FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

Manufacturer: FORD, Model Year: 2006,

Model line: TRANSIT,

Model: FORD TRANSIT 2006 7.G

Pages: 234, PDF Size: 33.19 MB

FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

TRANSIT 2006 7.G

FORD

FORD

https://www.carmanualsonline.info/img/11/5471/w960_5471-0.png

FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

Trending: charging, stop start, navigation, tow bar, torque, tire size, power steering

Page 181 of 234

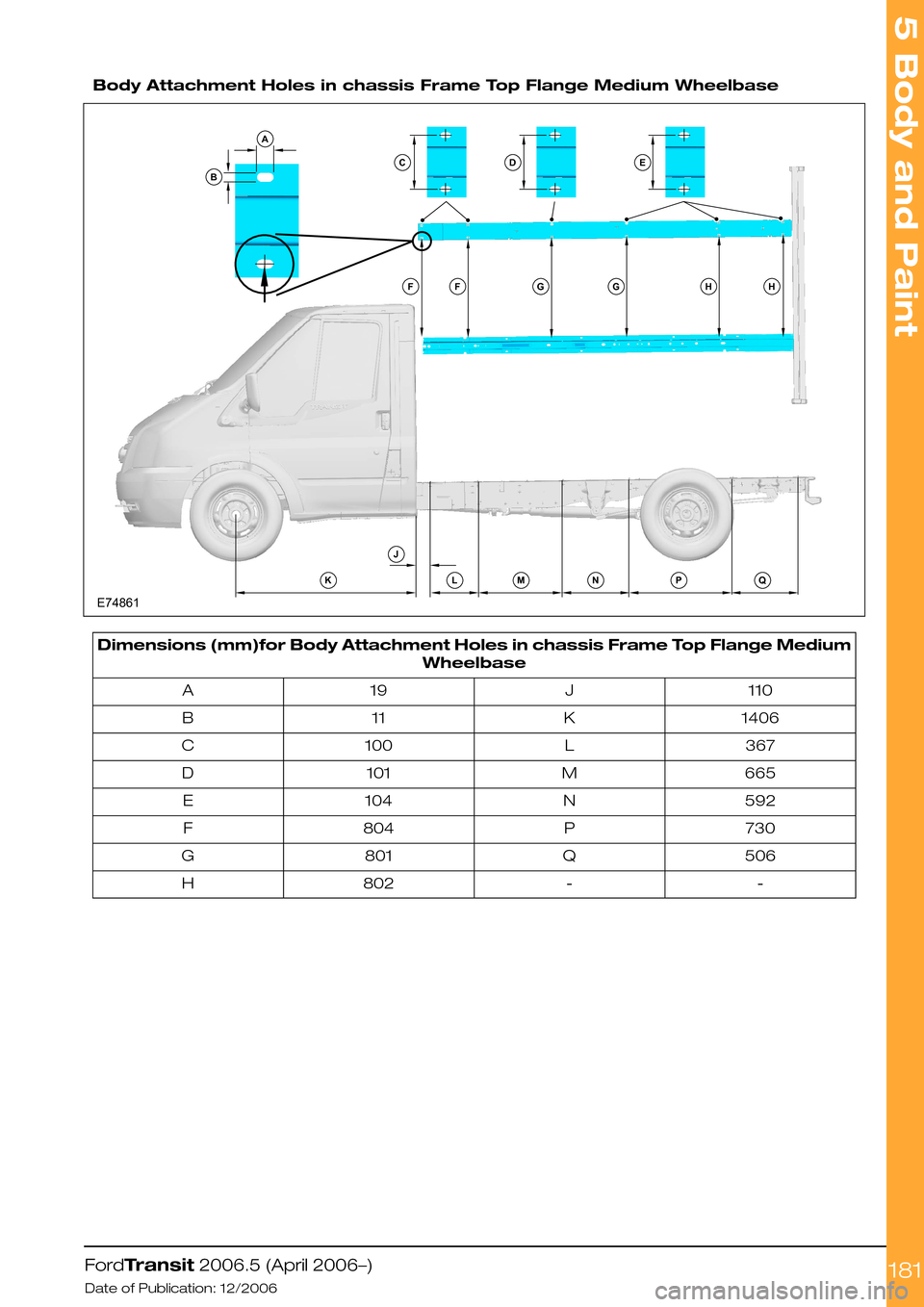

Body Attachment Holes in chassis Frame Top Flange Medium Wheelbase

Dimensions (mm)for Body Attachment Holes in chassis Frame Top Flange Medium

Wheelbase

110J19A

1406K11B

367L100C

665M101D

592N104E

730P804F

506Q801G

--802H

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

181E74861ABCFJKLMNPQFGGHHDE

Page 182 of 234

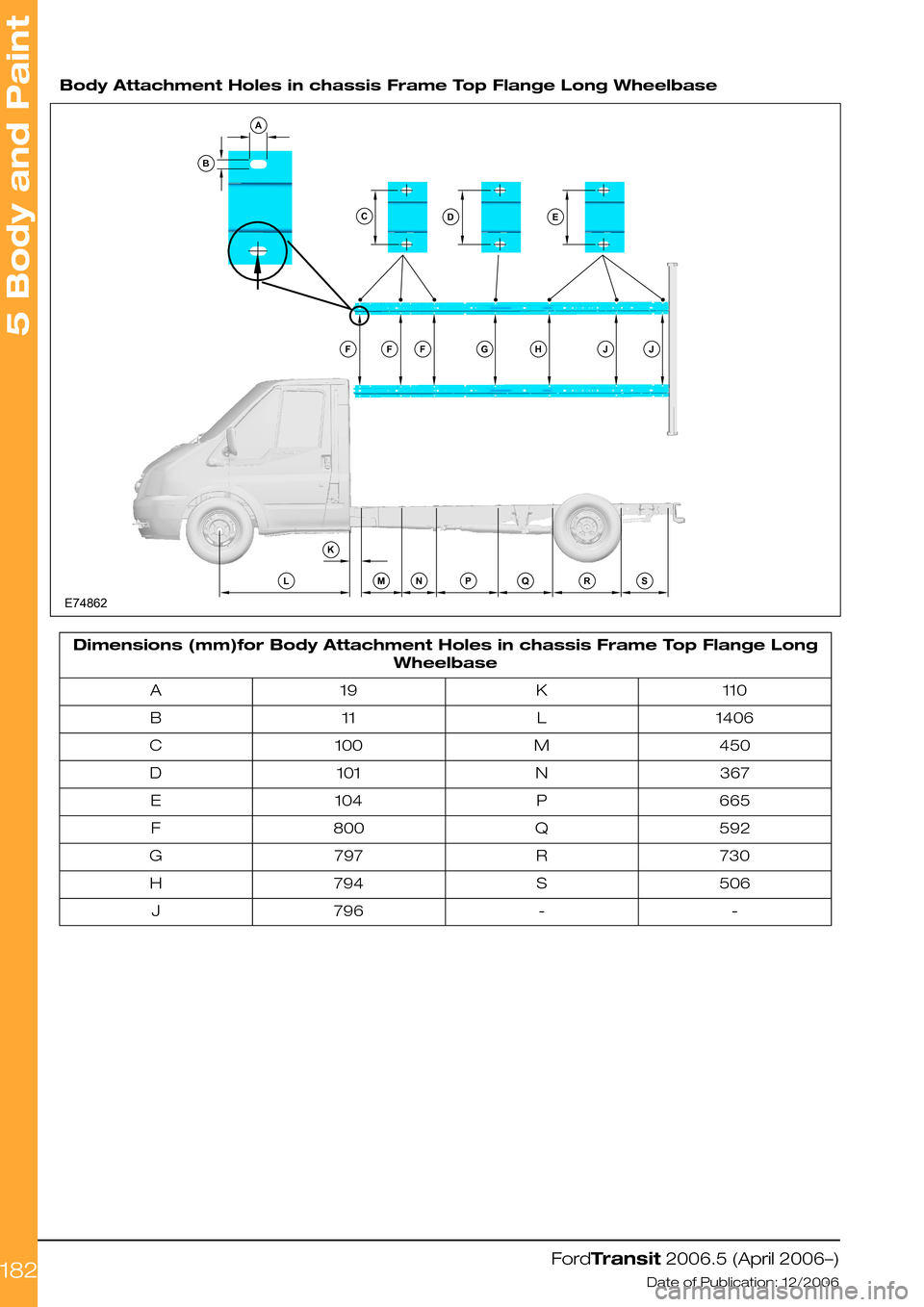

Body Attachment Holes in chassis Frame Top Flange Long Wheelbase

Dimensions (mm)for Body Attachment Holes in chassis Frame Top Flange Long

Wheelbase

110K19A

1406L11B

450M100C

367N101D

665P104E

592Q800F

730R797G

506S794H

--796J

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

182E74862ABFKLMNPQRSFFGHJJCDE

Page 183 of 234

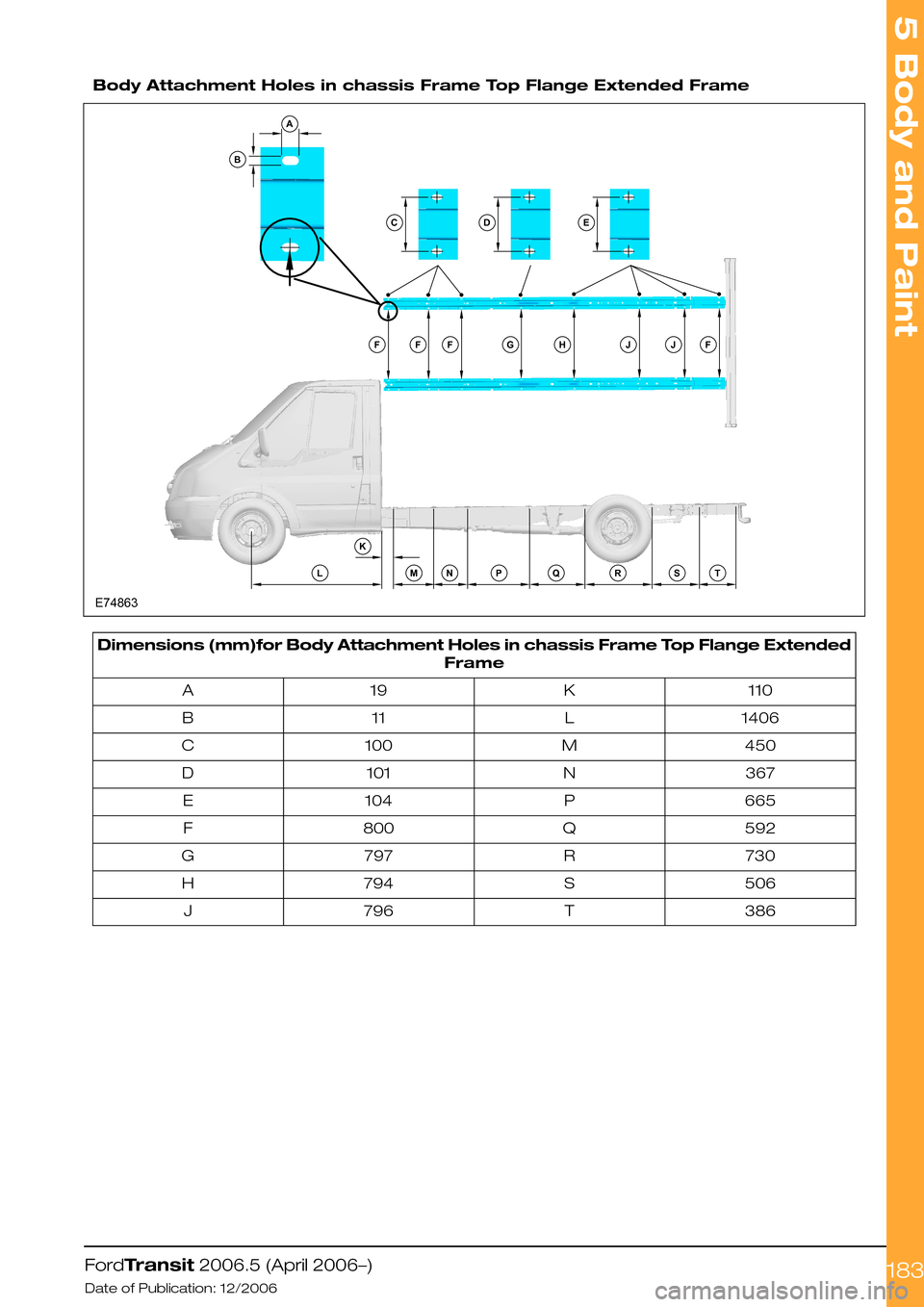

Body Attachment Holes in chassis Frame Top Flange Extended Frame

Dimensions (mm)for Body Attachment Holes in chassis Frame Top Flange Extended

Frame

110K19A

1406L11B

450M100C

367N101D

665P104E

592Q800F

730R797G

506S794H

386T796J

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

183E74863ABCFKLMNPQRSTFFGHJJFDE

Page 184 of 234

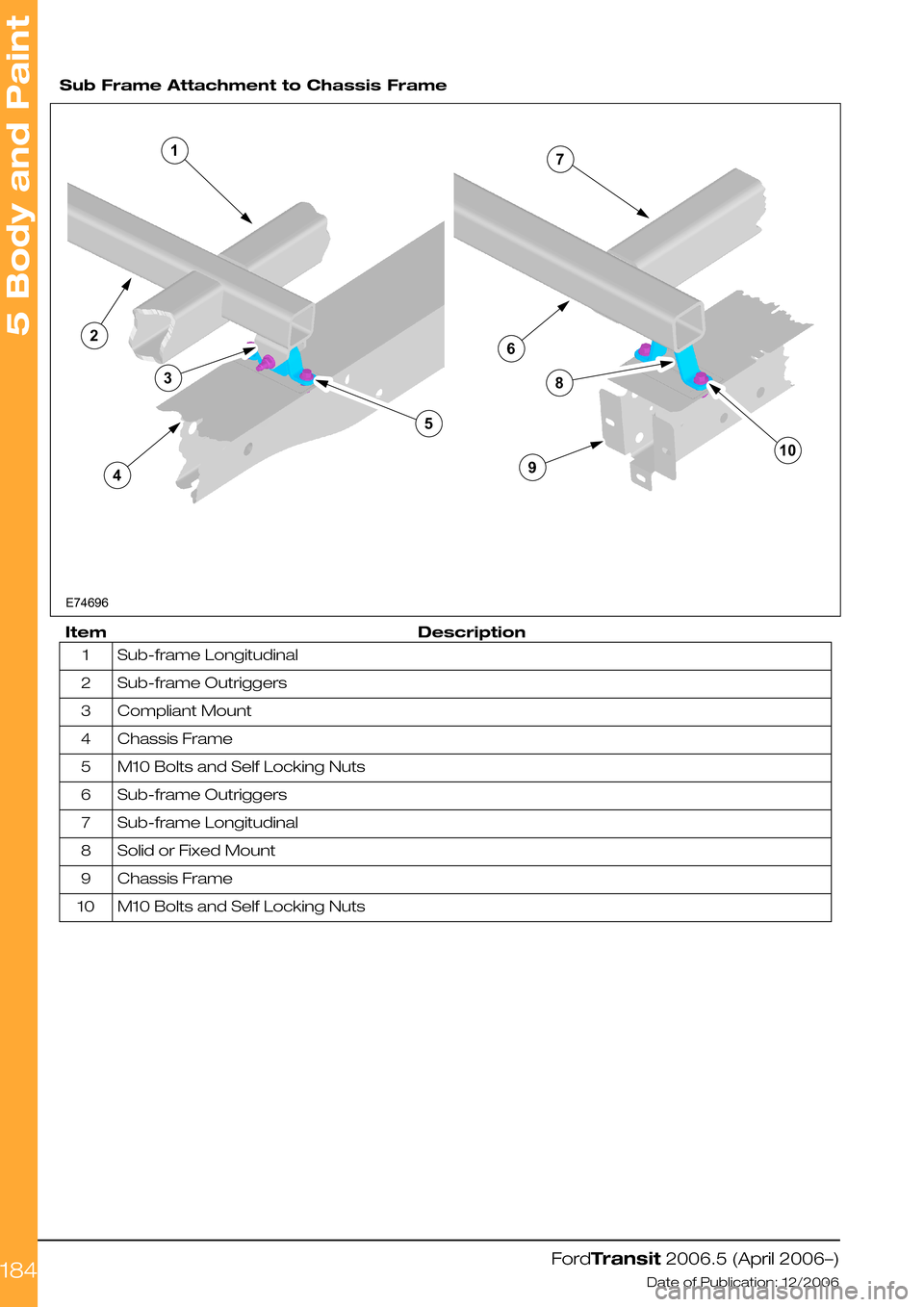

Sub Frame Attachment to Chassis Frame

DescriptionItem

Sub-frame Longitudinal1

Sub-frame Outriggers2

Compliant Mount3

Chassis Frame4

M10 Bolts and Self Locking Nuts5

Sub-frame Outriggers6

Sub-frame Longitudinal7

Solid or Fixed Mount8

Chassis Frame9

M10 Bolts and Self Locking Nuts10

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

184E7469617689102345

Page 185 of 234

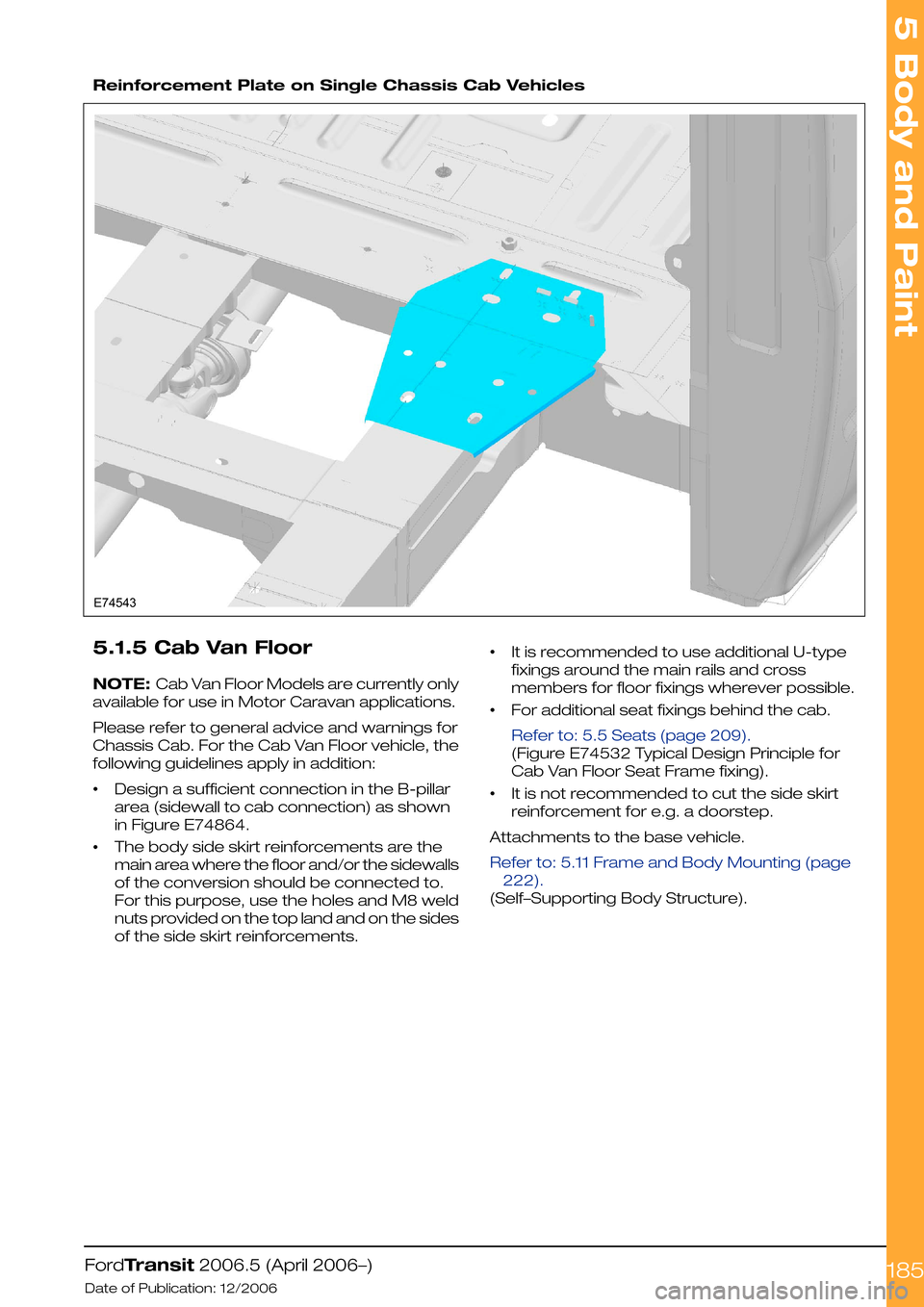

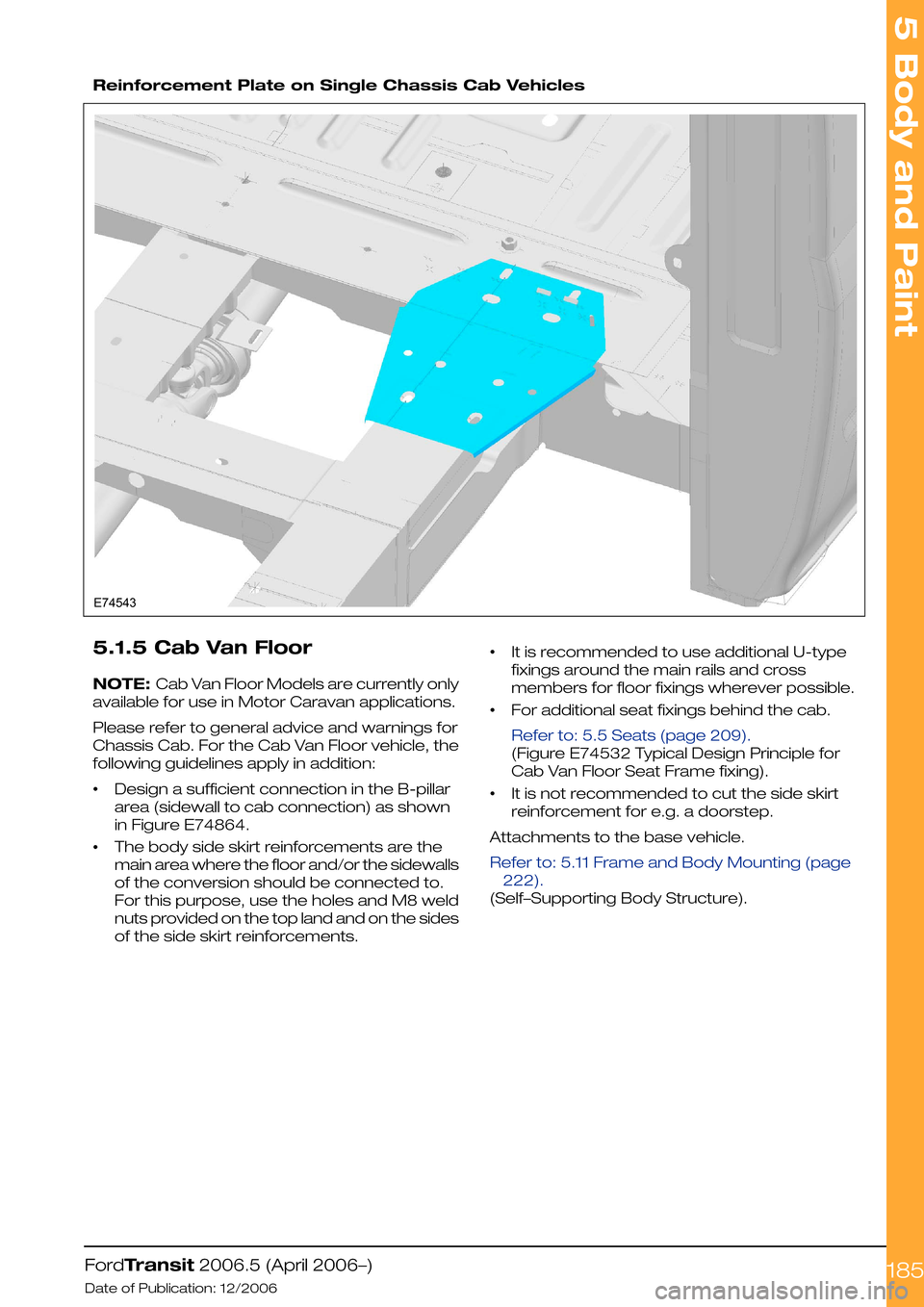

Reinforcement Plate on Single Chassis Cab Vehicles

5.1.5 Cab Van Floor

NOTE: Cab Van Floor Models are currently only

available for use in Motor Caravan applications.

Please refer to general advice and warnings for

Chassis Cab. For the Cab Van Floor vehicle, the

following guidelines apply in addition:

•Design a sufficient connection in the B-pillar

area (sidewall to cab connection) as shown

in Figure E74864.

•The body side skirt reinforcements are the

main area where the floor and/or the sidewalls

of the conversion should be connected to.

For this purpose, use the holes and M8 weld

nuts provided on the top land and on the sides

of the side skirt reinforcements.

•It is recommended to use additional U-type

fixings around the main rails and cross

members for floor fixings wherever possible.

•For additional seat fixings behind the cab.

Refer to: 5.5 Seats (page 209).

(Figure E74532 Typical Design Principle for

Cab Van Floor Seat Frame fixing).

•It is not recommended to cut the side skirt

reinforcement for e.g. a doorstep.

Attachments to the base vehicle.

Refer to: 5.11 Frame and Body Mounting (page

222).

(Self–Supporting Body Structure).

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

185E74543

Page 186 of 234

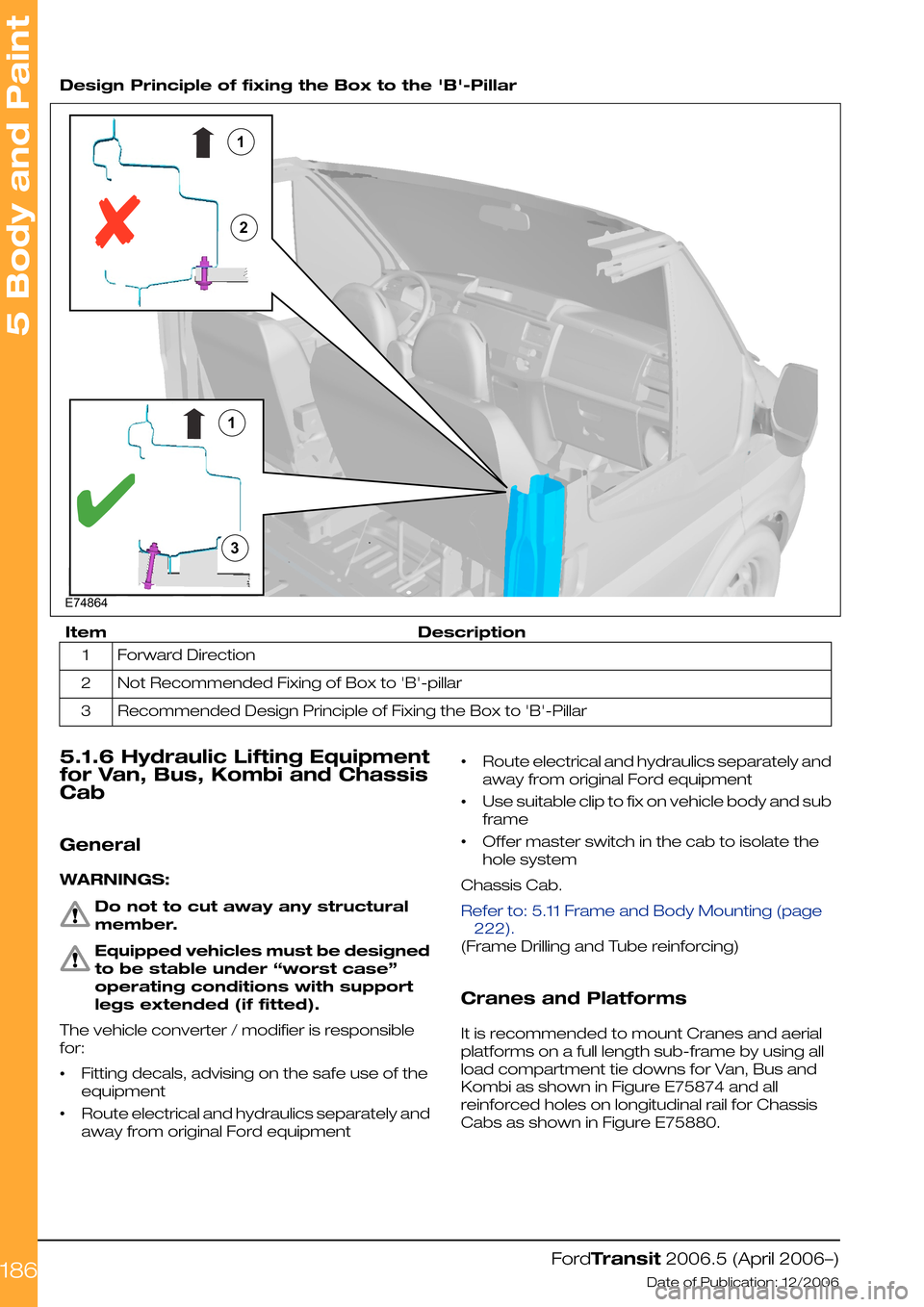

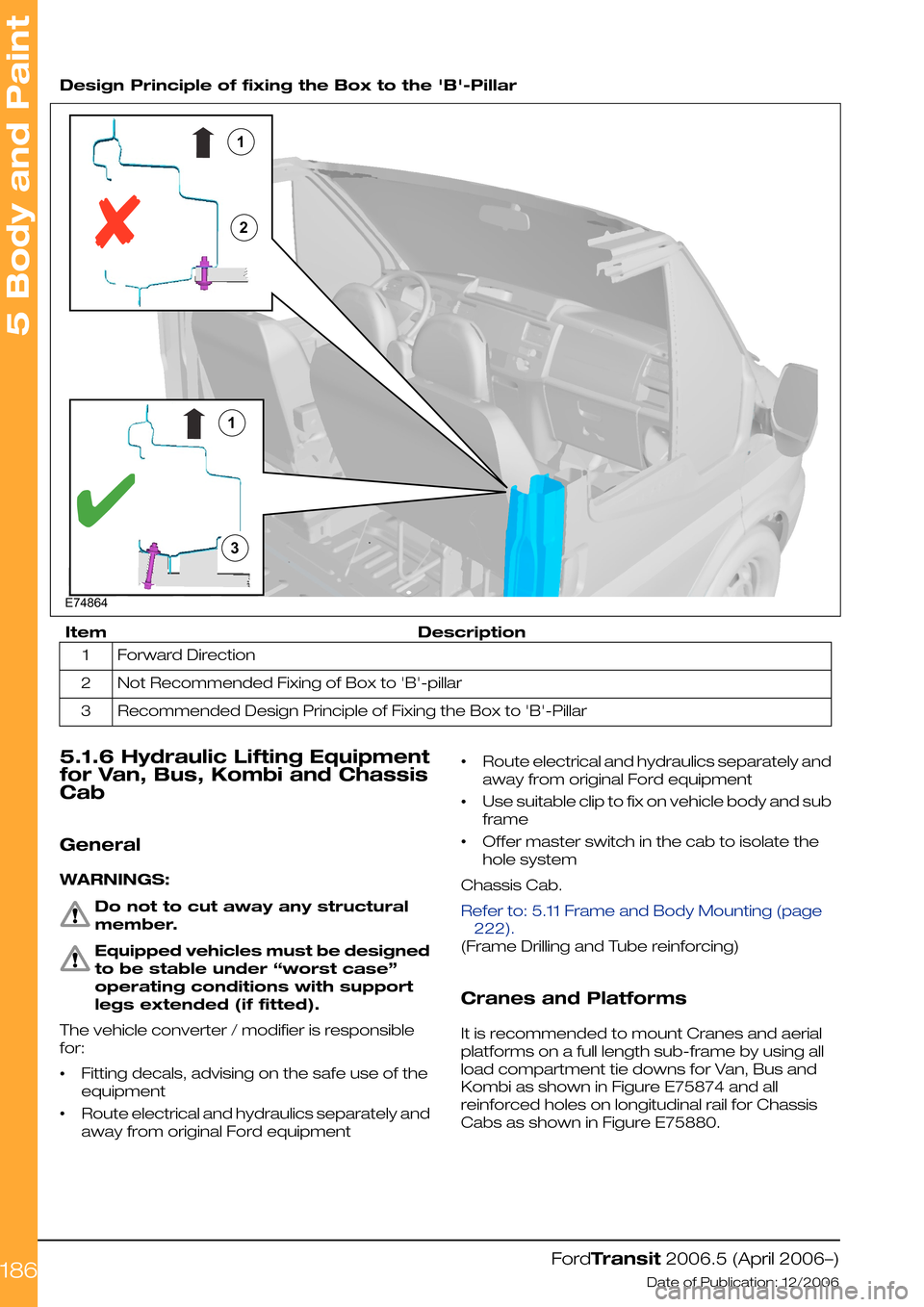

Design Principle of fixing the Box to the 'B'-Pillar

DescriptionItem

Forward Direction1

Not Recommended Fixing of Box to 'B'-pillar2

Recommended Design Principle of Fixing the Box to 'B'-Pillar3

5.1.6 Hydraulic Lifting Equipment

for Van, Bus, Kombi and Chassis

Cab

General

WARNINGS:

Do not to cut away any structural

member.

Equipped vehicles must be designed

to be stable under “worst case”

operating conditions with support

legs extended (if fitted).

The vehicle converter / modifier is responsible

for:

•Fitting decals, advising on the safe use of the

equipment

•Route electrical and hydraulics separately and

away from original Ford equipment

•Route electrical and hydraulics separately and

away from original Ford equipment

•Use suitable clip to fix on vehicle body and sub

frame

•Offer master switch in the cab to isolate the

hole system

Chassis Cab.

Refer to: 5.11 Frame and Body Mounting (page

222).

(Frame Drilling and Tube reinforcing)

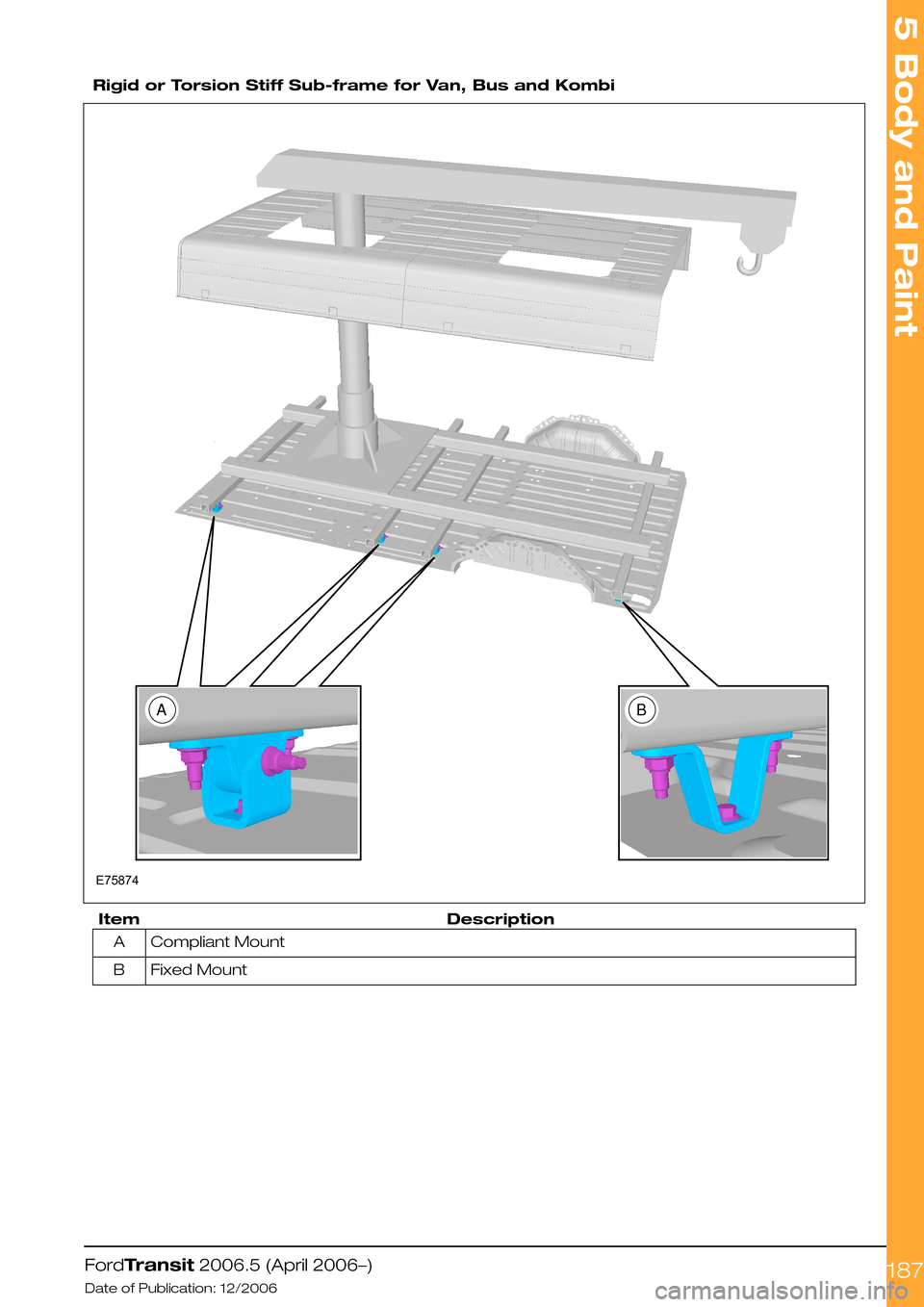

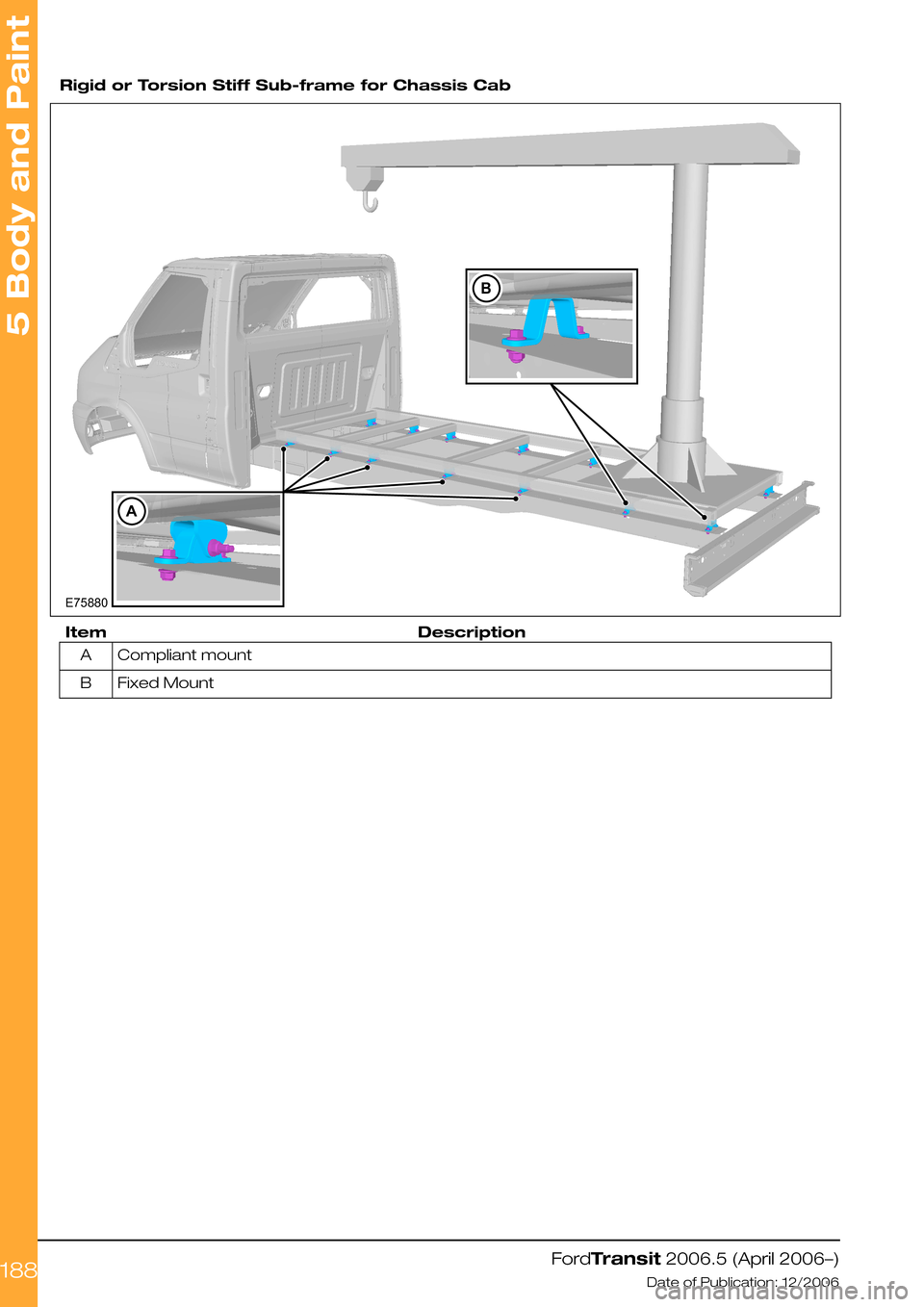

Cranes and Platforms

It is recommended to mount Cranes and aerial

platforms on a full length sub-frame by using all

load compartment tie downs for Van, Bus and

Kombi as shown in Figure E75874 and all

reinforced holes on longitudinal rail for Chassis

Cabs as shown in Figure E75880.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

1861123E74864

Page 187 of 234

Rigid or Torsion Stiff Sub-frame for Van, Bus and Kombi

DescriptionItem

Compliant MountA

Fixed MountB

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

187ABE75874

Page 188 of 234

Rigid or Torsion Stiff Sub-frame for Chassis Cab

DescriptionItem

Compliant mountA

Fixed MountB

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

188E75880AB

Page 189 of 234

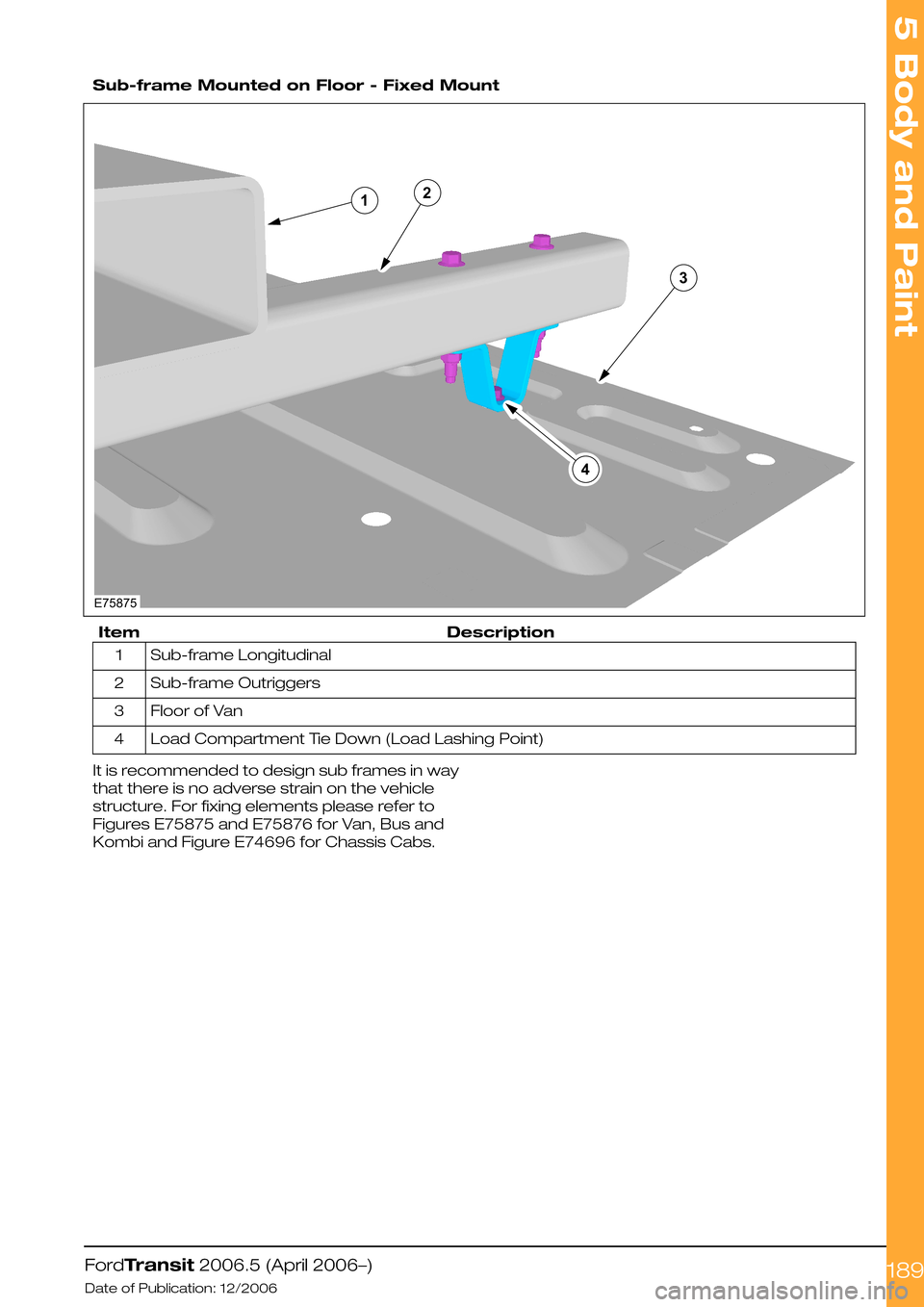

Sub-frame Mounted on Floor - Fixed Mount

DescriptionItem

Sub-frame Longitudinal1

Sub-frame Outriggers2

Floor of Van3

Load Compartment Tie Down (Load Lashing Point)4

It is recommended to design sub frames in way

that there is no adverse strain on the vehicle

structure. For fixing elements please refer to

Figures E75875 and E75876 for Van, Bus and

Kombi and Figure E74696 for Chassis Cabs.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

1891234E75875

Page 190 of 234

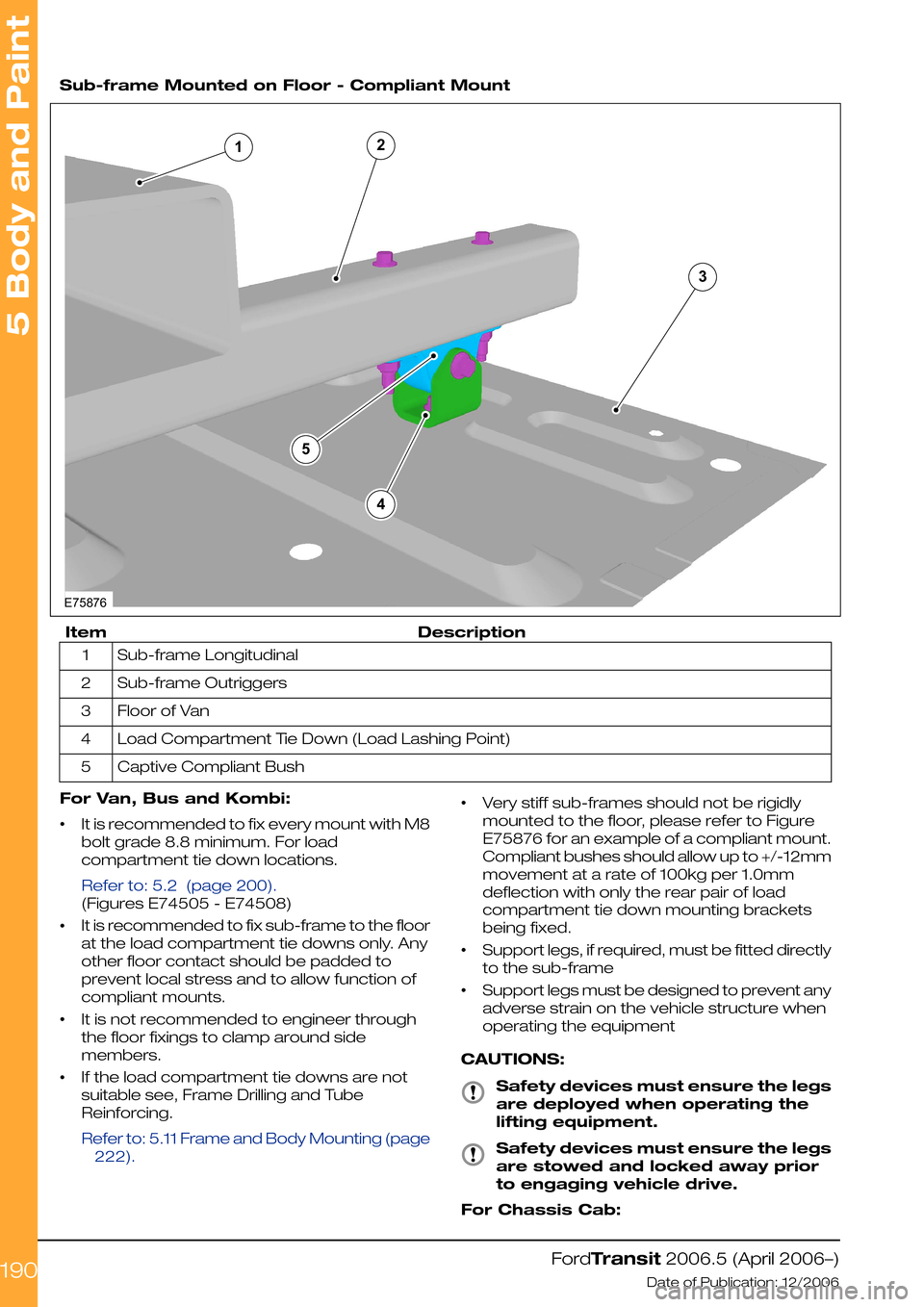

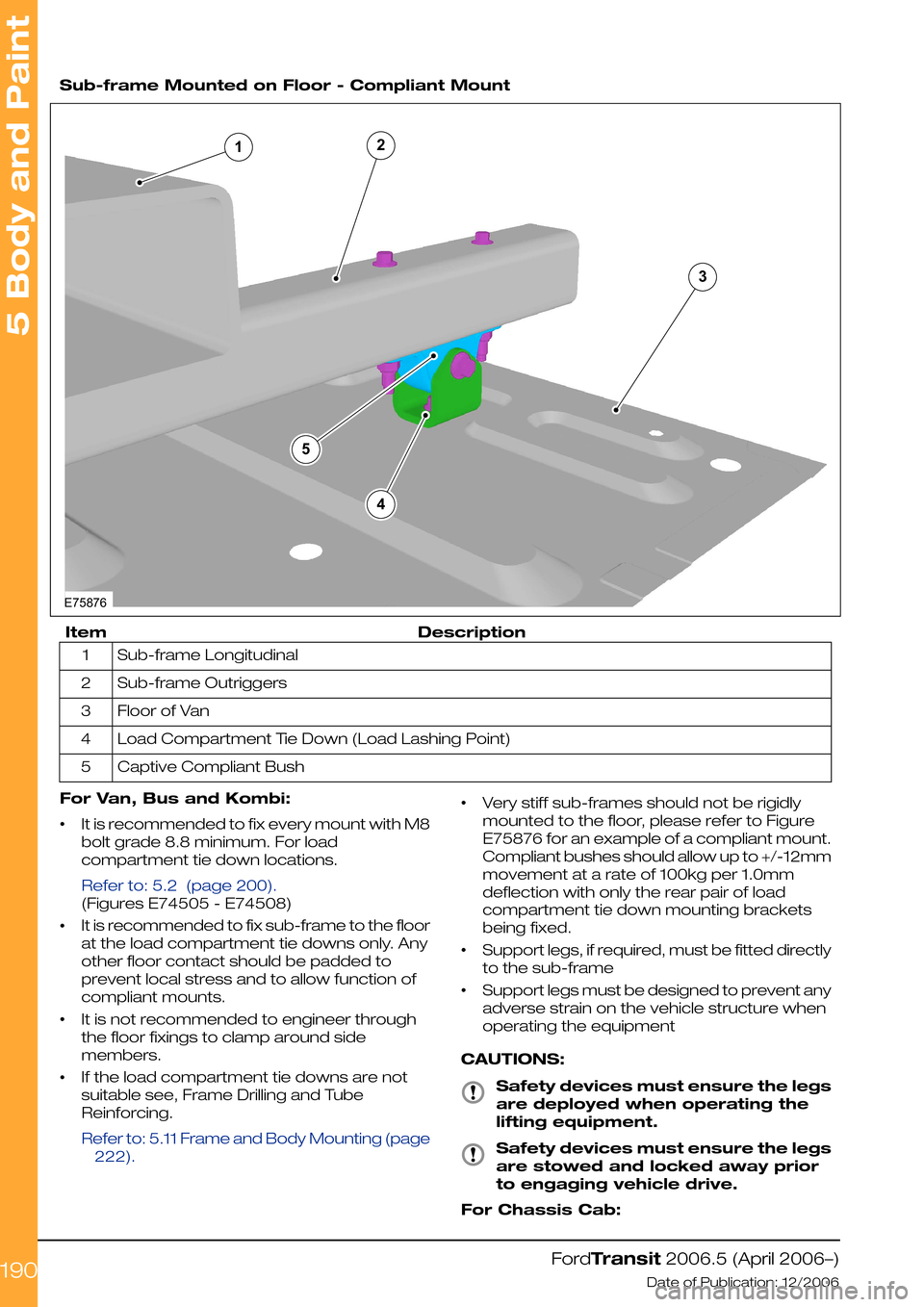

Sub-frame Mounted on Floor - Compliant Mount

DescriptionItem

Sub-frame Longitudinal1

Sub-frame Outriggers2

Floor of Van3

Load Compartment Tie Down (Load Lashing Point)4

Captive Compliant Bush5

For Van, Bus and Kombi:

•It is recommended to fix every mount with M8

bolt grade 8.8 minimum. For load

compartment tie down locations.

Refer to: 5.2 (page 200).

(Figures E74505 - E74508)

•It is recommended to fix sub-frame to the floor

at the load compartment tie downs only. Any

other floor contact should be padded to

prevent local stress and to allow function of

compliant mounts.

•It is not recommended to engineer through

the floor fixings to clamp around side

members.

•If the load compartment tie downs are not

suitable see, Frame Drilling and Tube

Reinforcing.

Refer to: 5.11 Frame and Body Mounting (page

222).

•Very stiff sub-frames should not be rigidly

mounted to the floor, please refer to Figure

E75876 for an example of a compliant mount.

Compliant bushes should allow up to +/-12mm

movement at a rate of 100kg per 1.0mm

deflection with only the rear pair of load

compartment tie down mounting brackets

being fixed.

•Support legs, if required, must be fitted directly

to the sub-frame

•Support legs must be designed to prevent any

adverse strain on the vehicle structure when

operating the equipment

CAUTIONS:

Safety devices must ensure the legs

are deployed when operating the

lifting equipment.

Safety devices must ensure the legs

are stowed and locked away prior

to engaging vehicle drive.

For Chassis Cab:

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

190E7587642351

Trending: fuse chart, navigation system, spare tire location, start stop button, towing, weight, turn signal