HONDA CIVIC 2003 7.G Workshop Manual

CIVIC 2003 7.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/5744/w960_5744-0.png

HONDA CIVIC 2003 7.G Workshop Manual

Trending: low beam, egr valve, intermittent wipers, wheel, reset, buttons, wheel alignment

Page 461 of 1139

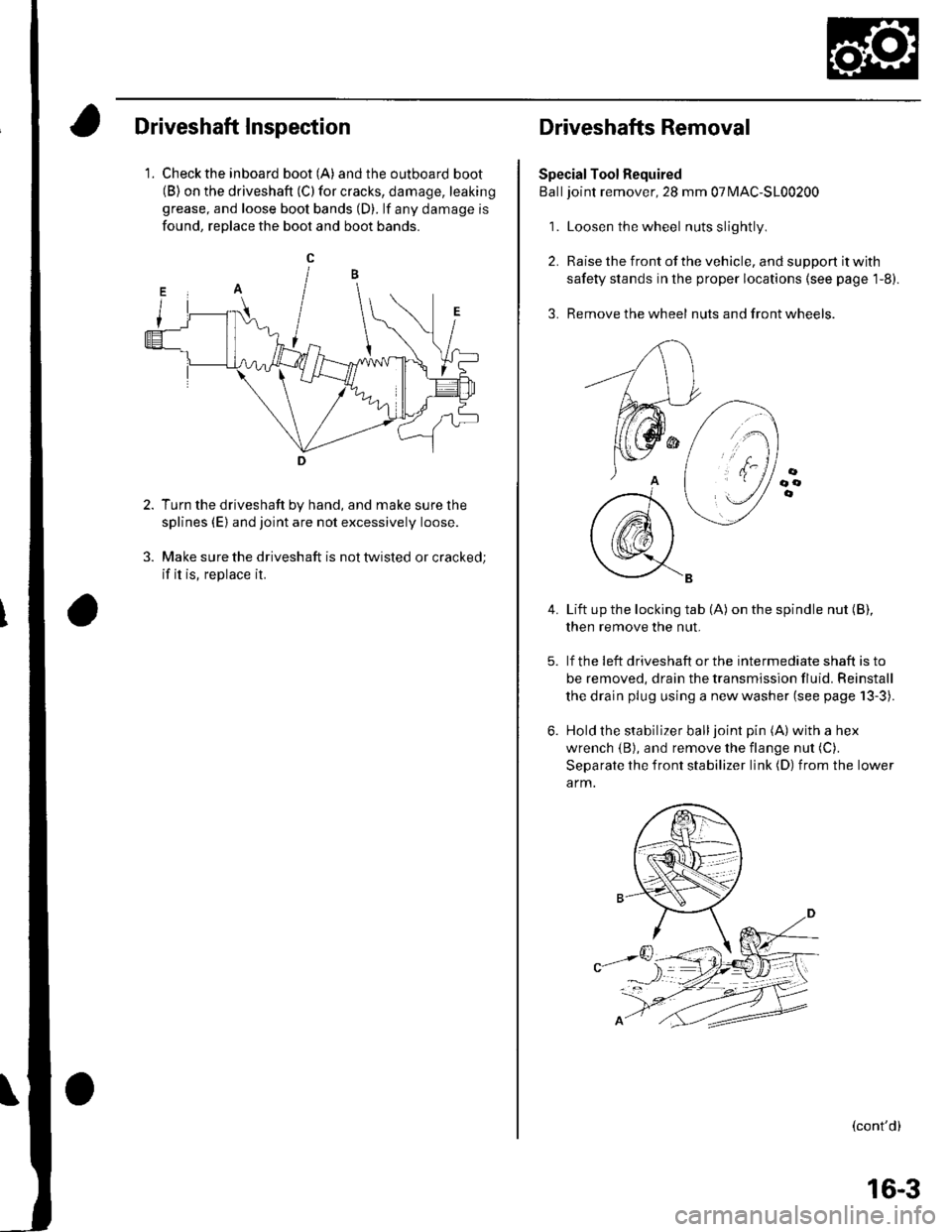

Gearshift Mechanism Replacement

SHIFT CABLE CLIPReplace.

8 x 1.25 mm22 N.m (2.2 kgf.m, 16 lbt ftl

--SHIFT LEVER KNOB

/ ,.-,'-' 8 N m {0.8 ksr.m. 5.8lbf.ft}

l'/

SHIFT LEVER HOUSING

{P/N 08798-9002}

r-Ll Rotate the shift cabletoward the opening.

6x1.0mm9.8Nm(1.0 kgf.m,7.2 tbf.fr)

COTTER PINS

qrBemove the shift cablefrom the shift lever bracket.{P/N 08798-9002)

13-51

Page 462 of 1139

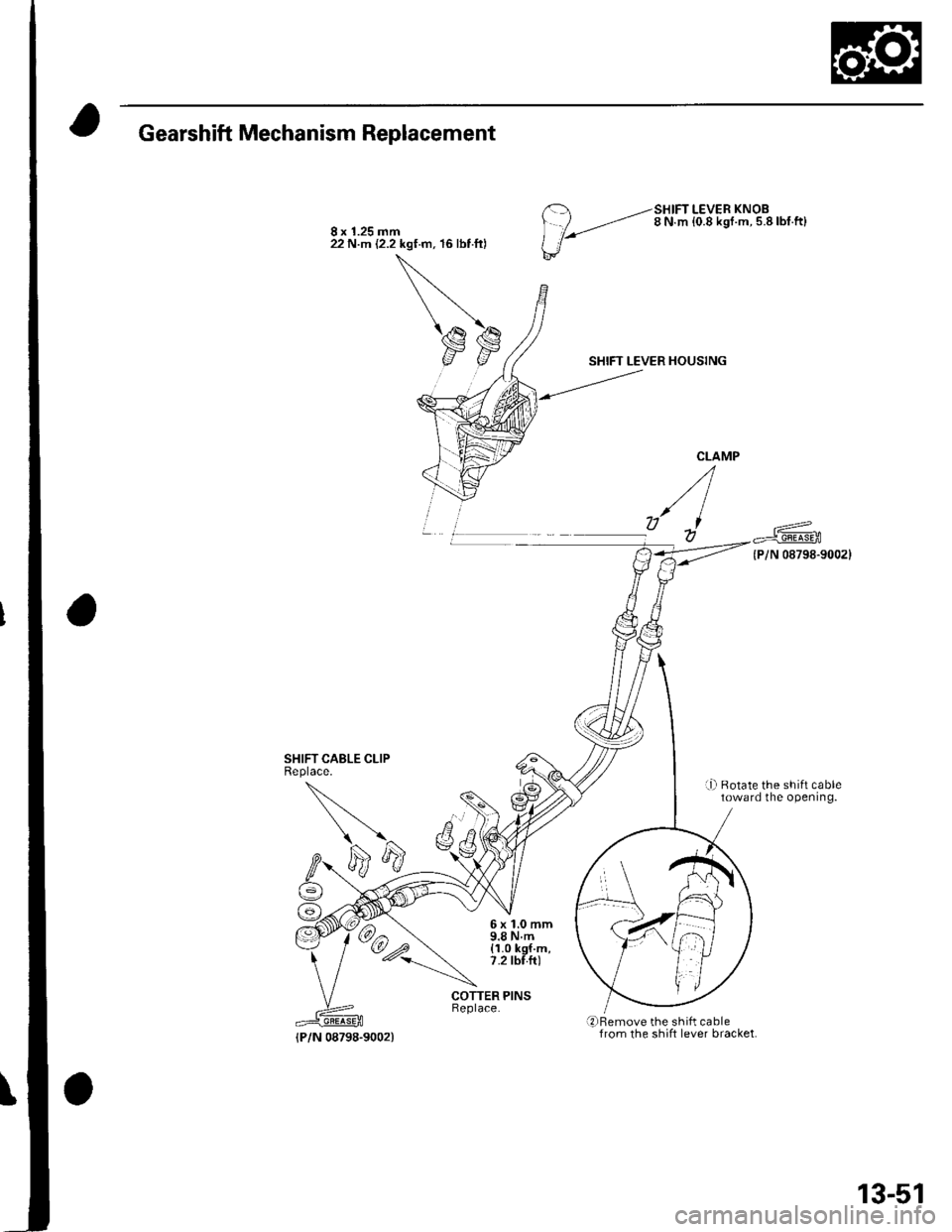

M/T Differential

Component Location Index

DRIVEN GEARBeplacement, page 13-53

Backlash Insoection. oaoe 13-53Feplacemeni, paoe I 3-5-3

\

\

,<-=- ,/BALL BEARING

/ ,/ Beplacemenl, page 13-54

I \c1 l/

=/

13-52

(

I

Page 463 of 1139

\

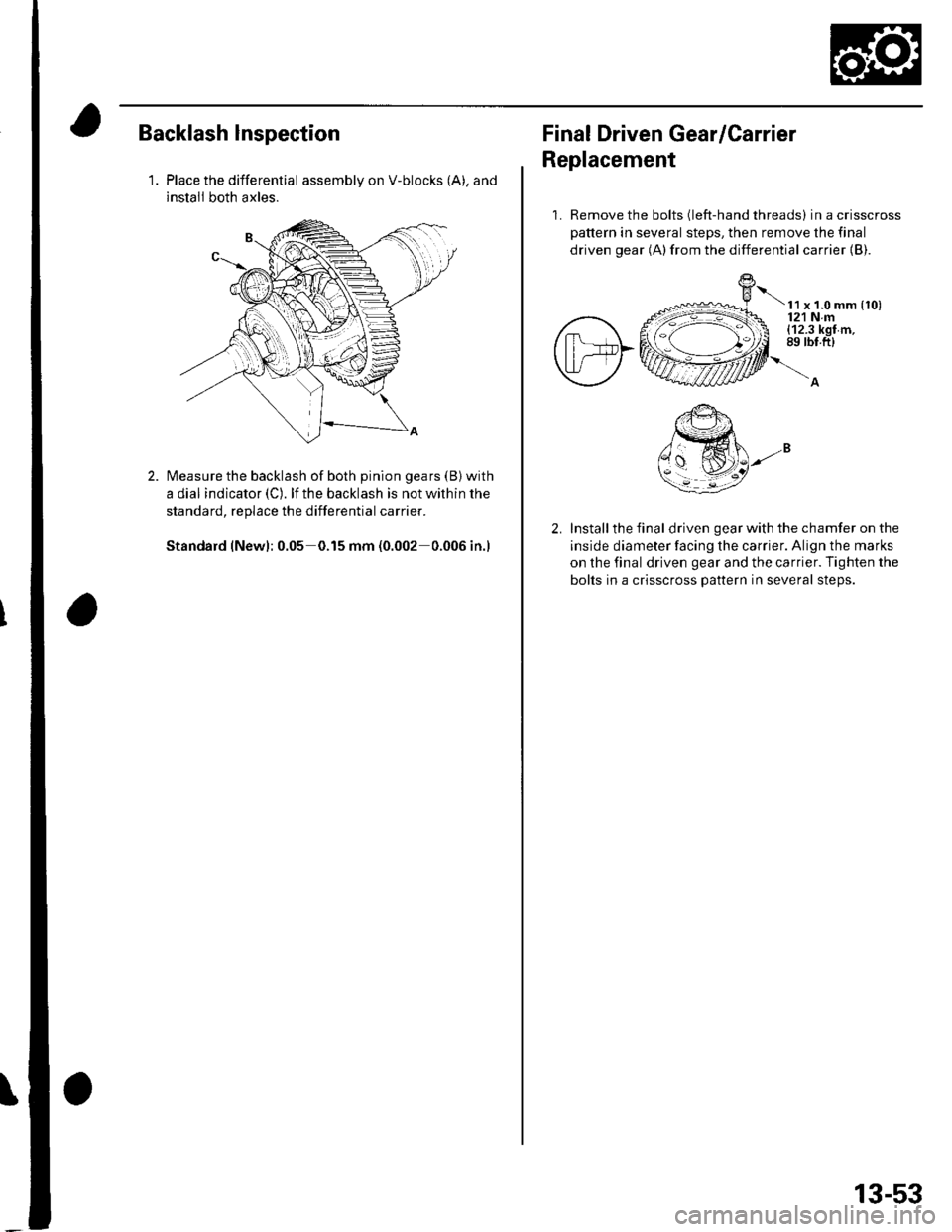

Backlash lnspection

1.Place the differential assembly on V-blocks (A), and

install both axles.

Measure the backlash of both pinion gears (B) with

a dial indicator (C). lf the backlash is not within the

standard, replace the differential carrier.

Standard (New): 0.05 0.15 mm (0.002 0.006 in.)

Final Driven Gear/Carrier

Replacement

1. Remove the bolts (left-hand threads) in a crisscross

pattern in several steps, then remove the final

driven gear (A)from the differential carrier {B).

t x t.o mm {to)121 Nm(12.3 kgf m,89 rbt.ft)

Install the final driven gear with the chamfer on the

inside diameter facing the carrier. Align the marks

on the final driven gear and the carrier. Tighten the

bolts in a crisscross pattern in several steps.

13-53

Page 464 of 1139

M/T Differential

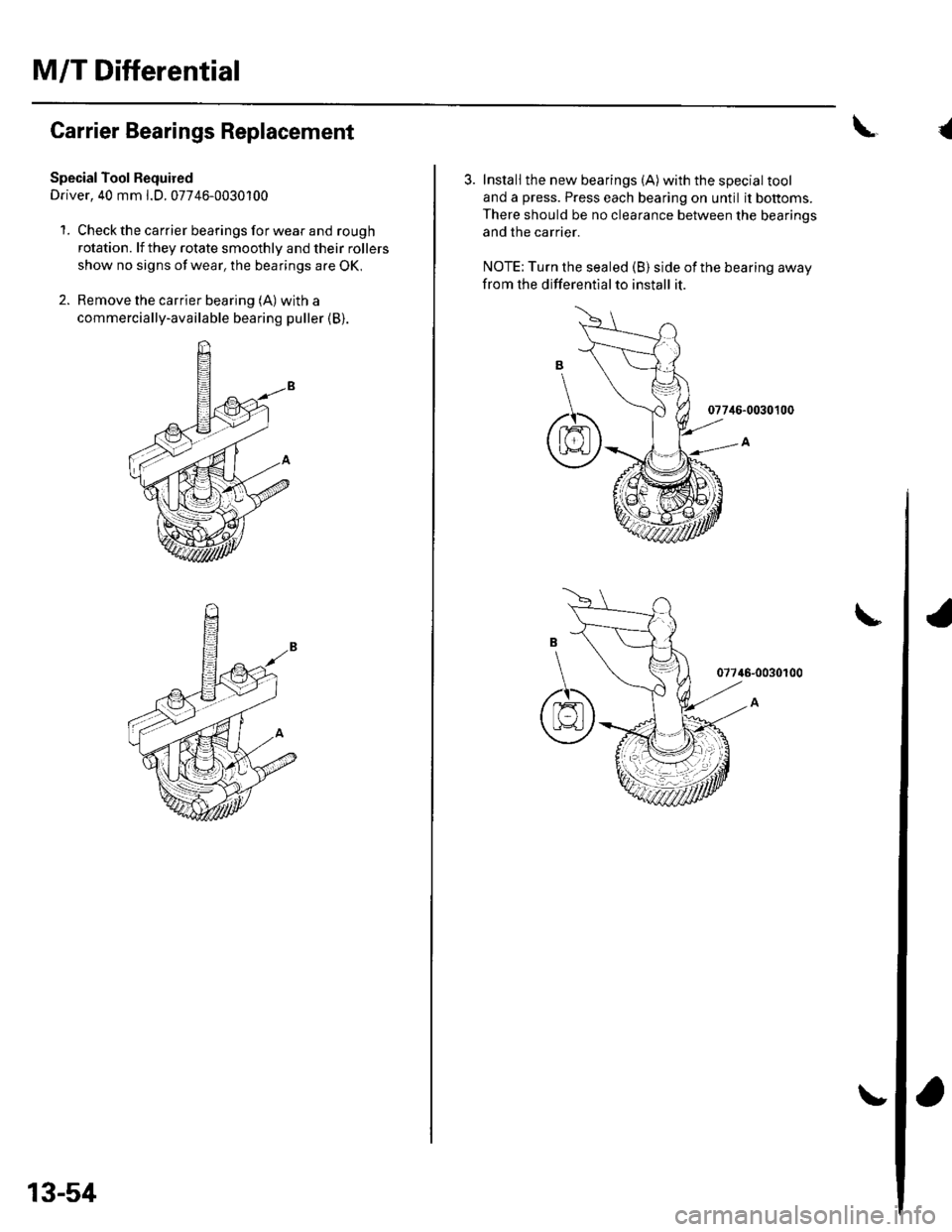

Carrier Bearings Replacement

Special Tool Bequired

Driver, 40 mm l.D. 07746-0030100

1. Check the carrier bearings for wear and rough

rotation. lf they rotate smoothly and their rollers

show no signs of wear, the bearings are OK,

2. Remove the carrier bearing (A) with a

commercially-available bearing puller (B).

13-54

\{

3. Install the new bearings (A)with the special tool

and a press. Press each bearing on until it bottoms.

There should be no clearance between the bearinos

and the carrier.

NOTE: Turn the sealed (B) side of the bearing away

from the differentialto install it.

077i16-0030100

07746-0030100

6

Page 465 of 1139

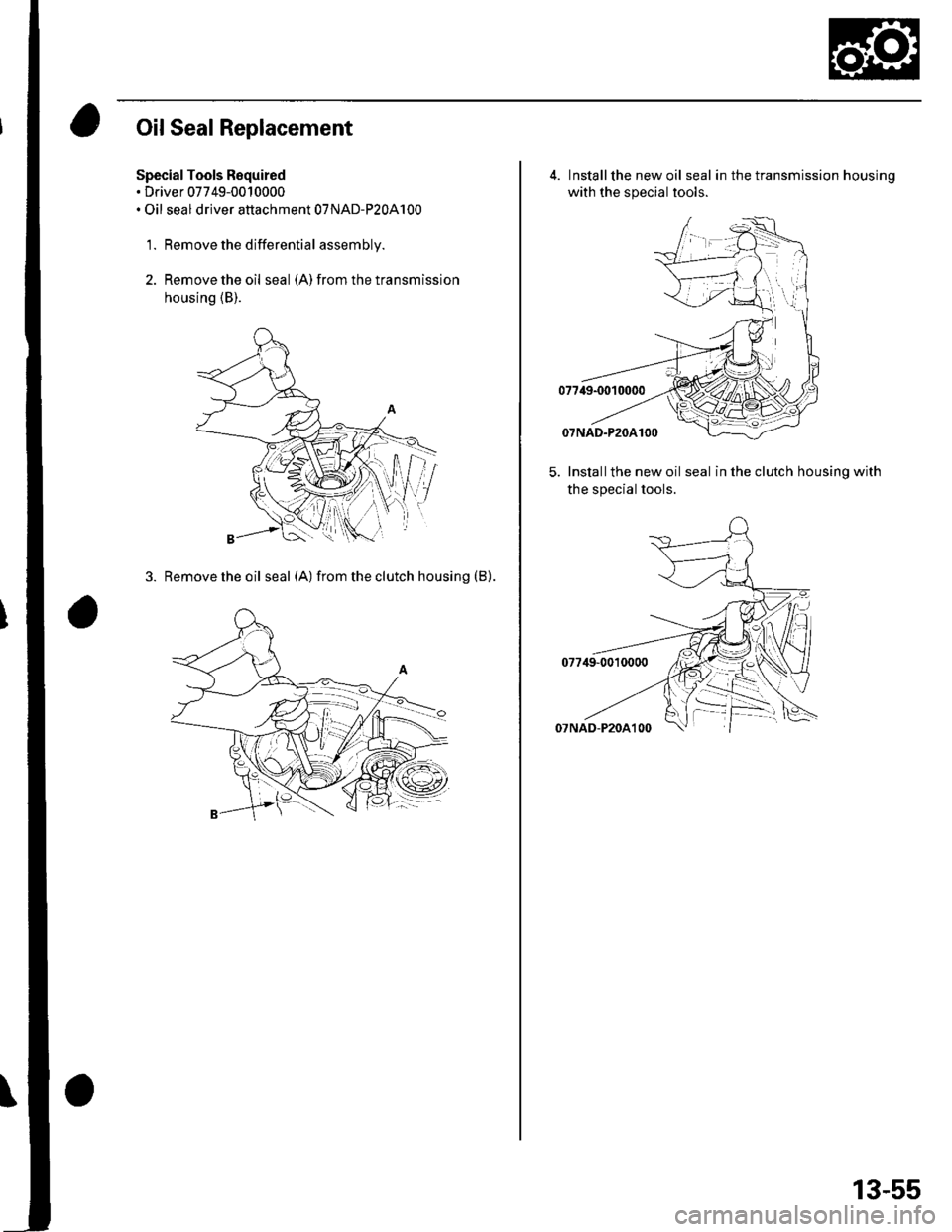

Oil Seal Replacement

Special Tools Required. Driver 07749-0010000. Oil seal driver attachment 07NAD-P20A100

1. Remove the differential assembly.

2. Remove the oil seal (A) from the transmission

housing (B).

3. Removetheoil seal (A) fromtheclutch housing (B).

4. Installthe new oil seal in the transmission housinq

with the special tools.

5. Installthe new oil seal in the clutch housing with

the special tools.

13-55

Page 466 of 1139

M/T Differential

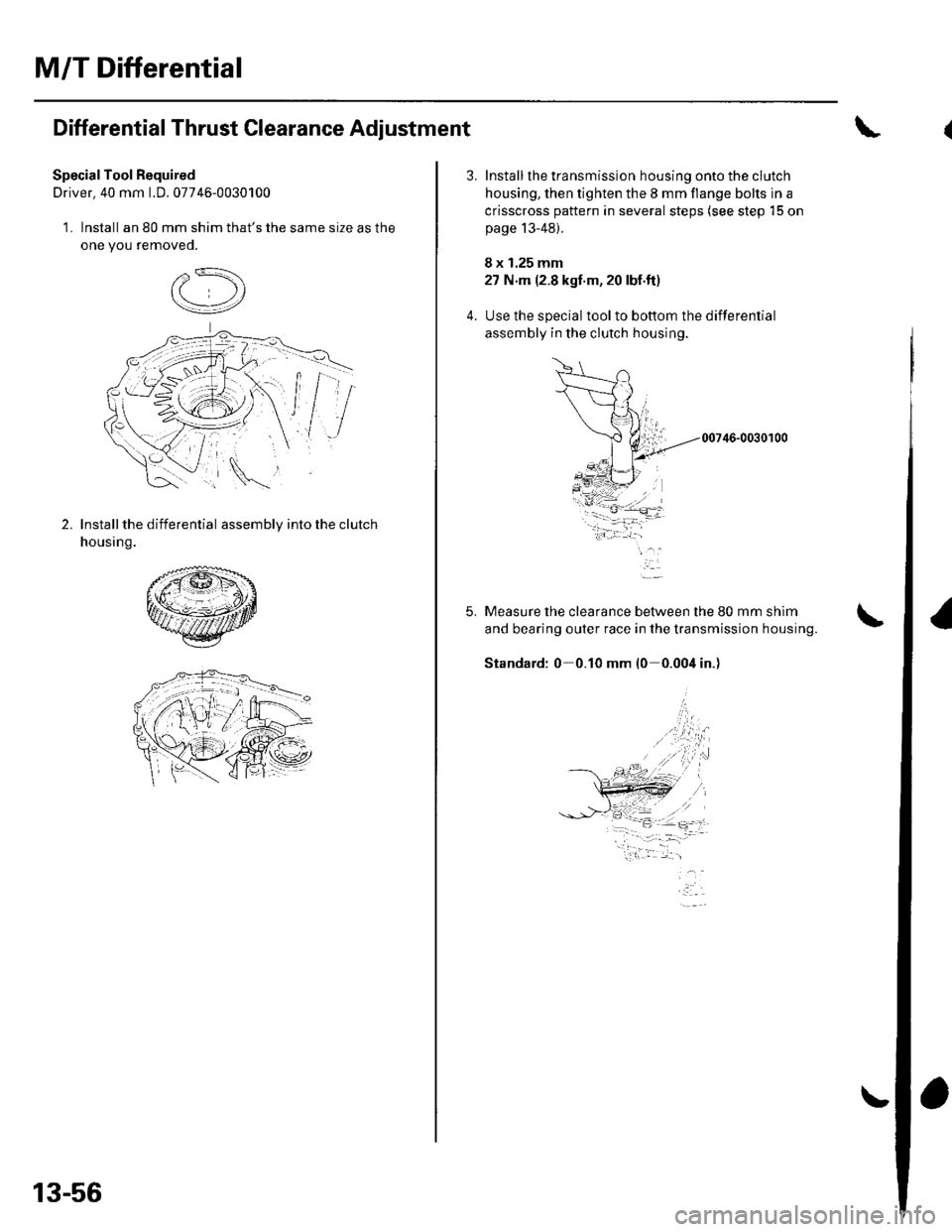

Differential Thrust Clearance Adjustment

SpecialTool Required

Driver. 40 mm LD. 07746-0030100

1. Install an 80 mm shim that's the same size as the

one you removeo.

2.Install the differential assembly into the clutch

housing.

13-56

5.

Install the transmission housing onto the clutch

housing, then tighten the 8 mm flange bolts in a

crisscross pattern in several steps (see step 15 on

page 13-48).

8 x 1.25 mm

27 N m (2.8 kgf'm, 20 lbf.ft)

Use the special toolto bottom the differential

assembly in the clutch housing.

00746-0030100

Measure the clearance between the 80 mm shim

and bearing outer race in the transmission housing.

Standard: 0 0.10 mm l0 0.004 in.)

-i.w.t ..1-- -- :,- -=.

Page 467 of 1139

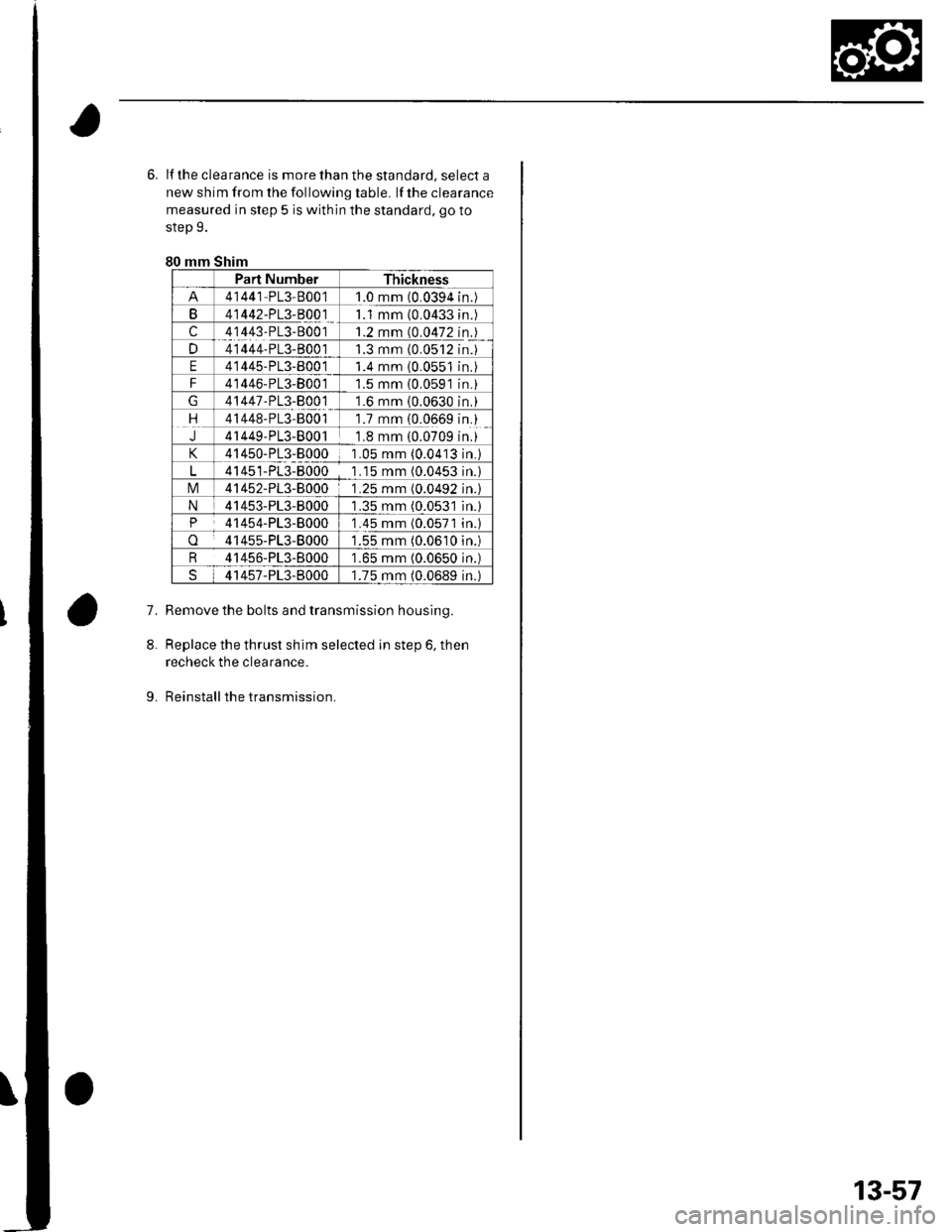

6. lf the clea rance is more than the standard, select a

new shim from the following table. lf the clearance

measured in step 5 is within the standard, go to

step 9.

80 mm Shim

Part NumberThickness

41441 PL3-80011.0 mm (0.0394n.

B41442-PL3-B00111 mm (0.0433n.

c41443-PL3-80011.2 mm (0.0472n.

D41444-PL3-B0011.3 mm {0.0512n.

E41445-PL3-800 11.4 mm 10.0551n.

F41446-PL3-80011.5 mm {0.0591n.

41447-PL3-800 11.6 mm (0.0630n.

rt41448-PL3-B0011.7 mm {0.0669n.

J41449-PL3-80011.8 mm (0.0709n.

41450-PL3-80001 .05 mm (0.0413n.)

41451-PL3-80001 .15 mm (0.0453n.l

tvl41452-PL3-80001.25 mm (0.0492n.l

N41453-PL3-80001.35 mm (0.053'ln.)

P41454-PL3-80001 .45 mm (0.0571n.l

o41455-PL3-80001.55 mm (0.0610n.)

R 41456-PL3-8000'1.65 mm (0.0650 in.)

41457-PL3-80001.75 mm (0.0689 in.)

7.Remove the bolts and transmission housing.

Replace the thrust shim selected in step 6, then

recheck the clearance.

Reinstall the transmission.

8.

9.

13-57

Page 468 of 1139

Driveline/Axle

SpecialTools ............. 16-2

Driveshaft Inspection ......................... 16-3

Driveshafts Removal .......................... 16-3

Driveshafts Disassembly ................... 16-5

Dynamic Damper Replacement ........ 16-8

Driveshafts Reassembly .................... 16-9

Driveshafts lnstallation ...................... 16-17

lntermediate Shaft Removal .............. 16-19

Intermediate Shaft Disassembly ................................. 16-20

lntermediate Shaft Reassembly .................................. 16-22

lntermediate Shaft lnstallation .................................... 16-24

Page 469 of 1139

Driveline/Axle

LSpecialTools

a\*

o@

tg r?)

[]

\J

,0)

Ref. No.Tool NumberDescriDtionOrv

n]

@

o

@

t9

6)

o(D

07GAD-PH70201

07MAC-S100200

07 NAF-SR30101

07xAc-001010A

07746-0010400

07746-0030400

07749-0010000

07947-S800100

Oil Seal Driver

BallJoint Remover, 28 mm

Half Shaft Base

Threaded Adapter, 22 x 1.5 mm

Attachment, 52 x 55 mm

uflver, J5 mm LU.

Driver

Oil Seal Driver

1

1

1

1

1

1

1

1

16-2

Page 470 of 1139

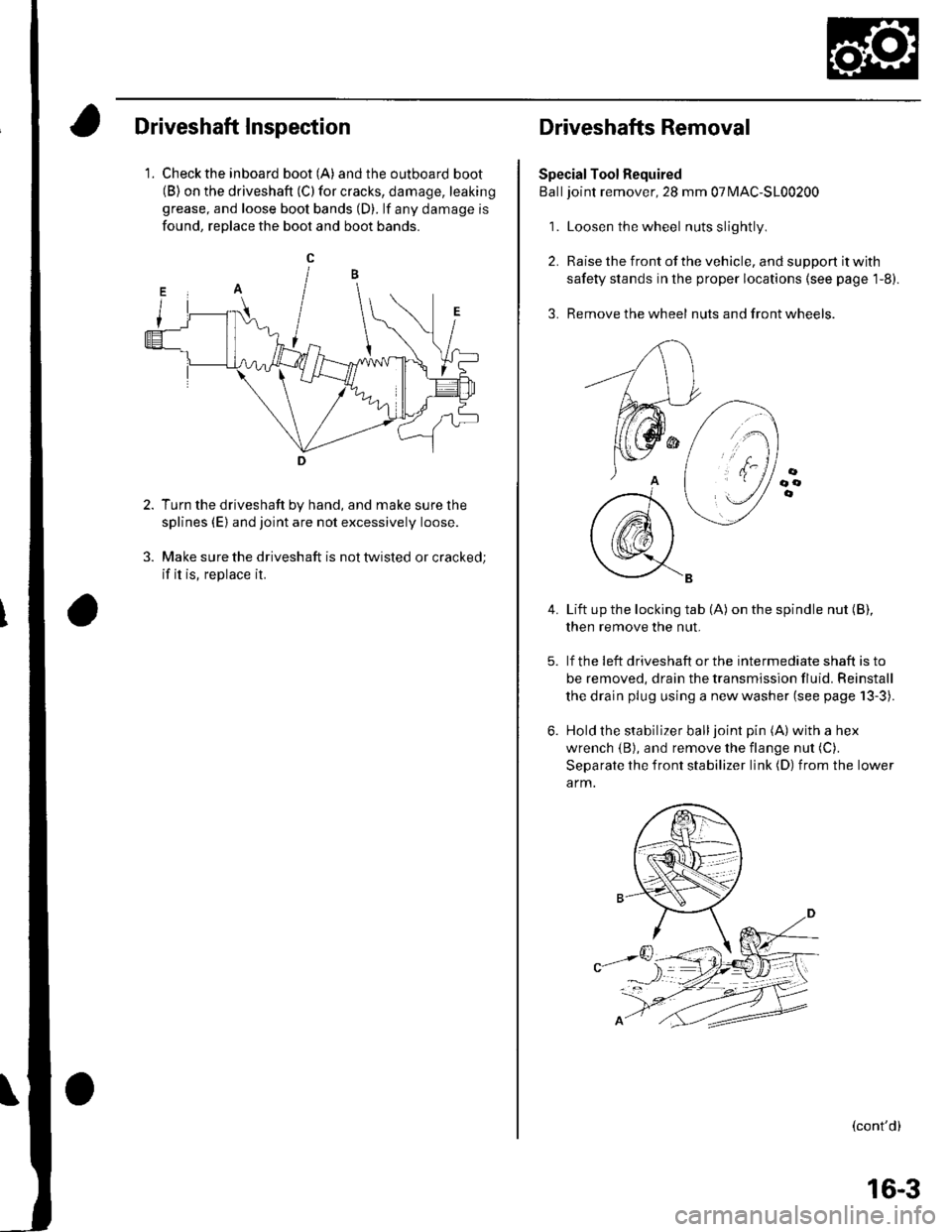

Driveshaft Inspection

1. Check the inboard boot (A) andthe outboard boot(B) on the driveshaft (C) for cracks, damage, leaking

grease, and loose boot bands (D). lf any damage is

found, reDlace the boot and boot bands.

Turn the driveshaft by hand, and make sure the

splines (E) and joint are not excessively loose.

Make sure the driveshaft is not twisted or cracked;

if it is, replace it.

Driveshafts Removal

Special Tool Required

Balljoint remover, 28 mm 07MAC-S100200

1. Loosen the wheel nuts slightly

2. Raise the front of the vehicle, and support it with

safety stands in the proper locations (see page 1-8).

3. Remove the wheel nuts and front wheels.

4.Lift up the locking tab (A) on the spindle nut (B),

then remove the nut.

lf the !eft driveshaft or the intermediate shaft is to

be removed, drain the transmission fluid. Reinstall

the drain plug using a new washer (see page 13-3).

Hold the stabilizer balljoint pin (A) with a hex

wrench {B), and remove the flange nut (C).

Separate the front stabilizer link (D) from the lower

a rm.

(cont'd)

16-3

Trending: Antenna, Wiring, Diesel, Engine model, tire size, child restraint, coolant

![HONDA CIVIC 2003 7.G Workshop Manual Driveline/Axle

LSpecialTools

a\*

o@

tg r?)

[]

\J

,0)

Ref. No.Tool NumberDescriDtionOrv

n]

@

o

@

t9

6)

o(D

07GAD-PH70201

07MAC-S100200

07 NAF-SR30101

07xAc-001010A

07746-0010400

07746-0030400

07749-00 HONDA CIVIC 2003 7.G Workshop Manual Driveline/Axle

LSpecialTools

a\*

o@

tg r?)

[]

\J

,0)

Ref. No.Tool NumberDescriDtionOrv

n]

@

o

@

t9

6)

o(D

07GAD-PH70201

07MAC-S100200

07 NAF-SR30101

07xAc-001010A

07746-0010400

07746-0030400

07749-00](/img/13/5744/w960_5744-468.png)