parking brake FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 12 of 413

02-01-01

02-01-01

GROUP

2

PART

2-1

PAGE

General Brake Service 02-01-01

PART

2-2

Brake System 02-02-01

PART

2-3

Specifications

PAGE

02-03-01

Part

2-1

General Brake Service

COMPONENT INDEX

ANTI SKID CONTROL SYSTEM

Tests

BRAKE BOOSTER

Adjustments

Cleaning

and

Inspection

Tests

BRAKE PEDAL

Free Height Test

Total Travel Test

DISC BRAKES

Cleaning

and

Inspection

Service Precautions

DRUM BRAKES

Cleaning

and

Inspection

HYDRAULIC SYSTEM BLEEDING

PARKING BRAKE CONTROL

Vacuum Release Test

PARKING BRAKE LINKAGE

Adjustment

PRESSURE DIFFERENTIAL VALVE

Adjustment (Centralize)

MODEL APPLICATION

All

Models

01-04

01-07

01-02

01-01

01-01

01-07

01-07

01-08

01-05

01-07

Ford

N/A

01-03

01-03

Mercury

N/A

01-03

01-03

Meteor

N/A

01-03

01-03

Cougar

N/A

N/A

01-03

Fairlane

N/A

N/A

01-03

F

alcon

N/A

N/A

01-03

Montego

N/A

N/A

01-03

Mustang

N/A

N/A

01-03

Lincoln-

Continental

N/A

01-03

01-04

Thunderbird

01-03

01-03

01-04

Continental-

Mark III

01-03

01-03

01-04

A page number indicates that the item

is for the

vehicle listed

at

the head

of the

column.

N/A indicates that the item

is not

applicable

to

the vehicle listed.

1 BRAKE SYSTEM TESTS

Always check

the

fluid level

in the

master cylinder before performing

the

test procedures.

If the

fluid level

is not

within

1/4

inch

of the top of the mas-

ter cylinder reservoirs,

add

Ford

Brake Fluid

—

Extra Heavy Duty —

Part Number C6AZ-19542-A

(ESA-

M6C25-A)

or

equivalent

for all

brake

applications.

The

extra heavy duty

brake fluid

is

colored blue

for

identifi-

cation purposes.

Do not mix low tem-

perature brake fluids with

the

speci-

fied brake fluid.

Should

one of the

wheel brakes

be

locked

and the

vehicle must

be

moved,

open

the

bleeder screw long enough

to

let

out a few

drops

of

brake fluid.

This bleeding operation will release

the brakes

but

will

not

correct

the

cause

of

trouble.

BRAKE PEDAL FREE

HEIGHT

AND

TRAVEL

MEASUREMENTS

With

the

engine running

for

full

power brake operation, measure

the

brake pedal free height,

and

check

the

brake pedal travel with

the use of the

Brake Pedal Pressure Gauge, Tool

WRE-5OO-5O

as

follows:

BRAKE PEDAL FREE HEIGHT

MEASUREMENT

1.

Insert

a

slender, sharp pointed

prod through

the

carpet

and

sound

deadener

to the

dash panel metal

and

measure

the

distance

to the

brake

pedal

(Fig. 1).

2.

If the

position

of the

pedal

is not

within specification, check

the

brake

pedal linkage

for

missing, worn,

or

damaged bushings,

or

loose attaching

bolts

and

replace them,

if

required.

3.

If the

pedal free height

is

still

out

of

specification, check

the

brake

pedal booster

or

master cylinder

to be

sure

the

correct parts

are

installed.

Replace

the

worn

or

damaged parts

as

necessary.

BRAKE PEDAL TRAVEL

MEASUREMENT

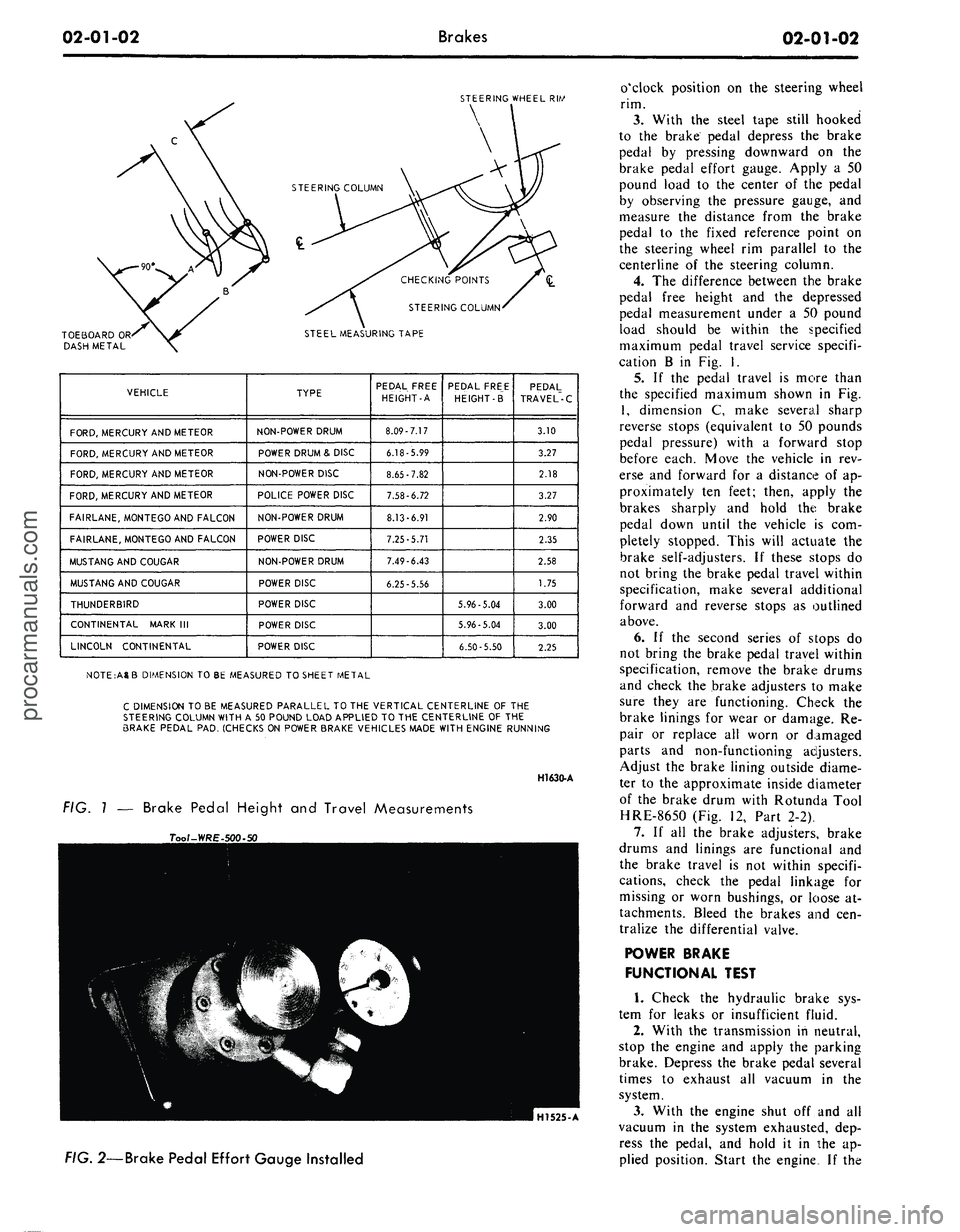

1.

Install

a

Brake Pedal Effort

Gauge

on the

brake pedal

pad

(Fig. 2).

2.

Hook

a

steel measuring tape

to

the brake pedal

as

shown

in Fig. 1.

Measure

and

record

the

distance from

the brake pedal free height position

to

the reference point, which

is at the six

procarmanuals.com

Page 13 of 413

02-01-02

Brakes

02*01-02

STEERING

WHEEL RIW

TOEBOARD

OR

DASH

METAL

CHECKING

POINTS

STEERING

COLUMN-

STEEL

MEASURING TAPE

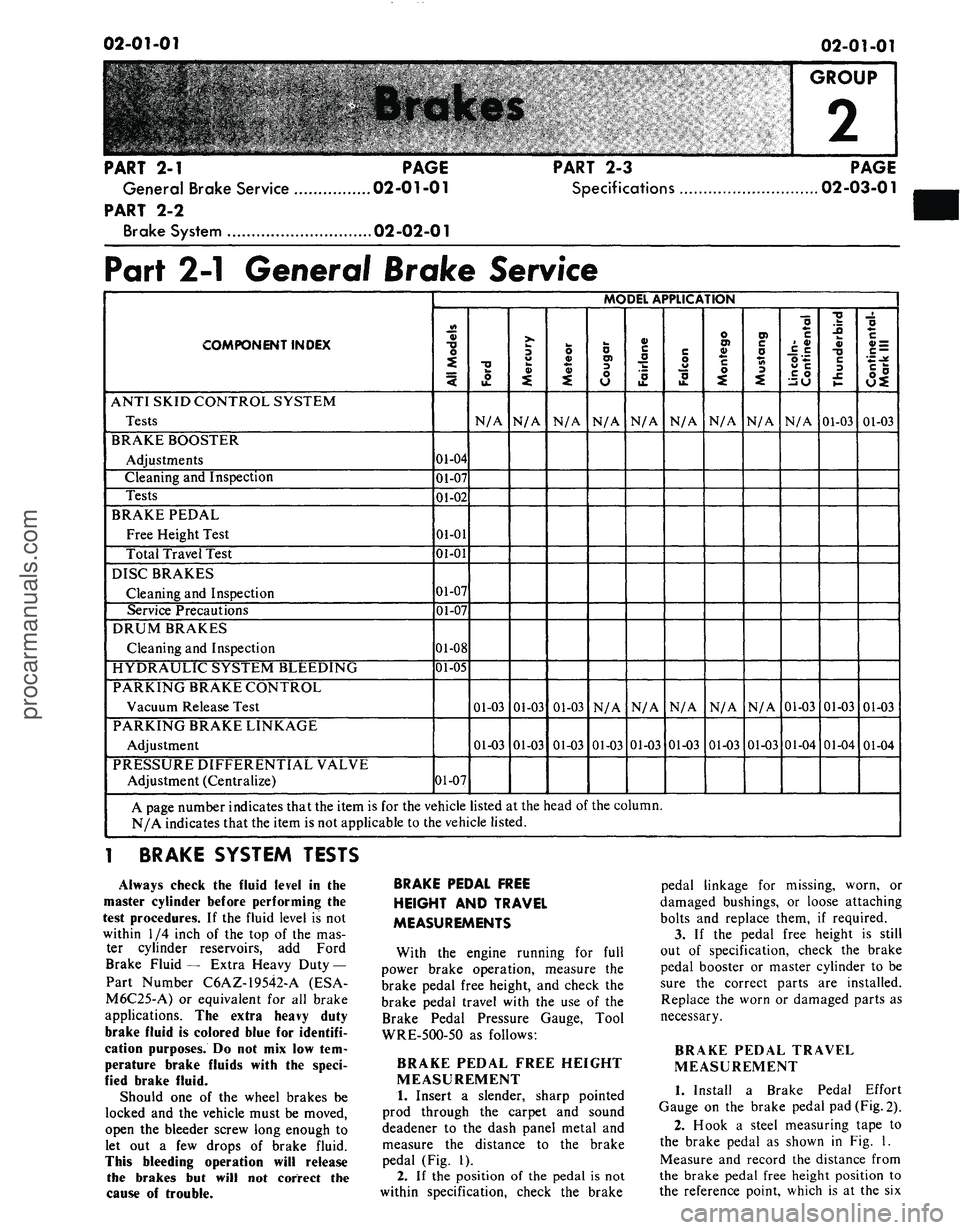

VEHICLE

FORD,

MERCURY AND METEOR

FORD,

MERCURY AND METEOR

FORD,

MERCURY AND METEOR

FORD,

MERCURY AND METEOR

FAIRLANE,

MONTEGO AND FALCON

FAIRLANE,

MONTEGO AND FALCON

MUSTANG

AND COUGAR

MUSTANG

AND COUGAR

THUNDERBIRD

CONTINENTAL

MARK III

LINCOLN

CONTINENTAL

TYPE

NON-POWER

DRUM

POWER

DRUM & DISC

NON-POWER

DISC

POLICE

POWER DISC

NON-POWER

DRUM

POWER

DISC

NON-POWER

DRUM

POWER

DISC

POWER

DISC

POWER

DISC

POWER

DISC

PEDAL

FREE

HEIGHT-A

8.09-7.17

6.18-5.99

8.65-7.82

7.58-6.72

8.13-6.91

7.25-5.71

7.49-6.43

6.25-5.56

PEDAL

FREE

HEIGHT-B"

5.96-5.04

5.96-5.04

6.50-5.50

PEDAL

TRAVEL-C

3.10

3.27

2.18

3.27

2.90

2.35

2.58

1.75

3.00

3.00

2.25

NOTE:AgB

DIMENSION TO BE MEASURED TO SHEET METAL

C

DIMENSION TO BE MEASURED PARALLEL TO THE VERTICAL CENTERLINE OF THE

STEERING

COLUMN WITH A 50 POUND LOAD APPLIED TO THE CENTERLINE OF THE

BRAKE

PEDAL PAD. (CHECKS ON POWER BRAKE VEHICLES MADE WITH ENGINE RUNNING

H1630-A

FIG. 1 — Brake Pedal Height and Travel Measurements

Tool-WRE-l

HI525-A

FIG.

2—Brake Pedal Effort Gauge Installed

o'clock position on the steering wheel

rim.

3.

With the steel tape still hooked

to the brake pedal depress the brake

pedal by pressing downward on the

brake pedal effort gauge. Apply a 50

pound load to the center of the pedal

by observing the pressure gauge, and

measure the distance from the brake

pedal to the fixed reference point on

the steering wheel rim parallel to the

centerline of the steering column.

4.

The difference between the brake

pedal free height and the depressed

pedal measurement under a 50 pound

load should be within the specified

maximum pedal travel service specifi-

cation B in Fig. I.

5.

If the pedal travel is more than

the specified maximum shown in Fig.

1,

dimension C, make several sharp

reverse stops (equivalent to 50 pounds

pedal pressure) with a forward stop

before each. Move the vehicle in rev-

erse and forward for a distance of ap-

proximately ten feet; then, apply the

brakes sharply and hold the brake

pedal down until the vehicle is com-

pletely stopped. This will actuate the

brake self-adjusters. If these stops do

not bring the brake pedal travel within

specification, make several additional

forward and reverse stops as outlined

above.

6. If the second series of stops do

not bring the brake pedal travel within

specification, remove the brake drums

and check the brake adjusters to make

sure they are functioning. Check the

brake linings for wear or damage. Re-

pair or replace all worn or damaged

parts and non-functioning adjusters.

Adjust the brake lining outside diame-

ter to the approximate inside diameter

of the brake drum with Rotunda Tool

HRE-8650 (Fig. 12, Part 2-2).

7.

If all the brake adjusters, brake

drums and linings are functional and

the brake travel is not within specifi-

cations, check the pedal linkage for

missing or worn bushings, or loose at-

tachments. Bleed the brakes and cen-

tralize the differential valve.

POWER BRAKE

FUNCTIONAL TEST

1.

Check the hydraulic brake sys-

tem for leaks or insufficient fluid.

2.

With the transmission in neutral,

stop the engine and apply the parking

brake. Depress the brake pedal several

times to exhaust all vacuum in the

system.

3.

With the engine shut off and all

vacuum in the system exhausted, dep-

ress the pedal, and hold it in the ap-

plied position. Start the engine If theprocarmanuals.com

Page 14 of 413

02-01-03

Brakes

02-01-03

vacuum system is operating, the pedal

will tend to fall away under foot pres-

sure and less pressure will be required

to hold the pedal in the applied posi-

tion. If no action is felt, the vacuum

booster system is not functioning.

If the brake pedal movement feels

spongy, bleed the hydraulic system to

remove air from the system. Refer to

Hydraulic System Bleeding, Part 1,

Section 2.

VACUUM TESTS—VACUUM

RELEASE PARKING BRAKES

Visually check the operation of the

brake linkage as the brake pedal is

depressed. Then, check the operation

of the brake linkage when the manual

release lever is activiated. These

checks should indicate whether the

manual parking brake control linkage

is operating properly or requires re-

pair or adjustment due to inability of

the parking brake to hold against

moderate vehicle movement. Perform

tests of the parking brake system and

controls after making certain the link-

age and manual controls operate

properly.

When testing a parking brake vacu-

um release system, a minimum of 10

inches of vacuum (Hg.) should be

available at all points where vacuum is

applied. This can be checked with a

Rotunda Fuel Pump Tester Gauge

(ARE345) and two Distributor Tester

hose adapters (Marked Q) connected

together with a coupling. This allows

the Fuel Pump Tester Gauge hose to

be adapted to any other vacuum hose

or rubber connector in the vacuum

systems.

Failure to maintain 10 inches of

vacuum (Hg.) during vacuum system

tests could be caused by a loose hose

connection, resulting in a vacuum

leak. When checking for vacuum be-

tween two points, trace the hose along

the entire routing to be sure it is not

crossed with another hose and con-

nected to the wrong connection.

All of the vacuum parking brake

control checks are to be performed

with the engine running at idle speed.

Leaks in the parking brake hoses or

a disconnected or improperly con-

nected hose can usually be found by

listening for a hissing sound along the

hose routings. Under no circumstances

should air pressure be applied to the

vacuum system as the actuator dia-

phragm in the parking brake vacuum

motor may be damaged.

1.

Start the engine and run it at

idle speed. With the transmission shift

control in neutral, depress the parking

brake pedal to apply the parking

brake. Move the transmission shift

control to D range and observe the

parking brake pedal to see that the

pedal moves upward and the parking

brake releases. If the parking brake

releases, the parking brake vacuum

control is working properly.

2.

If the parking brake does not re-

lease, test for vacuum at the steering

column neutral switch port in the

junction block, vacuum lines and the

parking brake release vacuum motor.

Use the Rotunda Vacuum and Fuel

Pump Tester 345. This can be accom-

plished by removing the hose from

each component and attaching it to

the vacuum gauge. Connect two dis-

tributor tester vacuum hose adapters

together with a coupling as a connec-

tor to attach the gauge. A minimum

of ten inches of vacuum is required to

actuate the parking brake vacuum

motor. Do not remove any of the vac-

uum hoses from the junction block

unless the junction block is being re-

placed, as the plastic nipples are thin

and very brittle and damage may re-

sult. If a minimum reading is not

present when checking each of the

aforementioned components, they

must be replaced.

ROAD TEST

A road test should be conducted

only when the operator is sure the

brakes will stop the vehicle.

If the road test reveals one or more

problem conditions, correct all mal-

functions of the vacuum system, brake

booster and hydraulic system prior to

removing brake drums, brake calipers,

brake shoes and linings or backing

plates.

ANTI-SKID CONTROL

SYSTEM TESTS

No adjustments or repairs are to be

performed on the skid control system.

Damaged or worn parts are to be re-

placed.

Refer to Ford Car and Truck Diag-

nosis Manual for Testing procedures.

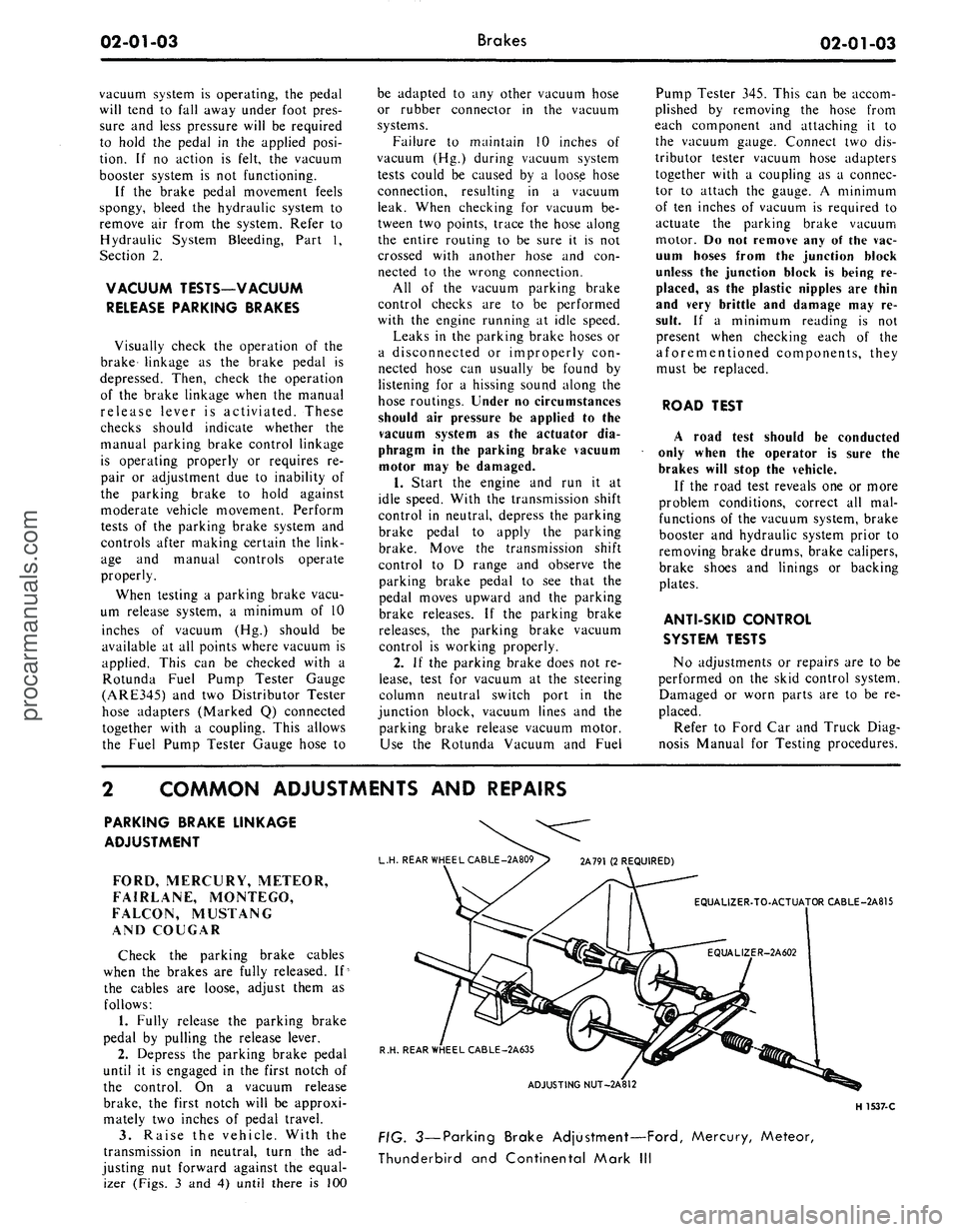

COMMON ADJUSTMENTS AND REPAIRS

PARKING BRAKE LINKAGE

ADJUSTMENT

FORD, MERCURY, METEOR,

FAIRLANE, MONTEGO,

FALCON, MUSTANG

AND COUGAR

Check the parking brake cables

when the brakes are fully released. If1

the cables are loose, adjust them as

follows:

1.

Fully release the parking brake

pedal by pulling the release lever.

2.

Depress the parking brake pedal

until it is engaged in the first notch of

the control. On a vacuum release

brake, the first notch will be approxi-

mately two inches of pedal travel.

3.

Raise the vehicle. With the

transmission in neutral, turn the ad-

justing nut forward against the equal-

izer (Figs. 3 and 4) until there is 100

L.H. REAR WHEEL CABLE -2A809> 2A791 (2 REQUIRED)

EQUALIZER-TO-ACTUATOR CABLE-2A815

R.H. REAR WHEEL CABLE-2A635

ADJUSTING NUT-2A812

H 1537-C

FIG. 3—Parking Brake Adjustment—Ford, Mercury, Meteor,

Thunderbird and Continental Mark IIIprocarmanuals.com

Page 15 of 413

02-01-04

Brakes

02-01-04

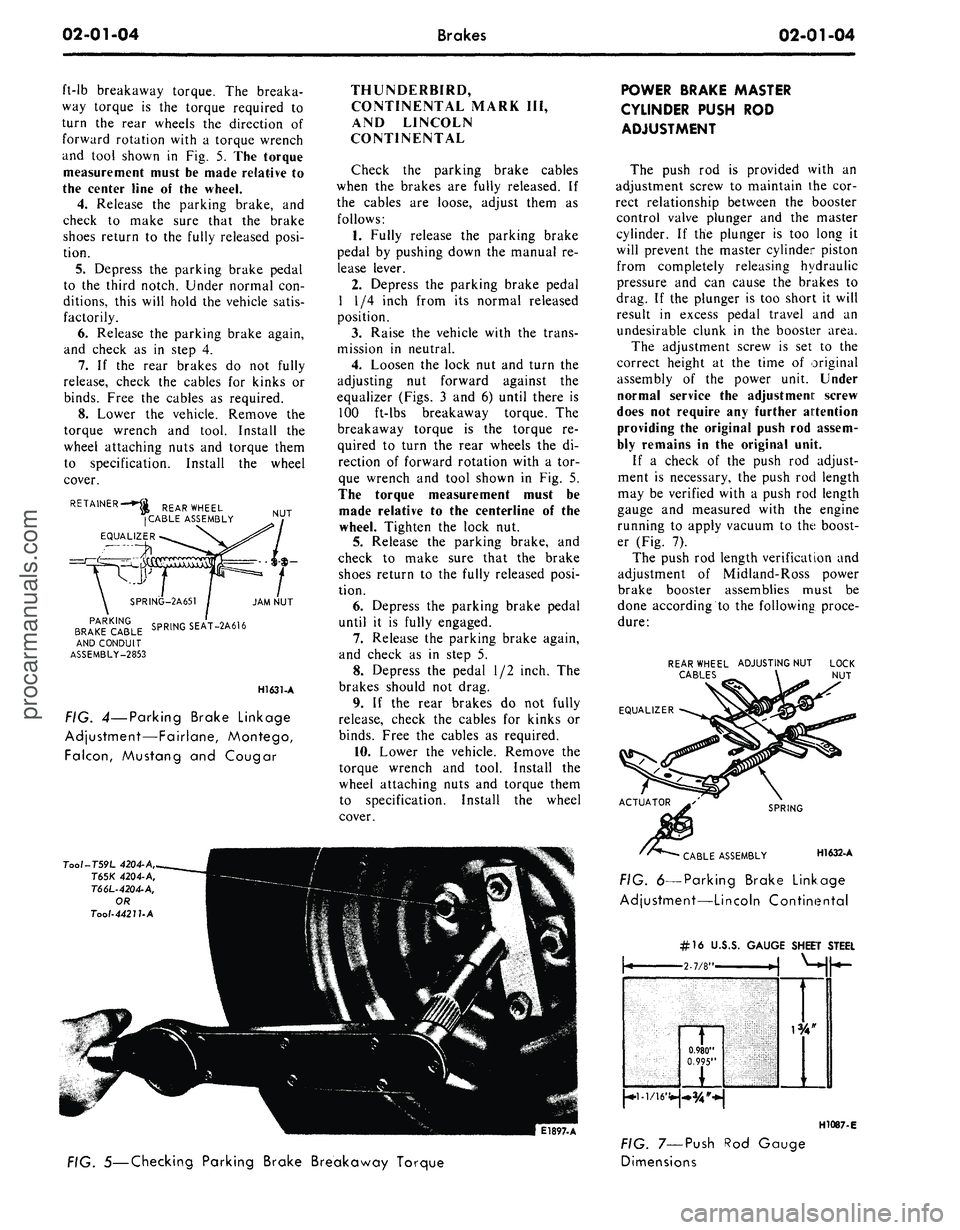

ft-lb breakaway torque.

The

breaka-

way torque

is the

torque required

to

turn

the

rear wheels

the

direction

of

forward rotation with

a

torque wrench

and tool shown

in Fig. 5. The

torque

measurement must

be

made relative

to

the center line

of the

wheel.

4.

Release

the

parking brake,

and

check

to

make sure that

the

brake

shoes return

to the

fully released posi-

tion.

5.

Depress

the

parking brake pedal

to

the

third notch. Under normal

con-

ditions, this will hold

the

vehicle satis-

factorily.

6. Release

the

parking brake again,

and check

as in

step

4.

7.

If the

rear brakes

do not

fully

release, check

the

cables

for

kinks

or

binds.

Free

the

cables

as

required.

8. Lower

the

vehicle. Remove

the

torque wrench

and

tool. Install

the

wheel attaching nuts

and

torque them

to specification. Install

the

wheel

cover.

RETAINER-*^ REAR WHEEL

(CABLE ASSEMBLY

EQUALIZER

NUT

PARKING

BRAKE CABLE

AND CONDUIT

ASSEMBLY-2853

SPRING-2A651

SPRING SEAT-2A616

JAM NUT

H1631-A

FIG. 4—Parking Brake Linkage

Adjustment—Fairlane, Montego,

Falcon,

Mustang

and

Cougar

THUNDERBIRD,

CONTINENTAL MARK

III,

AND LINCOLN

CONTINENTAL

Check

the

parking brake cables

when

the

brakes

are

fully released.

If

the cables

are

loose, adjust them

as

follows:

1.

Fully release

the

parking brake

pedal

by

pushing down

the

manual

re-

lease lever.

2.

Depress

the

parking brake pedal

1

1/4

inch from

its

normal released

position.

3.

Raise

the

vehicle with

the

trans-

mission

in

neutral.

4.

Loosen

the

lock

nut and

turn

the

adjusting

nut

forward against

the

equalizer (Figs.

3 and 6)

until there

is

100 ft-lbs breakaway torque.

The

breakaway torque

is the

torque

re-

quired

to

turn

the

rear wheels

the di-

rection

of

forward rotation with

a tor-

que wrench

and

tool shown

in Fig. 5.

The torque measurement must

be

made relative

to the

centerline

of the

wheel. Tighten

the

lock

nut.

5.

Release

the

parking brake,

and

check

to

make sure that

the

brake

shoes return

to the

fully released posi-

tion.

6. Depress

the

parking brake pedal

until

it is

fully engaged.

7.

Release

the

parking brake again,

and check

as in

step

5.

8. Depress

the

pedal

1/2

inch.

The

brakes should

not

drag.

9.

If the

rear brakes

do not

fully

release, check

the

cables

for

kinks

or

binds.

Free

the

cables

as

required.

10.

Lower

the

vehicle. Remove

the

torque wrench

and

tool. Install

the

wheel attaching nuts

and

torque them

to specification. Install

the

wheel

cover.

Tool-T59L

4204-A,

T65K

4204-A,

T66L-4204-A,

OR

Tool-4421UA

E1897-A

POWER BRAKE MASTER

CYLINDER PUSH

ROD

ADJUSTMENT

The push

rod is

provided with

an

adjustment screw

to

maintain

the cor-

rect relationship between

the

booster

control valve plunger

and the

master

cylinder.

If the

plunger

is too

long

it

will prevent

the

master cylinder piston

from completely releasing hydraulic

pressure

and can

cause

the

brakes

to

drag.

If the

plunger

is too

short

it

will

result

in

excess pedal travel

and an

undesirable clunk

in the

booster area.

The adjustment screw

is set to the

correct height

at the

time

of

original

assembly

of the

power unit. Under

normal service

the

adjustment screw

does

not

require

any

further attention

providing

the

original push

rod

assem-

bly remains

in the

original unit.

If

a

check

of the

push

rod

adjust-

ment

is

necessary,

the

push

rod

length

may

be

verified with

a

push

rod

length

gauge

and

measured with

the

engine

running

to

apply vacuum

to the

boost-

er (Fig.

7).

The push

rod

length verification

and

adjustment

of

Midland-Ross power

brake booster assemblies must

be

done according

to the

following proce-

dure:

REAR WHEEL ADJUSTING NUT

CABLES

EQUALIZER

SPRING

CABLE ASSEMBLY H1632-A

FIG. 6—Parking Brake Linkage

Adjustment—Lincoln Continental

FIG. 5—Checking Parking Brake Breakaway Torque

#16

U.J

\

0.980"

0.995"

FIG. 7—Push

Dimensions

>.S. GAUGE SHEET

i

1

STEEL

H1087-E

Rod Gaugeprocarmanuals.com

Page 21 of 413

02-02-02

Brake

System

02-02-02

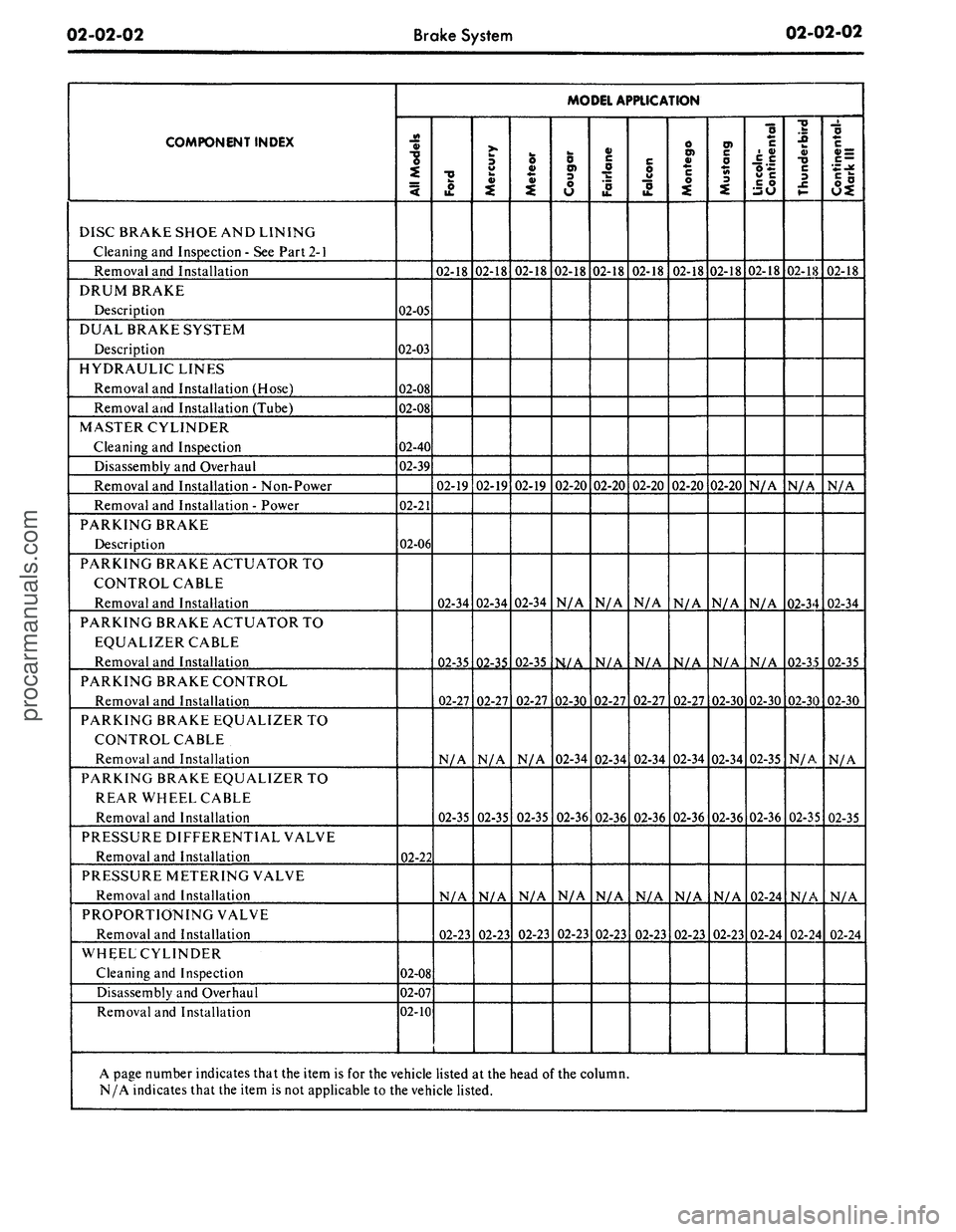

COMPONENT INDEX

DISC BRAKE SHOE AND LINING

Cleaning and Inspection

-

See

Part 2-1

Removal and Installation

DRUM BRAKE

Description

DUAL BRAKE SYSTEM

Description

HYDRAULIC LINES

Removal

and

Installation (Hose)

Removal

and

Installation (Tube)

MASTER CYLINDER

Cleaning

and

Inspection

Disassembly

and

Overhaul

Removal

and

Installation - Non-Power

Removal

and

Installation - Power

PARKING BRAKE

Description

PARKING BRAKE ACTUATOR

TO

CONTROL CABLE

Removal

and

Installation

PARKING BRAKE ACTUATOR

TO

EQUALIZER CABLE

Removal

and

Installation

PARKING BRAKE CONTROL

Removal

and

Installation

PARKING BRAKE EQUALIZER

TO

CONTROL CABLE

Removal

and

Installation

PARKING BRAKE EQUALIZER

TO

REAR WHEEL CABLE

Removal

and

Installation

PRESSURE DIFFERENTIAL VALVE

Removal

and

Installation

PRESSURE METERING VALVE

Removal

and

Installation

PROPORTIONING VALVE

Removal

and

Installation

WHEELCYLINDER

Cleaning

and

Inspection

Disassembly

and

Overhaul

Removal

and

Installation

MODEL APPLICATION

All

Models

02-05

02-03

02-08

02-08

02-40

02-39

02-21

02-06

02-22

02-08

02-07

02-10

Ford

02-18

02-19

02-34

02-35

02-27

N/A

02-35

N/A

02-23

Mercury

02-18

02-19

02-34

02-35

02-27

N/A

02-35

N/A

02-23

Meteor

02-18

02-19

02-34

02-35

02-27

N/A

02-35

N/A

02-23

Cougar

02-18

02-20

N/A

N/A

02-30

02-34

02-36

N/A

02-23

Fairlane

02-18

02-20

N/A

N/A

02-27

02-34

02-36

N/A

02-23

Falcon

02-18

02-20

N/A

N/A

02-27

02-34

02-36

N/A

02-23

Montego

02-18

02-20

N/A

N/A

02-27

02-34

02-36

N/A

02-23

Mustang

02-18

02-20

N/A

N/A

02-30

02-34

02-36

N/A

02-23

Lincoln-

Continental

02-18

N/A

N/A

N/A

02-30

02-35

02-36

02-24

02-24

Thunderbird

02-18

N/A

02-34

02-35

02-30

N/A

02-35

N/A

02-24

Continental-

Mark III

02-18

N/A

02-34

02-35

02-30

N/A

02-35

N/A

02-24

A page number indicates that the item

is for

the vehicle listed

at

the head

of

the column.

N/A indicates that the item is

not

applicable

to

the vehicle listed.

procarmanuals.com

Page 25 of 413

02-02-06

Brake

System

02-02-06

SHOE GUIDE (ANCHOR

PIN)

PLATE

SHOE GUIDE (ANCHOR

PIN)

PLATE

WASHER

PRIMARY SHOE

-TC

-ANCHOR

SPRING

PARKING

BRAKE LEVER

RETAINING

CLIP

SECONDARY

SHOE

PRIMARY

SHOE

CABLE HOOK

PARKING

BRAKE CABLE

AND HOUSING

PIVOT

NUT

AUTOMATIC

ADJUSTER

SPRING

H

1649-

A

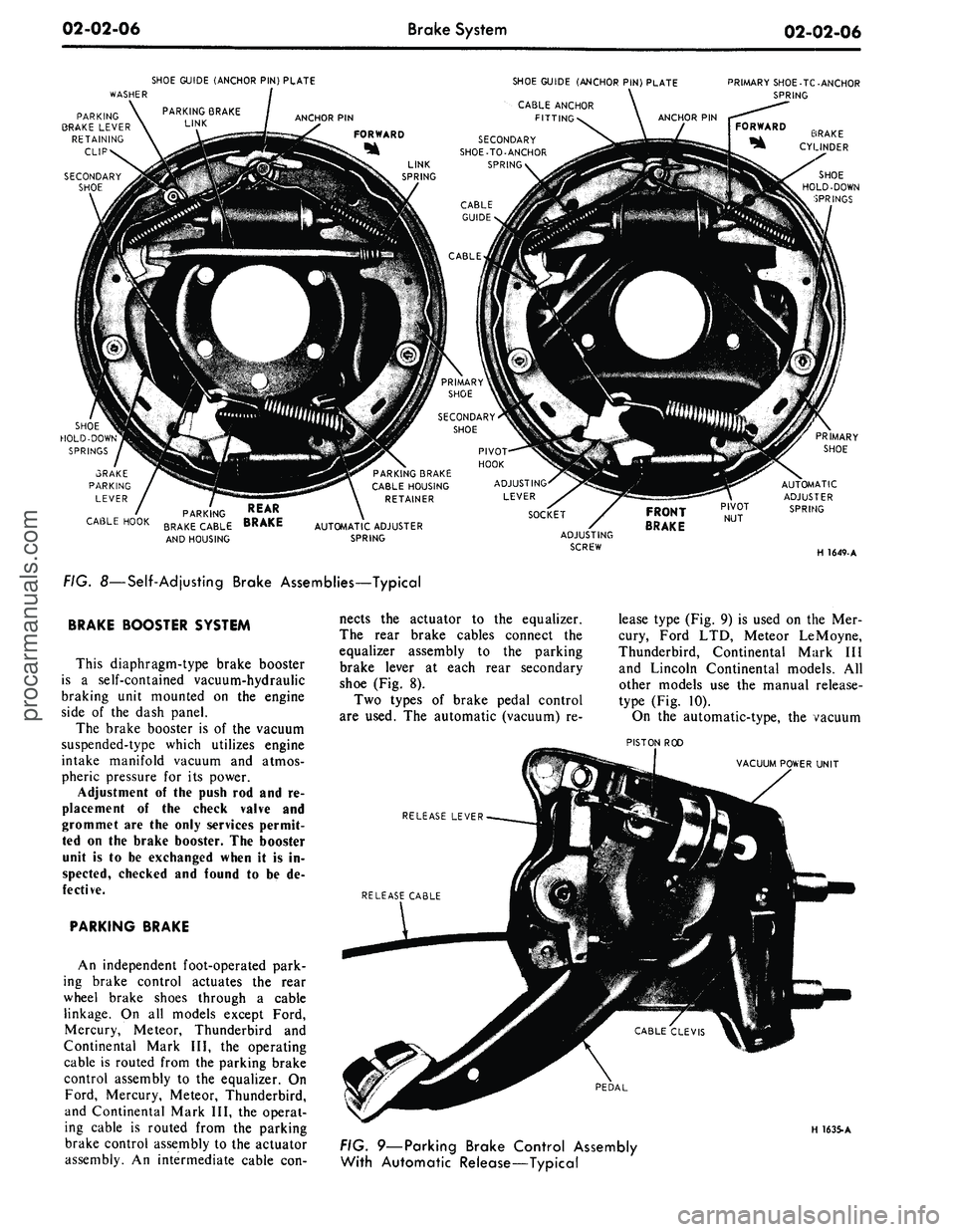

FIG. 8—Self-Adjusting Brake Assemblies—Typical

BRAKE BOOSTER SYSTEM

This diaphragm-type brake booster

is

a

self-contained vacuum-hydraulic

braking unit mounted

on the

engine

side

of the

dash panel.

The brake booster

is of the

vacuum

suspended-type which utilizes engine

intake manifold vacuum

and

atmos-

pheric pressure

for its

power.

Adjustment

of the

push

rod and re-

placement

of the

check valve

and

grommet

are the

only services permit-

ted

on the

brake booster.

The

booster

unit

is to be

exchanged when

it is in-

spected, checked

and

found

to be de-

fective.

PARKING BRAKE

An independent foot-operated park-

ing brake control actuates

the

rear

wheel brake shoes through

a

cable

linkage.

On all

models except Ford,

Mercury, Meteor, Thunderbird

and

Continental Mark

III, the

operating

cable

is

routed from

the

parking brake

control assembly

to the

equalizer.

On

Ford, Mercury, Meteor, Thunderbird,

and Continental Mark

III, the

operat-

ing cable

is

routed from

the

parking

brake control assembly

to the

actuator

assembly.

An

intermediate cable

con-

nects

the

actuator

to the

equalizer.

The rear brake cables connect

the

equalizer assembly

to the

parking

brake lever

at

each rear secondary

shoe

(Fig. 8).

Two types

of

brake pedal control

are used.

The

automatic (vacuum)

re-

lease type

(Fig. 9) is

used

on the Mer-

cury, Ford

LTD,

Meteor LeMoyne,

Thunderbird, Continental Mark

III

and Lincoln Continental models.

All

other models

use the

manual release-

type

(Fig. 10).

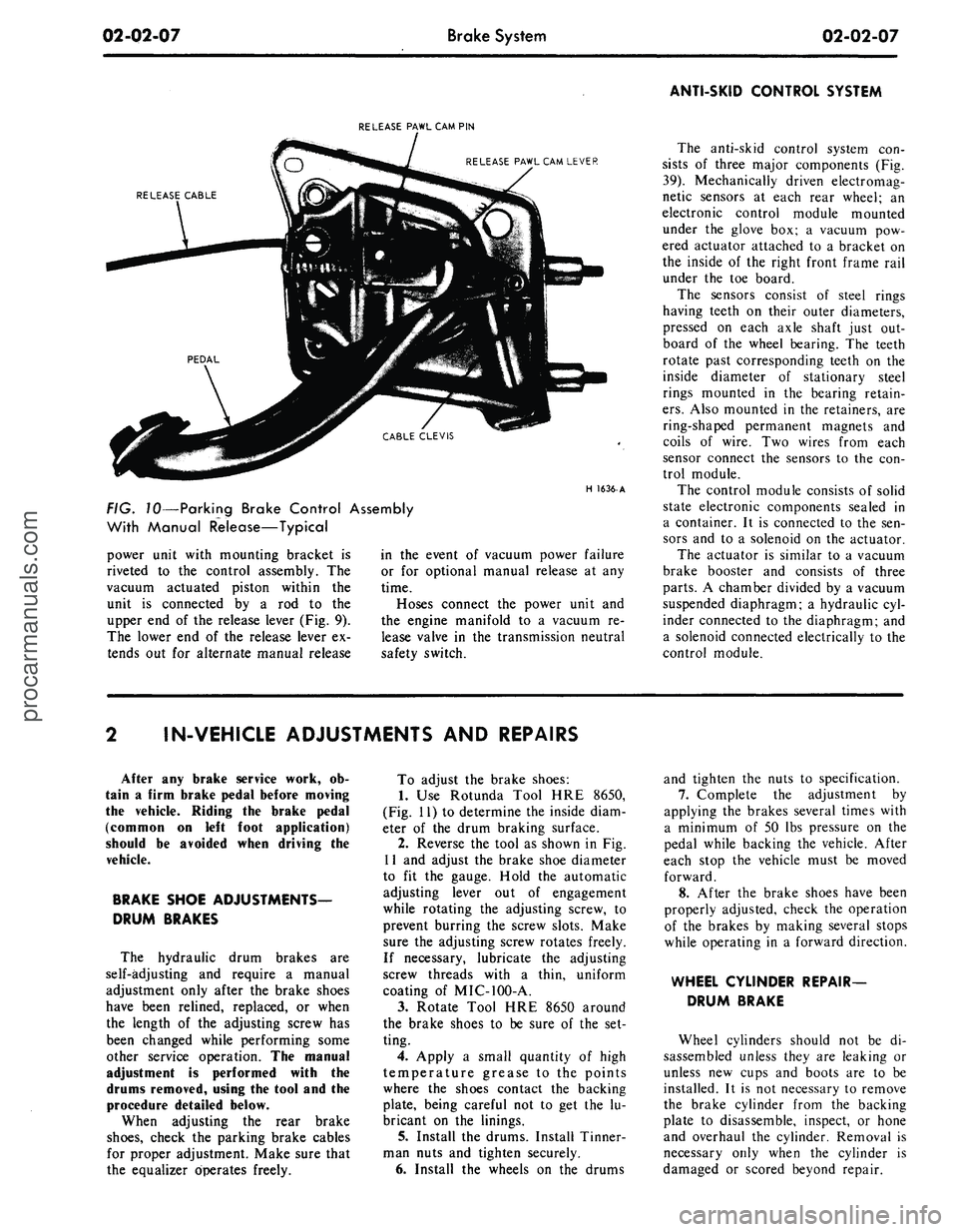

On

the

automatic-type,

the

vacuum

PISTON

ROD

VACUUM POWER UNIT

RELEASE LEVER

PEDAL

H 1635-A

FIG. 9—Parking Brake Control Assembly

With Automatic Release—Typicalprocarmanuals.com

Page 26 of 413

02-02-07

Brake System

02-02-07

ANTI-SKID CONTROL SYSTEM

RELEASE PAWL CAM PIN

RELEASE PAWL CAM LEVER

RELEASE CABLE

H

1636-

A

FIG. 10—Parking Brake Control Assembly

With Manual Release—Typical

power unit with mounting bracket is

riveted to the control assembly. The

vacuum actuated piston within the

unit is connected by a rod to the

upper end of the release lever (Fig. 9).

The lower end of the release lever ex-

tends out for alternate manual release

in the event of vacuum power failure

or for optional manual release at any

time.

Hoses connect the power unit and

the engine manifold to a vacuum re-

lease valve in the transmission neutral

safety switch.

The anti-skid control system con-

sists of three major components (Fig.

39).

Mechanically driven electromag-

netic sensors at each rear wheel; an

electronic control module mounted

under the glove box; a vacuum pow-

ered actuator attached to a bracket on

the inside of the right front frame rail

under the toe board.

The sensors consist of steel rings

having teeth on their outer diameters,

pressed on each axle shaft just out-

board of the wheel bearing. The teeth

rotate past corresponding teeth on the

inside diameter of stationary steel

rings mounted in the bearing retain-

ers.

Also mounted in the retainers, are

ring-shaped permanent magnets and

coils of wire. Two wires from each

sensor connect the sensors to the con-

trol module.

The control module consists of solid

state electronic components sealed in

a container. It is connected to the sen-

sors and to a solenoid on the actuator.

The actuator is similar to a vacuum

brake booster and consists of three

parts.

A chamber divided by a vacuum

suspended diaphragm; a hydraulic cyl-

inder connected to the diaphragm; and

a solenoid connected electrically to the

control module.

IN-VEHICLE ADJUSTMENTS AND REPAIRS

After any brake service work, ob-

tain a firm brake pedal before moving

the vehicle. Riding the brake pedal

(common on left foot application)

should be avoided when driving the

vehicle.

BRAKE SHOE ADJUSTMENTS—

DRUM BRAKES

The hydraulic drum brakes are

self-adjusting and require a manual

adjustment only after the brake shoes

have been relined, replaced, or when

the length of the adjusting screw has

been changed while performing some

other service operation. The manual

adjustment is performed with the

drums removed, using the tool and the

procedure detailed below.

When adjusting the rear brake

shoes,

check the parking brake cables

for proper adjustment. Make sure that

the equalizer operates freely.

To adjust the brake shoes:

1.

Use Rotunda Tool HRE 8650,

(Fig. 11) to determine the inside diam-

eter of the drum braking surface.

2.

Reverse the tool as shown in Fig.

11 and adjust the brake shoe diameter

to fit the gauge. Hold the automatic

adjusting lever out of engagement

while rotating the adjusting screw, to

prevent burring the screw slots. Make

sure the adjusting screw rotates freely.

If necessary, lubricate the adjusting

screw threads with a thin, uniform

coating of MIC-100-A.

3.

Rotate Tool HRE 8650 around

the brake shoes to be sure of the set-

ting.

4.

Apply a small quantity of high

temperature grease to the points

where the shoes contact the backing

plate, being careful not to get the lu-

bricant on the linings.

5. Install the drums. Install Tinner-

man nuts and tighten securely.

6. Install the wheels on the drums

and tighten the nuts to specification.

7.

Complete the adjustment by

applying the brakes several times with

a minimum of 50 lbs pressure on the

pedal while backing the vehicle. After

each stop the vehicle must be moved

forward.

8. After the brake shoes have been

properly adjusted, check the operation

of the brakes by making several stops

while operating in a forward direction.

WHEEL CYLINDER REPAIR-

DRUM BRAKE

Wheel cylinders should not be di-

sassembled unless they are leaking or

unless new cups and boots are to be

installed. It is not necessary to remove

the brake cylinder from the backing

plate to disassemble, inspect, or hone

and overhaul the cylinder. Removal is

necessary only when the cylinder is

damaged or scored beyond repair.procarmanuals.com

Page 28 of 413

02-02-09

Brake System

02-02-09

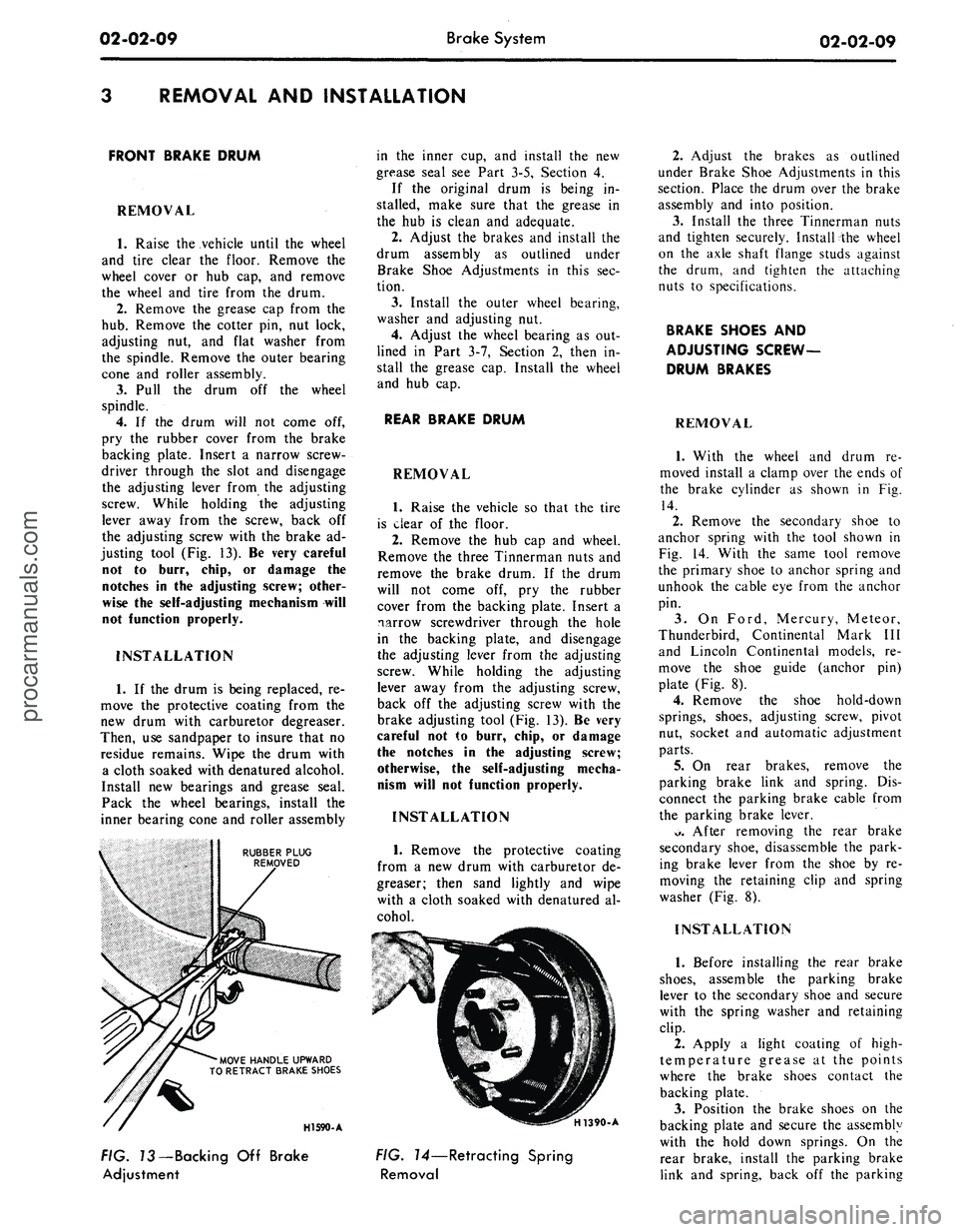

REMOVAL AND INSTALLATION

FRONT BRAKE DRUM

REMOVAL

1.

Raise the vehicle until the wheel

and tire clear the floor. Remove the

wheel cover or hub cap, and remove

the wheel and tire from the drum.

2.

Remove the grease cap from the

hub.

Remove the cotter pin, nut lock,

adjusting nut, and flat washer from

the spindle. Remove the outer bearing

cone and roller assembly.

3.

Pull the drum off the wheel

spindle.

4.

If the drum will not come off,

pry the rubber cover from the brake

backing plate. Insert a narrow screw-

driver through the slot and disengage

the adjusting lever from the adjusting

screw. While holding the adjusting

lever away from the screw, back off

the adjusting screw with the brake ad-

justing tool (Fig. 13). Be very careful

not to burr, chip, or damage the

notches in the adjusting screw; other-

wise the self-adjusting mechanism will

not function properly.

INSTALLATION

1.

If the drum is being replaced, re-

move the protective coating from the

new drum with carburetor degreaser.

Then, use sandpaper to insure that no

residue remains. Wipe the drum with

a cloth soaked with denatured alcohol.

Install new bearings and grease seal.

Pack the wheel bearings, install the

inner bearing cone and roller assembly

RUBBER PLUG

REMOVED

'MOVE HANDLE UPWARD

TO RETRACT BRAKE SHOES

in the inner cup, and install the new

grease seal see Part 3-5, Section 4.

If the original drum is being in-

stalled, make sure that the grease in

the hub is clean and adequate.

2.

Adjust the brakes and install the

drum assembly as outlined under

Brake Shoe Adjustments in this sec-

tion.

3.

Install the outer wheel bearing,

washer and adjusting nut.

4.

Adjust the wheel bearing as out-

lined in Part 3-7, Section 2, then in-

stall the grease cap. Install the wheel

and hub cap.

REAR BRAKE DRUM

REMOVAL

1.

Raise the vehicle so that the tire

is clear of the floor.

2.

Remove the hub cap and wheel.

Remove the three Tinnerman nuts and

remove the brake drum. If the drum

will not come off, pry the rubber

cover from the backing plate. Insert a

narrow screwdriver through the hole

in the backing plate, and disengage

the adjusting lever from the adjusting

screw. While holding the adjusting

lever away from the adjusting screw,

back off the adjusting screw with the

brake adjusting tool (Fig. 13). Be very

careful not to burr, chip, or damage

the notches in the adjusting screw;

otherwise, the self-adjusting mecha-

nism will not function properly.

INSTALLATION

1.

Remove the protective coating

from a new drum with carburetor de-

greaser; then sand lightly and wipe

with a cloth soaked with denatured al-

cohol.

HI 590-A

H1390-A

FIG. 73—Backing Off Brake

Adjustment

FIG. 14—Retracting Spring

Removal

2.

Adjust the brakes as outlined

under Brake Shoe Adjustments in this

section. Place the drum over the brake

assembly and into position.

3.

Install the three Tinnerman nuts

and tighten securely. Install the wheel

on the axle shaft flange studs against

the drum, and tighten the attaching

nuts to specifications.

BRAKE SHOES AND

ADJUSTING SCREW-

DRUM BRAKES

REMOVAL

1.

With the wheel and drum re-

moved install a clamp over the ends of

the brake cylinder as shown in Fig.

14.

2.

Remove the secondary shoe to

anchor spring with the tool shown in

Fig. 14. With the same tool remove

the primary shoe to anchor spring and

unhook the cable eye from the anchor

pin.

3.

On Ford, Mercury, Meteor,

Thunderbird, Continental Mark III

and Lincoln Continental models, re-

move the shoe guide (anchor pin)

plate (Fig. 8).

4.

Remove the shoe hold-down

springs, shoes, adjusting screw, pivot

nut, socket and automatic adjustment

parts.

5.

On rear brakes, remove the

parking brake link and spring. Dis-

connect the parking brake cable from

the parking brake lever.

*>.

After removing the rear brake

secondary shoe, disassemble the park-

ing brake lever from the shoe by re-

moving the retaining clip and spring

washer (Fig. 8).

INSTALLATION

1.

Before installing the rear brake

shoes,

assemble the parking brake

lever to the secondary shoe and secure

with the spring washer and retaining

clip.

2.

Apply a light coating of high-

temperature grease at the points

where the brake shoes contact the

backing plate.

3.

Position the brake shoes on the

backing plate and secure the assembly

with the hold down springs. On the

rear brake, install the parking brake

link and spring, back off the parkingprocarmanuals.com

Page 29 of 413

02-02-10

Brake System

02-02-10

brake adjustment then connect the

parking brake cable to the parking

brake lever (Fig. 8).

4.

Install the shoe guide (anchor

pin) plate on the anchor pin when so

equipped.

5.

Place the cable eye over the an-

chor pin with the crimped side toward

the backing plate.

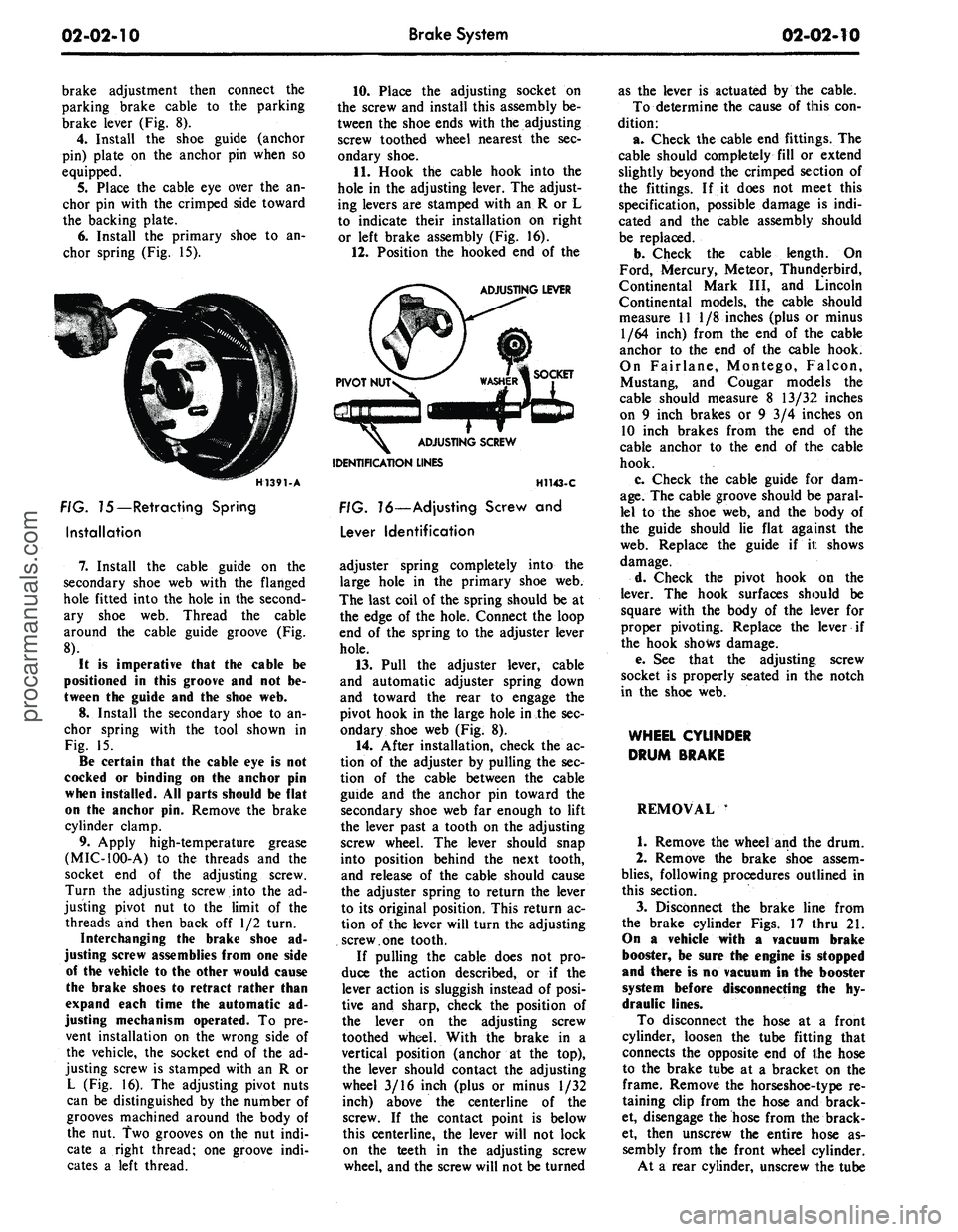

6. Install the primary shoe to an-

chor spring (Fig. 15).

H1391-A

FIG. 75—Retracting Spring

Installation

7.

Install the cable guide on the

secondary shoe web with the flanged

hole fitted into the hole in the second-

ary shoe web. Thread the cable

around the cable guide groove (Fig.

8).

It

is

imperative that

the

cable

be

positioned

in

this groove

and not be-

tween

the

guide

and the

shoe

web.

8.

Install the secondary shoe to an-

chor spring with the tool shown in

Fig. 15.

Be certain that

the

cable

eye is not

cocked

or

binding

on the

anchor

pin

when installed.

All

parts should

be

flat

on

the

anchor

pin.

Remove

the

brake

cylinder clamp.

9. Apply high-temperature grease

(MIC-100-A) to the threads and the

socket end of the adjusting screw.

Turn the adjusting screw into the ad-

justing pivot nut to the limit of the

threads and then back off 1/2 turn.

Interchanging

the

brake shoe

ad-

justing screw assemblies from

one

side

of

the

vehicle

to the

other would cause

the brake shoes

to

retract rather than

expand each time

the

automatic

ad-

justing mechanism operated.

To pre-

vent installation on the wrong side of

the vehicle, the socket end of the ad-

justing screw is stamped with an R or

L (Fig. 16). The adjusting pivot nuts

can be distinguished by the number of

grooves machined around the body of

the nut. Two grooves on the nut indi-

cate a right thread; one groove indi-

cates a left thread.

10.

Place the adjusting socket on

the screw and install this assembly be-

tween the shoe ends with the adjusting

screw toothed wheel nearest the sec-

ondary shoe.

11.

Hook the cable hook into the

hole in the adjusting lever. The adjust-

ing levers are stamped with an R or L

to indicate their installation on right

or left brake assembly (Fig. 16).

12.

Position the hooked end of the

ADJUSTING LEVER

IDENTIFICATION LINES

H1143-C

FIG. 16—Adjusting Screw

and

Lever Identification

adjuster spring completely into the

large hole in the primary shoe web.

The last coil of the spring should be at

the edge of the hole. Connect the loop

end of the spring to the adjuster lever

hole.

13.

Pull the adjuster lever, cable

and automatic adjuster spring down

and toward the rear to engage the

pivot hook in the large hole in the sec-

ondary shoe web (Fig. 8).

14.

After installation, check the ac-

tion of the adjuster by pulling the sec-

tion of the cable between the cable

guide and the anchor pin toward the

secondary shoe web far enough to lift

the lever past a tooth on the adjusting

screw wheel. The lever should snap

into position behind the next tooth,

and release of the cable should cause

the adjuster spring to return the lever

to its original position. This return ac-

tion of the lever will turn the adjusting

screw.one tooth.

If pulling the cable does not pro-

duce the action described, or if the

lever action is sluggish instead of posi-

tive and sharp, check the position of

the lever on the adjusting screw

toothed wheel. With the brake in a

vertical position (anchor at the top),

the lever should contact the adjusting

wheel 3/16 inch (plus or minus 1/32

inch) above the centerline of the

screw. If the contact point is below

this centerline, the lever will not lock

on the teeth in the adjusting screw

wheel, and the screw will not be turned

as the lever is actuated by the cable.

To determine the cause of this con-

dition:

a. Check the cable end fittings. The

cable should completely fill or extend

slightly beyond the crimped section of

the fittings. If it does not meet this

specification, possible damage is indi-

cated and the cable assembly should

be replaced.

b.

Check the cable length. On

Ford, Mercury, Meteor, Thunderbird,

Continental Mark III, and Lincoln

Continental models, the cable should

measure 11 1/8 inches (plus or minus

1/64 inch) from the end of the cable

anchor to the end of the cable hook.

On Fairlane, Montego, Falcon,

Mustang, and Cougar models the

cable should measure 8 13/32 inches

on 9 inch brakes or 9 3/4 inches on

10 inch brakes from the end of the

cable anchor to the end of the cable

hook.

c. Check the cable guide for dam-

age.

The cable groove should be paral-

lel to the shoe web, and the body of

the guide should lie flat against the

web.

Replace the guide if it shows

damage.

d. Check the pivot hook on the

lever. The hook surfaces should be

square with the body of the lever for

proper pivoting. Replace the lever if

the hook shows damage.

e. See that the adjusting; screw

socket is properly seated in the notch

in the shoe web.

WHEEL CYLINDER

DRUM BRAKE

REMOVAL '

1.

Remove the wheel and the drum.

2.

Remove the brake shoe assem-

blies,

following procedures outlined in

this section.

3.

Disconnect the brake line from

the brake cylinder Figs. 17 thru 21.

On

a

vehicle with

a

vacuum brake

booster,

be

sure

the

engine

is

stopped

and there

is no

vacuum

in the

booster

system before disconnecting

the hy-

draulic lines.

To disconnect the hose at a front

cylinder, loosen the tube fitting that

connects the opposite end of the hose

to the brake tube at a bracket on the

frame. Remove the horseshoe-type re-

taining clip from the hose and brack-

et, disengage the hose from the brack-

et, then unscrew the entire hose as-

sembly from the front wheel cylinder.

At a rear cylinder, unscrew the tubeprocarmanuals.com

Page 35 of 413

02-02-16

Brake System

02-02-16

fitting that connects the tube to the

cylinder. Do not pull the metal tube

away from the cylinder. Pulling the

tube out of the cylinder connection

will bend the metal tube and make in-

stallation difficult. The tube will sepa-

rate from the cylinder when the cylin-

der is removed from the backing

plate.

4.

On all except the front wheels on

Ford, Mercury, and Meteor models,

remove the wheel cylinder attaching

bolts and lock washers and remove the

cylinder. On the front wheel of Ford,

Mercury and Meteor models, remove

the nut and washer that attaches the

cylinder to the anchor pin. Remove

the cylinder from the anchor pin.

INSTALLATION

Wipe the end(s) of the hydraulic

line to remove any foreign matter be-

fore making connections.

1.

On all models except Ford, Mer-

cury and Meteor, to install a front

wheel cylinder, position the cylinder to

the backing plate. Install the two lock

washers and attaching bolts. Torque

them to specifications.

On Ford, Mercury and Meteor

models, to install a front wheel cylin-

der, position the cylinder on the an-

chor pin against the backing plate. In-

stall the washer and cylinder attaching

nut on the anchor pin, and torque it

to specification. Lock the washer re-

tainer securely.

2.

Install a new copper gasket over

the hose fitting. Thread the hose into

the cylinder and tighten it to specified

torque.

3.

Engage the opposite end of the

hose to the bracket on the frame. In-

stall the horseshoe-type retaining clip,

and connect the brake tube to the

hose with the tube fitting nut. Tighten

the nut to specification with tool

1112-144.

4.

To install a rear wheel cylinder,

place the rear wheel cylinder into po-

sition. Enter the tubing into the cylin-

der, and start the tube fitting nut into

the threads of the cylinder.

5.

Secure the cylinder to the back-

ing plate by installing the attaching

bolts and lock washers.

6. Tighten the tube fitting nut to

specification with tool 1112-144.

7.

Install the links in the ends of

the wheel cylinder, install the shoes

and adjuster assemblies, and adjust

the shoes as outlined in this section.

8. Adjust the brakes (Part 2-2, Sec-

tion 2). Install the brake drum and

wheel. Bleed the brakes and centralize

the differential valve as outlined in

Part 2-1, Section 2.

BRAKE BACKING PLATE

DRUM BRAKE

REMOVAL

1.

Remove the wheel and brake

drum. Disconnect the brake line from

the brake cylinder.

2.

Remove the brake shoe and ad-

juster assemblies and the wheel cylin-

der as outlined in this section. On the

rear wheels, disconnect the parking

brake lever from the cable.

3.

If the rear backing plate is being

replaced, remove the axle shaft from

the applicable rear axle as outlined in

Group 4, Part 4-2— Rear Axle, Sec-

tion 2, disengage parking brake cable

retainer from backing plate. Remove

the backing plate and gasket.

If the front backing plate is being

replaced, remove the bolts and nuts

that secure the backing plate to the

front wheel spindle and remove the

plate and gasket.

INSTALLATION

If a rear backing plate is to be re-

placed, position a new rear backing

plate and gasket on the attaching

bolts in the axle housing flange. Insert

parking brake cable into backing plate

and secure retaining fingers. Install

the rear axle shaft for applicable rear

axle.

Refer to Group 4, Part 4-2 —

Rear Axle, Section 2 for the proper

installation procedure.

1.

If the front brake backing plate

is to be replaced, position a new front

backing plate and gasket to the wheel

spindle and install the attaching bolts

and nuts.

2.

Install the wheel cylinder and

connect the brake line as outlined in

this section.

3.

Install the brake shoe and ad-

juster assemblies as outlined in this

section. On a rear brake, connect the

parking brake cable to the lever.

4.

Adjust the brake shoes (Section

2),

and install the brake drums and

wheels. Bleed the brake system and

centralize the differential valve as out-

lined in Part 2-1, Section 2.

DISC BRAKE CALIPER

ASSEMBLY

ALL MODELS EXCEPT

LINCOLN CONTINENTAL

Removal

Refer to Figs. 22 and 23.

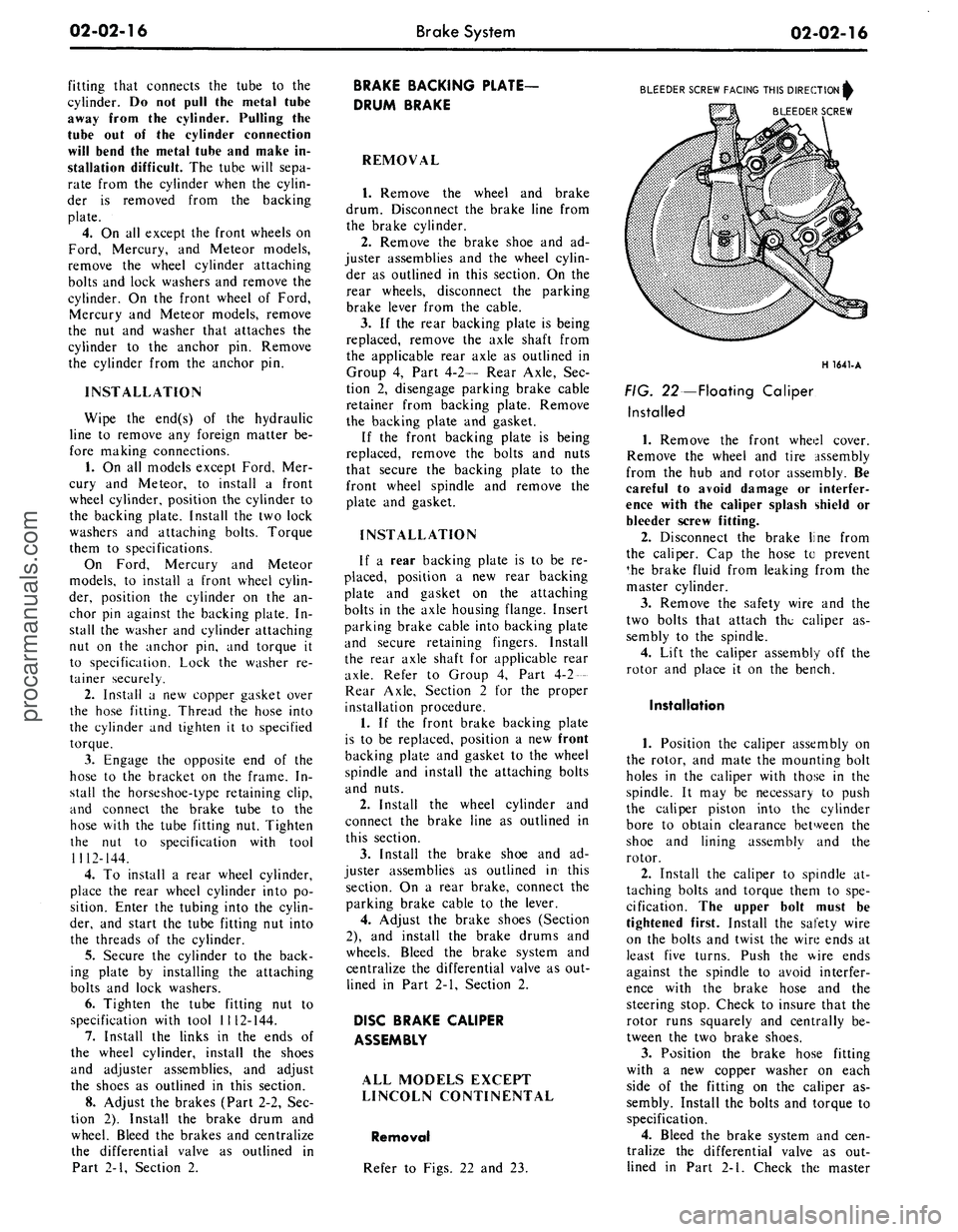

BLEEDER SCREW FACING THIS DIRECTION^

BLEEDER SCREW

H 1641-A

FIG. 22—Floating Caliper

Installed

1.

Remove the front wheel cover.

Remove the wheel and tire assembly

from the hub and rotor assembly. Be

careful to avoid damage or interfer-

ence with the caliper splash shield or

bleeder screw fitting.

2.

Disconnect the brake line from

the caliper. Cap the hose to prevent

*he brake fluid from leaking from the

master cylinder.

3.

Remove the safety wire and the

two bolts that attach the caliper as-

sembly to the spindle.

4.

Lift the caliper assembly off the

rotor and place it on the bench.

Installation

1.

Position the caliper assembly on

the rotor, and mate the mounting bolt

holes in the caliper with those in the

spindle. It may be necessary to push

the caliper piston into the cylinder

bore to obtain clearance between the

shoe and lining assembly and the

rotor.

2.

Install the caliper to spindle at-

taching bolts and torque them to spe-

cification. The upper bolt must be

tightened first. Install the safety wire

on the bolts and twist the wire ends at

least five turns. Push the wire ends

against the spindle to avoid interfer-

ence with the brake hose and the

steering stop. Check to insure that the

rotor runs squarely and centrally be-

tween the two brake shoes.

3.

Position the brake hose fitting

with a new copper washer on each

side of the fitting on the caliper as-

sembly. Install the bolts and torque to

specification.

4.

Bleed the brake system and cen-

tralize the differential valve as out-

lined in Part 2-1. Check the masterprocarmanuals.com