HONDA CIVIC 2003 7.G Workshop Manual

Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 431 of 1139

Shift Forks Glearance Inspection

NOTE: The synchro sleeve and synchro hub should be

replaced as a set.

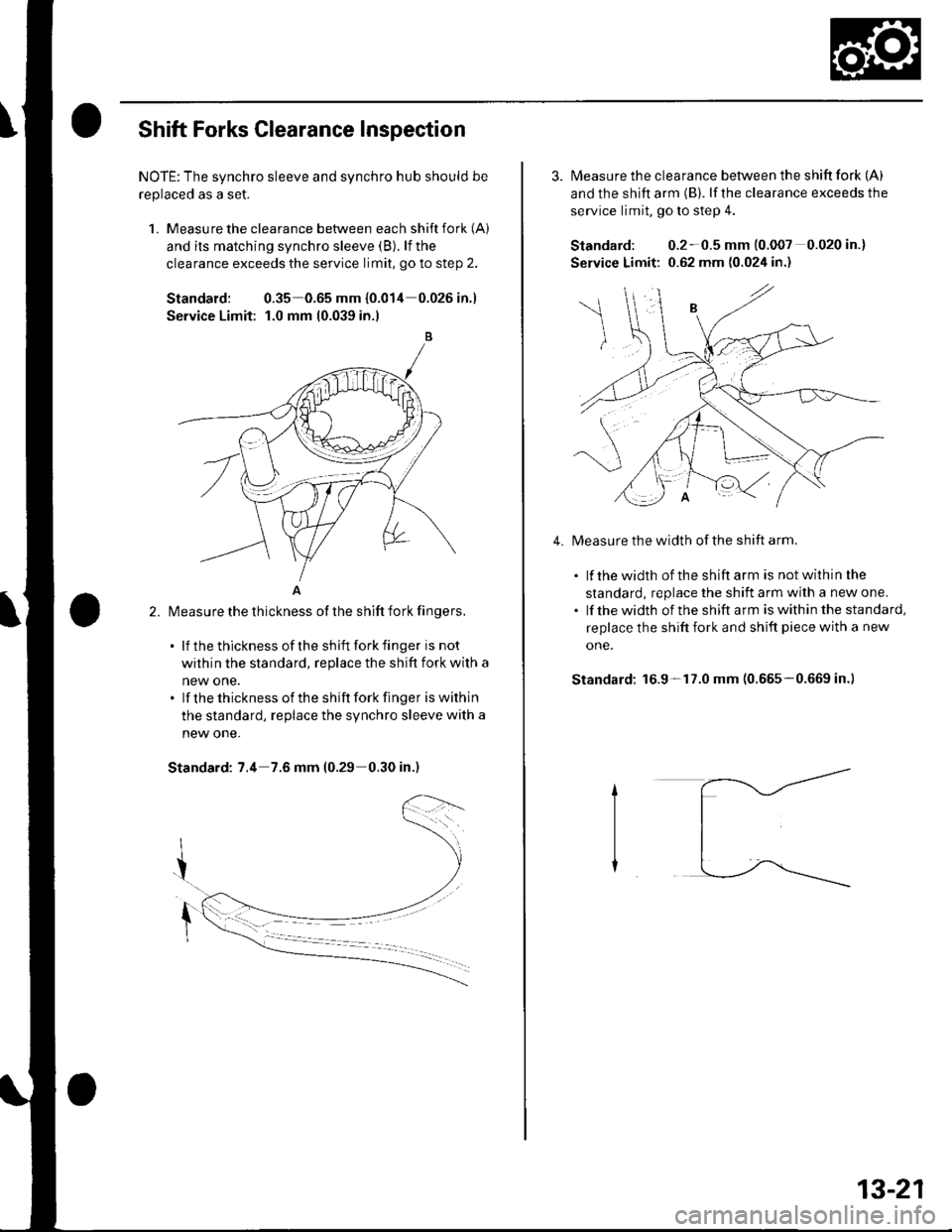

1. Measu re the clearance between each shift fork (A)

and its matching synchro sleeve (B). lf the

clearance exceeds the service limit, go to step 2.

Standard: 0.35 0.65 mm {0.014 0.026in.1

Service Limit: 1.0 mm 10.039 in.l

A

l\4easure the thickness of the shift fork fingers.

. lf thethicknessof theshift forkfinger is not

within the standard, replace the shift fork with a

new one.. lf thethicknessof the shift forkfinger iswithin

the standard, replace the synchro sleeve with a

new one.

Standard: 7.4 7.6 mm (0.29-0.30 in.)

2.

3. Measure the clearance between the shift fork (A)

and the shift arm (B). lf the clearance exceeds the

service limit, go to slep 4.

Standard: 0.2-0.5 mm (0.007 0.020 in.)

Service Limit: 0.62 mm (0.024 in.)

Measure the width of the shift arm.

. lf thewidth of theshiftarm is notwithinthe

standard, replace the shift arm with a new one.. lf thewidth of the shift arm iswithinthe standard,

replace the shift fork and shift piece with a new

one.

Standard: 16.9-17.0 mm (0.665-0.669 in.)

4.

13-21

Page 432 of 1139

Manual Transmission

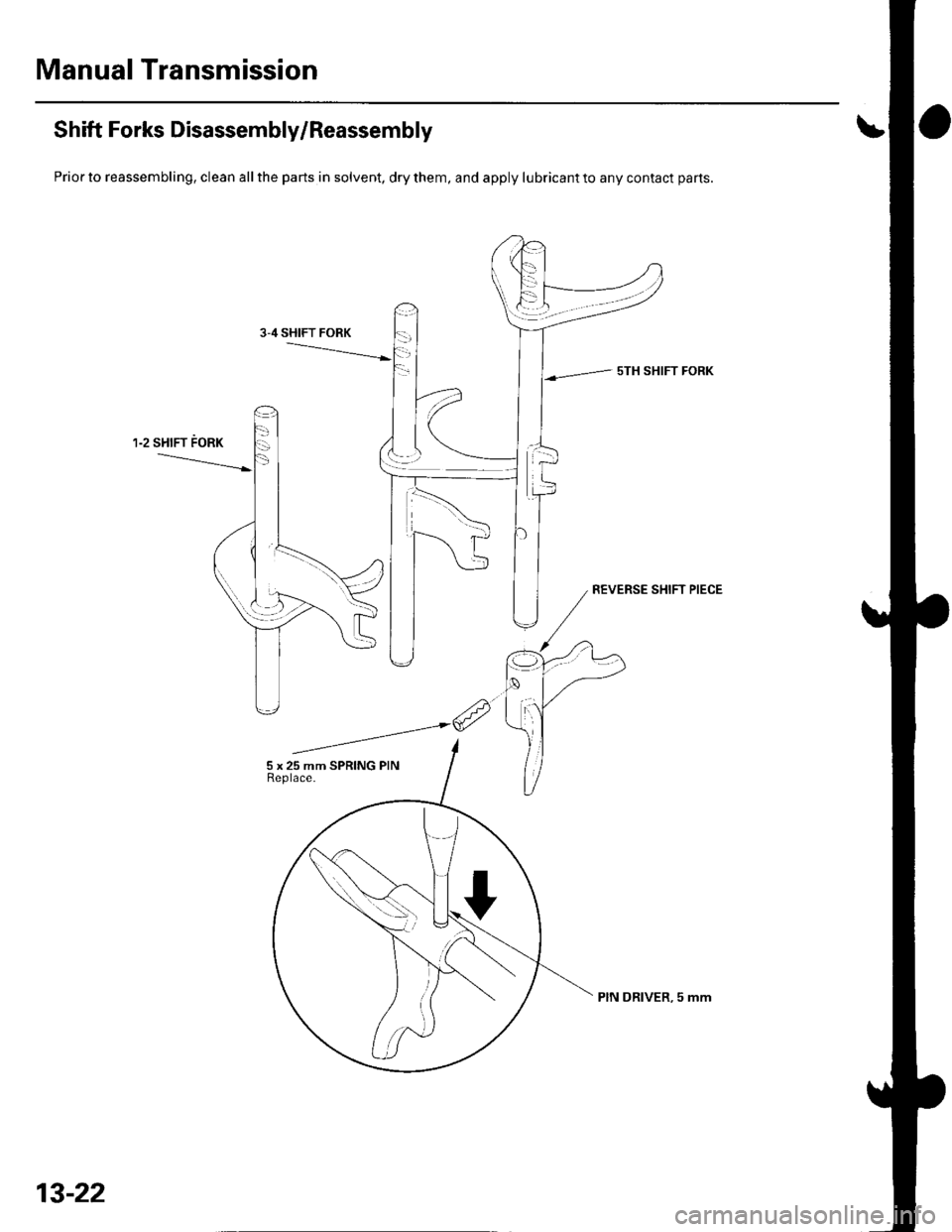

Shift Forks Disassembly/Reassembly

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact parts.

sTH SHIFT FORK

13-22

PIN DRIVER, 5 mm

Page 433 of 1139

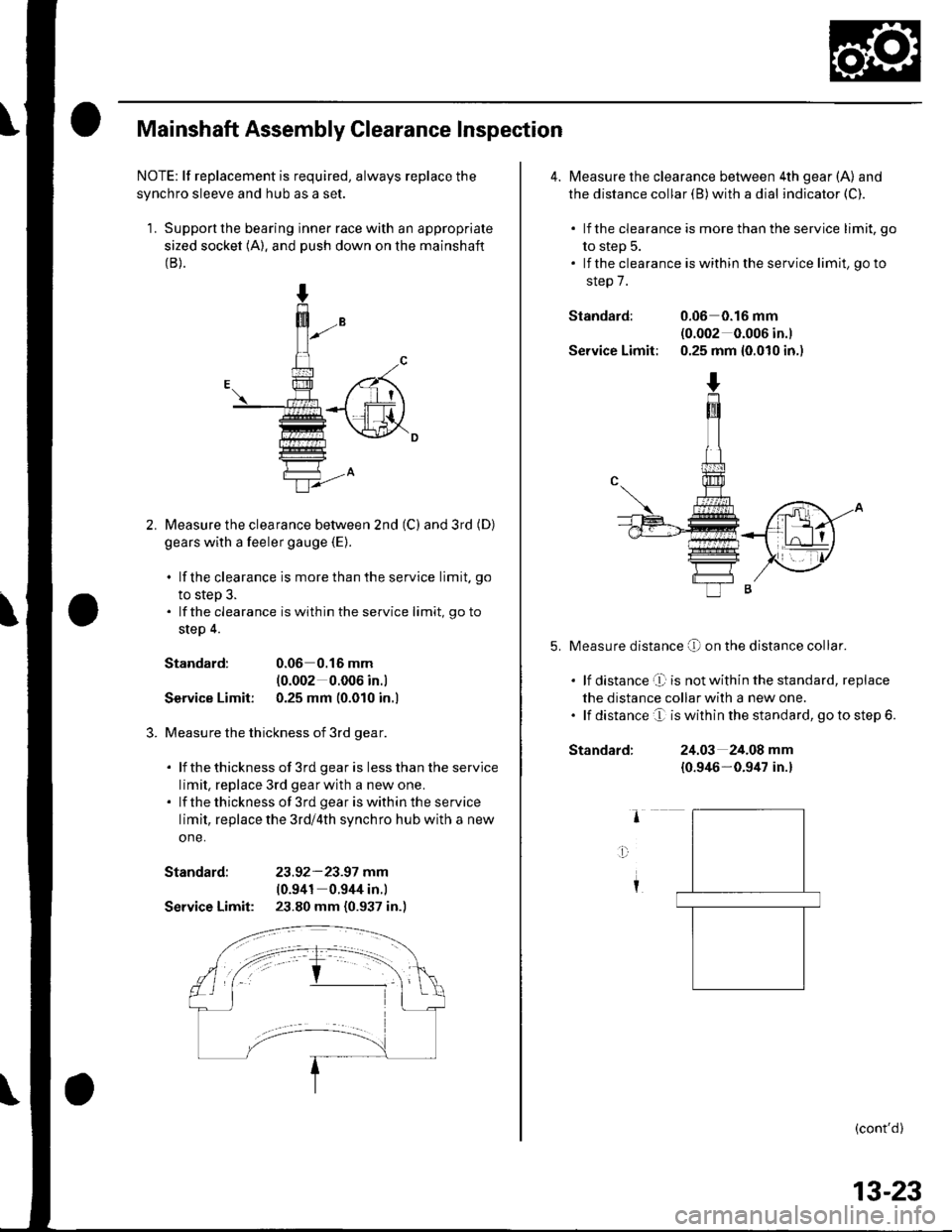

Mainshaft Assembly Clearance Inspection

NOTE: lf replacement is required, always replace the

synchro sleeve and hub as a set.

1. Support the bearing inner race with an appropriate

sized socket (A). and push down on the mainshaft(B).

Measure the clearance bet\iveen 2nd (C) and 3rd (D)

gears with a feeler gauge {E).

. lf the clearance is more than the service limit. go

to step 3.. lf the clearance is within the service limit, go to

step 4.

Standard:0.06 0.16 mm

{0.002 0.006 in.l

Service Limit: 0.25 mm (0.010 in.l

Measure the thickness of 3rd gear.

. lf thethickness of 3rd gearis lessthanthe service

limit, replace 3rd gearwith a new one.. lf thethickness of 3rd geariswithintheservice

limit, replace the 3rd/4th synchro hub with a new

one.

Standard: 23.92-23.97 mm(0.941 0.944 in.)

Service Limit: 23.80 mm (0.937 in.)

4. Measure the clearance between 4th gear (A) and

the distance collar (B) with a dial indicator (C).

. lf the clearance is more than the service limit, go

to step 5.. lf the clearance is within the service limit, go to

step 7.

Standard: 0.06 0.16 mnl(0.002 0.006 in.)

Service Limit: 0.25 mm {0.010 in.)

Measure distance O on the distance co[ar.

. lf distance't is notwithin the standard, replace

the distance collar with a new one.. lf distance e is within the standard, go to step 6.

Standard:24.03 24.08 mm

{0.946-0.9/u in.}

(cont'd)

13-23

Page 434 of 1139

Manual Transmission

Mainshaft Assembly Clearance Inspection (cont'd)

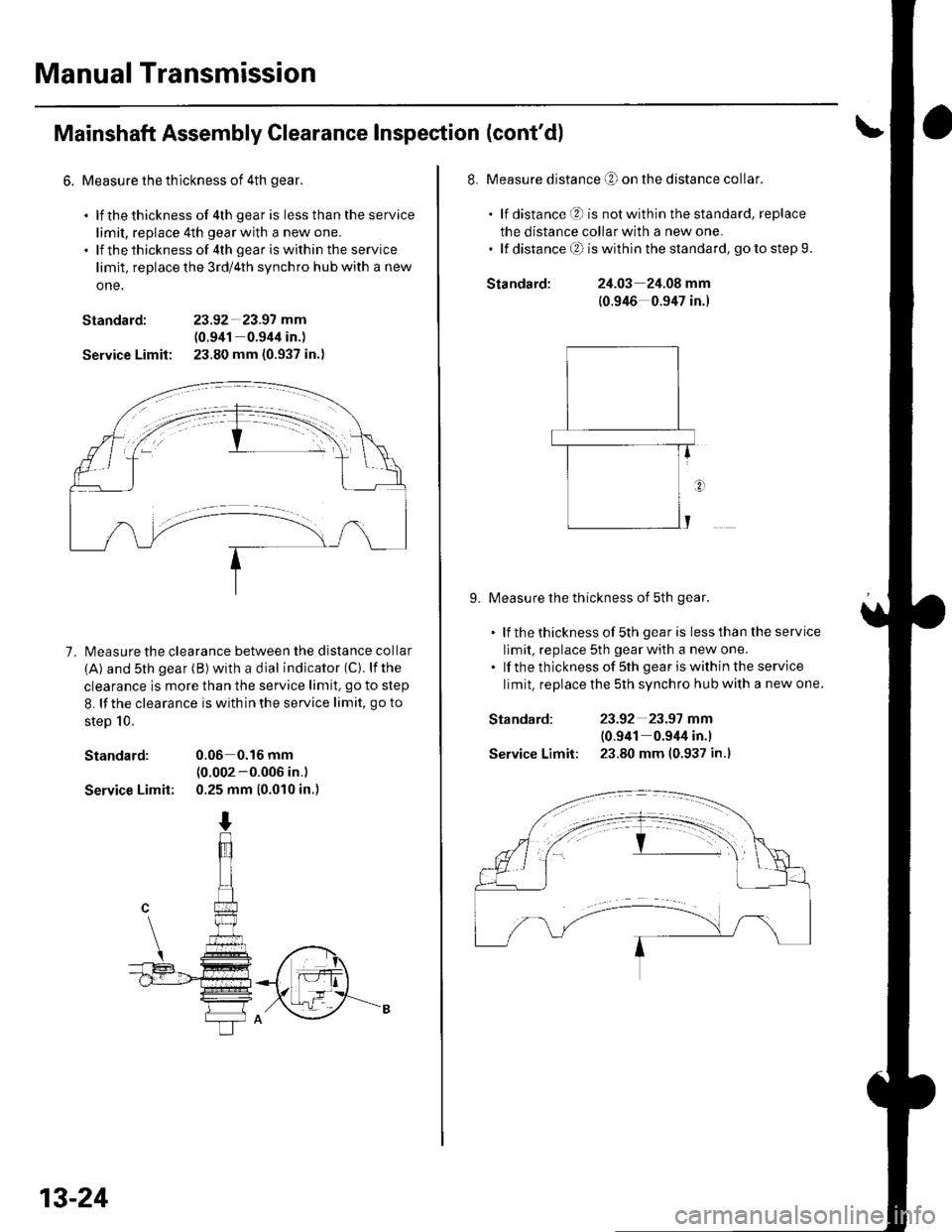

6. Measure the thlckness of 4th gear.

. lf thethickness of 4th gear is lessthantheservice

limit, replace 4th gear with a new one.. lf thethicknessof 4th geariswithin the service

limit. replace the 3rd/4th synchro hub with a new

one.

Standard: 23.92 23.97 mm

(0.941 0.944 in.)

Service Limit: 23.80 mm (0.937 in.)

7. l\4easure the clearance between the distance collar

(A) and sth gear (B) with a dial indicator (C). lfthe

clearance is more than the service limit. go to step

8. lf the clearance is with in the service limit, go to

steD 10.

Standard: 0.06 0.16 mm(0.002-0.006 in.)

Service Limit: 0.25 mm (0.010 in.)

13-24

Standard:

Standard:

Service Limit:

8. Measure distance O on the distance collar.

. lf distance O is notwithinthestandard, replace

the distance collar with a new one.' lf distanceO iswithinthe standard, gotostep9.

24.03 24.08 mm

(0.946 0.947 in.)

9. Measure the thickness of 5th gear.

. lf thethicknessof 5th gearis lessthantheservice

limit, replace 5th gear with a new one.. lf the thickness of sth gear iswithin the service

limit. replace the 5th synchro hub with a new one.

23-92 23.97 mm

10.941 0.944 in.l

23.80 mm (0.937 in.l

Page 435 of 1139

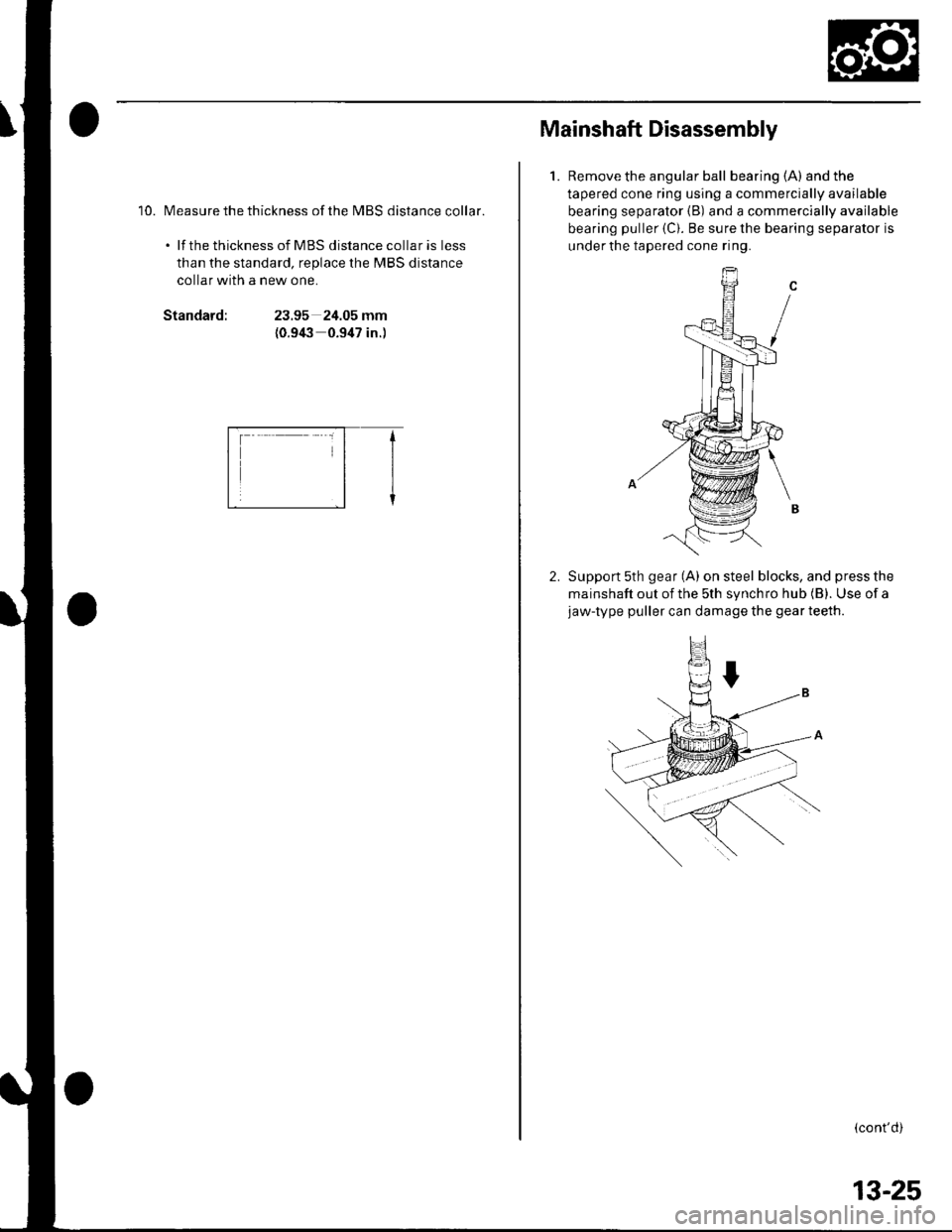

'10. Measure the thickness ofthe MBS distance collar.

. lf the thickness of MBS distance collar is less

than the standard, replace the MBS distance

collar with a new one.

Standard:23.95 24.05 mm

{0.9(3 0.947 in.)

E-f

Mainshaft Disassembly

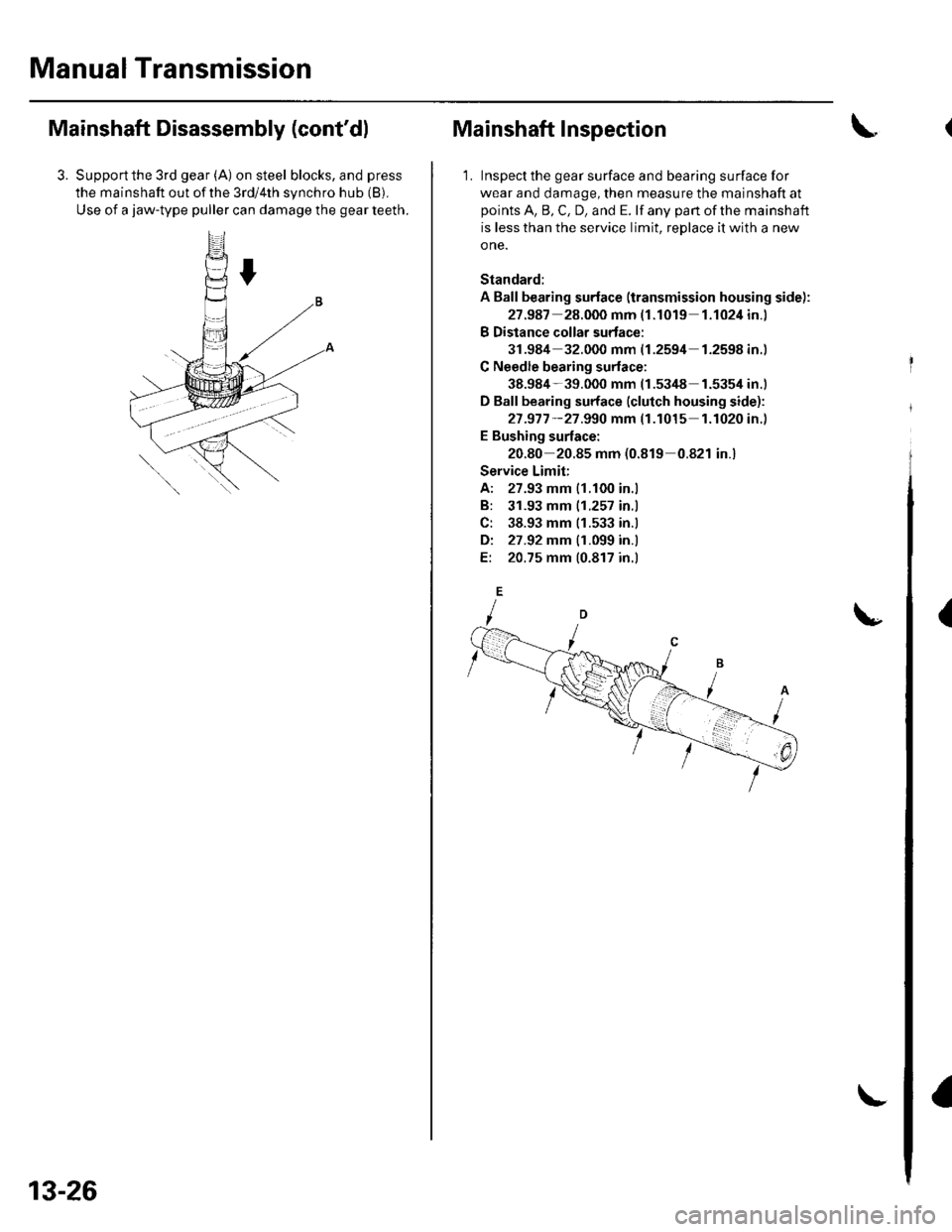

1.Remove the angular ball bearing (A) and the

tapered cone ring using a commercially available

bearing separator {B) and a commercially available

bearing puller {C). Be sure the bearing separator is

under the tapered cone ring.

Support 5th gear (A) on steel blocks, and press the

mainshaft out of the sth synchro hub (B). Use of ajaw-type puller can damage the gear teeth.

(cont'd)

13-25

Page 436 of 1139

Manual Transmission

Mainshaft Disassembly (cont'dl

3. Supportthe 3rd gear (A) on steel blocks, and press

the mainshaft out of the 3rd/4th synchro hub (B).

Use of a jaw-type puller can damage the gear teeth.

13-26

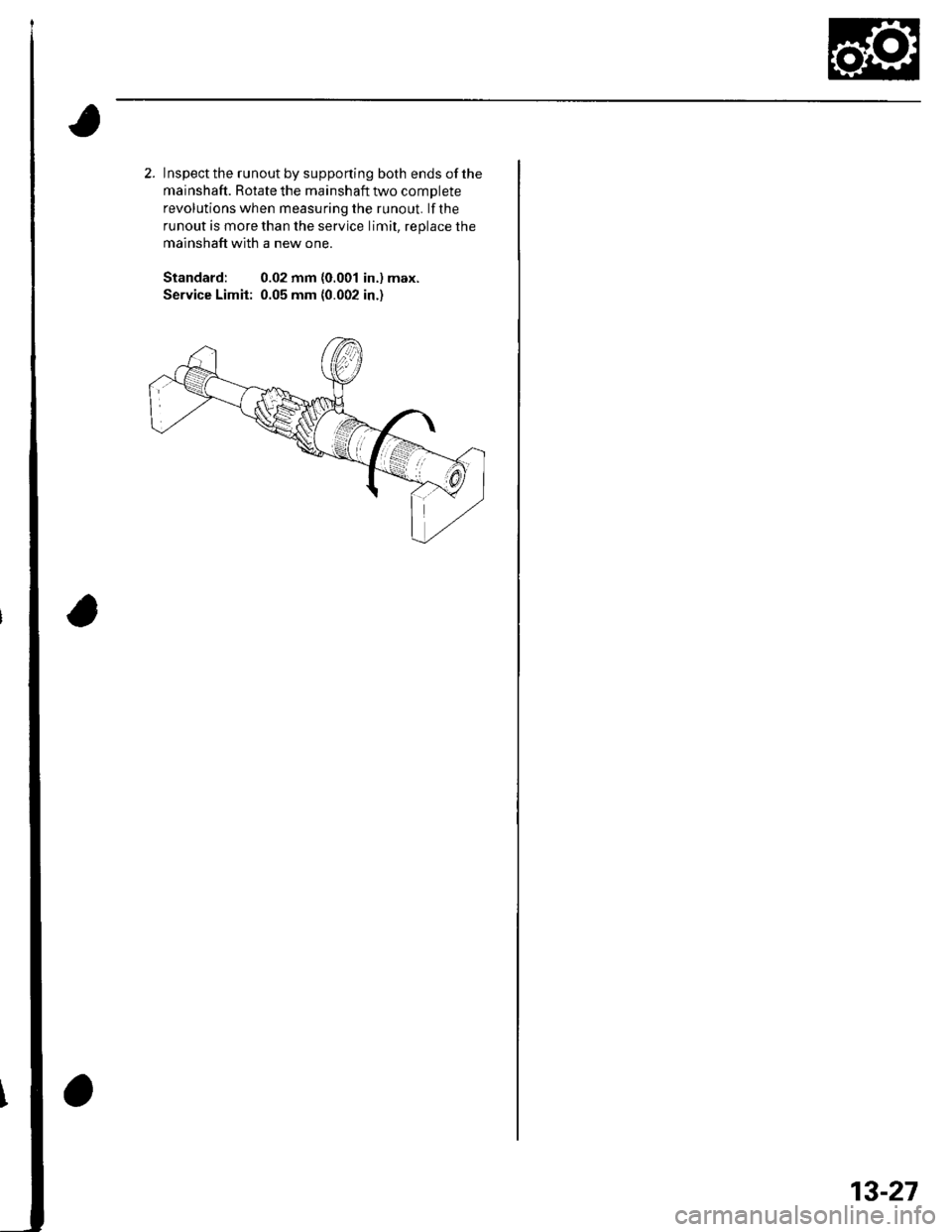

Mainshaft Inspection

1. Inspect the gear surface and bearing surface for

wear and damage, then measure the mainshaft at

points A, B, C, D, and E. lf any part of the mainshaft

is less than the service limit, reDlace it with a new

o ne.

Standard:

A Ball bearing surface (transmission housing side):

27.987 28.000 mm (1.1019 1.1024in.)

B Distance collar surtace:

31.984 32.000 mm {1.2594 1.2598in.)

C Needle bearing surlace:

38.984-39.000 mm (1.53/t8 1.5354 in.)

D Ball bearing surface (clutch housing side):

27 .977 -27 .990 mm (1.1015 1.1020in.)

E Bushing surface:

20.80 20.85 mm (0.819 0.821 in.)

Service Limit;

A: 27.93 mm 11.100 in.l

B: 31.93 mm |.1.257 in.l

C: 38.93 mm 11.533 in.l

Di 27.92 mm {1.099 in.l

E: 20.75 mm 10.817 in.l

{

Page 437 of 1139

2. Inspect the runout by supponing both ends of the

mainshaft. Rotate the mainshaft two complete

revolutions when measuring the runout. lf the

runout is more than the service limit. reolace the

mainshaft with a new one.

Standard: 0.02 mm (0.001 in.) max.

Service Limit: 0.05 mm (0.002 in.)

13-27

Page 438 of 1139

Manual Transmission

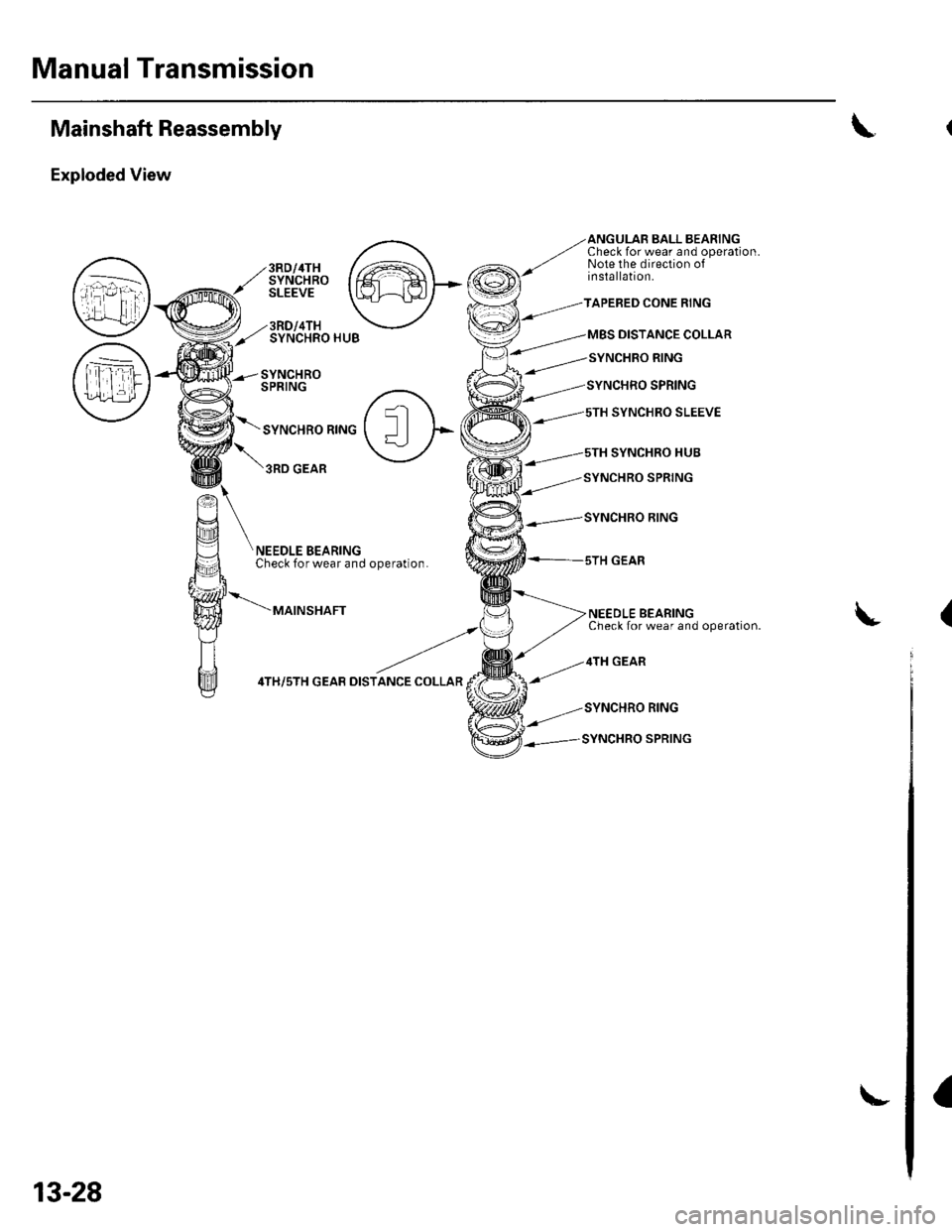

Mainshaft Reassembly

Exploded View

A

QJ'

frfl

Y7

ANGULAB BALL BEARINGCheck for wear and operation.Note the direction ofinstallation.3RD/4THSYNCHROSLEEVE

3RD/4THSYNCHRO HUB

SYNCHROSPRING

SYNCHRO RING

TAPEBED CONE RING

MBS DISTANCE COLLAR

SYNCHRO SLEEVE

NEEDLE BEARINGCheck for wear and operation.

GEAR

SYNCHRO RING

SYNCHRO SPRING

NEEDLE BEARINGCheck for wear and operation.

MAINSHAFT

4TH/5TH GEAB DISTANCE COLLAR

\(

a

13-28

Page 439 of 1139

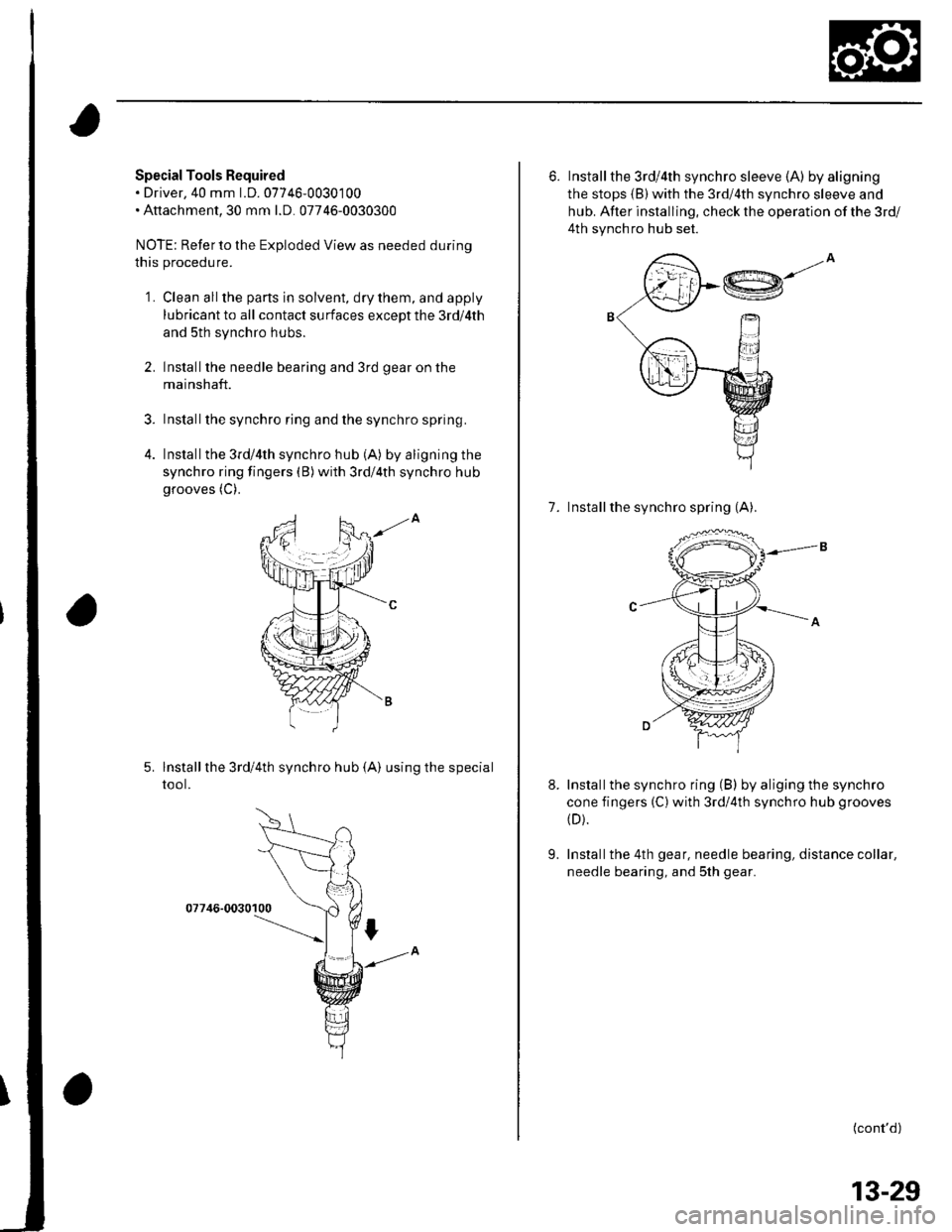

Special Tools Required. Driver,40 mm 1.D.07746-0030100. Attachment,30 mm l.D. 07746-0030300

NOTE: Refer to the Exploded View as needed during

this procedu re.

2.

4.

'1.Clean all the parts in solvent, dry them, and apply

lubricant to all contact su rfaces except the 3rd/4th

and 5th synchro hubs.

Installthe needle bearing and 3rd gear on the

mainshaft.

Installthe synchro ring and the synchro spring.

Installthe 3rd/4th synchro hub (A) by aligning the

synchro ring fingers (B)with 3rd/4th synchro hub

grooves (C).

-A

lnstallthe 3rd/4th synchro hub {A) using the special

tool.

07746-0030100

6. Installthe 3rd/4th synchro sleeve (A) by aligning

the stops (B)with the 3rd/4th synchro sleeve and

hub. After installing, check the operation of the 3rd/

4th synchro hub set.

@--

7. Installthe synchro spring (A).

Installthe synchro ring (B) by aliging the synchro

cone fingers (C)with 3rd/4th synchro hub grooves

(D).

Installthe 4th gear, needle bearing, distance collar,

needle bearing, and sth gear.

(cont'd)

9.

13-29

Page 440 of 1139

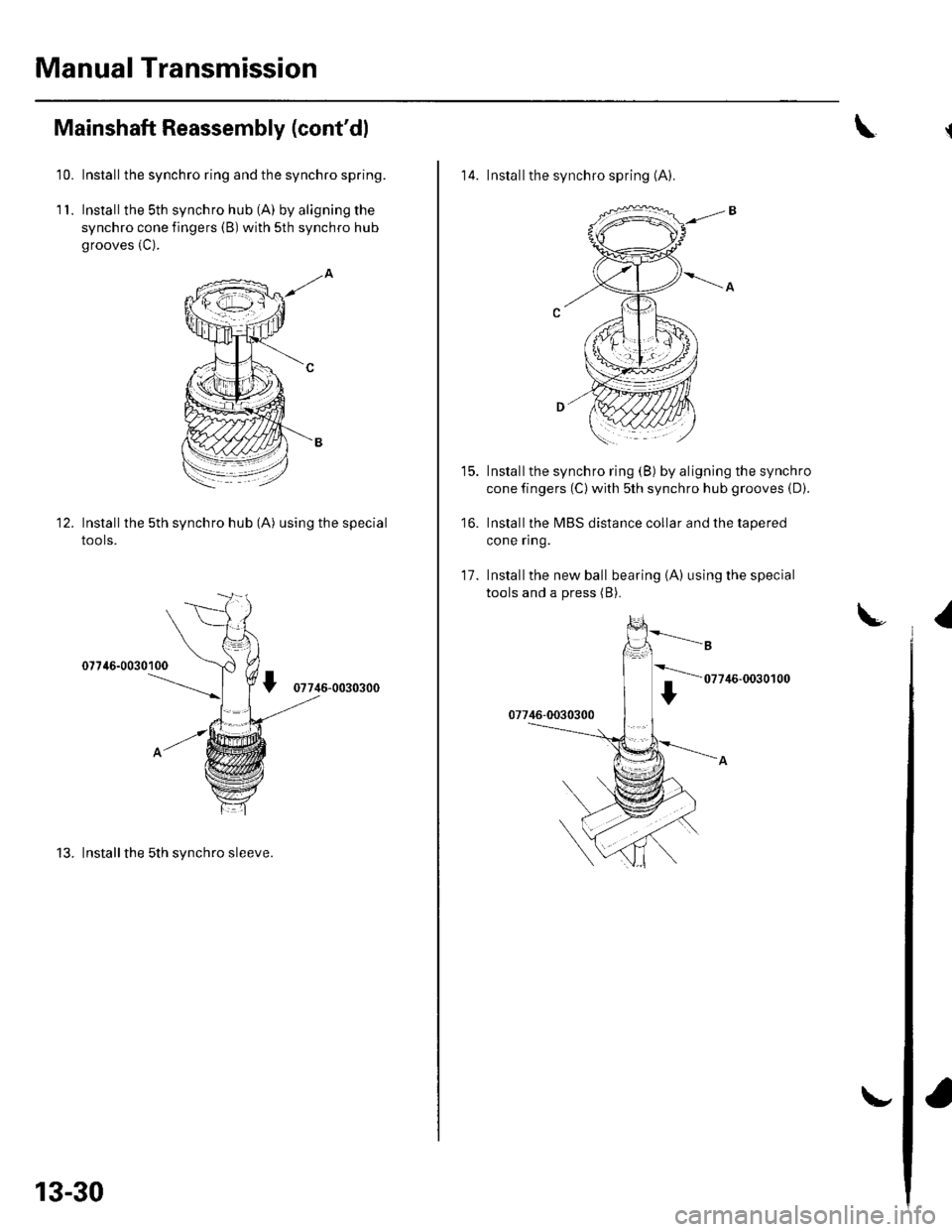

Manual Transmission

Mainshaft Reassembly (cont'dl

10. Installthe synchro ring and the synchro spring.

1 '1. Installthe sth synchro hub (A) by aligning the

synchro cone fingers (B) with sth synchro hub

grooves (C).

Installthe 5th synchro hub (A) using the special

tools.

07746-0030100

07746-0030300

13. Installthe 5th synchro sleeve.

12.

13-30

\.

\

14. Installthe synchro spring (A).

Installthe synchro ring (B) by aligning the synchro

cone fingers (C) with sth synchro hub grooves (D).

Installthe MBS distance collar and the tapered

cone ring.

Installthe new ball bearing {A) using the special

tools and a press (B).

t5.

16.

11.

U1

07746-0030100