for metering of fuel and air supply

- 'Px2xx' for metering of fuel and air supply

- 'Px3xx' for ignition system - combustion

misfires

- 'Px4xx' for auxiliary emission control

equipment

- 'Px5xx' for vehicle speed, idle setting and

other related inputs

- 'Px6xx' for trip computer and other related

outputs

- 'Px7xx' for transmission.

- 'Px8xx' for transmission.

- 'Px9xx' category to be determined

- 'PxOxx' category to be determined

When a concern occurs, the actions taken

include storage of the relevant information and

actuation of the MIL occurs in line with the

relevant legislation.

MIL Code List

I PO030 I Heated oxygen sensor (H02S) heater open circuit I

! '

-1 H02S heater low voltage I

I PO032 I H02S heater high voltage I

MILCode

PO036 1- ' Catalyst monitor sensor heater open circuit I

Description

PO037

I PO054 I Catalyst monitor sensor heater resistance out of limits I

Catalyst monitor sensor heater low voltage

PO038

PO053

I PO106 I Manifold absolute pressure (MAP) sensor plausibility malfunction I

-

Catalyst monitor sensor heater high voltage

H02S heater resistance out of limits

I PO107 I MAP sensor circuit low input I

PO108

PO1 09 MAP sensor

circuit high input

MAP sensor temporary malfunction

PO1 12

PO113

I PO117 I ECT circuit low input I

Intake air temperature (IAT) circuit low input

IAT circuit high input

I

2006.0 Fiesta 1212006 G384566en

PO114

PO1 16

PO118

IAT intermittent failure

Engine coolant temperature (ECT) signal stuck at low level

ECT circuit high input

procarmanuals.com

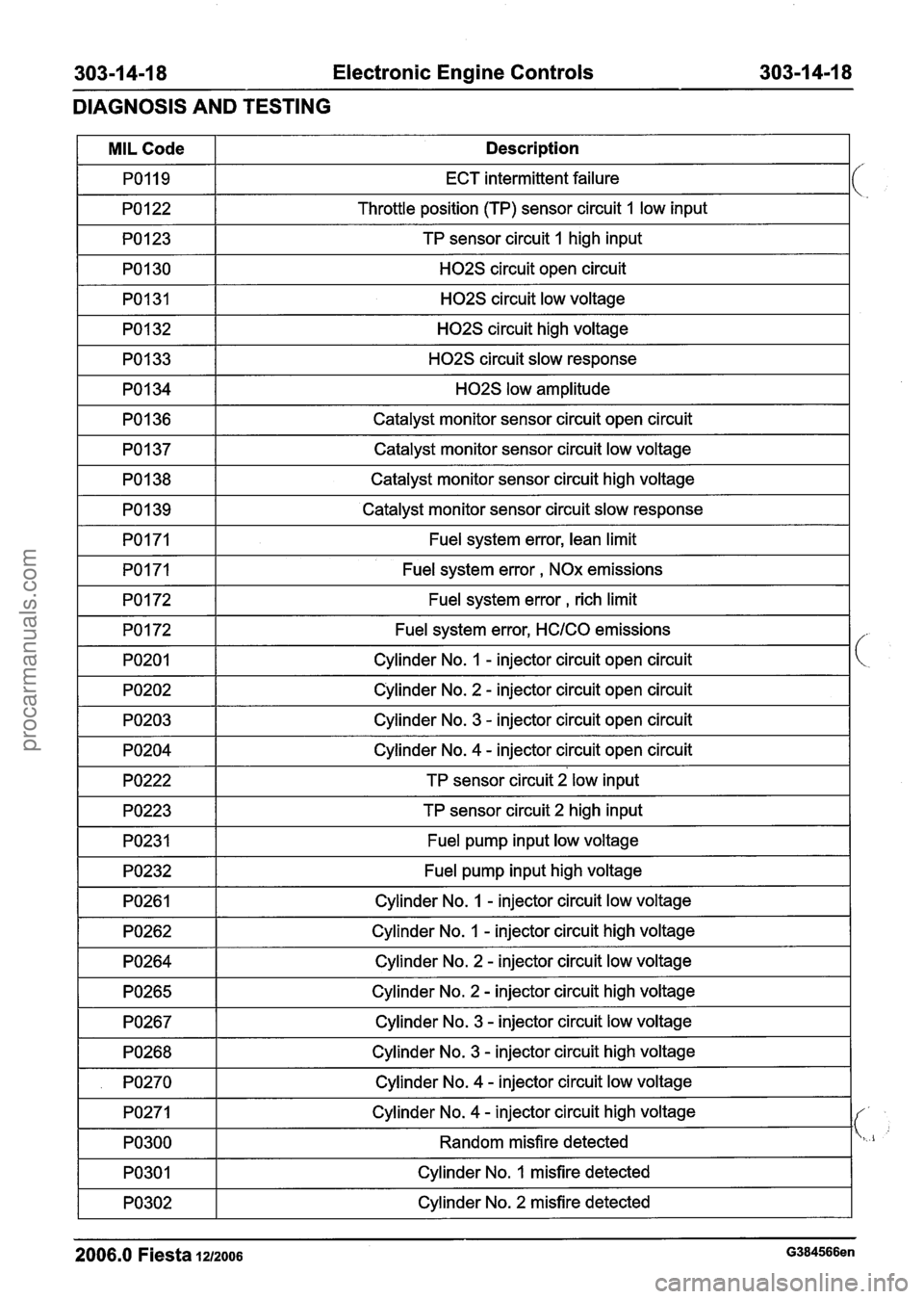

Page 942 of 1226

303-1 4-1 8 Electronic Engine Controls 303-1 4-1 8

DIAGNOSIS AND TESTING

I PO123 I TP sensor circuit I high input I

MIL Code

PO119

PO 1 22

I PO130 I H02S circuit open circuit I

Description

ECT intermittent failure

Throttle position

(TP) sensor circuit 1 low input

I PO131 I H02S circuit low voltage I

pol34 r- HO~S IOW amplitude I

PO1 32

PO1 33

I PO136 I Catalyst monitor sensor circuit open circuit I

H02S circuit high voltage

H02S circuit slow response

I PO137 I Catalyst monitor sensor circuit low voltage I

PO1 38

PO1 39

I PO172 I Fuel system error, rich limit I

Catalyst monitor sensor circuit high voltage

Catalyst monitor sensor circuit slow response

PO171

PO171

Fuel system error, lean limit

Fuel system error

, NOx emissions

PO172

PO201

I PO203 I Cylinder No. 3 - injector circuit open circuit I

Fuel system error, HClCO emissions

Cylinder No.

I - injector circuit open circuit

PO202

I PO204 I Cylinder No. 4 - injector circuit open circuit I

Cylinder No. 2 - injector circuit open circuit

-1 TP sensor circuit 2 low input I

1 PO223 1 TP sensor circuit 2 high input I

I PO231 I Fuel pump input low voltage I

PO232

PO261

Fuel pump input high voltage

Cylinder No.

1 - injector circuit low voltage

PO262

PO264

1 PO267 1 Cylinder No. 3 - injector circuit low voltage I

Cylinder No. 1 - injector circuit high voltage

Cylinder No.

2 - injector circuit low voltage

PO265

1 PO268 1 Cylinder No. 3 - injector circuit high voltage I

-- -

Cylinder No. 2 - injector circuit high voltage I

I . PO270 I Cylinder No. 4 - injector circuit low voltage I

PO271

PO300

Cylinder No. 4 - injector circuit high voltage

Random misfire detected

PO301

2006.0 Fiesta 1212006 G384566en

Cylinder No. 1 misfire detected

PO302

-- -

Cylinder No. 2 misfire detected

procarmanuals.com

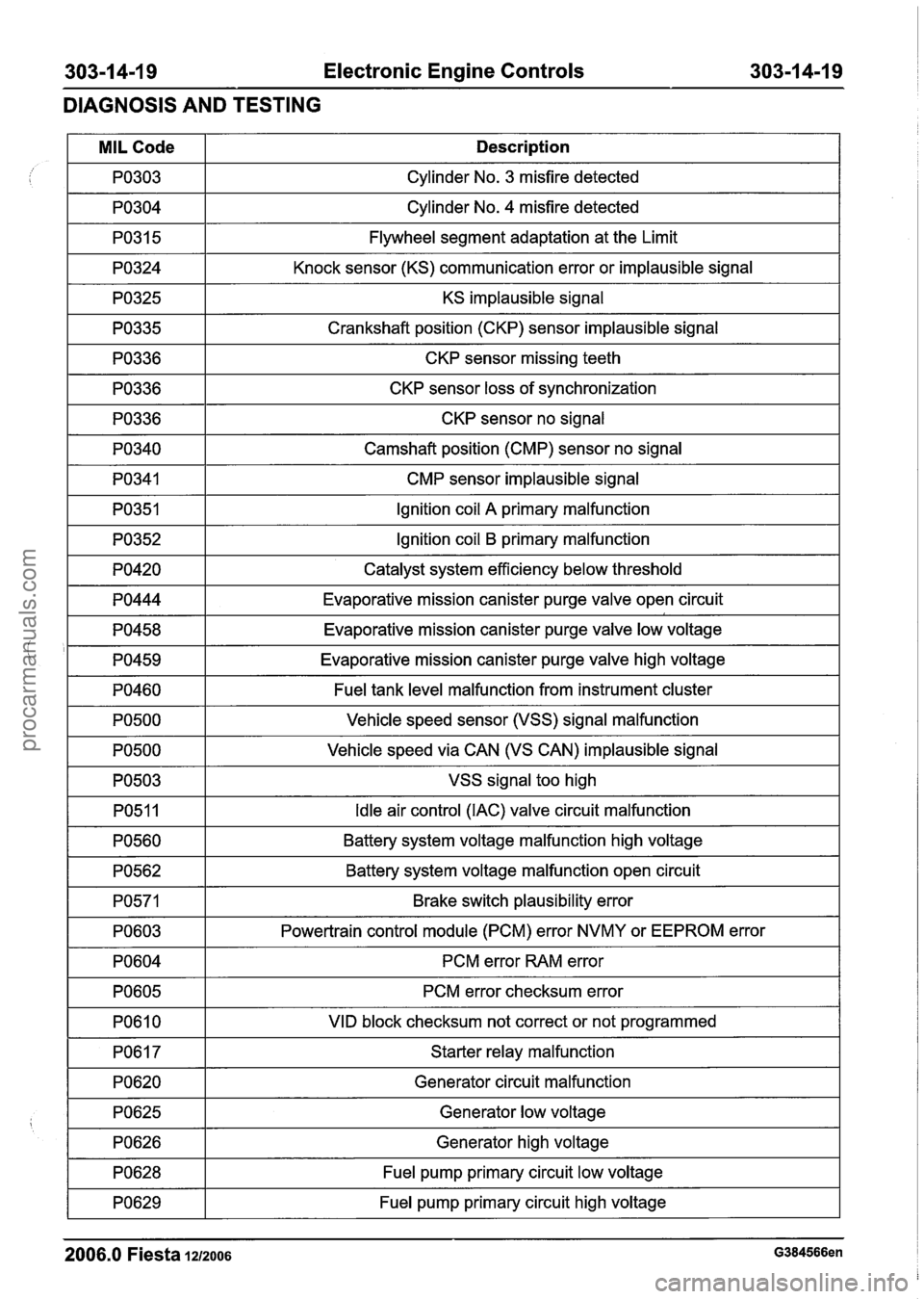

Page 943 of 1226

Electronic Engine Controls

DIAGNOSIS AND TESTING

I PO304 I Cylinder No. 4 misfire detected I

/ I

KS implausible signal I

MIL Code

PO303

PO31 5

PO324

1 PO335 1 Crankshaft position (CKP) sensor implausible signal I

Description

Cylinder No. 3 misfire detected

Flywheel segment adaptation at the Limit

Knock sensor (KS) communication error or implausible signal

1 PO336 1 CKP sensor missing teeth I

1 PO336 1 CKP sensor loss of synchronization I

1 PO336 1 CKP sensor no signal I

I PO340 I Camshaft position (CMP) sensor no signal I

I PO341 I CMP sensor implausible signal I

I PO351 I Ignition coil A primary malfunction I

1 PO352 1 Ignition coil B primary malfunction I

I PO420 I Catalyst system efficiency below threshold I

1 PO444 1 Evaporative mission canister purge valve open circuit I

1 PO458 1 Evaporative mission canister purge valve low voltage I

I '1 PO459 1 Evaporative mission canister purge valve high voltage I

I PO460 I Fuel tank level malfunction from instrument cluster I

-3 I VSS signal too high I

PO500

PO500

Vehicle speed sensor (VSS) signal malfunction

Vehicle speed via CAN (VS CAN) implausible signal

PO51 1

PO560

I PO603 I Powertrain control module (PCM) error NVMY or EEPROM error 1

Idle air control (IAC) valve circuit malfunction

Battery system voltage malfunction high voltage

PO562

PO571

I PO604 I PCM error RAM error I

Battery system voltage malfunction open circuit

Brake switch plausibility error

PO605 I PCM error checksum error I

I PO610 I VID block checksum not correct or not programmed I

I PO617 I Starter relay malfunction I

I PO620 I Generator circuit malfunction I

1 PO628 1 Fuel pump primary circuit low voltage I

I

7 1 Fuel pump primary circuit high voltage I

2006.0 Fiesta 1212006 G384566en

PO625

PO626

Generator low voltage

Generator high voltage

procarmanuals.com

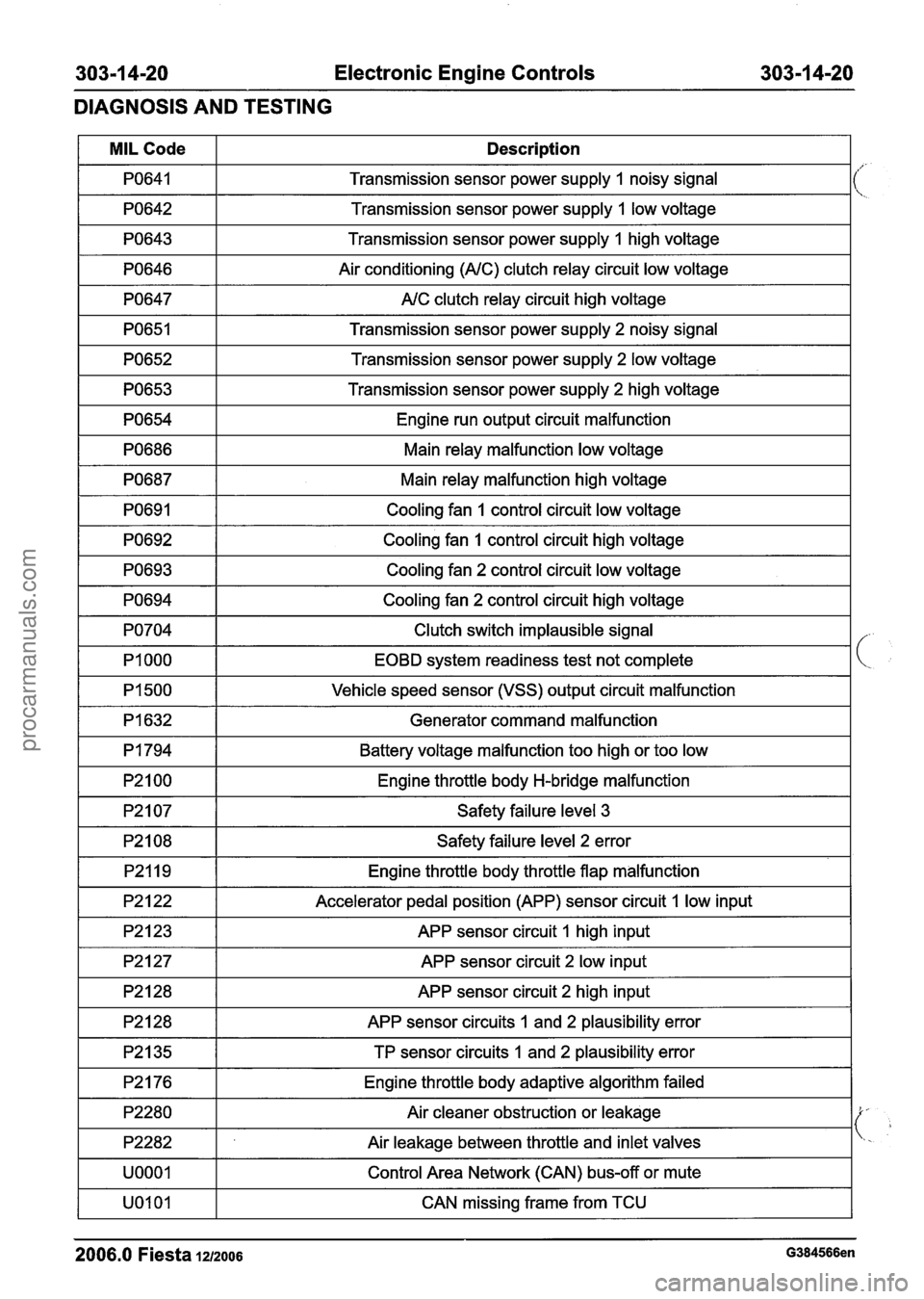

Page 944 of 1226

303-1 4-20 Electronic Engine Controls 303-1 4-20

DIAGNOSIS AND TESTING

1 PO643 1 Transmission sensor power supply 1 high voltage I

MIL Code

PO641

PO642

1 PO646 1 Air conditioning (NC) clutch relay circuit low voltage I

1 PO647 1 NC clutch relay circuit high voltage I

Description

Transmission sensor power supply 1 noisy signal

Transmission sensor power supply

I low voltage

I PO651 I Transmission sensor power supply 2 noisy signal I

i

PO652

PO653

Transmission sensor power supply 2 low voltage

Transmission sensor power supply

2 high voltage

PO654

PO686

1 PO692 1 Cooling fan 1 control circuit high voltage I

Engine run output circuit malfunction

Main relay malfunction low voltage

PO687

PO691

1 PO693 1 Cooling fan 2 control circuit low voltage I

Main relay malfunction high voltage

Cooling fan

1 control circuit low voltage

1 PO694 1 Cooling fan 2 control circuit high voltage I

I PI500 I Vehicle speed sensor (VSS) output circuit malfunction I

PO704

PI 000

Generator command malfunction I

Clutch switch implausible signal

EOBD system readiness test not complete

I P2107 I Safety failure level 3 I

PI 794

P2100

I P2108 I Safety failure level 2 error I

Battery voltage malfunction too high or too low

Engine throttle body H-bridge malfunction

APP sensor circuit 1 high input I

P2119

P2122

1 P2127 1 APP sensor circuit 2 low input I

Engine throttle body throttle flap malfunction

Accelerator pedal position (APP) sensor circuit

1 low input

1 P2128 1 APP sensor circuit 2 high input I

1 P2176 1 Engine throttle body adaptive algorithm failed 1

P2128

P2135

APP sensor circuits I and 2 plausibility error

TP sensor circuits 1 and 2 plausibility error

I UOOOl I Control Area Network (CAN) bus-off or mute I

P2280

P2282

I UOlOl I CAN missing frame from TCU I

Air cleaner obstruction or leakage

Air leakage between throttle and inlet valves

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 945 of 1226

303-1 4-21 Electronic Engine Controls 303-1 4-21

DIAGNOSIS AND TESTING

lnspection and Verification

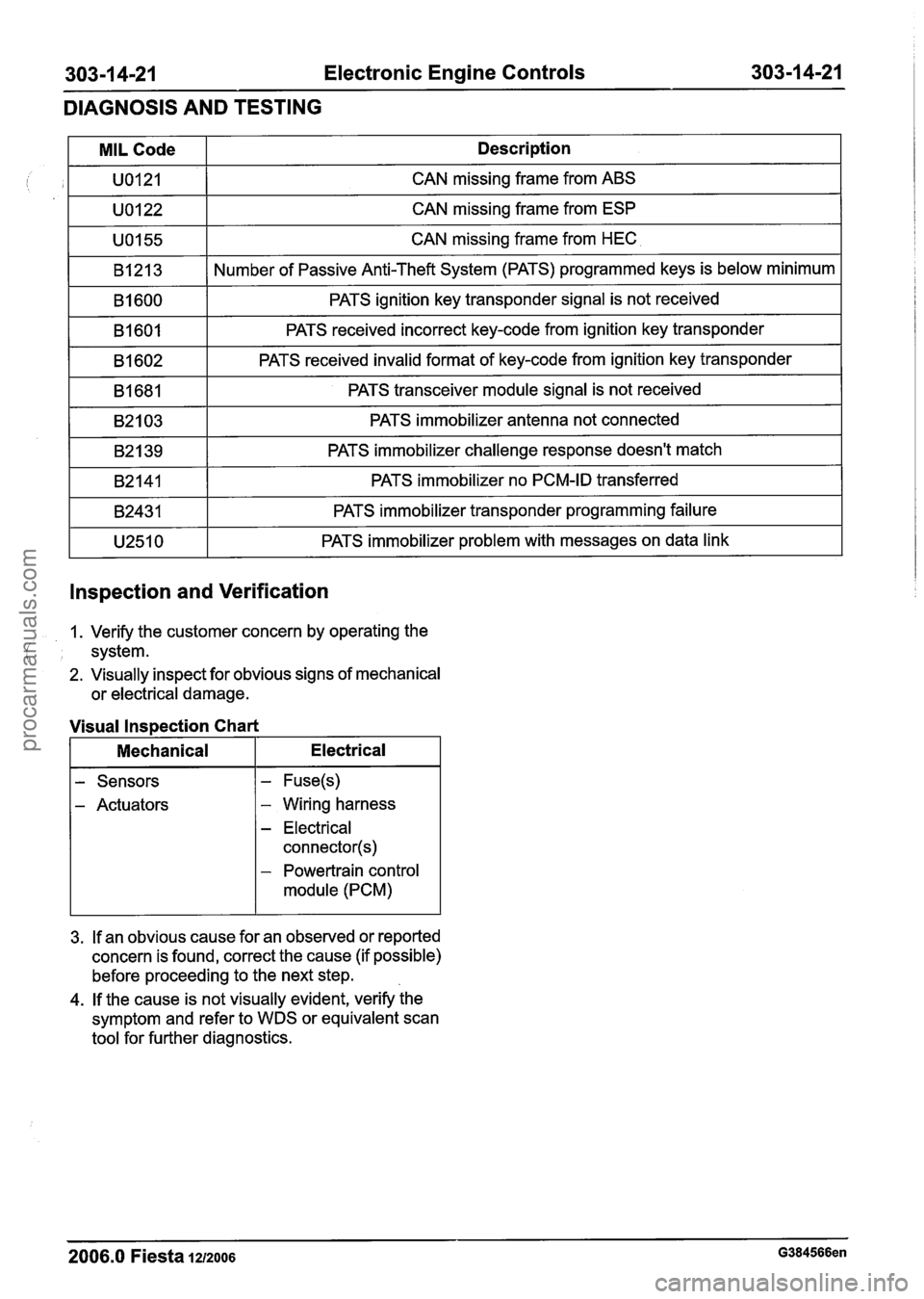

MIL Code

U0121

U0122

U0155

B1213

B1600

B1601

B1602

B1681

B2103

B2139

B2141

B2431

U2510

1. Verify the customer concern by operating the

( I system.

2. Visually inspect for obvious signs of mechanical

or electrical damage. Description

CAN missing frame from ABS

CAN missing frame from ESP

CAN missing frame from HEC

Number of Passive Anti-Theft System (PATS) programmed keys is below minimum

PATS ignition key transponder signal is not received

PATS received incorrect key-code from ignition key transponder

PATS received invalid format of key-code from ignition key transponder

PATS transceiver module signal is not received

PATS immobilizer antenna not connected

PATS immobilizer challenge response doesn't match

PATS immobilizer no PCM-ID transferred

PATS immobilizer transponder programming failure

PATS immobilizer problem with messages on data link

Visual Inspection Chart

Mechanical

I Electrical

- Sensors

- Actuators - Wiring harness

- Electrical

connector(s)

- Powertrain control

module (PCM)

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the

symptom and refer to WDS or equivalent scan

tool for further diagnostics.

- -

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 946 of 1226

303-1 4-22 Electronic Engine Controls

REMOVAL AND INSTALLATION

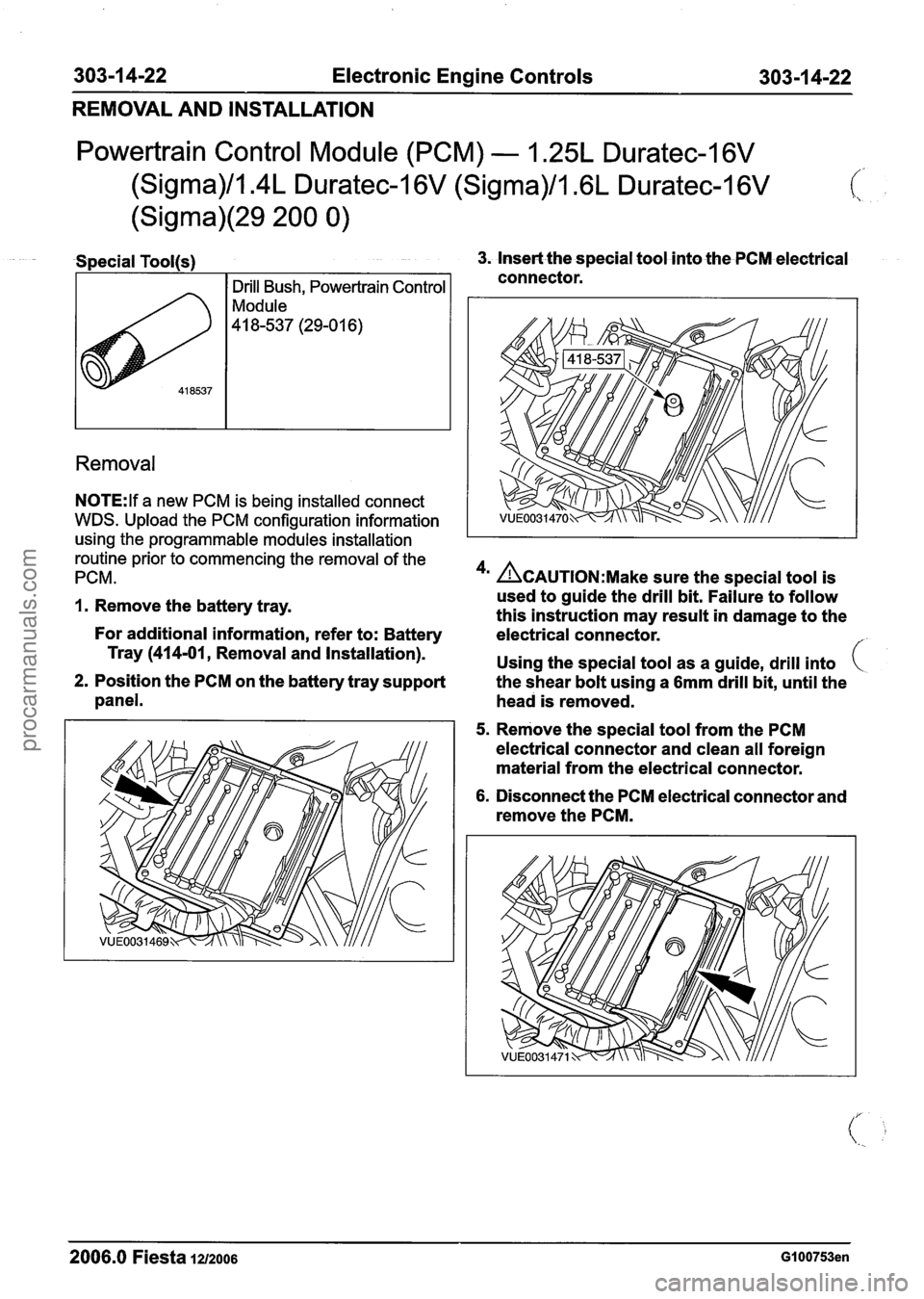

Powertrain Control Module (PCM) - I .25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V (Sigma)/l .6L Duratec-1 6V

(Sigma)(29 200 0)

c

Removal

Special Tool(s) 3. Insert the special tool into the PCM electrical

N0TE:lf a new PCM is being installed connect

WDS. Upload the PCM configuration information

using the programmable modules installation

routine prior to commencing the removal of the

PCM. Drill

Bush, Powertrain Control

Module

4 1 8-537 (29-0 1 6)

1. Remove the battery tray. connector.

For additional information, refer to: Battery

Tray (414-01, Removal and Installation).

2. Position the PCM on the battery tray support

panel.

4m ACAUTION:M~~~ sure the special tool is

used to guide the drill bit. Failure to follow

this instruction may result in damage to the

electrical connector.

f

Using the special tool as a guide, drill into (

the shear bolt using a 6mm drill bit, until the

head is removed.

5. Remove the special tool from the PCM

electrical connector and clean all foreign

material from the electrical connector.

6. Disconnect the PCM electrical connector and

remove the PCM.

2006.0 Fiesta 1212006 GI 00753en

procarmanuals.com

Page 947 of 1226

303-1 4-23 Electronic Engine Controls 303-1 4-23

REMOVAL AND INSTALLATION

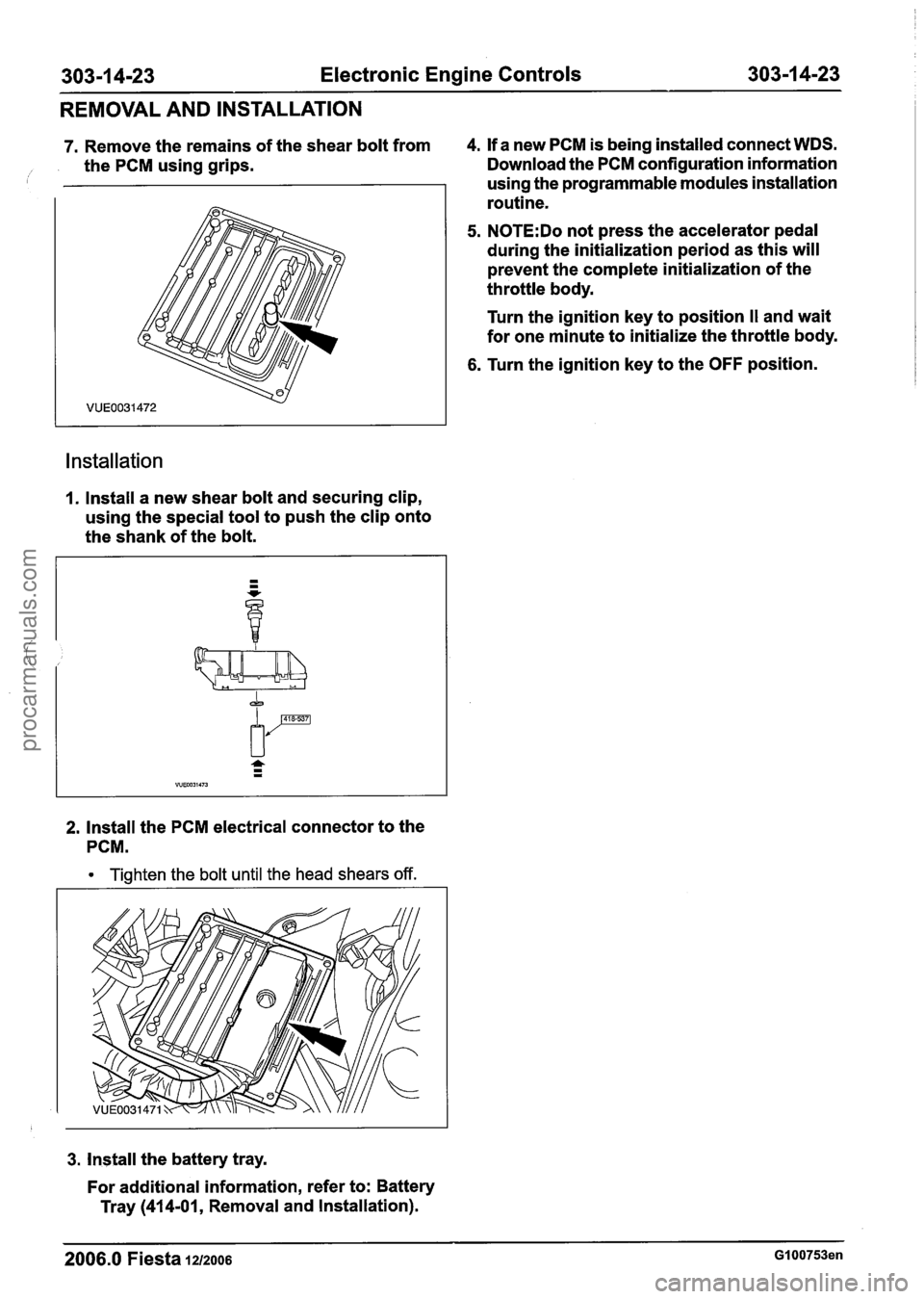

7. Remove the remains of the shear bolt from 4.

If a new PCM is being installed connect WDS.

/ the PCM using grips. Download the PCM configuration information

using the programmable modules installation

routine.

5. N0TE:Do not press the accelerator pedal

during the initialization period as this will

prevent the complete initialization of the

throttle body.

Turn the ignition key to position

I1 and wait

for one minute to initialize the throttle body.

6. Turn the ignition key to the OFF position.

Installation

I. Install a new shear bolt and securing clip,

using the special tool to push the clip onto

the shank of the bolt.

2. Install the PCM electrical connector to the

PCM.

Tighten the bolt until the head shears off.

3. Install the battery tray.

For additional information, refer to: Battery

Tray

(414-01, Removal and Installation).

procarmanuals.com

Page 948 of 1226

303-1 4-24 Electronic Engine Controls 303-1 4-24

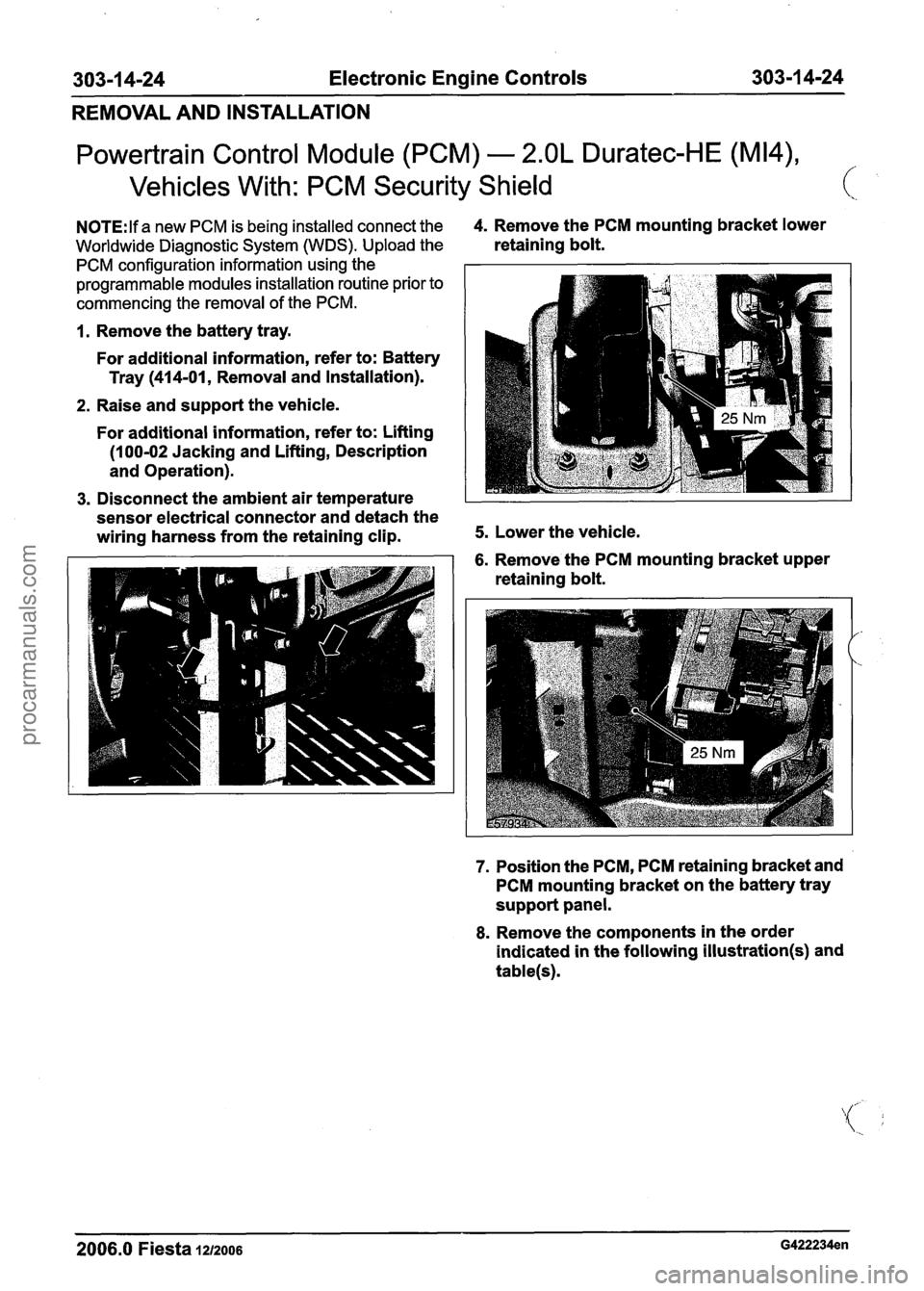

Powertrain Control Module (PCM) - 2.OL Duratec-HE (M14),

Vehicles With: PCM Security Shield c

N0TE:lf a new PCM is being installed connect the 4. Remove the PCM mounting bracket lower

Worldwide Diagnostic System (WDS). Upload the retaining bolt.

PCM configuration information using the

programmable modules installation routine prior to

commencing the removal of the PCM.

1. Remove the battery tray.

For additional information, refer to: Battery

Tray

(414-01, Removal and Installation).

2. Raise and support the vehicle.

For additional information, refer to: Lifting

(1 00-02 Jacking and Lifting, Description

and Operation).

3. Disconnect the ambient air temperature

sensor electrical connector and detach the

wiring harness from the retaining clip.

5. Lower the vehicle.

6. Remove the PCM mounting bracket upper

retaining bolt.

7. Position the PCM, PCM retaining bracket and

PCM mounting bracket on the battery tray

support panel.

8. Remove the components in the order

indicated in the following

illustration(s) and

table(s).

2006.0 Fiesta 1212006 G422234en

procarmanuals.com

Page 949 of 1226

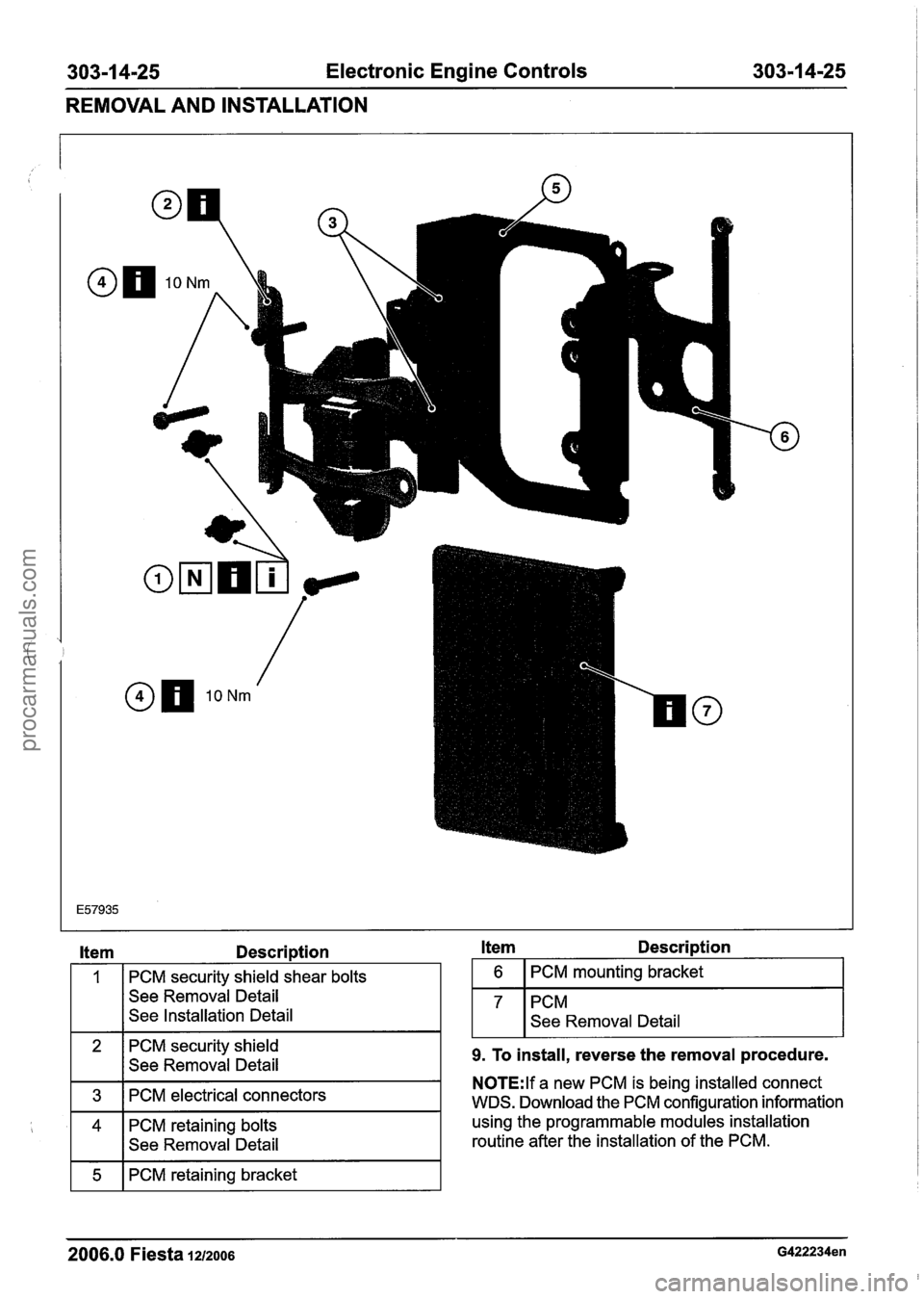

303-1 4-25 Electronic Engine Controls 30311 4-25

REMOVAL AND INSTALLATION

Item Description

2 PCM security shield

I I See Removal Detail

1

11FEKGPCMitrica1 connectors I

PCM security shield shear bolts

See Removal Detail

See Installation Detail

PCM retaining bolts

See Removal Detail

-- -

1 5 1 PCM retaining bracket I

Item Descri~tion

1 6 1 PCM mounting bracket I

1 I removal Detail

9. To install, reverse the removal procedure.

N0TE:lf a new PCM is being installed connect

WDS. Download the PCM configuration information

using the programmable modules installation

routine after the installation of the PCM.

2006.0 Fiesta 121~0o6 G422234en

procarmanuals.com

Page 950 of 1226

30311 4-26 Electronic Engine Controls 303-1 4-26

REMOVAL AND INSTALLATION

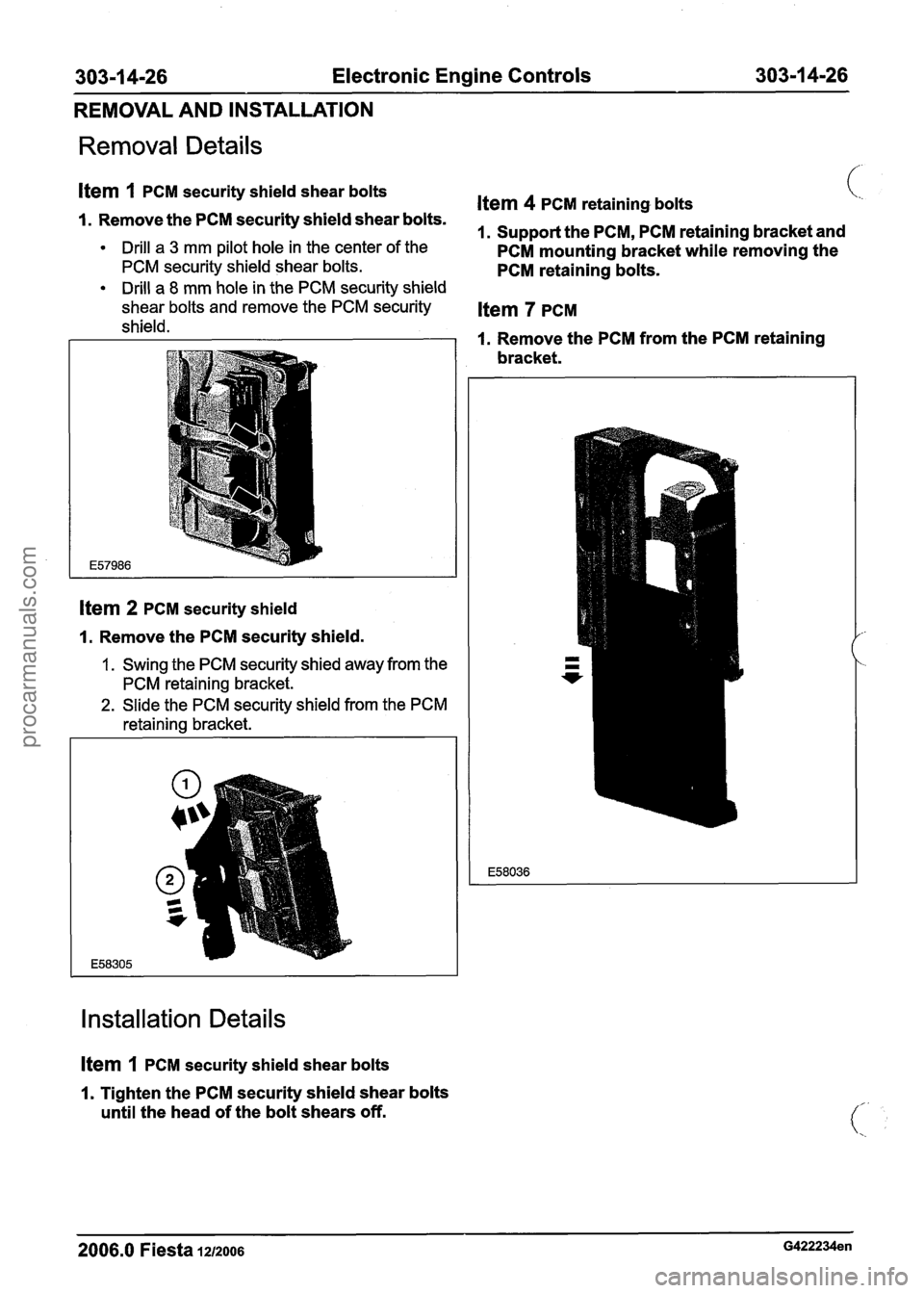

Removal Details

Item 1 PCM security shield shear bolts Item 4 PCM retaining bolts 1. Remove the PCM security shield shear bolts. 1. Support the PCM, PCM retaining bracket and Drill a 3 mm pilot hole in the center of the PCM mounting bracket while removing the PCM security shield shear bolts. PCM retaining bolts. Drill a 8 mm hole in the PCM security shield

shear bolts and remove the PCM security

Item 7 PCM

shield. I. Remove the PCM from the PCM retaining

bracket.

Item 2 PCM security shield

I. Remove the PCM security shield.

1. Swing the PCM security shied away from the

PCM retaining bracket.

2. Slide the PCM security shield from the PCM

retaining bracket.

Installation Details

Item 1 PCM security shield shear bolts

1. Tighten the PCM security shield shear bolts

until the head of the bolt shears off.

2006.0 Fiesta 1212006 G422234en

procarmanuals.com