instrument panel FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 124 of 413

03-05-11

Steering Columns

And

Linkage

03-05-11

9. Check

the

operation

of the

steer-

ing tilt mechanism

(if so

equipped)

and

the

switches.

THUNDERBIRD

AND

CONTINENTAL MARK

III

Removal

1.

Remove

the

instrument panel

lower outer finish panel, instrument

panel steering column plate

and

cover.

2.

Disconnect

the

negative cable

from

the

battery.

3.

Remove

the

bolt that attaches

the flexible coupling

to the

steering

shaft.

4.

Disconnect

the

shift

rod

from

the

lever

at the

lower

end of the

column.

5.

Remove

the

four screws that

at-

tach

the

column retainer

to the

dash

panel.

6. Working from

the

underside

of

the instrument panel disconnect

the

steering column tilt-control cable from

the vacuum motor

and

mounting

bracket

(if so

equipped)

(Fig. 14).

7.

Disconnect

the

turn signal

switch,

and

emergency flasher wires

at

the connectors. Disconnect

the

wires

from

the

neutral start switch.

8. While supporting

the

steering

column, remove

the

four bolts that

at-

tach

the

lower clamp

to the

upper

clamp

(Fig. 14).

Lift

the

column from

the vehicle.

Installation

1.

Position

the

column

in the

vehi-

cle making sure that

the

steering shaft

engages

the

flex coupling.

1.

Install

the

column retainer-

to-dash panel attaching screws,

but do

not tighten them.

3.

Install

the

lower clamp

and the

attaching nuts. Tighten

the

nuts fing-

ertight.

4.

Move

the

lower flange

as re-

quired

to

center

the

steering shaft

in

the tube. Aligning procedures

are de-

tailed

in

Part

3-1.

Tighten

the

lower

flange attaching nuts when

the

shaft

is

centered.

5.

Connect

the

shift

rod to the

shift

lever

at the

lower

end of the

column.

6. Install

and

tighten

the

flex

cou-

pling attaching bolt.

7.

Tighten

the

instrument panel-

to-clamp attaching nuts.

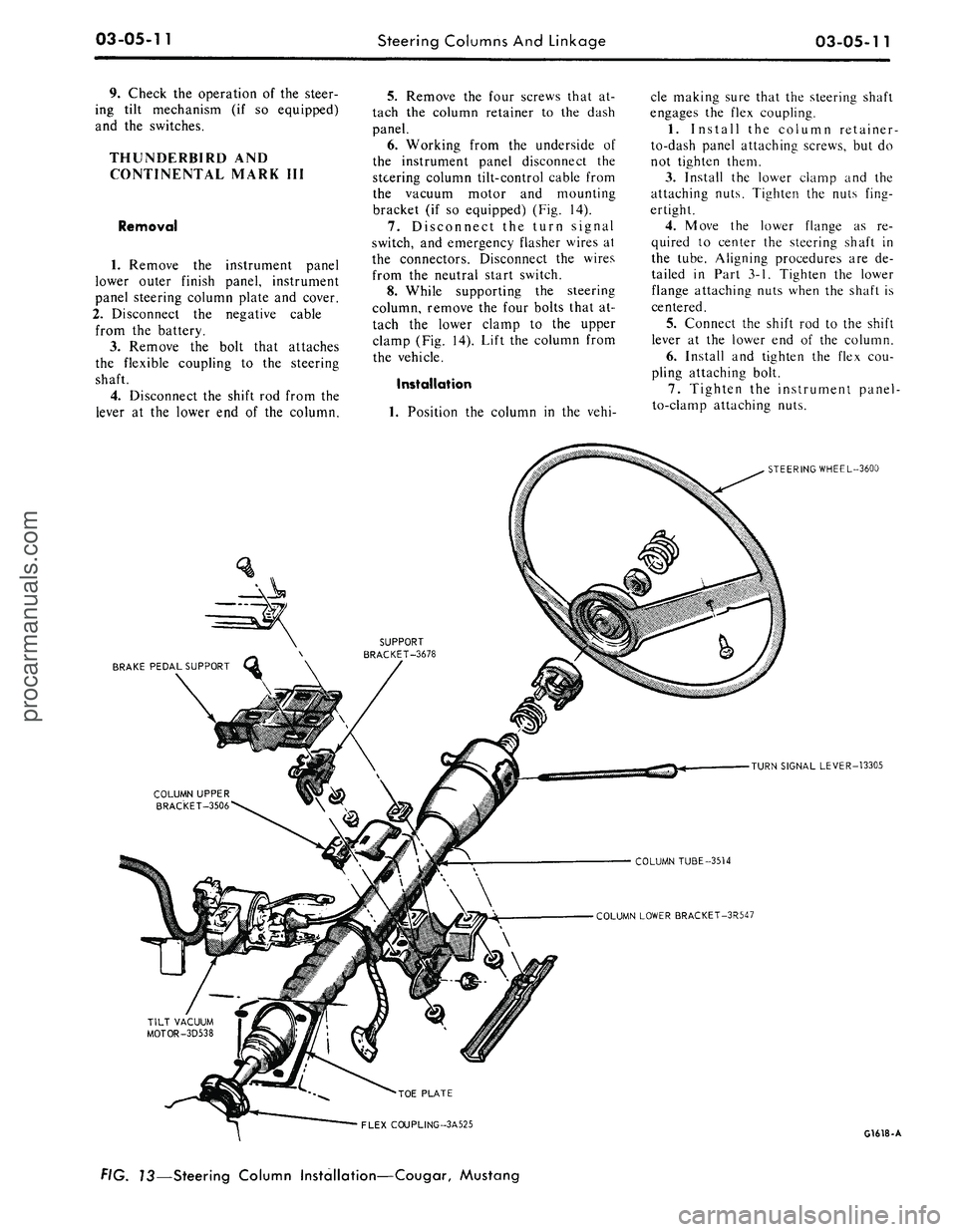

BRAKE PEDAL SUPPORT

STEERING WHEEL-3600

TURN SIGNAL LEVER-13305

COLUMN TUBE-3514

COLUMN LOWER BRACKET-3R547

•TOE PLATE

FLEX COUPLING-3A525

G1618-A

f/G.

73—Steering Column Installation—Cougar, Mustangprocarmanuals.com

Page 127 of 413

03-05-14

Steering Columns And Linkage

03-05-14

8. Connect the turn signal and

emergency flasher switch wires at the

multiple connectors. Connect the wires

to the neutral start switch. Adjust-

ments for the neutral start switch are

detailed in Group 7 of this manual.

9. Connect the tilt-column control

cable to the release cable retainer and

vacuum motor (if so equipped). To re-

move cable slack, loosen the bracket

attaching screw and pull it slightly

toward the column, then tighten the

screw. If difficulty in adjusting this

control is experienced, the retainer

slot may be filed to gain additional

travel.

10.

Install the instrument panel

steering column plate and cover and

the instrument panel lower outer fin-

ish panel.

11.

Connect the negative cable to

the battery.

12.

Start the engine and check the

operation of the steering column and

switches.

LINCOLN CONTINENTAL

Removal

1.

Disconnect the battery.

2.

Disconnect the rod from the

lever at the lower end of the selector

tube.

Loosen the clamp bolt that locks

the flexible coupling to the steering

shaft.

3.

Working from the underside of

the steering wheel spoke, remove the

two screws that secure the crash pad.

Remove the pad. Do not use a ham-

mer or knock-off type wheel puller.

Striking the puller or shaft may cause

damage to the bearings and/or col-

lapsible column. Remove the steering

wheel as shown in Fig. 15.

4.

Remove the instrument panel

steering column finish plate.

5.

Remove the four screws that at-

tach the lower retainer to the dash

panel.

6. Disconnect the turn signal switch

and emergency flasher wires at the

connectors. Disconnect the wires from

the neutral start switch.

7.

While supporting the steering

column, remove the bolts that attach

the lower clamp to the upper bracket

(Fig. 15). Lift the column from the ve-

hicle.

Installation

1.

Position the column in the vehi-

cle,

making sure that the steering

shaft engages the flex coupling.

2.

Install the column retainer-

to-dash panel attaching screws, but do

not tighten them.

3.

Install the lower clamp and the

attaching nuts. Tighten the nuts fing-

ertight.

4.

Move the lower flange as re-

quired to center the steering shaft in

the tube. Aligning procedures are de-

tailed in Part 3-1. Tighten the lower

flange attaching nuts when the shaft is

centered.

5.

Connect the shift rod to the shift

lever at the lower end of the column.

6. Install and tighten the flex cou-

pling attaching bolt.

7.

Tighten the instrument panel-

to-clamp attaching nuts.

8. Connect the turn signal and

emergency flasher switch wirss at the

multiple connectors. Connect the wires

to the neutral start switch. Adjust-

ments for the neutral start switch are

detailed in Group 7 of this manual.

9. Install the instrument panel

steering column finish plate.

10.

Install the steering wheel and

crash pad.

MAJOR REPAIR OPERATIONS

STEERING COLUMN

SHIFT TUBE REPLACEMENT

STATIONARY COLUMN

WITH STANDARD

TRANSMISSION

Removal

1.

Working from the underside of

the steering wheel spoke, remove the

two screws that secure the crash pad.

Remove the pad. (On Continental

Mark III models, pry out the crash

pad insert and remove the two screws

that secure the crash pad. Remove the

crash pad. On models equipped with

steering wheel mounted speed con-

trols,

refer to Group 16 for removal

instructions).

2.

Remove the steering wheel from

the steering shaft with tool T67L-

3600-A (Fig. 1). Then, remove the

tool from the steering wheel. Do not

use a knock-off type steering Wheel

puller or strike the end of the steering

shaft with a hammer. Striking the

puller or shaft will damage the bear-

ing or the collapsible column.

3.

Remove the steering column

from the vehicle.

4.

Remove the selector lever from

the hub (Fig. 16).

5.

Remove the bearing upper snap

ring. It may be necessary to pull the

turn signal switch out to remove the

snap ring.

6. Remove the screws that attach

the shift tube bearing, shift arms, and

shift tube to the lower end of the

steering column.

7.

Slip the shift tube and steering

shaft from the lower end of the steer-

ing column tube. The upper bearing

has a slight press fit on the steering

shaft.

8. Remove the C-washer from the

upper end of the steering shaft, and

pull the shift tube from the steering

shaft.

9. Remove the shift tube bearing

from the lower end of the tube

Installation

1.

Position the shift tube bearing

(Fig. 16) on the tube and insert the

steering shaft in the shift tube.

2.

Install the C-washer on the

upper end of the steering shaft.

3.

Insert the shift tube and steering

shaft into the steerint column tube

and install the three attaching screws

at the lower end of the steering col-

umn tube.

4.

Position the bearing and insula-

tor on the shaft if it was disturbed

during removal. Work it down onto

the shaft as far as possible, then place

a piece of 3/4 ID x 2 1/8 inch pipe

over the end of shaft and install the

steering wheel attaching nut (Fig. 2).

5.

Tighten the nut until the bearing

is seated in the flange, then remove

the nut and pipe from the shaft.

6. Position the turn signal switch

on the flange and install the three at-

taching screws. Install the upper snap

ring.

7.

Install the selector lever and the

turn signal lever in the column.

8. Adjust and install the neutral

start switch as detailed in Group 7.

9. Install the steering column in the

vehicle.procarmanuals.com

Page 183 of 413

03-13-04

Specifications

03-13-04

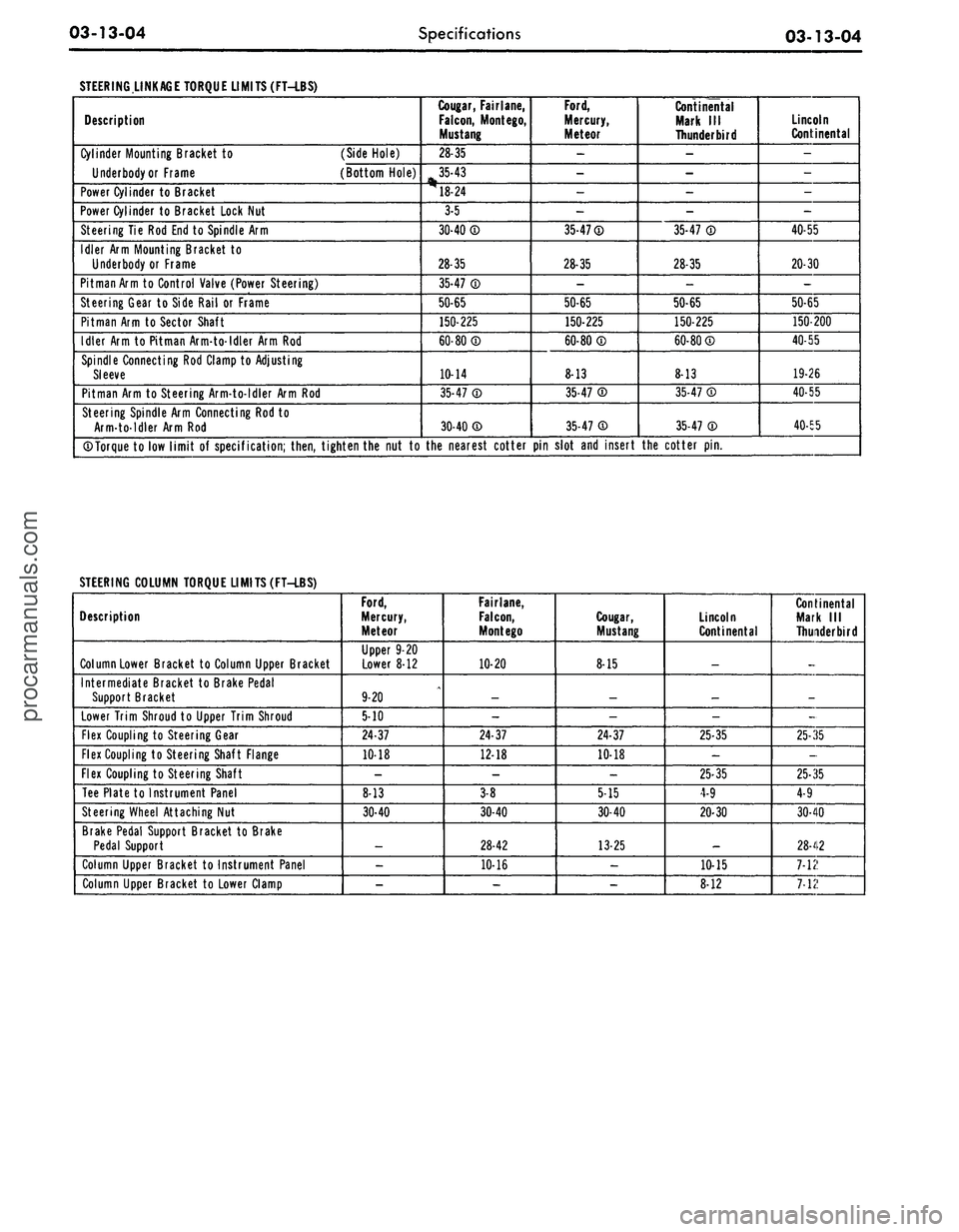

STEERING LINKAGE TORQUE LIMITS (FT-LBS)

Description

Cylinder Mounting Bracket

to

(Side Hole)

Underbodyor Frame (Bottom Hole)

Power Cylinder

to

Bracket

Power Cylinder

to

Bracket Lock

Nut

Steering

Tie Rod End to

Spindle

Arm

Idler

Arm

Mounting Bracket

to

Underbody

or

Frame

Pitman Arm

to

Control Valve (Power Steering)

Steering Gear

to

Side Rail

or

Frame

Pitman

Arm to

Sector Shaft

Idler

Arm to

Pitman Arm-to-ldler

Arm Rod

Spindle Connecting

Rod

Clamp

to

Adjusting

Sleeve

Pitman

Arm to

Steering Arm-to-ldler

Arm Rod

Steering Spindle

Arm

Connecting

Rod to

Arm-to-ldler

Arm Rod

Cougar, Fairlane,

Falcon,

Mont

ego,

Mustang

28-35

35-43

18-24

3-5

30-40

©

28-35

35-47

©

50-65

150-225

60-80®

10-14

35-47

©

30-40

©

Ford,

Mercury,

Meteor

-

-

-

-

35-47®

28-35

-

50-65

150-225

60-80

®

8-13

35-47

©

35-47

®

Continental

Mark

III

Thunder bird

-

-

-

-

35-47

©

28-35

-

50-65

150-225

60-80

©

8-13

35-47

©

35-47

©

Lincoln

Continental

-

-

-

-

40-55

20-30

-

50-65

150-200

40-55

19-26

40-55

40-55

CD

Torque

to low

limit

of

specification;

then,

tighten

the nut to the

nearest cotter

pin

slot

and

insert

the

cotter

pin.

STEERING COLUMN TORQUE LIMITS (FT-LBS)

Description

Column Lower Bracket

to

Column Upper Bracket

Intermediate Bracket

to

Brake Pedal

Support Bracket

Lower Trim Shroud

to

Upper Trim Shroud

Flex Coupling

to

Steering Gear

Flex Coupling

to

Steering Shaft Flange

Flex Coupling

to

Steering Shaft

Tee Plate

to

Instrument Panel

Steering Wheel Attaching

Nut

Brake Pedal Support Bracket

to

Brake

Pedal Support

Column Upper Bracket

to

Instrument Panel

Column Upper Bracket

to

Lower Clamp

Ford,

Mercury,

Meteor

Upper

9-20

Lower

8-12

9-20

5-10

24-37

10-18

-

8-13

30-40

_

-

-

Fairlane,

Falcon,

Mont

ego

10-20

_

-

24-37

12-18

-

3-8

30-40

28-42

10-16

-

Cougar,

Mustang

8-15

_

-

24-37

10-18

-

5-15

30-40

13-25

-

-

Lincoln

Continental

_

_

-

25-35

-

25-35

4-9

20-30

_

10-15

8-12

Continental

Mark

III

Thunder bird

_

_

-

25-35

-

25-35

4-9

30-40

28-42

7-12

7-1?procarmanuals.com

Page 263 of 413

05-03-05

Clutch

05-03-05

4.

Remove the bolt that secures the

left air vent control cable bracket to

the instrument panel. Position the

control cable to one side.

5.

Remove the retaining clip and

flat washer from the clutch pedal

shaft. Then, remove the shaft, bush-

ing, clutch pedal and brake pedal

from the support.

6. Remove the bushings from the

pedal shaft, and transfer the pedal

pad.

7.

Lubricate the clutch pedal shaft

bushings and position them on the

shaft. Then, position the brake pedal

and clutch pedal in the pedal support.

8. Install the flat washer and re-

taining clip on the pedal shaft.

9. Position the assist spring to the

pedal and bracket. Pry the bracket

forward and install the lower bolt.

Torque the bolts to specifications.

10.

Position the master cylinder

push rod, bushing, and washers on the

brake pedal and secure with a retain-

ing clip.

11.

Connect the equalizer rod to

the clutch pedal and secure it in place

with a retaining clip.

12.

Position the air vent control

cable bracket to the instrument panel

and secure with the attaching bolt.

13.

Adjust the clutch pedal free

travel.

EQUALIZER BAR AND/OR

BUSHING REMOVAL AND

INSTALLATION

FORD, MERCURY

AND METEOR

1.

Raise the vehicle and disconnect

the clutch pedal-to-equalizer rod at

the equalizer bar (Fig. 1).

2.

Disconnect the return spring and

retaining spring at the release lever.

Separate the release lever rod from

the release lever.

3.

Remove the equalizer bar frame

bracket from the frame.

4.

Remove the equalizer bar from

the pivot on the flywheel housing.

5.

Remove the wire clip to replace

the outer bushing and the snap ring

from the inner pivot stud to replace

the inner bushing.

6. Position the flat washer, felt

washer and bushing on the inner and

outer pivots. Secure these parts with

the snap ring.

7.

Position the equalizer bar on the

inner pivot and bolt the equalizer bar

frame bracket to the frame. Torque

the attaching bolts to specification.

8. Install the clutch release rod, re-

turn spring and retaining spring.

9. Connect the clutch pedal rod to

the equalizer bar.

10.

Adjust the clutch pedal free

travel.

MUSTANG, COUGAR,

MONTEGO, FALCON,

FAIRLANE (EXCEPT

MONTEGO AND FAIRLANE

WITH 390 V-8)

1.

Disconnect the clutch pedal

equalizer rod at the equalizer bar

(Figs.

2 and 3).

2.

Raise the vehicle and disconnect

the release lever, return spring at the

lever.

3.

Remove the equalizer bar outer

bracket and bushing assembly.

4.

Remove the release rod from the

equalizer bar, and then remove the

equalizer bar. Remove the bushing

and washers from the inner mounting

stud.

5.

Position the equalizer bar, wash-

ers,

inner bushing, and retainer on the

inner stud.

6. After positioning the outer bush-

ing, install the outer bracket (with the

equalizer bar in place).

7.

Connect the release rod and the

release lever return spring.

8. Lower the vehicle. Connect the

clutch pedal equalizer rod to the

equalizer baY and secure with the re-

taining pin.

9. Adjust the clutch pedal free trav-

el as required.

MONTEGO AND

FAIRLANE—390 V-8

1.

Disconnect the clutch pedal

equalizer rod at the equalizer bar (Fig.

2).

2.

Raise the vehicle and disconnect

the return spring at the release lever.

Disconnect the release lever rod from

the equalizer lever.

3.

Remove the equalizer bar center

bolt.

4.

Separate the equalizer bar and

remove both sections from the vehicle.

5.

Remove the bolts retaining the

equalizer bar inner bracket to the fly-

wheel housing and remove the bracket

and bushing assembly.

6. Remove the equalizer bar outer

bracket and bushing assembly.

7.

Remove the snap ring, bushing,

and felt washer from each bracket as-

sembly.

8. Position a felt washer, and bush-

ing on each bracket assembly and se-

cure with the snap ring.

9. Install the outer bracket and

bushing assembly to the frame (Fig.

2).

Torque the bracket attaching bolts

to specifications.

10.

Position the outer section of the

equalizer bar on the outer bracket

pivot.

11.

Connect the two sections of the

equalizer bar. Insert the inner bracket

pivot into the equalizer bar and install

the assembly to the flywheel housing.

Torque the attaching bolts to specifi-

cations.

12.

Install the equalizer bar center

bolt and torque to specifications.

Make sure that both ends of the

equalizer bar are against the felt

washers.

13.

Connect the release rod and the

release lever return spring.

14.

Adjust the clutch pedal free

travel.

15.

Lower the vehicle. Connect the

clutch pedal equalizer rod to the

equalizer bar and secure with the re-

taining clip.

16.

Check the free travel at the

pedal for conformance to specifica-

tions.

Readjust if necessary.

REMOVAL AND INSTALLATION

CLUTCH REMOVAL

1.

Raise the vehicle on a hoist.

2.

Disconnect the drive shaft from

the rear U-joint flange. Then, slide the

drive shaft off the transmission output

shaft. Insert the appropriate tool over

the output shaft and into the extension

housing oil seal.

3.

Disconnect the speedometer

cable from the extension housing.

4.

Disconnect the gear shift rods

from the transmission. If the vehicle is

equipped with a four-speed transmis-

sion, remove the bolts that secure the

four-speed transmission, disconnect

the front brake cable from the cross-

member and remove the crossmem-

member from the vehicle.

5.

Remove the bolts that attach the

transmission to the flywheel housing.

6. Move the transmission rearward

until the input shaft clears the fly-

wheel housing, then remove it from

the vehicle.

7.

Disconnect the clutch release

lever retaining spring from the release

lever.procarmanuals.com