lock HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 672 of 1413

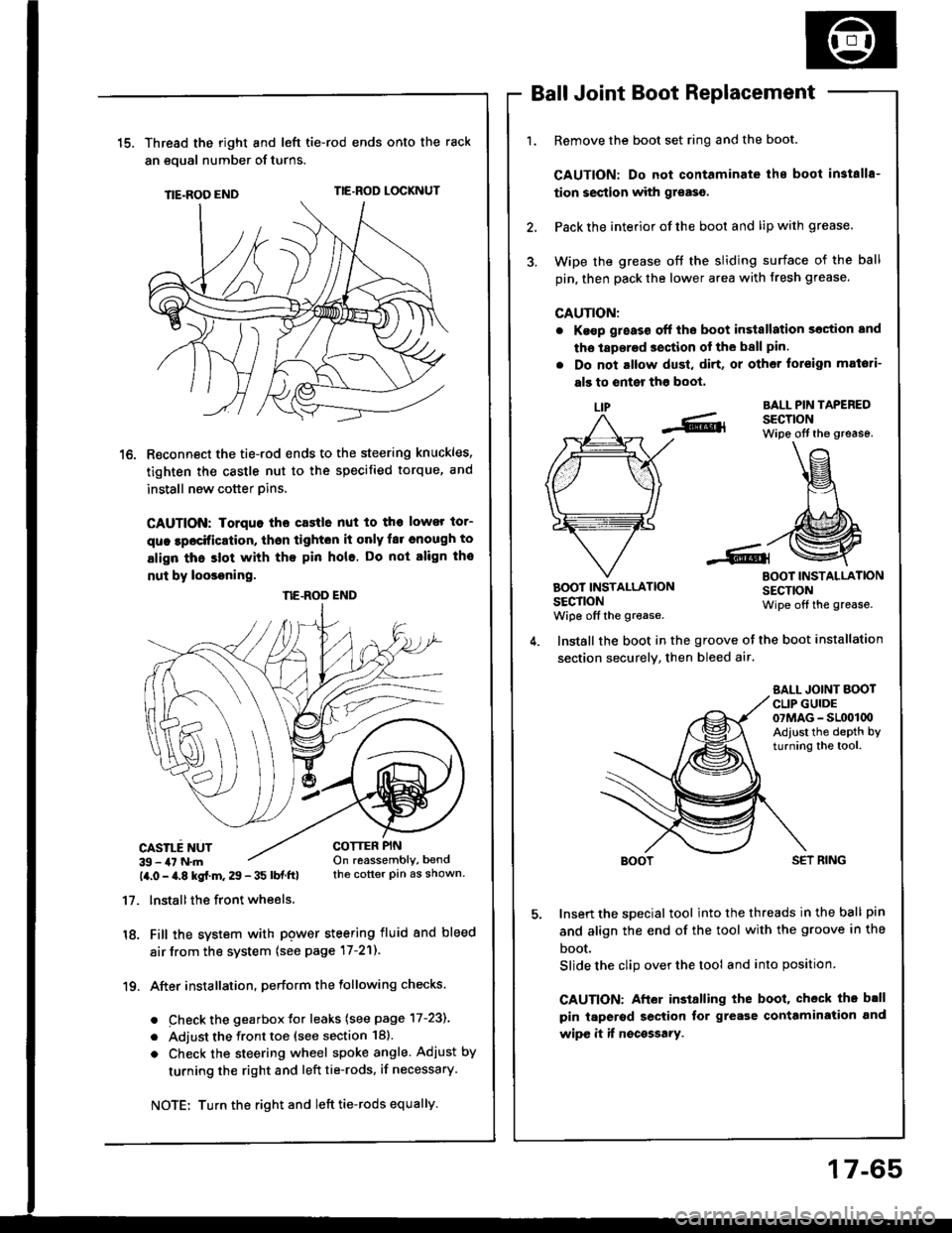

15.Thread the right and lefi tie-rod ends onto the rack

an eoual number of turns.

TIE-ROO ENDTIE.ROD LOCKNUT

R€connect the tie-rod ends to the steering knuckles,

tighten the castle nut to the specified torque, and

install new cotter pins.

CAUTION: Iorquo tho castle nut to tho lower tor-

que lpocification, thsn tighton it only far cnough to

align thc slot with tho pin hole. Do not align tho

nut by loosoning.

CASILE NUT39 - 47 N.m14.0 - a.8 kgf.m. 29 - 35 lbf ftl

17. lnstallthe front wheels.

18. Fill the system with pgwer steering fluid and bleed

air from the system (see page 17-21).

19. After installation. perform the following checks.

. Check the gearbox Jor leaks (see page 17-231

. Adjust the front toe (see section 18).

o Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

Ball Joint Boot Replacement

Remove the boot set ring and the boot.

CAUTION: Do not contaminate ihe boot in3talls-

tion section with gr€aso.

Pack the interior of the boot and lip with grease.

Wipe the grease off the sliding surface of the ball

pin, then pack the lower area with fresh grease.

CAUTION:

. Ke€p g;eass off the boot in3tallation section and

tho laperad section of the ball pin.

. Do not altow dust, di.t, or other toreign mat6ti-

als to enter tho boot,

LIPBALL PIN TAPEREDSECTIONWipe off the grease.

BOOT INSTALLATIONSECTIONwiDe off the grease.

BOOT INSTALLATIONSECTIONWipe off the grease.

COTTER PINOn reassembly, bendthe cotter pin as shown.

Install the boot in the groove ot the boot installation

section securely, then bleed air.

SALL JOINT BOOTCLIP GUIDE07MAG - SL(x)l00Adiust the depth byturning the tool.

SET RING

Insert the special tool into the threads in the ball pin

and align the end of the tool with the groove in the

boot.

Slide the clip over the tool and into position

CAUTION: After installing the boot, check th. b.ll

pin taperod section tor grease contamiration and

wipe it if nocossary.

NE.ROD END

Turn the right and left tie-rods equally.

17-65

Page 914 of 1413

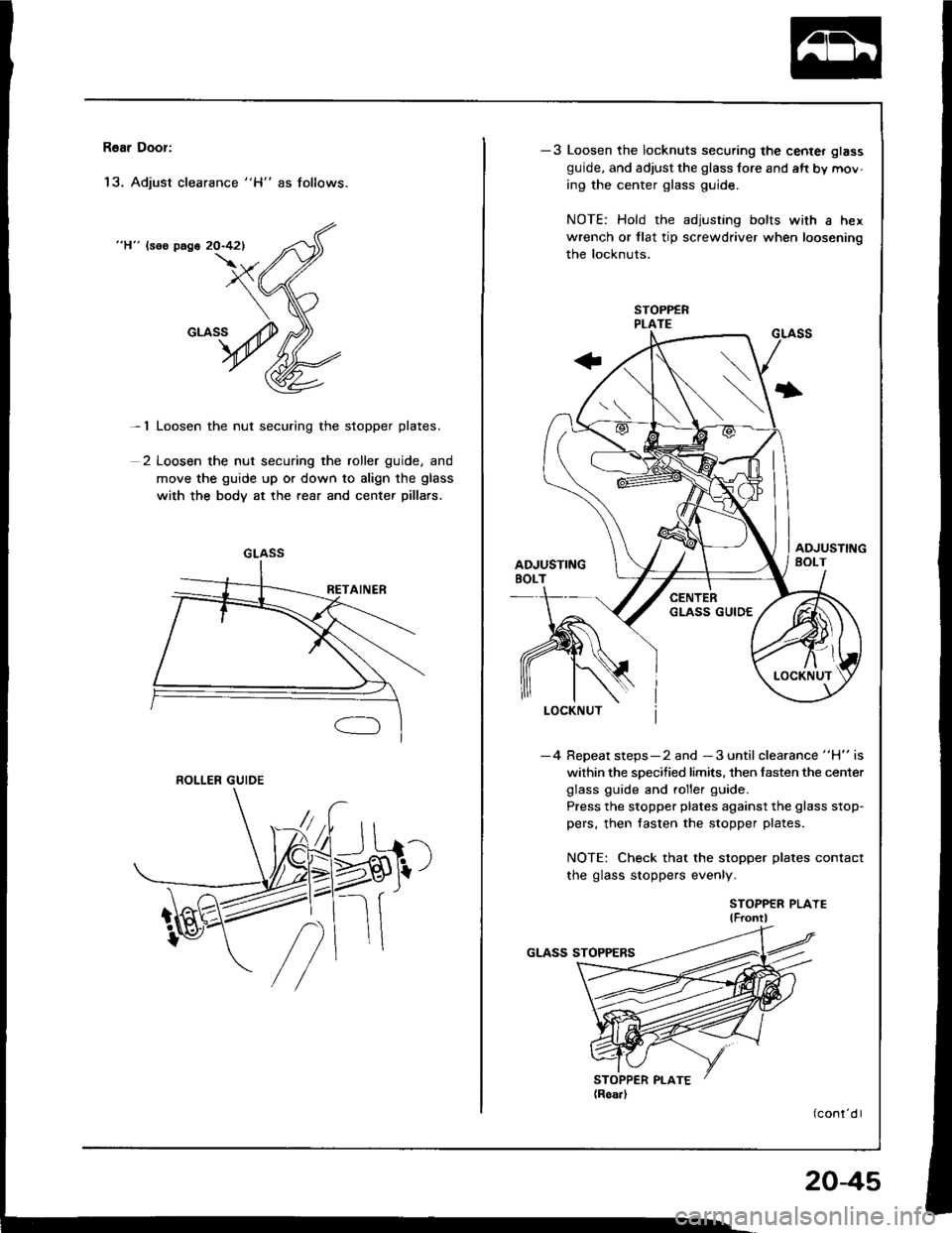

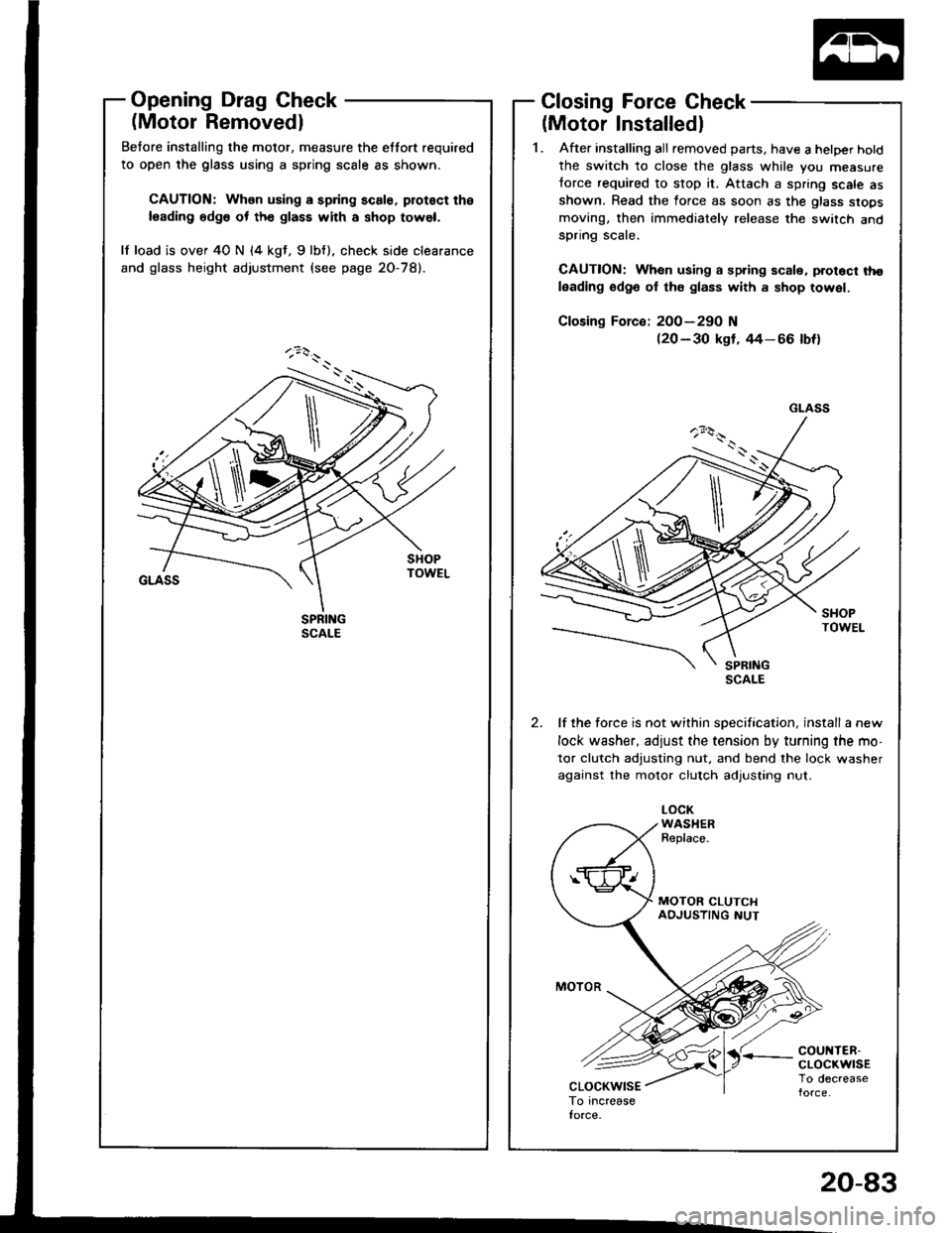

R6ar Door:

'13. Adjust clearance "H" as follows.

"H" lsos page 20-421

- 1 Loosen the nut securing the stopper plates.

2 Loosen the nut securing the roller guide, and

move the guide up or down to align the glass

with the body at the rear and center pillars.

GLASS

ROLLER GUIDE

-3 Loosen the locknuts securing the center glass

guide, and adjust the glass fore and aft by mov-

ing the center glass guide.

NOTE: Hold the adjusting bolts with a hex

wrench or tlat tip screwdriver when loosening

the locknuts.

I

-4 Repeat steps-2 and -3 until clearance "H" is

within the specified limits. then fasten the center

glass guide and roller guide.

Press the stopper plates against the glass stop-

pers, then fasten the stopper plates.

NOTE: Check that the stopper plates contact

the glass stoppers evenly.

STOPPER PLAYElF ontl

204s

Page 915 of 1413

Doors

14. Adjust clearance "8" as follows.

"8" (see page 20-421

Lower the glass 1O mm {0.39 in).

Push the glass outward 1O mm (O.39 inl. then

push the inside stabilizers against the glsss light-

ly. Fasten the inside stabilizers.

NOTE: Check that the glass moves smoothly.

Glass Adjustment (cont'dl

-l

-2

20-46

-3 Loosen the upper locknut on the center glass

guide, and turn the adiusting bolt until cleatance"B" is within the soecified value.

ADJUSTING EOLT

LOCKNUT12 x 1.25 mm22 N.m 12.2 kgf.m,16 tbt.ft)

*

GLASS

NOTE: Do not adjust the lower adjusting bolts

on the center glass guide.

-4 Move the glass up and down to seat it, then

measure clearance "8" at the designated lo-

cattons.

- 5 Measure clea.ance "H" again to make sure it

is still wilhin the specified limits at the desig-

nated locations.

NOTE: Repeat the above steps until the correct

clearances afe obtained.

Page 952 of 1413

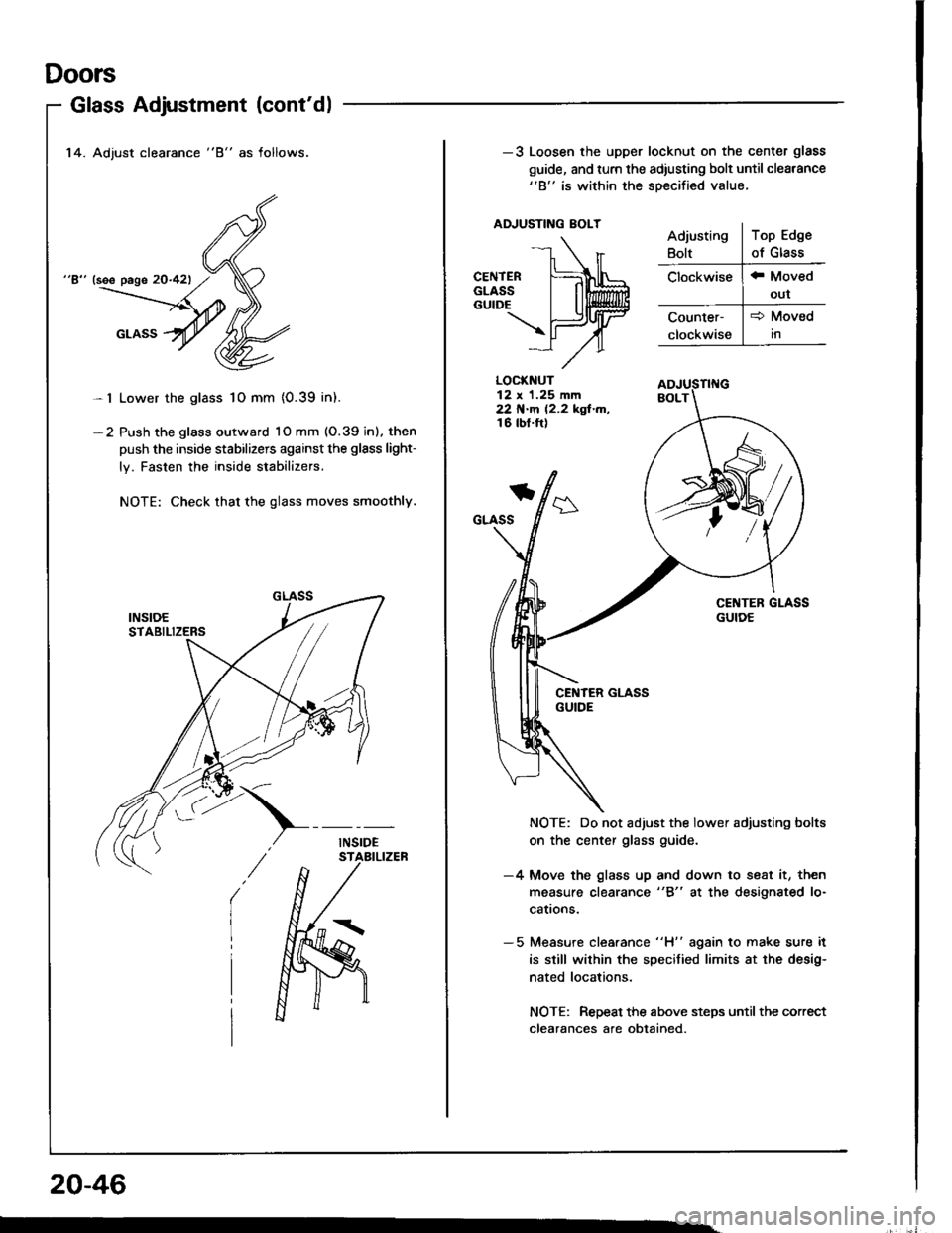

Opening Drag Check

(Motor Removedl

Betore installing the motor, measure the etfort required

to open the glass using a spring scale as shown.

CAUTION: When using a spring scale, protoct the

leading edg6 ot th€ glass with a shop towel.

lf load is over 40 N (4 kgt, 9lbf). check side clearance

and glass height adjustment (see page 2O-78).

Closing Force Check

(Motor Installedl

1. After installing all removed parts, have a hetper hotd

the switch to close the glass while you measure

torce required to stop it. Attach a spring scale asshown. Read the force as soon as the glass siops

moving, then immediately release the switch andspnng scare.

CAUTION: When using a spring scale, protoct tho

leading odge ol th€ glass with a shop towel.

200-290 N(20 - 30 kgf, rt4- 66 lbf)

lf the force is not within specification, install a new

lock washer, adjust the tension by turning the mo-

tor clutch adjusting nut, and bend the lock washer

against the motor clutch adjusting nut.

LOCKWASHERReplace.

'r coul{TER-cLocKwrsETo decrease

GLASS

\

20-83

Page 959 of 1413

Moonroof

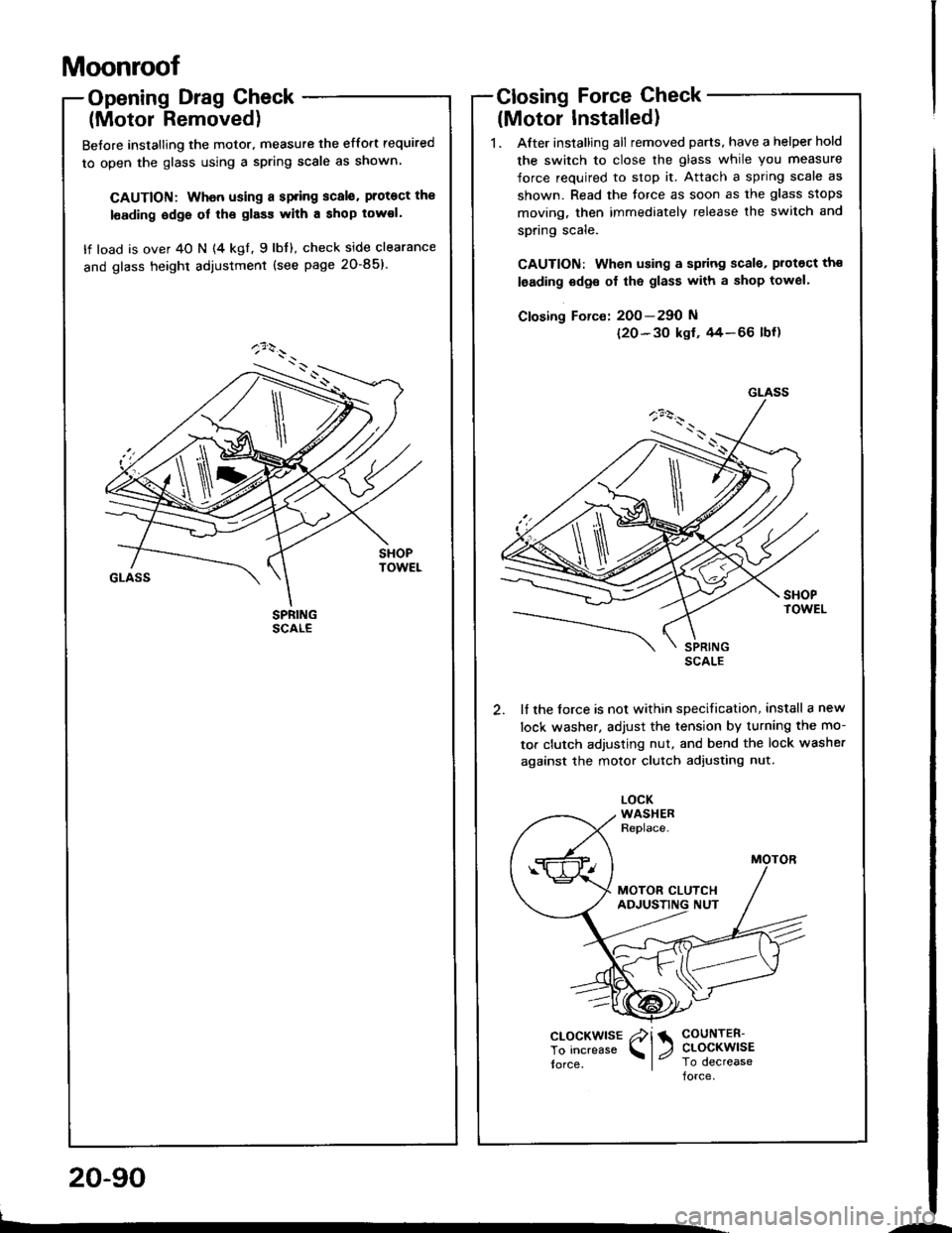

Opening Drag Check

(Motor Removed)

Before installing the motor. measure the effort required

to open the glass using a spring scale as shown

CAUTION: Whon using a spring scalo. protoct the

l€ading odge ol the glass with a shop tow€I.

lf load is over 40 N (4 kgl, 9lbt), check side clearance

and glass height adiustment (see page 20-85)'

Closing Force Check

lMotor Installed)

1. After installing all removed parts, have a helper hold

the switch to close the glass while you measure

force required to stop it. Attach a spring scale as

shown. Read the torce as soon as the glass stops

moving, then immediately release the switch and

spring scale.

CAUTION: When using a sp ng scala. protect th€

leading odge ol the glass with a shop towel'

Closing Force: 200-290 N

120-30 ksf. 44-66 lbf)

lf the lorce is not within specification, install a new

lock washer. adjust the tension by turnang the mo-

tor clutch adjusting nut, and bend the lock washe.

against the motor clutch adjusting nut.

GLASS

\

clocKwlsE /i 1 coutren-

To increase l, ctocKwlsE

torce, I Io decreaseforce

L.

20-90

--

Page 963 of 1413

lnterior Trim

Replacement lcont'dl

Sodan

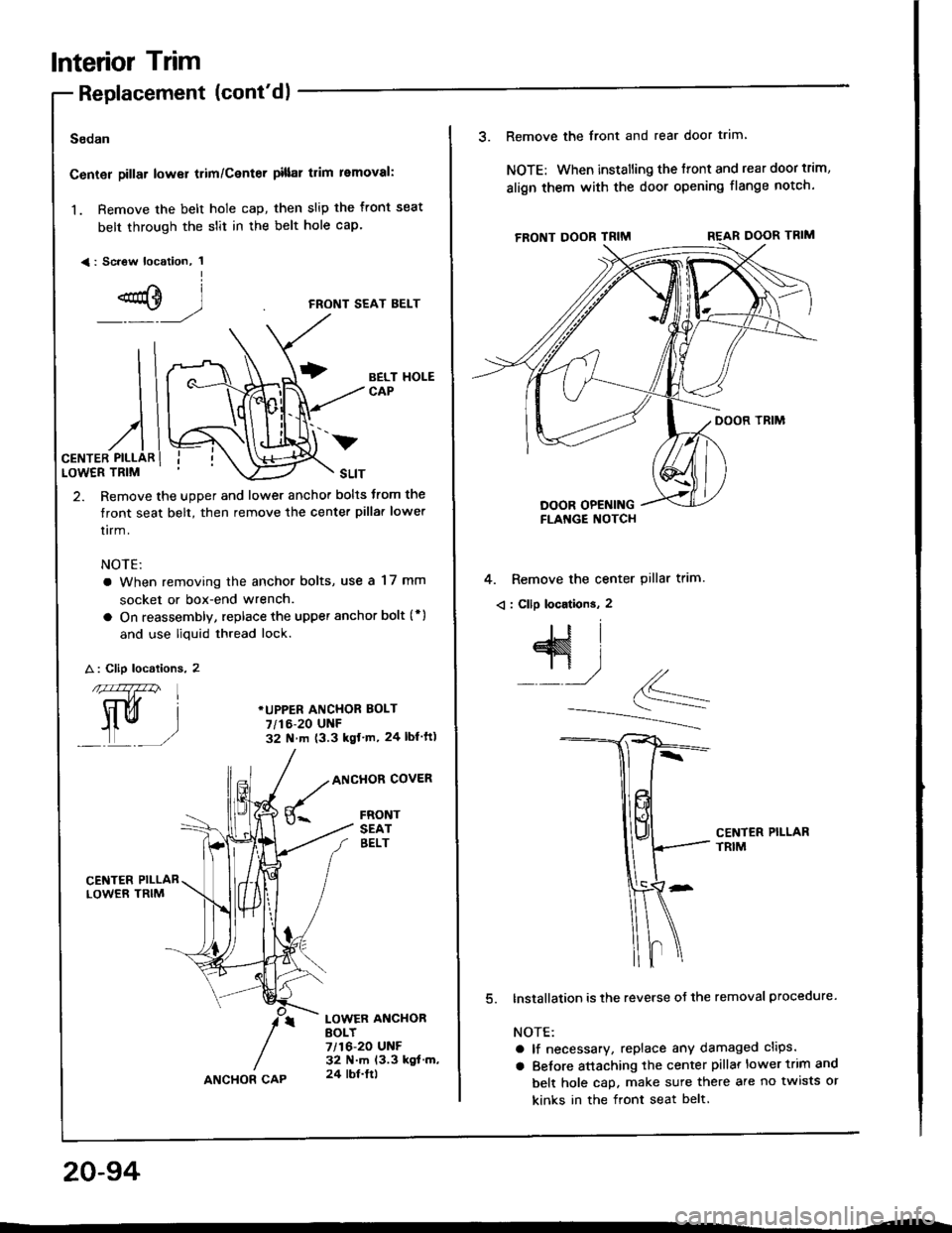

Center pillar lower trim/Center pillal trim removal:

1. Remove the belt hole cap, then slip the front seat

belt through the slit in the belt hole cap.

<: Sc.ew location, 1I

e)

)

2. Remove the upper and lower anchor bolts trom the

tront seat belt, then remove the center pilla. lower

tirm.

NOTE:

a When removing the anchor bolts, use a 17 mm

socket or box-end wrench.

a On reassembly, replace the upper anchor bolt (* )

and use liquid thread lock.

CENTER PILLARLOWER TRIM

FRONT SEAT BELT

BELT HOLECAP

*UPPER ANCHOR EOLT

7/t6-20 UNF32 N m (3.3 kgf'm, 24 lbl ft)

A : Clip localions. 2

nfa147zzn

trui

L_,)

ANCHOR COVER

FRONTSEATEELT

CENTER PILLARLOWER TRIM

LOWER ANCHORBOLY7/16-20 UNF32 N.m 13.3 kgt.m,24 lbt.ltlANCHOR CAP

20-94

v

3. Remove the front and rear door trim

NOTE: When installing the ffont and rear door trim,

align them with the door opening flange notch.

4. Remove the center pillar trim.

< : Cllp locations. 2

CENTER PILLARTRIM

lnstallation is the reverse oJ the removal procedure.

NOTE:

a lf necessary, replace any damaged clips.

a Belore attaching the center pillar lower trim and

belt hole cap. make sure there are no twists or

kinks in the front seat belt.

Page 964 of 1413

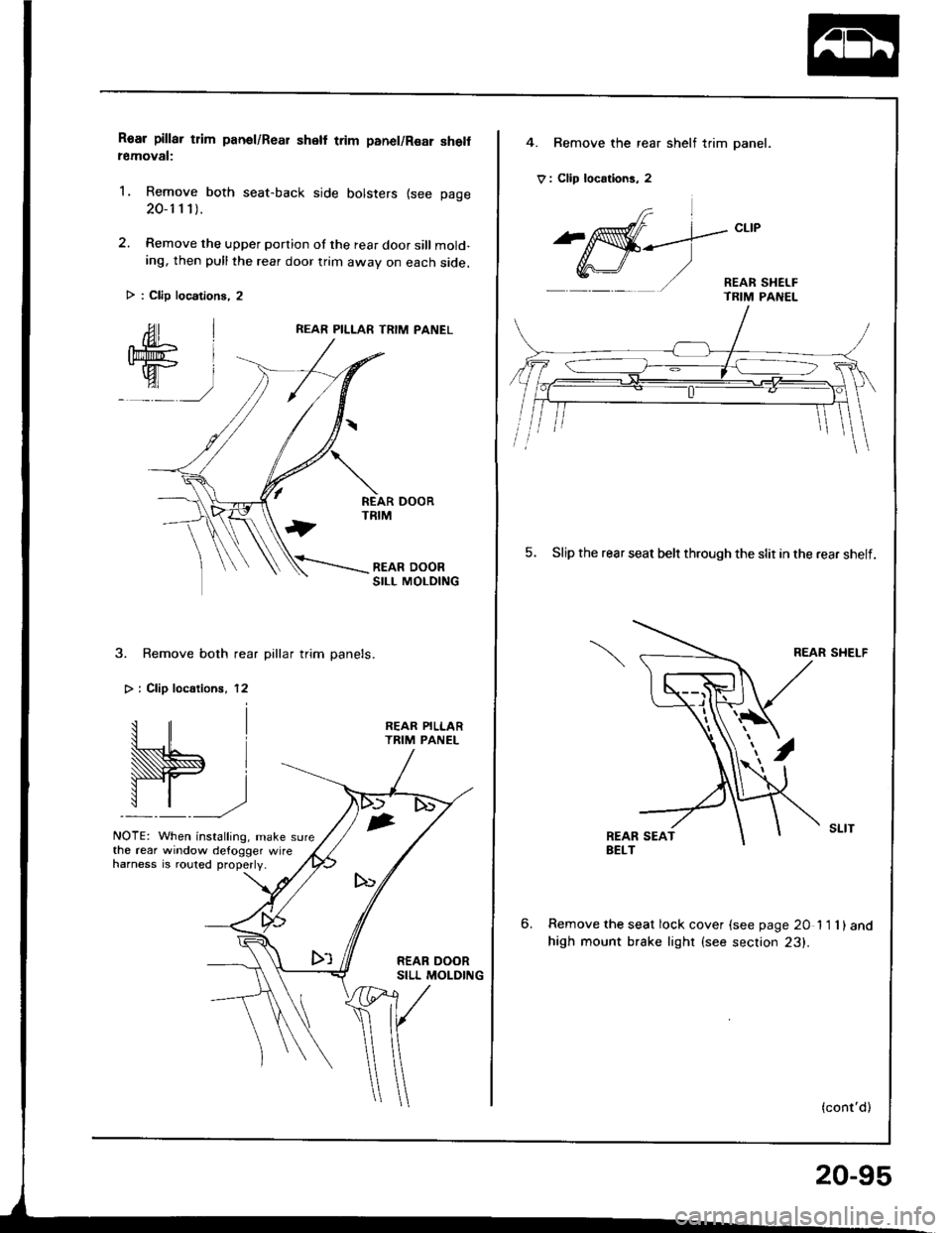

Roar pillar tlim panel/Rear shell trim panel/Rsar she removal:

1. Remove both seat-back side bolsters {see page

20-1 1 1).

2. Remove the upper portion of the rear door sill mold-ing, then pull the rear door trim awav on each side.

REAR PILLAR TRIM PANEL

3. Remove both rear pillar trim panels.

> i Clip localionr, 12

W.,

NOTE: When installing, make sure

REAR PILLARTRIM PANEL

the rear window defogger wireharness is .outed properly.

> : Clip locations, 2

4. Bemove the rear shelf trim panel.

V : Clip locrtions, 2

frl

^affi-_--.]-"t't

Y,r\-J/ '/ - REAR sHEr-F- TRIM PANEL

5. Slip the rear seat belr through the slit in the rear shelf.

REAR SHELF

6.Remove the seat lock cover {see page 20 11 1)and

high mount brake lighr (see section 23).

(cont'd)

20-95

Page 967 of 1413

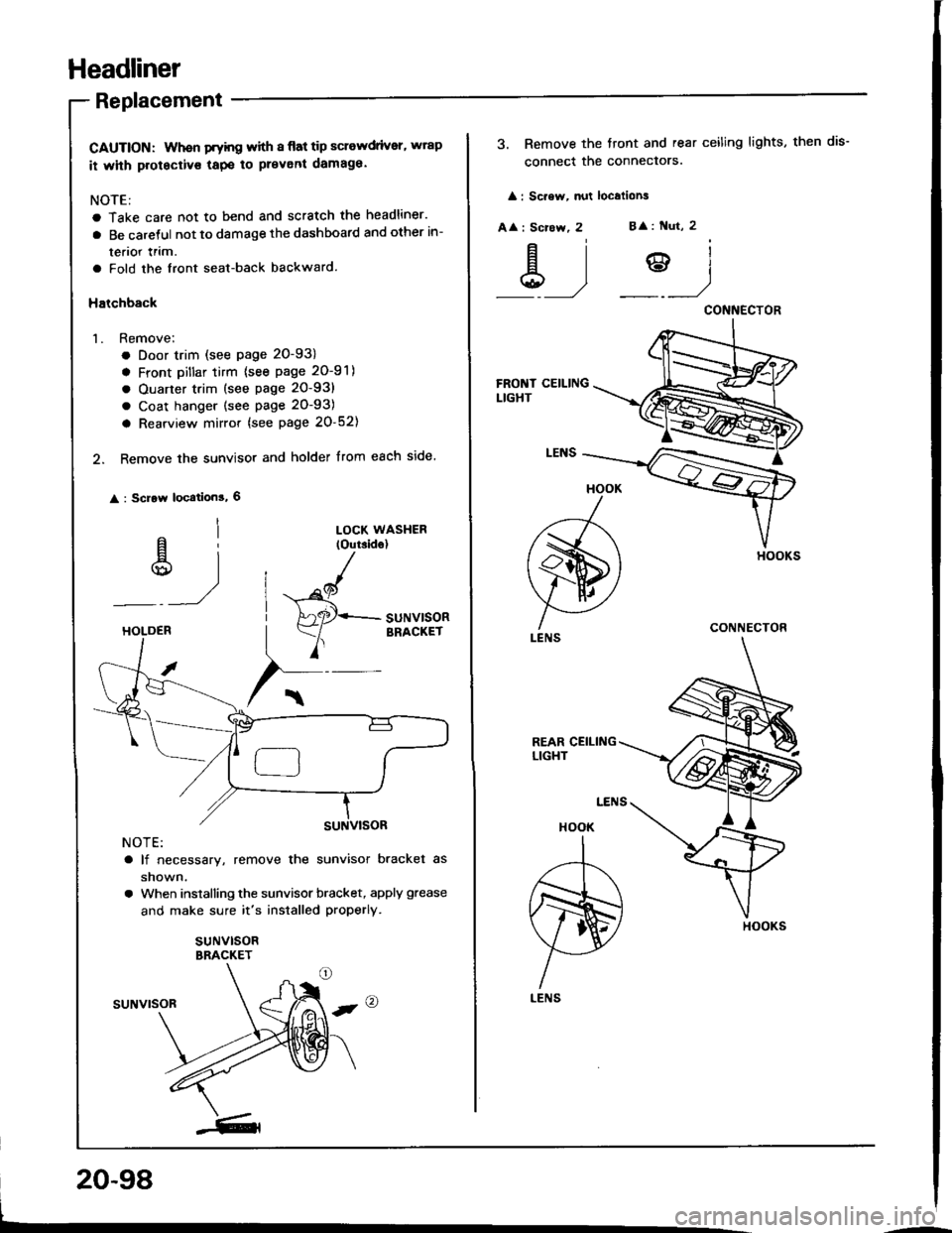

Headliner

Replacement

CAUTION: Whon Fyhg with I flat tip sclewdrivsr, wrap

it whh protectivs tapo to prevent damaga.

NOTE:

a Take care not to bend and scratch the headliner.

a Be caretul not to damage the dashboard and other in-

terior lrim.

a Fold the front seat-back backward.

Halchback

1. Remove;

. Door trim (see page 20-93)

a Front Dillar tirm {see page 20-91)

a Ouarter trim (see page 20-93)

a Coat hanger (see page 20-93)

a Rearview mirror {see page 20-52)

2. Remove the sunvisor and holder from each side.

: Scrow location!, 6

al

u)

LOCK WASHER(Outside)

"^/

HAaqr+- SUNV|SOR

Y

BRACKETHOLDEB

NOTE:

a lf necessary, remove the sunvisor bracket as

shown.

a When installing the sunvisor bracket, apply grease

and make sure it's installed properly.

suNvlsoRBRACKET

suNvrsoR

20-98

3. Remove the tront and rear ceiling lights, then dis-

connect the conneclors.

: Sc.ew, nut localions

A

: Scrcw, 2B

: Nut, 2

&)?)

HOOK

A

ffi)

LENS

HOOK

I

,r--T-\

m)

H

LENS

CONNECTOR

CONNECTOR

HOOKS

Page 969 of 1413

Headliner

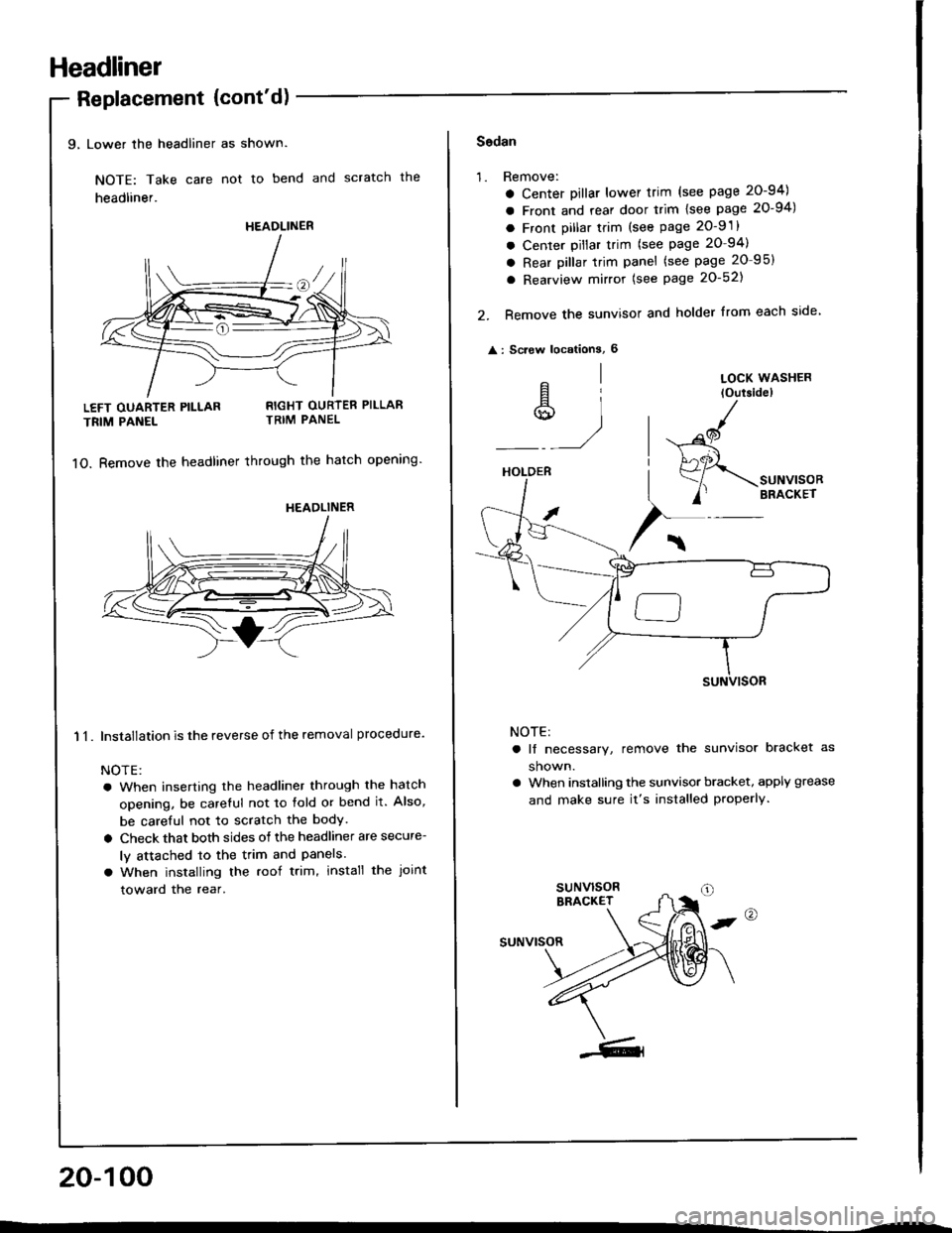

9, Lower the headliner as shown.

NOTE: Take care not to bend and scratch the

headliner.

Replacement {cont'd)

LEFT OUARTER PILLAR

TRIM PANEL

11.

RIGHT OURTER PILLARTRIM PANEL

1O. Bemove the headliner through the hatch opening'

Installation is the reverse of the removal procedure.

NOTE:

a When inserting the headliner through the hatch

opening, be careful not to fold or bend it. Also,

be careful not to scratch the bodY.

a Check that both sides of the headliner are secure-

ly attached to the trim and Panels.

a When installing the roof trim, install the Joint

toward the rear.

20-100

HEADLINER

HEADLINER

Sodan

'1.Remove:

a Center Dillar lower trim (see page 20-94)

a Front and rear door trim lsee page 20-94)

a Front pillar trim (see page 2O-9 .

a Center pillar trim (see page 20-94)

a Rear pillar trim panel (see page 20 95)

a Rearview mirror (see Page 20-521

Remove the sunvisor and holder from each side

: Screw locationS, 6

2.

^l

s,1

LOCK WASHER

loutsidel

HOLDER

/

$-.unu,"o"

/' BRACKET

NOTE:

a lf necessary, remove the sunvisor bracket as

shown.

a When installing the sunvisor bracket, apply grease

and make sure it's installed properly.

,@

suNvrsoR

Page 972 of 1413

Seats

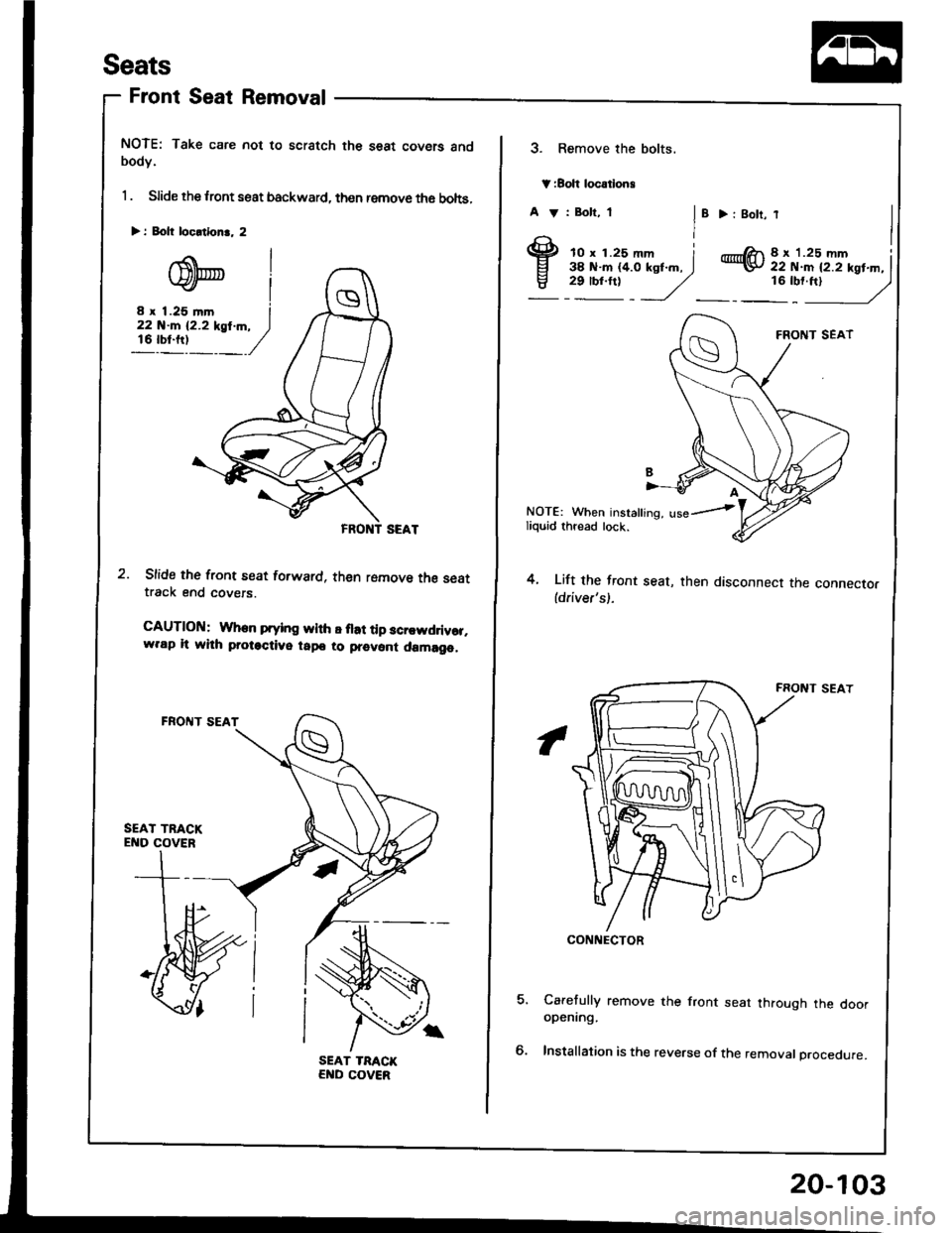

Front Seat Removal

NOTE: Take care not to scratch the seat covers andbodY.

1 . Slide the lront seat backward, then remove th6 bohs,

Slide the front seat forward, then romove the seattrack end covers.

CAUTlOltl: When prying wlth E flat tip scr.wddvor,w.ap lt whh protactive tapo to prevont damago,

> i Eolt locltlon.. 2

3. Remove the bolts.

V:Boh locatlong

A V : Bolt, 1

I'

> : 8olt,

@8 x '1.25 mm Iii i.:iiil..i'xst.^. I16:t'ftt

- /)

4.

NOTE: When insralling, use--iliquid thread lock.

Lift the front seat, then disconnect the connector(driver's).

Carefully remove the front seat through the dooropening.

Installation is the reverse of the removal procedure.

CONNECTOR

20-103