steering FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 157 of 413

03-09-05

Saginaw Design Integral Power Steering Gear

03-09-05

Tool . T59L -100S

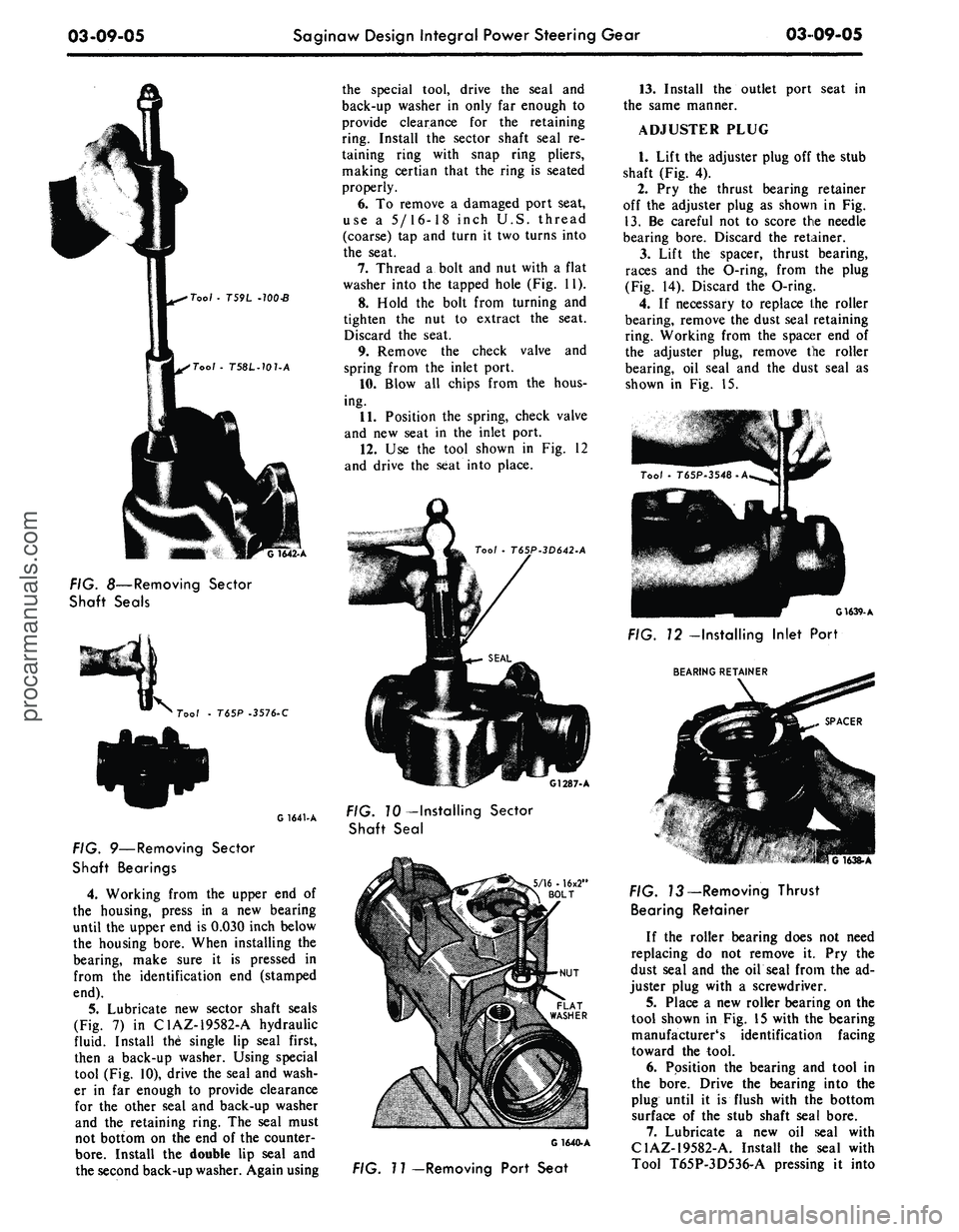

FIG. 8—Removing Sector

Shaft Seals

Too/

-

T65P -3576-C

G 1641-A

FIG. 9—Removing Sector

Shaft Bearings

4.

Working from

the

upper

end of

the housing, press

in a new

bearing

until

the

upper

end

is

0.030 inch below

the housing bore. When installing

the

bearing, make sure

it is

pressed

in

from

the

identification

end

(stamped

end).

5.

Lubricate

new

sector shaft seals

(Fig.

7) in

C1AZ-19582-A hydraulic

fluid. Install

the

single

lip

seal first,

then

a

back-up washer. Using special

tool

(Fig. 10),

drive

the

seal

and

wash-

er

in far

enough

to

provide clearance

for

the

other seal

and

back-up washer

and

the

retaining ring.

The

seal must

not bottom

on the end of

the

counter-

bore.

Install

the

double

lip

seal

and

the second back-up washer. Again using

the special tool, drive

the

seal

and

back-up washer

in

only

far

enough

to

provide clearance

for the

retaining

ring. Install

the

sector shaft seal

re-

taining ring with snap ring pliers,

making certian that

the

ring

is

seated

properly.

6.

To

remove

a

damaged port seat,

use

a

5/16-18 inch

U.S.

thread

(coarse)

tap and

turn

it

two

turns into

the seat.

7.

Thread

a

bolt

and nut

with

a

flat

washer into

the

tapped hole

(Fig.

11).

8. Hold

the

bolt from turning

and

tighten

the nut to

extract

the

seat.

Discard

the

seat.

9. Remove

the

check valve

and

spring from

the

inlet port.

10.

Blow

all

chips from

the

hous-

ing.

11.

Position

the

spring, check valve

and

new

seat

in the

inlet port.

12.

Use the

tool shown

in Fig. 12

and drive

the

seat into place.

.

T65P-3D642-A

G1287-

A

FIG.

10

— Installing Sector

Shaft Seal

5/16

•

16x2"

BOLT

13.

Install

the

outlet port seat

in

the same manner.

ADJUSTER PLUG

1.

Lift

the

adjuster plug

off

the

stub

shaft

(Fig.

4).

2.

Pry the

thrust bearing retainer

off

the

adjuster plug

as

shown

in Fig.

13.

Be

careful

not to

score

the

needle

bearing bore. Discard

the

retainer.

3.

Lift

the

spacer, thrust bearing,

races

and the

O-ring, from

the

plug

(Fig.

14).

Discard

the

O-ring.

4.

If

necessary

to

replace

the

roller

bearing, remove

the

dust seal retaining

ring. Working from

the

spacer

end of

the adjuster plug, remove

the

roller

bearing,

oil

seal

and the

dust seal

as

shown

in Fig. 15.

G1639-A

FIG.

12

-Installing Inlet Port

BEARING RETAINER

G1640-A

FIG. 11 —Removing Port Seat

C1638-A

FIG. 73—Removing Thrust

Bearing Retainer

If

the

roller bearing does

not

need

replacing

do not

remove

it. Pry the

dust seal

and the oil

seal from

the ad-

juster plug with

a

screwdriver.

5.

Place

a new

roller bearing

on the

tool shown

in Fig.

15

with

the

bearing

manufacturer's identification facing

toward

the

tool.

6. Position

the

bearing

and

tool

in

the bore. Drive

the

bearing into

the

plug until

it is

flush with

the

bottom

surface

of the

stub shaft seal bore.

7.

Lubricate

a new oil

seal with

C1AZ-19582-A. Install

the

seal with

Tool T65P-3D536-A pressing

it

intoprocarmanuals.com

Page 158 of 413

03-09-06

Saginaw Design Integral Power Steering Gear

03-09-06

ADJUSTER

PLUG

DUST

SEAL

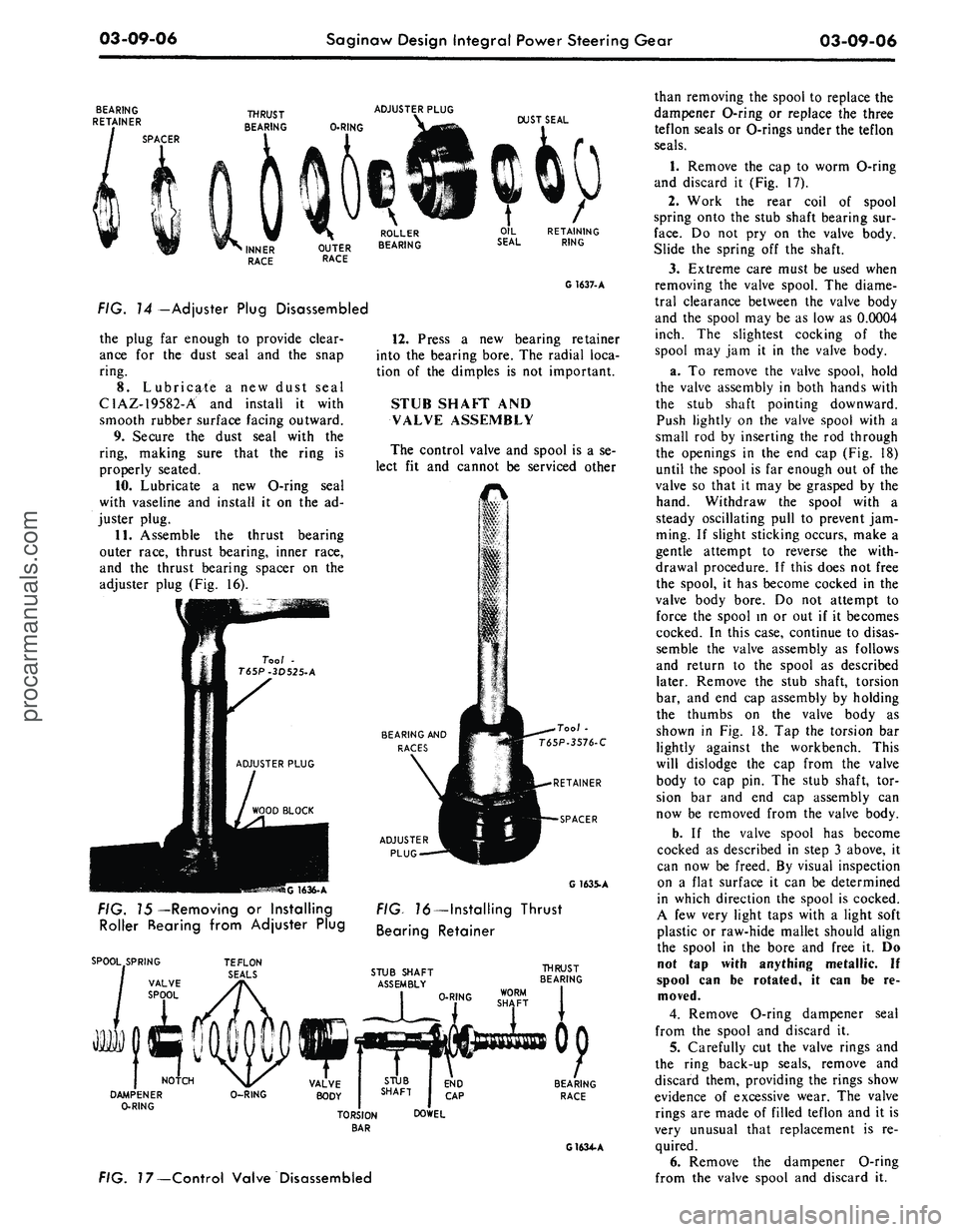

FIG. 14 —Adjuster Plug Disassembled

the plug far enough to provide clear-

ance for the dust seal and the snap

ring.

8. Lubricate a new dust seal

C1AZ-19582-A and install it with

smooth rubber surface facing outward.

9. Secure the dust seal with the

ring, making sure that the ring is

properly seated.

10.

Lubricate a new O-ring seal

with vaseline and install it on the ad-

juster plug.

11.

Assemble the thrust bearing

outer race, thrust bearing, inner race,

and the thrust bearing spacer on the

adjuster plug (Fig. 16).

OIL

RETAINING

SEAL

RING

G

1637-A

12.

Press a new bearing retainer

into the bearing bore. The radial loca-

tion of the dimples is not important.

STUB SHAFT AND

VALVE ASSEMBLY

The control valve and spool is a se-

lect fit and cannot be serviced other

BEARING

AND

RACES

1636-A

FIG. 15 —Removing or Installing

Roller Rearing from Adjuster Plug

G

1635-A

FIG.

76

—Installing Thrust

Bearing Retainer

SPOOL

SPRING

DOWEL

BEARING

RACE

G1634-A

FIG. 77—Control Valve Disassembled

than removing the spool to replace the

dampener O-ring or replace the three

teflon seals or O-rings under the teflon

seals.

1.

Remove the cap to worm O-ring

and discard it (Fig. 17).

2.

Work the rear coil of spool

spring onto the stub shaft bearing sur-

face.

Do not pry on the valve body.

Slide the spring off the shaft.

3.

Extreme care must be used when

removing the valve spool. The diame-

tral clearance between the valve body

and the spool may be as low as 0.0004

inch. The slightest cocking of the

spool may jam it in the valve body.

a. To remove the valve spool, hold

the valve assembly in both hands with

the stub shaft pointing downward.

Push lightly on the valve spool with a

small rod by inserting the rod through

the openings in the end cap (Fig. 18)

until the spool is far enough out of the

valve so that it may be grasped by the

hand. Withdraw the spool with a

steady oscillating pull to prevent jam-

ming. If slight sticking occurs, make a

gentle attempt to reverse the with-

drawal procedure. If this does not free

the spool, it has become cocked in the

valve body bore. Do not attempt to

force the spool in or out if it becomes

cocked. In this case, continue to disas-

semble the valve assembly as follows

and return to the spool as described

later. Remove the stub shaft, torsion

bar, and end cap assembly by holding

the thumbs on the valve body as

shown in Fig. 18. Tap the torsion bar

lightly against the workbench. This

will dislodge the cap from the valve

body to cap pin. The stub shaft, tor-

sion bar and end cap assembly can

now be removed from the valve body.

b.

If the valve spool has become

cocked as described in step 3 above, it

can now be freed. By visual inspection

on a flat surface it can be determined

in which direction the spool is cocked.

A few very light taps with a light soft

plastic or raw-hide mallet should align

the spool in the bore and free it. Do

not tap with anything metallic. If

spool can be rotated, it can be re-

moved.

4.

Remove O-ring dampener seal

from the spool and discard it.

5.

Carefully cut the valve rings and

the ring back-up seals, remove and

discard them, providing the rings show

evidence of excessive wear. The valve

rings are made of filled teflon and it is

very unusual that replacement is re-

quired.

6. Remove the dampener O-ring

from the valve spool and discard it.procarmanuals.com

Page 159 of 413

03-09-07

Saginaw Design Integral Power Steering Gear

03-09-07

VALVE SPOOL

DAMP EN

ERO-RING

TORSION BAR

G 1633-A

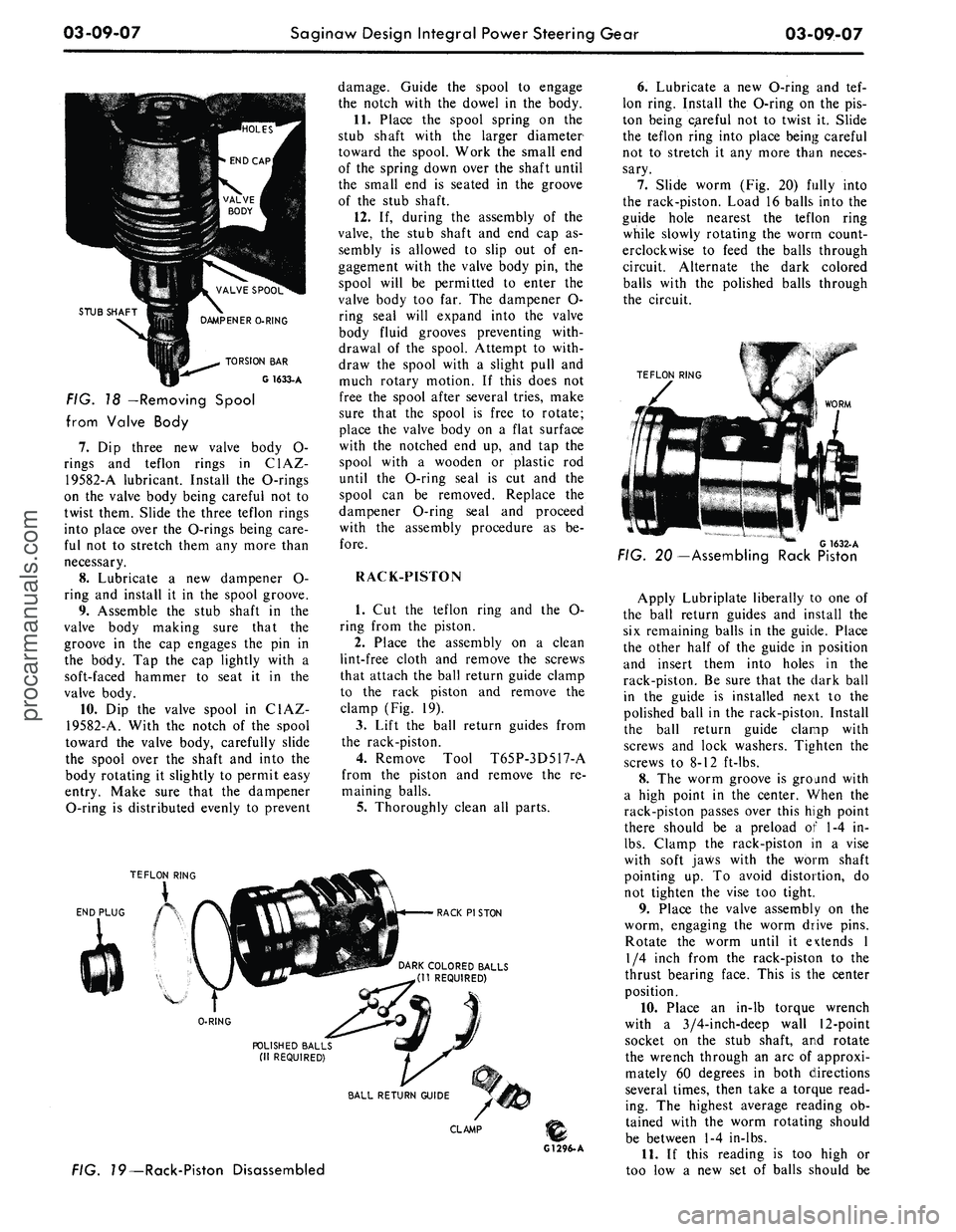

FIG. 18 —Removing Spool

from Valve Body

7.

Dip three new valve body O-

rings and teflon rings in C1AZ-

19582-A lubricant. Install the O-rings

on the valve body being careful not to

twist them. Slide the three teflon rings

into place over the O-rings being care-

ful not to stretch them any more than

necessary.

8. Lubricate a new dampener O-

ring and install it in the spool groove.

9. Assemble the stub shaft in the

valve body making sure that the

groove in the cap engages the pin in

the body. Tap the cap lightly with a

soft-faced hammer to seat it in the

valve body.

10.

Dip the valve spool in C1AZ-

19582-A. With the notch of the spool

toward the valve body, carefully slide

the spooi over the shaft and into the

body rotating it slightly to permit easy

entry. Make sure that the dampener

O-ring is distributed evenly to prevent

TEFLON RING

damage. Guide the spool to engage

the notch with the dowel in the body.

11.

Place the spool spring on the

stub shaft with the larger diameter

toward the spool. Work the small end

of the spring down over the shaft until

the small end is seated in the groove

of the stub shaft.

12.

If, during the assembly of the

valve, the stub shaft and end cap as-

sembly is allowed to slip out of en-

gagement with the valve body pin, the

spool will be permitted to enter the

valve body too far. The dampener O-

ring seal will expand into the valve

body fluid grooves preventing with-

drawal of the spool. Attempt to with-

draw the spool with a slight pull and

much rotary motion. If this does not

free the spool after several tries, make

sure that the spool is free to rotate;

place the valve body on a flat surface

with the notched end up, and tap the

spool with a wooden or plastic rod

until the O-ring seal is cut and the

spool can be removed. Replace the

dampener O-ring seal and proceed

with the assembly procedure as be-

fore.

RACK-PISTON

1.

Cut the teflon ring and the O-

ring from the piston.

2.

Place the assembly on a clean

lint-free cloth and remove the screws

that attach the ball return guide clamp

to the rack piston and remove the

clamp (Fig. 19).

3.

Lift the ball return guides from

the rack-piston.

4.

Remove Tool T65P-3D517-A

from the piston and remove the re-

maining balls.

5.

Thoroughly clean all parts.

END PLUG

RACK PI STON

DARK COLORED BALLS

(11 REQUIRED)

V

0-RING

POLISHED BALLS

(II REQUIRED)

BALL RETURN GUIDE

CLAMP

B

G1296. A

6. Lubricate a new O-ring and tef-

lon ring. Install the O-ring on the pis-

ton being qareful not to twist it. Slide

the teflon ring into place being careful

not to stretch it any more than neces-

sary.

7.

Slide worm (Fig. 20) fully into

the rack-piston. Load 16 balls into the

guide hole nearest the teflon ring

while slowly rotating the worm count-

erclockwise to feed the balls through

circuit. Alternate the dark colored

balls with the polished balls through

the circuit.

TEFLON RING

FIG. 19—Rack-Piston Disassembled

G 1632-A

FIG. 20—Assembling Rack Piston

Apply Lubriplate liberally to one of

the ball return guides and install the

six remaining balls in the guide. Place

the other half of the guide in position

and insert them into holes in the

rack-piston. Be sure that the dark ball

in the guide is installed next to the

polished ball in the rack-piston. Install

the ball return guide clamp with

screws and lock washers. Tighten the

screws to 8-12 ft-lbs.

8. The worm groove is ground with

a high point in the center. V/hen the

rack-piston passes over this high point

there should be a preload of 1-4 in-

lbs.

Clamp the rack-piston in a vise

with soft jaws with the worm shaft

pointing up. To avoid distortion, do

not tighten the vise too tight.

9. Place the valve assembly on the

worm, engaging the worm drive pins.

Rotate the worm until it extends 1

1/4 inch from the rack-piston to the

thrust bearing face. This is the center

position.

10.

Place an in-lb torque wrench

with a 3/4-inch-deep wall 12-point

socket on the stub shaft, and rotate

the wrench through an arc of approxi-

mately 60 degrees in both directions

several times, then take a torque read-

ing. The highest average reading ob-

tained with the worm rotating should

be between 1-4 in-lbs.

11.

If this reading is too high or

too low a new set of balls should beprocarmanuals.com

Page 160 of 413

03-09-08

Saginaw Design Integral Power Steering Gear

03-09-08

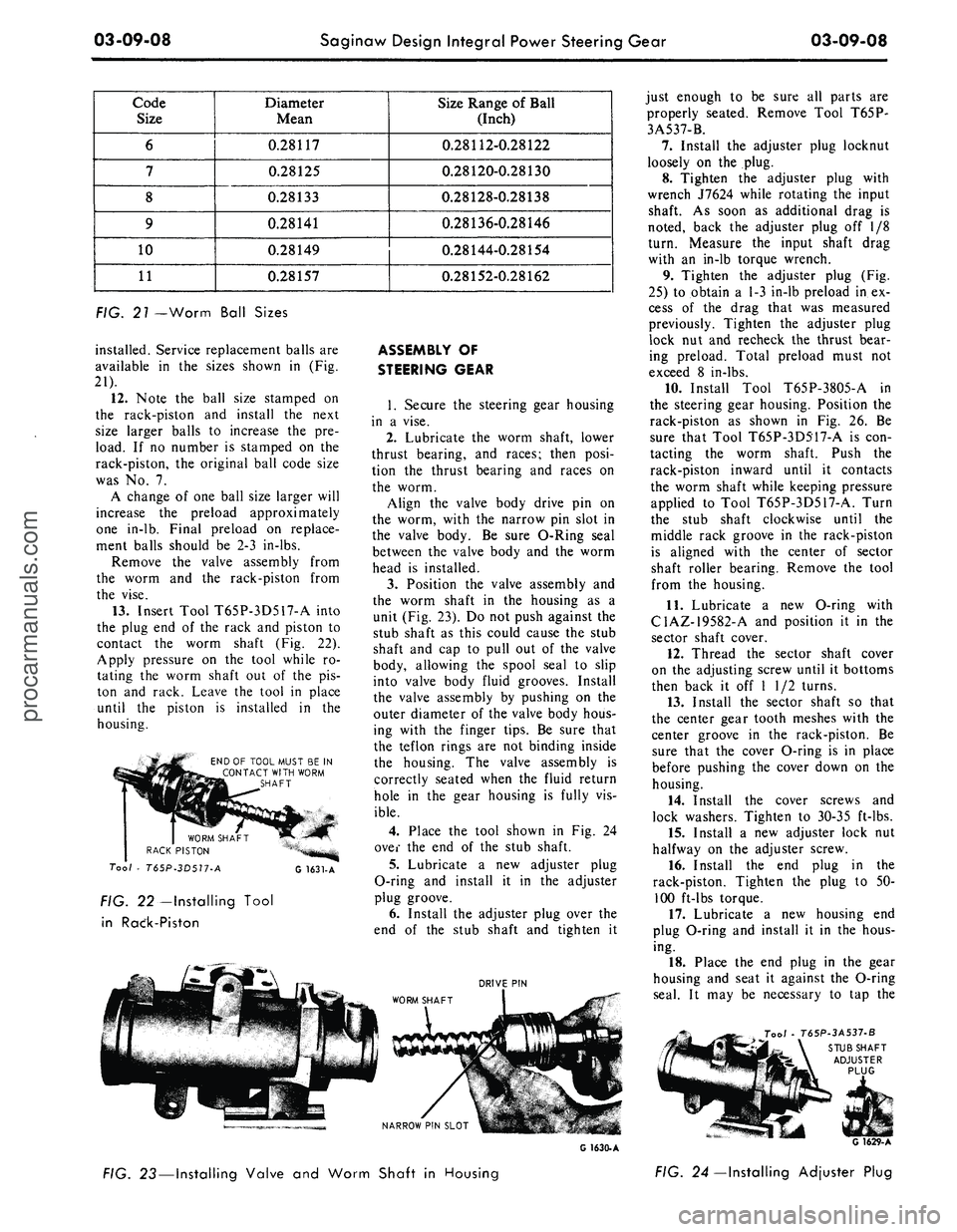

Code

Size

6

7

8

9

10

11

Diameter

Mean

0.28117

0.28125

0.28133

0.28141

0.28149

0.28157

Size Range of Ball

(Inch)

0.28112-0.28122

0.28120-0.28130

0.28128-0.28138

0.28136-0.28146

0.28144-0.28154

0.28152-0.28162

FIG. 21 —Worm Ball Sizes

installed. Service replacement balls are

available in the sizes shown in (Fig.

21).

12.

Note the ball size stamped on

the rack-piston and install the next

size larger balls to increase the pre-

load. If no number is stamped on the

rack-piston, the original ball code size

was No. 7.

A change of one ball size larger will

increase the preload approximately

one in-lb. Final preload on replace-

ment balls should be 2-3 in-lbs.

Remove the valve assembly from

the worm and the rack-piston from

the vise.

13.

Insert Tool T65P-3D517-A into

the plug end of the rack and piston to

contact the worm shaft (Fig. 22).

Apply pressure on the tool while ro-

tating the worm shaft out of the pis-

ton and rack. Leave the tool in place

until the piston is installed in the

housing.

END OF TOOL MUST BE IN

CONTACT WITH WORM

SHAFT

Tool * T65P-3D517-A

FIG. 22—Installing Tool

in Raek-Piston

G 1631-A

ASSEMBLY OF

STEERING GEAR

1.

Secure the steering gear housing

in a vise.

2.

Lubricate the worm shaft, lower

thrust bearing, and races; then posi-

tion the thrust bearing and races on

the worm.

Align the valve body drive pin on

the worm, with the narrow pin slot in

the valve body. Be sure O-Ring seal

between the valve body and the worm

head is installed.

3.

Position the valve assembly and

the worm shaft in the housing as a

unit (Fig. 23). Do not push against the

stub shaft as this could cause the stub

shaft and cap to pull out of the valve

body, allowing the spool seal to slip

into valve body fluid grooves. Install

the valve assembly by pushing on the

outer diameter of the valve body hous-

ing with the finger tips. Be sure that

the teflon rings are not binding inside

the housing. The valve assembly is

correctly seated when the fluid return

hole in the gear housing is fully vis-

ible.

4.

Place the tool shown in Fig. 24

over the end of the stub shaft.

5.

Lubricate a new adjuster plug

O-ring and install it in the adjuster

plug groove.

6. Install the adjuster plug over the

end of the stub shaft and tighten it

DRIVE PIN

just enough to be sure all parts are

properly seated. Remove Tool T65P-

3A537-B.

7.

Install the adjuster plug locknut

loosely on the plug.

8. Tighten the adjuster plug with

wrench J7624 while rotating the input

shaft. As soon as additional drag is

noted, back the adjuster plug off 1/8

turn. Measure the input shaft drag

with an in-lb torque wrench.

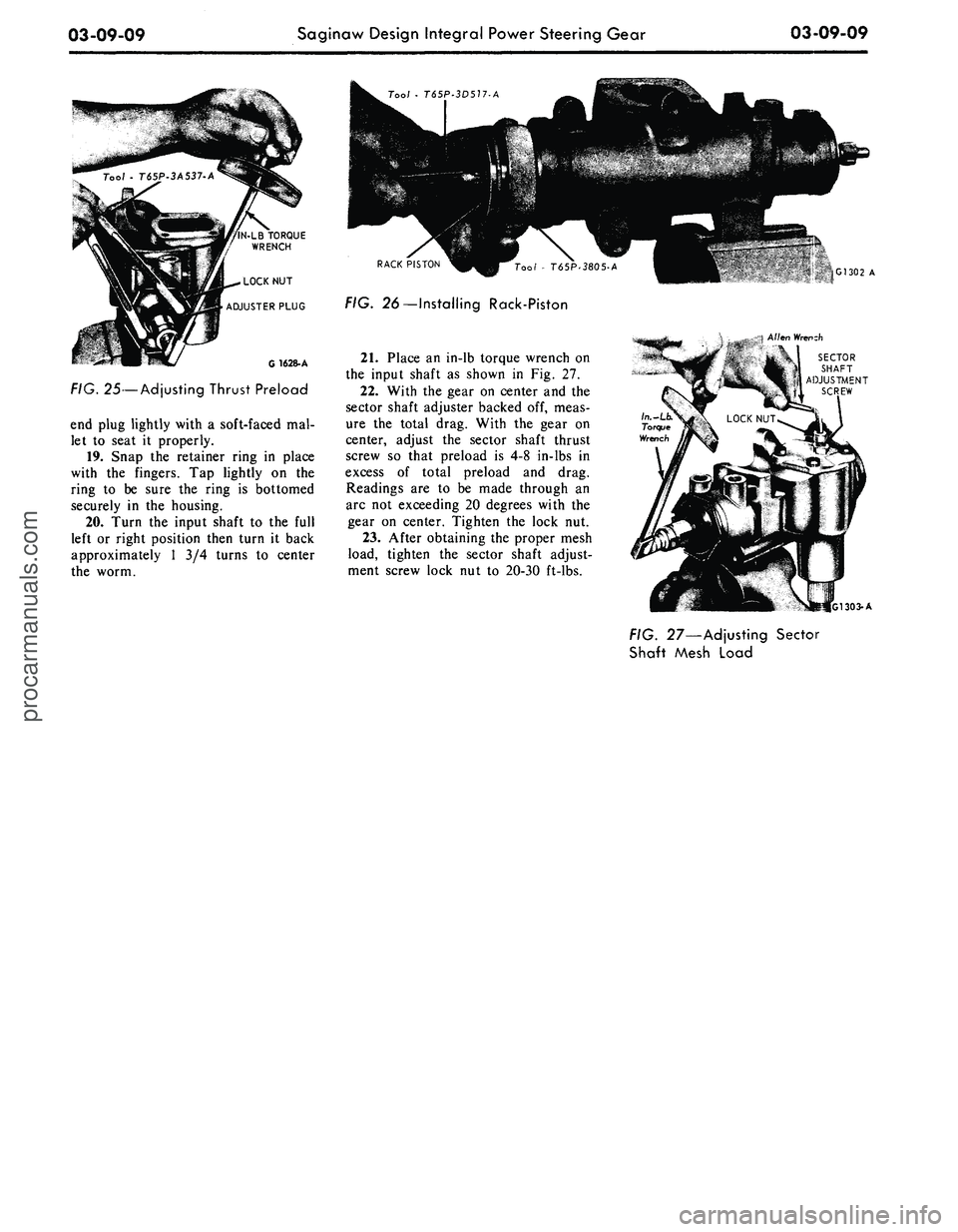

9. Tighten the adjuster plug (Fig.

25) to obtain a 1-3 in-lb preload in ex-

cess of the drag that was measured

previously. Tighten the adjuster plug

lock nut and recheck the thrust bear-

ing preload. Total preload must not

exceed 8 in-lbs.

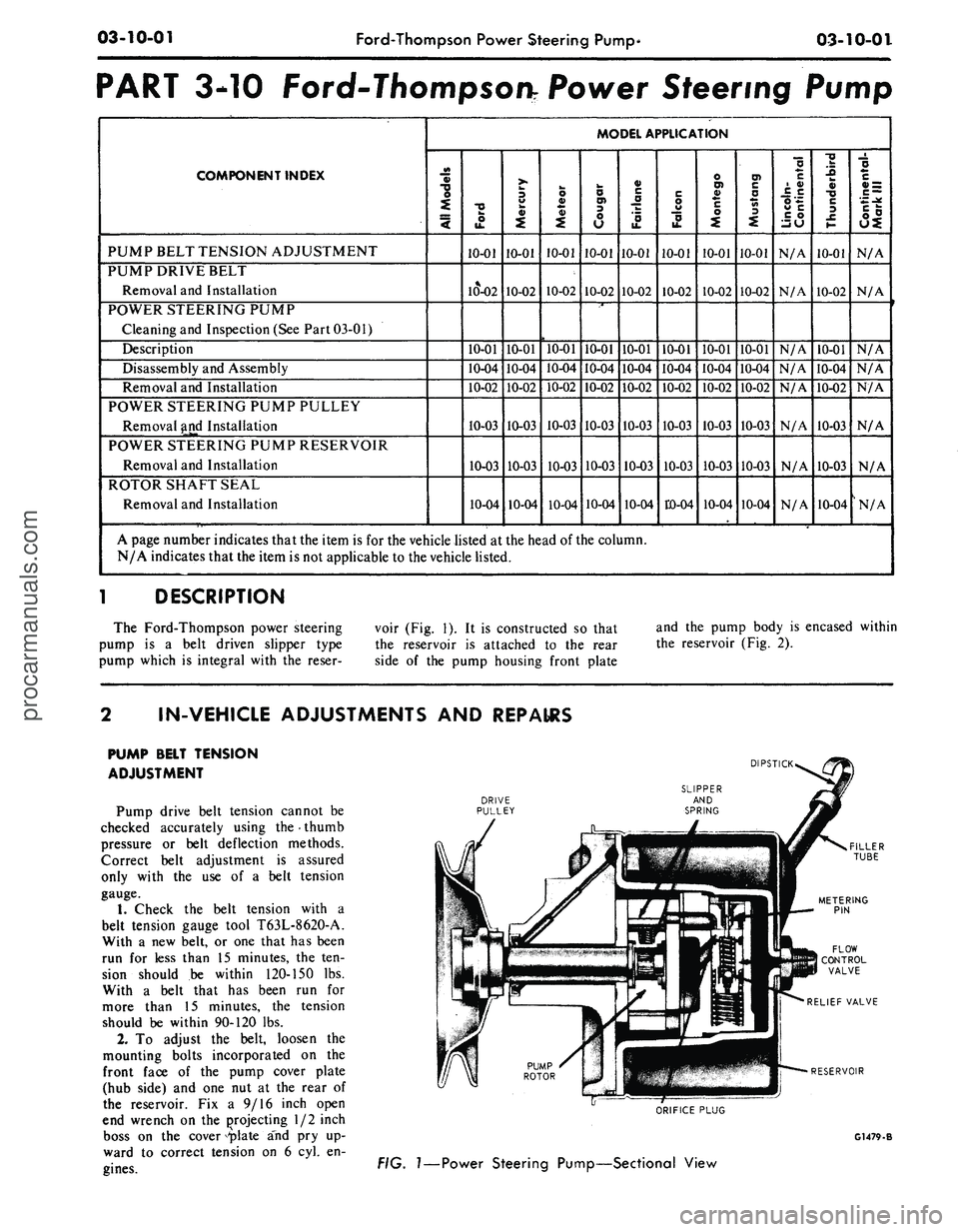

10.

Install Tool T65P-3805-A in

the steering gear housing. Position the

rack-piston as shown in Fig. 26. Be

sure that Tool T65P-3D517-A is con-

tacting the worm shaft. Push the

rack-piston inward until it contacts

the worm shaft while keeping pressure

applied to Tool T65P-3D517-A. Turn

the stub shaft clockwise until the

middle rack groove in the rack-piston

is aligned with the center of sector

shaft roller bearing. Remove the tool

from the housing.

11.

Lubricate a new O-ring with

C1AZ-19582-A and position it in the

sector shaft cover.

12.

Thread the sector shaft cover

on the adjusting screw until it bottoms

then back it off 1 1/2 turns.

13.

Install the sector shaft so that

the center gear tooth meshes with the

center groove in the rack-piston. Be

sure that the cover O-ring is in place

before pushing the cover down on the

housing.

14.

Install the cover screws and

lock washers. Tighten to 30-35 ft-lbs.

15.

Install a new adjuster lock nut

halfway on the adjuster screw.

16.

Install the end plug in the

rack-piston. Tighten the plug to 50-

100 ft-lbs torque.

17.

Lubricate a new housing end

plug O-ring and install it in the hous-

ing.

18.

Place the end plug in the gear

housing and seat it against the O-ring

seal. It may be necessary to tap the

Tool

T65P-3A537-B

STUB SHAFT

ADJUSTER

PLUG

G 1630-A

FIG. 23—Installing Valve and Worm Shaft in Housing

G 1629-A

FIG. 24 —Installing Adjuster Plugprocarmanuals.com

Page 161 of 413

03-09-09

Saginaw Design Integral Power Steering Gear

03-09-09

Tool • T65P-3D517-A

LOCK NUT

ADJUSTER PLUG

G1628-A

FIG. 25

—

Adjusting Thrust Preload

end plug lightly with

a

soft-faced mal-

let

to

seat

it

properly.

19.

Snap

the

retainer ring

in

place

with

the

fingers.

Tap

lightly

on the

ring

to be

sure

the

ring

is

bottomed

securely

in the

housing.

20.

Turn

the

input shaft

to the

full

left

or

right position then turn

it

back

approximately

1 3/4

turns

to

center

the worm.

RACK PISTON

Tool - T65P.3805-A

FIG. 26—Installing Rack-Piston

21.

Place

an

in-lb torque wrench

on

the input shaft

as

shown

in Fig. 27.

22.

With

the

gear

on

center

and the

sector shaft adjuster backed

off,

meas-

ure

the

total drag. With

the

gear

on

center, adjust

the

sector shaft thrust

screw

so

that preload

is 4-8

in-lbs

in

excess

of

total preload

and

drag.

Readings

are to be

made through

an

arc

not

exceeding

20

degrees with

the

gear

on

center. Tighten

the

lock

nut.

23.

After obtaining

the

proper mesh

load, tighten

the

sector shaft adjust-

ment screw lock

nut to

20-30 ft-lbs.

jG1302

A

G1303-A

FIG. 27—Adjusting Sector

Shaft Mesh Loadprocarmanuals.com

Page 162 of 413

03-10-01

Ford-Thompson Power Steering Pump*

03-10-01

PART 3-10 Ford-Thompsonr Power Steering Pump

COMPONENT INDEX

PUMP BELT TENSION ADJUSTMENT

PUMP DRIVE BELT

Removal and Installation

POWER STEERING PUMP

Cleaning and Inspection (See Part 03-01)

Description

Disassembly and Assembly

Removal and Installation

POWER STEERING PUMP PULLEY

Removal and Installation

POWER STEERING PUMP RESERVOIR

Removal and Installation

ROTOR SHAFT SEAL

Removal and Installation

MODEL APPLICATION

All

Models

Ford

10-01

l5-O2

10-01

10-04

10-02

10-03

10-03

10-04

Mercury

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Meteor

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Cougar

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Fairlane

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Falcon

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Montego

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Mustang

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Lincoln-

Continental

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Thunderbird

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Continental-

Mark

III

N/A

N/A

N/A

N/A

N/A

N/A

N/A

'N/A

A page number indicates that the item is for the vehicle listed at the head of the column.

N/A indicates that the item is not applicable to the vehicle listed.

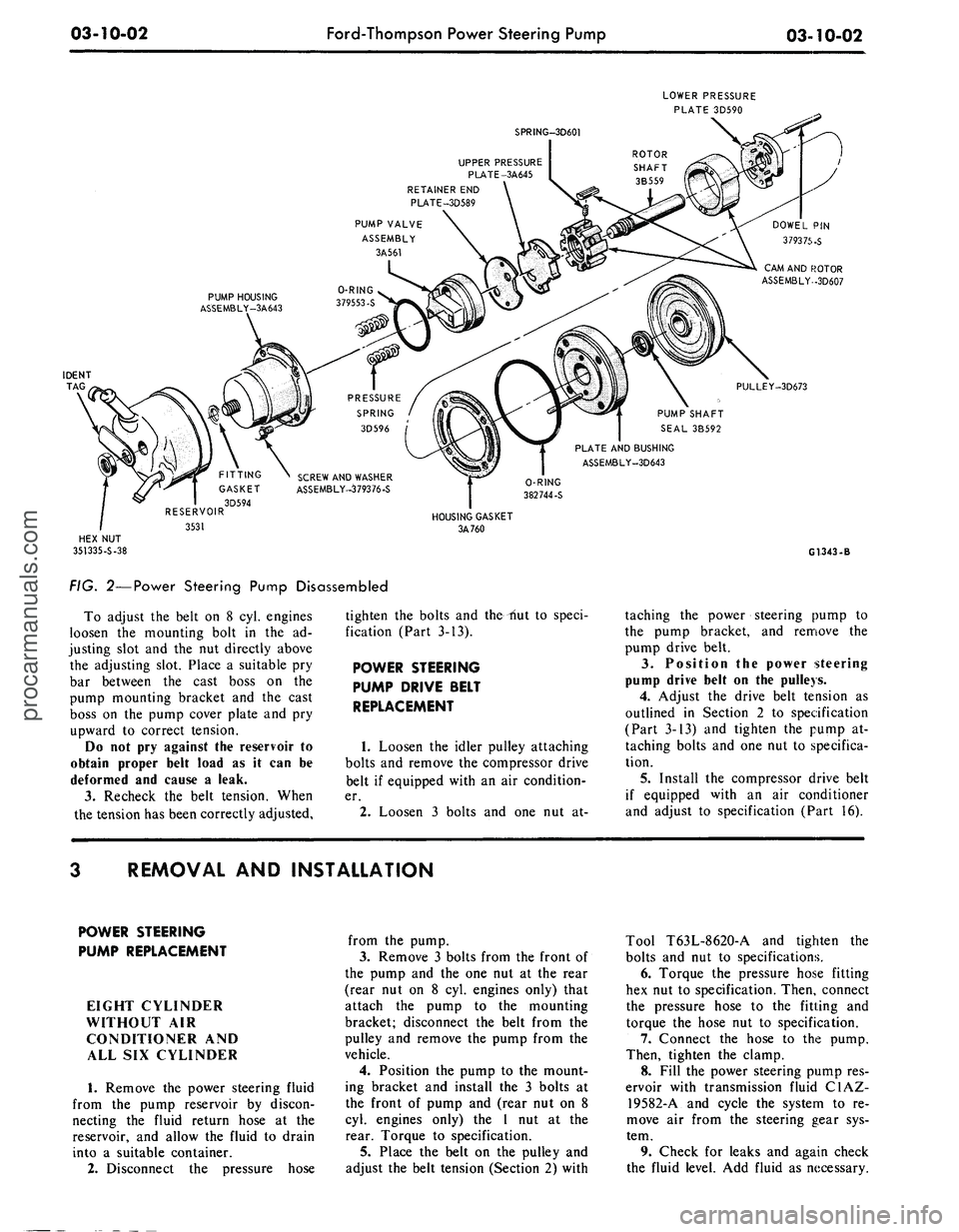

1

DESCRIPTION

The Ford-Thompson power steering

pump is a belt driven slipper type

pump which is integral with the reser-

voir (Fig. 1). It is constructed so that

the reservoir is attached to the rear

side of the pump housing front plate

and the pump body is encased within

the reservoir (Fig. 2).

IN-VEHICLE ADJUSTMENTS AND REPAIRS

PUMP BELT TENSION

ADJUSTMENT

Pump drive belt tension cannot be

checked accurately using the

•

thumb

pressure or belt deflection methods.

Correct belt adjustment is assured

only with the use of a belt tension

gauge.

1.

Check the belt tension with a

belt tension gauge tool T63L-8620-A.

With a new belt, or one that has been

run for less than 15 minutes, the ten-

sion should be within 120-150 lbs.

With a belt that has been run for

more than 15 minutes, the tension

should be within 90-120 lbs.

2.

To adjust the belt, loosen the

mounting bolts incorporated on the

front face of the pump cover plate

(hub side) and one nut at the rear of

the reservoir. Fix a 9/16 inch open

end wrench on the nrojecting 1/2 inch

boss on the cover -'plate a"hd pry up-

ward to correct tension on 6 cyl. en-

gines.

DIPSTICK.

DRIVE

PULLEY

RELIEF VALVE

RESERVOIR

ORIFICE PLUG

G1479-B

FIG.

1—Power

Steering Pump—Sectional View

procarmanuals.com

Page 163 of 413

03-10-02

Ford-Thompson Power Steering Pump

03-10-02

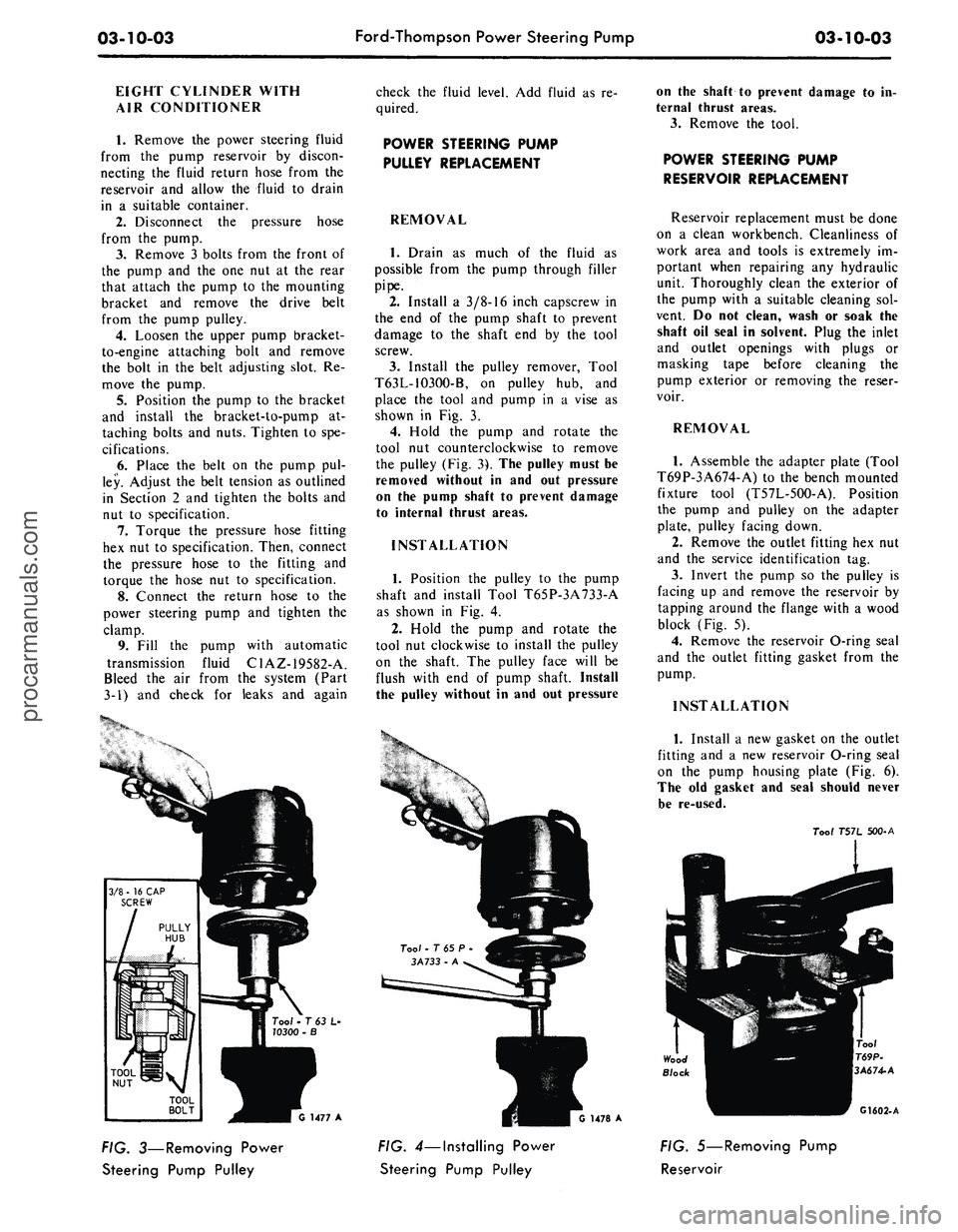

LOWER PRESSURE

PLATE 3D590

SPRING-3D601

UPPER PRESSURE

PLATE -3A645

RETAINER END

PLATE-3D589

CAM AND ROTOR

ASSEMBLY-

-3D607

SCREW AND WASHER

ASSEMBLY-379376-S

PULLEY-3D673

PUMP SHAFT

SEAL 3B592

PLATE AND BUSHING

ASSEMBLY-3D643

0-RING

382744-S

HOUSING GASKET

3A760

G1343-B

FIG. 2—Power Steering Pump Disassembled

To adjust the belt on 8 cyl. engines

loosen the mounting bolt in the ad-

justing slot and the nut directly above

the adjusting slot. Place a suitable pry

bar between the cast boss on the

pump mounting bracket and the cast

boss on the pump cover plate and pry

upward to correct tension.

Do not pry against the reservoir to

obtain proper belt load as it can be

deformed and cause a leak.

3.

Recheck the belt tension. When

the tension has been correctly adjusted,

tighten the bolts and the fiut to speci-

fication (Part 3-13).

POWER STEERING

PUMP DRIVE BELT

REPLACEMENT

1.

Loosen the idler pulley attaching

bolts and remove the compressor drive

belt if equipped with an air condition-

er.

2.

Loosen 3 bolts and one nut at-

taching the power steering pump to

the pump bracket, and remove the

pump drive belt.

3.

Position the power steering

pump drive belt on the pulleys.

4.

Adjust the drive belt tension as

outlined in Section 2 to specification

(Part 3-13) and tighten the pump at-

taching bolts and one nut to specifica-

tion.

5.

Install the compressor drive belt

if equipped with an air conditioner

and adjust to specification (Part 16).

REMOVAL AND INSTALLATION

POWER STEERING

PUMP REPLACEMENT

EIGHT CYLINDER

WITHOUT AIR

CONDITIONER AND

ALL SIX CYLINDER

1.

Remove the power steering fluid

from the pump reservoir by discon-

necting the fluid return hose at the

reservoir, and allow the fluid to drain

into a suitable container.

2.

Disconnect the pressure hose

from the pump.

3.

Remove 3 bolts from the front of

the pump and the one nut at the rear

(rear nut on 8 cyl. engines only) that

attach the pump to the mounting

bracket; disconnect the belt from the

pulley and remove the pump from the

vehicle.

4.

Position the pump to the mount-

ing bracket and install the 3 bolts at

the front of pump and (rear nut on 8

cyl.

engines only) the 1 nut at the

rear. Torque to specification.

5.

Place the belt on the pulley and

adjust the belt tension (Section 2) with

Tool T63L-8620-A and tighten the

bolts and nut to specifications.

6. Torque the pressure hose fitting

hex nut to specification. Then, connect

the pressure hose to the fitting and

torque the hose nut to specification.

7.

Connect the hose to the pump.

Then, tighten the clamp.

8. Fill the power steering pump res-

ervoir with transmission fluid C1AZ-

19582-A and cycle the system to re-

move air from the steering gear sys-

tem.

9. Check for leaks and again check

the fluid level. Add fluid as necessary.procarmanuals.com

Page 164 of 413

03-10-03

Ford-Thompson Power Steering Pump

03-10-03

EIGHT CYLINDER WITH

AIR CONDITIONER

1.

Remove the power steering fluid

from the pump reservoir by discon-

necting the fluid return hose from the

reservoir and allow the fluid to drain

in a suitable container.

2.

Disconnect the pressure hose

from the pump.

3.

Remove 3 bolts from the front of

the pump and the one nut at the rear

that attach the pump to the mounting

bracket and remove the drive belt

from the pump pulley.

4.

Loosen the upper pump bracket-

to-engine attaching bolt and remove

the bolt in the belt adjusting slot. Re-

move the pump.

5.

Position the pump to the bracket

and install the bracket-to-pump at-

taching bolts and nuts. Tighten to spe-

cifications.

6. Place the belt on the pump pul-

ley. Adjust the belt tension as outlined

in Section 2 and tighten the bolts and

nut to specification.

7.

Torque the pressure hose fitting

hex nut to specification. Then, connect

the pressure hose to the fitting and

torque the hose nut to specification.

8. Connect the return hose to the

power steering pump and tighten the

clamp.

9. Fill the pump with automatic

transmission fluid C1AZ-19582-A.

Bleed the air from the system (Part

3-1) and check for leaks and again

check the fluid level. Add fluid as re-

quired.

POWER STEERING PUMP

PULLEY REPLACEMENT

REMOVAL

1.

Drain as much of the fluid as

possible from the pump through filler

pipe.

2.

Install a 3/8-16 inch capscrew in

the end of the pump shaft to prevent

damage to the shaft end by the tool

screw.

3.

Install the pulley remover, Tool

T63L-1O3OO-B, on pulley hub, and

place the tool and pump in a vise as

shown in Fig. 3.

4.

Hold the pump and rotate the

tool nut counterclockwise to remove

the pulley (Fig. 3). The pulley must be

removed without in and out pressure

on the pump shaft to prevent damage

to internal thrust areas.

INSTALLATION

1.

Position the pulley to the pump

shaft and install Tool T65P-3A733-A

as shown in Fig. 4.

2.

Hold the pump and rotate the

tool nut clockwise to install the pulley

on the shaft. The pulley face will be

flush with end of pump shaft. Install

the pulley without in and out pressure

on the shaft to prevent damage to in-

ternal thrust areas.

3.

Remove the tool.

POWER STEERING PUMP

RESERVOIR REPLACEMENT

Reservoir replacement must be done

on a clean workbench. Cleanliness of

work area and tools is extremely im-

portant when repairing any hydraulic

unit. Thoroughly clean the exterior of

the pump with a suitable cleaning sol-

vent. Do not clean, wash or soak the

shaft oil seal in solvent. Plug the inlet

and outlet openings with plugs or

masking tape before cleaning the

pump exterior or removing the reser-

voir.

REMOVAL

1.

Assemble the adapter plate (Tool

T69P-3A674-A) to the bench mounted

fixture tool (T57L-5OO-A). Position

the pump and pulley on the adapter

plate, pulley facing down.

2.

Remove the outlet fitting hex nut

and the service identification tag.

3.

Invert the pump so the pulley is

facing up and remove the reservoir by

tapping around the flange with a wood

block (Fig. 5).

4.

Remove the reservoir O-ring seal

and the outlet fitting gasket from the

pump.

INSTALLATION

Tool • T 63 L-

10300 -

G 1477 A

FIG. 3—Removing Power

Steering Pump Pulley

1478 A

FIG. 4—Installing Power

Steering Pump Pulley

1.

Install a new gasket on the outlet

fitting and a new reservoir O-ring seal

on the pump housing plate (Fig. 6).

The old gasket and seal should never

be re-used.

Too/

T57L 500-A

G1602-A

FIG. 5—Removing Pump

Reservoirprocarmanuals.com

Page 165 of 413

03-10-04

Ford-Thompson Power Steering Pump

03-10-04

OUTLET FITTING

GASKET

Wood Block

0-RING SEAL

G1345-

-500-

A

G1603- A

FIG. 6—Gasket Locations

FIG.

7—Installing

Reservoir

on Pump—Typical

2.

Apply vaseline to the reservoir

O-ring seal and to the inside edge of

the new reservoir flange. Do not twist

the O-ring seal.

3.

Position the reservoir over the

pump and align the notch in the reser-

voir flange with the notch in the outer

diameter of the plate and bushing as-

sembly.

4.

Install the reservoir on the pump

and O-ring seal with a plastic or rub-

ber hammer and a block of wood as

shown in Fig. 7. Tap at the rear of the

reservoir and on the outer edges only.

5.

Inspect the assembly to be sure

the reservoir is evenly seated on the

pump housing plate.

6. Position the service identification

tag on the outlet fitting and install the

outlet fitting hex nut. Torque the nut

to specification (Part 3-13). Do not

exceed specification.

MAJOR REPAIR OPERATIONS

DISASSEMBLY

Disassembly of the pump and its

subassemblies must be made on a

clean work bench. In repairing any

hydraulically operated unit, cleanliness

is of utmost importance. Clean the ex-

terior of the unit with a suitable sol-

vent and drain as much of the fluid as

possible.

If only the reservoir is to be re-

moved, plug the inlet and outlet open-

ings with masking tape or plugs. Do

not immerse the shaft oil seal in sol-

vent. If only the rotor shaft seal is to

be replace, see Rotor Shaft Seal Re-

placement outlined in this section.

1.

Assemble the adapter plate (Tool

T69P-3A674-A) to the bench mount-

ed holding fixture Tool T57L-5OO-A

(Fig. 8).

2.

Position the pump assembly,

with pulley assembled, on the adapter

plate, pulley facing down.

3.

Remove the outlet fitting nut and

the service identification tag.

4.

Invert the pump assembly and,

using a block of wood and a rubber or

plastic hammer, remove the pump res-

ervoir and seal by tapping around the

flange of the reservoir and on the und-

erside of the filler neck.

5.

Again invert the pump assembly,

loosen and remove the pump housing

retention bolts and remove the pump

housing.

6. If necessary, remove the fol-

lowing components from the pump

housing: the housing cover, the O-ring

seal and the pressure springs. These

components normally will remain in

the pump housing when it is removed.

7.

Remove and discard the pump

cover gasket.

8. Remove the retainer end plate

and upper pressure plate (in some

pumps, the end plate and upper pres-

sure plate are integral).

9. Remove the loose fitting dowel

pin. Be careful not to bend the fixed

dowel pin which remains in the hous-

ing plate assembly.

10.

Remove the rotor assembly

being careful to prevent the springs

and slippers from falling out and be-

coming lost. Do not disassemble fur-

ther unless the lower pressure plate,

housing plate, rotor shaft and/or seal

is to be replaced.

11.

Invert the pump assembly and,

using Tool T63L-1O3OO-B, remove the

pulley.

12.

Clean any rust, road dirt, burrs,

scoring, etc. from the pulley end of

the rotor shaft prior to removal of the

shaft from the housing plate. The

shaft must come out without restric-

tions to prevent scoring or damage to

the bushing. Remove the pump rotor

shaft.

13.

Remove the lower pressure

plate.

PARTS REPAIR OR

REPLACEMENT

ROTOR SHAFT

SEAL REPLACEMENT

Removal

1.

Remove the pulley from the

rotor shaft as described under Power

Steering Pump Pulley Removal.

2.

Position the pump assembly in

T57L-500-A

T69P-3A674-A

•

G1604-A

FIG. 8—Adapter Plate Installationprocarmanuals.com

Page 166 of 413

03-10-05

Ford-Thompson Power Steering Pump

03-10-05

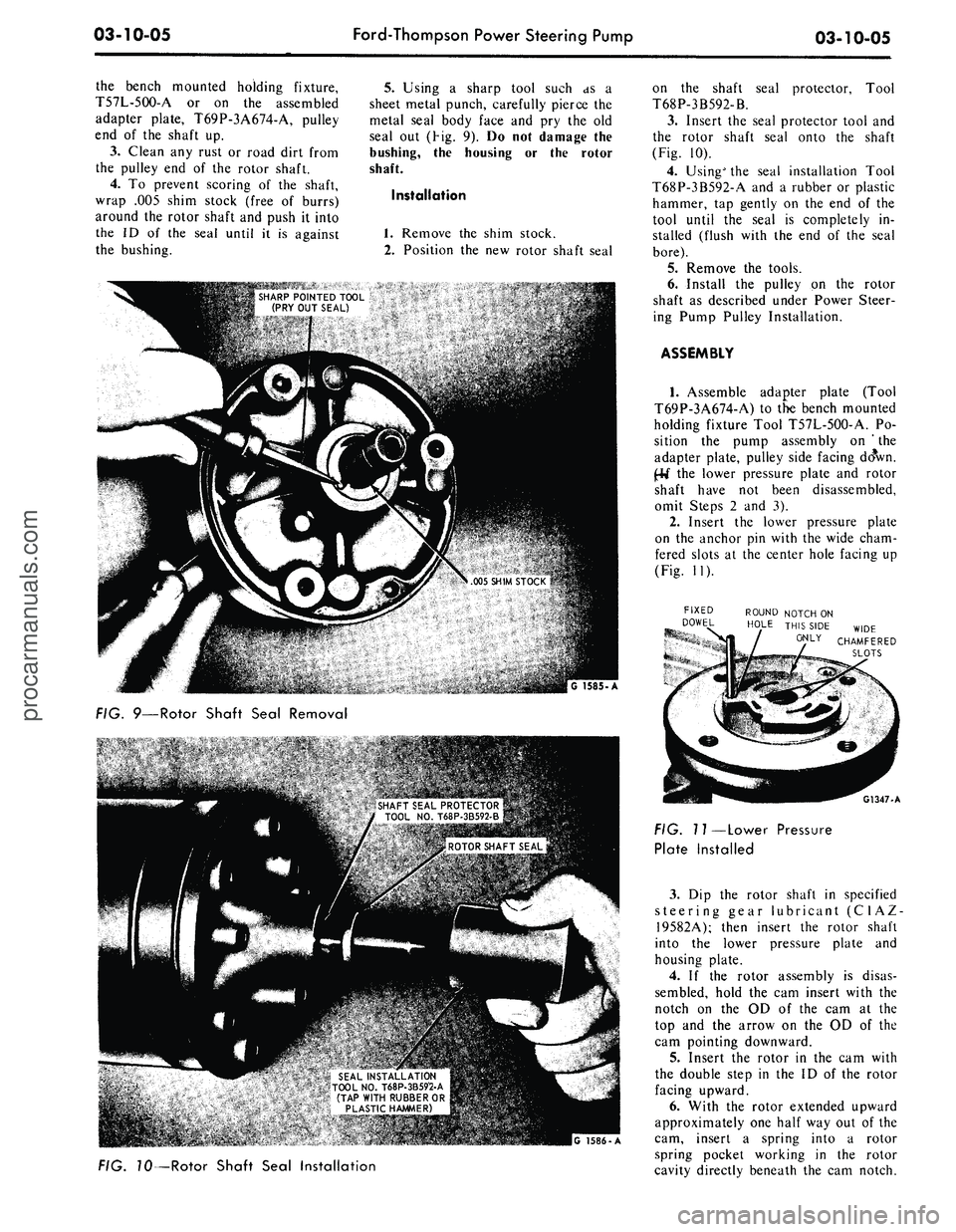

the bench mounted holding fixture,

T57L-5OO-A or on the assembled

adapter plate, T69P-3A674-A, pulley

end of the shaft up.

3.

Clean any rust or road dirt from

the pulley end of the rotor shaft.

4.

To prevent scoring of the shaft,

wrap .005 shim stock (free of burrs)

around the rotor shaft and push it into

the ID of the seal until it is against

the bushing.

5.

Using a sharp tool such as a

sheet metal punch, carefully pierce the

metal seal body face and pry the old

seal out (Hg. 9). Do not damage the

bushing, the housing or the rotor

shaft.

Installation

1.

Remove the shim stock.

2.

Position the new rotor shaft seal

.* SHARP POINTED TOOL

(PRY OUT SEAL)

FIG. 9—Rotor Shaft Seal Removal

s- •:?

. SHAFT SEAL PROTECTOR

TOOL NO. T68P-3B592-B

on the shaft seal protector, Tool

T68P-3B592-B.

3.

Insert the seal protector tool and

the rotor shaft seal onto the shaft

(Fig. 10).

4.

Using" the seal installation Tool

T68P-3B592-A and a rubber or plastic

hammer, tap gently on the end of the

tool until the seal is completely in-

stalled (flush with the end of the seal

bore).

5.

Remove the tools.

6. Install the pulley on the rotor

shaft as described under Power Steer-

ing Pump Pulley Installation.

ASSEMBLY

1.

Assemble adapter plate (Tool

T69P-3A674-A) to the bench mounted

holding fixture Tool T57L-5OO-A. Po-

sition the pump assembly on ' the

adapter plate, pulley side facing doVn.

JrM" the lower pressure plate and rotor

shaft have not been disassembled,

omit Steps 2 and 3).

2.

Insert the lower pressure plate

on the anchor pin with the wide cham-

fered slots at the center hole facing up

(Fig. 11).

FIXED ROUND NOTCH ON

DOWEL HOLE THIS SIDE WIDE

0NLY CHAMFERED

SLOTS

G1347-A

FIG. 10—Rotor Shaft Seal Installation

FIG. 11—Lower Pressure

Plate Installed

3.

Dip the rotor shaft in specified

steering gear lubricant (C1AZ

19582A); then insert the rotor shaft

into the lower pressure plate and

housing plate.

4.

If the rotor assembly is disas-

sembled, hold the cam insert with the

notch on the OD of the cam at the

top and the arrow on the OD of the

cam pointing downward.

5.

Insert the rotor in the cam with

the double step in the ID of the rotor

facing upward.

6. With the rotor extended upward

approximately one half way out of the

cam, insert a spring into a rotor

spring pocket working in the rotor

cavity directly beneath the cam notch.procarmanuals.com