wheel FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 37 of 413

02-02-18

Brake System

02-02-18

the brake hose connector

and

bracket

assembly.

3.

Remove

the two

bolts retaining

the brake hose bracket

and

caliper

as-

sembly

to the

spindle. Take care

to

avoid loosening

the

bridge bolts that

hold

the two

halves

of the

caliper

to-

gether.

4.

Lift

the

caliper assembly

off the

rotor

and

place

it on the

bench.

Installation

1.

If the

caliper assembly

is to be

replaced, transfer

the

steel tubing

and

the bleeder screw

to the new

caliper.

2.

Position

the

caliper assembly

on

the rotor,

and

mate

the

mounting bolt

holes

in the

caliper with those

in the

spindle.

It may be

necessary

to

push

the caliper pistons into

the

cylinder

bores

to

obtain clearance between

the

shoe

and

lining assembly

and the

rotor.

The

shoe

and

lining assemblies

should

be

seated properly

on the

bridges.

3.

Install

the

caliper

to

spindle

re-

taining bolts

and

torque them

to

spec-

ification. Check

to

insure that

the

rotor runs squarely

and

centrally

be-

tween

the two

halves

of the

caliper.

These should

be

approximately 0.090-

0.120 inch clearance between

the

cali-

per

and the

rotor outside diameter

(Fig.

6).

4.

Position

the

steel transfer tube

brake hose bracket

and

caliper assem-

bly

to the

spindle. Install

the

retaining

bolts then torque them

to

specifica-

tion.

5.

Connect

the

front wheel steel

transfer tube from

the

caliper

to the

front brake hose connector. Check

the

hose

for

proper installation

(Fig. 21).

6. Bleed

the

brake system

and cen-

tralize

the

differential valve

as out-

lined

in

Part

2-1.

Check

the

master

cylinder fluid level

and add the

speci-

fied fluid,

as

required. Pump

the

brake pedal several times

to

actuate

the piston seals

and to

position

the

shoe

and

lining assemblies.

7.

Install

the

wheel

and

tire assem-

bly

and the

wheel cover.

8. Road test

the

vehicle.

DISC BRAKE SHOE

AND

LINING

ALL MODELS EXCEPT

LINCOLN CONTINENTAL

Removal

1.

Remove

the

wheel

and

tire from

the

hub and

rotor assembly.

2.

Remove

the

caliper from

the ve-

hicle following

the

procedures outlined

under Disc Brake Caliper Assembly.

3.

To

facilitate removal

of the

cali-

per assemblies,

the

piston

may

have

to

be pushed into

its

bore. Apply

a

steady inward pressure against

the

inner shoe

and

lining assembly. Main-

tain

the

pressure

for at

least

a

minute.

4.

Slide

the two

outer shoe retain-

ing clips

off the

retaining pins

(Fig.

23).

5.

Remove

the two

retaining pins

from

the

outer shoe, then remove

the

shoe from

the

stationary caliper.

6. Slide

the

inner brake shoe

out-

ward until

it is

free

of the

hold-down

springs, then remove

the

brake shoe.

7.

Remove

the

caliper locating pins

and stabilizer attaching bolts, then

re-

move

and

discard

the

stabilizer

or sta-

bilizers.

8. Remove

the

locating

pin

insula-

tors from

the

anchor plate.

Installation

When installing

new

shoes

and lin-

ings

it

will

be

necessary

to

force

the

piston

to the

bottom

of its

bore.

Apply sufficient pressure

to

overcome

the grip

of the

piston seal

on the pis-

ton.

1.

Install

new

caliper locating

pin

insulators

in the

anchor plate.

2.

Position

the

caliper assembly

in

the anchor plate.

3.

Position

the new

stabilizer

or

stabilizers

and

install

the

caliper locat-

ing pins

to

engage approximately four

threads.

If

the

caliper locating pins

are

rust-

ed

or

corroded they should

be re-

placed.

Apply water

or

isopropyl alcohol

to

the caliper locating pins before instal-

lation.

Oil or

grease must

not be

used

on

the

locating pins.

4.

Position

the

outer brake shoe

on

the caliper

and

install

the two

retain-

ing pins

and

clips.

5.

Install

the

inner brake shoe

so

that

the

ears

of

shoe

are on top of the

anchor plate bosses

and

under

the

shoe hold-down springs.

6. Position

the

shoe

and

lining

assemblies

so

that

the

caliper assem-

bly

can be

placed over

the

rotor.

Ro-

tate

a

hammer handle between

the lin-

ings

to

reset

the

stabilizers.

7.

Install

the

caliper assembly over

the rotor

and on the

spindle. Install

the

two

caliper attaching bolts,

and

torque them

to

specifications.

The

upper bolt must

be

tightened first.

In-

stall

the

safety wire

and

twist

the

ends

at least five turns. Push

the

wire ends

against

the

spindle

to

avoid interfer-

ence with

the

brake hose

and the

steering stop.

8. With moderate pressure applied

to

the

brake pedal, torque

the

stabiliz-

er attaching screws

and

caliper locat-

ing pins

to

specification.

LINCOLN CONTINENTAL

Removal

1.

Remove

the

wheel

and

tire

as-

sembly from

the hub and

rotor assem-

bly.

Be

careful

to

avoid damage

or in-

terference with

the

caliper splash

shield, bleeder screw fitting

or

transfer

tube.

2.

Remove

the two

bolts that retain

the caliper splash shield,

and

remove

the shield

(Fig. 4).

3.

To

facilitate removal

and

instal-

lation

of the

shoe

and

lining assem-

blies,

the

pistons must

be

pushed into

their bores. Apply

a

steady inward

pressure against each shoe

and

lining

assembly toward

its

respective caliper

housing

on

each side

of the

rotor

(Fig.

6).

Maintain

the

pressure

for at

least

a minute.

If the

pistons will

not go ifi

easily, force them

in

with water pump

pliers.

4.

Grasp

the

metal flange

on the

outer

end of the

shoe with

two

pairs

of pliers

and

pull

the

shoe

out of the

caliper (Fig.

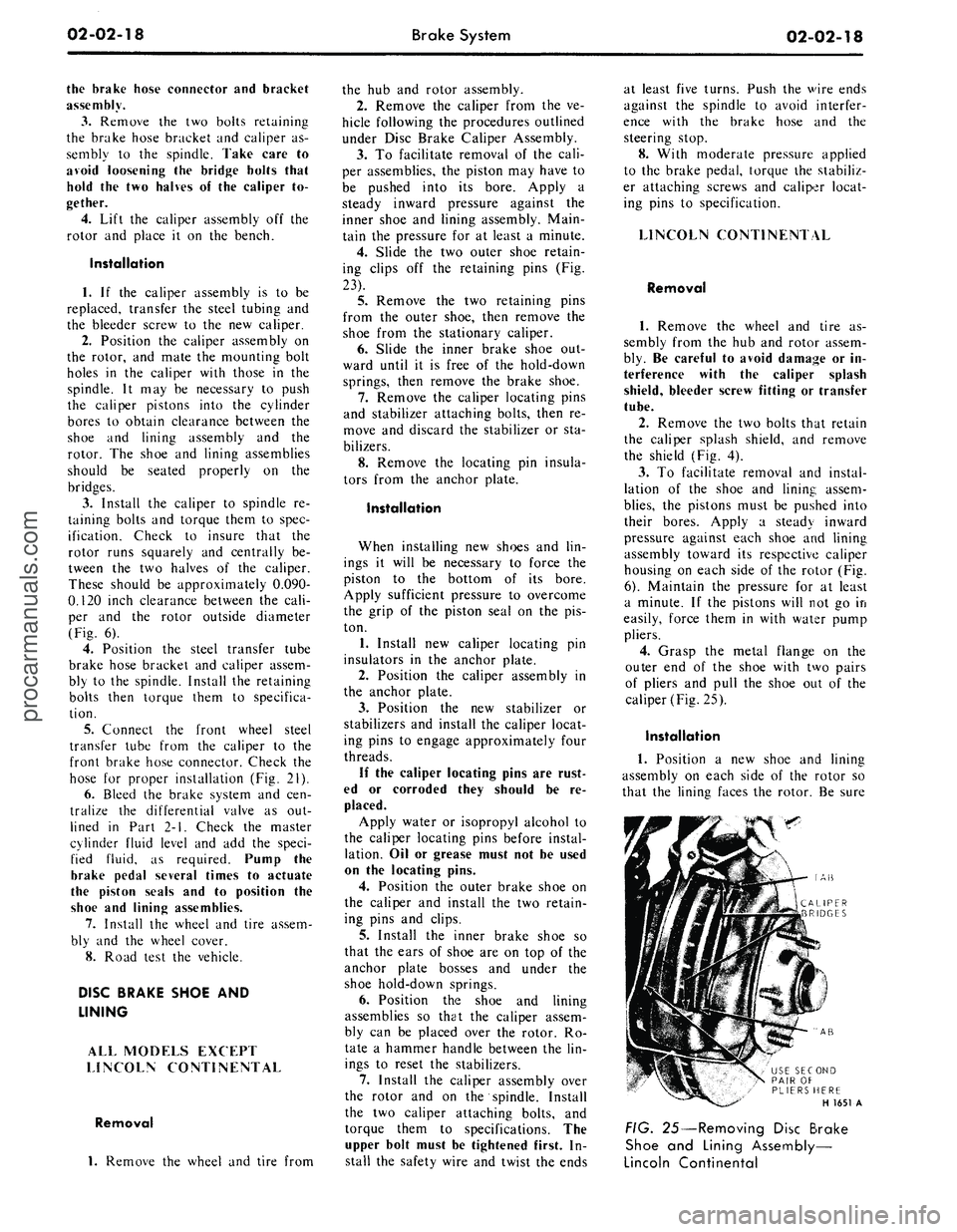

25).

Installation

1.

Position

a new

shoe

and

lining

assembly

on

each side

of the

rotor

so

that

the

lining faces

the

rotor.

Be

sure

AB

AB

USE SECOND

PAIR

OF

PLIERS HERE

H 1651

A

FIG. 25—Removing Disc Brake

Shoe

and

Lining Assembly—

Lincoln Continentalprocarmanuals.com

Page 38 of 413

02-02-19

Brake System

02-02-19

that the tabs on the shoe flanges seat

fully against the caliper bridges (Fig.

25).

2.

Install the caliper splash shield

and secure the shield to the caliper

with two retaining bolts (Fig. 4).

3.

Pump the brake pedal several

times until a firm pedal is obtained

and the shoe and lining assemblies are

properly seated.

4.

Install the wheel and tire assem-

bly on the hub and rotor assembly.

5.

Check and refill the master cyl-

inder reservoir with specified brake

fluid as required.

6. Road test the car.

It should not be necessary to bleed

the system after a shoe and lining re-

placement.

FRONT WHEEL HUB AND

ROTOR ASSEMBLY-

DISC BRAKES

REMOVAL

1.

Remove the wheel and tire from

the hub (Figs. 23 and 24). Be careful

to avoid damage or interference with

the bleeder screw fitting. On Lincoln

Continental models be careful to avoid

damage to the caliper splash shield or

transfer tube.

2.

Remove the caliper assembly

from the spindle and the rotor. If the

caliper does not require servicing, it is

not necessary to disconnect the brake

hose or remove the caliper from the

vehicle. Position the caliper out of the

way, and support it with a wire to

avoid damaging the caliper or stretch-

ing the hose. Insert a clean cardboard

spacer between the linings to prevent

the piston from coming out of the cyl-

inder bore while the caliper is re-

moved.

Handle the rotor and caliper assem-

blies in such a way as to avoid defor-

mation of the rotor and nicking,

scratching or contamination of the

brake linings.

3.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly.

4.

Remove the hub and rotor as-

sembly from the spindle.

INSTALLATION

1.

If the rotor is being replaced, re-

move the protective coating from the

new rotor with carburetor degreaser.

Pack a new set of bearings with speci-

fied grease (M-1C75B), and install the

inner bearing cone and roller assembly

in the inner cup. Pack grease lightly

between the lips of a new grease seal

and install the seal (Figs. 23 and 24).

If the original rotor is being in-

stalled, make sure that the grease in

the hub is clean and adequate, that

the inner bearing and grease seal are

lubricated and in good condition, and

that the rotor braking surfaces are

clean.

2.

Install the hub and rotor assem-

bly on the spindle.

3.

Lubricate and install the outer

wheel bearing, washer and adjusting

nut.

4.

Adjust the wheel bearings to

specification, and then install the nut

lock, cotter pin, and grease cap. The

wheel bearing adjustment is especially

important with disc brakes.

5. Mount the caliper assembly on

the spindle following the Disc Brake

Caliper Assembly Installation proce-

dure in this section.

DISC BRAKE ROTOR

SPLASH SHIELD

REMOVAL

1.

Remove the caliper and the hub

and rotor assembly as outlined under

Removal in the foregoing procedure

(it is not necessary to disconnect hy-

draulic connections).

2.

Remove the three bolts that at-

tach the splash shield to the spindle,

and remove the shield (Figs. 23 and

24).

3.

Remove and discard the splash

shield to spindle gasket.

INSTALLATION

1.

Install a new splash shield to

spindle gasket.

2.

If the shield is bent, straighten it

out before installation. Position the

shield to the mounting bracket, install

the attaching bolts, nuts and torque

them to specification.

3.

Install the hub and rotor assem-

bly and the caliper as outlined under

Installation in the foregoing proce-

dure.

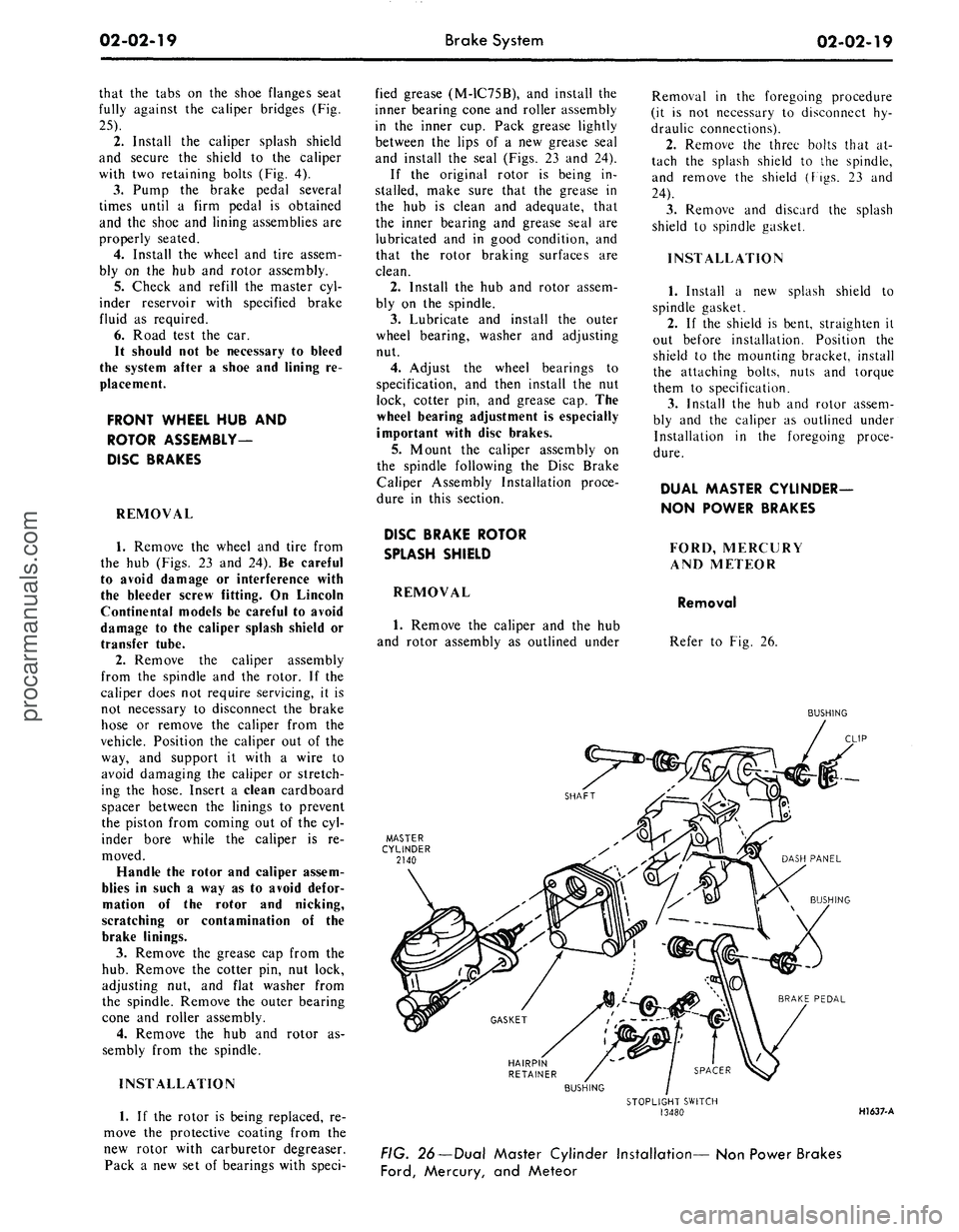

DUAL MASTER CYLINDER—

NON POWER BRAKES

FORD, MERCURY

AND METEOR

Removal

Refer to Fig. 26.

BUSHING

HAIRPIN

RETAINER

BUSHING

STOPLIGHT SWITCH

13480

HI 637-A

FIG. 26—Dual Master Cylinder Installation— Non Power Brakes

Ford,

Mercury, and Meteorprocarmanuals.com

Page 54 of 413

02-02-35

Brake System

02-02-35

4.

Attach a wire to the end of the

cable to assist in routing new cable.

5.

Lower the vehicle.

6. Remove the parking brake front

cable ball retaining clip from the

clevis.

7.

Disconnect the cable ball from

the notch in the brake clevis.

8.. Remove the hairpin retainer and

remove the cable assembly from the

brake control assembly.

9. Pull the cable assembly up through

the opening in the floor and remove

the wire from the end of the cable.

Installation

Refer to Fig. 36.

1.

Connect the wire to the end of

the cable assembly and pull the cable

down through the opening in the

floor. Remove the wire.

2.

Connect the cable assembly to

the brake control assembly and in-

stall the hairpin retainer.

3.

Position the ball end of the

cable in the notch of the brake clevis.

4.

Raise the vehicle on a hoist.

5.

Pull the cable grommet into po-

sition and route the cable through

the access holes in the side rail and

under the fuel line.

6. Insert the cable into the body

bracket and install the hairpin re-

tainer.

7.

Position the spring, spring seat,

and equalizer on the cable and install

the two nuts.

8. Adjust the parking brake.

LINCOLN CONTINENTAL

Removal

1.

Raise the car on a hoist. Dis-

connect the parking brake cable from

the equalizer lever underneath the

car (Fig. 38).

2.

Remove the retaining clip at the

cable bracket, and disengage the cable

from the bracket (Fig. 38).

3.

Remove the supporting clip re-

taining bolts and remove the support

plate from the underbody.

4.

Lower the car on a hoist.

5.

With the parking brake in the

fully released position, disconnect the

cable at the control assembly.

6. Raise the vehicle on a hoist. Re-

move the left front fender apron

splash shield retaining bolts and the

splash shield.

7.

Remove the two bolts securing

the parking brake control to equaliz-

er cable bracket to the dash panel

and remove the cable from the vehicle.

Installation

1.

Route the parking brake control

to equalizer cable to the control as-

sembly and the equalizer, and install

the two bolts that retain the cable

to the dash panel (Fig. 38).

2.

Install the left fror%/ender apron

splash shield and the ^u attaching

bolts.

3.

Lower the vehicle.

4.

Connect the control cable to the

clevis on the control assembly.

5.

Raise the car on a hoist.

6. Position the supporting clip and

cable on the vehicle and install the

retaining bolts. Do not tighten the

bolts.

Position the cable armor ap-

proximately 1/2 inch to the right of

the clip (looking toward the rear of

the car) and tighten the retaining

bolts.

7.

Position the equalizer control

cable to the support bracket and in-

stall the retaining hairpin clip.

8. Connect the ball end of the con-

trol cable to the equalizer lever.

9. Adjust the parking brake linkage

(Part

2-1,

Section 2).

10.

Check the operation of the auto-

matic release mechanism.

PARKING BRAKE

ACTUATOR-TO-EQUALIZER

CABLE

FORD, MERCURY,

METEOR, THUNDERBIRD

AND CONTINENTAL

MARK III

Removal

Refer to Figs. 34 and 37.

1.

Raise the vehicle on a hoist.

2.

Remove the lock and adjusting

nut which retains the cable to the

equalizer.

3.

Remove the cable end from the

equalizer.

4.

Unhook the cable from the act-

uator, and remove from the vehicle. *

Installation

1.

Insert new cable end into act-

uator.

2.

Insert cable end into equalizer

and tighten the adjusting nut snug.

Install the lock nut.

3.

Adjust the parking brake cable

tension and check operation as out-

lined in Part

2-1,

Section 2.

4.

Lower the vehicle.

PARKING BRAKE EQUALIZER

TO REAR WHEEL CABLE

FORD, MERCURY,

METEOR, THUNDERBIRD

AND CONTINENTAL

MARK III

Removal

1.

Raise the vehicle and tffosen the

parking brake equalizer rod" adjusting

nut. Disconnect the equalizer from the

rear cables (Figs. 34 and 37).

2.

Compress the prongs on the left

cable-to-frame side member retainer

so the prong can pass through the

side-member. Remove the clip that at-

taches the left cable to the left lower

arm. Pull the cable thru the frame left

side member.

3.

Compress the prongs on the

right cable-to-frame side member re-

tainer bracket so the prong can pass

through the bracket. Remove the clips

retaining the right cable to the frame

crossmember.

4.

Remove the rear wheel cover and

wheel. Remove the three Tinnerman

nuts that hold the brake drum in place

and remove the drum.

5.

Working on the wheel side of the

rear brake, remove the automatic

brake adjuster spring. Compress the

prongs on the parking brake cable re-

tainer so that they can pass through

the hole in the brake backing plate.

Draw the cable retainer through the

hole.

6. With the spring tension off the

parking brake lever, lift the cable out

of the slot in the lever and remove the

cable through the backing plate hole.

Installation

1.

Pull enough of the parking brake

cable through the housing so that the

end of the cable may be inserted over

the slot in the parking brake lever on

the rear brake shoe.

2.

Pull the excess slack from the

cable, and insert the cable housing

into the brake backing plate access

hole so that the retainer prongs ex-

pand. The prongs must be securely

locked in place. Install the automatic

brake adjuster spring.

3.

Position the right hand cable and

the two retaining clips and screws on

the rear crossmember. Compress the

prongs on the right cable and position

the cable in the retaining bracket on

the frame side member. Be sure theprocarmanuals.com

Page 55 of 413

02-02-36

Brake System

02-02-36

locating stripe on the cable is midway

between the retaining clips and tighten

all retaining clip screws.

4.

Position the left cable, retaining

clip and screw on the left lower sus-

pension arm. Compress the prongs on

the left cable and position the cable

through the frame side-member. The

prongs must be securely locked in

place.

5.

Insert the ball ends of the cables

into the equalizer assembly.

6. Install the rear drum(s) and

tighten the three Tinnerman nuts and

secure the drum. Install the wheel and

tire and the wheel cover.

7.

Adjust the parking brake linkage

as outlined in Part 2-1, Section 2. Ad-

just the rear brakes, as required (Part

2-1,

Section 2).

FAIRLANE, MONTEGO,

MUSTANG AND COUGAR—

EXCEPT STATION WAGON

Removal

1.

Remove the equalizer lock nut

and adjusting nut, equalizer, spring

and spring seat.

2.

With the cables slack, discon-

nect the ball-ends from the connector

(Figs.

35 and 36).

3.

Remove the cable from the re-

tainer hooks (station wagon models)

and the underbody guide (convertible

models) if required.

4.

Remove the hairpin lock retain-

ing the cable housing to the side rail

bracket.

5.

Remove the wheel cover, wheel

and tire and the rear brake drum as

outlined in Section 2.

6. Remove self-adjuster springs to

allow clearance to remove cable re-

tainer from the backing plate. Discon-

nect the rear end of the cable from the

parking brake lever on the brake shoe.

Disengage the cable housing retaining

grommet or steel-pronged Hi-Hat

from the backing plate and withdraw

the cable and housing from the in-

board side of the backing plate.

7.

Slide the cable and housing out

of the side rail bracket.

Installation

1.

Insert the rear end of the cable

through the side rail bracket and pull

the cable and housing into position.

2.

Insert the rear end of the cable

and housing through the hole in the

backing plate from the inboard side.

3.

Connect the cable to the parking

brake lever on the brake shoe and in-

stall the cable housing retaining grom-

met or steel-pronged Hi-Hat in the

backing plate.

4.

Install the self-adjuster springs.

Position the cable housing in the side

rail bracket and install the hairpin

type retainer.

5.

Install rear hub and drum as-

sembly, wheel and tire assemblies and

wheel cover as outlined in Section 2.

6. Position the cable retainer hooks

(station wagon models) in the under-

body guide (convertible models) and

install the connector, thus hooking the

two cables together.

7.

Insert the cable into the equaliz-

er and install the equalizer, spring

seat, spring, adjusting nut and lock

nut to the front, parking brake control

cable.

8. Adjust the parking brake^as di-

rected in Part 2-1, Section 2.

FAIRLANE AND MONTEGO

STATION WAGONS AND

FALCON PASSENGER

MODELS

Removal and Installation

Refer to Fig. 35.

Generally follow the procedure

given above, omitting separation of

the cables, since the parking brake

rear cable assemblies supplied for

these models is in one piece. Removal

and installation of both rear wheels,

tires and drums will also be required.

LINCOLN CONTINENTAL

Removal

1.

Raise the car. Remove the rear

wheel cover. Remove the wheel and

tire as an assembly.

2.

Remove the three Tinnerman

nuts that hold the brake drum in

place, and remove the drum.

3.

Remove the brake shoe retract-

ing springs.

4.

Loosen the equalizer rod adjust-

ing nut and disconnect the cable from

the equalizer (Fig. 38).

5.

Remove the hairpin-type retainer

clip that secures the cable housing to

the body bracket, and pull the cable

and housing out of the bracket (Fig.

38).

6. Remove the cable to underbody

clamp attaching nuts and the clamp.

Disengage the cable housing from the

hook-type retainer at the spring U-

bolt.

7.

Working on the wheel side of the

backing plate (Fig. 38), compress the

prongs on the cable retainer so that it

can pass through the hole in the back-

ing plate. Draw the cable retainer out

of the hole.

8. With the spring tension off the

parking brake lever, lift the cable out

of the slot in the lever and remove it

through the backing plate hols.

Installation

1.

Pull enough of the cable through

the cable housing so that the end of

the cable may be inserted through the

backing plate hole from the inner side

and engage the cable end with the slot

in the parking brake lever.

2.

Pull the excess slack from the

cable and insert the cable housing into

the backing plate access hole (Fig.

38).

The prongs must be securely

locked in place.

3.

Install the brake shoe retracting

springs.

4.

Position the cable to the under-

body and install the retaining clamp

so that the cable conduit armor ex-

tends forward of the clamp as shown

in Fig. 38. Install the clamp retaining

nuts.

5.

Hook the cable housing to the

retainer at the spring U-bolt.

6. Engage the forward end of the

cable housing with the frame bracket

and secure it with the hairpin-type

clip.

7.

Insert the ball end of the cable

into the equalizer.

8. Make a preliminary brake ad-

justment with the use of Tool HRA-

8650 (Fig. 11).

9. Install the rear drum. Tighten

the three Tinnerman nuts that secure

the drum. Install the wheel and wheel

cover.

10.

Adjust the parking brake link-

age.

11.

Lower the vehicle.

ANTI-SKID CONTROL

ACTUATOR

REMOVAL

Refer to Fig. 39.

1.

Working in the passenger com-

partment, under the glove box, remove

the screw that attaches the forward

end of the control module retainer to

the support assembly. Lower the for-

ward end of the control module re-

tainer and remove the module assem-

bly.procarmanuals.com

Page 57 of 413

02-02-38

Brake System

02-02-38

2.

Disconnect the actuator solenoid

and warning switch harness connectors

from the control module.

3.

Remove the two wiring harness

grommets from the dash panel and

push the wiring harness and connec-

tors through the openings in the dash

panel.

4.

Working in the engine compart-

ment loosen the hose clamp and re-

move the air hose from the air filter.

5.

Remove the engine air cleaner-

Loosen the hose clamp and remove

the vacuum hose from the vacuum

manifold fitting.

6. Raise the vehicle on a hoist.

7.

Disconnect the exhaust pipes

from the exhaust manifold and sup-

port with wire to provide access to the

actuator assembly.

8. Remove the bolt retaining the

actuator ground wire to the rear outer

corner of the engine right bank.

9. Loosen the tube nuts and discon-

nect the brake system hydraulic tubes

from the hydraulic valve housing.

10.

Remove the three nuts retaining

the actuator assembly to the actuator

support bracket.

11.

Remove the three bolts that re-

tain the actuator mounting bracket to

the side rail and remove the mounting

bracket.

12.

Remove the actuator assembly

from the vehicle and place it on a

bench.

13.

Remove the air and vacuum

hoses from the actuator.

INSTALLATION

1.

Install the air and vacuum hoses

on the new actuator.

2.

Place the actuator assembly into

position under the vehicle, routing the

air and vacuum hoses up between the

engine and fender apron and inserting

the solenoid leads through the holes in

the firewall.

3.

Position the ground wire to the

rear of the engine block and install re-

taining bolt.

4.

Position the actuator mounting

bracket to the frame side rail and in-

stall the three retaining bolts.

5.

Position the actuator assembly

to the mounting bracket and install

the three retaining nuts.

6. Connect the hydraulic tubes to

the hydraulic valve assembly and

tighten the tube nuts to specifications.

7.

Connect the exhaust pipes to the

exhaust manifolds.

8. Lower the vehicle.

9. Pull the actuator solenoid and

brake warning switch wiring harness

through the two holes in the dash

panel from inside the car. Seat the

wiring harness grommets in the dash

panel.

10.

Connect the actuator solenoid

and brake warning switch wiring har-

ness connectors to the control mo-

dules.

'

11.

Position the control module in

the bracket under the glove box and

install the retaining screw.

12.

In the engine compartment con-

nect the air hose to the air filter and

position the hose clamp.

13.

Connect the vacuum hose to the

engine vacuum manifold fitting. In-

stall the engine air cleaner.

14.

Bleed the rear brake system and

centralize the pressure differential

valve.

15.

Raise the rear wheels. Apply

the brakes with the rear wheels turn-

ing to verify proper operation of the

anti-skid control system.

ANTI-SKID CONTROL MODULE

REMOVAL

Refer to Fig. 39.

1.

Remove the retaining strap hold-

ing the harnesses.

2.

Remove the screw that attaches

the forward end of the control module

retainer to the support assembly.

3.

Lower the forward end of the

control module and retainer from the

support assembly; move the module

and retainer forward slightly until the

flange clears the slot in the support

assembly.

4.

Disconnect the five wiring har-

ness plugs from the control module.

5.

Remove the control module from

the vehicle.

INSTALLATION

1.

Connect the five wiring harness

plugs to the control module. Only one

arrangement is possible.

2.

Position the control module in

the retainer, orienting the module per

the markings on it, and insert the re-

tainer flange into the slot at the rear

of the support assembly.

3.

Pivot the retainer and control

module upward and align the screw

hole in the forward end of the retainer

with the hole in the support bracket

assembly. Install the retaining screw.

4.

Test the vehicle on the hoist to

verify correct operation of the skid

control system.

5.-

Secure the wiring to the module

support extension with the retaining

strap.

ANTI-SKID CONTROL SENSOR

REMOVAL

Refer to Fig. 39.

1.

Raise the vehicle on a hoist.

2.

Remove the rear wheel and tire

assembly.

3.

Remove the three Tinnerman

nuts (3) and remove the brake drum.

4.

Disconnect the sensor lead from

the rear wiring harness.

5.

Unseat the sensor lead grommet

pushing it to the inside of the brake

assembly.

6. Remove the four nuts that retain

the sensor to the backing plate and

pull the axle shaft, sensor assembly

and wheel bearing assembly from the

axle housing.

7.

Press the wheel bearing retainer

and wheel bearing off the axle shaft

(Refer to Part 4-2).

8. Remove the sensor assembly and

press the rotor off the shaft with tool

T69P-2B384-A Detail 2 and TOOL

1225-DA.

INSTALLATION

1.

Press a new rotor onto the axle

shaft. Install a new sensor assembly

on the shaft with tool T69P-

2B384-ADetail 1 and TOOL 1225-

DA, and press the bearing and bear-

ing retainer onto the shaft (Refer to

Part 4-2).

2.

Insert the axle shaft assembly in

the rear axle housing onto the four

backing plate retaining bolts, feeding

the sensor lead through the hole in the

backing plate.

3.

Seat the sensor lead grommet in

the backing plate.

4.

Install the four nuts on the re-

taining bolts and tighten to specifica-

tions.

5.

Connect the sensor lead to the

rear wiring harness and install two re-

taining straps.

6. Install the rear brake drum and

retain with the Tinnerrhan drum re-

taining nuts.

7.

Install the rear wheel and tire as-

sembly and tighten the wheel nuts to

specifications.

8. Test the vehicle on the hoist to

verify proper operation of the skid

control system.procarmanuals.com

Page 58 of 413

02-02-39

Brake System

02-02-39

MAJOR REPAIR OPERATIONS

BRAKE DRUM REFINISHING

Minor scores on a brake drum can

be removed with sandpaper. A drum

that is excessively scored or shows a

total indicator runout of over 0.007

inch should be turned down. Remove

only enough stock to eliminate the

scores and true up the drum. The refi-

nished diameter must not exceed 0.060

inch oversize.

Check the inside diameter of the

brake drum with a brake drum mi-

crometer (Tool FRE-14^1).

If the drum diameter is less than

0.030 inch oversize after refinishing^

standard lining may be installed. If

the drum diameter is 0.030—0.060

inch oversize after refinishing, oversize

lining must be installed.

After a drum is turned down, wipe

the refinished surface with a cloth

soaked in clean denatured alcohol. If

one drum is turned down, the opposite

drum on the same axle should also be

cut down to the same size.

ROTOR REFINISHING

Rotunda Disc Brake Attachment,

FRE-2249-2, is the only recommended

tool to refinish the disc brake rotors.

The step-by-step resurfacing procedure

provided with the tool must be ad-

hered to.

The finished braking surfaces of the

rotor must be flat and parallel within

0.0007 inch; lateral runout must not

exceed 0.003 inch total indicator read-

ing, and the surface finish of the brak-

ing surfaces are to be 80/15 micro

inches. The minimum limiting dimen-

sions (Figs. 11 and 12, Part 2-1) from

the inboard bearing cup to the out-

board rotor face and from the inboard

bearing cup to the inboard rotor face

must be observed when removing ma-

terial from the rotor braking surfaces.

On all models except Lincoln Con-

tinental, the limiting dimensions are to

be measured with a ball and gage bar

(Rotunda Kit FRE-70160).

BRAKE SHOE RELINING

Brake linings that are worn to with-

in 1/32 inch of the rivet head or are

less than 0.030 inch thick (bonded lin-

ing) or have been contaminated with

brake fluid, grease or oil must be re-

placed. Failure to replace worn linings

will result in a scored drum. When it

is necessary to replace linings, they

must also be replaced on the wheel on

the opposite side of the vehicle.

Inspect brake shoes for distortion,

cracks, or looseness. If this condition

exists,

the shoe must be discarded. Do

not attempt to repair a defective brake

shoe.

1.

Wash the brake shoes thoroughly

in a clean solvent. Remove all burrs

or rough spots from the shoes.

2.

Check the inside diameter of the

brake drum with a brake drum mi-

crometer (tool FRE-1431). If the di-

ameter is less than 0.030 inches over-

size,

standard lining may be installed.

If the diameter is 0.030—0.060 inches

oversize, oversize lining should be in-

stalled.

3.

Position the new lining on the

shoe.

Starting in the center, insert and

secure the rivets, working alternately

towards each end. Replacement lin-

ings are ground and no further grind-

ing is required.

4.

Check the clearance between the

shoe and lining. The lining must seat

tightly against the shoe with not more

than 0.008 inch clearance between any

two rivets.

RETAINER - 2B245

DUAL MASTER CYLINDER

DISASSEMBLY

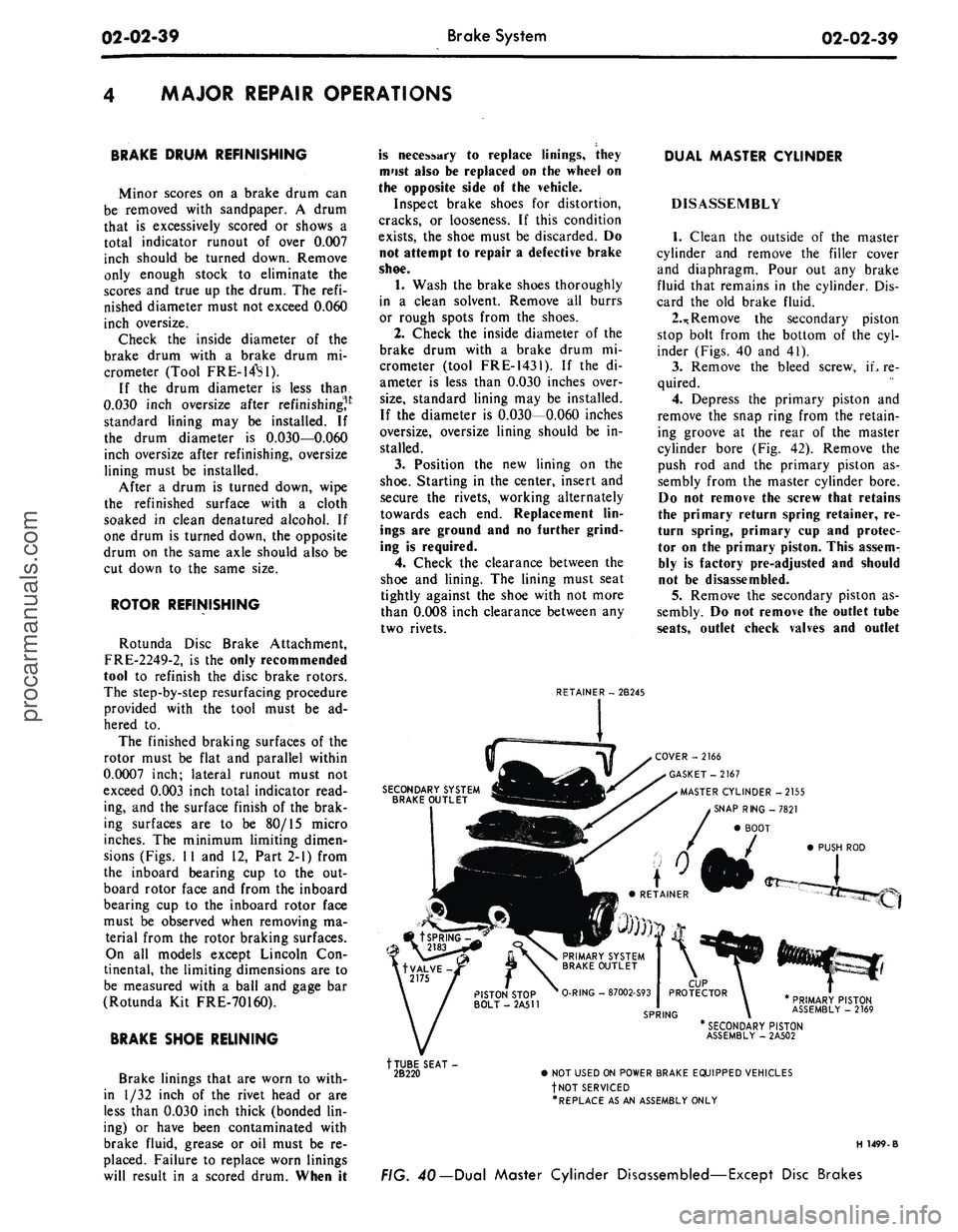

1.

Clean the outside of the master

cylinder and remove the filler cover

and diaphragm. Pour out any brake

fluid that remains in the cylinder. Dis-

card the old brake fluid.

2.*

Remove the secondary piston

stop bolt from the bottom of the cyl-

inder (Figs. 40 and 41).

3.

Remove the bleed screw, iL re-

quired.

4.

Depress the primary piston and

remove the snap ring from the retain-

ing groove at the rear of the master

cylinder bore (Fig. 42). Remove the

push rod and the primary piston as-

sembly from the master cylinder bore.

Do not remove the screw that retains

the primary return spring retainer, re-

turn spring, primary cup and protec-

tor on the primary piston. This assem-

bly is factory pre-adjusted and should

not be disassembled.

5.

Remove the secondary piston as-

sembly. Do not remove the outlet tube

seats,

outlet check valves and outlet

SECONDARY SYSTEM

BRAKE OUTLET

COVER -2166

GASKET-2167

MASTER CYLINDER -2155

SNAP RING -7821

BOOT

PUSH ROD

PRIMARY PISTON

ASSEMBLY - 2169

tTUBE SEAT-

2B220

* SECONDARY PISTON

ASSEMBLY - 2A502

• NOT USED ON POWER BRAKE EQUIPPED VEHICLES

fNOT SERVICED

•REPLACE AS AN ASSEMBLY ONLY

H 1499-B

FIG. 40— Dual Master Cylinder Disassembled—Except Disc Brakesprocarmanuals.com

Page 63 of 413

02-03-02

Specifications

02-03-02

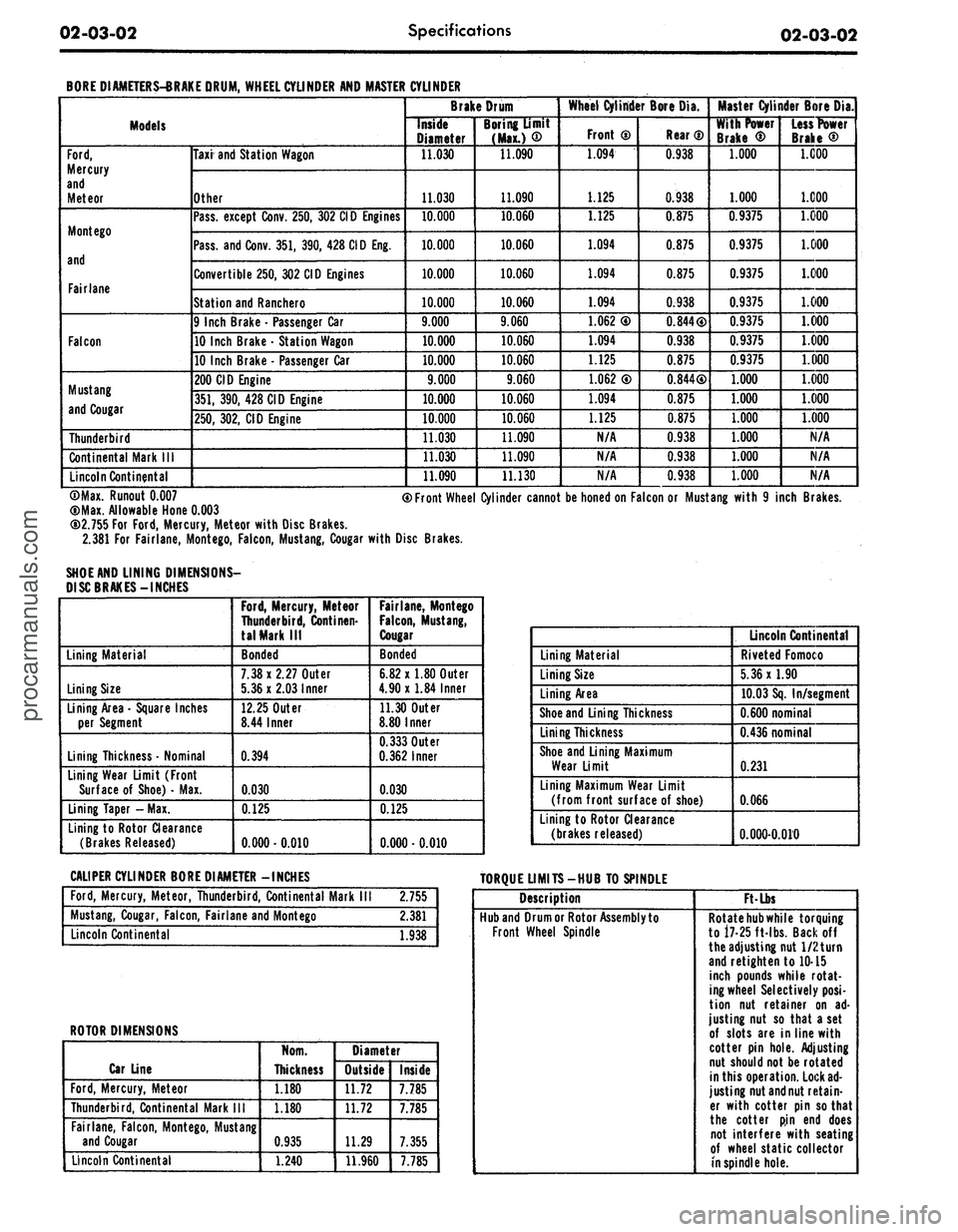

BORE DIAMETERS-BRAKE DRUM, WHEEL CYLINDER AND MASTER

Models

Ford,

Mercury

and

Meteor

Mont ego

and

Fairlane

Falcon

Mustang

and Cougar

Thunderbird

Continental Mark

III

Lincoln Continental

Taxi and Station Wagon

Other

Pass, except Conv. 250, 302 CID Engines

Pass, and Conv. 351, 390, 428 CID Eng.

Convertible 250, 302 CID Engines

Station and Ranchero

9 Inch Brake

-

Passenger Car

10 Inch Brake

•

Station Wagon

10 Inch Brake

•

Passenger Car

200 CID Engine

351,

390, 428 CID Engine

250,

302, CID Engine

CYLINDER

Brake Drum

Inside

Diameter

11.030

11.030

10.000

10.000

10.000

10.000

9.000

10.000

10.000

9.000

10.000

10.000

11.030

11.030

11.090

Boring Umit

(Max.)

®

11.090

11.090

10.060

10.060

10.060

10.060

9.060

10.060

10.060

9.060

10.060

10.060

11.090

11.090

11.130

Wheel Cylinder Bore Dia.

Front

0

1.094

L_ U25

1.125

1.094

1.094

1.094

1.062

0

1.094

1.125

1.062

®

1.094

1.125

N/A

N/A

N/A

Rear

®

0.938

0.938

0.875

0.875

0.875

0.938

0.844®

0.938

0.875

0.844®

0.875

0.875

0.938

0.938

0.938

Master Cylinder Bore Dia.

With Power

Brake

®

1.000

1.000

0.9375

0.9375

0.9375

0.9375

0.9375

0.9375

0.9375

1.000

1.000

1.000

1.000

1.000

1.000

Less Power

Brake

®

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

N/A

N/A

N/A

©Max. Runout

0.007

(DMax. Allowable Hone

0.003

CD2.755 For

Ford,

Mercury, Meteor with Disc Brakes.

2.381 For Fairlane, Montego, Falcon, Mustang, Cougar with Disc Brakes.

SHOE AND LINING DIMENSIONS-

DISC BRAKES-INCHES

® Front Wheel Cylinder cannot be honed on Falcon or Mustang with

9

inch Brakes.

Lining Material

Lining Size

Lining Area

-

Square Inches

per Segment

Lining Thickness • Nominal

Lining Wear Limit (Front

Surface

of

Shoe)

•

Max.

Lining Taper -Max.

Lining to Rotor Clearance

(Brakes Released)

Ford,

Mercury, Meteor

Thunderbird, Continen-

tal Mark

III

Bonded

7.38x2.27

Outer

5.36x2.03

Inner

12.25 Outer

8.44 Inner

0.394

0.030

0.125

0.000-0.010

Fairlane, Montego

Falcon,

Mustang,

Cougar

Bonded

6.82 x 1.80 Outer

4.90x1.84 Inner

11.30 Outer

8.80 Inner

0.333

Outer

0.362

Inner

0.030

0.125

0.000

• 0.010

Lining Material

Lining Size

Lining Area

Shoe and Lining Thickness

Lining Thickness

Shoe and Lining Maximum

Wear Limit

Lining Maximum Wear Limit

(from front surface

of

shoe)

Lining to Rotor Clearance

(brakes released)

Lincoln Continental

Riveted Fomoco

5.36x1.90

10.03 Sq. In/segment

0.600

nominal

0.436

nominal

0.231

0.066

0.000-0.010

CALIPER CYLINDER BORE DIAMETER -INCHES

TORQUE LIMITS-HUB TO SPINDLE

Ford,

Mercury, Meteor, Thunderbird, Continental Mark

2.755

Mustang, Cougar, Falcon, Fairlane and Montego

2.381

Lincoln Continental

1.938

ROTOR DIMENSIONS

Car Line

Ford,

Mercury, Meteor

Thunderbird, Continental Mark

III

Fairlane, Falcon, Montego, Mustang

and Cougar

Lincoln Continental

Norn.

Thickness

1.180

1.180

0.935

1.240

Diameter

Outside

11.72

11.72

11.29

11.960

Inside

7.785

7.785

7.355

7.785

Description

Hub and Drum or Rotor Assembly to

Front Wheel Spindle

Ft-Lbs

Rotate

hub

while torquing

to 17-25 ft-lbs. Backoff

the adjusting nut 1/2 turn

and retighten to 10-15

inch pounds while rotat-

ing wheel Selectively

posi-

tion

nut

retainer

on ad-

justing nut

so

that a set

of slots are in line with

cotter pin hole. Adjusting

nut should not be rotated

in this operation. Lock

ad-

justing nut and nut retain-

er with cotter pin so that

the cotter

pin end

does

not interfere with seating

of wheel static collector

in spindle hole.procarmanuals.com

Page 64 of 413

02-03-03

Specifications

02-03-03

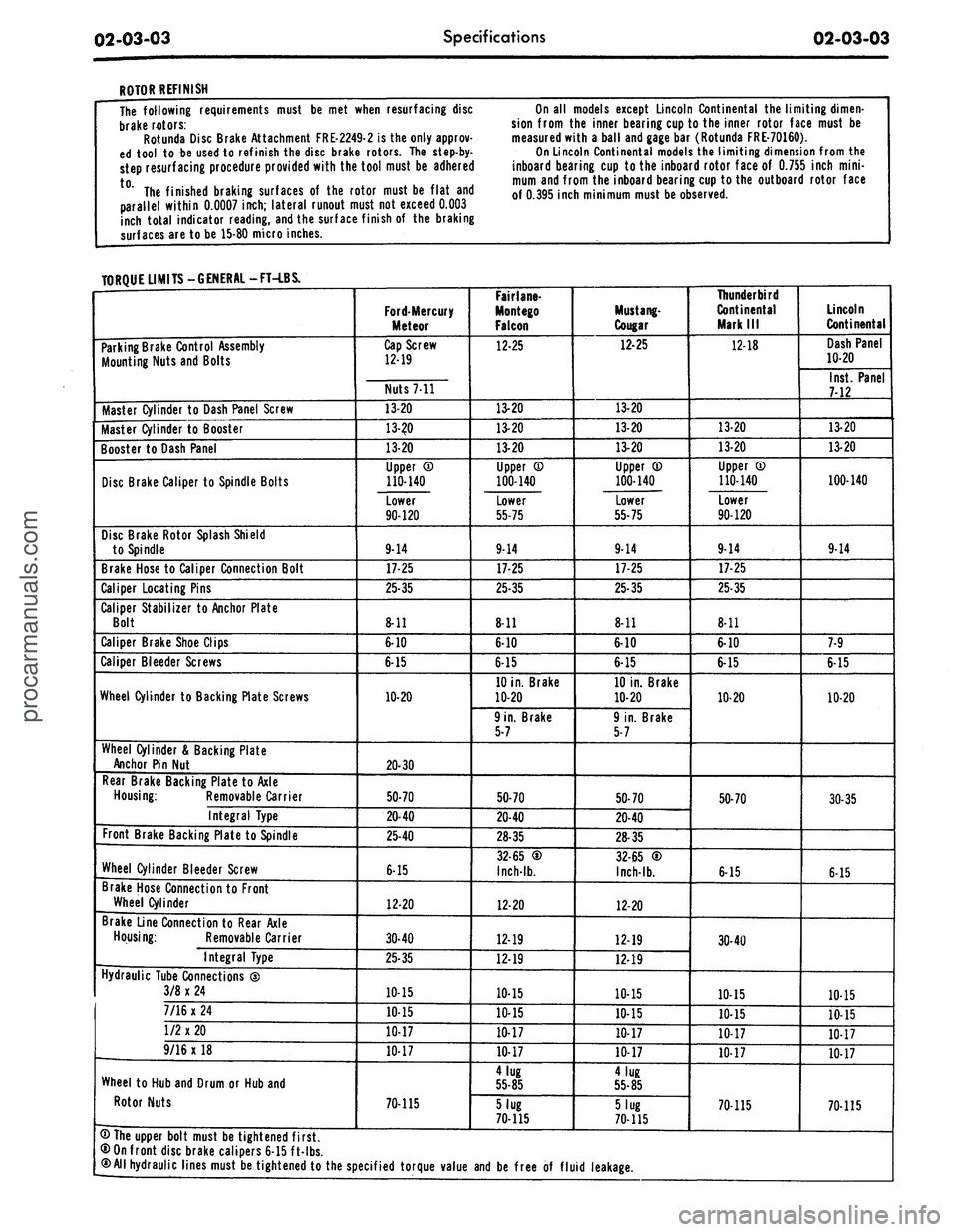

ROTOR REFINISH

The following requirements must be met when resurfacing disc

brake rotors:

Rotunda Disc Brake Attachment FRE-2249-2 is the only approv-

ed tool to be used to ref inish the disc brake rotors. The step-by-

step resurfacing procedure provided with the tool must be adhered

t0" The finished braking surfaces of the rotor must be flat and

parallel within 0.0007

inch;

lateral runout must not exceed 0.003

inch total indicator reading, and the surface finish of the braking

surfaces are to be 15-80 micro inches.

On all models except Lincoln Continental the limiting dimen-

sion from the inner bearing cup to the inner rotor face must be

measured with a ball and gage bar (Rotunda FRE-70160).

On Lincoln Continental models the limiting dimension from the

inboard bearing cup to the inboard rotor face of 0.755 inch

mini-

mum and from the inboard bearing cup to the outboard rotor face

of 0.395 inch minimum must be observed.

TORQUE LIMITS -GENERAL -FT-LBS.

Parking Brake Control Assembly

Mounting Nuts and Bolts

Master Cylinder to Dash Panel Screw

Master Cylinder to Booster

Booster to Dash Panel

Disc Brake Caliper to Spindle Bolts

Disc Brake Rotor Splash Shield

to Spindle

Brake Hose to Caliper Connection Bolt

Caliper Locating Pins

Caliper Stabilizer to Anchor Plate

Bolt

Caliper Brake Shoe Clips

Caliper Bleeder Screws

Wheel Cylinder to Backing Plate Screws

Wheel Cylinder & Backing Plate

Anchor Pin Nut

Rear Brake Backing Plate to Axle

Housing:

Removable Carrier

Integral Type

Front Brake Backing Plate to Spindle

Wheel Cylinder Bleeder Screw

Brake Hose Connection to Front

Wheel Cylinder

Brake Line Connection to Rear Axle

Housing:

Removable Carrier

Integral Type

Hydraulic Tube Connections ®

3/8 x 24

7/16 x 24

1/2 x 20

9/16 x 18

Wheel to Hub and Drum or Hub and

Rotor Nuts

Ford-Mercury

Meteor

Cap Screw

12-19

Nuts 7-11

13-20

13-?0

13-20

Upper ©

110-140

Lower

90-120

9-14

17-25

25-35

8-11

6-10

6-15

10-20

20-30

50-70

IPo

25-40

6-15

12-20

30-40

25-35

10-15

10-15

10-17

10-17

70-115

Fair

lane-

Montego

Falcon

12-25

13-20

13-20

13-20

Upper CD

100-140

Lower

55-75

9-14

17-25

25-35

8-11

6-10

6-15

10 in. Brake

10-20

9 in. Brake

5-7

50-70

20-40

28-35

32-65 ®

Inch-lb.

12-20

12-19

12-19

10-15

10-15

10-17

10-17

4 lug

55-85

5 lug

70-115

Mustang-

Cougar

12-25

13-20

13-20

13-20

Upper ©

100-140

Lower

55-75

9-14

17-25

25-35

8-11

6-10

6-15

10 in. Brake

10-20

9 in. Brake

5-7

50-70

20-40

28-35

32-65 ®

Inch-lb.

12-20

12-19

12-19

10-15

10-15

10-17

10-17

4 lug

55-85

5 lug

70-115

Thunderbird

Continental

Mark III

1218

13-20

13-20

Upper ©

110-140

Lower

90-120

9-14

17-25

25-35

8-11

6-10

6-15

10-20

50-70

6-15

30-40

10-15

10-15

10-17

10-17

70-115

Lincoln

Continental

Dash Panel

10-20

Inst. Panel

712

13-20

13-20

100-140

9-14

7-9

6-15

10-20

30-35

6-15

10-15

10-15

10-17

10-17

70-115

® The upper bolt must be tightened first.

® On front disc brake calipers 6-15 ft-lbs.

® All hydraulic lines must be tightened to the specified torque value and be free of fluid leakage.procarmanuals.com

Page 66 of 413

03-01-01

PART

3-1

PAGE

Suspension,

Steering, Wheels and

Tires,

General Service 03-01-01

PART

3-2

Suspension 03-02-01

PART

3-3

Automatic

Air

Leveling System ....03-03-01

PART

3-4

Automatic

Air

Leveling System

Lincoln Continental 03-04-01

PART

3-5

Steering Columns and Linkage ... 03-05-01

PART

3-6

Manual Steering 03-06-01

PART

3-7

Ford Design Non-Integral Power

Steering System

03-07-01

PART

3-8

PAGE

Ford Design Integral Power

Steering Gear 03-08-01

PART

3-9

Saginaw Design Integral Power

Steering Gear 03-09-01

PART

3-10

Ford-Thompson Power Steering

Pump 03-10-01

PART

3-11

Eaton Power Steering Pump 03-1

1-01

PART 3-12

Wheels and Tires 03-1 2-01

PART

3-13

Specifications

03-13-01

PART

3-1

Suspension,Steering, Wheels

and

Tires—General Service

COMPONENT INDEX

CASTER AND CAMBER ADJUSTMENTS

FRONT

END

INSPECTION

FRONT WHEEL ALIGNMENT CHECKS

LUBRICANT CHECKING PROCEDURE

POWER STEERING GEAR CLEANING

AND INSPECTION

POWER STEERING PRELIMINARY TESTS

POWER STEERING PUMP

Cleaning

and

Inspection

Flow

and

Pressure Tests

POWER STEERING SYSTEM FLUSHING

SHOCK ABSORBER CHECKS

STEERING WHEEL SPOKE POSITION

Adjustment

TOE-IN ADJUSTMENT

WHEEL BALANCING

MODEL APPLICATION

All

Models

01-08

01-03

01-07

01-09

01-02

01-11

01-07

01-07

01-07

Ford

01-05

01-09

01-02

01-09

Mercury

01-05

01-09

01-02

01-09

Meteor

01-05

01-09

01-02

01-09

Cougar

01-06

01-09

01-02

01-09

Fairlane

01-06

01-09

01-02

01-09

Falcon

01-06

01-09

01-02

01-09

Montego

01-06

01-09

01-02

Gl-09

Mustang

01-06

01-09

01-02

01-09

Lincoln-

Continental

01-06

01-09

01-03

N/A

Thunderbird

01-05

01-09

01-02

01-09

Continental-

Mark

III

01-05

01-10

01-03

N/A

A page number indicates that

the

item

is for the

vehicle listed

at the

head

of the

column.

N/A indicates that

the

item

is not

applicable

to the

vehicle listed.

procarmanuals.com

Page 67 of 413

03-01-02

Suspension — Steering, Wheels And Tires — General Service

03-01-02

1 TESTING

POWER STEERING-

PRELIMINARY TESTS

The following preliminary checks

should always be made before per-

forming any operations.

AIR BLEEDING

Air in the power steering system

(shown by bubbles in the fluid) should

be bled. After making sure that the

reservoir is filled to specification (the

fluid must be at normal operating

temperature when the check is made),

turn the steering wheel through its full

travel three or four times. Do not hold

the wheels against their stops. Re-

check the fluid level.

CHECK FLUID LEVEL

Run the engine until the fluid is at

normal operating temperature. Then

turn the steering wheel all the way to

the left and right several times, and

shut off the engine.

Check the fluid level in the power

steering reservoir. The level must show

on the cross hatching between the bot-

tom of the dipstick and the full mark

(Fig. 1). If the level is low, add

enough automatic transmission fluid

C1AZ-19582-A to raise the level to

the F mark on the dipstick. Do not

overfill the reservoir.

CHECK PUMP BELT

If the pump belt is broken, glazed,

or worn, replace it with a new belt.

Use only the specified type of belt.

Refer to Part 3-13 for belt adjustment

procedure.

CHECK FOR FLUID

LEAKS

With the engine idling, turn the

steering wheel from stop to stop sever-

al times. Check all possible leakage

points. Tighten all loose fittings, and

replace any damaged lines or defective

seats.

CHECK TURNING EFFORT

With the front wheels properly al-

igned and tire pressures correct, check

the effort required to turn the steering

wheel.

G 1508- A

FIG.

1—Power

Steering Pump

Dipstick

1.

With the vehicle on dry concrete,

set the parking brakes.

2.

With the engine warmed up and

running at idle speed, turn the steering

wheel to the left and right several

times to warm the fluid.

3.

Attach a pull scale to the rim of

the steering wheel. Measure the pull

required to turn the wheel one com-

plete revolution in each direction. The

effort required to rotate the steering

wheel should not exceed specifications

given in Part 3-13.

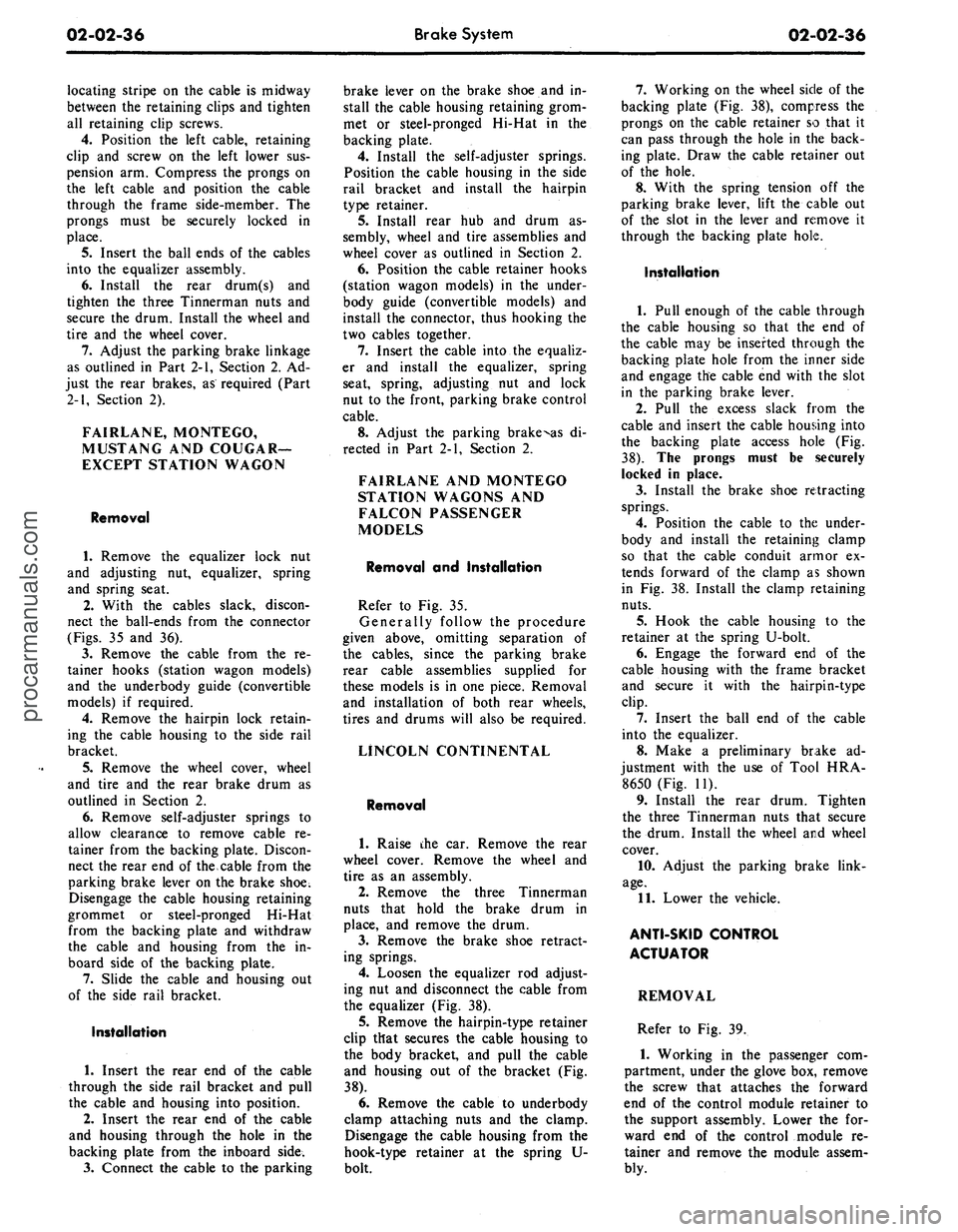

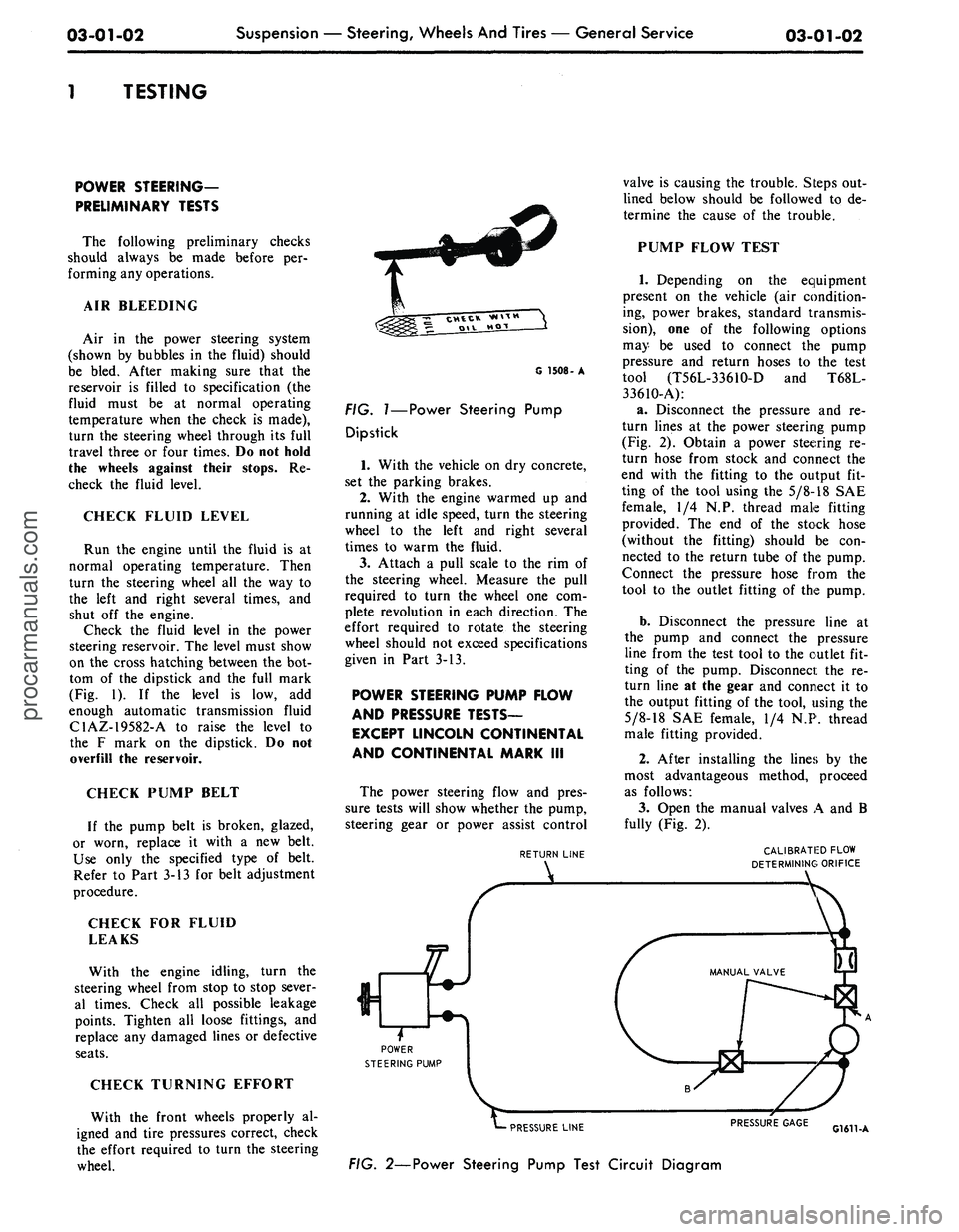

POWER STEERING PUMP FLOW

AND PRESSURE TESTS—

EXCEPT LINCOLN CONTINENTAL

AND CONTINENTAL MARK III

The power steering flow and pres-

sure tests will show whether the pump,

steering gear or power assist control

RETURN LINE

POWER

STEERING PUMP

Sr

valve is causing the trouble. Steps out-

lined below should be followed to de-

termine the cause of the trouble.

PUMP FLOW TEST

1.

Depending on the equipment

present on the vehicle (air condition-

ing, power brakes, standard transmis-

sion),

one of the following options

may be used to connect the pump

pressure and return hoses to the test

tool (T56L-3361O-D and T68L-

33610-A):

a. Disconnect the pressure and re-

turn lines at the power steering pump

(Fig. 2). Obtain a power steering re-

turn hose from stock and connect the

end with the fitting to the output fit-

ting of the tool using the

5/8-18

SAE

female, 1/4 N.P. thread male fitting

provided. The end of the stock hose

(without the fitting) should be con-

nected to the return tube of the pump.

Connect the pressure hose from the

tool to the outlet fitting of the pump.

b.

Disconnect the pressure line at

the pump and connect the pressure

line from the test tool to the outlet fit-

ting of the pump. Disconnect the re-

turn line at the gear and connect it to

the output fitting of the tool, using the

5/8-18

SAE female, 1/4 N.P. thread

male fitting provided.

2.

After installing the lines by the

most advantageous method, proceed

as follows:

3.

Open the manual valves A and B

fully (Fig. 2).

CALIBRATED FLOW

DETERMINING ORIFICE

PRESSURE LINE

FIG. 2—Power Steering Pump Test Circuit Diagram

PRESSURE GAGE

G1611-Aprocarmanuals.com