Page 98 HONDA INTEGRA 1994 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 116 of 1413

Cylinder Head

Removal

Engine removal is not required or this procedure.

CAUTION: To avoid damaging tho cylinder head, wail

u[tilths.nginc coolant tsmperaturo drops bolow 100"F(38'Cl bafore loos6ning tho retaining bolts.

NOTE;

. Inspect the timing belt before removing the cylinder

head.

Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDc) {page 6-51).

Mark all emissions hoses betore disconnecting them.

Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before- Disconnecting the battery.- Removing the No.32 (7.5 A) fuse trom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect power to the radio 8nd turn it

on.

When the word "CODE" is displaved. enter the cus-

tomer's 5-digit code to restore radio operation,

Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

Relieve fuel pressure (see section 111.

l@ Do not 3moke whilo working on fuel

a

a

'1.

systgm. ko6p opon tlamo ot Spark away trom work

aroa. Drain fugl only into an approved containsr,

4. Disconnect the fuel feed hose.

SERVIC€ BOLT15 N.m (1.5 kgtm, rl bf.tt)WASHERSReplace.

BANJO BOLT

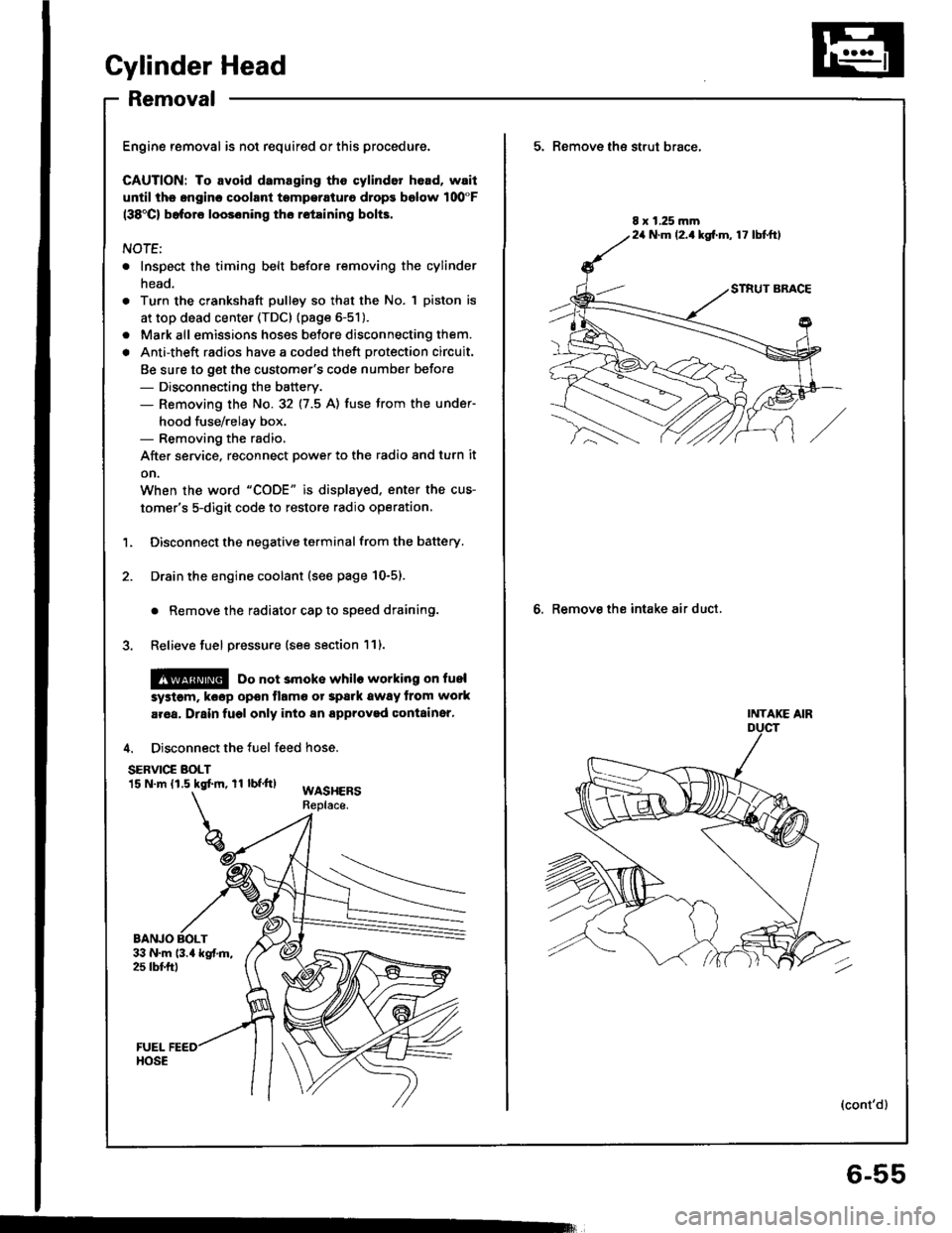

5. Remove th€ strut brace,

6. Remove the intake air duct.

8 x 1.25 mm24 N.m (2.1kg[.m, 17 lbtftl

INTAKE AIR

(cont'd)

6-55

Page 119 of 1413

Cylinder Head

Removal (cont'dl

Remove the heat shield from the P/S bracket (see

page 5-18).

Remove the air conditioning (Ay'Cl compressor belt(see page 6-49).

Remove the alternator belt {s€e page 6-49).

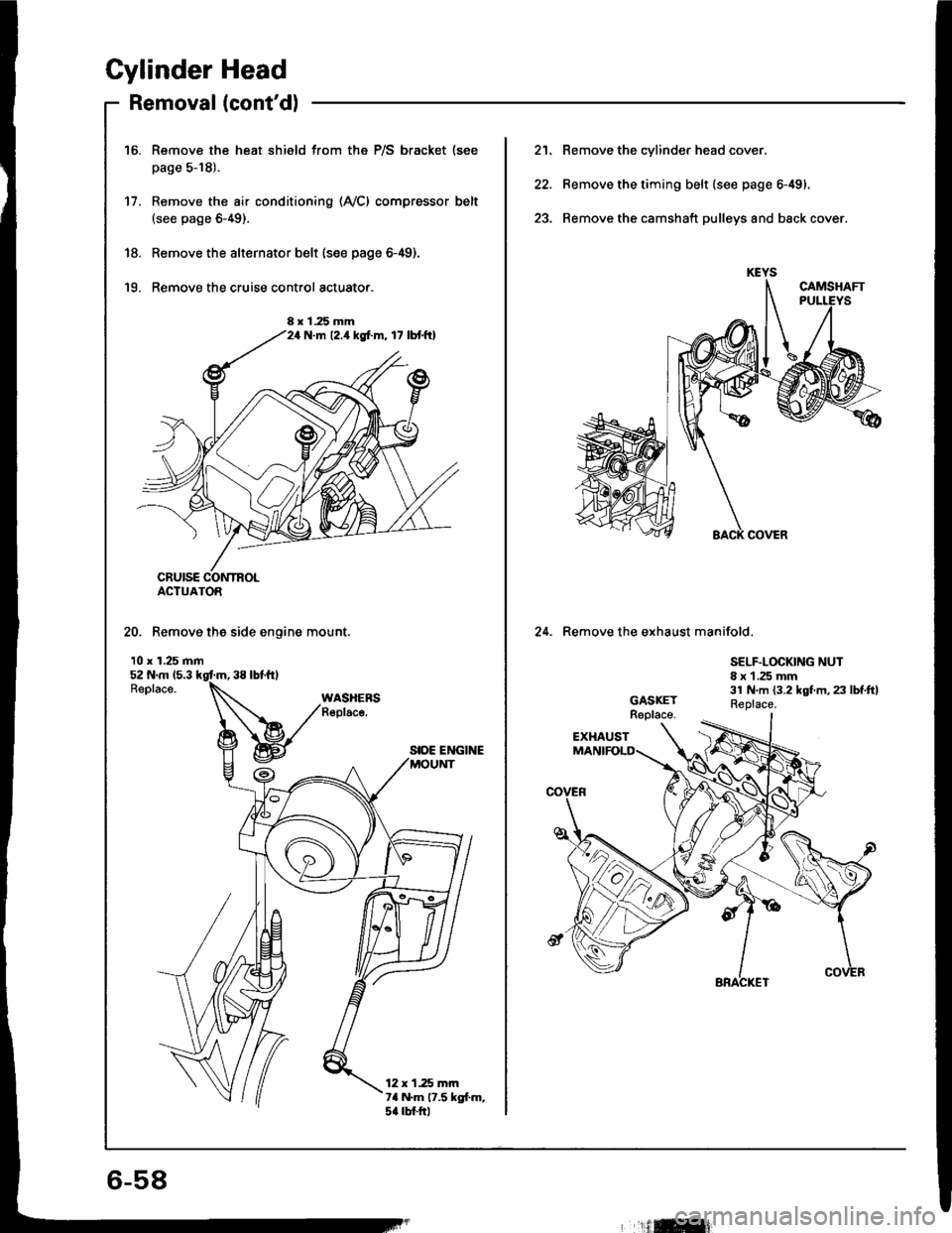

Remove the cruise control actuato..

16.

17.

'18.

'19.

ACTUATOR

20. Remove the side engine mount.

10 x 1.25 mm

SIDE ENGINE

12 x 1.25 mrn7a N.m 17.5 kgl.m,5a rbtftl

8 x 1.25 mmN.m 12.4 kgf.m, 17 lbtftl

21. Remove the cylinder head cover.

22. Remove the timing belt (see page 6-49).

23. Remove the camshaft pulleys and back cover.

24. Remove the exhaust manifold.

SELF.LOCKING NUT8 x 1 .25 mm31 N.m {3.2 kgt m, 23 lbf.ftlReplace.

6-58

'ilffi{

Page 120 of 1413

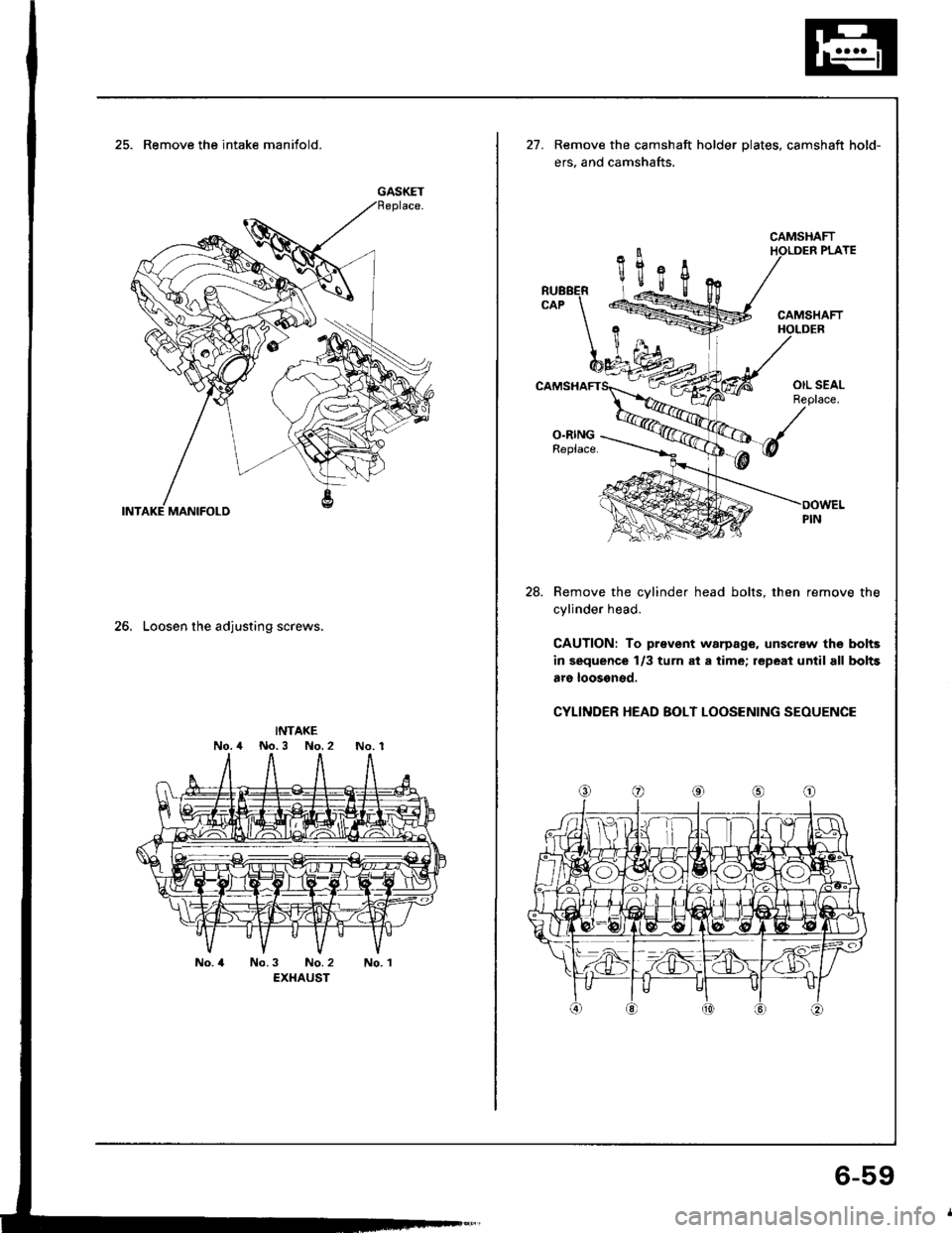

25. Remove the intake manifold.

26. Loosen the adjusting screws.

INTAKENo.4 No.3 No.2No. 1

No. 4No.3 No. 2EXHAUSTNo. 1

GASKET

21.Remove the camshaft holder plates, camshaft hold-

ers, and camshafts.

CAMSHAFT

28. Remove the cylinder head bolts, then remove the

cylinder head.

CAUTION: To prsvent warpage, unscrew th€ bolts

in sequence l/3 turn at a time; repeat until all bolts

aro loosoned.

CYLINDER HEAD BOLT LOOSENING SEOUENCE

6-59

Page 122 of 1413

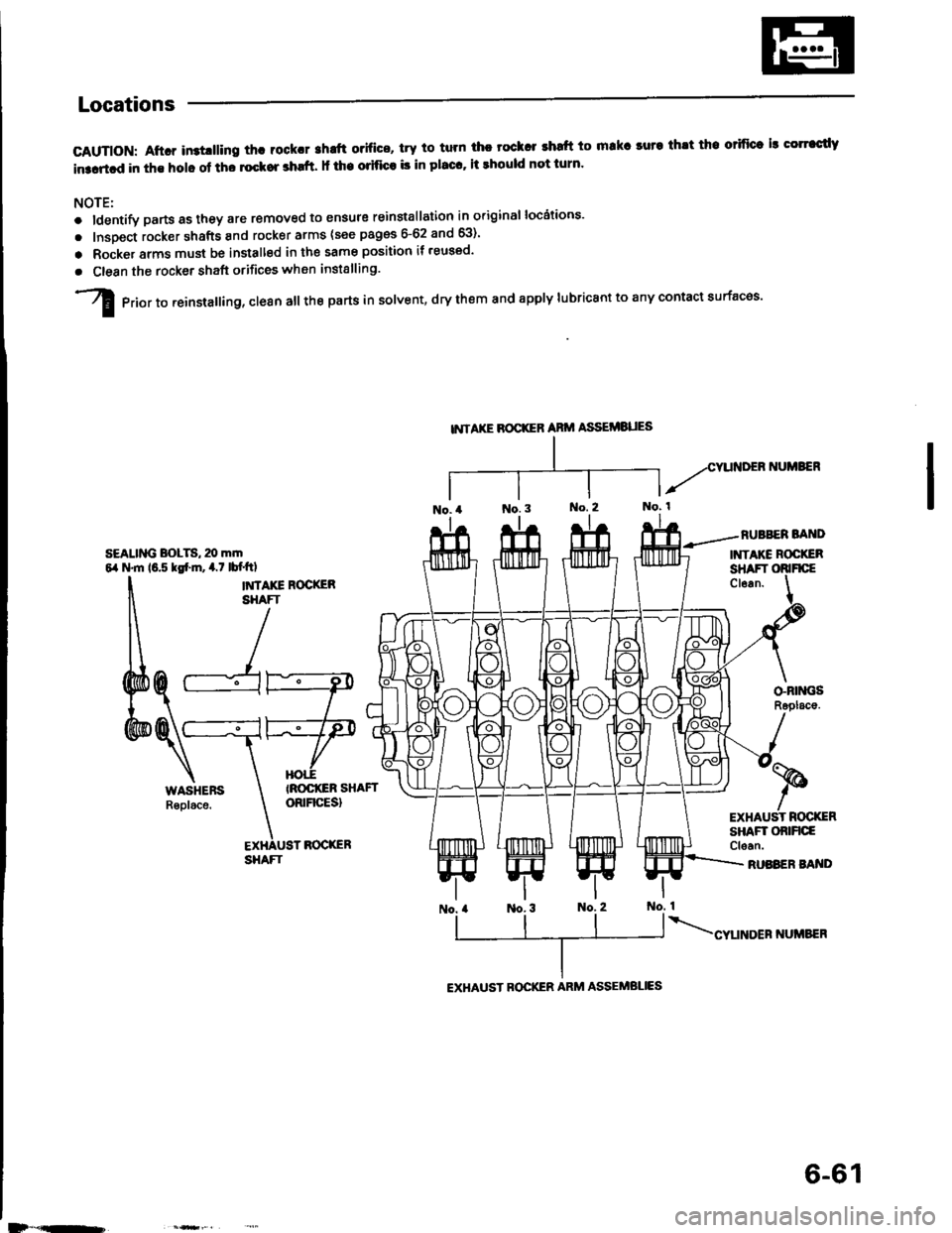

Locations

GAUTION: Aftcr in3tlllino th! roCk.r shrft o.ifice, trY to tum ihc tock r .hatt to makr luta thlt tho orifice ls corrccdY

in3artcd in the holc of tho lockor shrft. It the oritice b in placc' it should not turn'

NOTE:

o ldentify partsastheyare removed to ensure reinstallation in original locdtions'

. lnsoect rocker shafts and rocker arms (see pages 6-62 and 63)'

o Rocke. arms must be installed in the same position it reused'

. Clean the rocker shaft orifices when installing.

I erio, to ,einstalling, clesn all the parts in solvent, dry them and spply lubricant to any contact surfacos'

NTAKE BOCXER ARII,I ASSEi/IBUES

RUBBER BA D

INTAKE ROCXERsEALlMi BoLTS, 20 m|tr64 N.m 16.5 ksf.]n, 4.7 lbf.ftl

I

&

tu

SHAFTCl6an.

ry

ryHOII

o-nrM;sR6placo.

TROCIGR SHAFToRrFrcEsl

BOCXER

RUASER BA'{DSHAFT

-%

t

EXHAUST ROC(ER

EXHAUST B(rcKER ARM ASSEMBLIES

D*"'-,

6-61

Page 126 of 1413

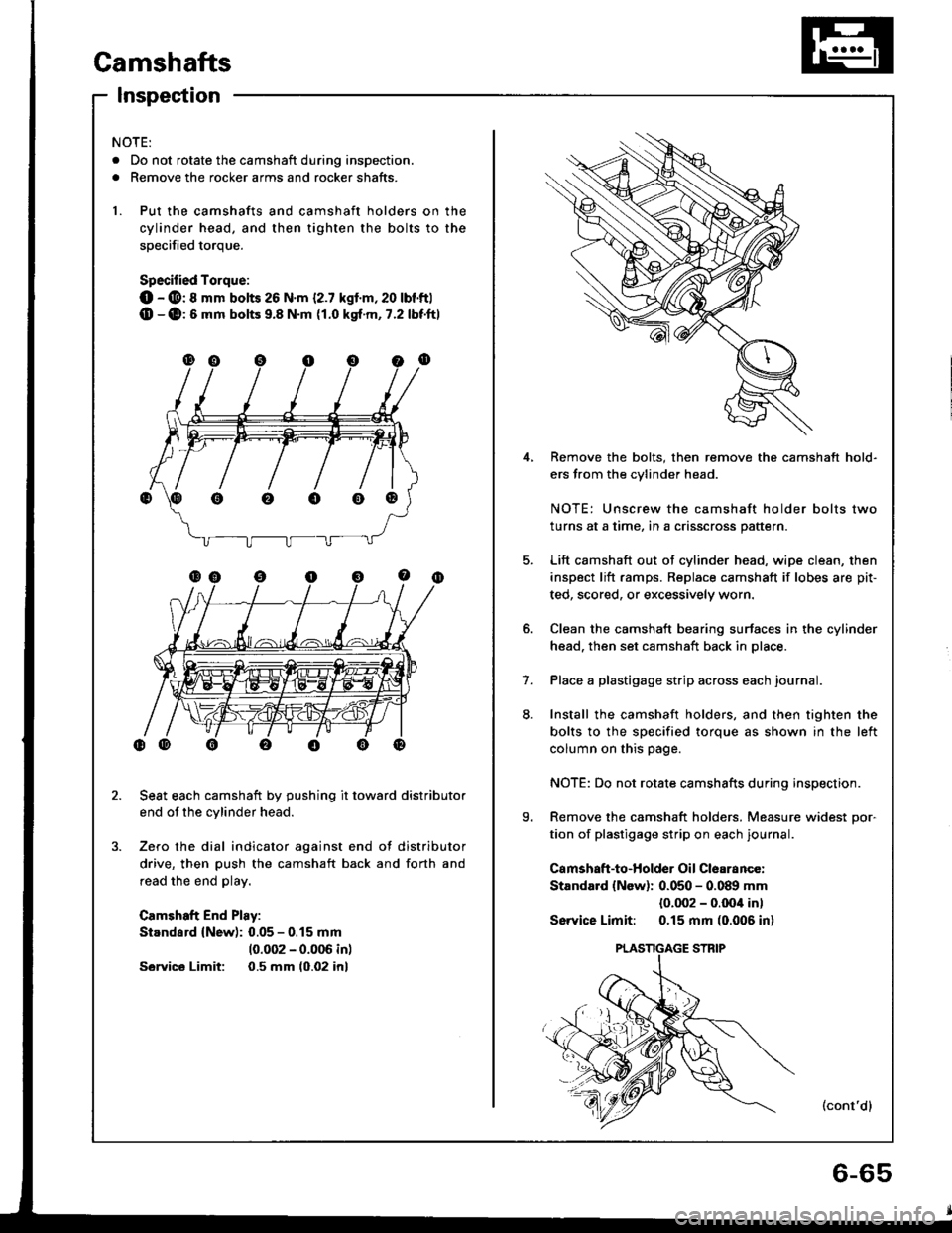

Camshafts

Inspection

4,

5.

9.

1.

Remove the bolts, then remove the camshaft hold-

ers from the cvlinder head.

NOTE: Unscrew the camshaft holder bolts two

turns at a time, in a crisscross pattern.

Lift camshaft out of cylinder head. wipe clean, then

inspect lift ramps. Replace camshaft if lobes are pit-

ted, scored, or excessively worn.

Clean the camshaft bearing surfaces in the cylinder

head. then set camshaft back in place.

Place a plastigage strip across each journal.

Install the camshaft holders, and then tighten the

bolts to the specified torque as shown in the left

column on this page.

NOTE: Do not rotate camshafts during inspection.

Remove the camshaft holders. Measure widest Dor-

tion of plastigage strip on each journal.

Camshaft-to-Holder Oil Clearance:

Standard {New): 0.050 - 0.089 mm

{0.002 - o.Ooil in)

Sswice Limit: 0.15 mm (0.006 in)

(cont'dl

NOTE:

. Do not rotate the camshaft during inspection.

. Remove the rocker arms and rocker shafts.

1. Put the camshafts and camshaft holders on the

cylinder head, and then tighten the bolts to the

soecified torque.

Specified Torque:

O - @: 8 mm bolts 26 N.m {2.7 kgl.m,20 lbt'ftl(D -(D:6 mm bolts 9.8 N.m {1.0 kgt.m, 7.2 lbf'ftl

Seat each camshaft by pushing it toward distributor

end of the cylinder head.

Zero the dial indicator against end of distributor

drive, then push the camshaft back and forth and

read the end play.

Camshaft End Play:

Standard (New): 0.05 - 0.15 mm

10.002 - 0.006 inl

Sawics Limit: 0.5 mm (0.02 inl

oooo@

Page 133 of 1413

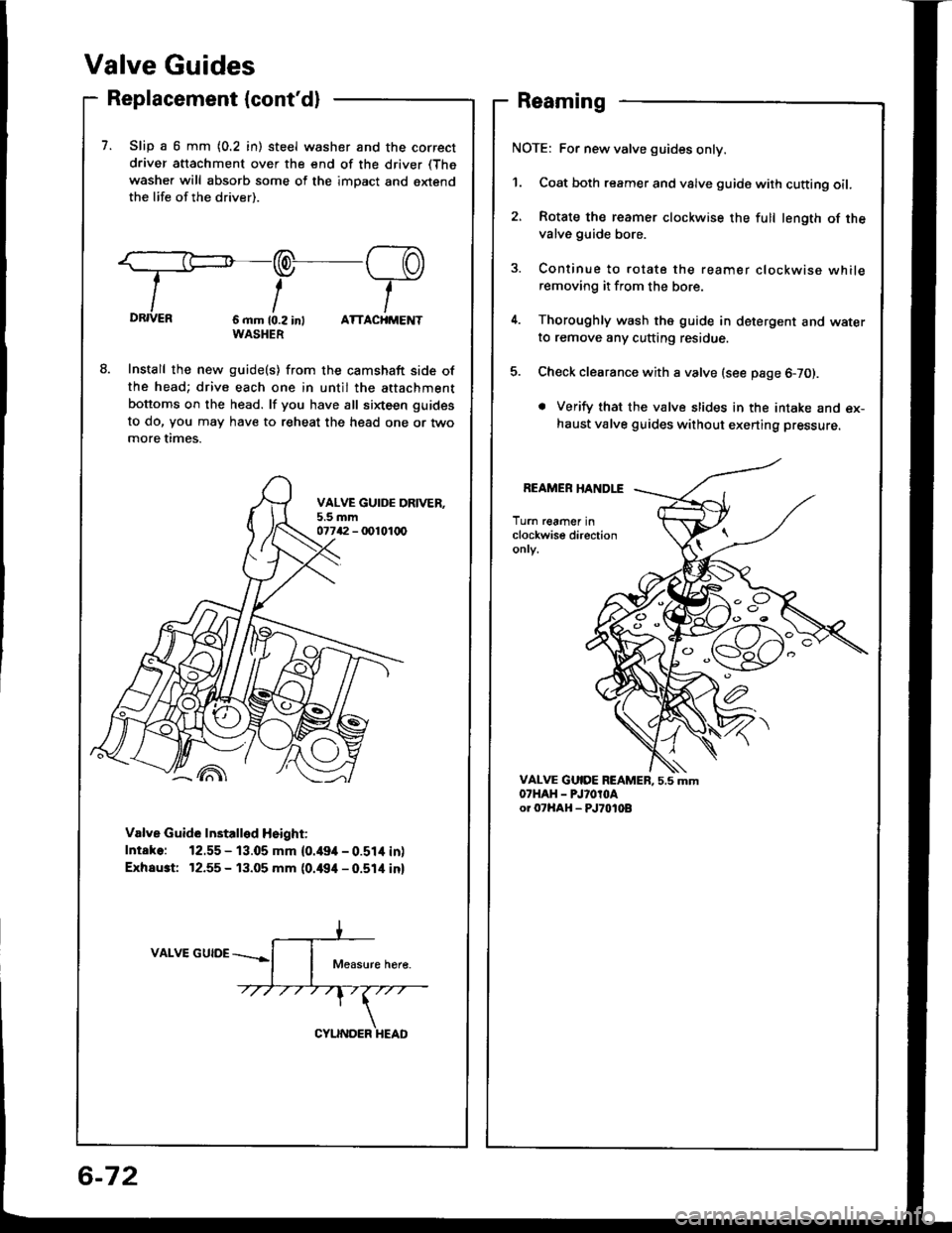

Valve Guides

Replacement (cont'dl

7. Slip a 6 mm {0.2 in) steel washer and the correct

driver attachment over the end of the driver (The

washer will absorb some of the imDact and extendthe life of the driver).

:=:-/--PDRIVER6 mm 10.2 int ATTACHMENTWASHER

Install the new guide(s) from the camshaft side ofthe head; drive each one in until the attachment

bottoms on the head. lf you have all sixteen guides

to do, Vou may have to reheat the head one or twomore times.

Valve Guide Installed Height:

Intake: 12.55 - 13.05 mm {0.49it - 0.51it inl

Exhaust 12.55 - 13.05 mm {0.494 - 0.514 inl

VALVE GUIDE

Reaming

NOTE: For new valve guides only.

1. Coat both reamer and valve guide with cutting oil.

2, Rotate the reamer clockwise the full length of thevalve guide bore.

3. Continue to rotate the reamer clockwise whileremoving it from the bore.

4. Thoroughly wash the guide in detergent and waterto remove any cutting residue.

5. Check clearance with a valve (see page 6-70).

. Verify that the valve slides in the intake and ex-haust valve guides without exerting pressure.

REAMER HANDLE

Turn reamer inclockwise directiononry.

C'

o

a

-'{)

6-72

Page 135 of 1413

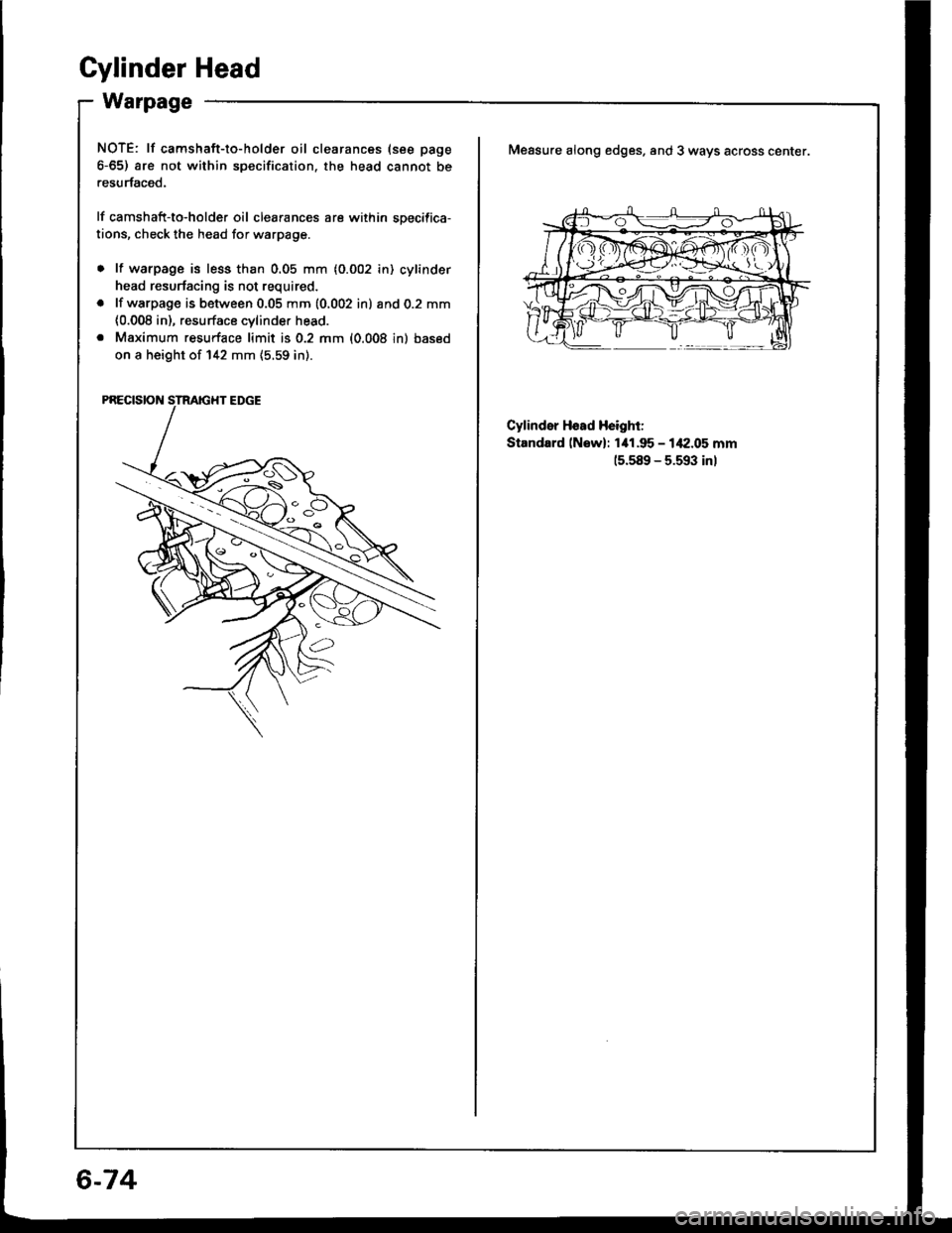

Gylinder Head

Warpage

NOTE: lf camshaft-to-holder oil clearances (see page

6-65) are not within specification. the head cannot be

.esurfaced.

lf camshaft-to-holder oil clearances are within sDecifica-

tions, check the head for warpage.

Measure along edges. and 3 ways across center.

lf warpage is less than 0.05 mm {0.002 in) cylinder

head resurfacing is not required.

lf warpage is between 0.05 mm {0,002 in) and 0.2 mm

{0.008 in), resurface cvlinder head.

Maximum resurface limit is 0.2 mm {0.008 in) based

on a height of 142 mm (5.59 in).

PRECISION STRAIGHT EDGE

Cylindsr Hssd Height:

Standard lNsw): 1i11.95 - 1,f2.05 mm

15.s89 - 5.593 inl

6-74

Page 136 of 1413

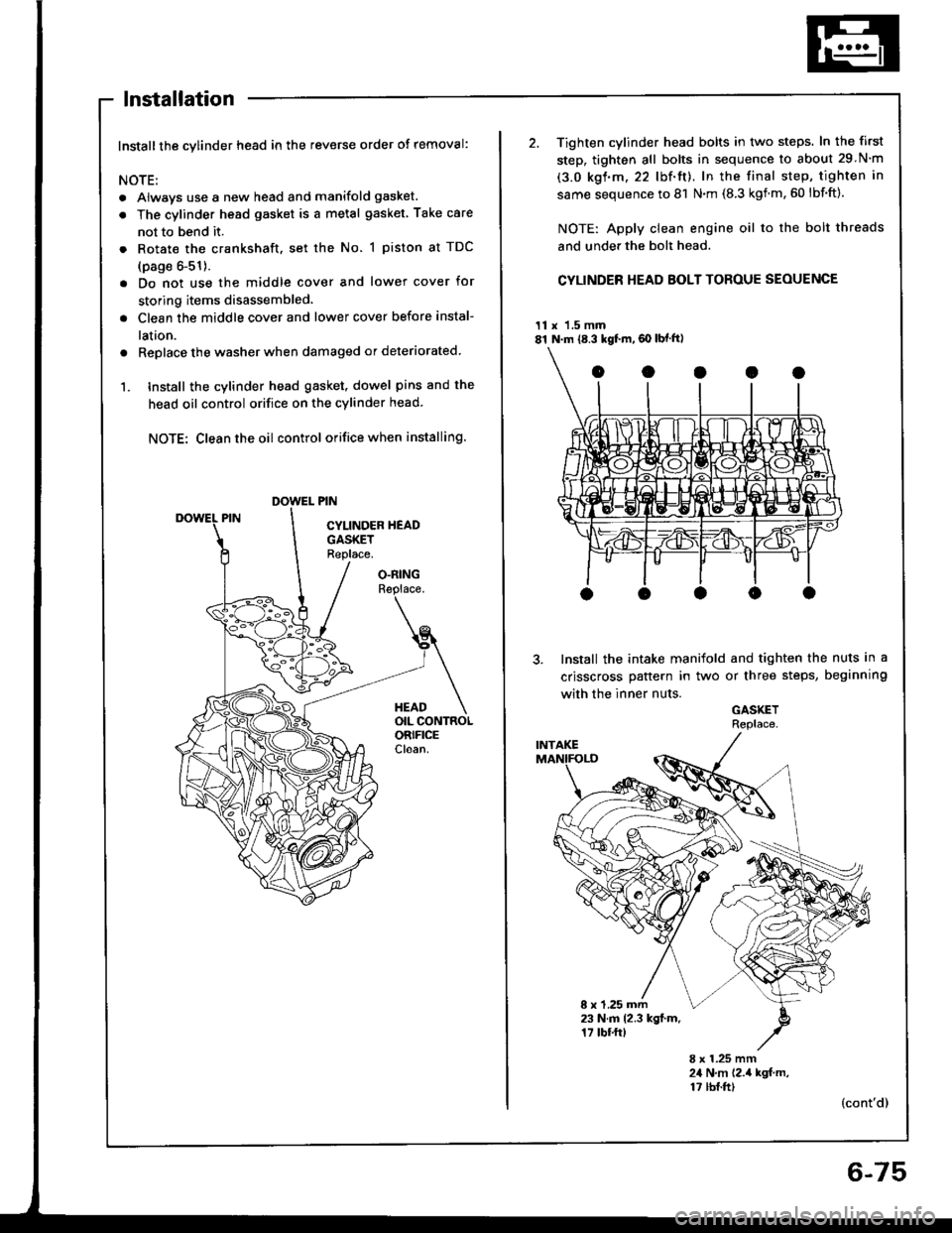

lnstallation

Installthe cylinder head in the reverse order of removal:

NOTE:

. Always use a new head and manifold gasket.

. The cylinder head gasket is a metal gasket Take care

not to bend it.

. Rotate the crankshaft, set the No. 1 piston at TDC

(page 6-51).

. Do not use the middle cover and lower cover for

storing items disassembled.

. Clean the middle cover and lower cover before instal-

lation.

a Replace the washer when damaged or deteriorated

1. tnstall the cylinder head gasket. dowel pins and the

head oil control orifice on the cylinder head

NOTE: Clean the oil control orifice when installing.

O.RINGReplace.

HEADOIL CONTROLORIFICECloan.

2. Tighten cylinder head bolts in two steps. In the first

step, tighten all bolts in sequence to about 29 N'm

(3.0 kgf.m.22 lbf'ft). In the final step, tighten in

same sequence to 81 N.m (8.3 kgnm.60 lbf'ft).

NOTE: Apply clean engine oil to the bolt threads

and under the bolt head.

CYLINDER HEAD BOLT TOROUE SEOUENCE

11 x 1.5 mm81 N.m {8.3 kgf.m,60 lbf ft)

Install the intake manifold and tighten the nuts in a

crisscross pattern in two or three steps, beginning

with the inner nuts.

GASKETRePlace

8 x 1.25 mm23 N.m 12.3 kgl.m.17 tbf.ftt

8 x 1.25 mm24 N,m 12.,4 kgf m,17 tbf.ft)(cont'd)

6-75

Page 139 of 1413

11.

12.

13.

Cylinder Head

Installation lcont'd)

lnstallthe timing belt lsee page 6-51).

Adjust the valve clearance (see page 6-44).

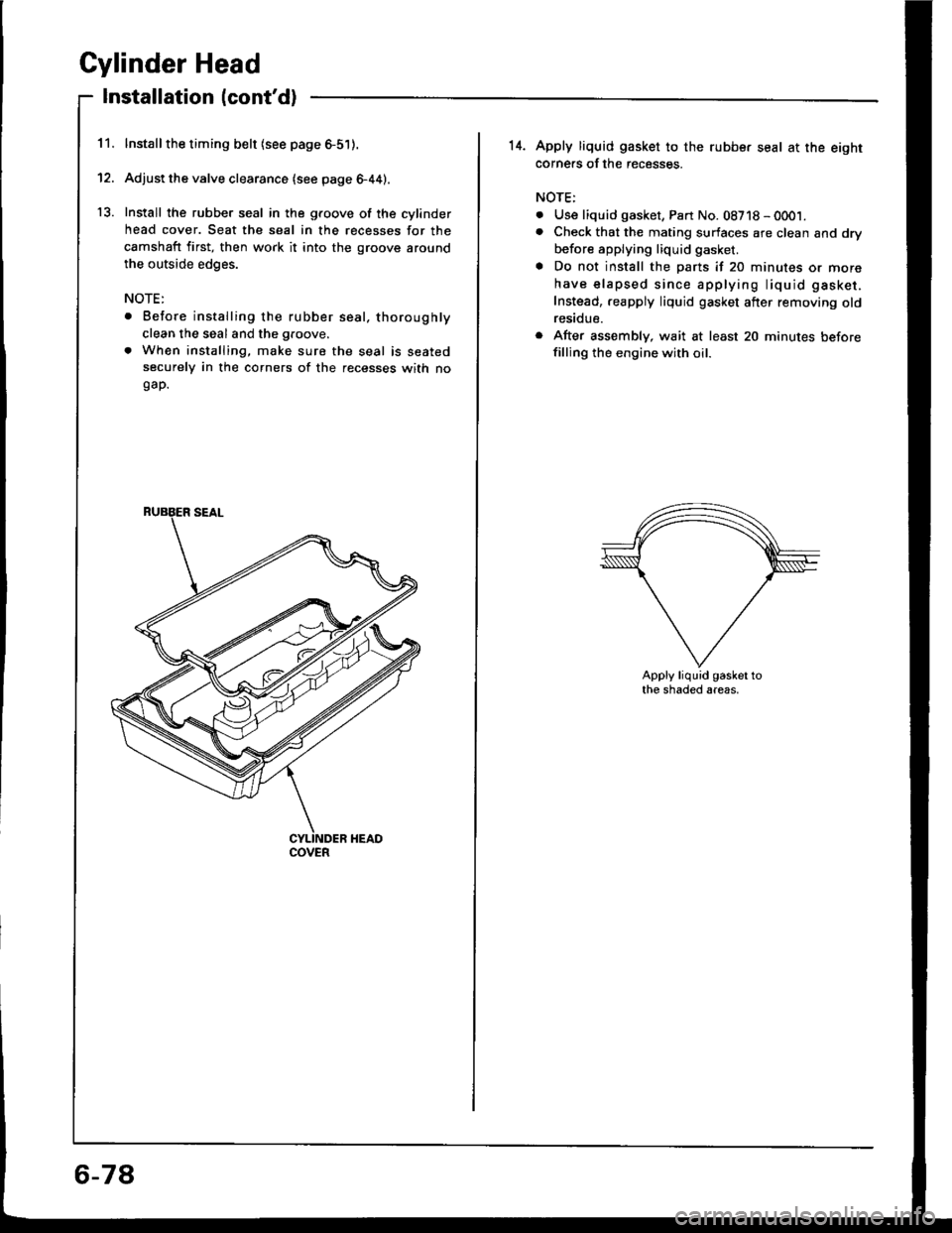

Install the rubber seal in the groove of the cylinder

head cover. Seat the seal in the recesses for the

camshaft first, then work it into the groove around

the outside edges.

NOTE:

. Before installing the rubber seal. thoroughly

clean the seal and the groove.

. When installing, make sure the seal is seatedsecurely in the corners of the recesses with nogap.

COVER

6-78

14. Apply liquid gasket to the rubbe. seal at the eightcorne.s of the recesses.

NOTE:

. Use liquid gasket, Part No. 08718 - 0001.. Check that the mating surfaces are clean and dry

before applying liquid gasket.

a Do not install the parts if 20 minutes or more

have elapsed since applying liquid gasket.

Instead,.eapply liquid gasket after removing oldresidue.

r After assembly, wait at least 20 minutes beforefilling the engine with oil.

Apply liquid gasket tothe shaded areas.

Page 143 of 1413

lllustrated Index

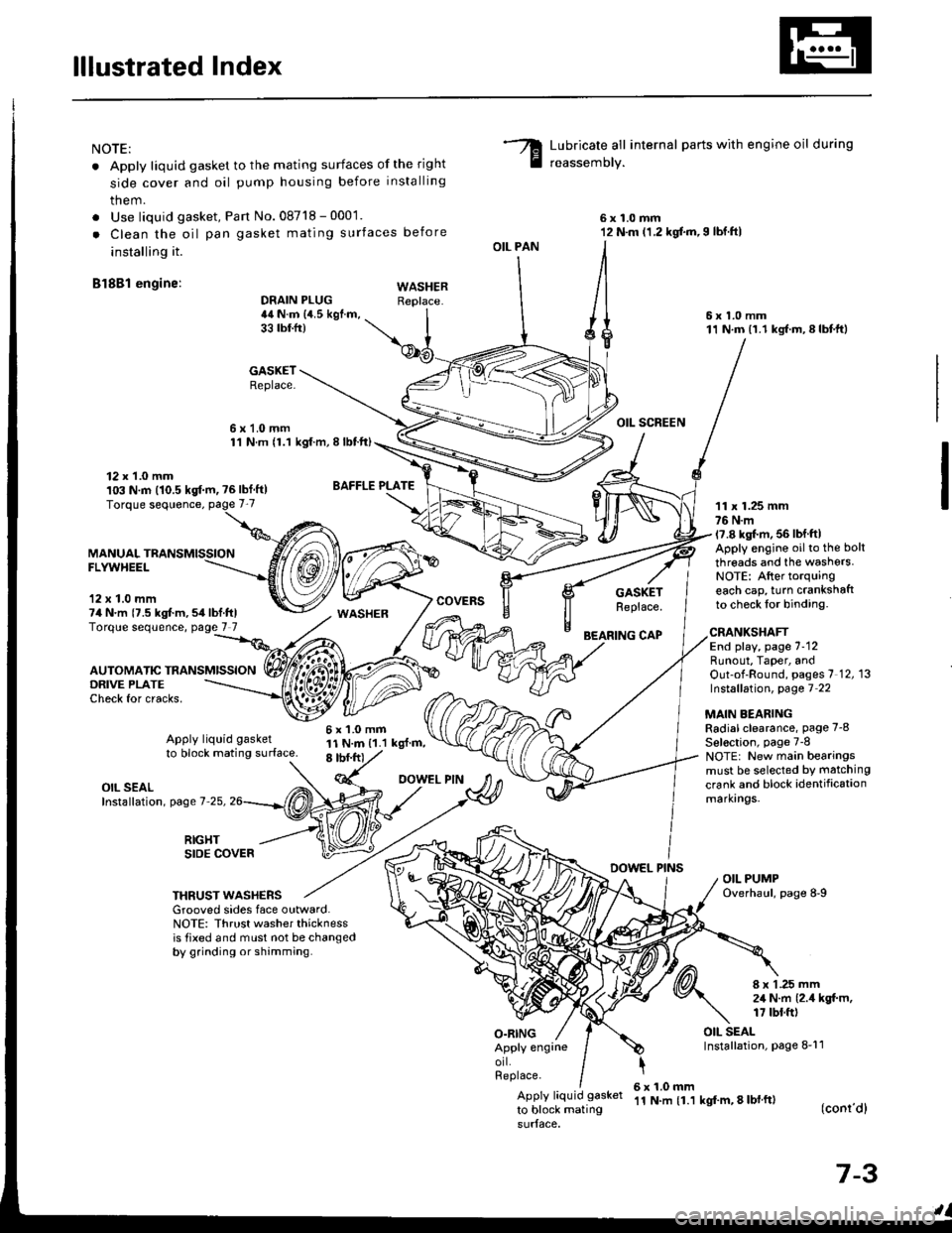

NOTE:

. Apply liquid gasket to the mating surfaces of the right

side cover and oil pump housing before installing

them.

. Use liquid gasket, Pan No.08718 - 0001.

. Clean the oil pan gasket mating surfaces before

installing it.

Bl8Bl engine: wAsHEF

Lubricate all internal parts with engine oil during

reassemory.

6x1.0mm12 N.m (1.2 kgf.m,I lbf.ftl

6x1.0mm11 N.m (1.1 kgf.m,8lbtft)

OIL SCREEN

11 x 1.25 mm76 N.m17.8 kgl.m, 56 lbf ftlApply engine oilto the bolt

threads and the washers.NOTE: After torquingeach cap, turn crankshaftto check lor binding.

DRAIN PLUG44 N.m {4.5 kgf.m,33 tbtfr)

GASKETReplace.

6x1.0mm1'l N.m {1.1 kgt.m, I lbtft)

OIL PAN

O.RING

GASKETReplace.

BEARING CAP

12 x 1.0 mm103 N.m (10.5 kgf.m, ?6lbf ft)

MANUALFLYWHEEL

'12 x 1.0 mm74 N.m {7.5 kgt m,54lbf.ftlTorque sequence, page 7 7

DRIVE PLATECheck for cracks,

AUTOMATIC TRANSMISSION

WASHER

6x1.0mm11 N.m {1.1 kgl.m,8 tbf.frt

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of-Round, pages 7 12, 13Instsllation, page 7 22

MAIN BEARINGRadial clearance, page 7-8

Sel€ction, page 7-8NOTE: New main bearingsmust be selected by matching

crank and block identificationmarkrngs.

Apply liquid gasket

to block mating surface.

OIL SEALInstallation, page 7-25,

RIGHTSIDE COVERDOWEL PINSOIL PUMPOverhaul, page 8-9THRUST WASHERSGrooved sides face outward.NOTE: Thrust washer thicknessis tixed and must not be changedby grinding or shamming.

8 x 1 .25 mm2,1 N.m {2.4 kgt m,17 tbt.ft)

OIL SEALInstallation, page 8-11Apply engrneorl.Replace.

Apply liquid gasket

to block mating

6x1.0mm'11 N.m {1.1 kgf'm, 8 lbl ft)(conr'dl

7-3