tow bar FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 58 of 413

02-02-39

Brake System

02-02-39

MAJOR REPAIR OPERATIONS

BRAKE DRUM REFINISHING

Minor scores on a brake drum can

be removed with sandpaper. A drum

that is excessively scored or shows a

total indicator runout of over 0.007

inch should be turned down. Remove

only enough stock to eliminate the

scores and true up the drum. The refi-

nished diameter must not exceed 0.060

inch oversize.

Check the inside diameter of the

brake drum with a brake drum mi-

crometer (Tool FRE-14^1).

If the drum diameter is less than

0.030 inch oversize after refinishing^

standard lining may be installed. If

the drum diameter is 0.030—0.060

inch oversize after refinishing, oversize

lining must be installed.

After a drum is turned down, wipe

the refinished surface with a cloth

soaked in clean denatured alcohol. If

one drum is turned down, the opposite

drum on the same axle should also be

cut down to the same size.

ROTOR REFINISHING

Rotunda Disc Brake Attachment,

FRE-2249-2, is the only recommended

tool to refinish the disc brake rotors.

The step-by-step resurfacing procedure

provided with the tool must be ad-

hered to.

The finished braking surfaces of the

rotor must be flat and parallel within

0.0007 inch; lateral runout must not

exceed 0.003 inch total indicator read-

ing, and the surface finish of the brak-

ing surfaces are to be 80/15 micro

inches. The minimum limiting dimen-

sions (Figs. 11 and 12, Part 2-1) from

the inboard bearing cup to the out-

board rotor face and from the inboard

bearing cup to the inboard rotor face

must be observed when removing ma-

terial from the rotor braking surfaces.

On all models except Lincoln Con-

tinental, the limiting dimensions are to

be measured with a ball and gage bar

(Rotunda Kit FRE-70160).

BRAKE SHOE RELINING

Brake linings that are worn to with-

in 1/32 inch of the rivet head or are

less than 0.030 inch thick (bonded lin-

ing) or have been contaminated with

brake fluid, grease or oil must be re-

placed. Failure to replace worn linings

will result in a scored drum. When it

is necessary to replace linings, they

must also be replaced on the wheel on

the opposite side of the vehicle.

Inspect brake shoes for distortion,

cracks, or looseness. If this condition

exists,

the shoe must be discarded. Do

not attempt to repair a defective brake

shoe.

1.

Wash the brake shoes thoroughly

in a clean solvent. Remove all burrs

or rough spots from the shoes.

2.

Check the inside diameter of the

brake drum with a brake drum mi-

crometer (tool FRE-1431). If the di-

ameter is less than 0.030 inches over-

size,

standard lining may be installed.

If the diameter is 0.030—0.060 inches

oversize, oversize lining should be in-

stalled.

3.

Position the new lining on the

shoe.

Starting in the center, insert and

secure the rivets, working alternately

towards each end. Replacement lin-

ings are ground and no further grind-

ing is required.

4.

Check the clearance between the

shoe and lining. The lining must seat

tightly against the shoe with not more

than 0.008 inch clearance between any

two rivets.

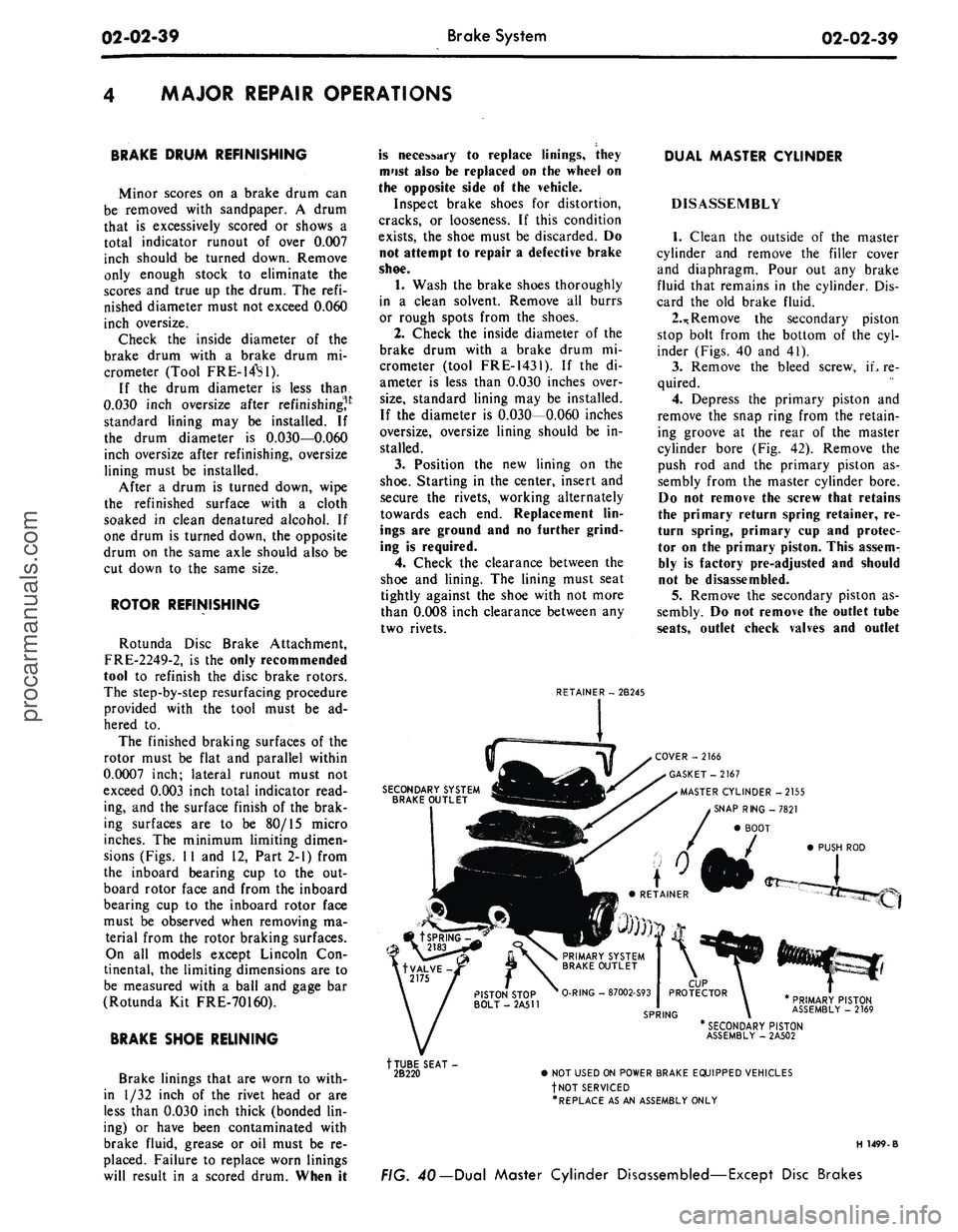

RETAINER - 2B245

DUAL MASTER CYLINDER

DISASSEMBLY

1.

Clean the outside of the master

cylinder and remove the filler cover

and diaphragm. Pour out any brake

fluid that remains in the cylinder. Dis-

card the old brake fluid.

2.*

Remove the secondary piston

stop bolt from the bottom of the cyl-

inder (Figs. 40 and 41).

3.

Remove the bleed screw, iL re-

quired.

4.

Depress the primary piston and

remove the snap ring from the retain-

ing groove at the rear of the master

cylinder bore (Fig. 42). Remove the

push rod and the primary piston as-

sembly from the master cylinder bore.

Do not remove the screw that retains

the primary return spring retainer, re-

turn spring, primary cup and protec-

tor on the primary piston. This assem-

bly is factory pre-adjusted and should

not be disassembled.

5.

Remove the secondary piston as-

sembly. Do not remove the outlet tube

seats,

outlet check valves and outlet

SECONDARY SYSTEM

BRAKE OUTLET

COVER -2166

GASKET-2167

MASTER CYLINDER -2155

SNAP RING -7821

BOOT

PUSH ROD

PRIMARY PISTON

ASSEMBLY - 2169

tTUBE SEAT-

2B220

* SECONDARY PISTON

ASSEMBLY - 2A502

• NOT USED ON POWER BRAKE EQUIPPED VEHICLES

fNOT SERVICED

•REPLACE AS AN ASSEMBLY ONLY

H 1499-B

FIG. 40— Dual Master Cylinder Disassembled—Except Disc Brakesprocarmanuals.com

Page 89 of 413

03-02-13

Suspension

03-02-13

BALL JOINT BOLT HEAD

STABILIZER

F1370-A

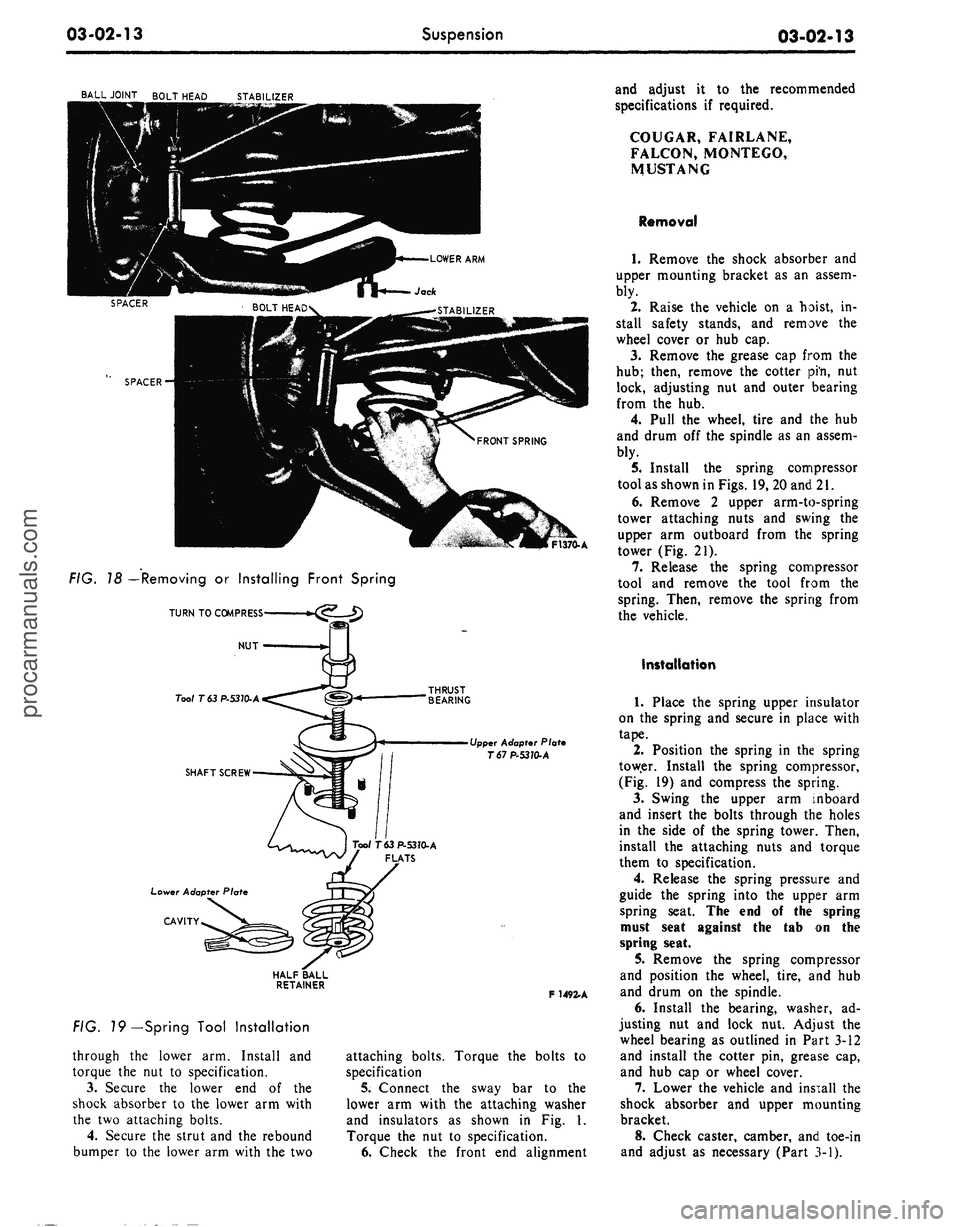

FIG. 18 —Removing or Installing Front Spring

TURN TO COMPRESS

NUT

•

Tool T 63 P-53J0-A

SHAFT SCREW

Lower Adapter Plate

CAVITY

Upper Adapter Plate

T67P-5370-A

FIG. 79—Spring Tool Installation

through the lower arm. Install and

torque the nut to specification.

3.

Secure the lower end of the

shock absorber to the lower arm with

the two attaching bolts.

4.

Secure the strut and the rebound

bumper to the lower arm with the two

F

1492.

A

attaching bolts. Torque the bolts to

specification

5.

Connect the sway bar to the

lower arm with the attaching washer

and insulators as shown in Fig. 1.

Torque the nut to specification.

6. Check the front end alignment

and adjust it to the recommended

specifications if required.

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1.

Remove the shock absorber and

upper mounting bracket as an assem-

bly.

2.

Raise the vehicle on a hoist, in-

stall safety stands, and remove the

wheel cover or hub cap.

3.

Remove the grease cap from the

hub;

then, remove the cotter pin, nut

lock, adjusting nut and outer bearing

from the hub.

4.

Pull the wheel, tire and the hub

and drum off the spindle as an assem-

bly.

5.

Install the spring compressor

tool as shown in Figs. 19, 20 and 21.

6. Remove 2 upper arm-to-spring

tower attaching nuts and swing the

upper arm outboard from the spring

tower (Fig. 21).

7.

Release the spring compressor

tool and remove the tool from the

spring. Then, remove the spring from

the vehicle.

Installation

1.

Place the spring upper insulator

on the spring and secure in place with

tape.

2.

Position the spring in the spring

tower. Install the spring compressor,

(Fig. 19) and compress the spring.

3.

Swing the upper arm inboard

and insert the bolts through the holes

in the side of the spring tower. Then,

install the attaching nuts and torque

them to specification.

4.

Release the spring pressure and

guide the spring into the upper arm

spring seat. The end o! the spring

must seat against the tab on the

spring seat.

5. Remove the spring compressor

and position the wheel, tire, and hub

and drum on the spindle.

6. Install the bearing, washer, ad-

justing nut and lock nut. Adjust the

wheel bearing as outlined in Part 3-12

and install the cotter pin, grease cap,

and hub cap or wheel cover.

7.

Lower the vehicle and install the

shock absorber and upper mounting

bracket.

8. Check caster, camber, and toe-in

and adjust as necessary (Part 3-1).procarmanuals.com

Page 90 of 413

03-02-14

Suspension

03-02-14

FRONT SPRING AND

LOWER ARM

LINCOLN CONTINENTAL

Removal

1.

Raise the vehicle. Place a sup-

port under each underbody side rail to

the rear of the lower arm in the lifting

pad area.

2.

Remove the wheel and tire from

the hub.

3.

Remove 2 bolts and washers that

attach the caliper to the spindle. Re-

move the caliper from the rotor and

wire it to the underbody to prevent

damage to the brake hose.

4.

Remove the hub and rotor from

the spindle.

5.

Loosen the splash shield to pro-

vide clearance at the end of the arm

when it is lowered.

6. Remove the shock absorber.

7.

Disconnect the stabilizing strut

(drag strut) from the lower arm.

8. Disconnect the stabilizer bar

from the suspension bar.

9. Remove the cotter pin from the

slotted nut attaching the lower ball

joint to the end of the spindle boss.

Loosen the nut one to two turns.

10.

Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig.

13.

The tool should seat firmly against

the ends of both studs, and not

against the lower stud nut.

11.

Turn the wrench until both

studs are under tension, then, tap the

spindle with a hammer near the lower

stud to loosen it from the spindle. Do

not loosen the stud with tool pressure

alone.

12.

Place a jack under the outer

end of the lower arm and raise the

arm several inches.

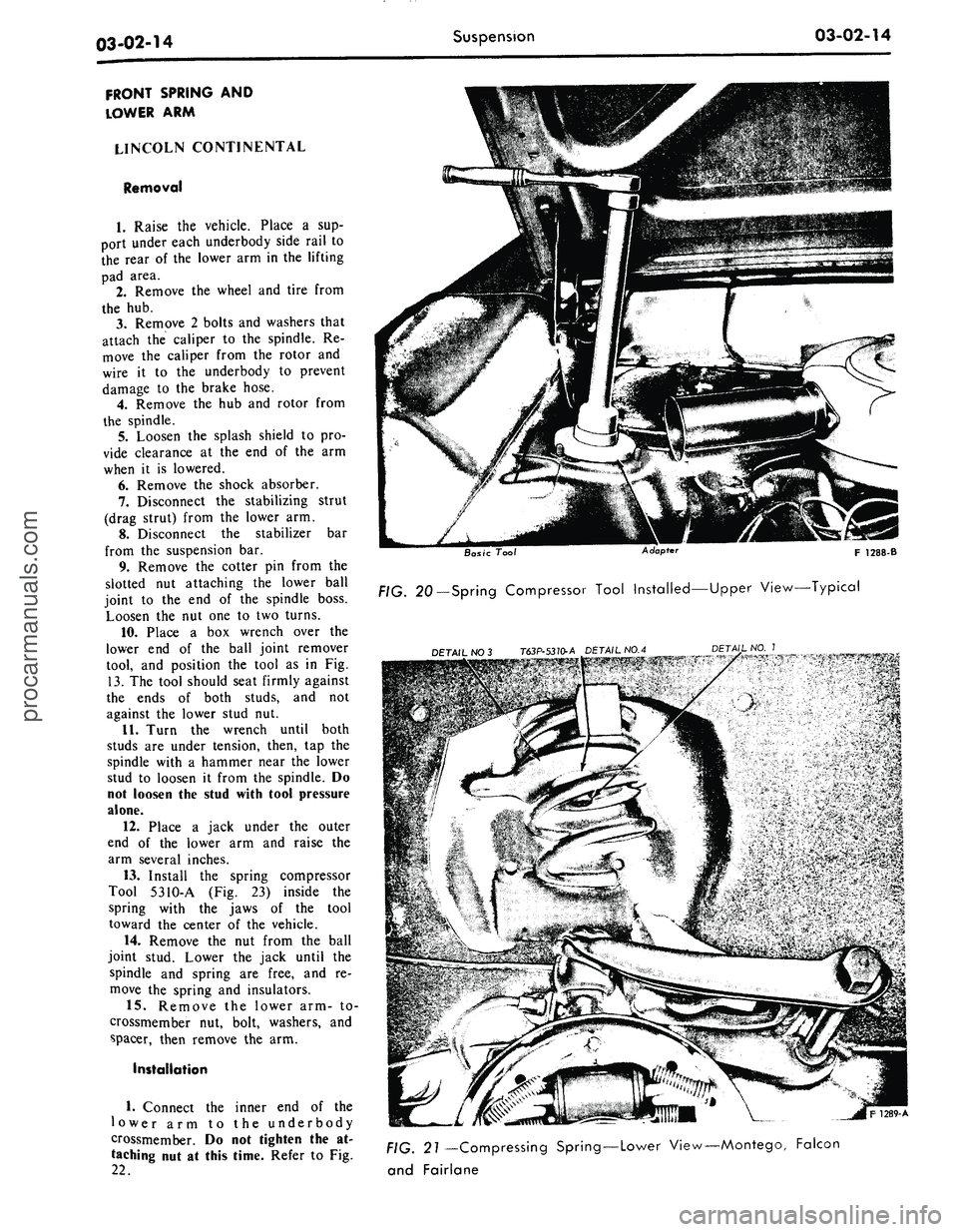

13.

Install the spring compressor

Tool 5310-A (Fig. 23) inside the

spring with the jaws of the tool

toward the center of the vehicle.

14.

Remove the nut from the ball

joint stud. Lower the jack until the

spindle and spring are free, and re-

move the spring and insulators.

15.

Remove the lower arm- to-

crossmember nut, bolt, washers, and

spacer, then remove the arm.

Installation

1.

Connect the inner end of the

lower arm to the underbody

crossmember. Do not tighten the at-

taching nut at this time. Refer to Fig.

22.

Basic Tool Adapter F 1288-B

FIG. 20—Spring Compressor Tool Installed—Upper View—Typical

DETAIL NO 3 T63P-5310-A DETAIL NO.4

DETAIL

NO.

I

21 —Compressing Spring—Lower View—Montego, Falcon

and Fairlaneprocarmanuals.com

Page 159 of 413

03-09-07

Saginaw Design Integral Power Steering Gear

03-09-07

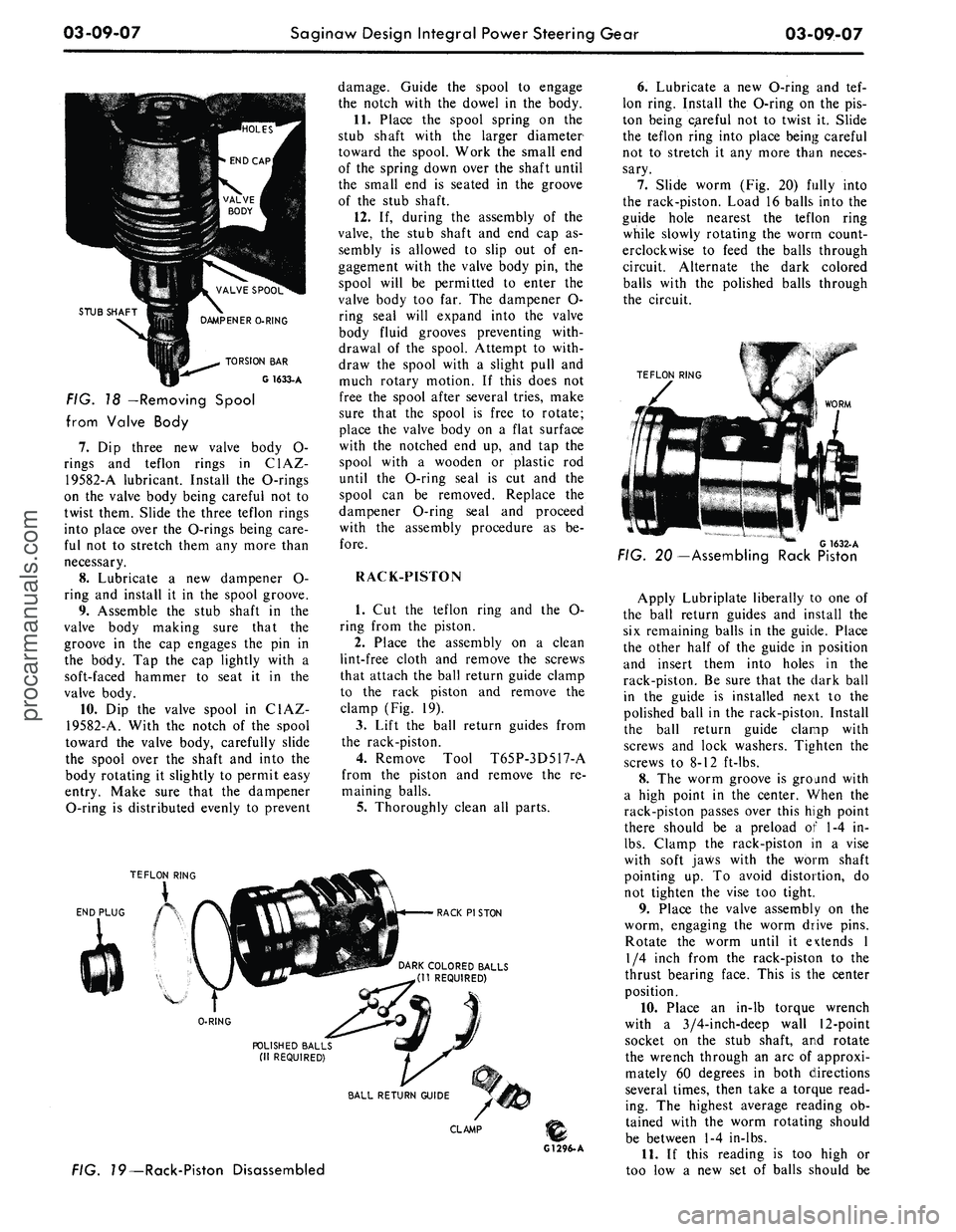

VALVE SPOOL

DAMP EN

ERO-RING

TORSION BAR

G 1633-A

FIG. 18 —Removing Spool

from Valve Body

7.

Dip three new valve body O-

rings and teflon rings in C1AZ-

19582-A lubricant. Install the O-rings

on the valve body being careful not to

twist them. Slide the three teflon rings

into place over the O-rings being care-

ful not to stretch them any more than

necessary.

8. Lubricate a new dampener O-

ring and install it in the spool groove.

9. Assemble the stub shaft in the

valve body making sure that the

groove in the cap engages the pin in

the body. Tap the cap lightly with a

soft-faced hammer to seat it in the

valve body.

10.

Dip the valve spool in C1AZ-

19582-A. With the notch of the spool

toward the valve body, carefully slide

the spooi over the shaft and into the

body rotating it slightly to permit easy

entry. Make sure that the dampener

O-ring is distributed evenly to prevent

TEFLON RING

damage. Guide the spool to engage

the notch with the dowel in the body.

11.

Place the spool spring on the

stub shaft with the larger diameter

toward the spool. Work the small end

of the spring down over the shaft until

the small end is seated in the groove

of the stub shaft.

12.

If, during the assembly of the

valve, the stub shaft and end cap as-

sembly is allowed to slip out of en-

gagement with the valve body pin, the

spool will be permitted to enter the

valve body too far. The dampener O-

ring seal will expand into the valve

body fluid grooves preventing with-

drawal of the spool. Attempt to with-

draw the spool with a slight pull and

much rotary motion. If this does not

free the spool after several tries, make

sure that the spool is free to rotate;

place the valve body on a flat surface

with the notched end up, and tap the

spool with a wooden or plastic rod

until the O-ring seal is cut and the

spool can be removed. Replace the

dampener O-ring seal and proceed

with the assembly procedure as be-

fore.

RACK-PISTON

1.

Cut the teflon ring and the O-

ring from the piston.

2.

Place the assembly on a clean

lint-free cloth and remove the screws

that attach the ball return guide clamp

to the rack piston and remove the

clamp (Fig. 19).

3.

Lift the ball return guides from

the rack-piston.

4.

Remove Tool T65P-3D517-A

from the piston and remove the re-

maining balls.

5.

Thoroughly clean all parts.

END PLUG

RACK PI STON

DARK COLORED BALLS

(11 REQUIRED)

V

0-RING

POLISHED BALLS

(II REQUIRED)

BALL RETURN GUIDE

CLAMP

B

G1296. A

6. Lubricate a new O-ring and tef-

lon ring. Install the O-ring on the pis-

ton being qareful not to twist it. Slide

the teflon ring into place being careful

not to stretch it any more than neces-

sary.

7.

Slide worm (Fig. 20) fully into

the rack-piston. Load 16 balls into the

guide hole nearest the teflon ring

while slowly rotating the worm count-

erclockwise to feed the balls through

circuit. Alternate the dark colored

balls with the polished balls through

the circuit.

TEFLON RING

FIG. 19—Rack-Piston Disassembled

G 1632-A

FIG. 20—Assembling Rack Piston

Apply Lubriplate liberally to one of

the ball return guides and install the

six remaining balls in the guide. Place

the other half of the guide in position

and insert them into holes in the

rack-piston. Be sure that the dark ball

in the guide is installed next to the

polished ball in the rack-piston. Install

the ball return guide clamp with

screws and lock washers. Tighten the

screws to 8-12 ft-lbs.

8. The worm groove is ground with

a high point in the center. V/hen the

rack-piston passes over this high point

there should be a preload of 1-4 in-

lbs.

Clamp the rack-piston in a vise

with soft jaws with the worm shaft

pointing up. To avoid distortion, do

not tighten the vise too tight.

9. Place the valve assembly on the

worm, engaging the worm drive pins.

Rotate the worm until it extends 1

1/4 inch from the rack-piston to the

thrust bearing face. This is the center

position.

10.

Place an in-lb torque wrench

with a 3/4-inch-deep wall 12-point

socket on the stub shaft, and rotate

the wrench through an arc of approxi-

mately 60 degrees in both directions

several times, then take a torque read-

ing. The highest average reading ob-

tained with the worm rotating should

be between 1-4 in-lbs.

11.

If this reading is too high or

too low a new set of balls should beprocarmanuals.com

Page 208 of 413

04-02-11

Rear Axle — Removable Carrier Type

04-02-11

If the axle housing is new, install a

new vent. The hose attaching portion

must face toward the front of the ve-

hicle.

2.

If leather-type wheel bearing ser-

vice seals are to be installed, soak the

new rear wheel bearing oil seals in

SAE 10 oil for 1/2 hour before instal-

lation. Wipe a small amount of an oil

resistant sealer on the outer edge of

each seal before it is installed. Do not

put any of the sealer on the sealing

lip.

Install the oil seals in the ends of

the axle housing with one of the tools

shown in Fig. 10 and 12.

3.

Position the replacement axle

housing under the vehicle, and raise

the axle with a hoist or floor jack.

Connect the suspension lower arms to

their mounting brackets on the axle

housing with pivot bolts and nuts. Do

not tighten the bolts and nuts at this

point.

4.

Position the suspension upper

arm in its mounting bracket on the

axle housing, and install the adjusting

bolt, eccentric washers, lock washer

and nut. Leave the bolt and nut loose

at this point.

5.

Position the brake lines to the

axle housing, and secure with the re-

taining clips.

6. Install the brake backing plates

on the axle housing flanges.

7.

Connect the track bar to the

mounting stud, install the washer and

attaching nut, and torque to specifica-

tions.

8. Position the rear coil springs and

insulators in the pockets provided.

9. Connect the lower studs of the

two rear shock absorbers to the

mounting brackets on the axle hous-

ing. Install the attaching nuts, and

torque to specifications.

10.

Connect the vent tube to the

vent on the housing. If axle housing is

new, install a new vent.

11.

Clean the mating surfaces of

the axle housing and differential car-

rier. Position the carrier on the

mounting studs on the housing using a

new gasket between carrier and hous-

ing. Install the copper washers and the

carrier-to-housing attaching nuts, and

torque to specifications.

12.

Make sure that both the front

and rear pivot bolts of the upper and

the two lower arms are loose, and

then raise the axle assembly to con-

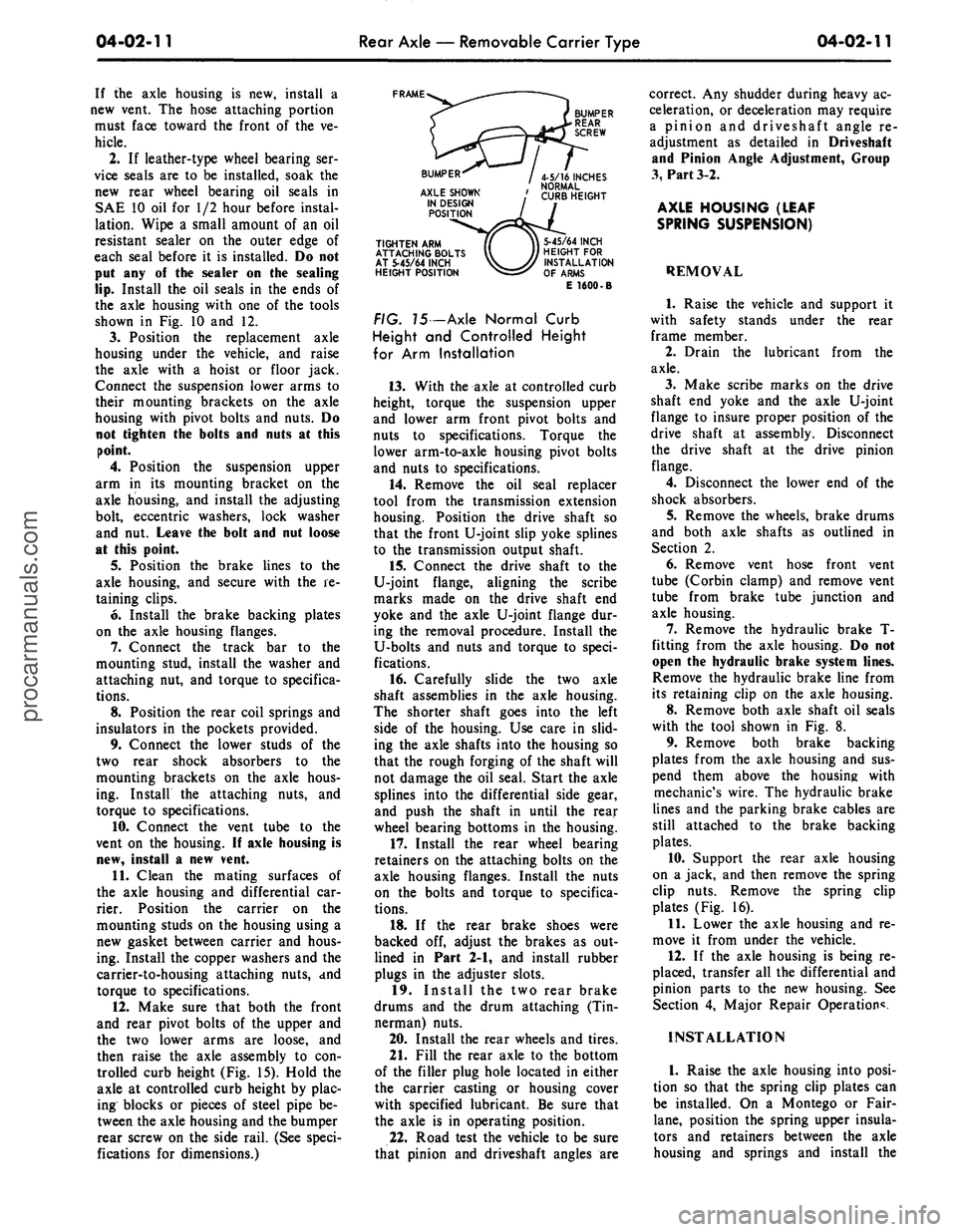

trolled curb height (Fig. 15). Hold the

axle at controlled curb height by plac-

ing blocks or pieces of steel pipe be-

tween the axle housing and the bumper

rear screw on the side rail. (See speci-

fications for dimensions.)

FRAME

TIGHTEN ARM

ATTACHING BOLTS

AT 5-45/64 INCH

HEIGHT POSITION

5-45/64 INCH

HEIGHT FOR

INSTALLATION

OF ARMS

E 1600-B

FIG. 75 -Axle Normal Curb

Height and Controlled Height

for Arm Installation

13.

With the axle at controlled curb

height, torque the suspension upper

and lower arm front pivot bolts and

nuts to specifications. Torque the

lower arm-to-axle housing pivot bolts

and nuts to specifications.

14.

Remove the oil seal replacer

tool from the transmission extension

housing. Position the drive shaft so

that the front U-joint slip yoke splines

to the transmission output shaft.

15.

Connect the drive shaft to the

U-joint flange, aligning the scribe

marks made on the drive shaft end

yoke and the axle U-joint flange dur-

ing the removal procedure. Install the

U-bolts and nuts and torque to speci-

fications.

16.

Carefully slide the two axle

shaft assemblies in the axle housing.

The shorter shaft goes into the left

side of the housing. Use care in slid-

ing the axle shafts into the housing so

that the rough forging of the shaft will

not damage the oil seal. Start the axle

splines into the differential side gear,

and push the shaft in until the rear

wheel bearing bottoms in the housing.

17.

Install the rear wheel bearing

retainers on the attaching bolts on the

axle housing flanges. Install the nuts

on the bolts and torque to specifica-

tions.

18.

If the rear brake shoes were

backed off, adjust the brakes as out-

lined in Part 2-1, and install rubber

plugs in the adjuster slots.

19.

Install the two rear brake

drums and the drum attaching (Tin-

nerman) nuts.

20.

Install the rear wheels and tires.

21.

Fill the rear axle to the bottom

of the filler plug hole located in either

the carrier casting or housing cover

with specified lubricant. Be sure that

the axle is in operating position.

22.

Road test the vehicle to be sure

that pinion and driveshaft angles are

correct. Any shudder during heavy ac-

celeration, or deceleration may require

a pinion and driveshaft angle re-

adjustment as detailed in Driveshaft

and Pinion Angle Adjustment, Group

3,

Part 3-2.

AXLE HOUSING (LEAF

SPRING SUSPENSION)

REMOVAL

1.

Raise the vehicle and support it

with safety stands under the rear

frame member.

2.

Drain the lubricant from the

axle.

3.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly. Disconnect

the drive shaft at the drive pinion

flange.

4.

Disconnect the lower end of the

shock absorbers.

5.

Remove the wheels, brake drums

and both axle shafts as outlined in

Section 2.

6. Remove vent hose front vent

tube (Corbin clamp) and remove vent

tube from brake tube junction and

axle housing.

7.

Remove the hydraulic brake T-

fitting from the axle housing. Do not

open the hydraulic brake system lines.

Remove the hydraulic brake line from

its retaining clip on the axle housing.

8. Remove both axle shaft oil seals

with the tool shown in Fig. 8.

9. Remove both brake backing

plates from the axle housing and sus-

pend them above the housing with

mechanic's wire. The hydraulic brake

lines and the parking brake cables are

still attached to the brake backing

plates.

10.

Support the rear axle housing

on a jack, and then remove the spring

clip nuts. Remove the spring clip

plates (Fig. 16).

11.

Lower the axle housing and re-

move it from under the vehicle.

12.

If the axle housing is being re-

placed, transfer all the differential and

pinion parts to the new housing. See

Section 4, Major Repair Operation*.

INSTALLATION

1.

Raise the axle housing into posi-

tion so that the spring clip plates can

be installed. On a Montego or Fair-

lane,

position the spring upper insula-

tors and retainers between the axle

housing and springs and install theprocarmanuals.com

Page 235 of 413

04-04-04

Rear Axle — Ford Light-Duty (WER)

04-04-04

REMOVAL AND INSTALLATION

AXLE HOUSING

Refer to Fig. 7.

REMOVAL

1.

Raise the vehicle on a hoist.

2.

Remove the wheels and tires

from the brake drums.

3.

Position a drain pan and loosen

the rear axle cover to housing attach-

ing bolts. Drain the housing.

4.

Remove the attaching (Tinner-

man) nuts that secure the brake drums

to the axle shaft flanges, and then re-

move the drums (Fig. 7).

5.

Remove the axle housing cover

bolts,

cover and gasket. Discard the

gasket. Remove the drain pan.

6. Disconnect the drive shaft at the

drive pinion companion flange. Re-

move the drive shaft from the trans-

mission extension housing. Install an

oil seal replacer tool in the transmis-

sion housing to prevent leakage. Refer

to the transmission group for the ap-

propriate tool.

7.

Disconnect the lower end of the

shock absorbers at the mounting

brackets.

8. Disconnect the track bar from

the axle housing stud. If the axle

housing is to be replaced, transfer the

stud to the new housing.

9. Position safety stands under the

rear frame members. Lower the vehi-

cle with the hoist and allow the axle

to lower far enough to relieve rear

spring tension.

10.

Remove the pinion shaft lock

bolt and pinion shaft (Fig. 2), differ-

ential pinion gears and thrust washers.

11.

Push the axle shaft(s) inward

toward the center of the axle housing.

Remove the C-locks from the inner

ends of the axles (Fig. 3). Remove the

axle shafts from the housing. Extreme

care must be used to avoid contacting

the axle shaft seal lip with any portion

of the axle shaft other than the seal

journal.

12.

Disconnect the vent hose from

the rear vent tube and remove all

brake lines from the axle housing re-

taining clips.

13.

Remove the brake backing

plate attaching nuts and the plates

from the axle housing. Suspend the

plates above the axle housing with

mechanics wire. The hydraulic brake

lines and the parking brake cables will

remain attached to the brake backing

plates.

14.

Support the rear axle housine

on a jack.

15.

Remove the right and left rear

springs and insulators.

16.

Remove the nuts, washers and

pivot bolts that connect the suspension

lower arms to the axle housing. Dis-

connect both arms from the axle

housing.

17.

Disconnect the upper suspen-

sion arm from the axle housing by re-

moving the pivot bolt, nut, lock wash-

er and two eccentric washers.

18.

Lower the rear axle to the floor

with the jack and remove the axle

from under the vehicle.

19.

Remove the wheel bearings and

oil seals with the tool shown in Fig. 4.

20.

If the axle housing is being re-

placed, transfer all the differential and

pinion parts to the new housing. Refer

to Section 4, Major Repair Operation

for the procedure.

INSTALLATION

1.

Lightly coat the wheel bearing

rollers with axle lubricant. Install

wheel bearings in the axle housing

with the tool shown in Fig. 5. The

bearings should seat firmly against the

shoulder.

2.

Wipe all lubricant from the oil

seal bore before installing the seal. If

axle housing is being replaced, new

seals must be installed.

3.

Inspect the original seal for

nicks,

scuffs or abnormal wear, and

replace if necessary. New seals are

pre-packed with lubricant and do not

require an oil soak.

4.

Install the seal with the tool

shown in Fig. 6. Installation without

the use of the proper tool will distort

the seal and cause leakage.

5. Raise the rear axle into position

under the vehicle with a hoist or floor

jack. Connect the suspension lower

arms to their mounting brackets on

the axle housing with pivot bolts and

nuts.

Do not tighten the mounting

bolts at this point.

6. Position the suspension upper

arm in its mounting bracket on the

axle housing and install the adjusting

bolt, eccentric washers, lock washer

and nut. Do not tighten the mounting

bolt at this point.

7.

Place the rear coil springs and

insulators into position in the pockets

provided.

8. Place the brake backing plates

on the axle housing flanges, install 4

attaching bolts and nuts and torque

them to specifications.

9. Position the brake lines to the

axle housing and secure them with the

retaining clips. If the axle housing is

new, install a new vent. When install-

ing the new axle vent apply a small

amount of Locktite (C5AZ-19554-B)

to prevent oil leakage between vent

and axle housing. Connect the vent

tube to the vent.

10.

Install the pinion side gears and

thrust washer.

11.

Slide the axle shafts into place

in the axle housing. Exercise care that

splines or any portion of the axle

shafts do not damage the oil seals and

that they engage with the splines of

the differential side gears.

12.

Install the axle shaft C-lock O-

ring and C-lock on the inner end of

the shaft and push the shaft outward

so that the shaft lock seats in the

counterbore of the differential side

gear.

13.

Position the pinion differential

gears and thrust washers 180 degrees

apart to the differential side gears.

Revolve the gear assembly until the

holes in the differential case are al-

igned with the pinion gears.

14.

Position the differential pinion

shaft through the case and pinions, al-

igning the hole in the shaft with the

lock bolt hole. Install the lock bolt

and tighten it to specification.

15.

Clean the gasket mounting sur-

face of the rear axle housing and the

cover. Install a new cover gasket,

cover and the attaching bolts. Torque

the bolts to specification.

16.

Raise the rear axle on a hoist

and remove the safety stands.

17.

Connect the track bar to the

mounting stud. Install the washer and

nut. Torque the nut to specification.

18.

Connect the two rear shock ab-

sorbers to the mounting brackets on

the axle housing and torque the at-

taching nuts to specification.

19.

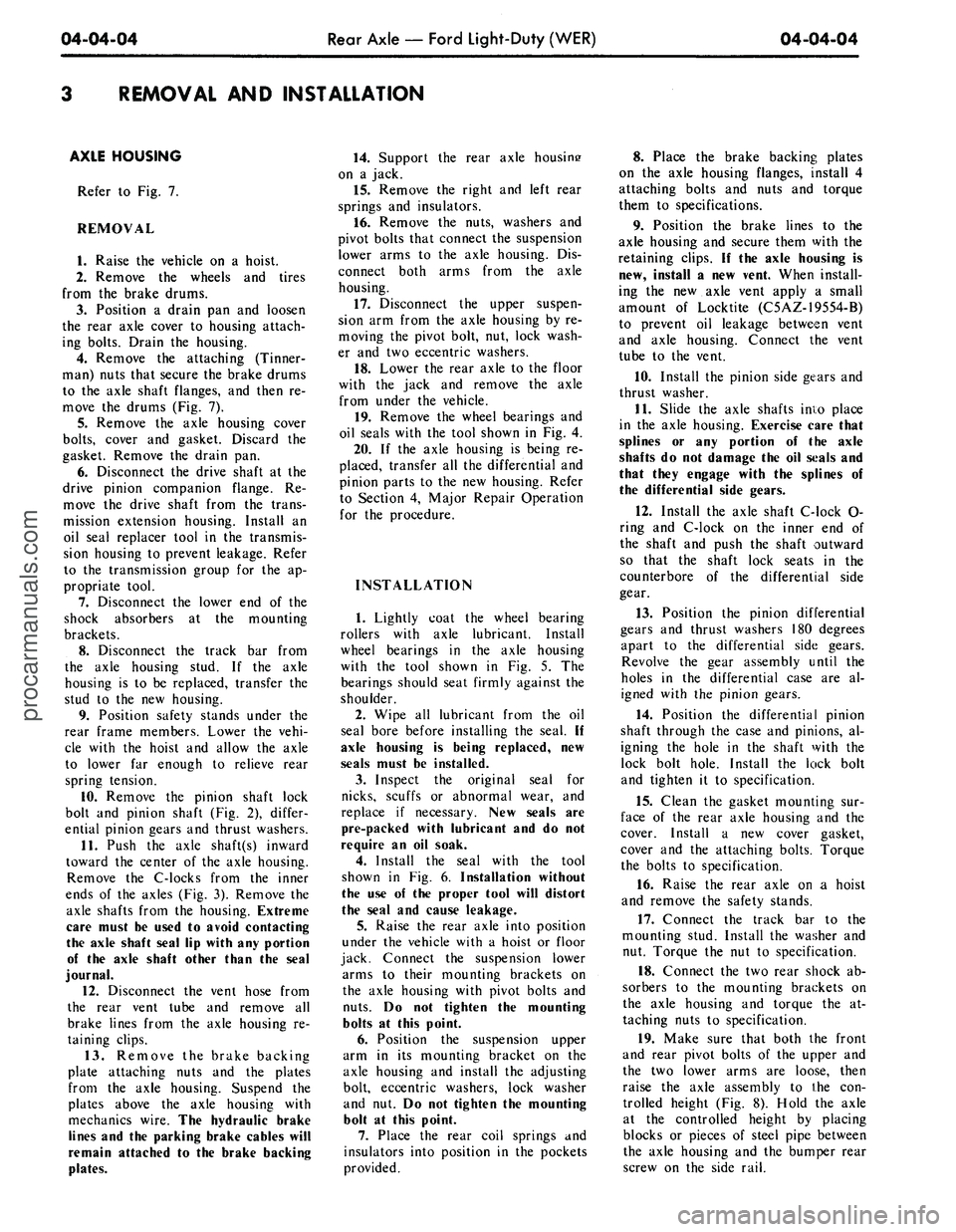

Make sure that both the front

and rear pivot bolts of the upper and

the two lower arms are loose, then

raise the axle assembly to the con-

trolled height (Fig. 8). Hold the axle

at the controlled height by placing

blocks or pieces of steel pipe between

the axle housing and the bumper rear

screw on the side rail.procarmanuals.com