lock HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 634 of 1413

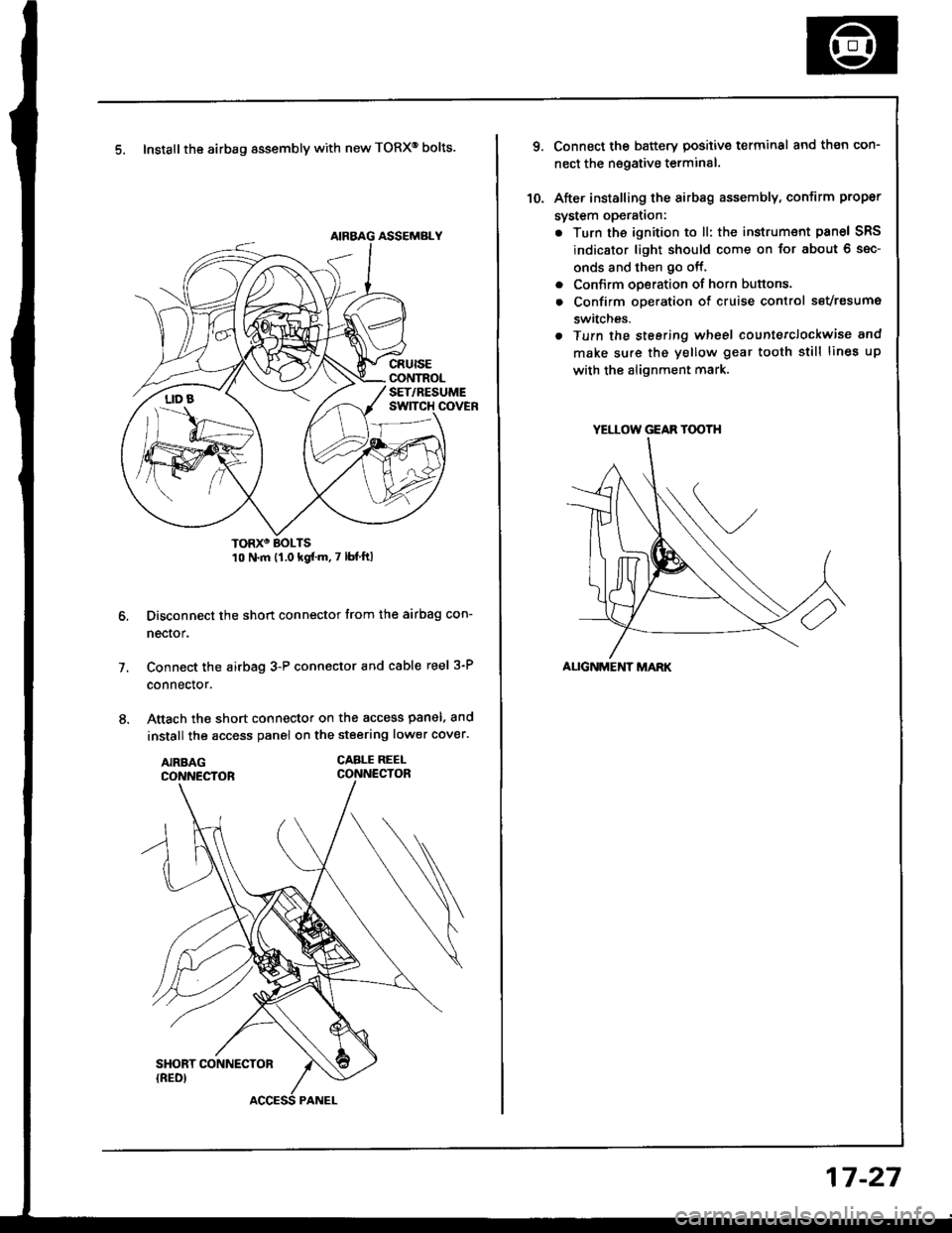

5. Install the airbag assembly with new TORXo bolts.

TORXO BOLTS10 N.m {1.0 kgf'm.7 lbf ftl

Disconnect the short connector trom the airbag con-

nector.

Connect the airbag 3-P connector and cable reel 3-P

connector.

Attach the short connector on the access panel. and

install the access panel on the steering lower cover.

CABLE REEI-CONNECTOR

7.

YELLOW GEAR TOOTH

ALIGNMENT MARK

10.

Connect the battery positive terminal and th€n con-

nect the nsgative terminal.

After installing the sirbag assembly, confirm proper

system opera(on:

. Turn the ignition to ll: the instrum€nt pan6l SRS

indicator light should come on for about 6 sec-

onds and then go off,

. Confirm operation of horn buttons.

. Confirm oDeration of cruise control sevresume

switches.

a Turn the steering wheel countetclockwise and

make su.e the yellow gear tooth still lines up

with the alignment mark.

17-27

Page 637 of 1413

Steering Column

lnspection

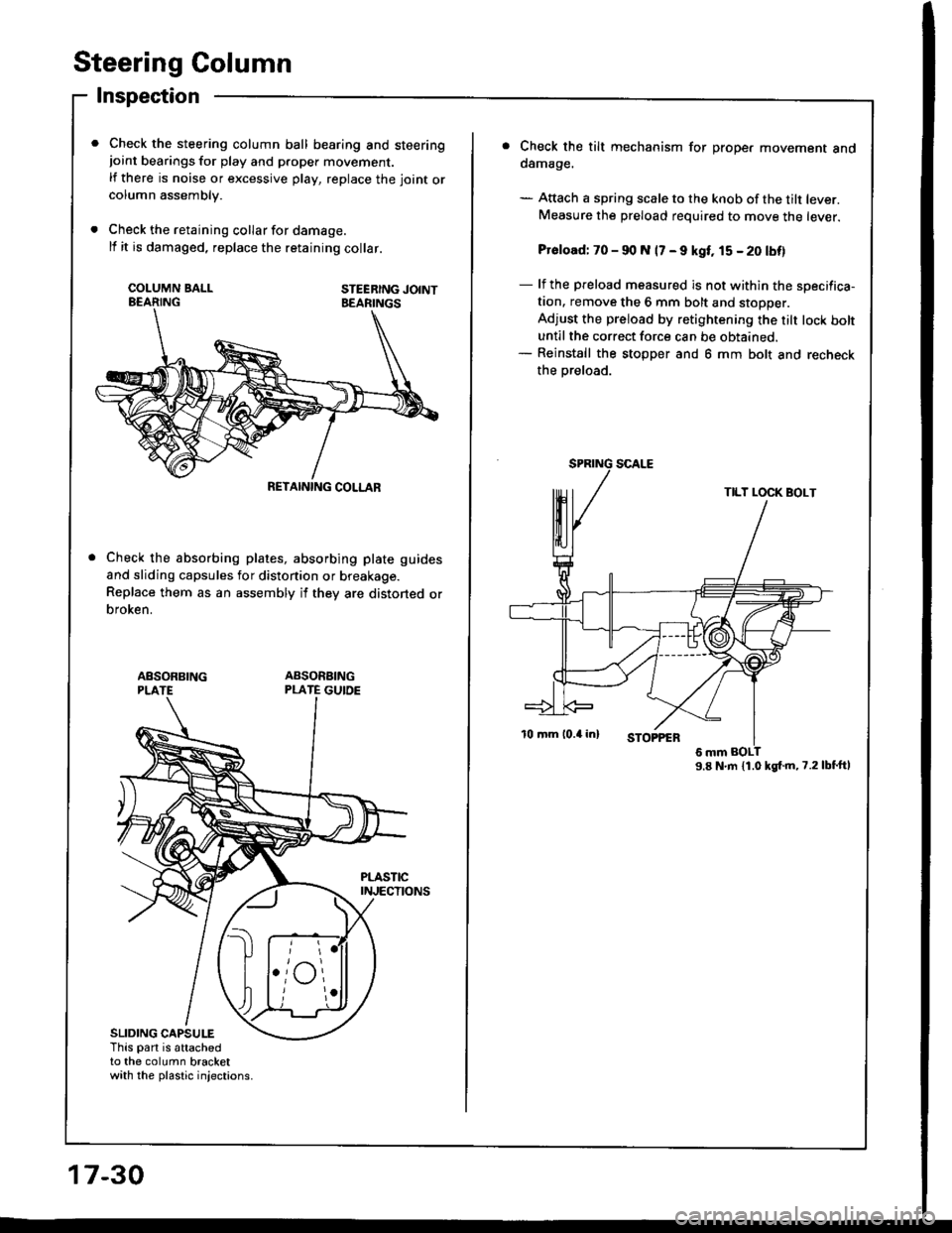

Check the steering column ball bearing and steeringjoint bearings for play and proper movement.

lf there is noise or excessive play, replace the joint orcolumn assembly.

Check the retaining collar for damage.

lf it is damaged, replace the retaining collar.

COI-UMN BALLEEARINGSTEERING JOINTBEARINGS

RETAINING COLLAR

Check the absorbing plates, absorbing plate guides

and sliding capsules for distonion or breakage.

Replace them as an assembly if they are distoned orbroken.

ABSONBING

SLIDING CAPSULEThis part is attachedto the column bracketwith the plastic injections.

17-30

Check the tilt mechanism for proper movement andoamage.

- Attach a spring scale to the knob of the tilt lever.Measure the preload required to move the lever.

Pr6load: 70 - 90 N 17 - 9 kgt, 15 - 20 tbf)

- lf the preload measured is not within the sDecifica-tion. remove the 6 mm bolt and stoDDer.

Adjust the preload by retightening the rilt tock boltuntil the correct force can be obtained.- Reinstall the stopper and 6 mm bolt and recheck

the Dreload.

9.8 N'm {1.0 kgt.m,7.2lbt'ftl

TILT LOCK BOLT

Page 651 of 1413

Power Steering Pump

lnstallation

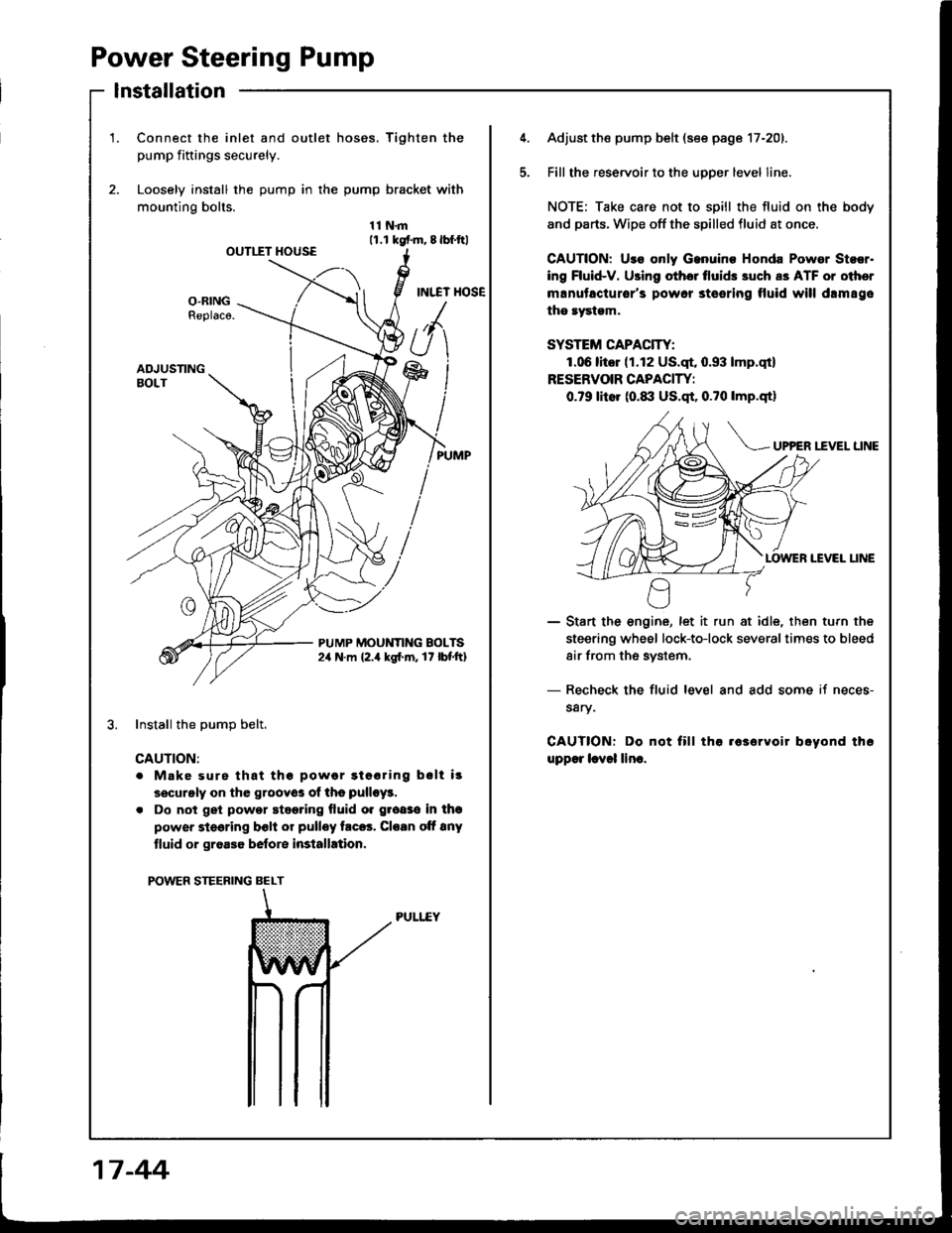

1.Connect the inlet and outlet hoses. Tighten the

pump fiftings securely.

Loosely install the pump in the pump bracket with

mounting bolts.

11N.m11.r kgf.m, 8lbf.ftlOUTIIT HOUSE

INI.TT HOSEO-RINGReplaco.

ADJUSTINGBOLT

PUMP MOUNTING BOLTS2,r N.m {2.4 kgl.m. 17 lbf'ft}

Install the DumD belt.

CAUTION:

. Make surs that thg powor gtooring bslt i!

securgly on the grooyos of ths pulloy!.

. Do not get powor stggring fluid o. groaso in thg

power steering bclt or pulley trc6. Cloan oft 8ny

tluid or groa36 belore installation.

POWER STEERING BELT

PULI..EY

5.

Adjust the pump belt (see page 17-201.

Fill the reservoir to the uoDer level line.

NOTE; Take care not to spill the fluid on the body

and parts. Wipe off the spilled fluid at once.

GAUTION: Uro only Ganuino Honda Powor Stsor.

ing Fluid-V. Using othor tlui& 3uch a3 ATF or oiher

manutacturor's powor steering tluid will drm89e

the rystgm.

SYSTEM CAPACITY:

1.06litor (1.12 US.qt, 0.93 lmp.qt)

RESERVOIR CAPACIW:

0.79 litor (0.1|:| US.qt, 0.?0 lmp.qtl

UP?ER I.fVEL LINE

IEVEI LINE

- Start the engine, let it run at idle, then turn the

steering wheel lock-to-lock severaltimes to bleed

air from the system.

- Recheck the fluid level and add some if neces-

s8ry.

CAUTIONT Do not fill tha .63ervoir boyond th6

upp€r lcvol lino.

17 -44

Page 652 of 1413

Steering Gearbox

Removal

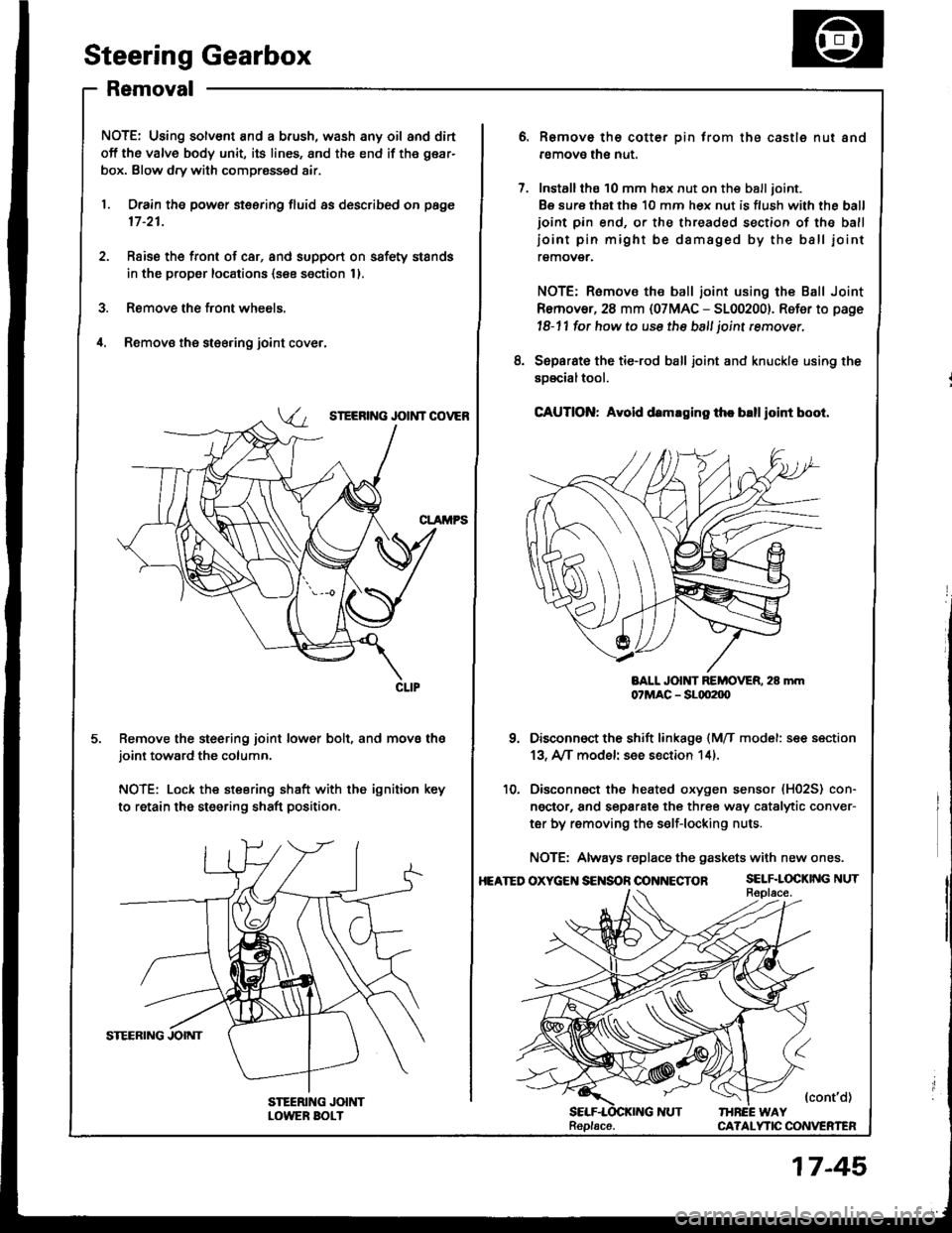

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit, its lines, and the end if the gear-

box. Blow dry with compressed air.

1. Drain the power steering fluid as described on page

17 -21.

2. Rsise the front of car, and support on safety stands

in the propsr locations (see section 1).

3. Remove the front wheels.

il. Removs the st€ering joint cove.,

SIEERING JOIi{T COVEB

Remove the steering joint lower bolt, and move thejoint toward the column.

NOTE: Lock the steering shaft with the ignition key

to retain the steering shaft position.

Remove the cotter pin trom the castle nut and

removo the nut.

Installthe 10 mm hex nut on the balljoint.

Be sure that ths 10 mm hex nut is flush with the ball

ioint pin end, or the threaded section of the ball

ioint pin might be damaged by the ball iointremover.

NOTE: Remove the ball joint using the Ball Joint

Remover, 28 mm {07MAC - 5100200}. Refer to page

l8-11 fot how to use the ball joint rcmover,

Separat€ the tie-rod ball joint and knuckle using the

soscialtool.

CAUTION: Avold d.maging th. blllloint boot.

BALL JOlt{T REMOVER. 28 mm07MAC - SLqt2|X)

Disconnect the shift linkage {MfI model: see section

13, A/[ model see section 14).

Disconnect the heated oxygen sensor (H02S) con-

ngctor, and separate the three way catalytic conver-

ter by removing the s€lf-locking nuts.

NOTE: Always replace the gaskets with new ones.

OXycEt{S€NSOnOONNECTOR SELF.LOCKINGNUT

{cont'd)IHREE WAYCA?ALYTIC CONVERTEN

8.

10.

HEATED

Replacs.

17-45

Page 655 of 1413

Steering Gearbox

Disassembly

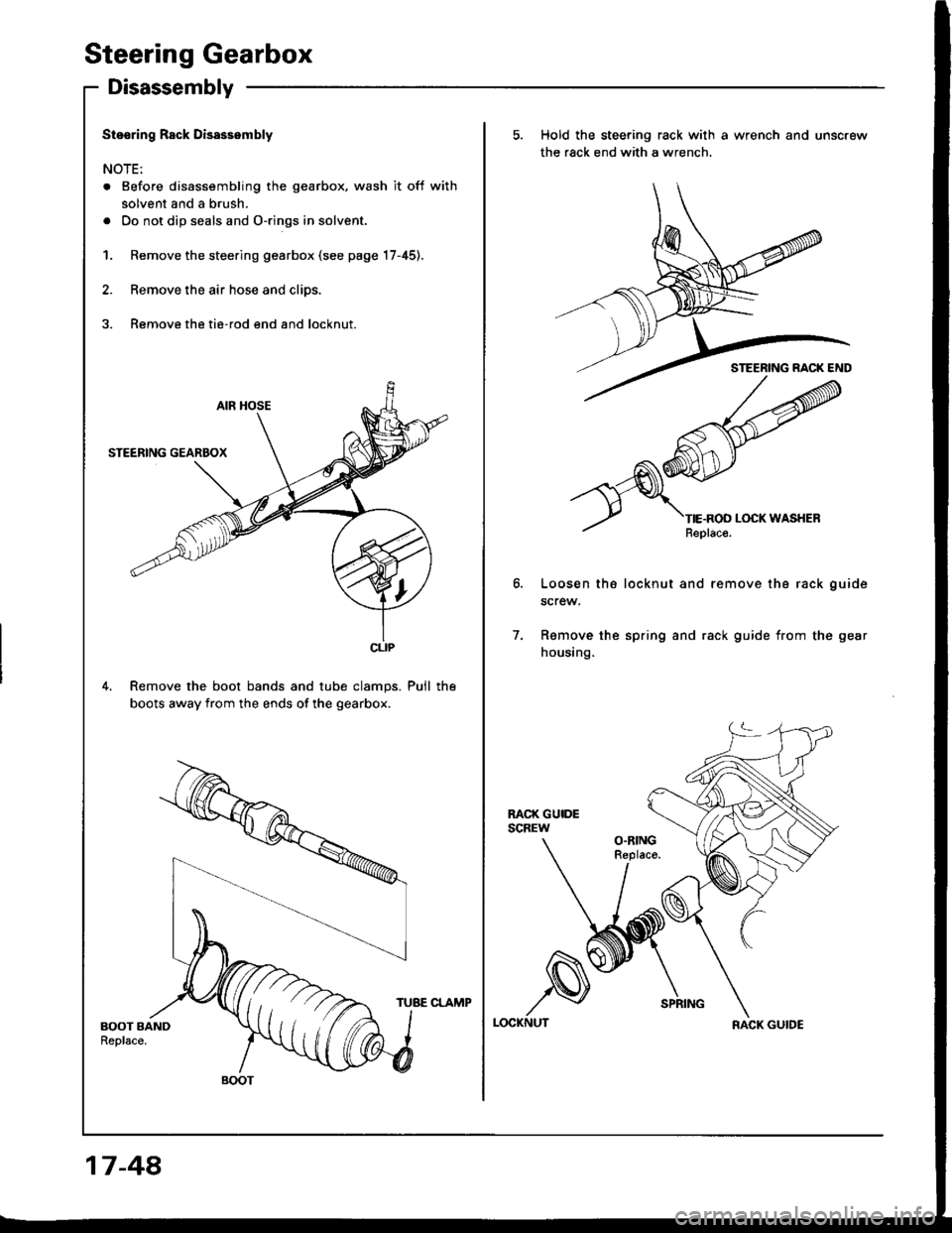

Stssring Rack Disassembly

NOTE:

. Before disassembling the gearbox, wash it off with

solvent and a brush.

. Do not dip seals and O-rings in solvent.

1. Remove the steering gearbox (see page 17-45).

2. Remove the air hose and clips.

3. Remove the tie-rod end and locknut.

4. Remove the boot bands and tube clamps. Pull the

boots away from the ends of the gearbox.

CLIP

BOOT

5. Hold the steering rack with a wrench and unscrew

the rack end with a wrench.

Loosen th6 locknut and remove tha rack guide

screw.

Ramove the spring and rack guide from the gear

housing.

7.

LOCKNUTRACK GUIDE

17-48,

TUBE CLAMP

Page 660 of 1413

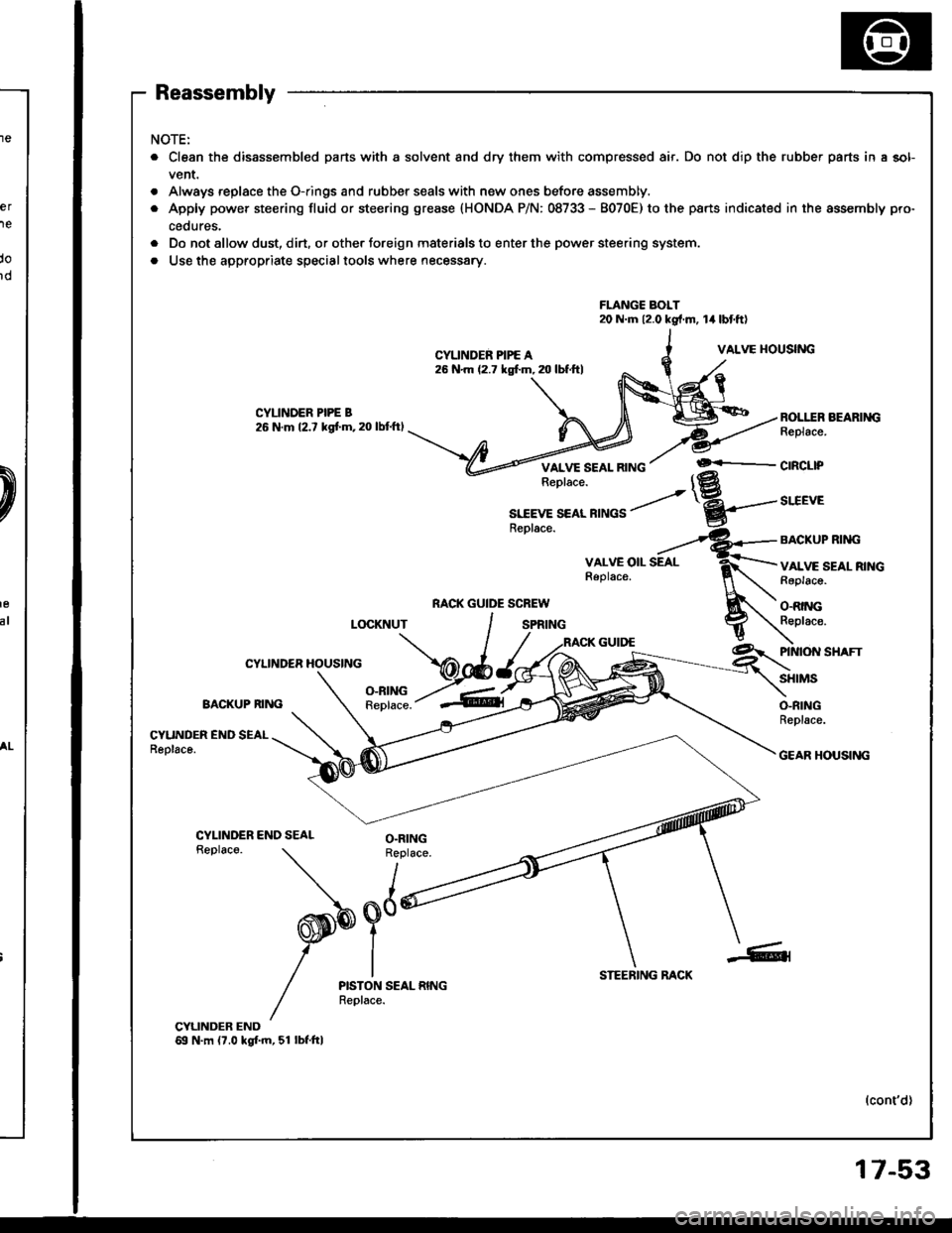

Reassembly

NOTE:

. Clean the disassembled parts with a solvent and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly.

. Apply power steering fluid or steering grease {HONDA P/N: 08733 - 8070E) to the parts indicated in the assembly pro-

cedures.

. Do not allow dust, dirt. or other foreign materials to enter the power steering system.

. Use the appropriate specialtools where necessary.

FLANGC BOLT20 N.m 12.0 kg{.m, lil lbt'ftl

CYLINDER PIPE A26 N'm (2.7 kgf.m, 20 lbf.ftl

VALVE I{OUSING

BOLI..ER BEARINGReplace.

VALVE SEAL RINGReplace.+-cncl|P

RACK GUIDE SCREW

S1IEVE SEAI RINGSReolace.

SITEVE

BACKUP RIM}

VALVE SEAL RINGRaplacs.

O.RINGReplac€.LOCKNUT

CYLINDER HOUSING

O-RINGBACKUP RING Replace.

\

PINION SHAFT

SHIMS

O-RINGReplace.

CYUNDER END SEALReolace.GEAR HOUSING

CYLINDER END SEALReplaco.O.RINGReplace.

I

x nd#$Y

IPISTON SEAL RINGReplace.

STEERING RACK

(cont'd)

17-53

Page 667 of 1413

Steering Gearbox

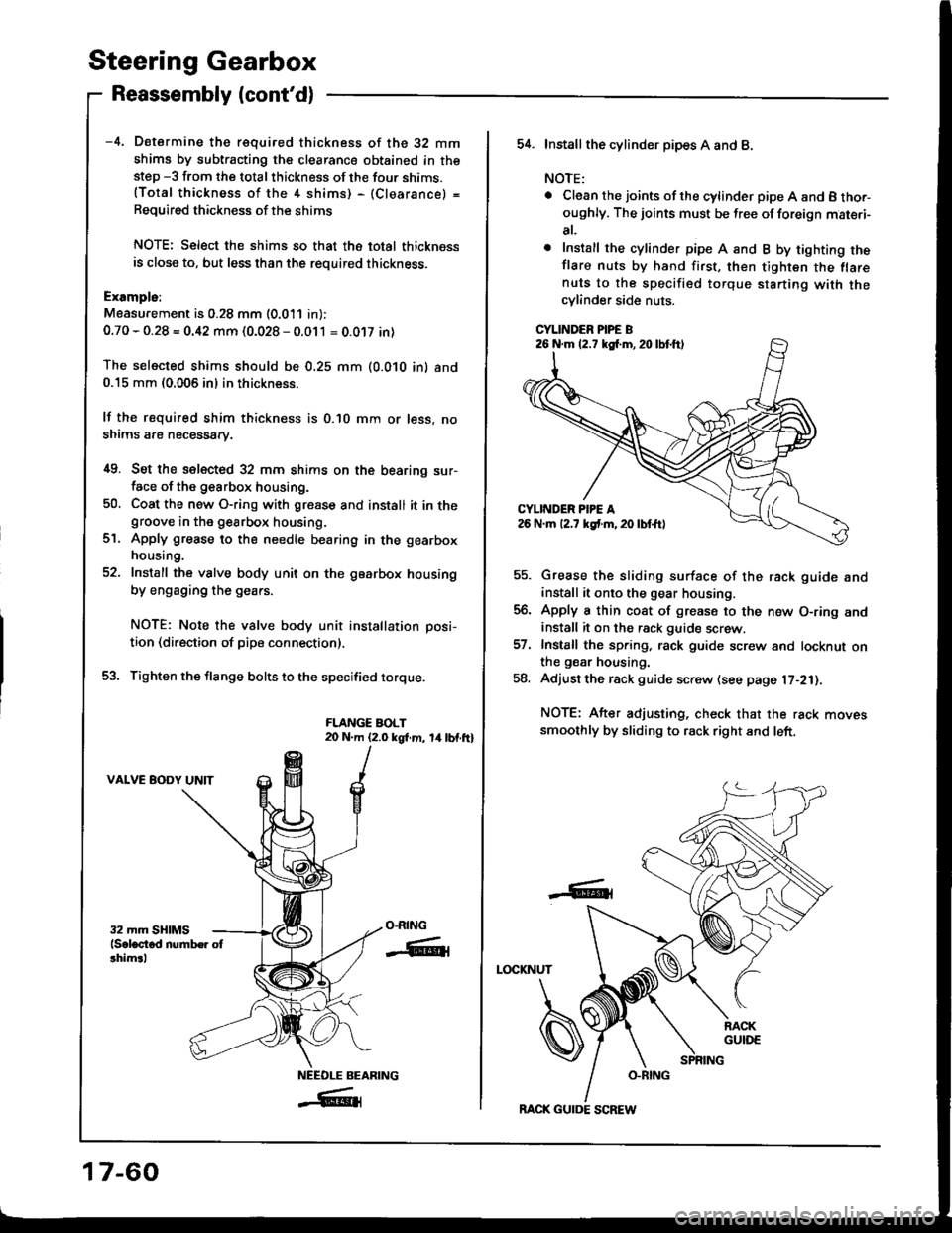

Reassembly lcont'd)

-4. Determine the requifed thickness of the 32 mm

shims by subtracting the clearance obtained in thestep -3 from the total thickness of the four shims.(Total thickness of the 4 shims) - (Clearance) =

Required thickness of the shims

NOTE: Select the shims so that th6 total thicknessis close to, but less than the required thickness.

Exampls:

Measu.ement is 0.28 mm (0.011 in):

0.70 - 0.28 = 0.42 mm (0.028 - 0.011 = 0.0't7 in)

The selected shims should be 0.25 mm (O.O1O in) and0.15 mm (0.005 in) in thickness.

lf the required shim thickness is 0.lO mm or less, no

shims are necessary.

i[9. Set the selected 32 mm shims on the bearing sur-face of the g€arbox housing.

50, Coat the new O-ring with gresse and install it in thegroove in the gearbox housing.

Apply grease to the needle bearing in the gearbox

housing.

Install the valve body unit on the gearbox housing

by engaging the gears.

NOTE: Note the valve body unit installation posi-

tion (direction of pipe connection).

Tighten the flange bolts to the specified torque.

FLANGE BOLT20 N.m (2.0 kgt m, 14lbf.ft)

VALVE BODY UNIT

ct.

O-RING

-ffiti

NEEOLE BEARING

_#{

17-60

BACK GUIDE SCREW

54. Installthe cylind6r pipes A and B.

NOTE:

. Clean the joints ofthe cylinder pipe A and B tho.-oughly. The joints must be free of foreign mat€.i-

at,

o Install the cylinder pipe A and B by tighting theflare nuts by hand first, then tighten the flarenuts to the specified torque starting with thecylinder side nuts.

CYLINDER PIPE B

Grease the sliding surface of the rack guide andinstall it onto the gear housing.

Apply a thin coat of grease to the n€w O-ring andinstall it on the rack guide screw.

Install the spring, rack guide screw and locknut onthe gear housing.

Adjust the rack guide screw (see page l7-21).

NOTE: After adjusting, check that the rack movessmoothly by sliding to rack right and left.

LOCKNUT

-6t

26 N.m (2.7 kg{.m,20lbtft)

Page 668 of 1413

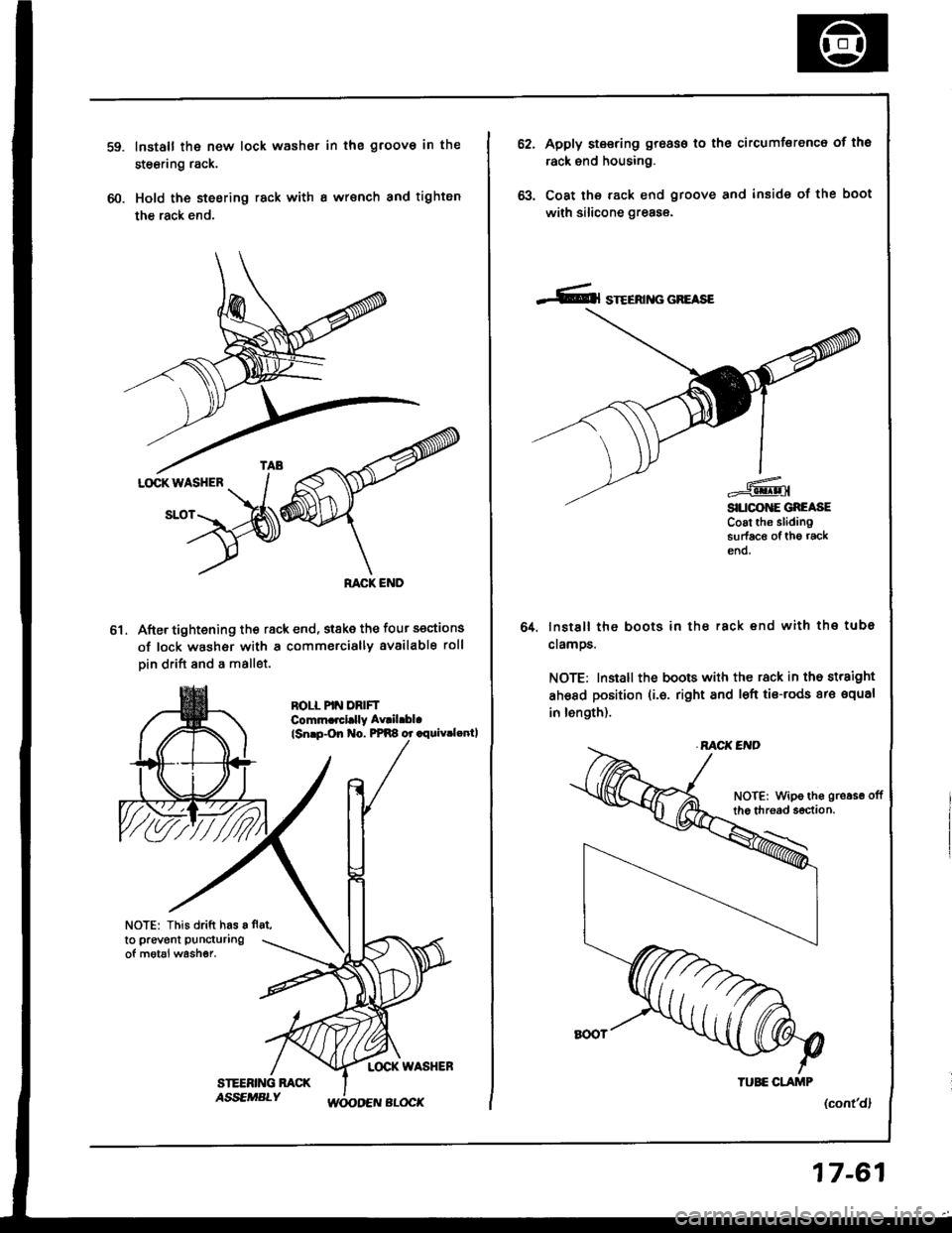

60.

Install the new lock washor in the groov€ in the

steering rack.

Hold the steering rack with I wrsnch and tighten

the rack end.

After tightening th€ rack end, stske the four sections

of lock washer with a commercially available roll

Din drift and a mallet.

ROLL PIN DRIFTComm.rcl.lly Av|il.bl.

lsnrp-On No. PPR8 or .rquiv.lenll

NOTE: This drift has a fl8t,

to prevent puncturing

of motal washer.

ol

62.Apply steering groass to the circumferenc6 of tho

rack end housing.

Coat the rack end groove and inside of the boot

with silicone greas€.

lnstsll the boots in ths rack end with the tube

clamos.

NOTE: Install the boots with the rack in the straight

ahsad position (i.6. right and l€ft tis-rods ar€ squal

in length).

(cont'dl

64.

NOTE: Wipe ths gro.se offthe thread s€ction.

TUEE CLAJTIP

17-61

Page 669 of 1413

Steering Gearbox

Reassembly (cont'dl

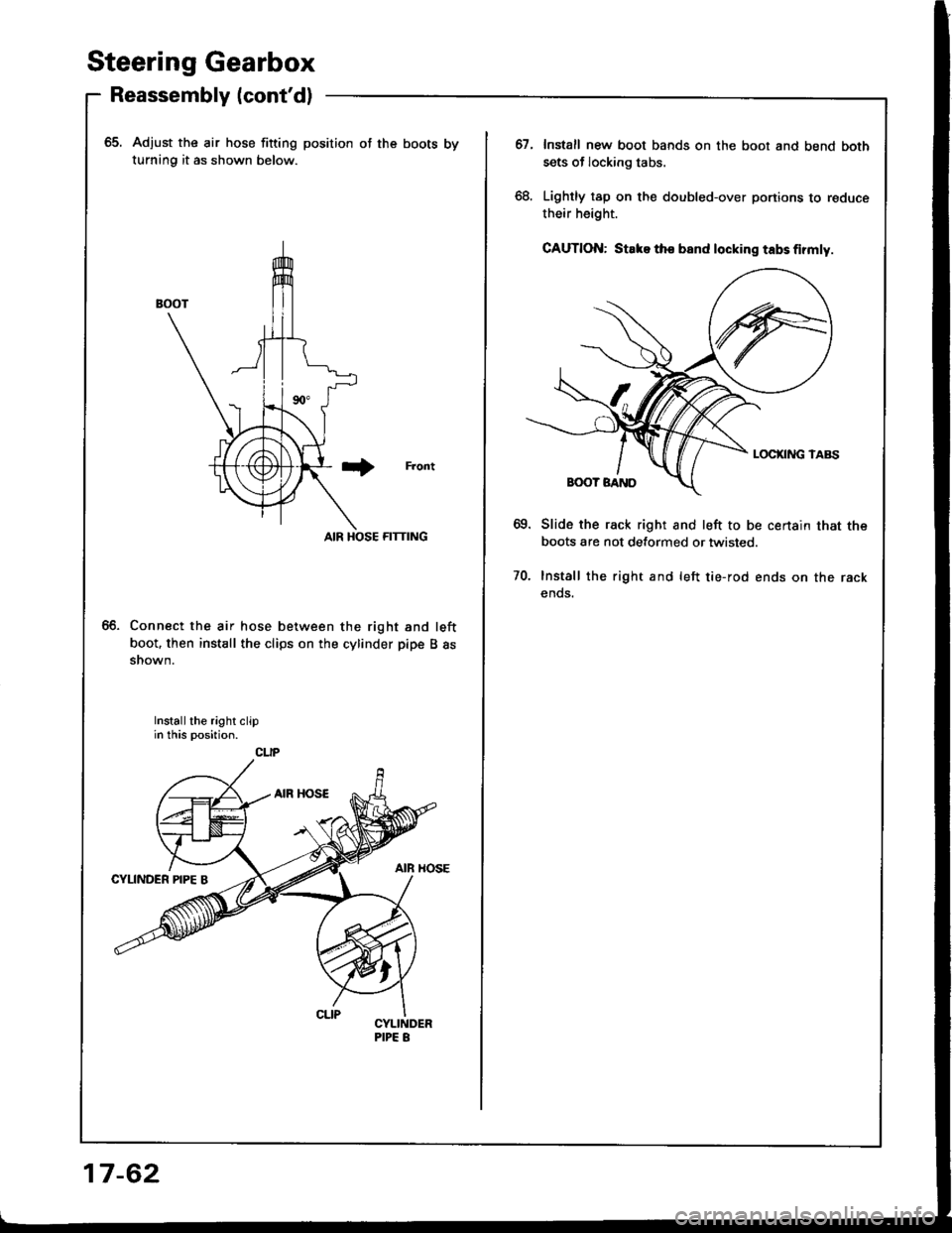

65. Adjust the air hose fitting position of the boots by

turning it as shown below.

Front

AIR HOSE FITTING

Connect the air hose between the right and left

boot. then install the clips on the cylinder pipe B assnown.

Install the right clipin this position.

CLIP

17-62

67.Install new boot bands on the boot and bend both

sets of locking tabs.

Lightly tap on the doubled-over portions to reduce

their height.

GAUTION: Stake tho band locking tabs firmly.

Slide the rack right and left to be certain that the

boots are not detormed or twisted.

Install the right and left tie-rod ends on the rack

ends.

70.

Page 671 of 1413

Steering Gearbox

Installation (cont'd)

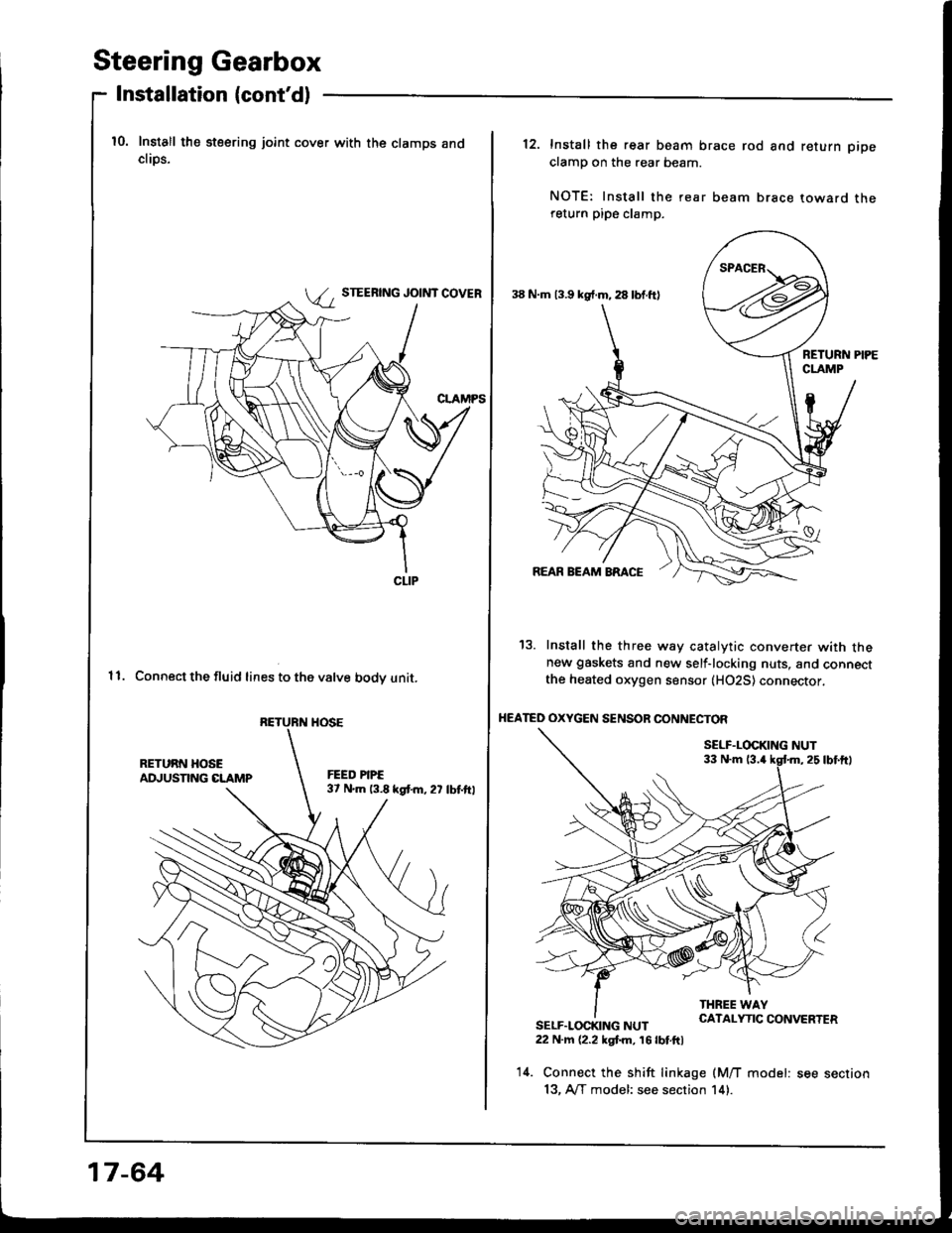

10. Install the steering joint cover with the clamps andcliDs.

STEERING JOINT COVER

11. Connect the fluid lines to the valve bodv unit.

CLIP

RETURN HOSE

17-64

38 N.m 13.9 kg{.m, 28 lbf.ft)

12. Install the rear beam brace rod and return pipe

clamp on the rear beam.

NOTE: Install the rear beam brace toward thereturn pipe clamp.

13. Install the three way catalytic converter with thenew gaskets and new self-locking nuts, and connectthe heated oxygen sensor (H02S) connector,

HEATED OXYGEN SENSOR CONNECTOF

SELF.LOCKING NUT33 N.m 13.4

SELF.LOCKING NUT22 N.m (2.2 kgt m, 16 lbt.ftl

14. Connect the shift linkage (M/T model: see section

13, A/T model: see section 14).