check transmission fluid FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 383 of 413

07-04-14

C-6 Automatic Transmission

07-04-14

taching bolt to turn the converter to

gain access to the nuts.

5.

Remove the rear mount to

crossmember attaching bolt.

6. Remove the two crossmember-

to-frame attaching bolts.

7.

Remove the two engine rear

support-to-extension housing attaching

bolts.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the manual linkage

rod from the lever at the transmission.

On a column shift, use tool T67P-

7341-A to remove the rod.

10.

Remove the two bolts securing

the bellcrank bracket to the converter

housing.

11.

Raise the transmission with a

transmission jack to provide clearance

to remove the crossmember.

12.

Remove the rear mount from

the crossmember and remove the

crossmember from the side supports.

13.

Lower the transmission to gain

access to the oil cooler lines.

14.

Disconnect each oil line from

the fittings on the transmission.

15.

Disconnect the vacuum line

from the diaphragm located at the

right rear of the transmission. Remove

the metal line from the retaining clip

on the transmission.

16.

Disconnect the speedometer

cable from the extension housing.

17.

Remove the bolt that secures

the transmission fluid filler tube to the

cylinder block. Lift the filler tube and

the dipstick from the transmission.

18.

Secure the transmission to the

jack with the chain.

19.

Remove the converter housing-

to-cylinder block attaching bolts.

20.

Carefully move the transmission

away from the engine and, at the

same time, lower it to clear the und-

erside of the vehicle.

21.

Remove the converter and

mount the transmission in a holding

fixture.

INSTALLATION—FORD

MERCURY AND METEOR

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission to the

jack with the chain.

4.

Rotate the flywheel to place two

converter mounting stud holes that are

adjacent to the drain plug holes in a

vertical position.

5.

Rotate the converter so that the

studs and drain plugs are in alignment

with those in the flywheel.

6. Move the transmission toward

the cylinder block until they are in

contact. Install and torque the attach-

ing bolts to specification making sure

that the vacuum tube retaining clips

are properly positioned.

7.

Remove the transmission jack

chain from around the transmission.

8. Install a new Oring on the lower

end of the transmission filler tube. In-

sert the tube in the transmission case

and secure the tube to the engine with

the attaching bolt.

9. Connect the speedometer cable

to the extension housing.

10.

Connect the oil cooler lines to

the right side of transmission case.

11.

Connect the vacuum line to the

vacuum diaphragm making sure that

the metal tube is secured in the retain-

ing clip.

12.

Position the cross member on

the side supports. Position the rear

mount on the crossmember and install

the attaching bolt and nut.

13.

Secure the engine rear support

to the extension housing and torque

the bolts to specification.

14.

Lower the transmission and re-

move the jack.

15.

Secure the crossmember to the

side supports with the attaching bolts

and torque them to specification.

16.

Position the bellcrank bracket

to the converter housing and install

the two attaching bolts.

17.

Connect the downshift rod to

the transmission downshift lever.

18.

Connect the selector rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

19.

Secure the converter-to-flywheel

attaching nuts and torque them to

specification. Use a wrench on the

crankshaft pulley attaching nut to ro-

tate the flywheel. Do not use a wrench

on the converter attaching nuts to ro-

tate it.

20.

Install the converter housing

dust shield and secure it with the at-

taching bolts.

21.

Secure the starter motor in

place with the attaching bolts. Con-

nect the cable to the terminal on the

starter.

22.

Install the driveshaft.

23.

Adjust the shift linkage as de-

tailed in Section 2.

24.

Lower the vehicle.

25.

Fill the transmission to the cor-

rect level with the specified lubricant.

Start the engine and shift the trans-

mission to all ranges, then recheck the

fluid level.

REMOVAL—FAIRLANE,

MONTEGO, MUSTANG

AND COUGAR

1.

On Mustang and Cougar, dis-

connect the neutral switch wires from

the harness connector and the retain-

ing clip on the dash.

2.

Remove the bolt that secures the

filler tube to the rear of the right

cylinder head.

3.

Raise the vehicle on a hoist or

jack stands.

4.

Remove the converter drain plug

access cover from the lower end of the

converter housing.

5.

Place a drain pan under nhe con-

verter housing and remove the two

converter drain plugs. Install the plugs

after the fluid has drained.

6. Place the drain pan under the

transmission fluid pan. Starting at the

rear of the pan and working toward

the front, loosen the attaching bolts

and allow the fluid to drain. Finally

remove all of the pan attaching bolts

except two at the front, to allow the

fluid to further drain. After the fluid

has drained, install two bolts on the

rear side of the pan to temporarily

hold it in place.

7.

Disconnect the drive shaft from

the rear axle flange and remove it

from the transmission. Install tool

T61L-7657-A in the rear of the exten-

sion housing to prevent the fluid from

leaking.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the shift rod from the

manual lever. On a column shift, use

tool T67P-7341-A to remove the rod.

10.

Disconnect the speedometer

cable from the extension housing.

11.

Disconnect the rubber hose

from the vacuum diaphragm at the

rear of the transmission. Remove the

vacuum tube from the retaining clip at

the transmission.

12.

Disconnect the starter cable

from the terminal on the starter. Re-

move the starter attaching bolts and

remove it from the housing.

13.

Lift the fluid filler tube from

the transmission case.

14.

Remove the four converter-

to-flywheel attaching nuts.

15.

On a Mustang or Cougar, dis-

connect the complete exhaust system

and allow it to hang on the rear axle.

16.

Remove the two nuts that at-

tach the engine rear support to the

crossmember.

17.

Raise the transmission with a

jack just enough to remove the weight

from the crossmember.

18.

Remove the cotter pins from

the crossmember-to-frame side sup-procarmanuals.com

Page 388 of 413

07-04-19

C-6 Automatic Transmission

07-04-19

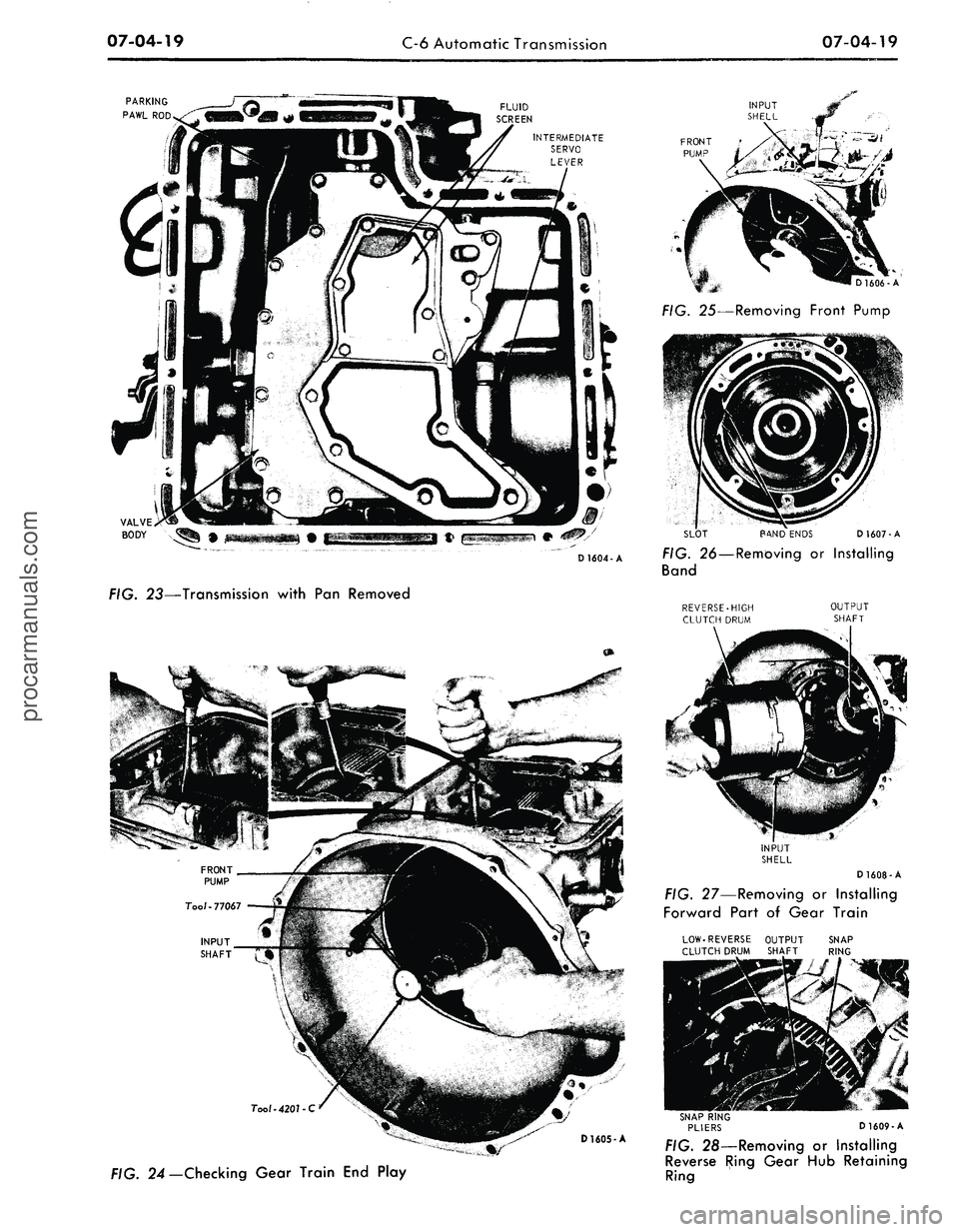

PARKING

PAWL

ROD

FLUID

SCREEN

INTERMEDIATE

SERVO

LEVER

FIG. 23—Transmission with Pan Removed

Tool-4201-C

D1605-A

D 1606-A

FIG. 25—Removing Front Pump

SLOT

BAND ENDS

D 1607-A

FIG. 26—Rembving or Installing

Band

REVERSE-HIGH OUTPUT

CLUTCH DRUM SHAFT

D 1608 -A

FIG. 27—Removing or Installing

Forward Part of Gear Train

LOW-REVERSE OUTPUT SNAP

CLUTCH DRUM SHAFT RING

D1609-A

FIG. 24— Checking Gear Train End Play

FIG. 28—Removing or Installing

Reverse Ring Gear Hub Retaining

Ringprocarmanuals.com

Page 394 of 413

07-04-25

C-6 Automatic Transmission

07-04-25

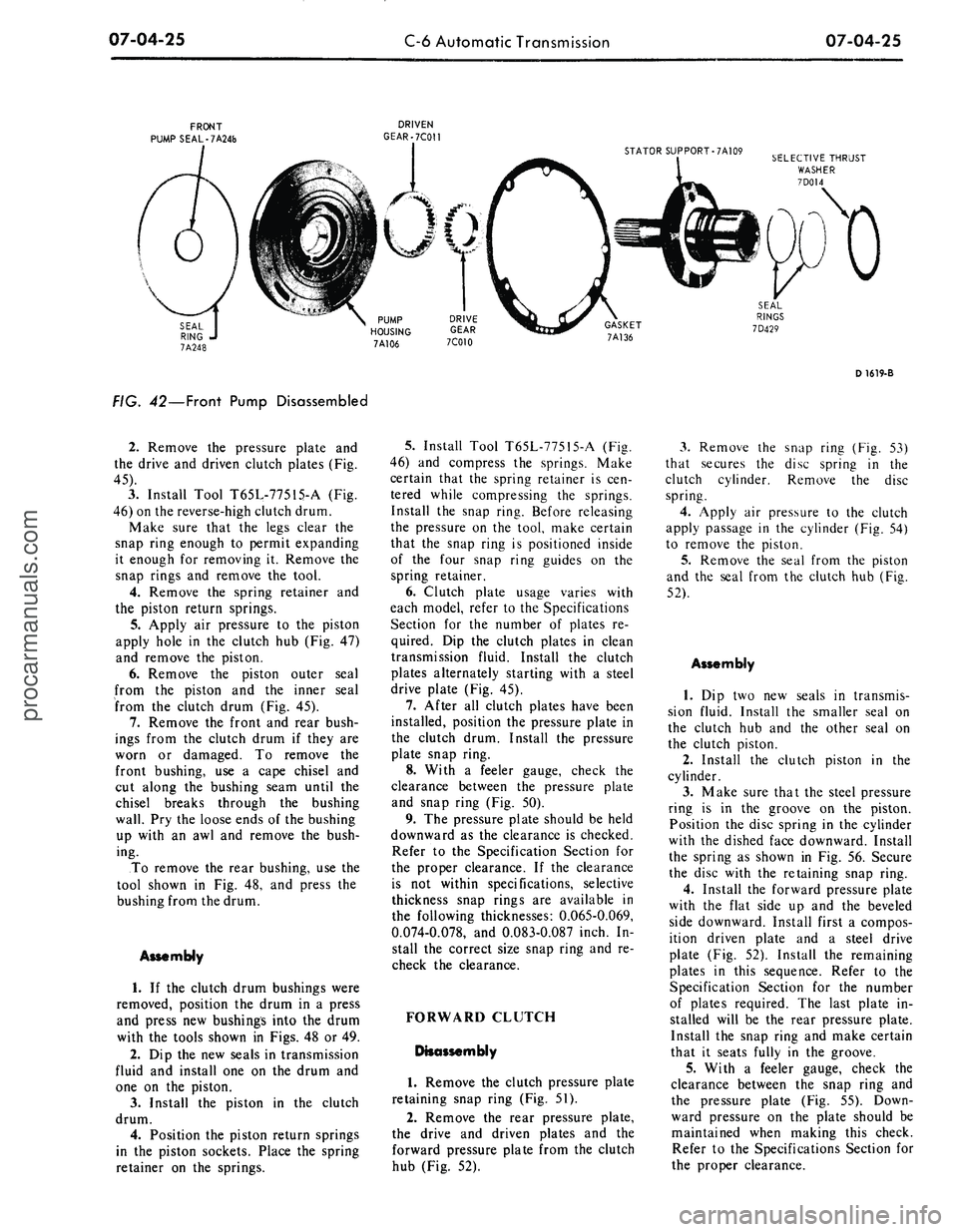

FRONT

PUMPSEAL-7A24&

DRIVEN

GEAR-7C011

FIG. 42—Front Pump Disassembled

STATOR SUPPORT-7A109

SELECTIVE THRUST

WASHER

7D014

GASKET

7A136

SEAL

RINGS

7D429

D 1619-B

2.

Remove the pressure plate and

the drive and driven clutch plates (Fig.

45).

3.

Install Tool T65L-77515-A (Fig.

46) on the reverse-high clutch drum.

Make sure that the legs clear the

snap ring enough to permit expanding

it enough for removing it. Remove the

snap rings and remove the tool.

4.

Remove the spring retainer and

the piston return springs.

5.

Apply air pressure to the piston

apply hole in the clutch hub (Fig. 47)

and remove the piston.

6. Remove the piston outer seal

from the piston and the inner seal

from the clutch drum (Fig. 45).

7.

Remove the front and rear bush-

ings from the clutch drum if they are

worn or damaged. To remove the

front bushing, use a cape chisel and

cut along the bushing seam until the

chisel breaks through the bushing

wall. Pry the loose ends of the bushing

up with an awl and remove the bush-

ing.

To remove the rear bushing, use the

tool shown in Fig. 48, and press the

bushing from the drum.

Assembly

1.

If the clutch drum bushings were

removed, position the drum in a press

and press new bushings into the drum

with the tools shown in Figs. 48 or 49.

2.

Dip the new seals in transmission

fluid and install one on the drum and

one on the piston.

3.

Install the piston in the clutch

drum.

4.

Position the piston return springs

in the piston sockets. Place the spring

retainer on the springs.

5.

Install Tool T65L-77515-A (Fig.

46) and compress the springs. Make

certain that the spring retainer is cen-

tered while compressing the springs.

Install the snap ring. Before releasing

the pressure on the tool, make certain

that the snap ring is positioned inside

of the four snap ring guides on the

spring retainer.

6. Clutch plate usage varies with

each model, refer to the Specifications

Section for the number of plates re-

quired. Dip the clutch plates in clean

transmission fluid. Install the clutch

plates alternately starting with a steel

drive plate (Fig. 45).

7.

After all clutch plates have been

installed, position the pressure plate in

the clutch drum. Install the pressure

plate snap ring.

8. With a feeler gauge, check the

clearance between the pressure plate

and snap ring (Fig. 50).

9. The pressure plate should be held

downward as the clearance is checked.

Refer to the Specification Section for

the proper clearance. If the clearance

is not within specifications, selective

thickness snap rings are available in

the following thicknesses: 0.065-0.069,

0.074-0.078, and 0.083-0.087 inch. In-

stall the correct size snap ring and re-

check the clearance.

FORWARD CLUTCH

Disassembly

1.

Remove the clutch pressure plate

retaining snap ring (Fig. 51).

2.

Remove the rear pressure plate,

the drive and driven plates and the

forward pressure plate from the clutch

hub (Fig. 52).

3.

Remove the snap ring (Fig. 53)

that secures the disc spring in the

clutch cylinder. Remove the disc

spring.

4.

Apply air pressure to the clutch

apply passage in the cylinder (Fig. 54)

to remove the piston.

5.

Remove the seal from the piston

and the seal from the clutch hub (Fig.

52).

Assembly

1.

Dip two new seals in transmis-

sion fluid. Install the smaller seal on

the clutch hub and the other seal on

the clutch piston.

2.

Install the clutch piston in the

cylinder.

3.

Make sure that the steel pressure

ring is in the groove on the piston.

Position the disc spring in the cylinder

with the dished face downward. Install

the spring as shown in Fig. 56. Secure

the disc with the retaining snap ring.

4.

Install the forward pressure plate

with the flat side up and the beveled

side downward. Install first a compos-

ition driven plate and a steel drive

plate (Fig. 52). Install the remaining

plates in this sequence. Refer to the

Specification Section for the number

of plates required. The last plate in-

stalled will be the rear pressure plate.

Install the snap ring and make certain

that it seats fully in the groove.

5.

With a feeler gauge, check the

clearance between the snap ring and

the pressure plate (Fig. 55). Down-

ward pressure on the plate should be

maintained when making this check.

Refer to the Specifications Section for

the proper clearance.procarmanuals.com

Page 397 of 413

07-04-28

C-6 Automatic Transmission

07-04-28

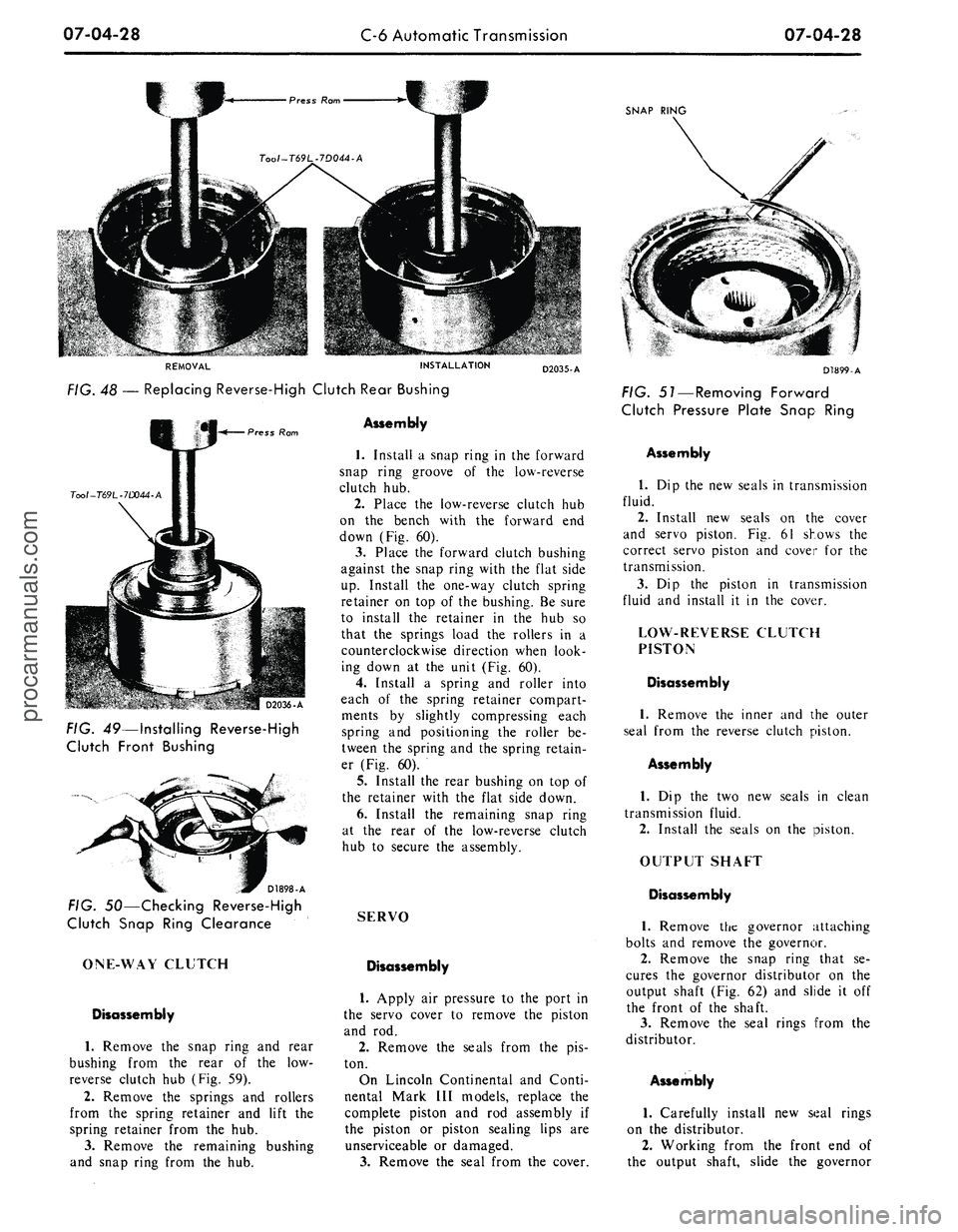

SNAP RING

REMOVAL INSTALLATION

FIG. 48 — Replacing Reverse-High Clutch Rear Bushing

D2035-A

Press Ram

Tool-T69L-7D044-A

D2036-A

FIG. 49—Installing Reverse-High

Clutch Front Bushing

D1898-A

FIG. 50—Checking Reverse-High

Clutch Snap Ring Clearance

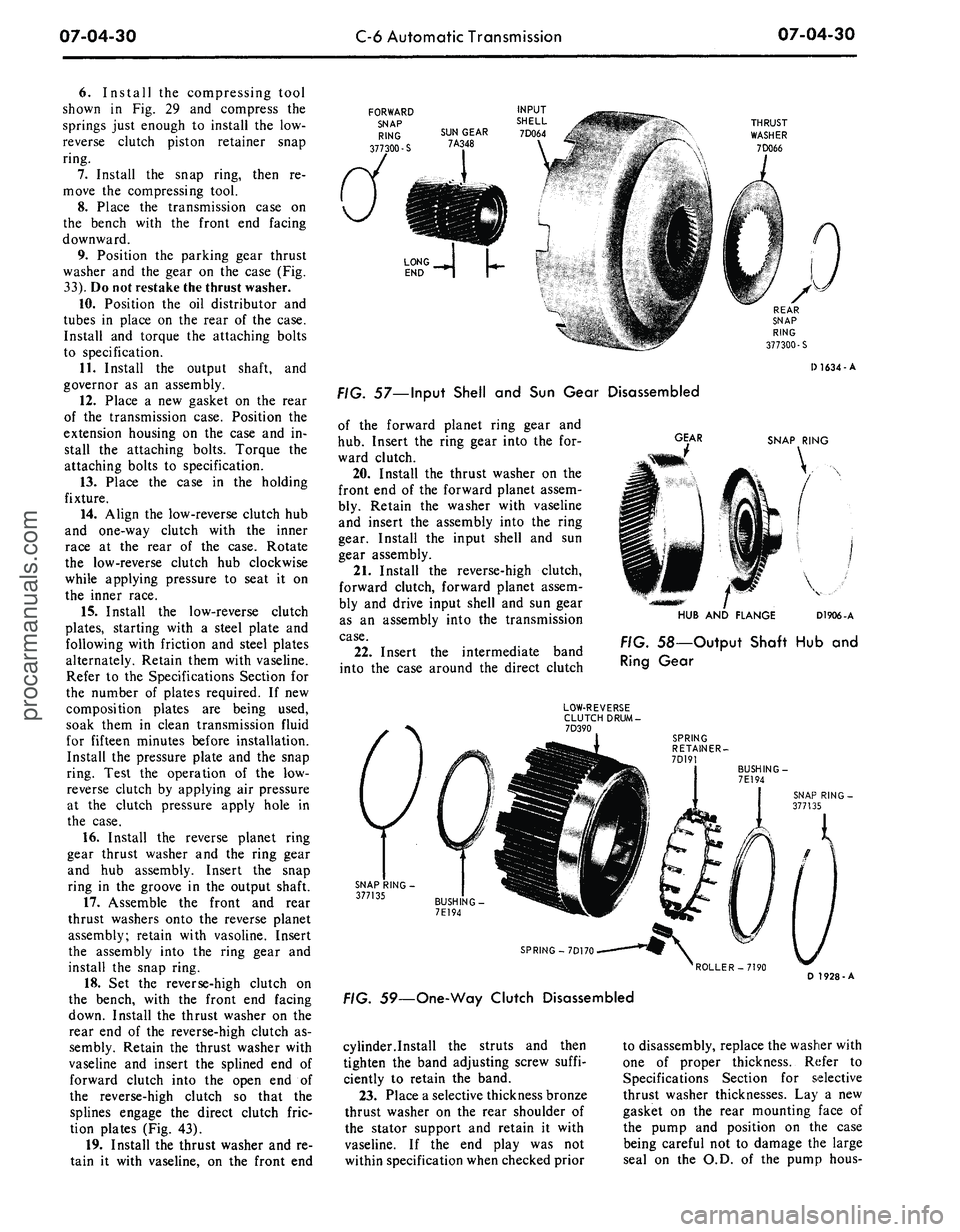

ONE-WAY CLUTCH

Disassembly

1.

Remove the snap ring and rear

bushing from the rear of the low-

reverse clutch hub (Fig. 59).

2.

Remove the springs and rollers

from the spring retainer and lift the

spring retainer from the hub.

3.

Remove the remaining bushing

and snap ring from the hub.

Assembly

1.

Install a snap ring in the forward

snap ring groove of the low-reverse

clutch hub.

2.

Place the low-reverse clutch hub

on the bench with the forward end

down (Fig. 60).

3.

Place the forward clutch bushing

against the snap ring with the flat side

up.

Install the one-way clutch spring

retainer on top of the bushing. Be sure

to install the retainer in the hub so

that the springs load the rollers in a

counterclockwise direction when look-

ing down at the unit (Fig. 60).

4.

Install a spring and roller into

each of the spring retainer compart-

ments by slightly compressing each

spring and positioning the roller be-

tween the spring and the spring retain-

er (Fig. 60).

5.

Install the rear bushing on top of

the retainer with the flat side down.

6. Install the remaining snap ring

at the rear of the low-reverse clutch

hub to secure the assembly.

SERVO

Disassembly

1.

Apply air pressure to the port in

the servo cover to remove the piston

and rod.

2.

Remove the seals from the pis-

ton.

On Lincoln Continental and Conti-

nental Mark III models, replace the

complete piston and rod assembly if

the piston or piston sealing lips are

unserviceable or damaged.

3.

Remove the seal from the cover.

D1899-A

FIG. 51—Removing Forward

Clutch Pressure Plate Snap Ring

Assembly

1.

Dip the new seals in transmission

fluid.

2.

Install new seals on the cover

and servo piston. Fig. 61 shows the

correct servo piston and cover for the

transmission.

3.

Dip the piston in transmission

fluid and install it in the cover.

LOW-REVERSE CLUTCH

PISTON

Disassembly

1.

Remove the inner and the outer

seal from the reverse clutch piston.

Assembly

1.

Dip the two new seals in clean

transmission fluid.

2.

Install the seals on the piston.

OUTPUT SHAFT

Disassembly

1.

Remove the governor attaching

bolts and remove the governor.

2.

Remove the snap ring that se-

cures the governor distributor on the

output shaft (Fig. 62) and slide it off

the front of the shaft.

3.

Remove the seal rings from the

distributor.

Assembly

1.

Carefully install new seal rings

on the distributor.

2.

Working from the front end of

the output shaft, slide the governorprocarmanuals.com

Page 399 of 413

07-04-30

C-6 Automatic Transmission

07-04-30

6. Install the compressing tool

shown in Fig. 29 and compress the

springs just enough to install the low-

reverse clutch piston retainer snap

ring.

7.

Install the snap ring, then re-

move the compressing tool.

8. Place the transmission case on

the bench with the front end facing

downward.

9. Position the parking gear thrust

washer and the gear on the case (Fig.

33).

Do not restake the thrust washer.

10.

Position the oil distributor and

tubes in place on the rear of the case.

Install and torque the attaching bolts

to specification.

11.

Install the output shaft, and

governor as an assembly.

12.

Place a new gasket on the rear

of the transmission case. Position the

extension housing on the case and in-

stall the attaching bolts. Torque the

attaching bolts to specification.

13.

Place the case in the holding

fixture.

14.

Align the low-reverse clutch hub

and one-way clutch with the inner

race at the rear of the case. Rotate

the low-reverse clutch hub clockwise

while applying pressure to seat it on

the inner race.

15.

Install the low-reverse clutch

plates,

starting with a steel plate and

following with friction and steel plates

alternately. Retain them with vaseline.

Refer to the Specifications Section for

the number of plates required. If new

composition plates are being used,

soak them in clean transmission fluid

for fifteen minutes before installation.

Install the pressure plate and the snap

ring. Test the operation of the low-

reverse clutch by applying air pressure

at the clutch pressure apply hole in

the case.

16.

Install the reverse planet ring

gear thrust washer and the ring gear

and hub assembly. Insert the snap

ring in the groove in the output shaft.

17.

Assemble the front and rear

thrust washers onto the reverse planet

assembly; retain with vasoline. Insert

the assembly into the ring gear and

install the snap ring.

18.

Set the reverse-high clutch on

the bench, with the front end facing

down. Install the thrust washer on the

rear end of the reverse-high clutch as-

sembly. Retain the thrust washer with

vaseline and insert the splined end of

forward clutch into the open end of

the reverse-high clutch so that the

splines engage the direct clutch fric-

tion plates (Fig. 43).

19.

Install the thrust washer and re-

tain it with vaseline, on the front end

FORWARD

SNAP

RING

377300-S

SUN

GEAR

7A348

•

INPUT

SHELL

7D064

\

THRUST

WASHER

7D066

-IT

REAR

SNAP

RING

377300-S

I)

1634-A

57—Input Shell and Sun Gear Disassembled

of the forward planet ring gear and

hub.

Insert the ring gear into the for-

ward clutch.

20.

Install the thrust washer on the

front end of the forward planet assem-

bly. Retain the washer with vaseline

and insert the assembly into the ring

gear. Install the input shell and sun

gear assembly.

21.

Install the reverse-high clutch,

forward clutch, forward planet assem-

bly and drive input shell and sun gear

as an assembly into the transmission

case.

22.

Insert the intermediate band

into the case around the direct clutch

GEAR

SNAP RING

HUB AND FLANGE

D1906-A

FIG. 58—Output Shaft Hub and

Ring Gear

LOW-REVERSE

CLUTCH

DRUM-

7D390

SPRING

RETAINER-

7D191

BUSHING

-

7E194

SPRING

-

7D170

ROLLER-7190

D 1928-A

FIG. 59—One-Way Clutch Disassembled

cylinder.Install the struts and then

tighten the band adjusting screw suffi-

ciently to retain the band.

23.

Place a selective thickness bronze

thrust washer on the rear shoulder of

the stator support and retain it with

vaseline. If the end play was not

within specification when checked prior

to disassembly, replace the washer with

one of proper thickness. Refer to

Specifications Section for selective

thrust washer thicknesses. Lay a new

gasket on the rear mounting face of

the pump and position on the case

being careful not to damage the large

seal on the O.D. of the pump hous-procarmanuals.com