FORD KUGA 2010 1.G Owners Manual

Manufacturer: FORD, Model Year: 2010, Model line: KUGA, Model: FORD KUGA 2010 1.GPages: 226, PDF Size: 8.07 MB

Page 161 of 226

Insert the screw-in towing eye into the

wheel brace.

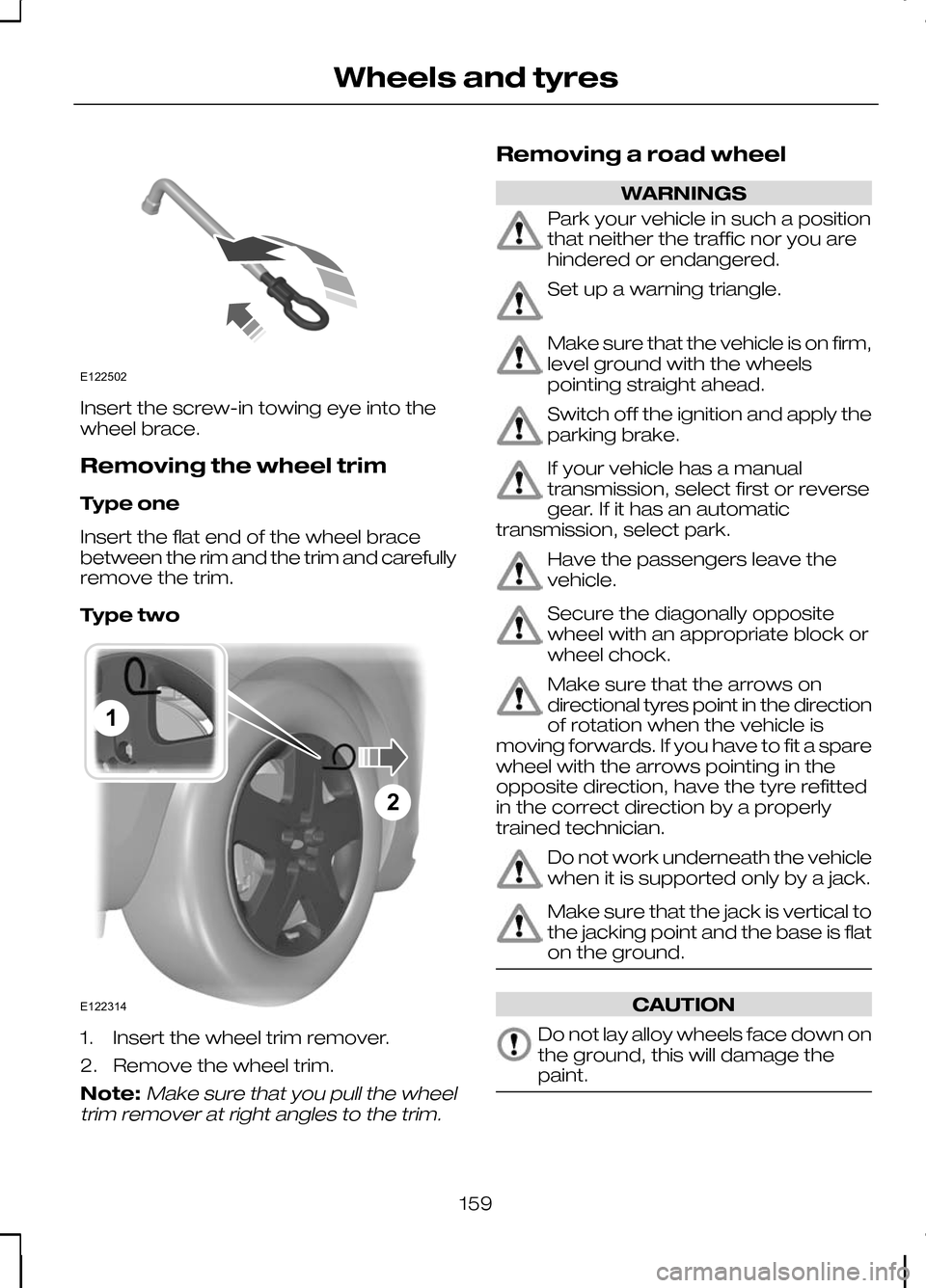

Removing the wheel trim

Type one

Insert the flat end of the wheel brace

between the rim and the trim and carefully

remove the trim.

Type two

1. Insert the wheel trim remover.

2. Remove the wheel trim.

Note:Make sure that you pull the wheel

trim remover at right angles to the trim.

Removing a road wheel WARNINGS

Park your vehicle in such a position

that neither the traffic nor you are

hindered or endangered.

Set up a warning triangle.

Make sure that the vehicle is on firm,

level ground with the wheels

pointing straight ahead.

Switch off the ignition and apply the

parking brake.

If your vehicle has a manual

transmission, select first or reverse

gear. If it has an automatic

transmission, select park. Have the passengers leave the

vehicle.

Secure the diagonally opposite

wheel with an appropriate block or

wheel chock.

Make sure that the arrows on

directional tyres point in the direction

of rotation when the vehicle is

moving forwards. If you have to fit a spare

wheel with the arrows pointing in the

opposite direction, have the tyre refitted

in the correct direction by a properly

trained technician. Do not work underneath the vehicle

when it is supported only by a jack.

Make sure that the jack is vertical to

the jacking point and the base is flat

on the ground.

CAUTION

Do not lay alloy wheels face down on

the ground, this will damage the

paint.

159

Wheels and tyresE122502 E12231421

Page 162 of 226

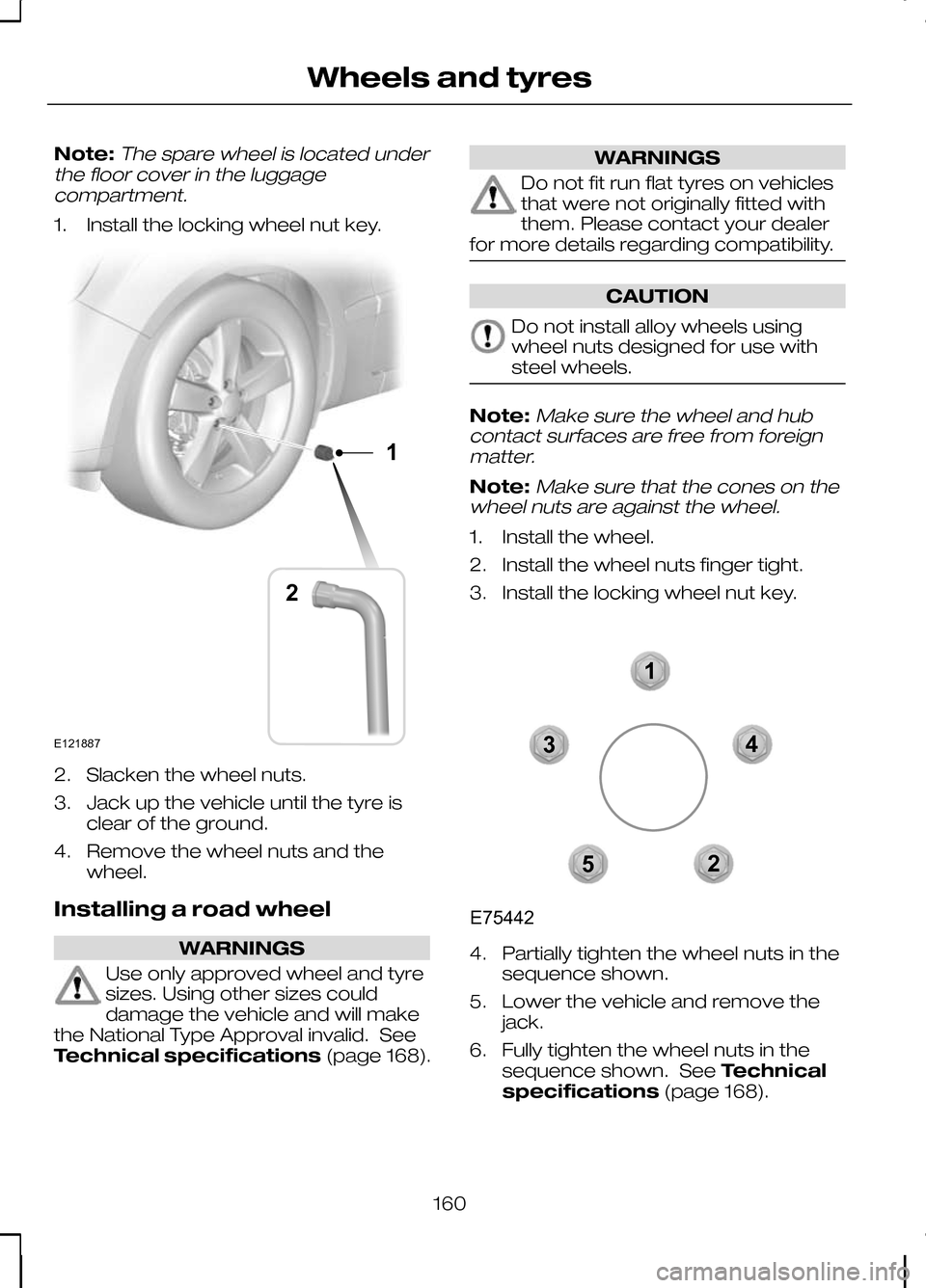

Note:The spare wheel is located under

the floor cover in the luggage compartment.

1. Install the locking wheel nut key. 2. Slacken the wheel nuts.

3. Jack up the vehicle until the tyre is

clear of the ground.

4. Remove the wheel nuts and the wheel.

Installing a road wheel WARNINGS

Use only approved wheel and tyre

sizes. Using other sizes could

damage the vehicle and will make

the National Type Approval invalid. See

Technical specifications (page 168). WARNINGS

Do not fit run flat tyres on vehicles

that were not originally fitted with

them. Please contact your dealer

for more details regarding compatibility. CAUTION

Do not install alloy wheels using

wheel nuts designed for use with

steel wheels.

Note:

Make sure the wheel and hub

contact surfaces are free from foreign matter.

Note:Make sure that the cones on the

wheel nuts are against the wheel.

1. Install the wheel.

2. Install the wheel nuts finger tight.

3. Install the locking wheel nut key. 4. Partially tighten the wheel nuts in the

sequence shown.

5. Lower the vehicle and remove the jack.

6. Fully tighten the wheel nuts in the sequence shown. See Technical

specifications (page 168).

160

Wheels and tyresE12188712 12345E75442

Page 163 of 226

7. Install the wheel trim using the ball of

your hand. WARNING

Have the wheel nuts checked for

tightness and the tyre pressure

checked as soon as possible.

Note:If the spare wheel is different in size

or construction to the road wheels, have this replaced as soon as possible.

TYRE REPAIR KIT

Your vehicle is not equipped with a spare

tyre, but does include an emergency tyre

repair kit that can be used to repair one

flat tyre.

The tyre repair kit is located in the

underfloor storage compartment. See

Storage compartments (page 98).

General information WARNINGS

Depending on the type and extent

of tyre damage, some tyres can

only be partially sealed or not sealed

at all. Loss of tyre pressure can affect

vehicle handling, leading to loss of vehicle

control. Do not use the tyre repair kit if the

tyre has already been damaged as

a result of being driven under

inflated. Do not use the tyre repair kit on run

flat tyres.

Do not try to seal damage other

than that located within the visible

tread of the tyre.

Do not try to seal damage to the

tyre’s sidewall. The tyre repair kit seals most tyre

punctures [with a diameter of up to six

millimetres (1/4 inch)] to temporarily

restore mobility.

Observe the following rules when using

the kit:

•

Drive with caution and avoid

making sudden steering or

driving manoeuvres, especially if

the vehicle is heavily loaded or you are

towing a trailer.

• The kit will provide you with an

emergency temporary repair, enabling

you to continue your journey to the

next vehicle or tyre dealer, or to drive

a maximum distance of

200 kilometres (125 miles).

• Do not exceed a

maximum speed

of 80 km/h (50 mph).

• Keep the kit out of the reach of

children.

• Only use the kit when the ambient

temperature is between –30°C (-22°F)

and +70°C (+158°F).

Using the tyre repair kit WARNINGS

Compressed air can act as an

explosive or propellant.

Never leave the tyre repair kit

unattended while in use.

CAUTION

Do not keep the compressor

operating for more than 10 minutes.

Note:

Use the tyre repair kit only for the

vehicle with which it was supplied.

161

Wheels and tyres

Page 164 of 226

•

Park your vehicle at the roadside so

that you do not obstruct the flow of

traffic and so that you are able to use

the kit without being in danger.

• Apply the parking brake, even if you

have parked on a level road, to make

sure that the vehicle will not move.

• Do not attempt to remove foreign

objects like nails or screws penetrating

the tyre.

• Leave the engine running while the kit

is in use, but not if the vehicle is in an

enclosed or poorly ventilated area (for

example, inside a building). In these

circumstances, switch the

compressor on with the engine turned

off.

• Replace the sealant bottle with a new

one before the expiry date (see top

of bottle) is reached.

• Inform all other users of the vehicle

that the tyre has been temporarily

sealed with the tyre repair kit and

make them aware of the special

driving conditions to be observed.

Inflating the tyre WARNINGS

Check the sidewall of the tyre prior

to inflation. If there are any cracks,

bumps or similar damage, do not

attempt to inflate the tyre. Do not stand directly beside the tyre

while the compressor is pumping.

Watch the sidewall of the tyre. If any

cracks, bumps or similar damage

appear, turn off the compressor and

let the air out by means of the pressure

relief valve B. Do not continue driving with

this tyre. WARNINGS

The sealant contains natural rubber

latex. Avoid contact with skin and

clothing. If this happens, rinse the

affected areas immediately with plenty of

water and contact your doctor. If the tyre inflation pressure does not

reach 1.8 bar (26 psi) within seven

minutes, the tyre may have suffered

excessive damage, making a temporary

repair impossible. In this case, do not

continue driving with this tyre. CAUTION

Screwing the bottle onto the bottle

holder will pierce the seal of the

bottle. Do not unscrew the bottle

from the holder as the sealant will escape. 162

Wheels and tyres

Page 165 of 226

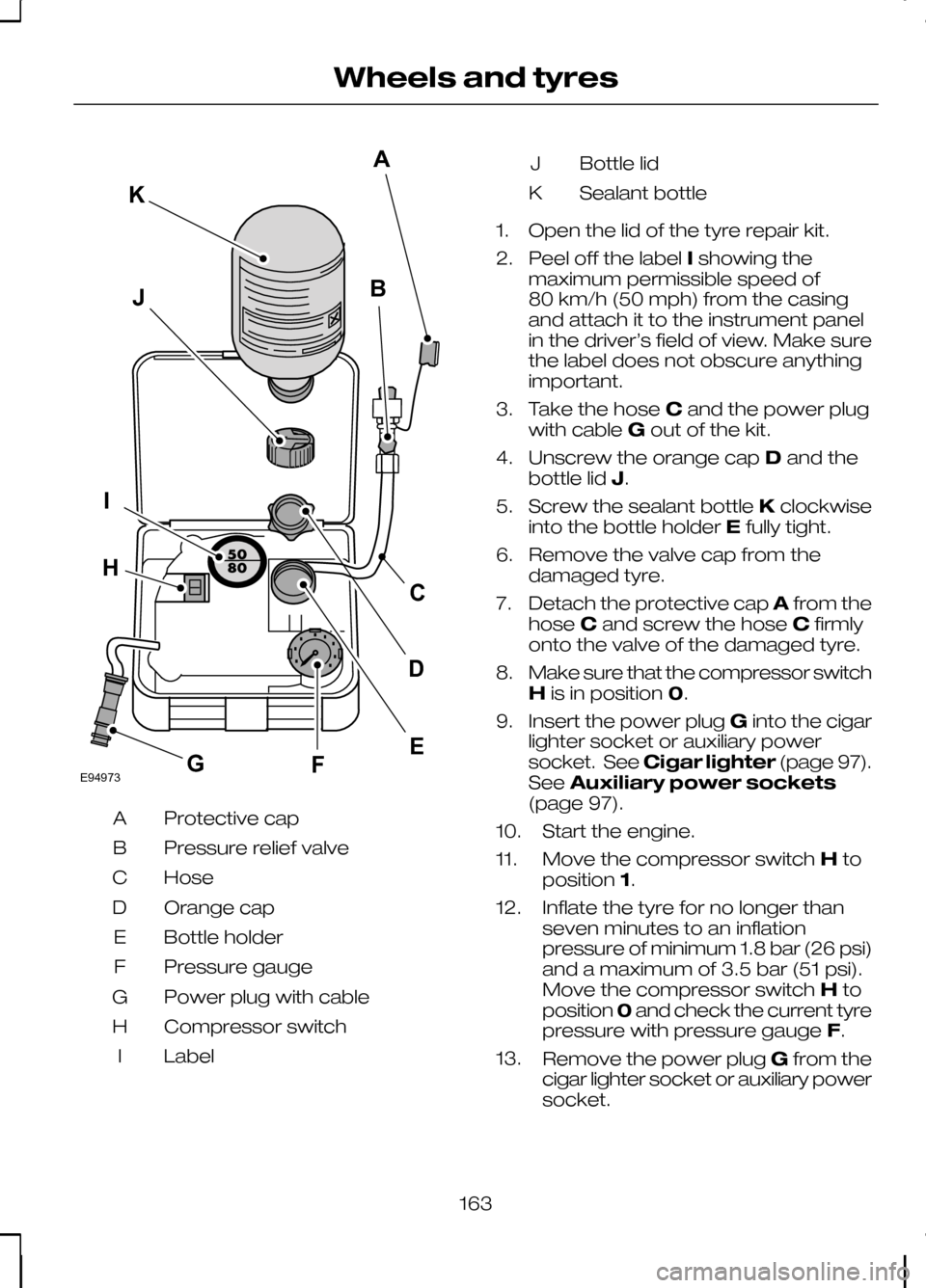

Protective cap

A

Pressure relief valve

B

Hose

C

Orange cap

D

Bottle holder

E

Pressure gauge

F

Power plug with cable

G

Compressor switch

H

Label

I Bottle lid

J

Sealant bottle

K

1. Open the lid of the tyre repair kit.

2. Peel off the label Ishowing the

maximum permissible speed of

80 km/h (50 mph) from the casing

and attach it to the instrument panel

in the driver’s field of view. Make sure

the label does not obscure anything

important.

3. Take the hose Cand the power plug

with cable Gout of the kit.

4. Unscrew the orange cap Dand the

bottle lid J.

5. Screw the sealant bottle Kclockwise

into the bottle holder Efully tight.

6. Remove the valve cap from the damaged tyre.

7. Detach the protective cap Afrom the

hose Cand screw the hose Cfirmly

onto the valve of the damaged tyre.

8. Make sure that the compressor switch

His in position 0.

9. Insert the power plug Ginto the cigar

lighter socket or auxiliary power

socket. See Cigar lighter (page 97).

See Auxiliary power sockets

(page 97).

10. Start the engine.

11. Move the compressor switch Hto

position 1.

12. Inflate the tyre for no longer than seven minutes to an inflation

pressure of minimum 1.8 bar (26 psi)

and a maximum of 3.5 bar (51 psi).

Move the compressor switch Hto

position 0and check the current tyre

pressure with pressure gauge F.

13. Remove the power plug Gfrom the

cigar lighter socket or auxiliary power

socket.

163

Wheels and tyresE94973BJIFECKAGHD

Page 166 of 226

14.

Quickly unscrew the hose Cfrom

the tyre valve and replace the

protective cap A. Fasten the valve

cap again.

15. Leave the sealant bottle Kin the

bottle holder E.

16. Make sure the kit, the bottle lid and the orange cap are stored safely, but

still easily accessible in the vehicle.

The kit will be required again when

you check the tyre pressure.

17. Immediately drive approximately three kilometres (two miles) so that

the sealant can seal the damaged

area.

Note:When pumping in the sealant

through the tyre valve, the pressure may rise up to 6 bar (87 psi) but will drop againafter about 30 seconds. WARNING

If you experience heavy vibrations,

unsteady steering behaviour or

noises while driving, reduce your

speed and drive with caution to a place

where it is safe for you to stop the vehicle.

Recheck the tyre and its pressure. If the

tyre pressure is less than 1.3 bar (19 psi)

or if there are any cracks, bumps or similar

damage visible, do not continue driving

with this tyre. Checking the tyre pressure

1. Stop the vehicle after driving

approximately three kilometres

(two miles). Check, and where

necessary, adjust the pressure of the

damaged tyre.

2. Attach the kit and read the tyre pressure from the pressure gauge F.

3. If the pressure of the sealant-filled tyre

is 1.3 bar (19 psi) or more, adjust it to

the specified pressure. See

Technical specifications (page

168). 4. Follow the inflation procedure once

again to top up the tyre.

5. Check the tyre pressure again from the pressure gauge F. If the tyre

pressure is too high, deflate the tyre

to the specified pressure using the

pressure relief valve B.

6. Once you have inflated the tyre to its correct tyre pressure, move the

compressor switch Hto position 0,

remove the power plug Gfrom the

socket, unscrew the hose C, fasten

the valve cap and replace the

protective cap A.

7. Leave the sealant bottle Kin the bottle

holder Eand store the kit away safely

in its original location.

8. Drive to the nearest tyre specialist to get the damaged tyre replaced.

Before the tyre is removed from the

rim, inform your tyre dealer that the

tyre contains sealant. Renew the kit

as soon as possible after it has been

used once.

Note:

Remember that emergency

roadside tyre repair kits only provide temporary mobility. Regulationsconcerning tyre repair after usage of tyrerepair kit may differ from country tocountry. You should consult a tyrespecialist for advice. WARNING

Before driving, make sure the tyre

is adjusted to the recommended

inflation pressure. See

Technical

specifications (page 168). Monitor the

tyre pressure until the sealed tyre is

replaced. Empty sealant bottles can be disposed

of together with normal household waste.

Return remains of sealant to your dealer

or dispose of it in compliance with local

waste disposal regulations.

164

Wheels and tyres

Page 167 of 226

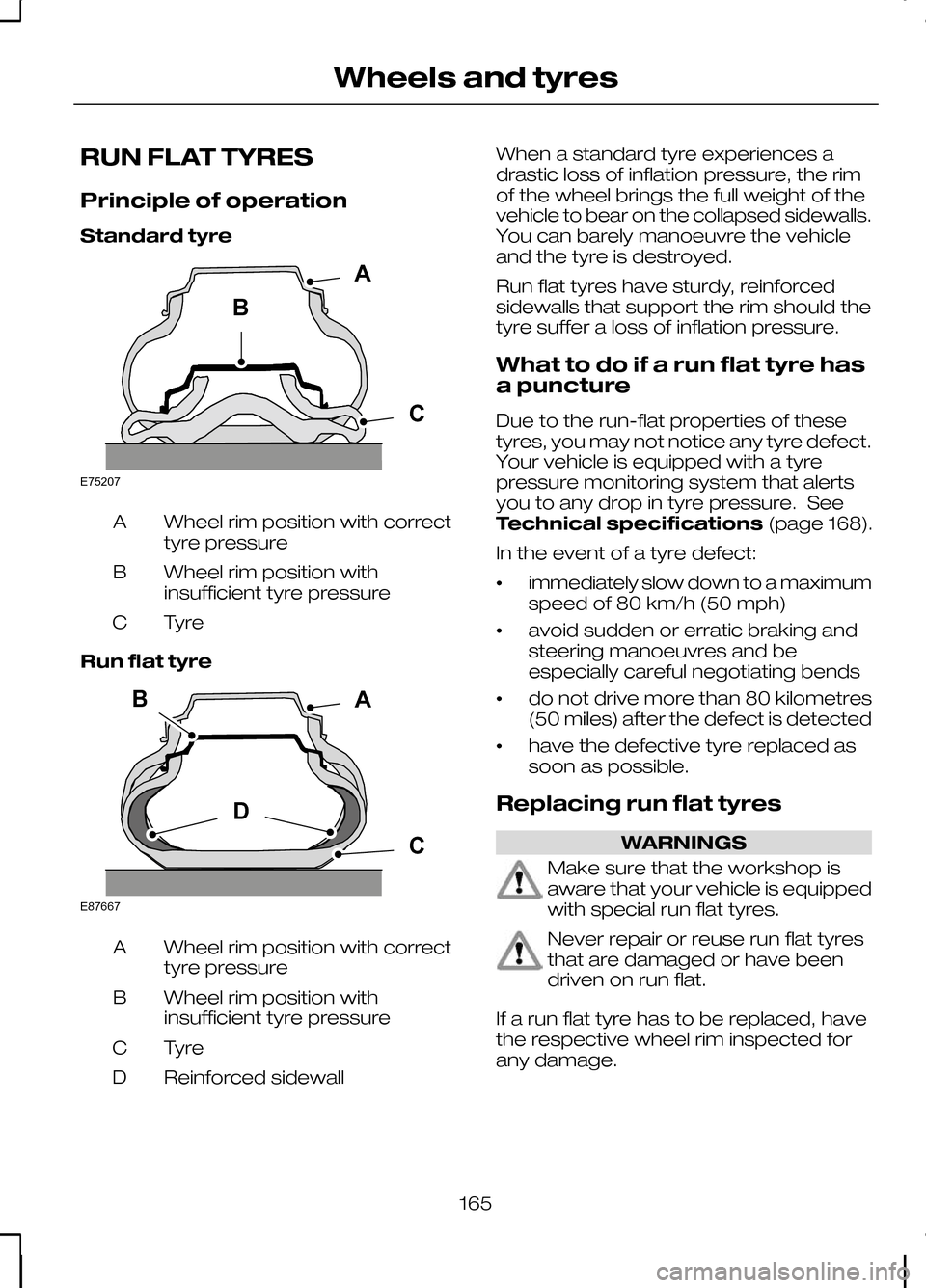

RUN FLAT TYRES

Principle of operation

Standard tyre

Wheel rim position with correct

tyre pressure

A

Wheel rim position with

insufficient tyre pressure

B

TyreC

Run flat tyre Wheel rim position with correct

tyre pressure

A

Wheel rim position with

insufficient tyre pressure

B

TyreC

Reinforced sidewall

D When a standard tyre experiences a

drastic loss of inflation pressure, the rim

of the wheel brings the full weight of the

vehicle to bear on the collapsed sidewalls.

You can barely manoeuvre the vehicle

and the tyre is destroyed.

Run flat tyres have sturdy, reinforced

sidewalls that support the rim should the

tyre suffer a loss of inflation pressure.

What to do if a run flat tyre has

a puncture

Due to the run-flat properties of these

tyres, you may not notice any tyre defect.

Your vehicle is equipped with a tyre

pressure monitoring system that alerts

you to any drop in tyre pressure. See

Technical specifications

(page 168).

In the event of a tyre defect:

• immediately slow down to a maximum

speed of 80 km/h (50 mph)

• avoid sudden or erratic braking and

steering manoeuvres and be

especially careful negotiating bends

• do not drive more than 80 kilometres

(50 miles) after the defect is detected

• have the defective tyre replaced as

soon as possible.

Replacing run flat tyres WARNINGS

Make sure that the workshop is

aware that your vehicle is equipped

with special run flat tyres.

Never repair or reuse run flat tyres

that are damaged or have been

driven on run flat.

If a run flat tyre has to be replaced, have

the respective wheel rim inspected for

any damage.

165

Wheels and tyresBACE75207 BDCAE87667

Page 168 of 226

WARNINGS

Do not fit a mixture of run flat and

standard tyres. In isolated cases, a

standard tyre can be temporarily

mounted on a vehicle otherwise equipped

with run flat tyres. It must be pointed out

to the driver that the standard tyre has no

runflat properties. Do not fit run flat tyres on vehicles

that were not originally fitted with

them. Please contact your dealer

for more details regarding compatibility. Run flat tyres may be sold and mounted

only by specially trained and certified tyre

dealers.

TYRE CARE

To make sure the front and rear tyres of

your vehicle wear evenly and last longer,

we recommend that you swap the tyres

from front to rear and vice versa at regular

intervals of between 5 000 and 10 000

km (3 000 and 6 000 miles).

CAUTION

Do not scrub the sidewalls of the

tyres when you are parking.

If you have to mount a kerb, do so slowly

and approach it with the wheels at

right-angles to the kerb. Examine the tyres regularly for cuts,

foreign objects and uneven wear of the

tread. Uneven wear could mean that the

wheel alignment is outside specification.

Check the tyre pressures (including the

spare) when cold, every two weeks.

USING WINTER TYRES

CAUTION

Make sure that you use the correct

wheel nuts for the type of wheel the

winter tyres are fitted to.

If winter tyres are used, make sure that

the tyre pressures are correct. See

Technical specifications

(page 168).

USING SNOW CHAINS WARNINGS

Do not exceed 40 km/h (25 mph)

when using 14 mm ( 0.6 inch) snow

chains or 50 km/h (30 mph) when

using 10 mm ( 0.4 inch) snow chains. Do not use snow chains on

snow-free roads.

Only fit snow chains to 235/60 R16

or 215/65 R16 tyres.

CAUTION

If your vehicle is fitted with wheel

trims, remove them before fitting

snow chains.

Note:The ABS will continue to operate

normally.

Only use small link snow chains.

Only use snow chains on the front wheels.

166

Wheels and tyresE70415

Page 169 of 226

Vehicles with stability control

(ESP)

Vehicles with stability control (ESP) may

exhibit some unusual driving

characteristics which can be avoided by

switching the system off. See

Using

stability control (page 113).

TYRE PRESSURE

MONITORING SYSTEM WARNINGS

The system does not relieve you of

your responsibility to regularly check

the tyre pressures.

The system will only provide a low

tyre pressure warning. It will not

inflate the tyres.

Do not drive on significantly

under-inflated tyres. This may cause

the tyres to overheat and fail.

Under-inflation reduces fuel efficiency,

tyre tread life and may also affect your

ability to drive the vehicle safely. CAUTIONS

Do not bend or damage the valves

when you are inflating the tyres.

Have tyres installed by properly

trained technicians.

The Deflation Detection System will alert

you if there is a change of air pressure in

any tyre. It does this by using the ABS

sensors to detect the rolling

circumference of the wheels. When the

circumference changes, this indicates low

pressure in a tyre, a warning message is

displayed in the information display and

the message indicator will illuminate. See

Information messages

(page 73).Apart from a too low tyre pressure or a

damaged tyre, the following situations can

affect the rolling circumference:

•

Vehicle load is uneven.

• When using a trailer or travelling up

and down an incline.

• Using snow chains.

• Driving on soft surfaces such as snow

or mud.

Note:The system will still function

correctly, but there may be an increased detection time.

If a low pressure warning message is

displayed in the information display, check

the tyre pressures as soon as possible

and inflate them to the recommended

pressure. See Technical

specifications (page 168).

If this happens frequently, have the cause

determined and rectified as soon as

possible.

System reset

Note:

Do not reset the system when the

vehicle is moving.

Note:You should reset the system

following any adjustment to the tyre pressures or any changing of tyres.

Note:Turn the ignition on.

Type 2 instrument cluster

1. Using the multifunction lever, navigate

to'SET' > T. Pres.

2. Press and hold the SET/RESET

button until the message Tyre

Pressure set appears.

Type 3 instrument cluster

1. Using the multifunction lever, navigate

tohold 'SET' to set Tyre Pres.

167

Wheels and tyres

Page 170 of 226

2.

Press and hold the SET/RESET

button until the message Tyre Pressure set

appears.

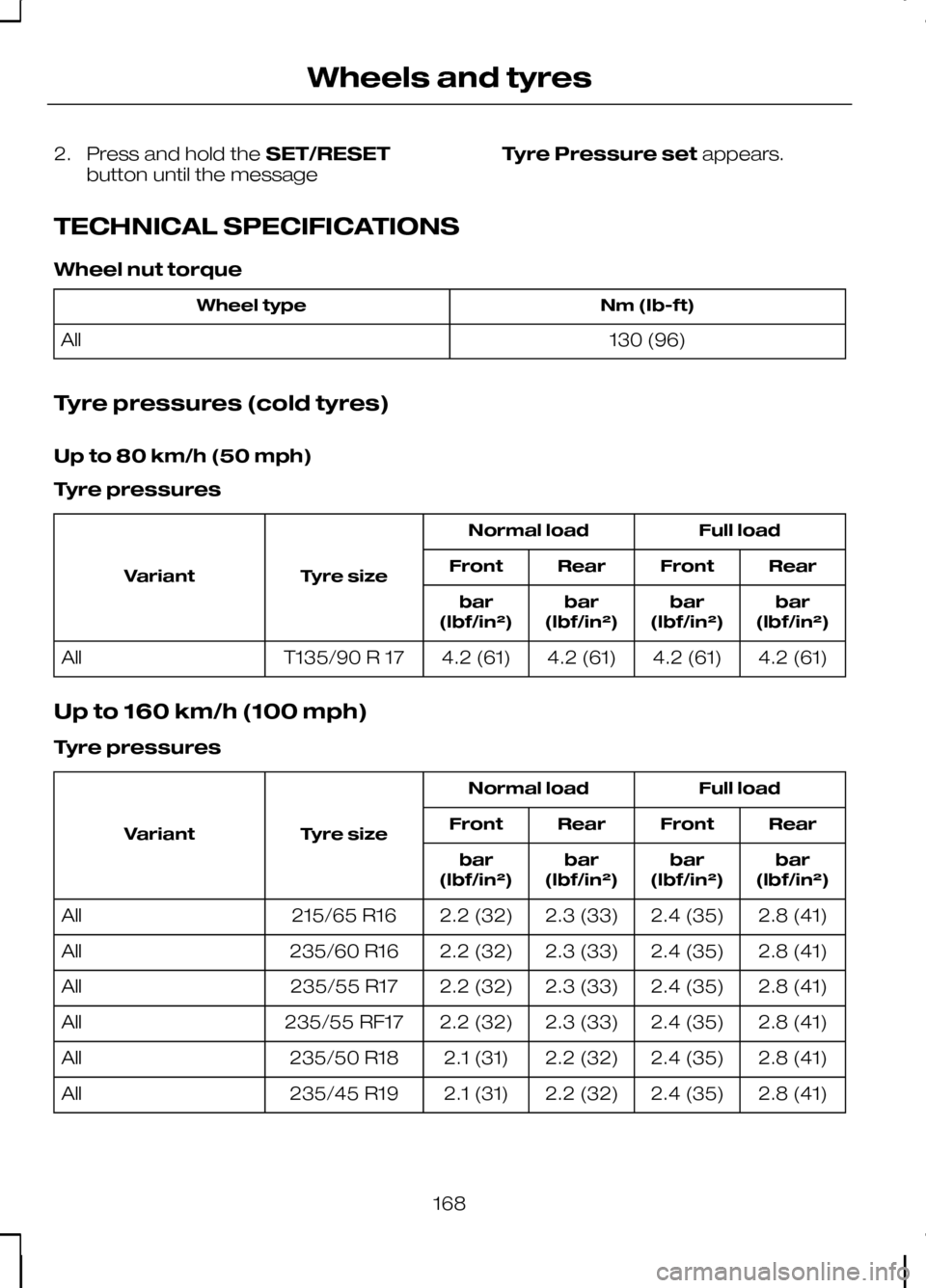

TECHNICAL SPECIFICATIONS

Wheel nut torque Nm (Ib-ft)

Wheel type

130 (96)

All

Tyre pressures (cold tyres)

Up to 80 km/h (50 mph)

Tyre pressures Full load

Normal load

Tyre size

Variant Rear

Front

Rear

Front

bar

(lbf/in²)

bar

(lbf/in²)

bar

(lbf/in²)

bar

(lbf/in²)

4.2 (61)

4.2 (61)

4.2 (61)

4.2 (61)

T135/90 R 17

All

Up to 160 km/h (100 mph)

Tyre pressures Full load

Normal load

Tyre size

Variant Rear

Front

Rear

Front

bar

(lbf/in²)

bar

(lbf/in²)

bar

(lbf/in²)

bar

(lbf/in²)

2.8 (41)

2.4 (35)

2.3 (33)

2.2 (32)

215/65 R16

All

2.8 (41)

2.4 (35)

2.3 (33)

2.2 (32)

235/60 R16

All

2.8 (41)

2.4 (35)

2.3 (33)

2.2 (32)

235/55 R17

All

2.8 (41)

2.4 (35)

2.3 (33)

2.2 (32)

235/55 RF17

All

2.8 (41)

2.4 (35)

2.2 (32)

2.1 (31)

235/50 R18

All

2.8 (41)

2.4 (35)

2.2 (32)

2.1 (31)

235/45 R19

All

168

Wheels and tyres