FORD TRANSIT 2006 7.G Body And Equipment Mounting Section Manual

Manufacturer: FORD, Model Year: 2006, Model line: TRANSIT, Model: FORD TRANSIT 2006 7.GPages: 234, PDF Size: 33.19 MB

Page 211 of 234

5.6 Glass, Frames and Mechanisms

5.6.1 Rear Windows

For windows, it is recommended to specify the

base vehicle as a Kombi or Bus body - however,

when converting a van, the following should be

adhered to:

•Cut the outer panel of the body side and door

to within 1mm of the inner panel flange.

•Do not cut across panel joints or pillars.

•Use approved glass for installation according

to legal requirements.

WARNING: Do not install seats in the

cargo area of a Van. In case rear

seats are required, always specify

the base vehicle as Kombi or Bus.

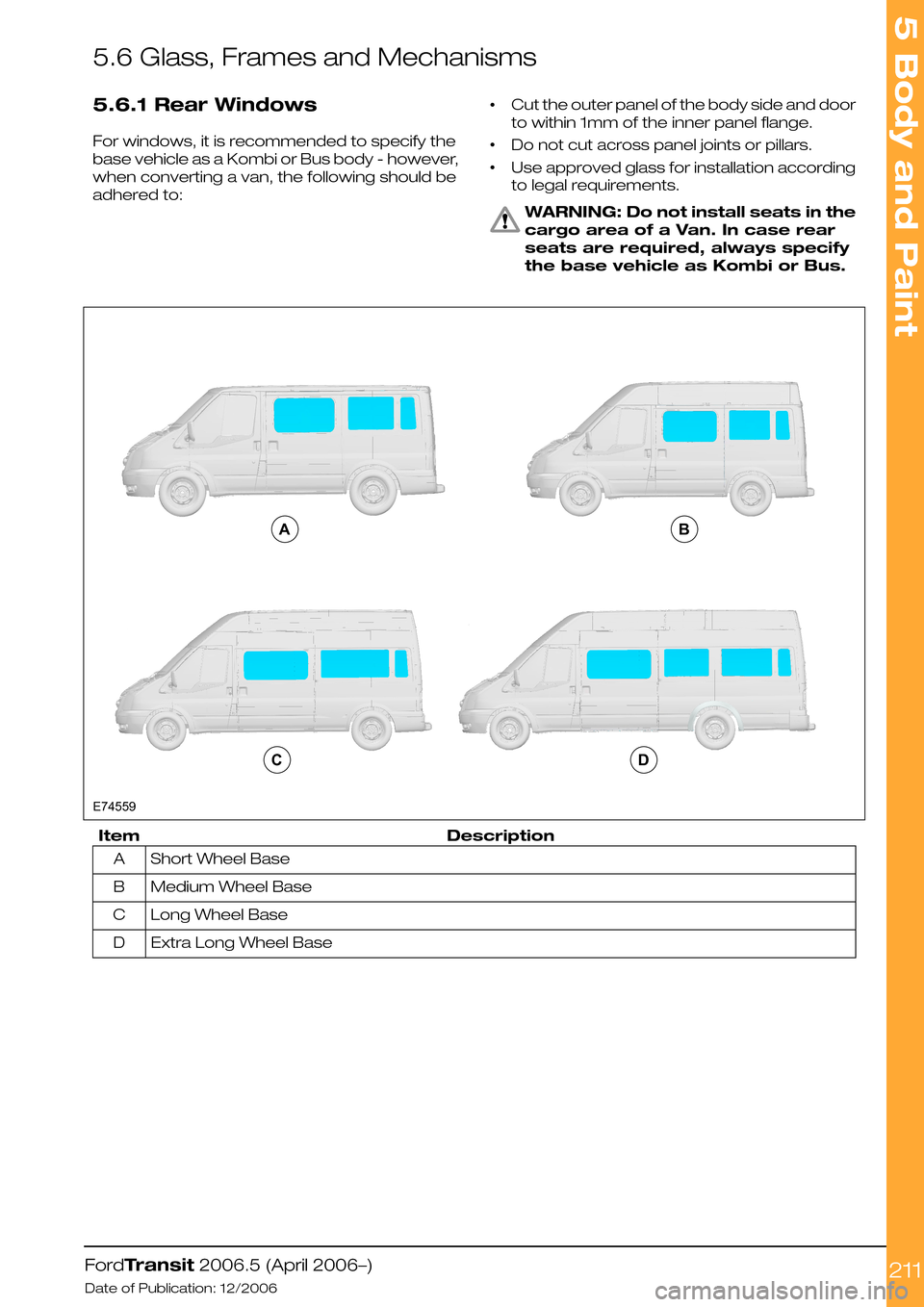

DescriptionItem

Short Wheel BaseA

Medium Wheel BaseB

Long Wheel BaseC

Extra Long Wheel BaseD

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

211E74559ABCD

Page 212 of 234

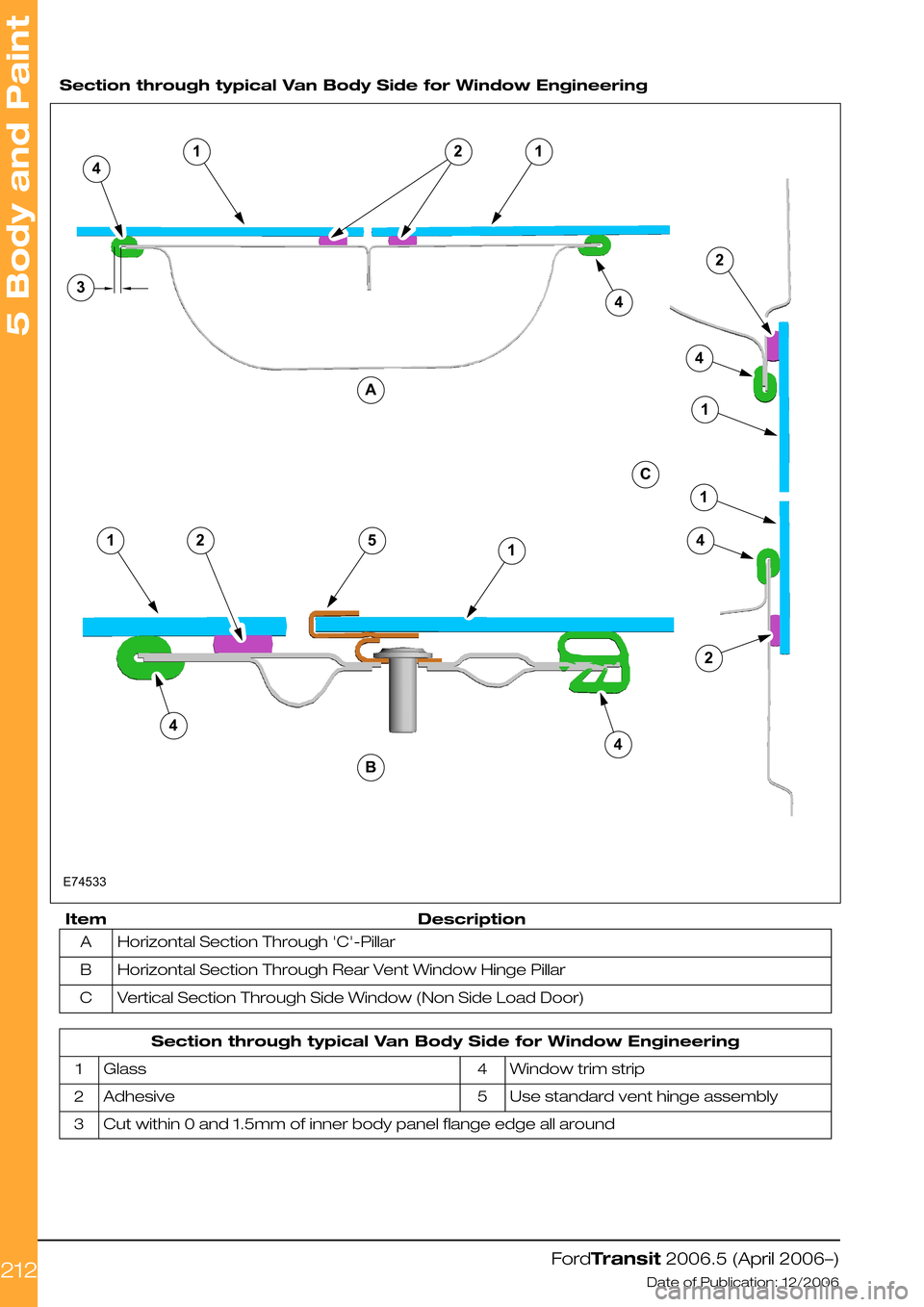

Section through typical Van Body Side for Window Engineering

DescriptionItem

Horizontal Section Through 'C'-PillarA

Horizontal Section Through Rear Vent Window Hinge PillarB

Vertical Section Through Side Window (Non Side Load Door)C

Section through typical Van Body Side for Window Engineering

Window trim strip4Glass1

Use standard vent hinge assembly5Adhesive2

Cut within 0 and 1.5mm of inner body panel flange edge all around3

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

2121413ABC21251424444211E74533

Page 213 of 234

5.6.2 Heated Windshield and

Heated Rear Window

WARNING: The base system should

not be tampered with (controlled by

Central Junction Box and multiplex

architecture) and no feeds taken

from the associated wiring or

controller.

These options are not suitable for aftermarket

or Vehicle Converter fit.

NOTE: For further information please contact

your local National Sales Company

representative, or Local Ford Dealer. If they are

unable to help you then please contact the

Vehicle Converter Advisory Service at

[email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

213

Page 214 of 234

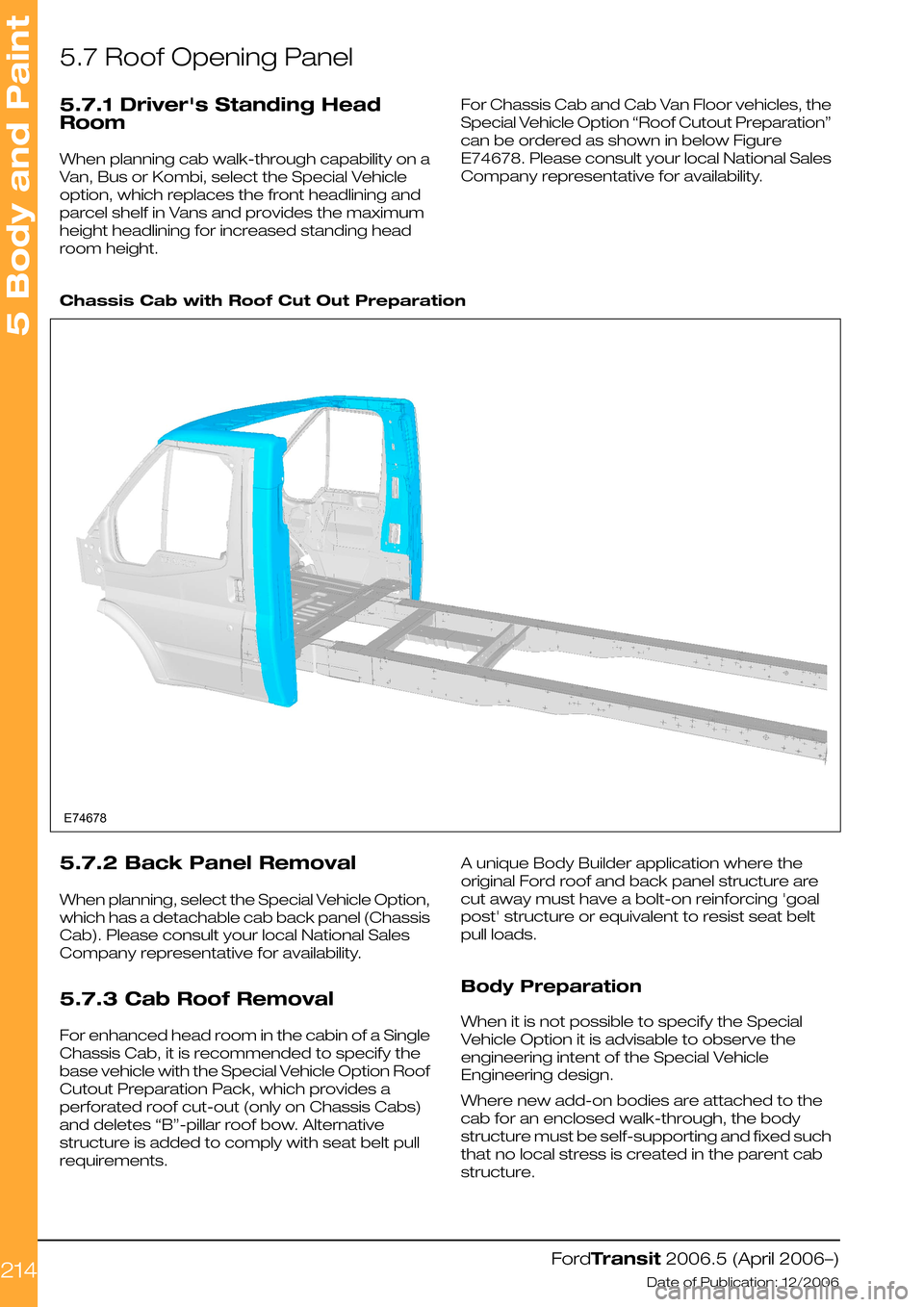

5.7 Roof Opening Panel

5.7.1 Driver's Standing Head

Room

When planning cab walk-through capability on a

Van, Bus or Kombi, select the Special Vehicle

option, which replaces the front headlining and

parcel shelf in Vans and provides the maximum

height headlining for increased standing head

room height.

For Chassis Cab and Cab Van Floor vehicles, the

Special Vehicle Option “Roof Cutout Preparation”

can be ordered as shown in below Figure

E74678. Please consult your local National Sales

Company representative for availability.

Chassis Cab with Roof Cut Out Preparation

5.7.2 Back Panel Removal

When planning, select the Special Vehicle Option,

which has a detachable cab back panel (Chassis

Cab). Please consult your local National Sales

Company representative for availability.

5.7.3 Cab Roof Removal

For enhanced head room in the cabin of a Single

Chassis Cab, it is recommended to specify the

base vehicle with the Special Vehicle Option Roof

Cutout Preparation Pack, which provides a

perforated roof cut-out (only on Chassis Cabs)

and deletes “B”-pillar roof bow. Alternative

structure is added to comply with seat belt pull

requirements.

A unique Body Builder application where the

original Ford roof and back panel structure are

cut away must have a bolt-on reinforcing 'goal

post' structure or equivalent to resist seat belt

pull loads.

Body Preparation

When it is not possible to specify the Special

Vehicle Option it is advisable to observe the

engineering intent of the Special Vehicle

Engineering design.

Where new add-on bodies are attached to the

cab for an enclosed walk-through, the body

structure must be self-supporting and fixed such

that no local stress is created in the parent cab

structure.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

214E74678

Page 215 of 234

Use metal fasteners through double thickness

flanges for example with nuts, bolts and spreader

plates where possible.

“Pop” type rivet structural value is only as good

as the material or thickness of the body panels,

therefore ensure the application is suitably

engineered.

Protect all metal edges to comply with interior

projection legislation.

Corrosion protect all cut or drilled metal edges

and repair any paint damage.

5.7.4 Roof Ventilation

General

Apertures must not cut through roof bows.

Ventilators must prevent direct entry of water

and dust.

A shut-off system should be available to prevent

fume ingress.

Interior and exterior projection legal requirements

must be maintained.

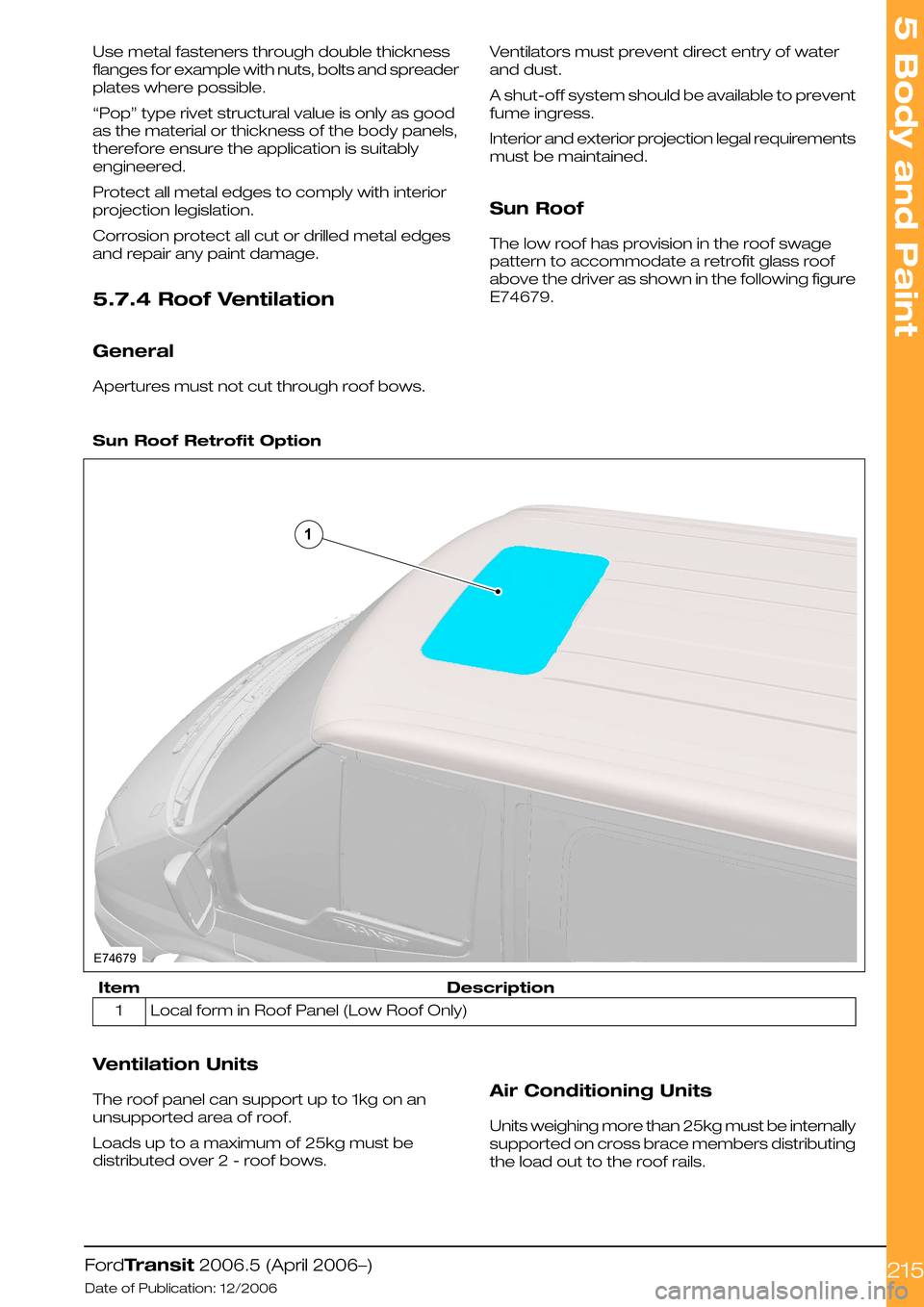

Sun Roof

The low roof has provision in the roof swage

pattern to accommodate a retrofit glass roof

above the driver as shown in the following figure

E74679.

Sun Roof Retrofit Option

DescriptionItem

Local form in Roof Panel (Low Roof Only)1

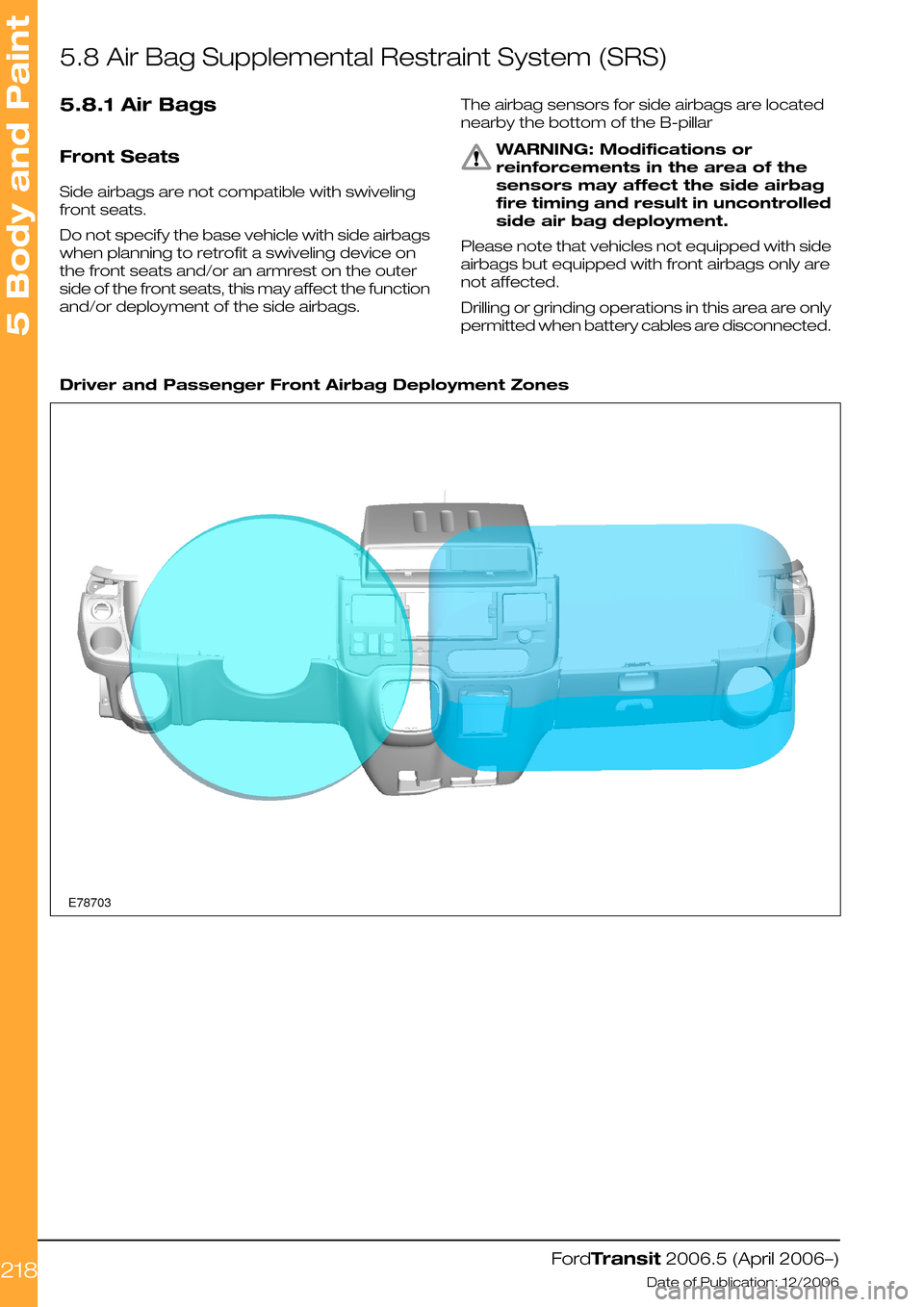

Ventilation Units

The roof panel can support up to 1kg on an

unsupported area of roof.

Loads up to a maximum of 25kg must be

distributed over 2 - roof bows.

Air Conditioning Units

Units weighing more than 25kg must be internally

supported on cross brace members distributing

the load out to the roof rails.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

215E746791

Page 216 of 234

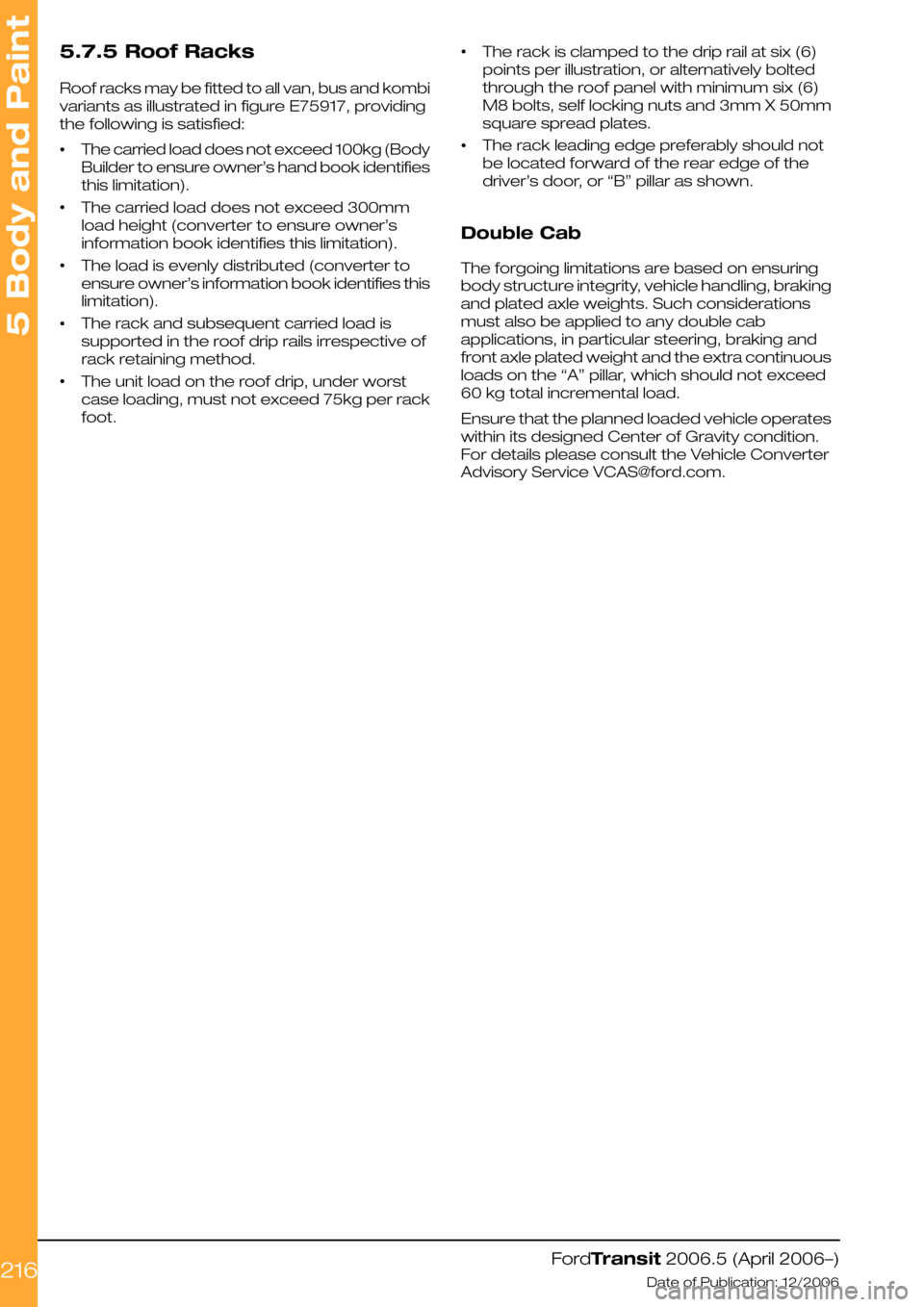

5.7.5 Roof Racks

Roof racks may be fitted to all van, bus and kombi

variants as illustrated in figure E75917, providing

the following is satisfied:

•The carried load does not exceed 100kg (Body

Builder to ensure owner’s hand book identifies

this limitation).

•The carried load does not exceed 300mm

load height (converter to ensure owner’s

information book identifies this limitation).

•The load is evenly distributed (converter to

ensure owner’s information book identifies this

limitation).

•The rack and subsequent carried load is

supported in the roof drip rails irrespective of

rack retaining method.

•The unit load on the roof drip, under worst

case loading, must not exceed 75kg per rack

foot.

•The rack is clamped to the drip rail at six (6)

points per illustration, or alternatively bolted

through the roof panel with minimum six (6)

M8 bolts, self locking nuts and 3mm X 50mm

square spread plates.

•The rack leading edge preferably should not

be located forward of the rear edge of the

driver’s door, or “B” pillar as shown.

Double Cab

The forgoing limitations are based on ensuring

body structure integrity, vehicle handling, braking

and plated axle weights. Such considerations

must also be applied to any double cab

applications, in particular steering, braking and

front axle plated weight and the extra continuous

loads on the “A” pillar, which should not exceed

60 kg total incremental load.

Ensure that the planned loaded vehicle operates

within its designed Center of Gravity condition.

For details please consult the Vehicle Converter

Advisory Service [email protected].

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

216

Page 217 of 234

Roof Rack Vehicle Converter Special Fit

DescriptionItem

Rear edge of Cab Doors 'B'-Pillar1

100Kg Maximum2

Maximum roof rack length Short Wheel Base:2500mm / Long Wheel Base 3282mm3

Maximum Load Height 300mm4

Drain Channel5

Roof Rack Supports each side, Short Wheel Base: 3 foot attachments / Long Wheel Base

4 foot attachments

6

Maximum 75Kg per attachment foot worst case7

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

217123564E75917

Page 218 of 234

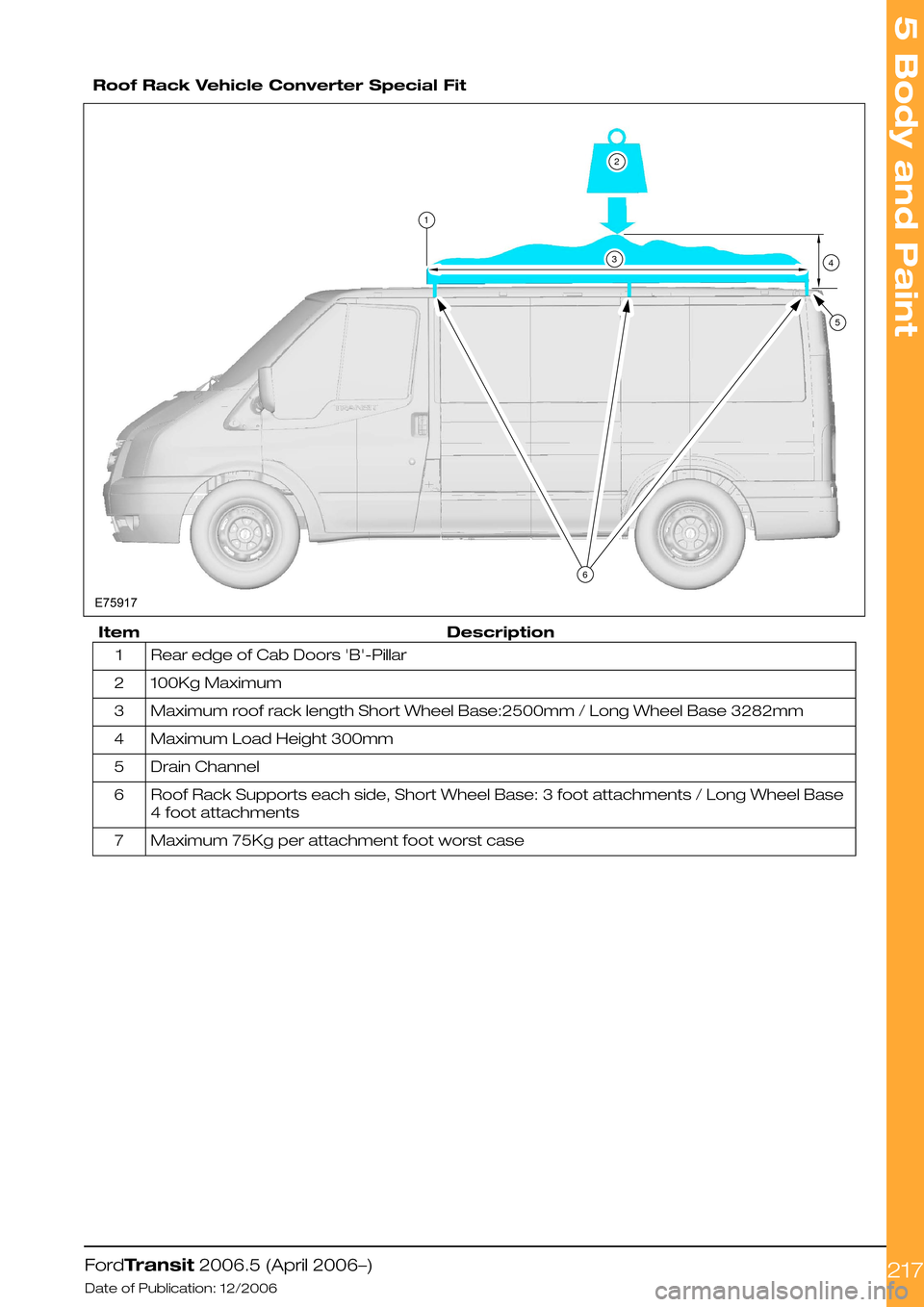

5.8 Air Bag Supplemental Restraint System (SRS)

5.8.1 Air Bags

Front Seats

Side airbags are not compatible with swiveling

front seats.

Do not specify the base vehicle with side airbags

when planning to retrofit a swiveling device on

the front seats and/or an armrest on the outer

side of the front seats, this may affect the function

and/or deployment of the side airbags.

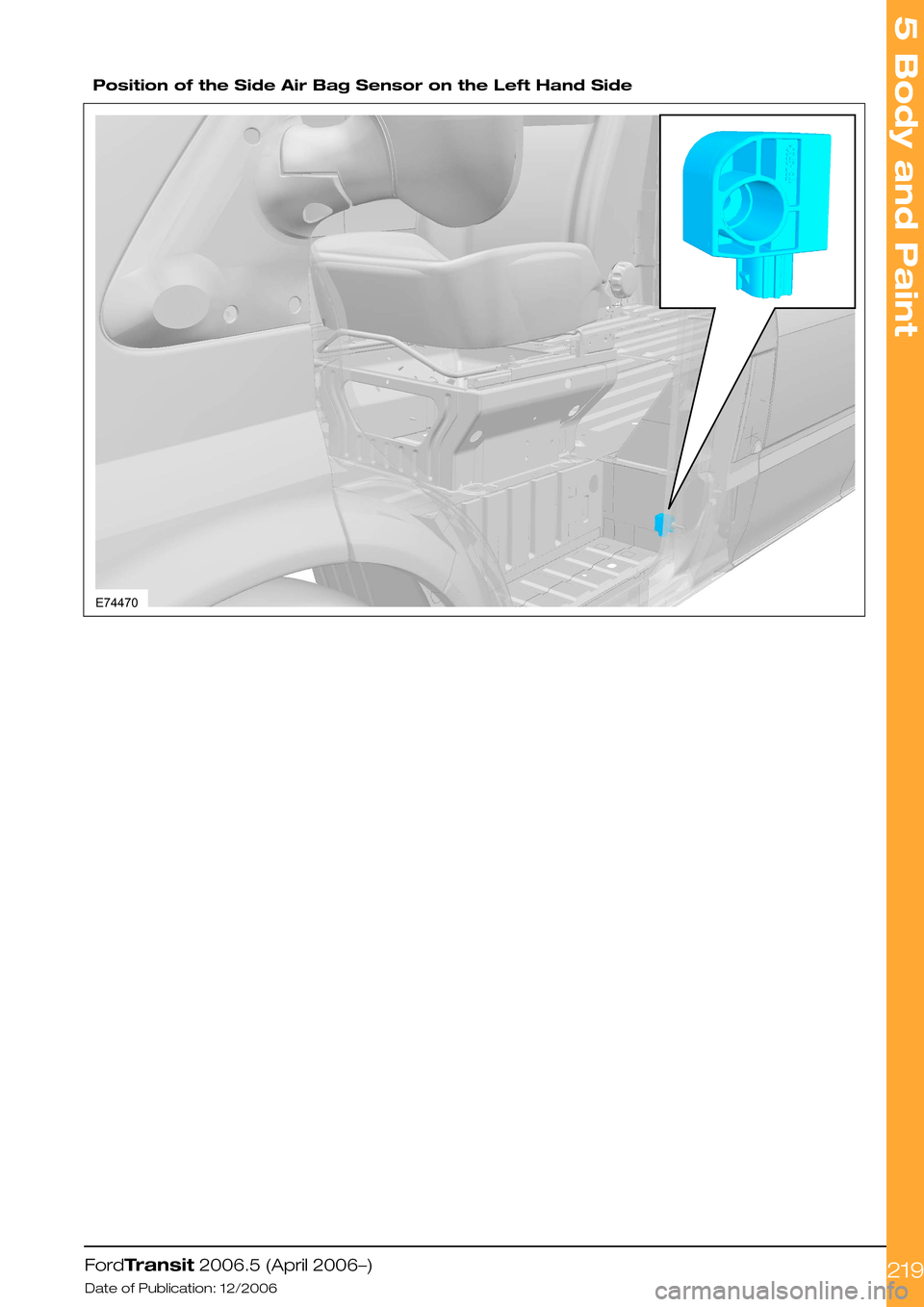

The airbag sensors for side airbags are located

nearby the bottom of the B-pillar

WARNING: Modifications or

reinforcements in the area of the

sensors may affect the side airbag

fire timing and result in uncontrolled

side air bag deployment.

Please note that vehicles not equipped with side

airbags but equipped with front airbags only are

not affected.

Drilling or grinding operations in this area are only

permitted when battery cables are disconnected.

Driver and Passenger Front Airbag Deployment Zones

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

218E78703

Page 219 of 234

Position of the Side Air Bag Sensor on the Left Hand Side

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

219E74470

Page 220 of 234

5.9 Safety Belt System

WARNING: Follow removal and

installation procedures for the seat

belt system to ensure correct

function of the restraints system.

The removal and reinstallation of the seat belt,

strainer or any component of the seat belt system

should be avoided. In case the removal and

re-installation system is required during the

conversion, however, follow the guidelines for

removal and installation of the seat belt system

as described in the workshop manual. Please

consult your local National Sales Company

representative for further information

When removing the seat belt system, a seat belt

webbing forked retainer should be applied to the

webbing 200mm below the webbing button stop.

This prevents a situation where all the webbing

runs back into the retractor and the retractor

becomes locked.

When reinstalling, fit the retractor to the body first

and gently pull the webbing out of the retractor

to allow fitment of the D loop. Then remove the

forked retainer. If the retractor is locked, allow a

small amount of webbing to reel back into the

retractor to allow the webbing lock to release. Do

not attempt to release the retractor by pulling on

the webbing with significant force or by manually

interfering with the locking mechanism.

FordTransit 2006.5 (April 2006–)

Date of Publication: 12/2006

5 Body and Paint

220