service indicator FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 195 of 413

04-01-08

General Axle Service

04 01-08

Too/-T57L-4067-A

E 1595-A

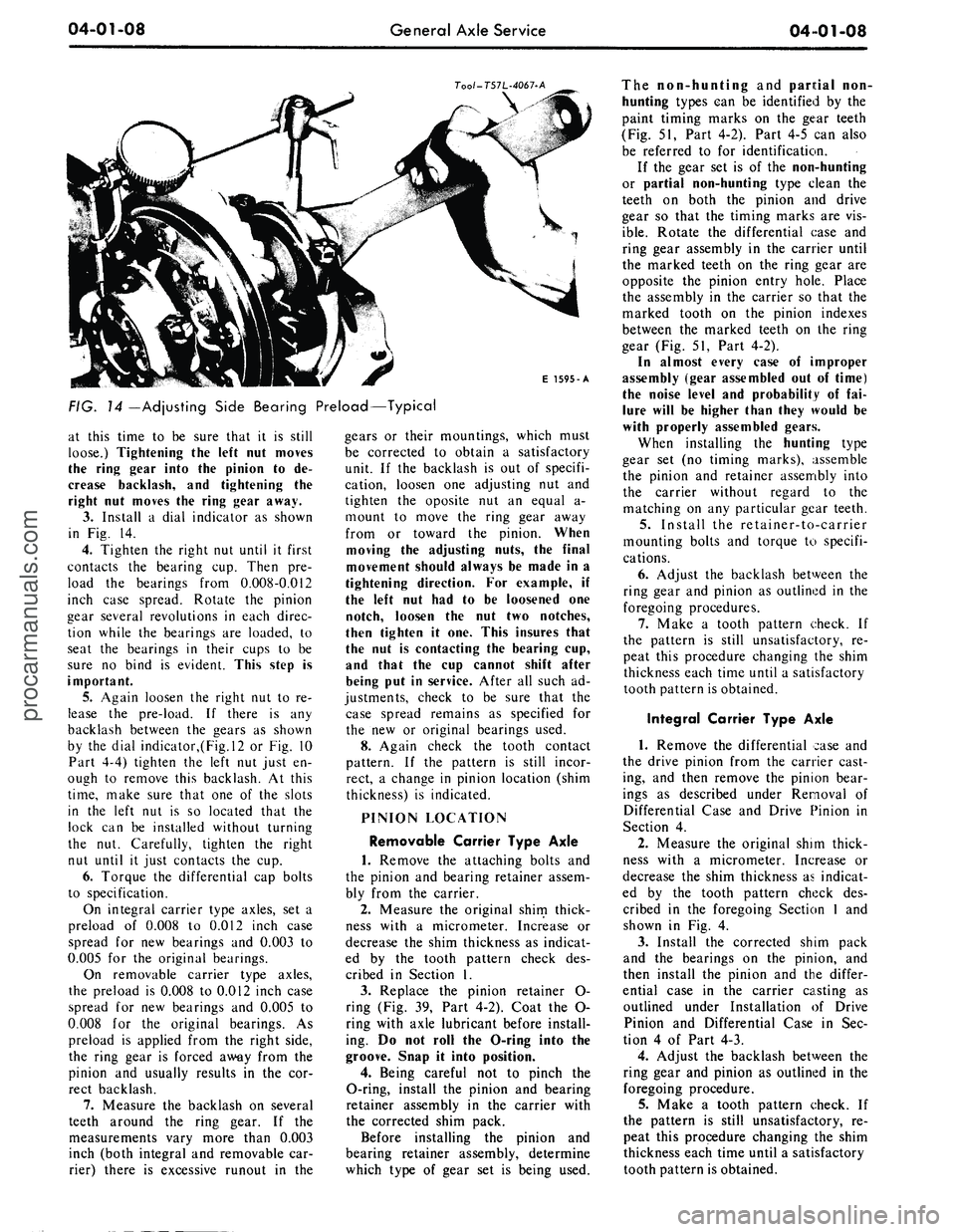

FIG.

14

—Adjusting Side Bearing Preload—Typical

at this time to be sure that it is still

loose.) Tightening the left nut moves

the ring gear into the pinion to de-

crease backlash, and tightening the

right nut moves the ring gear away.

3.

Install a dial indicator as shown

in Fig. 14.

4.

Tighten the right nut until it first

contacts the bearing cup. Then pre-

load the bearings from 0.008-0.012

inch case spread. Rotate the pinion

gear several revolutions in each direc-

tion while the bearings are loaded, to

seat the bearings in their cups to be

sure no bind is evident. This step is

important.

5. Again loosen the right nut to re-

lease the pre-load. If there is any

backlash between the gears as shown

by the dial indicator,(Fig.l2 or Fig. 10

Part 4-4) tighten the left nut just en-

ough to remove this backlash. At this

time,

make sure that one of the slots

in the left nut is so located that the

lock can be installed without turning

the nut. Carefully, tighten the right

nut until it just contacts the cup.

6. Torque the differential cap bolts

to specification.

On integral carrier type axles, set a

preload of 0.008 to 0.012 inch case

spread for new bearings and 0.003 to

0.005 for the original bearings.

On removable carrier type axles,

the preload is 0.008 to 0.012 inch case

spread for new bearings and 0.005 to

0.008 for the original bearings. As

preload is applied from the right side,

the ring gear is forced away from the

pinion and usually results in the cor-

rect backlash.

7.

Measure the backlash on several

teeth around the ring gear. If the

measurements vary more than 0.003

inch (both integral and removable car-

rier) there is excessive runout in the

gears or their mountings, which must

be corrected to obtain a satisfactory

unit. If the backlash is out of specifi-

cation, loosen one adjusting nut and

tighten the oposite nut an equal a-

mount to move the ring gear away

from or toward the pinion. When

moving the adjusting nuts, the final

movement should always be made in a

tightening direction. For example, if

the left nut had to be loosened one

notch, loosen the nut two notches,

then tighten it one. This insures that

the nut is contacting the bearing cup,

and that the cup cannot shift after

being put in service. After all such ad-

justments, check to be sure that the

case spread remains as specified for

the new or original bearings used.

8. Again check the tooth contact

pattern. If the pattern is still incor-

rect, a change in pinion location (shim

thickness) is indicated.

PINION LOCATION

Removable Carrier Type Axle

1.

Remove the attaching bolts and

the pinion and bearing retainer assem-

bly from the carrier.

2.

Measure the original shim thick-

ness with a micrometer. Increase or

decrease the shim thickness as indicat-

ed by the tooth pattern check des-

cribed in Section 1.

3.

Replace the pinion retainer O-

ring (Fig. 39, Part 4-2). Coat the O-

ring with axle lubricant before install-

ing. Do not roll the O-ring into the

groove. Snap it into position.

4.

Being careful not to pinch the

O-ring, install the pinion and bearing

retainer assembly in the carrier with

the corrected shim pack.

Before installing the pinion and

bearing retainer assembly, determine

which type of gear set is being used.

The non-hunting and pantial non-

hunting types can be identified by the

paint timing marks on the gear teeth

(Fig. 51, Part 4-2). Part 4-5 can also

be referred to for identification.

If the gear set is of the non-hunting

or partial non-hunting type clean the

teeth on both the pinion and drive

gear so that the timing marks are vis-

ible.

Rotate the differential case and

ring gear assembly in the carrier until

the marked teeth on the ring gear are

opposite the pinion entry hole. Place

the assembly in the carrier so that the

marked tooth on the pinion indexes

between the marked teeth on the ring

gear (Fig. 51, Part 4-2).

In almost every case of improper

assembly (gear assembled out of time)

the noise level and probability of fai-

lure will be higher than they would be

with properly assembled gears.

When installing the hunting type

gear set (no timing marks), assemble

the pinion and retainer assembly into

the carrier without regard to the

matching on any particular gear teeth.

5.

Install the retainer-to-carrier

mounting bolts and torque to specifi-

cations.

6. Adjust the backlash between the

ring gear and pinion as outlined in the

foregoing procedures.

7.

Make a tooth pattern check. If

the pattern is still unsatisfactory, re-

peat this procedure changing the shim

thickness each time until a satisfactory

tooth pattern is obtained.

Integral Carrier Type Axle

1.

Remove the differential case and

the drive pinion from the carrier cast-

ing, and then remove the pinion bear-

ings as described under Removal of

Differential Case and Drive Pinion in

Section 4.

2.

Measure the original shim thick-

ness with a micrometer. Increase or

decrease the shim thickness as indicat-

ed by the tooth pattern check des-

cribed in the foregoing Section 1 and

shown in Fig. 4.

3.

Install the corrected shim pack

and the bearings on the pinion, and

then install the pinion and the differ-

ential case in the carrier casting as

outlined under Installation of Drive

Pinion and Differential Case in Sec-

tion 4 of Part 4-3.

4.

Adjust the backlash between the

ring gear and pinion as outlined in the

foregoing procedure.

5.

Make a tooth pattern check. If

the pattern is still unsatisfactory, re-

peat this procedure changing the shim

thickness each time until a satisfactory

tooth pattern is obtained.procarmanuals.com

Page 196 of 413

04-01-09

General Axle Service

04-01-09

CLEANING AND INSPECTION

INSPECTION BEFORE

DISASSEMBLY OF CARRIER

(ALL AXLES)

The differential case or carrier

should be inspected before any parts

are removed from it. These inspec-

tions can help to find the cause of the

trouble and to determine the correc-

tions needed.

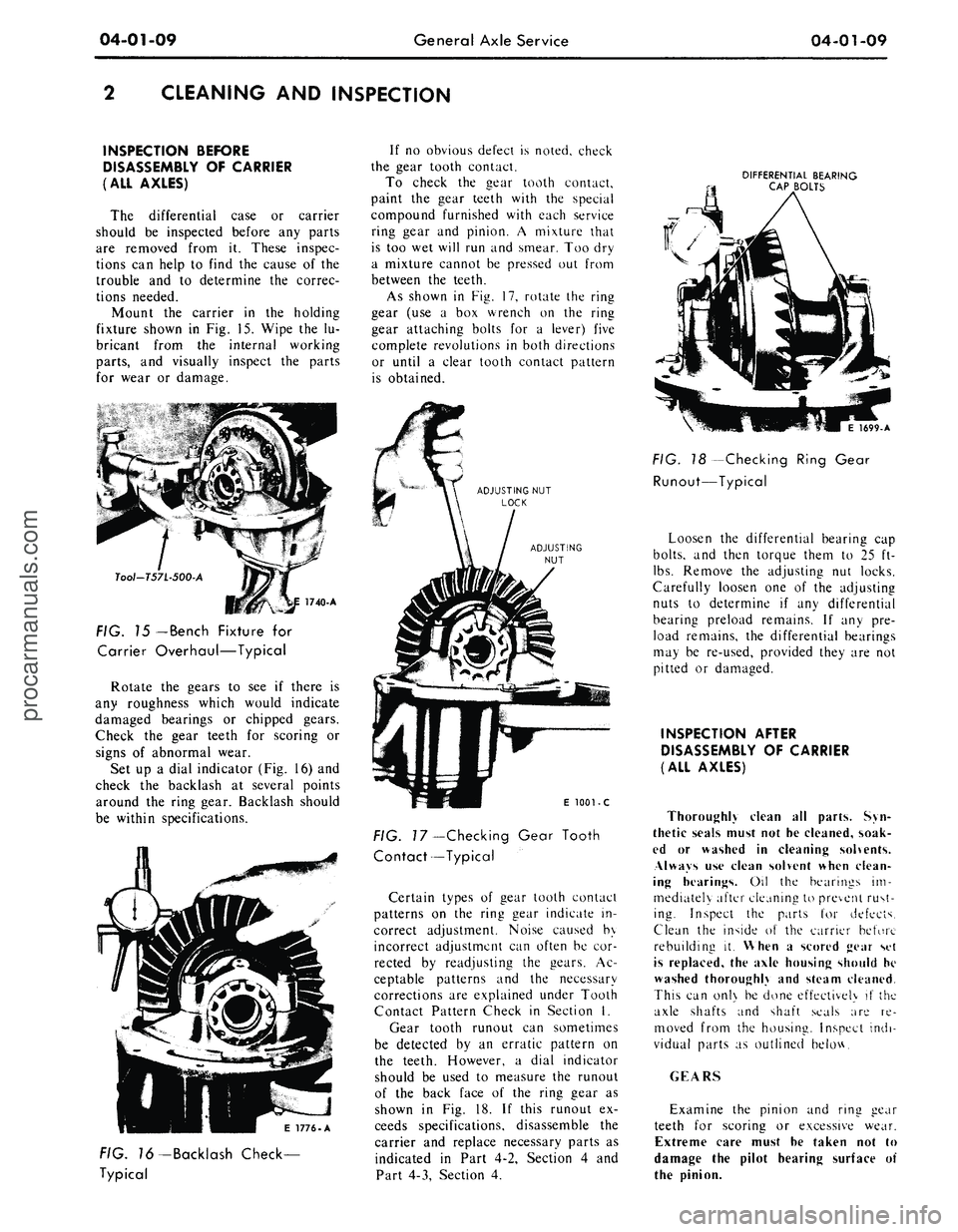

Mount the carrier in the holding

fixture shown in Fig. 15. Wipe the lu-

bricant from the internal working

parts,

and visually inspect the parts

for wear or damage.

Tool-T57L-500-A

FIG. 15

— Bench

Fixture for

Carrier Overhaul—Typical

Rotate the gears to see if there is

any roughness which would indicate

damaged bearings or chipped gears.

Check the gear teeth for scoring or

signs of abnormal wear.

Set up a dial indicator (Fig. 16) and

check the backlash at several points

around the ring gear. Backlash should

be within specifications.

If no obvious defect is noted, check

the gear tooth contact.

To check the gear tooth contact,

paint the gear teeth with the special

compound furnished with each service

ring gear and pinion. A mixture that

is too wet will run and smear. Too dry

a mixture cannot be pressed out from

between the teeth.

As shown in Fig. 17, rotate the ring

gear (use a box wrench on the ring

gear attaching bolts for a lever) five

complete revolutions in both directions

or until a clear tooth contact pattern

is obtained.

DIFFERENTIAL BEARING

CAP BOLTS

E 1776-A

FIG. 76-Backlash Check-

Typical

E

1001 - C

FIG.

7

7—Checking Gear Tooth

Contact—Typical

Certain types of gear tooth contact

patterns on the ring gear indicate in-

correct adjustment. Noise caused by

incorrect adjustment can often be cor-

rected by readjusting the gears. Ac-

ceptable patterns and the necessary

corrections are explained under Tooth

Contact Pattern Check in Section I.

Gear tooth runout can sometimes

be detected by an erratic pattern on

the teeth. However, a dial indicator

should be used to measure the runout

of the back face of the ring gear as

shown in Fig. 18. If this runout ex-

ceeds specifications, disassemble the

carrier and replace necessary parts as

indicated in Part 4-2, Section 4 and

Part 4-3, Section 4.

1699-A

FIG. 18 -Checking Ring Gear

Runout—Typical

Loosen the differential bearing cap

bolts,

and then torque them to 25 ft-

lbs.

Remove the adjusting nut locks.

Carefully loosen one of the adjusting

nuts to determine if any differential

bearing preload remains. If any pre-

load remains, the differential bearings

may be re-used, provided they are not

pitted or damaged.

INSPECTION AFTER

DISASSEMBLY OF CARRIER

(ALL AXLES)

Thoroughly clean all parts. Syn-

thetic seals must not he cleaned, soak-

ed or washed in cleaning solvents.

Always use clean solvent when clean-

ing hearings. Oil the bearings im-

mediately after cleaning to prevent rust-

ing. Inspect the parts for defects.

Clean the inside of the carrier before

rebuilding it. When a scored gear set

is replaced, the axle housing should he

washed thoroughly and steam cleaned.

This can onl\ be done effectively if the

axle shafts and shaft seals are re-

moved from the housing. Inspect indi-

vidual parts as outlined below.

GEARS

Examine the pinion and ring gear

teeth for scoring or excessive wear.

Extreme care must he taken not to

damage the pilot hearing surface of

the pinion.procarmanuals.com

Page 215 of 413

04-02-18

Rear Axle — Removable Carrier Type

04-02-18

E 1195-C

FIG. 41—Removing

or

Installing

Pinion

and

Retainer Assembly

10.

Hold

the

flange with

the

tool

shown

in Fig. 22

(Ford)

or Fig. 23

(Mercury),

and

torque

the

pinion shaft

nut

to 175

ft-lbs.

Do not

exceed

175

ft-Ibs

at

this time.

11.

Check

the

pinion bearing

pre-

load

as

shown

in Fig. 42.

Correct

pre-load will

be

obtained when

the

torque required

to

rotate

the

pinion

in

the retainer

is as

specified

in

Part

4-3.

If

the

torque required

to

rotate

the pin-

ion

is

less than specified, tighten

the

pinion shaft

nut a

little

at a

time until

Inch-Pound

Torque Wrench

E1899A

FIG. 42—Checking Pinion Bearing

Preload

the proper preload

is

established.

Do

not overtighten

the nut. If

excessive

preload

is

obtained

as a

result

of

over-

tightening, replace

the

collapsible

bearing spacer.

Do

not

back

off the

pinion shaft

nut

to establish pinion bearing preload.

If

the torque

on the

pinion shaft

nut is

less than

175

ft-lbs after bearing

pre-

load

is

established,

a new

collapsible

spacer must

be

used.

SOLID PINION BEARING

SPACER INSTALLATION

The spacer

is

serviced

in 20

sizes

listed

in

Part

4-5. The

manner

of sel-

ecting

the

size spacer required

for ob-

taining correct preload

is

included

in

the following assembly procedure.

1.

Install

the

drive pinion rear bear-

ing cone

and

roller assembly

on the

pinion shaft

as

shown

in

Figs.

38 or

39.

2.

Select

a new

solid spacer

of a

larger size (0.485 inch thick),

and

slide

it over

the

pinion shaft against

the

rear bearing.

The pinion bearing preload

can be

accurately measured only when

the

pinion shaft

nut is

torqued

to 180-

220 ft-lbs.

If a

spacer smaller than

re-

quired

was

used,

the

specified

180-

220 ft-lbs torque would damage

the

bearings.

For

this reason,

the

largest

spacer should

be

tried first. Then,

if

the bearings

are too

loose,

the

size

of

the spacer

can be

decreased until

the

correct preload

is

obtained.

3.

Position

the

bearing retainer

and

cup assembly

on the

pinion shaft

and

install

the

front bearing cone

and rol-

ler. Press

the

front bearing cone

and

roller assembly into position,

as

shown

in Fig. 38.

4.

Mount

the

retainer

in a

holding

fixture

as

shown

in Fig. 23, and

place

the slinger over

the

pinion shaft

and

against

the

front bearing.

5.

Install

the

U-joint flange with

the tool shown

in Fig. 46.

6. Hold

the

flange with

the

tool

shown

in Fig. 23 or 24, and

install

the

old pinion shaft

nut.

Using

a

ft-lb

tor-

que wrench, torque

the nut to

180-220

ft-lbs.

While tightening

the nut,

rotate

the bearing retainer

to

determine

the

existance

of any

bearing preload

which will

be

indicated

by a

slight

drag

in the

rotation

of the

retainer.

DETERMINING SPACER

SIZE FROM

PRELOAD READING

1.

If

bearing drag indicates

a pre-

load condition exists, apply

an

in-lb

torque wrench

to the

pinion

nut as

shown

in Fig. 42 and

read

the

torque

required

to

turn

the

shaft. Effort

should

be

12-1/2

to

32-1/2 in-lbs.

2.

If

preload

is the

correct valve,

proceed with assembly procedure

given

in

Final Assembly

of

Pinion

and

Retainer, which follows.

2.

If

preload exists,

but is

below

specification, select

the

correct spacer

from

Fig. 43 and

install, completing

assembly

as

shown

in

Final Assembly

of Pinion

and

Retainer.

DETERMINING SPACER

SIZE FROM

END

PLAY READING

1.

If no

perceptible preload

is

felt

when rotating

the

pinion shaft, install

a dial indicator

as

shown

in Fig. 44,

so that

the

indicator point

is

resting

on

the end of the

pinion gear shaft

(companion flange

end).

2.

Use

both hands

to

squeeze

the

pinion shaft

and the

bearing retainer

together

(Fig. 45).

Record

the

endplay

reading shown

on the

dial indicator.

3.

Disassemble

the

pinion shaft

and

retainer

and

install

the

correct spacer

as shown

in Fig. 43.

4.

Proceed with assembly

of the pin-

ion shaft

and

retainer

as

directed

in

Final Assembly

of

Pinion

and

Retain-

er.

FINAL ASSEMBLY

OF

PINION

AND

RETAINER

1.

Install

the

drive pinion rear bear-

ing cone

and

roller assembly

on the

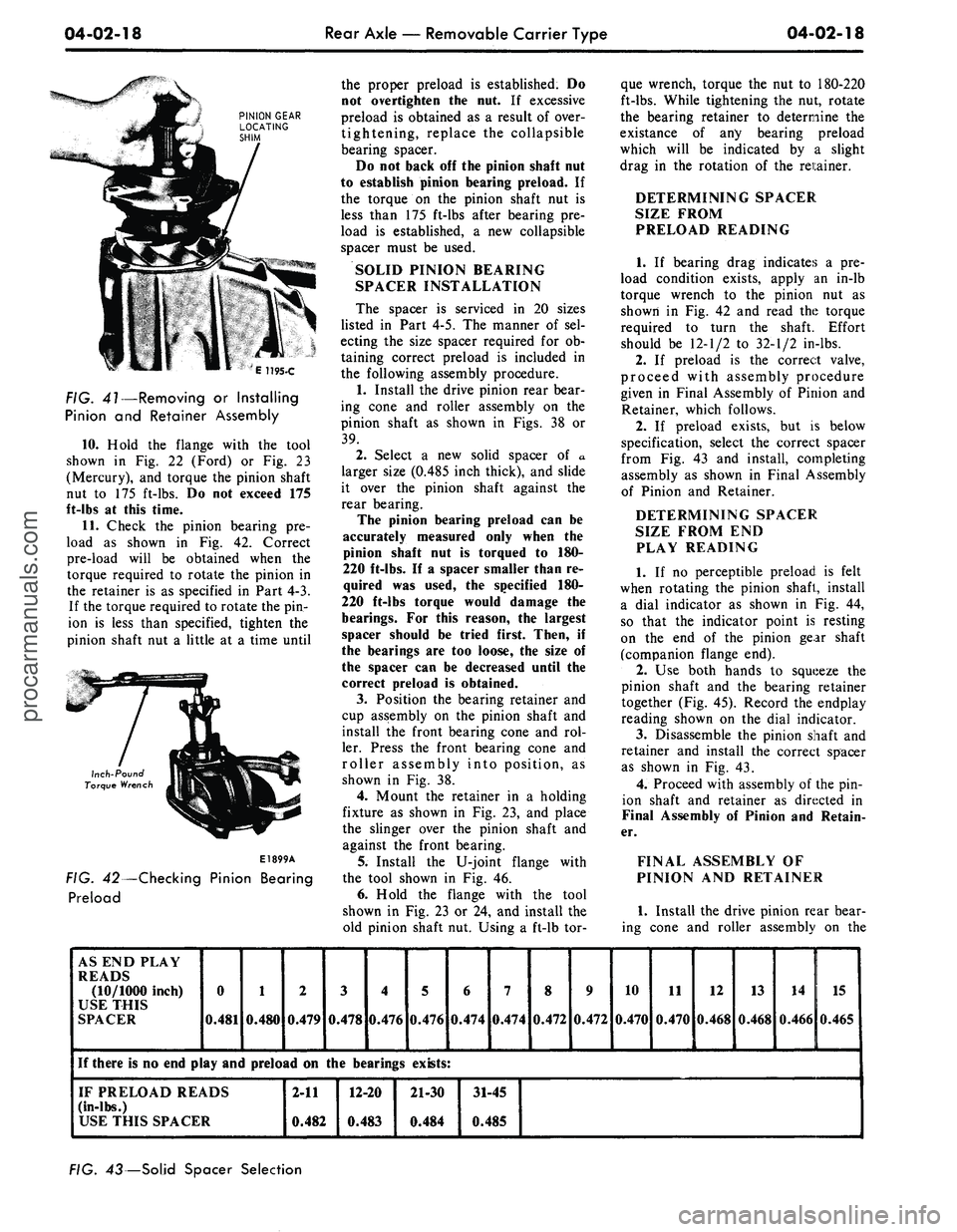

AS

END

PLAY

READS

(10/1000 inch)

USE THIS

SPACER

0

0.481

1

0.480

2

0.479

3

0.478

4

0.476

If there

is no end

play

and

preload

on the

bearings

IF PRELOAD READS

(in-lbs.)

USE THIS SPACER

2-11

0.482

12-20

0.483

5

0.476

6

0.474

7

0.474

8

0.472

9

0.472

10

0.470

11

0.470

12

0.468

13

0.468

14

0.466

15

0.465

exists:

21-30

0.484

31-45

0.485

FIG. 43— Solid Spacer Selectionprocarmanuals.com

Page 238 of 413

04-04-07

Rear Axle — Ford Light-Duty (WER)

04-04-07

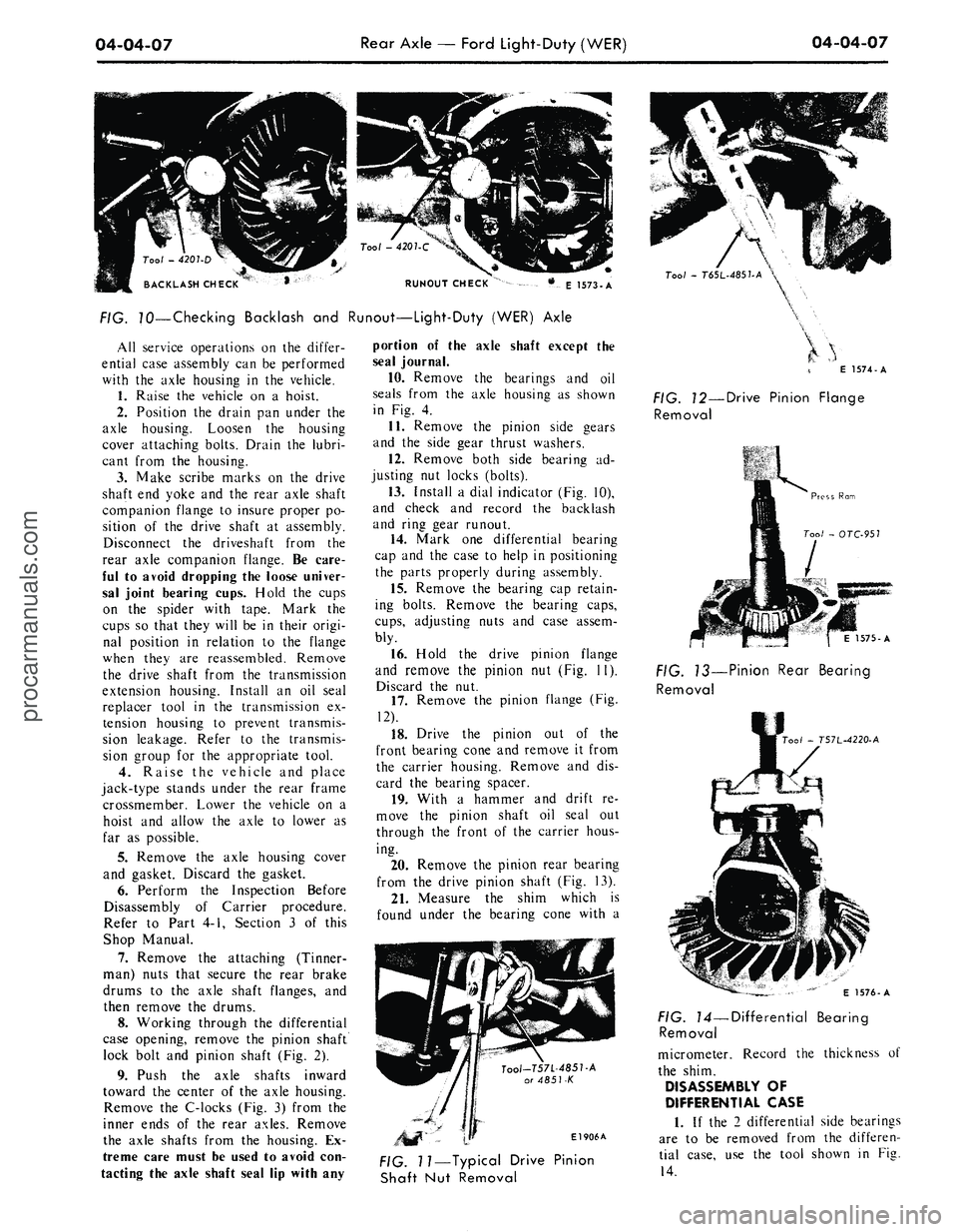

RUNOUT CHECK

E 1573-A

FIG. 70—Checking Backlash and Runout—Light-Duty (WER) Axle

All service operations on the differ-

ential case assembly can be performed

with the axle housing in the vehicle.

1.

Raise the vehicle on a hoist.

2.

Position the drain pan under the

axle housing. Loosen the housing

cover attaching bolts. Drain the lubri-

cant from the housing.

3.

Make scribe marks on the drive

shaft end yoke and the rear axle shaft

companion flange to insure proper po-

sition of the drive shaft at assembly.

Disconnect the driveshaft from the

rear axle companion flange. Be care-

ful to avoid dropping the loose univer-

sal joint bearing cups. Hold the cups

on the spider with tape. Mark the

cups so that they will be in their origi-

nal position in relation to the flange

when they are reassembled. Remove

the drive shaft from the transmission

extension housing. Install an oil seal

replacer tool in the transmission ex-

tension housing to prevent transmis-

sion leakage. Refer to the transmis-

sion group for the appropriate tool.

4.

Raise the vehicle and place

jack-type stands under the rear frame

crossmember. Lower the vehicle on a

hoist and allow the axle to lower as

far as possible.

5.

Remove the axle housing cover

and gasket. Discard the gasket.

6. Perform the Inspection Before

Disassembly of Carrier procedure.

Refer to Part 4-1, Section 3 of this

Shop Manual.

7.

Remove the attaching (Tinner-

man) nuts that secure the rear brake

drums to the axle shaft flanges, and

then remove the drums.

8. Working through the differential

case opening, remove the pinion shaft

lock bolt and pinion shaft (Fig. 2).

9. Push the axle shafts inward

toward the center of the axle housing.

Remove the C-locks (Fig. 3) from the

inner ends of the rear axles. Remove

the axle shafts from the housing. Ex-

treme care must be used to avoid con-

tacting the axle shaft seal lip with any

portion of the axle shaft except the

seal journal.

10.

Remove the bearings and oil

seals from the axle housing as shown

in Fig. 4.

11.

Remove the pinion side gears

and the side gear thrust washers.

12.

Remove both side bearing ad-

justing nut locks (bolts).

13.

Install a dial indicator (Fig. 10),

and check and record the backlash

and ring gear runout.

14.

Mark one differential bearing

cap and the case to help in positioning

the parts properly during assembly.

15.

Remove the bearing cap retain-

ing bolts. Remove the bearing caps,

cups,

adjusting nuts and case assem-

bly.

16.

Hold the drive pinion flange

and remove the pinion nut (Fig. 11).

Discard the nut.

17.

Remove the pinion flange (Fig.

12).

18.

Drive the pinion out of the

front bearing cone and remove it from

the carrier housing. Remove and dis-

card the bearing spacer.

19.

With a hammer and drift re-

move the pinion shaft oil seal out

through the front of the carrier hous-

ing.

20.

Remove the pinion rear bearing

from the drive pinion shaft (Fig. 13).

21.

Measure the shim which is

found under the bearing cone with a

Tool-T57L-485T-A

or 4851-K

El 906A

Tool

-

T6SL-485UA

\

E 1574-A

FIG. 12—Drive Pinion Flange

Removal

1575-A

FIG. 13—Pinion Rear Bearing

Removal

00/

- T57L-4220-A

FIG. 11—Typical Drive Pinion

Shaft Nut Removal

E 1576-A

FIG. 14—Differential Bearing

Removal

micrometer. Record the thickness of

the shim.

DISASSEMBLY OF

DIFFERENTIAL CASE

1.

If the 2 differential side bearings

are to be removed from the differen-

tial case, use the tool shown in Fig.

14.procarmanuals.com

Page 248 of 413

05-01-01

05-01-01

Clutch

GROUP

5

PART

5-1

PAGE

Drive Shaft 05-01-01

PART

5-2

General Clutch Service 05-02-01

PART

5-3

Clutch

PART

5-4

Specifications

PAGE

05-03-01

05-04-01

PART

5-1

Drive Shaft

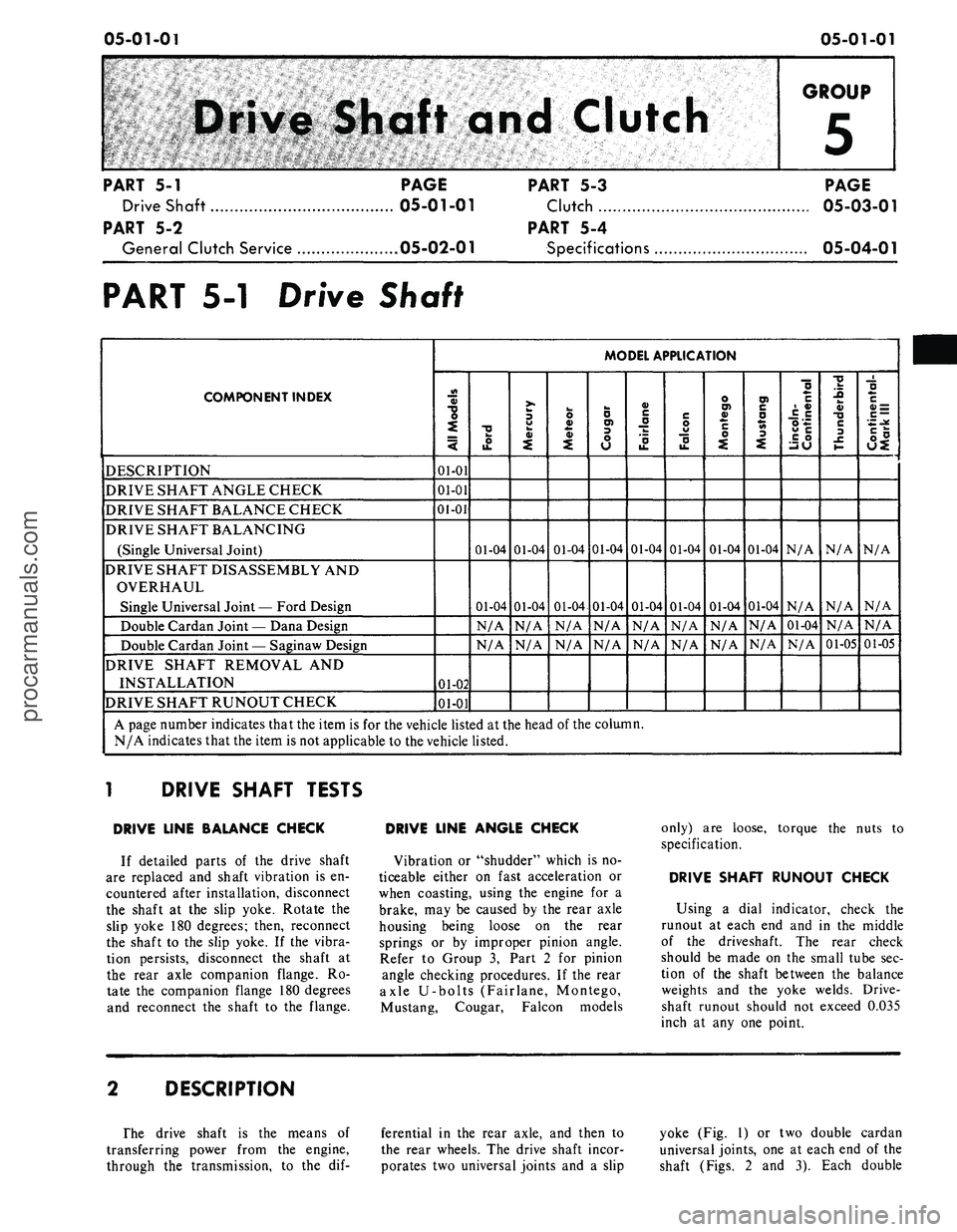

COMPONENT INDEX

DESCRIPTION

DRIVE SHAFT ANGLE CHECK

DRIVE SHAFT BALANCE CHECK

DRIVE SHAFT BALANCING

(Single Universal Joint)

DRIVE SHAFT DISASSEMBLY

AND

OVERHAUL

Single Universal Joint — Ford Design

Double Cardan Joint — Dana Design

Double Cardan Joint — Saginaw Design

DRIVE SHAFT REMOVAL

AND

INSTALLATION

DRIVE SHAFT RUNOUT CHECK

MODEL APPLICATION

All

Models

01-01

01-01

01-01

01-02

01-01

Ford

01-04

01-04

N/A

N/A

Mercury

01-04

01-04

N/A

N/A

Meteor

01-04

01-04

N/A

N/A

Cougar

01-04

01-04

N/A

N/A

Fairlane

01-04

01-04

N/A

N/A

Falcon

01-04

01-04

N/A

N/A

Montego

01-04

01-04

N/A

N/A

Mustang

01-04

01-04

N/A

N/A

Lincoln-

Continental

N/A

N/A

01-04

N/A

Thunderbird

N/A

N/A

N/A

01-05

Continental-

Mark

III

N/A

N/A

N/A

01-05

A page number indicates that the item

is for the

vehicle listed

at the

head

of

the column.

N/A indicates that

the

item

is not

applicable

to the

vehicle listed.

DRIVE SHAFT TESTS

DRIVE LINE BALANCE CHECK

If detailed parts

of the

drive shaft

are replaced

and

shaft vibration

is en-

countered after installation, disconnect

the shaft

at the

slip yoke. Rotate

the

slip yoke

180

degrees; then, reconnect

the shaft

to the

slip yoke.

If the

vibra-

tion persists, disconnect

the

shaft

at

the rear axle companion flange.

Ro-

tate

the

companion flange

180

degrees

and reconnect

the

shaft

to the

flange.

DRIVE LINE ANGLE CHECK

Vibration

or

"shudder" which

is no-

ticeable either

on

fast acceleration

or

when coasting, using

the

engine

for a

brake,

may be

caused

by the

rear axle

housing being loose

on the

rear

springs

or by

improper pinion angle.

Refer

to

Group

3,

Part

2 for

pinion

angle checking procedures.

If the

rear

axle U-bolts (Fairlane, Montego,

Mustang, Cougar, Falcon models

only)

are

loose, torque

the

nuts

to

specification.

DRIVE SHAFT RUNOUT CHECK

Using

a

dial indicator, check

the

runout

at

each

end and in the

middle

of

the

driveshaft.

The

rear check

should

be

made

on the

small tube

sec-

tion

of the

shaft between

the

balance

weights

and the

yoke welds. Drive-

shaft runout should

not

exceed 0.035

inch

at any one

point.

DESCRIPTION

The drive shaft

is the

means

of

transferring power from

the

engine,

through

the

transmission,

to the dif-

ferential

in the

rear axle,

and

then

to

the rear wheels.

The

drive shaft incor-

porates

two

universal joints

and a

slip

yoke

(Fig. 1) or two

double cardan

universal joints,

one at

each

end of the

shaft (Figs.

2 and 3).

Each double

procarmanuals.com

Page 255 of 413

05-02-01

General Clutch Service

05-02-01

PART

5-2

General Clutch Service

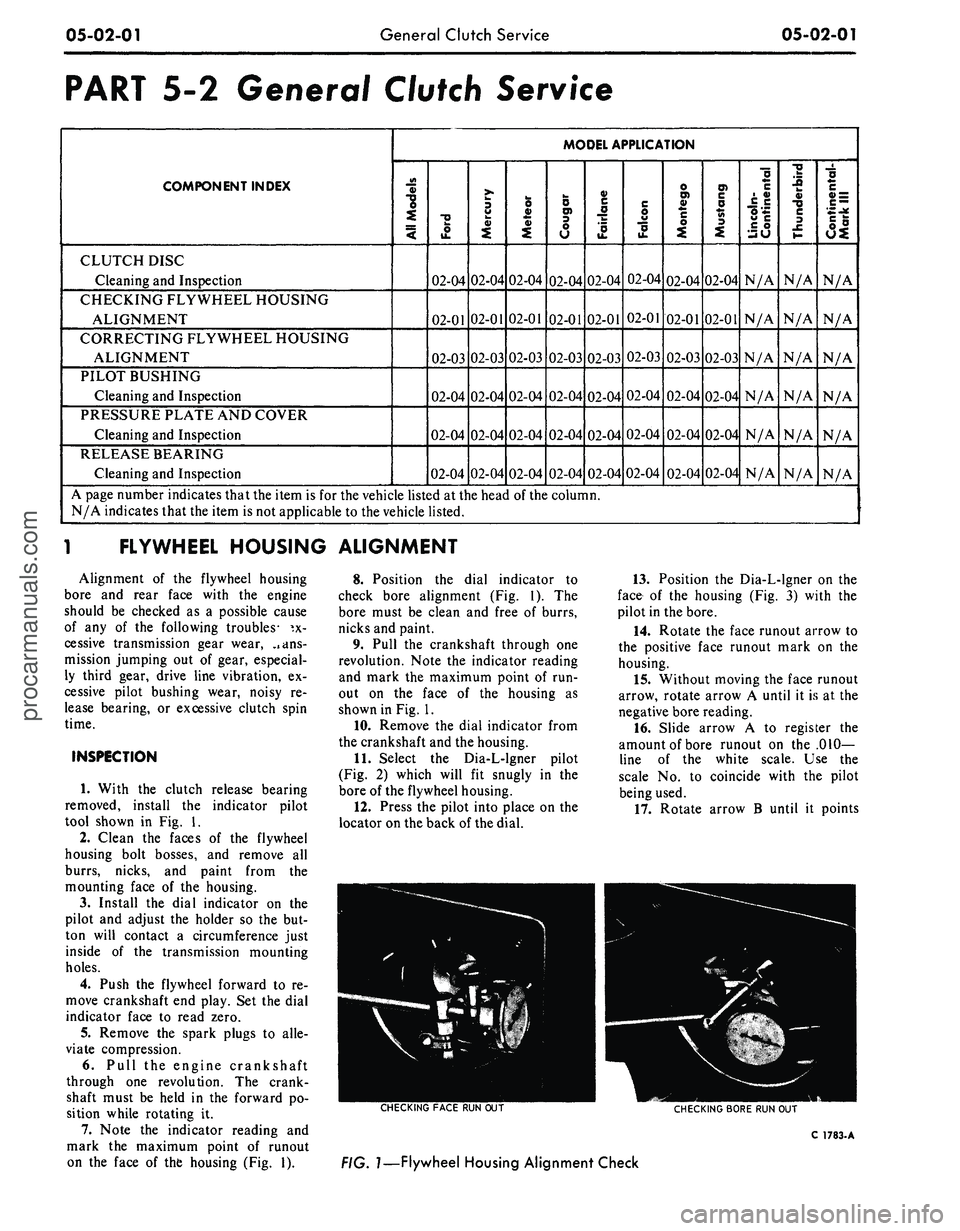

COMPONENT INDEX

MODEL APPLICATION

3

a>

1

o>

il

•U

i

!-

II

CLUTCH DISC

Cleaning and Inspection

02-04

02-04

02-04

02-04

02-04

02-04

02-04

02-04

N/A

N/A

N/A

CHECKING FLYWHEEL HOUSING

ALIGNMENT

02-01

02-01

02-01

02-01

02-01

02-01

02-01

02-01

N/A

N/A

N/A

CORRECTING FLYWHEEL HOUSING

ALIGNMENT

02-03

02-03

02-03

02-03

02-03

02-03

02-03

02-03

N/A

N/A

N/A

PILOT BUSHING

Cleaning and Inspection

02-04

02-04

02-04

02-04

02-04

02-04

02-04

02-04

N/A

N/A

N/A

PRESSURE PLATE AND COVER

Cleaning and Inspection

02-04

02-04

02-04

02-04

02-04

02-04

02-04

02-04

N/A

N/A

N/A

RELEASE BEARING

Cleaning and Inspection

02-04

02-04

02-04

02-04

02-04

02-04

02-04

02-04

N/A

N/A

N/A

A page number indicates that the item is for the vehicle listed at the head of the column.

N/A indicates that the item is not applicable to the vehicle listed.

l

FLYWHEEL HOUSING ALIGNMENT

Alignment of the flywheel housing

bore and rear face with the engine

should be checked as a possible cause

of any of the following troubles- ex-

cessive transmission gear wear, ..ans-

mission jumping out of gear, especial-

ly third gear, drive line vibration, ex-

cessive pilot bushing wear, noisy re-

lease bearing, or excessive clutch spin

time.

INSPECTION

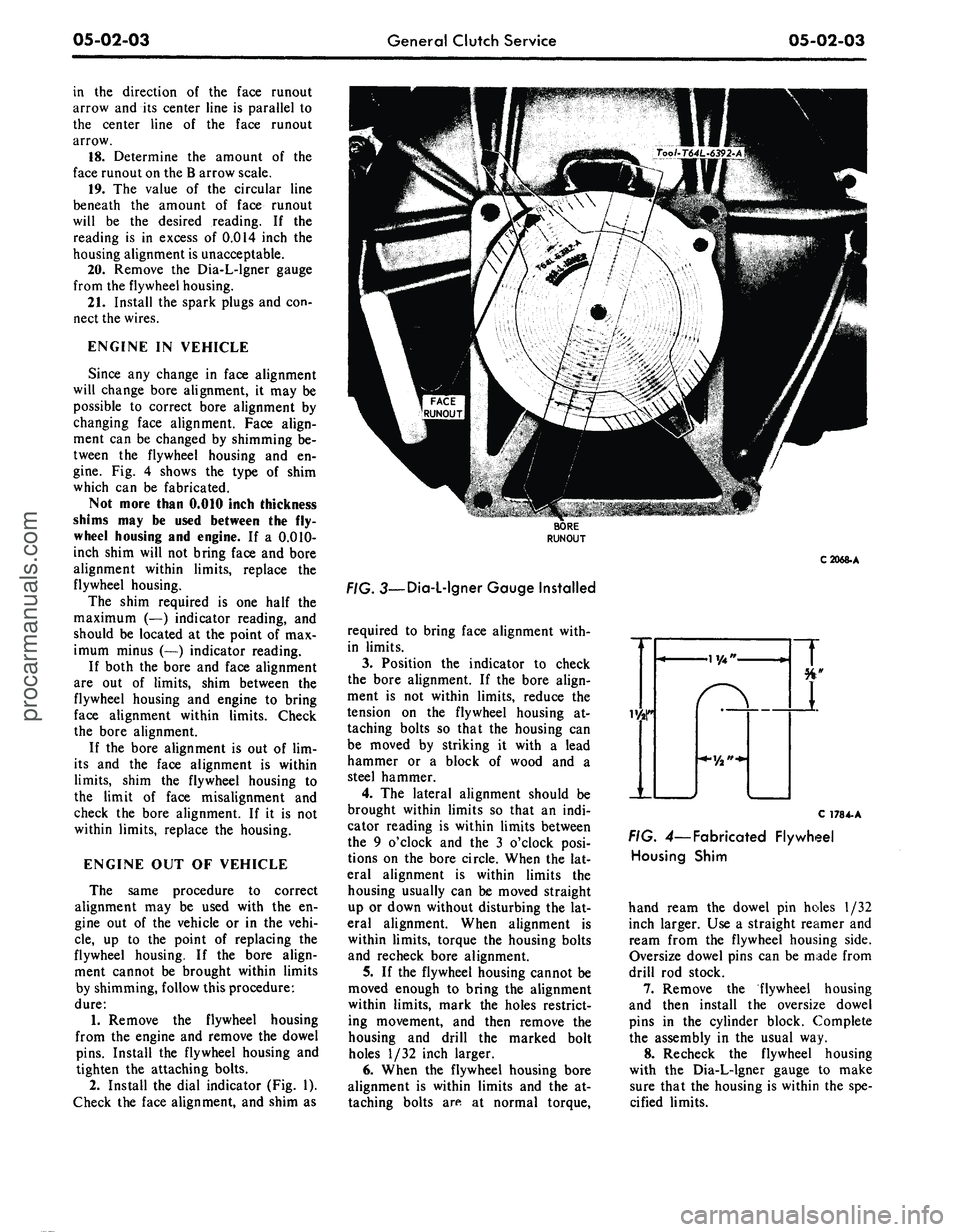

1. With the clutch release bearing

removed, install the indicator pilot

tool shown in Fig. 1.

2.

Clean the faces of the flywheel

housing bolt bosses, and remove all

burrs, nicks, and paint from the

mounting face of the housing.

3.

Install the dial indicator on the

pilot and adjust the holder so the but-

ton will contact a circumference just

inside of the transmission mounting

holes.

4.

Push the flywheel forward to re-

move crankshaft end play. Set the dial

indicator face to read zero.

5.

Remove the spark plugs to alle-

viate compression.

6. Pull the engine crankshaft

through one revolution. The crank-

shaft must be held in the forward po-

sition while rotating it.

7. Note the indicator reading and

mark the maximum point of runout

on the face of the housing (Fig. 1).

8. Position the dial indicator to

check bore alignment (Fig. 1). The

bore must be clean and free of burrs,

nicks and paint.

9. Pull the crankshaft through one

revolution. Note the indicator reading

and mark the maximum point of run-

out on the face of the housing as

shown in Fig. 1.

10.

Remove the dial indicator from

the crankshaft and the housing.

11.

Select the Dia-L-lgner pilot

(Fig. 2) which will fit snugly in the

bore of the flywheel housing.

12.

Press the pilot into place on the

locator on the back of the dial.

13.

Position the Dia-L-lgner on the

face of the housing (Fig. 3) with the

pilot in the bore.

14.

Rotate the face runout arrow to

the positive face runout mark on the

housing.

15.

Without moving the face runout

arrow, rotate arrow A until it is at the

negative bore reading.

16.

Slide arrow A to register the

amount of bore runout on the .010-

line of the white scale. Use the

scale No. to coincide with the pilot

being used.

17.

Rotate arrow B until it points

CHECKING

FACE

RUN OUT

CHECKING

BORE

RUN OUT

C

1783-

A

FIG.

1—Flywheel

Housing Alignment Checkprocarmanuals.com

Page 257 of 413

05-02-03

General Clutch Service

05-02-03

in the direction of the face runout

arrow and its center line is parallel to

the center line of the face runout

arrow.

18.

Determine the amount of the

face runout on the B arrow scale.

19.

The value of the circular line

beneath the amount of face runout

will be the desired reading. If the

reading is in excess of 0.014 inch the

housing alignment is unacceptable.

20.

Remove the Dia-L-lgner gauge

from the flywheel housing.

21.

Install the spark plugs and con-

nect the wires.

ENGINE IN VEHICLE

Since any change in face alignment

will change bore alignment, it may be

possible to correct bore alignment by

changing face alignment. Face align-

ment can be changed by shimming be-

tween the flywheel housing and en-

gine.

Fig. 4 shows the type of shim

which can be fabricated.

Not more than 0.010 inch thickness

shims may be used between the fly-

wheel housing and engine. If a 0.010-

inch shim will not bring face and bore

alignment within limits, replace the

flywheel housing.

The shim required is one half the

maximum (—) indicator reading, and

should be located at the point of max-

imum minus (—) indicator reading.

If both the bore and face alignment

are out of limits, shim between the

flywheel housing and engine to bring

face alignment within limits. Check

the bore alignment.

If the bore alignment is out of lim-

its and the face alignment is within

limits,

shim the flywheel housing to

the limit of face misalignment and

check the bore alignment. If it is not

within limits, replace the housing.

ENGINE OUT OF VEHICLE

The same procedure to correct

alignment may be used with the en-

gine out of the vehicle or in the vehi-

cle,

up to the point of replacing the

flywheel housing. If the bore align-

ment cannot be brought within limits

by shimming, follow this procedure:

dure:

1.

Remove the flywheel housing

from the engine and remove the dowel

pins.

Install the flywheel housing and

tighten the attaching bolts.

2.

Install the dial indicator (Fig. 1).

Check the face alignment, and shim as

C2068-A

. 3—Dia-L-lgner Gauge Installed

required to bring face alignment with-

in limits.

3.

Position the indicator to check

the bore alignment. If the bore align-

ment is not within limits, reduce the

tension on the flywheel housing at-

taching bolts so that the housing can

be moved by striking it with a lead

hammer or a block of wood and a

steel hammer.

4.

The lateral alignment should be

brought within limits so that an indi-

cator reading is within limits between

the 9 o'clock and the 3 o'clock posi-

tions on the bore circle. When the lat-

eral alignment is within limits the

housing usually can be moved straight

up or down without disturbing the lat-

eral alignment. When alignment is

within limits, torque the housing bolts

and recheck bore alignment.

5.

If the flywheel housing cannot be

moved enough to bring the alignment

within limits, mark the holes restrict-

ing movement, and then remove the

housing and drill the marked bolt

holes 1/32 inch larger.

6. When the flywheel housing bore

alignment is within limits and the at-

taching bolts are at normal torque,

C 178 4-A

FIG. 4— Fabricated Flywheel

Housing Shim

hand ream the dowel pin holes 1/32

inch larger. Use a straight reamer and

ream from the flywheel housing side.

Oversize dowel pins can be made from

drill rod stock.

7.

Remove the flywheel housing

and then install the oversize dowel

pins in the cylinder block. Complete

the assembly in the usual way.

8. Recheck the flywheel housing

with the Dia-L-lgner gauge to make

sure that the housing is within the spe-

cified limits.procarmanuals.com

Page 303 of 413

07-01-12

General Transmission Service

07-01-12

the transmission,

any

metal particles

or clutch plate

or

band material that

may have been carried into

the

cooler

should

be

removed from

the

system

by

flushing

the

cooler

and

lines before

the transmission

is put

back into serv-

ice.

In no

case should

an

automatic

transmission having

a

clutch

or

band

failure

or

other internal trouble result-

ing

in

fluid contamination,

be put

back into service without first flushing

the transmission

oil

cooler.

To flush

the oil

cooler, follow

the

instruct!

on >

provided with

the

Rotun-

da Automatic Transmission Torque

Converter

and

Cooler Cleaner

LRE-

60081.

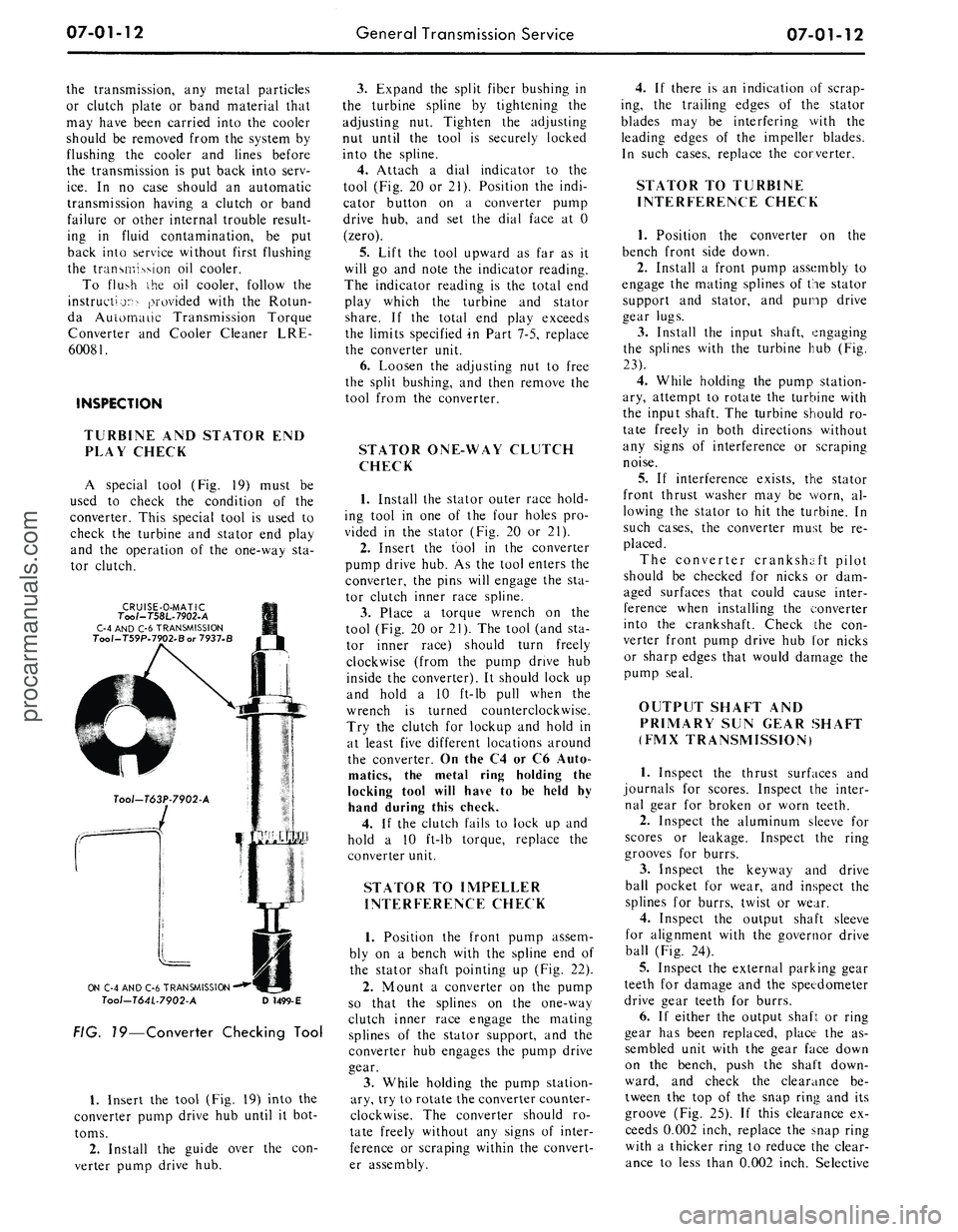

INSPECTION

TURBINE

AND

STATOR

END

PLAY CHECK

A special tool

(Fig. 19)

must

be

used

to

check

the

condition

of the

converter. This special tool

is

used

to

check

the

turbine

and

stator

end

play

and

the

operation

of the

one-way

sta-

tor clutch.

CRUISE-O-MATIC

Too/-T58L-7902-A

C-4 AND C-6 TRANSMISSION

Tool-T59P.7902.Bor 7937-B

ON C-4 AND C-6 TRANSMISSION

Tool-T64L-7902-A

D

1499-E

FIG. 19—Converter Checking Tool

1.

Insert

the

tool (Fig.

19)

into

the

converter pump drive

hub

until

it

bot-

toms.

2.

Install

the

guide over

the con-

verter pump drive

hub.

3.

Expand

the

split fiber bushing

in

the turbine spline

by

tightening

the

adjusting

nut.

Tighten

the

adjusting

nut until

the

tool

is

securely locked

into

the

spline.

4.

Attach

a

dial indicator

to the

tool (Fig.

20 or

21). Position

the

indi-

cator button

on a

converter pump

drive

hub, and set the

dial face

at 0

(zero).

5.

Lift

the

tool upward

as far as it

will

go and

note

the

indicator reading.

The indicator reading

is the

total

end

play which

the

turbine

and

stator

share.

If the

total

end

play exceeds

the limits specified

in

Part 7-5, replace

the converter unit.

6. Loosen

the

adjusting

nut to

free

the split bushing,

and

then remove

the

tool from

the

converter.

STATOR ONE-WAY CLUTCH

CHECK

1.

Install

the

stator outer race hold-

ing tool

in one of the

four holes

pro-

vided

in the

stator (Fig.

20 or 21).

2.

Insert

the

tool

in the

converter

pump drive hub.

As the

tool enters

the

converter,

the

pins will engage

the sta-

tor clutch inner race spline.

3.

Place

a

torque wrench

on the

tool (Fig.

20 or

21).

The

tool (and

sta-

tor inner race) should turn freely

clockwise (from

the

pump drive

hub

inside

the

converter).

It

should lock

up

and hold

a 10

ft-lb pull when

the

wrench

is

turned counterclockwise.

Try

the

clutch

for

lockup

and

hold

in

at least five different locations around

the converter.

On

the

C4

or C6

Auto-

matics,

the

metal ring holding

the

locking tool will have

to be

held

by

hand during this check.

4.

If the

clutch fails

to

lock

up and

hold

a 10

ft-lb torque, replace

the

converter unit.

STATOR

TO

IMPELLER

INTERFERENCE CHECK

1.

Position

the

front pump assem-

bly

on a

bench with

the

spline

end of

the stator shaft pointing

up

(Fig.

22).

2.

Mount

a

converter

on the

pump

so that

the

splines

on the

one-way

clutch inner race engage

the

mating

splines

of the

stator support,

and the

converter

hub

engages

the

pump drive

gear.

3.

While holding

the

pump station-

ary, try

to

rotate the converter counter-

clockwise.

The

converter should

ro-

tate freely without

any

signs

of

inter-

ference

or

scraping within

the

convert-

er assembly.

4.

If

there

is an

indication

of

scrap-

ing,

the

trailing edges

of the

stator

blades

may be

interfering with

the

leading edges

of the

impeller blades.

In such cases, replace

the

converter.

STATOR

TO

TURBINE

INTERFERENCE CHECK

1.

Position

the

converter

on the

bench front side down.

2.

Install

a

front pump assembly

to

engage

the

mating splines

of

the

stator

support

and

stator,

and

pump drive

gear lugs.

3.

Install

the

input shaft, engaging

the splines with

the

turbine

hub (Fig.

23).

4.

While holding

the

pump station-

ary, attempt

to

rotate

the

turbine with

the input shaft.

The

turbine should

ro-

tate freely

in

both directions without

any signs

of

interference

or

scraping

noise.

5.

If

interference exists,

the

stator

front thrust washer

may be

worn,

al-

lowing

the

stator

to hit the

turbine.

In

such cases,

the

converter must

be re-

placed.

The converter crankshaft pilot

should

be

checked

for

nicks

or dam-

aged surfaces that could cause inter-

ference when installing

the

converter

into

the

crankshaft. Check

the con-

verter front pump drive

hub for

nicks

or sharp edges that would damage

the

pump seal.

OUTPUT SHAFT

AND

PRIMARY

SUN

GEAR SHAFT

(FMX TRANSMISSION)

1.

Inspect

the

thrust surfaces

and

journals

for

scores. Inspect

the

inter-

nal gear

for

broken

or

worn teeth.

2.

Inspect

the

aluminum sleeve

for

scores

or

leakage. Inspect

the

ring

grooves

for

burrs.

3.

Inspect

the

keyway

and

drive

ball pocket

for

wear,

and

inspect

the

splines

for

burrs, twist

or

wear.

4.

Inspect

the

output shaft sleeve

for alignment with

the

governor drive

ball (Fig.

24).

5.

Inspect

the

external parking gear

teeth

for

damage

and the

speedometer

drive gear teeth

for

burrs.

6.

If

either

the

output shaft

or

ring

gear

has

been replaced, place

the as-

sembled unit with

the

gear face down

on

the

bench, push

the

shaft down-

ward,

and

check

the

clearance

be-

tween

the top of the

snap ring

and its

groove

(Fig. 25).

If

this clearance

ex-

ceeds 0.002 inch, replace

the

snap ring

with

a

thicker ring

to

reduce

the

clear-

ance

to

less than 0.002 inch. Selectiveprocarmanuals.com