lock HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 602 of 1413

Driveshafts

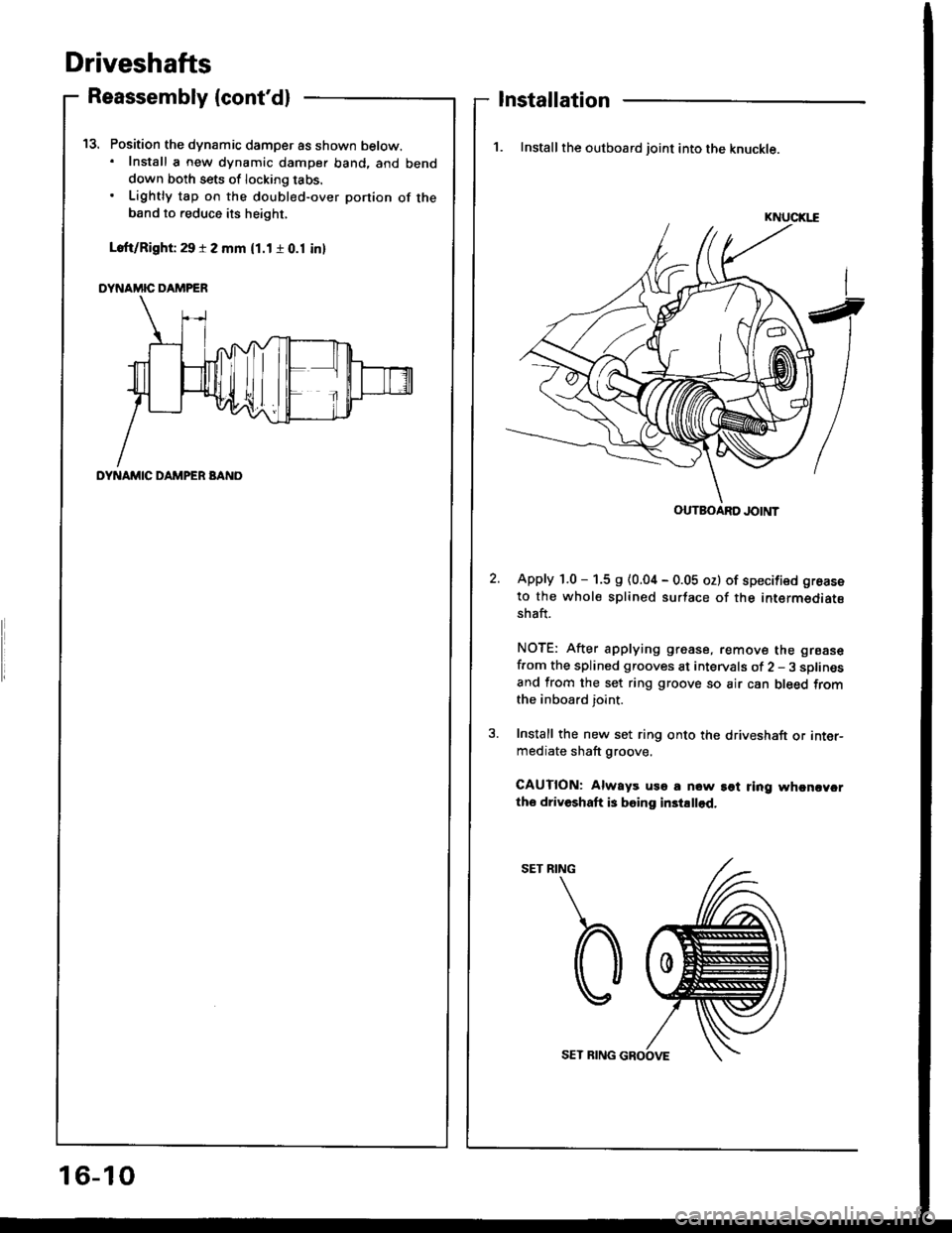

Position the dynamic damper as shown below.. Install a new dynamic damper band. and benddown both sets of locking tabs.

Lightly tap on the doubl€d-over ponion of theband to reduce its height,

Loft/Right 29 r 2 mm (1.1 r 0.1 inl

DYNAMIC DAMPER

t5.

Reassembly (cont'dl

DYNAMIC DAMPER BANO

Installation

1. Install the outboard joint into the knuckle.

KNUCIGE

Apply 1.0 - 1.5 s (0.04 - 0.05 oz) of specified groase

to the whole splined surtace of the intermediatsshaft.

NOTE: After applying grease, remove the grsase

f.om the splined grooves at intervals of 2 - 3 sDlinesand from the set ring groove so air can bleed fromthe inboard joint.

Install the new set ring onto the driveshaft or inter-mediate shaft groove.

CAUTION: Always uso a now sot ring whcncycrtho driveshaft is boing in3tallod.

RING

b

OUTBOARD JOINT

16-10

SET RING GROOVE

Page 603 of 1413

5.

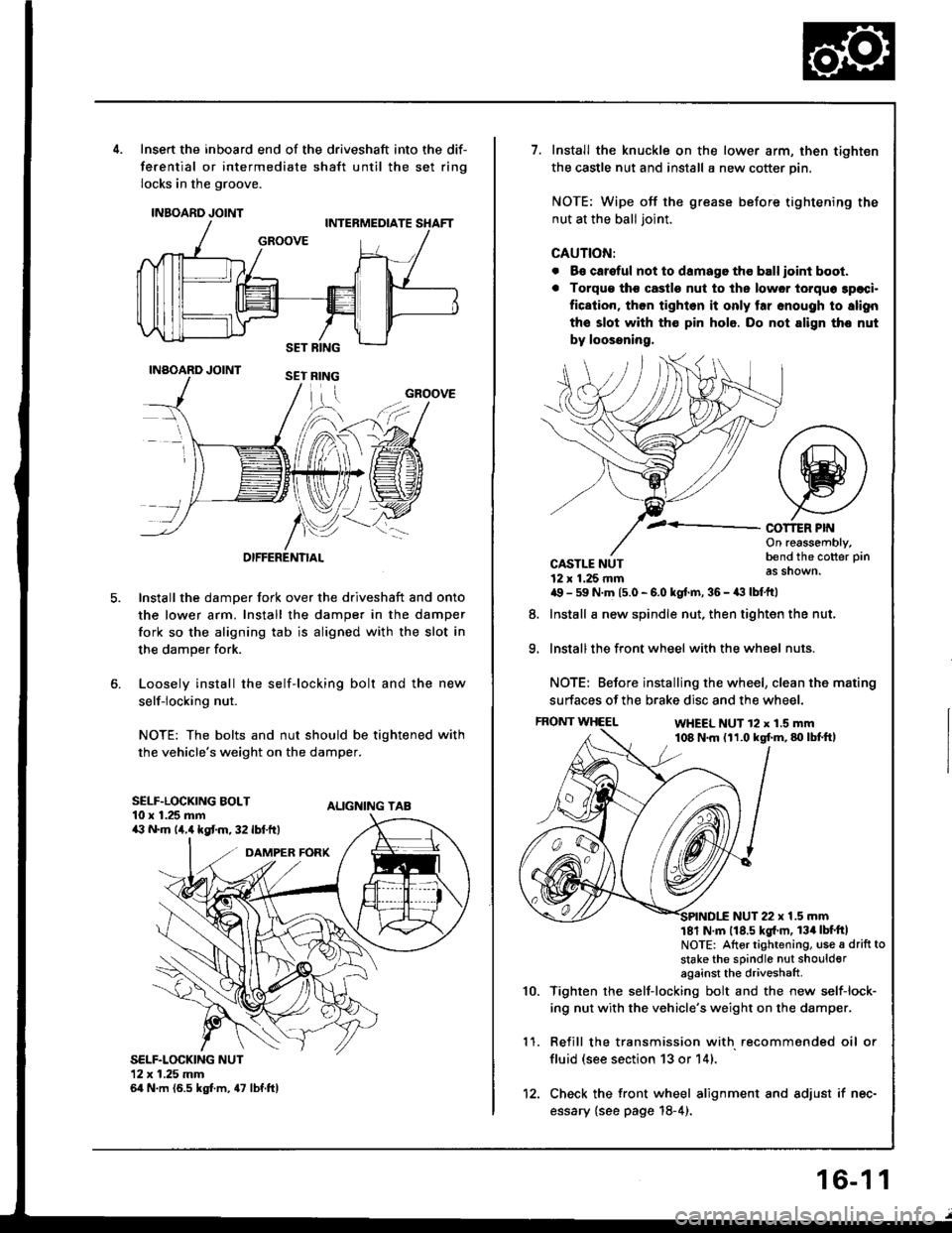

Insert the inboard end of the driveshaft into the dif-

ferential or intermediate shaft until the set ring

locks in the groove.

INBOARD JOINT

INAOARD JOINT

OIFFERENTIAL

Install the damper fork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damper fork.

Loosely install the self-locking bolt and the new

self-locking nut.

NOTE: The bolts and nut should be tightened with

the vehicle's weight on the damper.

ALIGNING TAB

SELF.LOCKING NUT12x 1.25 mm64 N.m (6.5 kgt m, 47 lbf.ftl

GROOVE

SELF.LOCKING BOLT10 x 1.25 mma:' N.m lir,4 kgt m, 32 lbf.ftt

1.Install the knuckle on the lower arm, then tighten

the castle nut and install a new cotter pin.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

CAUTION:

. B€ careful not to damago tho ball ioint boot.

. Torqu€ tho castle nut to ths lower torquo 3paci.

fication, then tighlon it only tar snough to slign

the slot with th€ pin hole. Do not align tho nut

by loossning,

COT1ER PIf{On reassembly,bend the cotter pin

as shown.

9.

CASTLE NUT12 x 1.25 rnma9 - 59 N.m 15.0 - 6.0 kgt.m, 36 - a:t lbtftl

Install a new spindle nut, then tighten the nut,

Install the front wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEELWHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbtft,

8.

1 '�I.

10.

NUT 22 x 1.5 mm181 N m 118.5 kgl'm, 134lbt'ftlNOTE: Altor tightening, use a drift to

stake the sPindle nut shoulderagainst the driveshaft

Tighten rhe self-locking bolt and the new self-lock-

ing nut with the vehicle's weight on the damper.

Refill the transmission with recommended oil or

fluid (see section 13 or 14).

Check the front wheel alignment and adjust if nec-

essary {see page 18-4).

12.

16-1 1

Page 609 of 1413

I

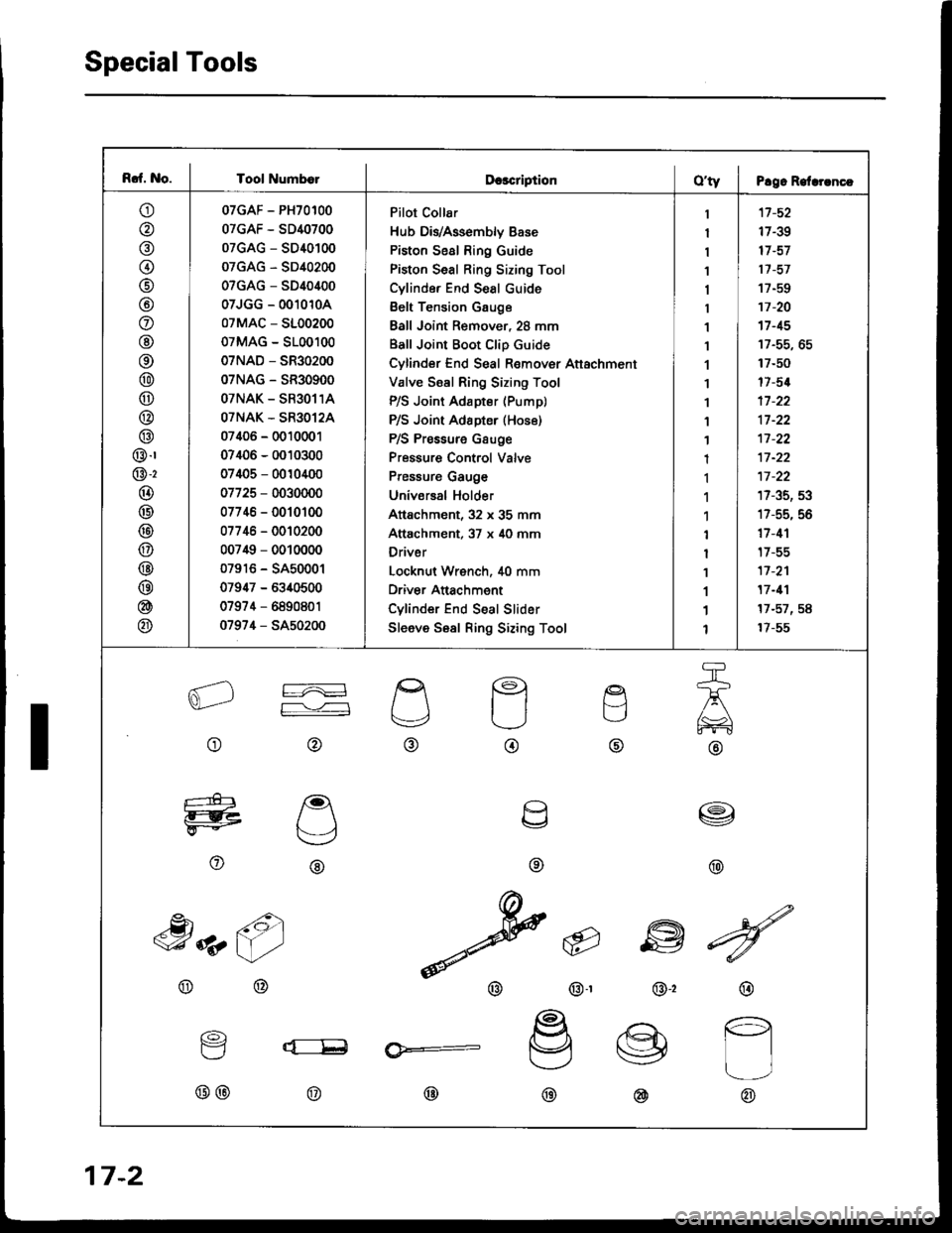

Rcf. No. I Tool Numb€lDcscriptionO'ty I P!9. Relrrrncc

o

@

@(t

@

@

o

@

@

@

@

@

@

@.r

@-2

@

@

@

@

@

@

@

@

07GAF - PH70100

07GAF - SD40700

07GAG - SD40100

07GAG - SD40200

07GAG - SD40400

07JGG - 0010104

07MAC - 5100200

07MAG - 5100100

07NAD - SR30200

07NAG - SR30900

OTNAK - SR3O11A

OTNAK - SR3O12A

07406 - 0010001

07406 - 0010300

07405 - 0010400

07725 - 0030000

07746 - 0010100

07746 - 0010200

007i$ - 0010000

07916 - SA50001

07947 - 6340500

07974 - 6890801

0797,1 - SA50200

Pilot Collar

Hub DivAssembly Base

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Cylinde. End Seal cuide

Belt Tension Gauge

Ball Joint Remover, 28 mm

Ball Joint Boot Clip Guide

Cylinder End Seal Remover Attachment

Valve Ssal Ring Sizing Tool

P/S Joint Adapter (Pump)

P/S Joint Adapter (Hos6)

P/S Pressure Gsuge

Pressure Control Valve

Pressure Gauge

Universal Holder

Attachment, 32 x 35 mm

Attachment, 37 x 40 mm

Driver

Locknut Wrench, i[0 mm

Driver Anachment

Cylinder End Seal Slider

Sleeve Sesl Ring Sizing Tool

1

I

1

1

1

1

1

1

1'I

1

1

1

1

1

1'l

1

I

1

1

1

1

'17 -52

17-39

17 -57

17 -57

17-EO

17 -20't7 -15

17-50

17-5{

17 -22

17 -22't1-22

17 -22

17-35, 53

17-55, 56

17 -1'l

t7-55

17 -2'l

17 -11

17-57,58

17-55

aL2

o

re

F--,'---l

@

g

t.-,

@

q

o

etl

TJ

@

a\,

@

e

U

\v

o

I

@

,h z6)

@

@-r

6

w

@,2

^dN

v

@

@

16)

Y

@@

lx:__E

@

@:

@@

17-2

Page 619 of 1413

Troubleshooting

General Troubleshooting {cont'd}

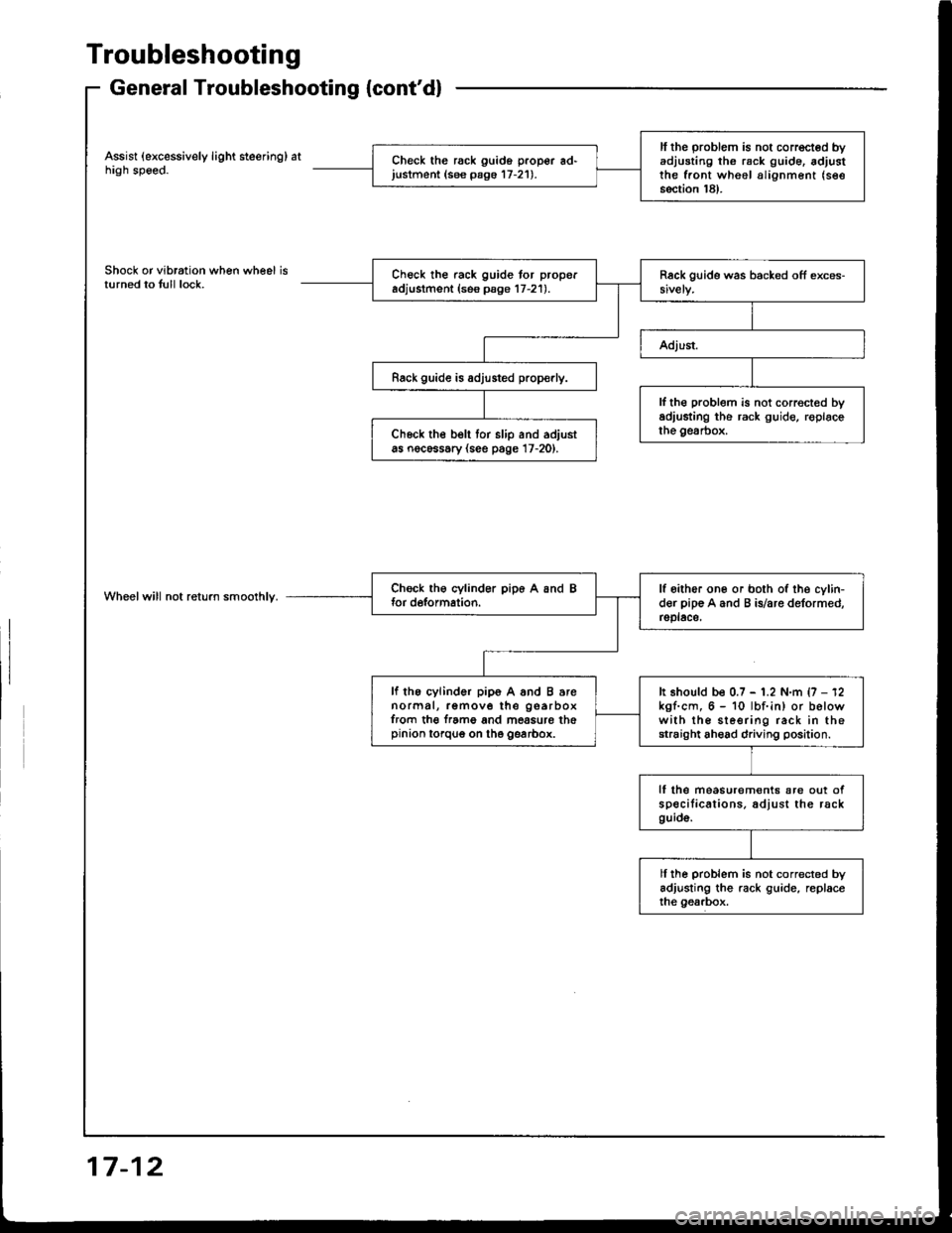

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to tull lock.

Wheelwill not return smoolhly.

ll the problem is not corrected byadjusting th6 rack g!ide. adjustthe front wheel alignment (see

section 18).

Check the rack guido proper ad'justment (see pago 17-21).

Check the rack guide tor properadjustment (ses psge 17-21).

Rack guide is adjusted prop€rly.

lf th€ problem is not correct€d byadiusting the rack guide, roplacethe gesrbox.Ch6ck the belt tor slip and adjustas nocessary (see page 17-20).

lf oither one or both of the cylin-der pip€ A and B is/are deformed,rsplace,

lf the cylinder pip6 A and B arenormal, remove the gearboxfrom th€ f.ame and mossure thepinion torqug on the gearbox.

It should be 0.7 - 1.2 N.m {7 - 12kgf.cm, 6 - 10 lbf.in) or belowwith the sleering rack in thestraight ahead driving position.

lf lhe measurem€nts are out ofspecilications. adjust the rackguid6.

ll ihe problem is not corrected byadjusting the rack guide, replaceihe gearbox.

17-12

Page 625 of 1413

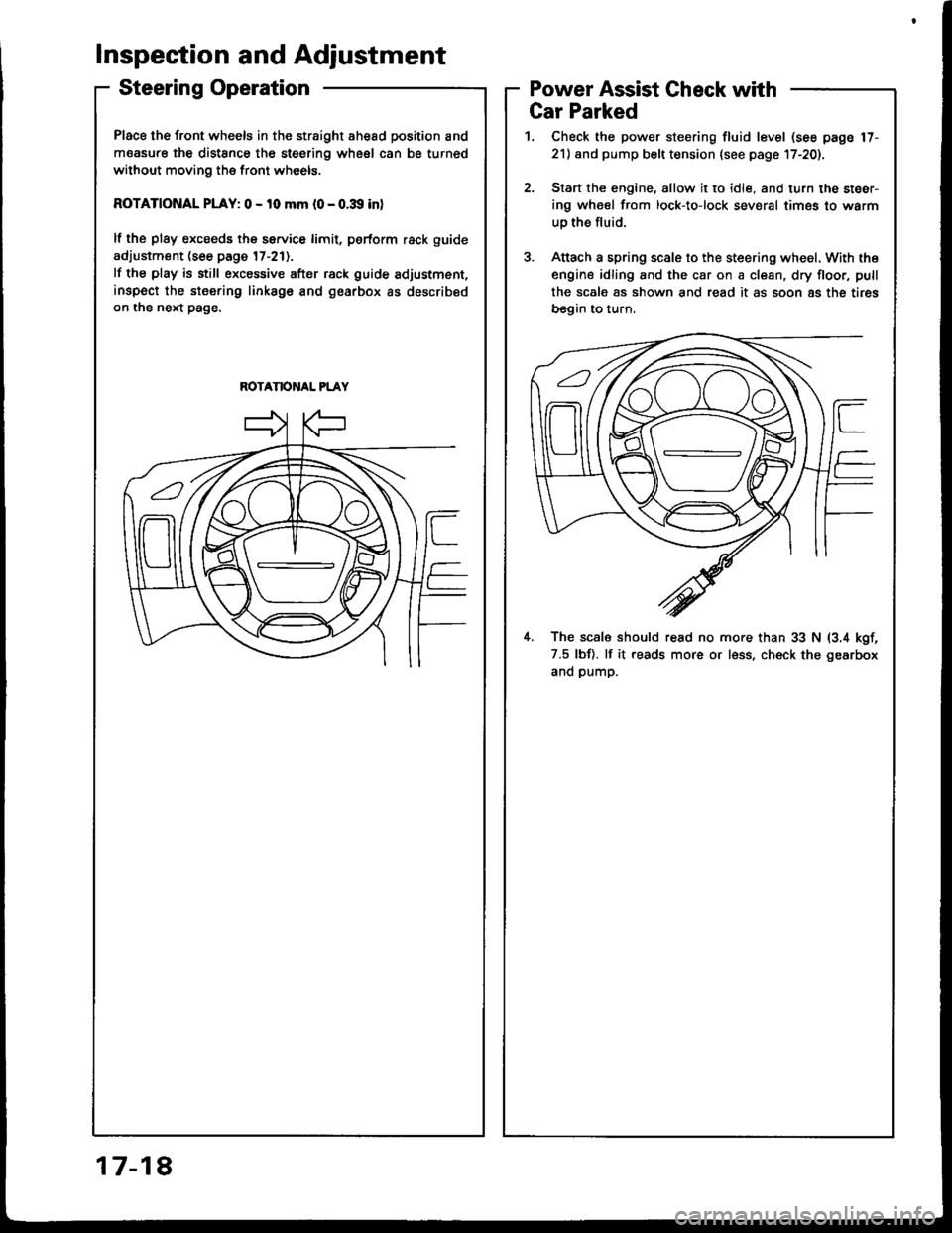

Place the front wheels in the straight ahesd position and

measure the distSnce the steering wheel can be turned

without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm l0 - o.:Xl inl

lf the plsy excseds the service limit, psrform rack guide

adjustment (see page 17-211.

lf the play is still excessive after rack guide adjustment,

inspect the stsering linksgo and gearbox as described

on the next page.

ROTANONAL PLAY

Inspection and Adjustment

Steering OperationPower Assist Gheck with

817-1

Gar Parked

1. Check the power steering fluid level (see page 17-

21) and pump belt tension lsee page l7-20).

2.Start the engine, allow it to idle, and turn the steer-

ing wheel from lock-to-lock sev€ral times to warm

uo the fluid.

Attach a spring scale to the steering wheel. With the

engine idling and the car on a clean, dry floor, pull

the scale as shown and read it as soon 8s the tires

begin to turn,

il. The scal6 should read no more than 33 N (3.4 kgf,

7.5 lbf). lf it reads more or less, ch€ck the gearbox

and pump.

Page 626 of 1413

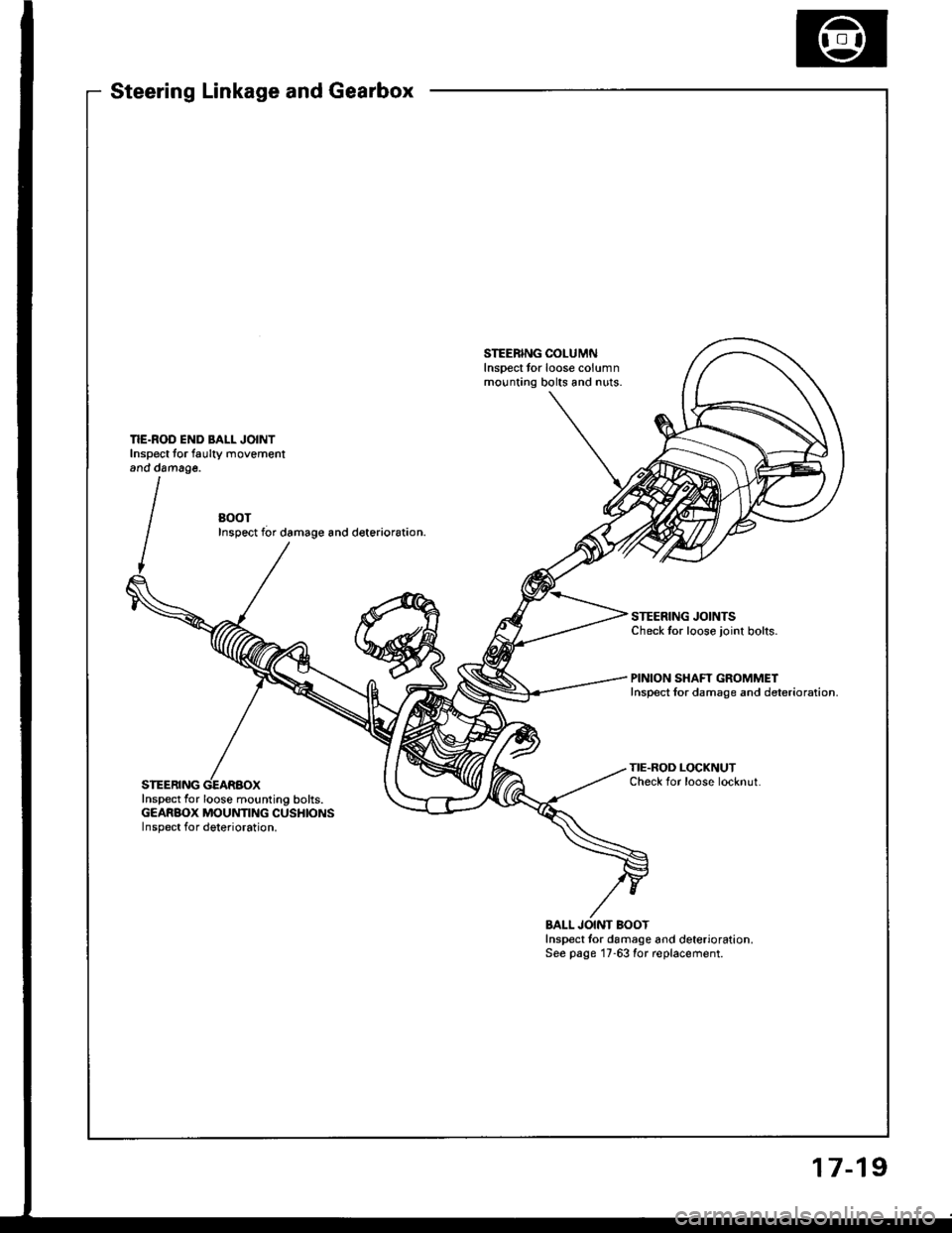

Steering Linkage and Gearbox

STEERING COLUMNlnsoect tor loose columnmounting bolts and nuts.

BOOTInspect f6r damage and deterior6tion.

STEERING JOINTSCheck tor loose joint bolts.

PINION SHAFT GROMMETInspect lor damage and deterioration.

STEERING

TIE.ROD LOCKNUTCheck for loose locknut.

Inspect lor loose mounting bolts.GEARBOX MOUNTING CUSHIONSInspect for deterioration.

BALL JOINT BOOTInspect tor damage and deterioration.See psge 17-63 for replacement.

17-19

Page 627 of 1413

Inspection and Adjustment

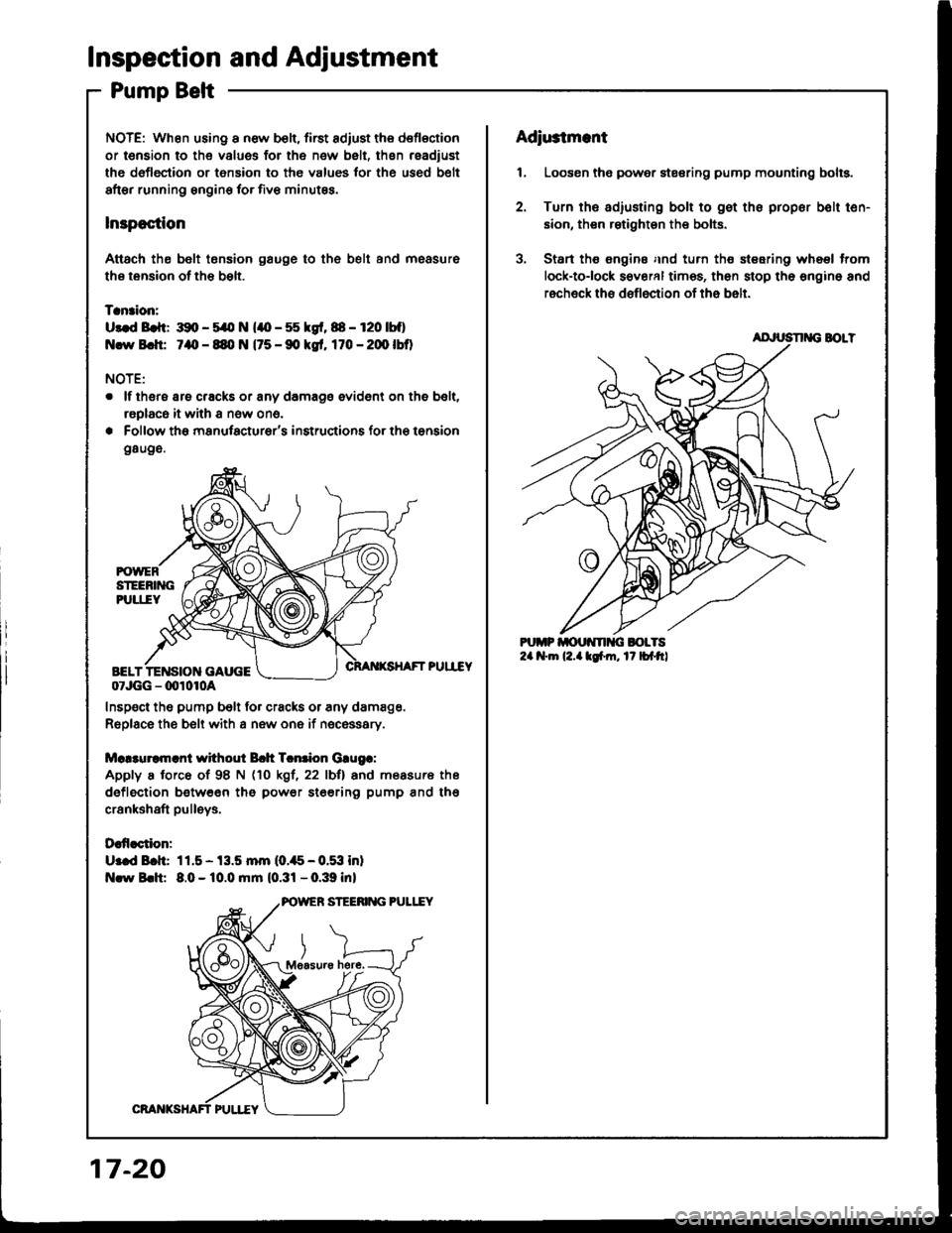

Pump Belt

NOTE: When using a new b€li, first adiust the deflection

or t€naion to the values for the new belt, thsn readiust

ths deflection or tension to the values tor the used b€lt

after running sngine for five minutss.

lnspoction

Attach th€ belt tonsion gauge to th6 belt and measure

ths tension of the bslt.

Tanaion:

U3.d Brft: 391, - 5/O N (lO - 55 kgf, 88 - r20 |bf)

Ncw Bch: 7aO - 89, N (75 - 90 kgt, 170 - 20O lbO

NOTE:

. lf thsre are cracks or any damage evident on the belt,

raplaca it with a now ono.

. Follow the manufacturer's insructions for the tonsion

g8uge.

PUII"EY

07JGG - 00r0r0a

Inspect the pump belt for cracks or any damage.

Replace the belt with a new one if nec€ssary.

Mc!3uramrnl without Bch Tcntion Grugr:

Apply a torce of 98 N (10 kgl, 22 lbll and measure ths

deflection between tho power ste€rin9 pump and tho

crankshaft pulleys.

Daffaction:

U:ed Bch: 11.5- 13.5 mm (0.,t5-0.53 inl

Nlw Brh: 8.0 - 10.0 mm (0.31 - 0.39 inl

here,

17-20

Adiu3tmant

1, Loosen the power stesring pump mounting bolts.

2. Turn ths adiusting bolt to gst the propor bolt ten-

sion, then rstighten the bolts.

3, Start ths €ngine and turn the steering wheel trom

lock-tolock s€veral times, then stop the engino and

recheck ths deflection of the belt.

AD'USN G BOLT

Page 628 of 1413

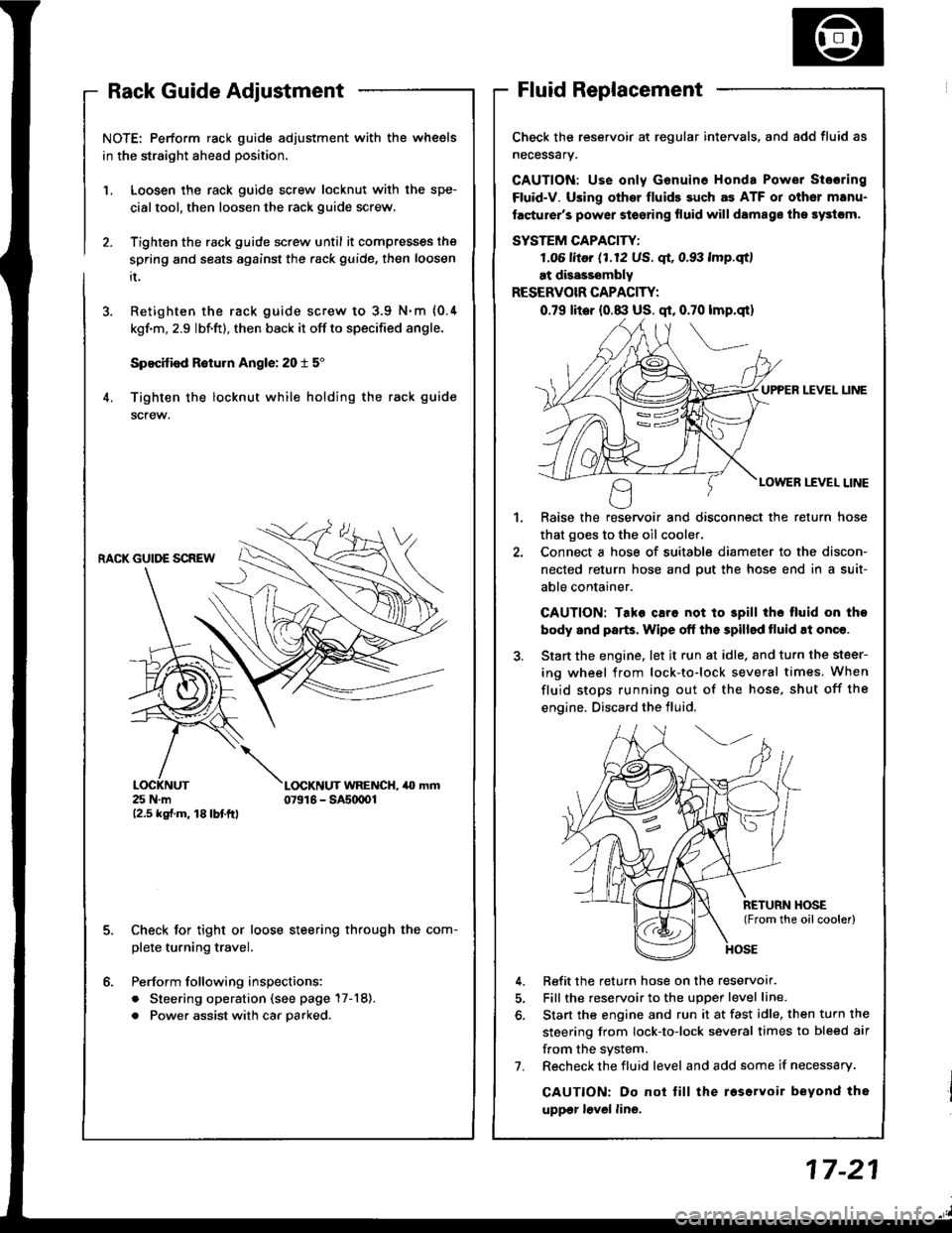

NOTE: Perform rack guide adjustment with the wheels

in the straight ahead position.

Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

Tighten the rack guide screw until it compresses the

spring and seats against the .ack guide, then loosen

it.

Retighten the rack guide screw to 3.9 N.m {0.4

kgf'm, 2.9 lbf.ft), then back it off to specified angle.

Specified R6turn Angle: 20 t 5"

Tighten the locknut while holding the rack guide

screw.

1.

6.

RACK GUIDE SCREW

25 N.m12.5 kgf.m, 18lbtftl

L(rcKNUT WRENCH, 40 mm07916 - SAs(xtOl

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-18).

. Power assist with car parked.

Check the reservoir at regular intervals. and add fluid as

necessary.

GAUTION: Use only Genuine Honda Power Stosring

Fluid-V. Using othsr fluids such as ATF or other manu-

facturer's power stoering fluid will damags ths systcm,

SYSTEM CAPACITY:

LO6 litor (1.12 US. qt, 0.93 lmp.qtl

at disasssmbly

RESERVOIR CAPACITY:

0.79 lit6r (0.8:l US. qt, 0.70 lmp.qt)

UPPER LEVEL UNE

LOWER LEVEL LINE

,l

Raise the reservoir and disconnect the return hose

that goes to the oil cooler.

Connect a hose of suitable diameter to the discon-

nected return hose and put the hose end in a suit-

able container.

CAUTION: Tako caro not to 3pill tho tluid on tho

body and parts. Wipe off the spilled tluid at onqe.

Start the engine. let it run at idle. and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid,

Refit the return hose on the reservor.

Fill the reservoir to the uDoer level line.

Start the engine and run it at fast idle, then turn the

steering from lock-to-lock several times to bleed air

f.om the system.

Recheck the fluid level and add some if necessary.

CAUTION: Do not lill the roservoir beyond tho

uppgr lovel line.

7.

Page 629 of 1413

lnspection and Adjustment

Pump Pressure Check

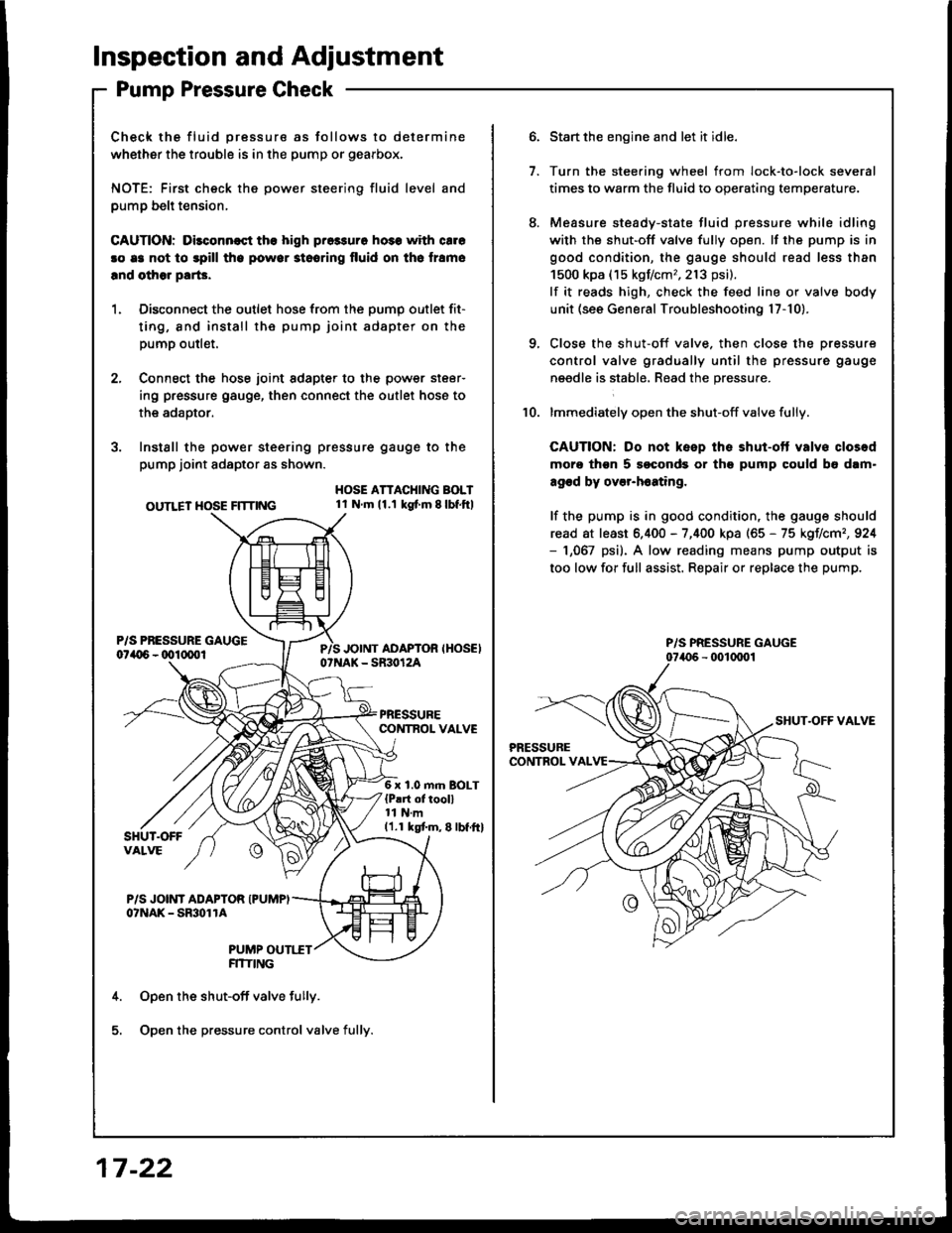

Check the fluid pressure as follows to determine

whether the trouble is in the pump or gearbox.

NOTE: First check the power steering fluid level and

pump belt tension,

CAUnON: Dilconn€st the high pros3uro ho3s with cale

!o e3 not to spill tho powor stooring fluid on th6 lramo

lnd olhor parG.

1. Disconnect the outlet hose from the oumo outlet fit-

ting, 8nd install the pump joint adapter on the

pump outlet.

2, Connect the hose joint sdapter to the power steer-

ing pressure gauge, then connect the outlet hose to

the adaotor.

3. Instsll the power steering pressure gauge to the

pump joint adaptor as shown.

OUTLET HOSE FlTnNG

HOSE ATTACHING BOLT1l Nm11.1 kg{ m 8lbf.ftl

6 x 1.0 m.n BOLT{P!rt of tooll11 N.m11.1 kgtm,8lbf.ftl

P/S JOINT ADAPTOR IPUMPIo?NAK - SmolrA

PUMP OUTI.TTFITIING

Open the shut-off valve fully.

Open the pressure control valve fully.

17 -22

1.

Start the engine and let it idle.

Turn the stee.ing wheel from lock-to-lock several

times to warm the fluid to operating temperature.

Measure steady-state fluid pressure while idling

with the shut-off valve fully open. lf the pump is in

good condition, the gauge should read less than

1500 kpa (15 kgf/cm,,213 psi).

lf it reads high, check the feed line or valve body

unit (see General Troubleshooting l7-10).

Close the shut-off valve. then close the pressure

control valve gradually until the pressure gauge

needle is stabl6, Read the pressure.

lmmediately open the shut-off valve fully.

CAUTION: Do not keep the shut-ott valvs closod

moro thgn 5 soconds or th9 pump could b6 dam"

agod by over-h6ating,

lf the pump is in good condition, the gauge should

read at least 6.400 - 7,400 kpa (65 - 75 kgIlcm,,924- 1,067 psi). A low reading means pump output is

too low for full assist. Repair or replace the pump.

10.

P/S PRESSURE GAUGE

Page 633 of 1413

Steering Wheel

Installation

Airbag installation

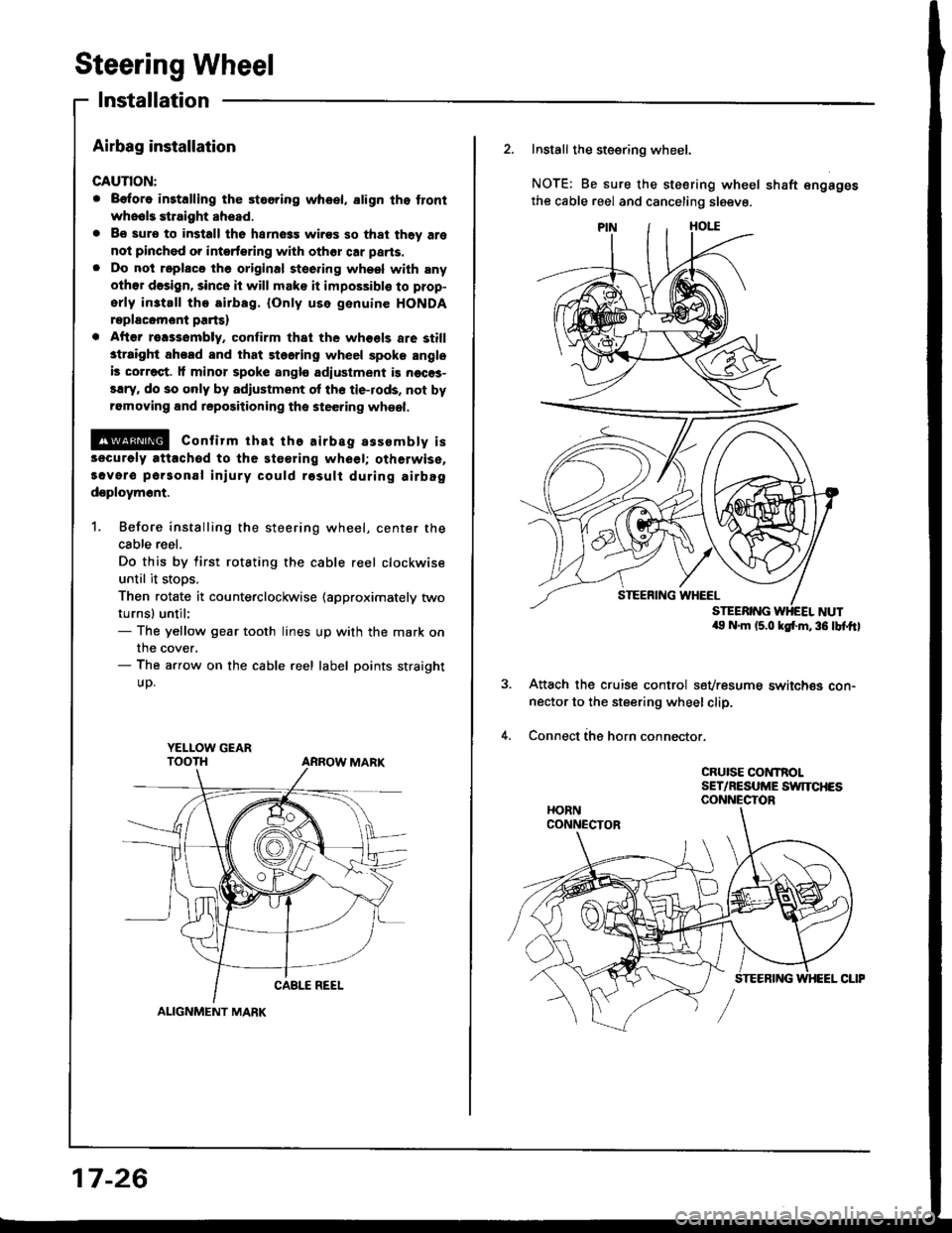

CAUTION:

. B€fore inrtalling the stooring wheel, align tho front

who6l3 etraight ahead.

. Bo sure to install the harness wires so that thGy are

not pinched or intorfsring with othor car parts.

. Do not roplace thc original stsoring wheel with any

othor design. since it will maks it impo$ibla to prop-

erly install the airbag. {Only use genuine HONDA

replscomont parts)

. After rols3embly. confirm thai the whoels are still

straight ahoad 8nd that steoring wheel spoke anglo

is correct. lf minor spoke anglo adiustment is noc€s-

srry, do so qnly by adlustment ol th€ tie-rods, not byromoving and repositioning the steering wh€€|.

@ contirm ihat the airbag assombly is

socurely attachsd to the stooring wheel; oth€rwise,

scvoro porsonal iniury could r€sult during airbag

doploym6nt.

1. Before installing the steering wheel, center the

cable reel.

Do this by tirst rotating the cable reel clockwise

until it stoos.

Then rotate it counterclockwise (approximately two

turnsl until:- The yellow gear tooth lines up with the mark on

the cover.- The arrow on the cable reel label points straight

UD.

YELI-OW GEAR

ALIGNMENT MARK

17-26

2. Install the steering wheel.

NOTE: Be sure the steering wheel shaft engages

the cable reel and canceling sleeve.

a9 N.m (5.0 ksf'm,36 lbf.ftl

Attach the cruise control sevresume switch€s con-nector to the steering wheel clip.

Connect ihe horn connector.

CRUISE CONTROLSET/NESUME SWITCHESCONNECTOR