roll HONDA INTEGRA 1994 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 600 of 1413

Driveshafts

Reassembly (cont'dl

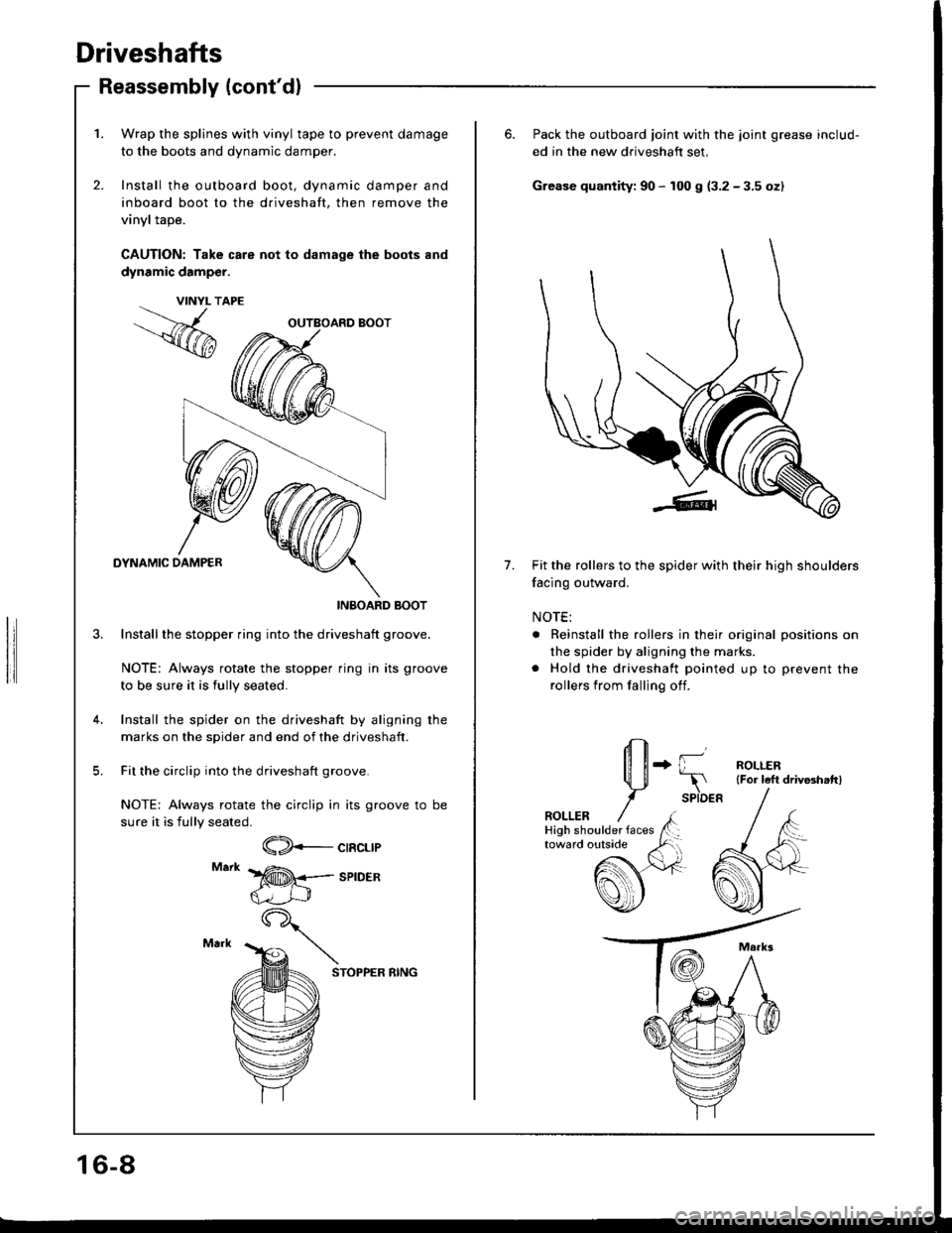

1. Wrap the splines with vinyl tape to prevent damage

to the boots and dynamic damper.

2. Install the outboard boot, dynamic damper and

inboard boot to the driveshaft, then remove the

vinyl tape.

CAUTION: Take care not to damage the boots and

dynamic damp€r.

DYNAMIC DAMPER

INBOARD BOOT

Installthe stopper ring into the driveshaft groove.

NOTE: Always rotate the stopper ring in its groove

to be sure it is fully seated.

Install the spider on the driveshaft by aligning rhe

marks on the spider and end of the driveshaft.

Fit the circlip into the driveshaft groove.

NOTE: Always rotate the circlip in its groove to be

sure it is fully seated.

VINYL T

,.%

CIRCLIP

SPIDER

STOPPER RING

OUTBOARD BOOT

16-8

6. Pack the outboard joint with the joint grease includ-

ed in the new driveshaft set,

Grease quantity: 90 - 100 g (3.2 - 3.5 oz)

7.Fit the rollers to the spider with their high shoulders

facing outward.

NOTE:

. Reinstall the rollers in their original positions on

the spider by aligning the marks.

. Hold the driveshaft pointed up to prevent the

rollers from falling off.

+ {l--r

SPIDER

ROLLER{For left driv8hattl

ROLLER

Page 601 of 1413

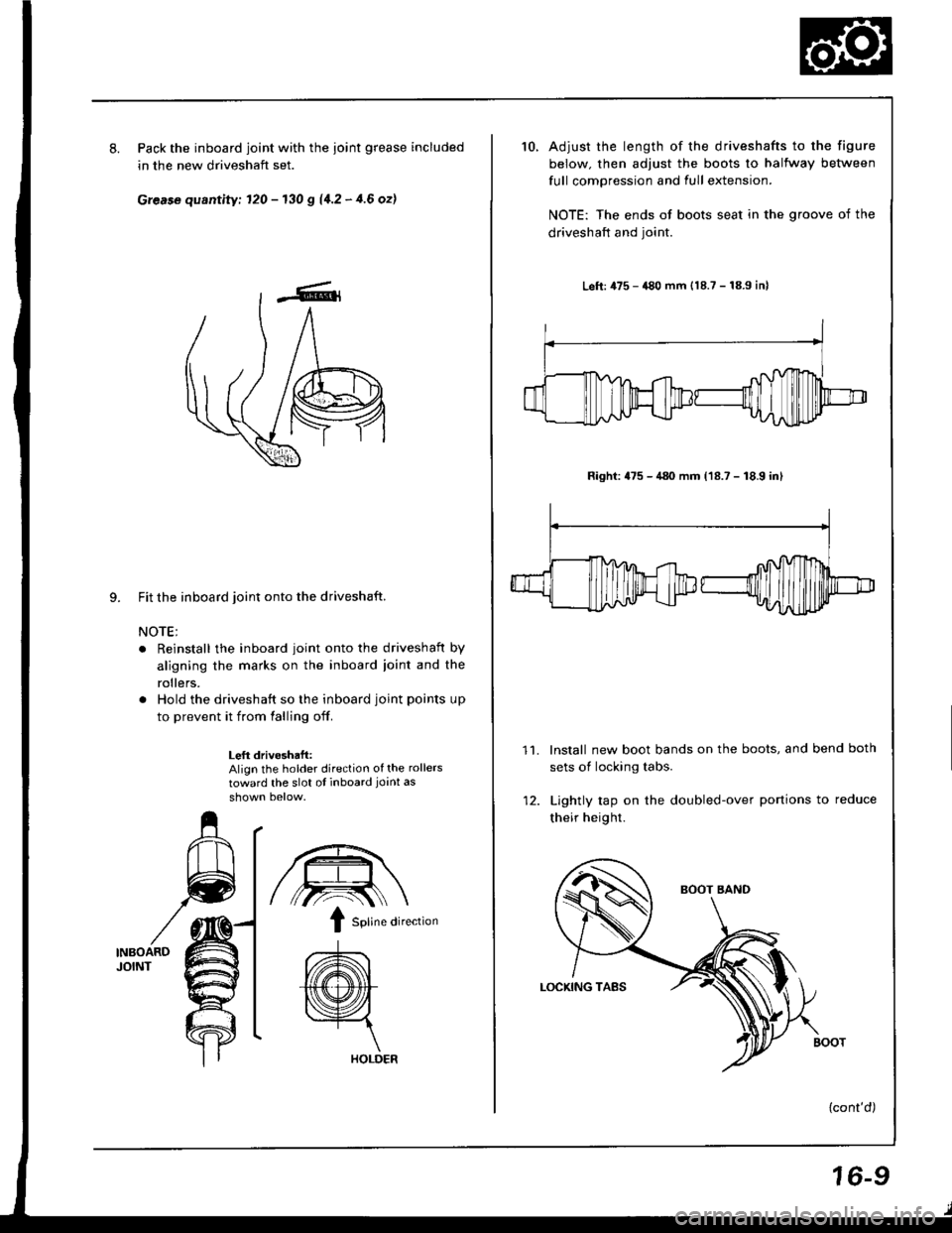

8.Pack the inboard joint with the ioint grease included

in the new driveshaft set.

Grease quantity; 120 - 130 g 11.2 - 4.6 ozl

9. Fit the inboard joint onto the driveshaft.

NOTE;

. Reinstall the inboard joint onto the driveshaft by

aligning the marks on the inboard ioint and the

rollers.

. Hold the driveshaft so the inboard joint points up

to prevent it from falling off.

Left drivoshaft:Align the holder direction of the rollers

toward the slot ot inboard joint as

INBOARDJOINT

/,.-:--\ \

I sotine di,ection

A\

{(@}

HOLDER

10.Adjust the length of the driveshafts to the figure

below. then adjust the boots to halfway between

full compression and full extension.

NOTE: The ends of boots seat in the groove of the

driveshaft and joint.

Left: 475 - 480 mm {18.7 - 18.9 inl

Right: 475 - 480 mm (18.7 - 18.9 inl

lnstall new boot bands on the boots, and bend both

sets of locking tabs.

Lightly rap on the doubled-over portions to reduce

their height.

{cont'd)

11.

16-9

Page 612 of 1413

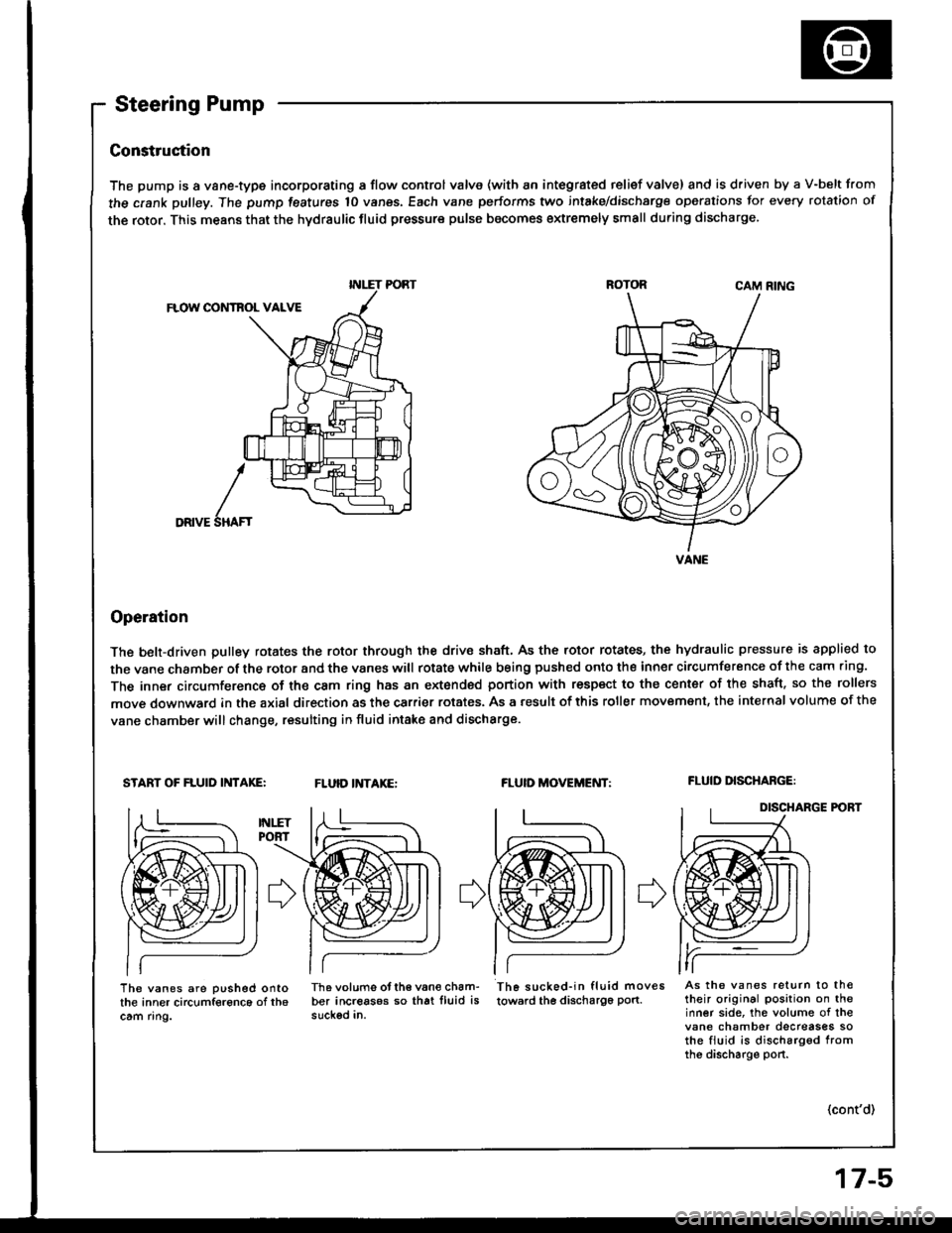

Construetion

The pump is a vane-type incorporating a flow control valve (with an integrated relief valve) and is driven by a V-belt from

the crank pulley. The pump features 10 vanes, Each vane performs two intake/dischsrge operations for every rotation of

the rotor. This means that the hydraulic fluid pressure pulse becomes extremely small during discharge.

CAM RING

FLOW CONTBOL VALVE

DRIVE

Operation

The belt-driven pulley rotates the rotor through the drive shaft, As the rotor rotates, the hydraulic pressure is applied to

the vane chamber of the rotor and the vanes witl rotate while being pushed onto the inner circumference of the cam .ing.

The inner circumference of the cam ring has an extonded portion with respect to the center of the shaft. so the rollers

move downward in the axial direction as the carrier rotates. As a result of this roller movemsnt, the internal volume of the

vane chamber will change, resulting in fluid intake and discharge.

START OF FLUID INTAKE:FLUID INTAKE:FLUID MOVEMENT:FLUID DISCHABGE:

DISCHARGE P('BT

I

SHAF'

The vanes are pushed ontothe inner circumference of th6cam ring.

Th6 volums otth€ van€ cham-ber increasos so that lluid issuckod in.

Th6 sucked-in fluid moves

towsrd the discha196 pon.As the vanes return to th€their original position on theinner side, the volume of thevane chamber decreases sothe fiuid is discharg6d fromthe discharge port.

(cont'd)

INLET PORT

VANE

Page 645 of 1413

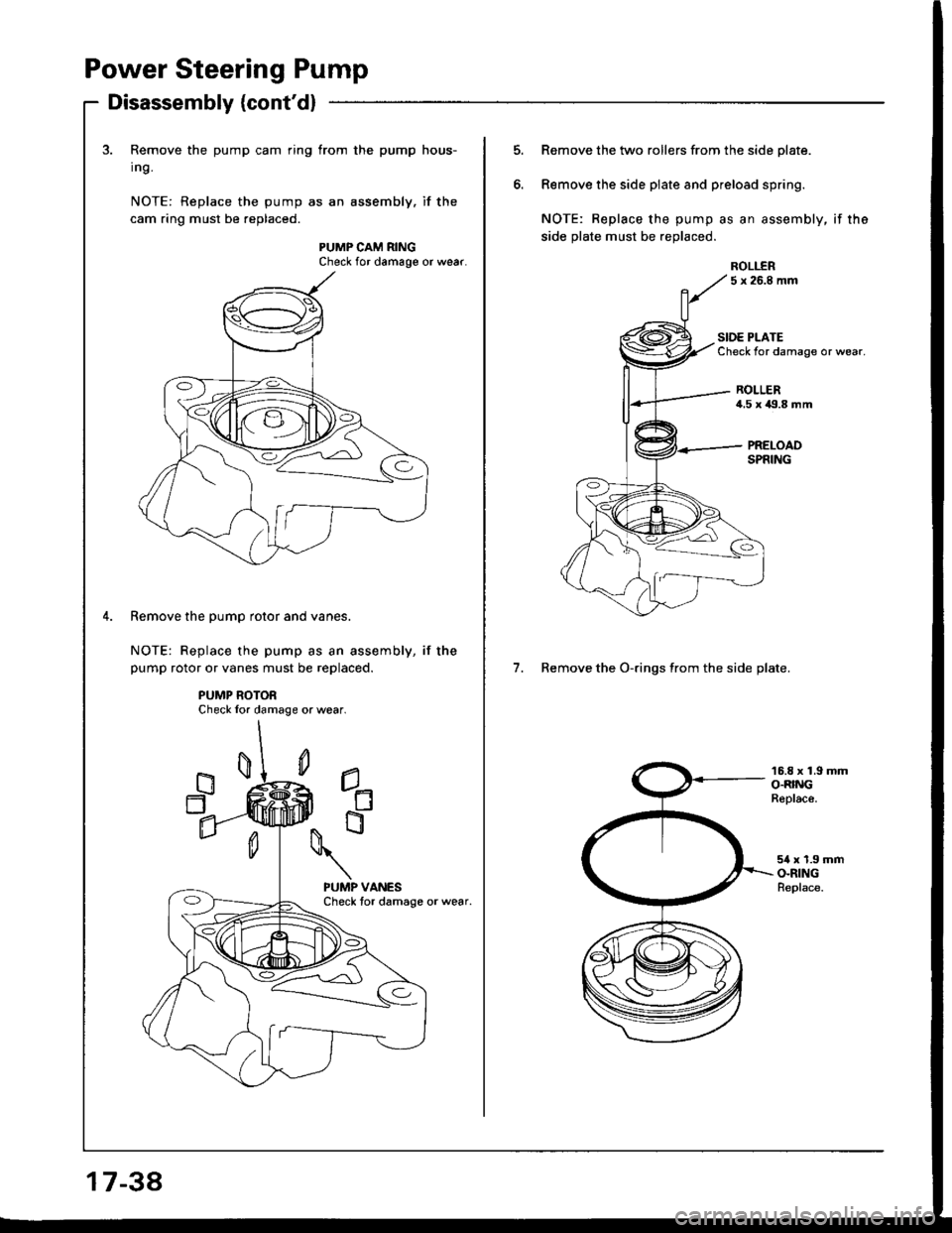

Power Steering Pump

Disassembly {cont'd}

3. Remove the pump cam ring from the pump hous-

Ing.

NOTE: Replace the pump as an assembly. if the

cam ring must be replaced.

PUMP CAM RINGCheck for damage or wear.

Remove the pump rotor and vanes.

NOTE: Replace the pump as an assembly, if the

pump rotor or vanes must be replaced.

PUMP ROTORCheck lor damage or wear.

1734

Remove the two rollers from the side plate.

Remove the side piate and preload spring.

NOTE: Replace the pump as an assembly, if the

side plate must be replaced.

5 x 26.8 mm

7. Remove the O-rings from the side plate.

SIDE PLATECheck for damage or wear.

ROLLER4,5 x 119.8 mm

16.8 x 1.9 mmO.RINGReplace.

54 x 1.9 mmO-RINGReplace.

ROLI..ER

Page 647 of 1413

Power Steering Pump

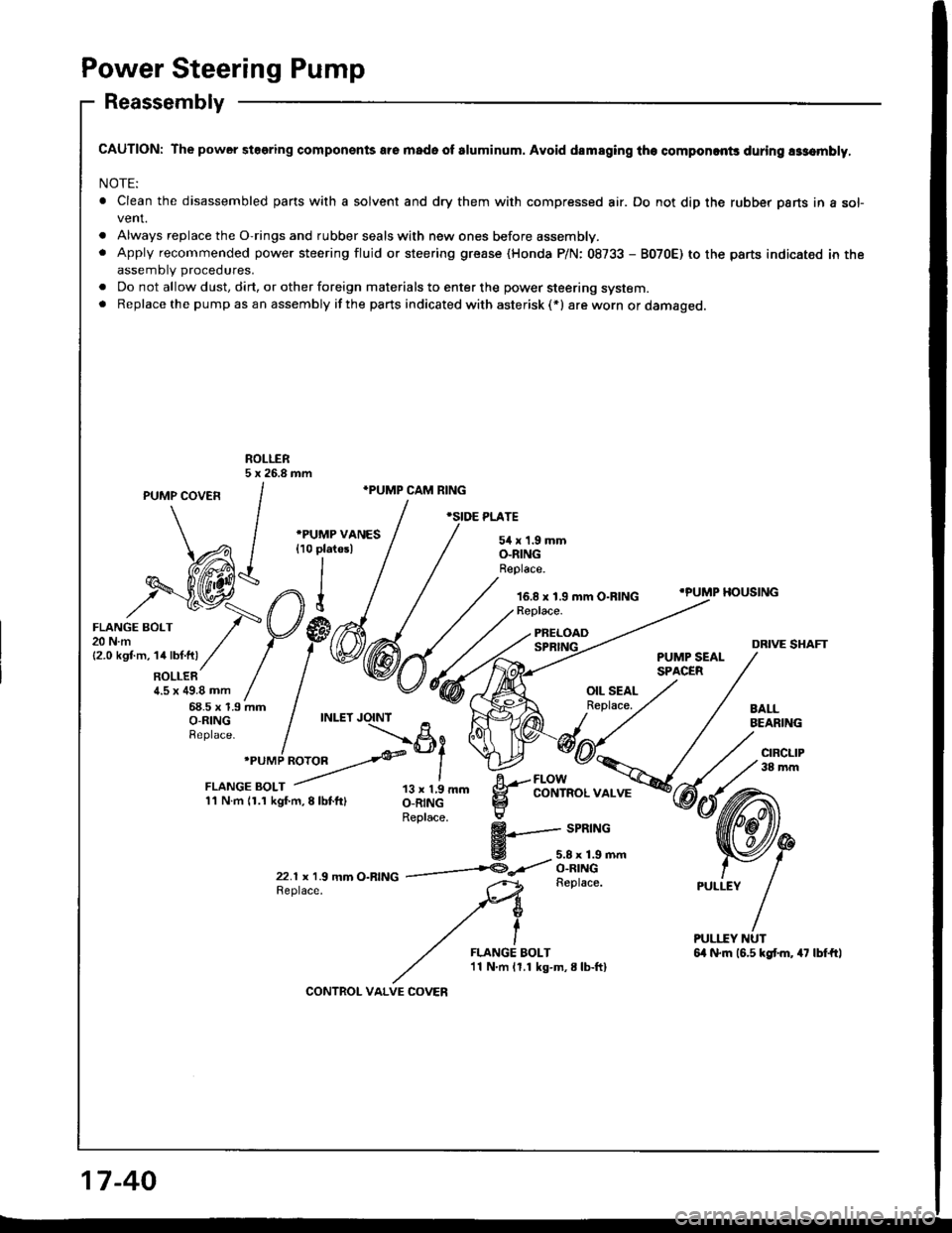

Reassembly

CAUTION: The power steering componsnts are mado of sluminum. Avoid dsmaging th€ componcnts during assombly,

NOTE:

. Clean the disassembled pans with a solvent and dry them with compressed air. Do not dip the rubber parts in a sofvent.

. Always replace the O-rings and rubber seals with new ones before assembly.. Apply recommended power steering fluid or steering grease (Honda P/N: 08733 - B070E) to the parts indicated in theassemblv procedures.

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.. Replacethe pump asan assembly ifthe parts indicated with asterisk (*) are worn or damaged.

ROLLER5 x 26.8 mm

PUMP covEn /

."'MP cAM RING

, / .",or r*r,

^ / -e^urrae vrues / / sirx1.smm

\Al {ro pratesl I / o_nrNc

dA-h1//EZil*l///'^ee'ace

o-ntNGReplace.

16.8 x 1.9 mm O-RING

\A I {ro Platesl

,h$;@:",n1

i'"otr

/-V#mtt.m,1a|t�t.fti// / / \E

RoLLER / |a.5 x ag.a mm / |68.5 x 1.9 mm Io-RING / INLET

Reptace.

I

.PUMP HOUSING

xf:.i'/pp@6{fr;ryDRIVE SHAFTPUMP SEALSPACERROLLER /1.5 x 49.8 mm /68.5 x 1.9 mmO-R|NG / INLET JO-INT

Replace.

I'PUMP ROTOR>ei

iiij:f:,ll-T;-,",,,, ll;il'- g--lblY""."*";

Replace. :

$+--- srntnc

E -5.8x1.9mm

22.r x r.9 mm o-RfNG ------t@-<'t o^::t:\-GReplace.Replace.

FLANGE BOLT'11 N.m 11.1 kg-m,8lb-ftI

17-40

CONTROL VALVE COVEN

Page 648 of 1413

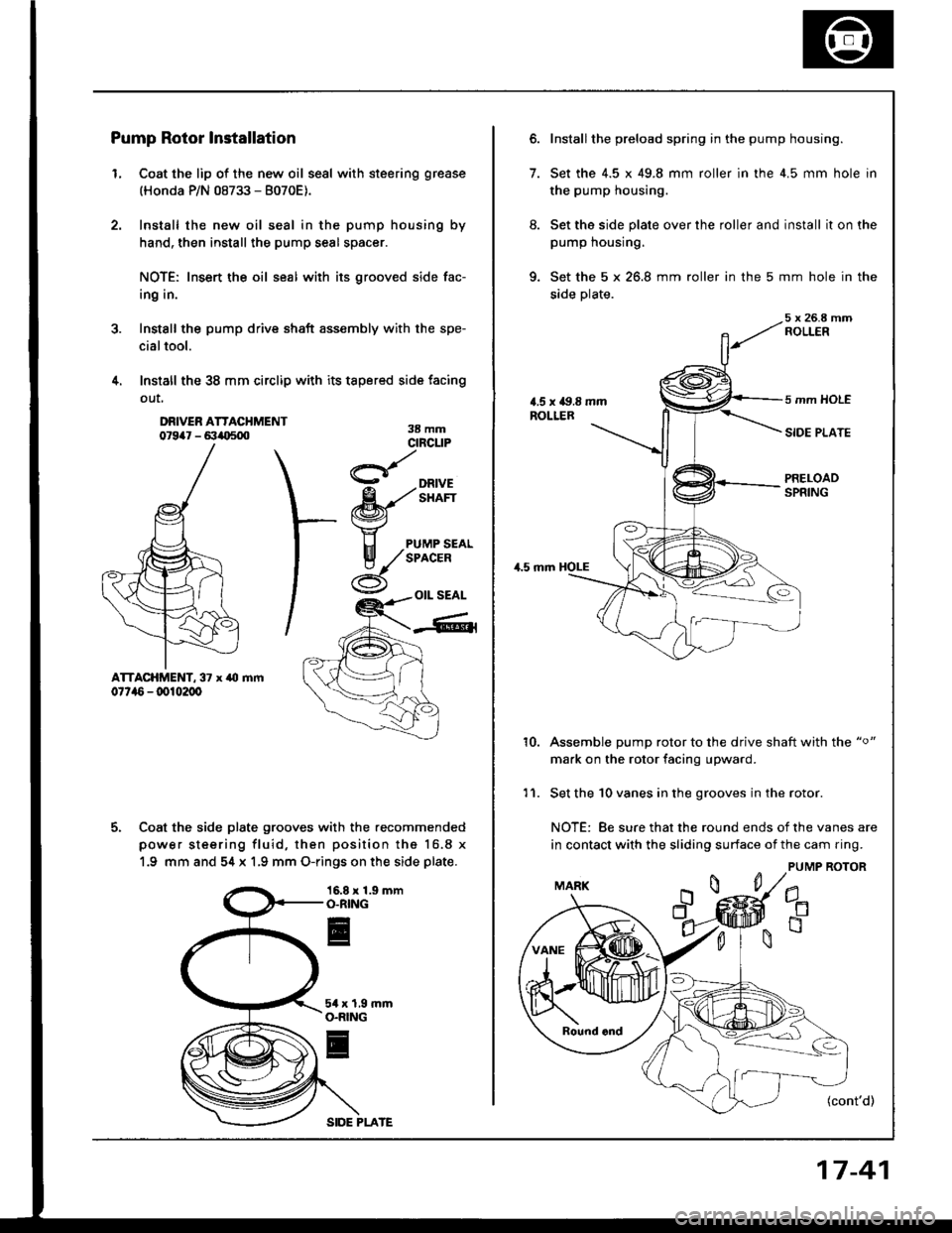

Pump Rotor Installation

L Coat the lip of the new oil seal with steering grease

(Honda P/N 08733 - 8070E).

Install the new oil seal in the pump housing by

hand, then install the pump seal spacer.

NOTE: Insert the oil seal with its grooved side fac-

ing in.

Install the pump drive shaft assembly with the spe-

cialtool.

Install the 38 mm circlip with its tapered side facing

out,

3.

4.

DRIVER ATTACHMENT07947 - 6:1io50038 mmcrncuP

- DRIVE

fu'/'i,Ert\=zl4

I"J PUMP SEALIf /sprcen

x,tY -ot seal

-Gll

ATTACHMENT, 37 x ,r0

07t,16 - dt102d,

5. Coat the side plate grooves with the recommended

power steering fluid, then position the 16.8 x

1.9 mm and 54 x 1,9 mm O-rings on the side plate.

16.8 x 1.9 mmO.RING

5a x 1,9O.RING

l

SIDE PLATE

17-41

6. Install the preload spring in the pump housing.

7. Set the 4.5 x 49.8 mm roller in the 4.5 mm hole in

the pump housing.

8. Set the side plate over the roller and install it on the

pump housrng.

9. Set the 5 x 26.8 mm roller in the 5 mm hole in the

side plate.

5 x 26.8 mmROLLER

5 mm HOLE

SIDE PLATE

PRELOADSPRING

,1.5 mm

10.Assemble pump rotor to the drive shaft with the "o"

mark on the rotor facing upward.

Set the 10 vanes in the grooves in the rotor.

NOTE: 8e sure that the round ends of the vanes are

in contact with the sliding surface of the cam ring.

PUMP ROTOR

(cont'd)

11.

Page 649 of 1413

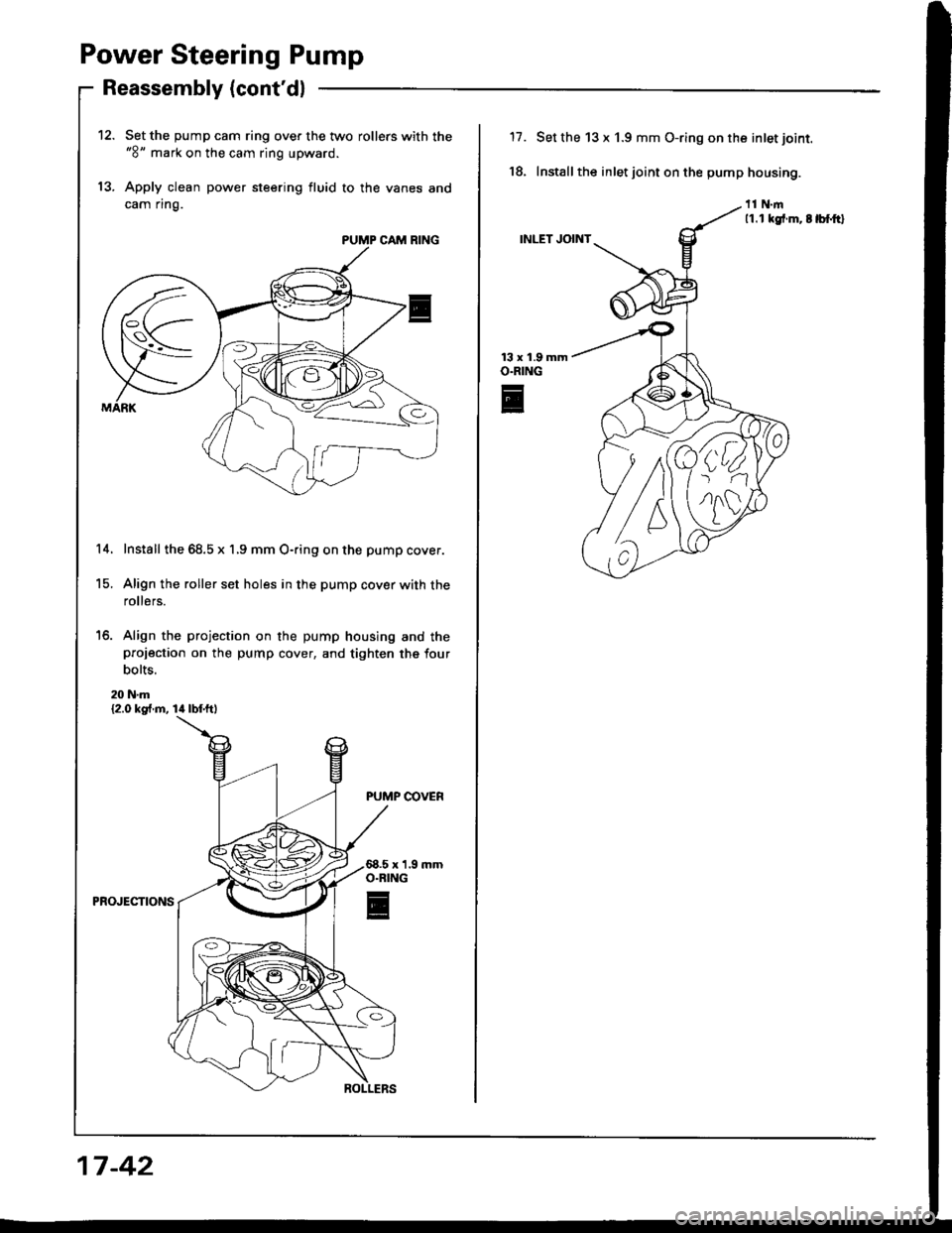

Power Steering Pump

Reassembly (cont'dl

Set the pump cam ring over the two rollers with the"8" mark on the cam ring upward.

Apply clean power steering fluid to the vanes and

cam ring.

Install the 68.5 x 1,9 mm O-ring on the pump cover.

Align the roller set holes in the pump cover with the

rollers.

'16. Align the projection on the pump housing and theprojection on the pump cover, and tighten the four

bolts.

20 N.m{2.0 kg .m, lil lbf.ftl

PUMP COVER

PROJECTIONS

13.

PUMP CAM RING

14.

15.

17 -42

17.

18.

13 x 1.9O.RING

E

Set the 13 x 1.9 mm O-ring on the inlet joint.

Install the inlet joint on the pump housing.

11.1 kgt.m. t lbf.ftl

INLET JOINT

T9

Page 659 of 1413

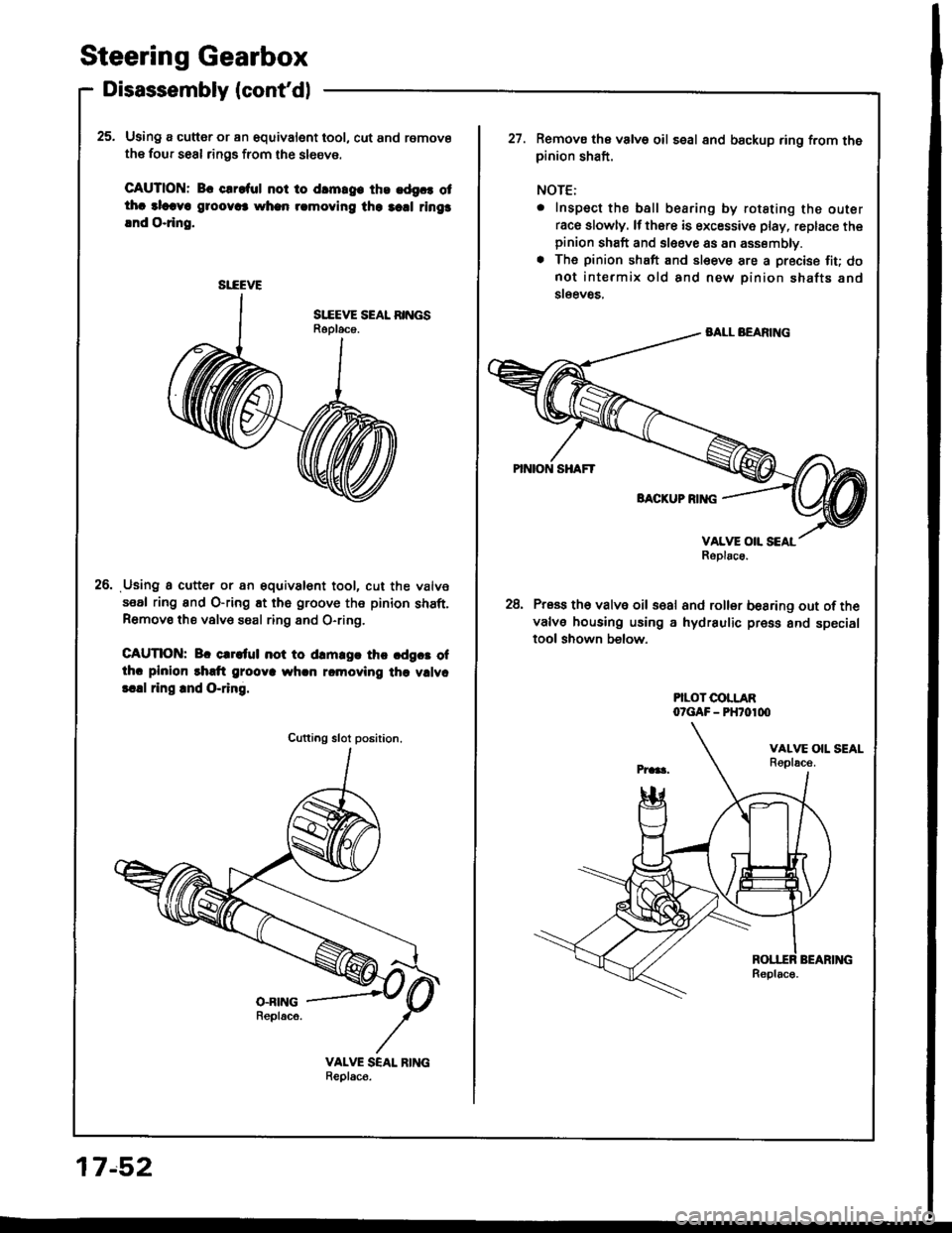

Steering Gearbox

Disassembly (cont'dl

25. Using a cutter or an equivalent tool, cut and remove

the four seal rings from the sl6eve.

CAUTION: Bc clroful not to drmrg. ths .dgc. otthc alcava g1oov6 whan rcmoving the 3cd rings

lnd O.ring.

Using a cutter or an gquivalent tool, cut the valve

seal ring and O-ring Et the groove the pinion shaft.Remove the valv€ saal ring 8nd O-ring,

CAUTION: Br crrltul not to drm.gr thc cdgct ofthc plnion rhdt grooya whcn rcmoving the vllvc

!.!l ring rnd O-ring.

26.

SI-EEVE

Cutting slot position.

17.52

Remova the valve oil seal 8nd backup ring from thepinion shaft.

NOTE:

. Inspect the ball bearing by rotating the outer

race slowly. lf thsre is excessive play, replace thepinion shaft and sleeve as an assembly.. The pinion shaft and sleeve are a precise fiu donot intermix old and new pinion shafts and

steev8s,

28, Press th6 valve oil s€al and roller besring out ofthe

valve housing using a hydraulic press and specialtool shown below.

PILOT COLLARO?GAF - PHTO1OO

Page 663 of 1413

Steering Gearbox

Reassembly (cont'd)

SI,-EEVE SEAL RINGSBe sure that thesear ings are notturned up, theninstall.

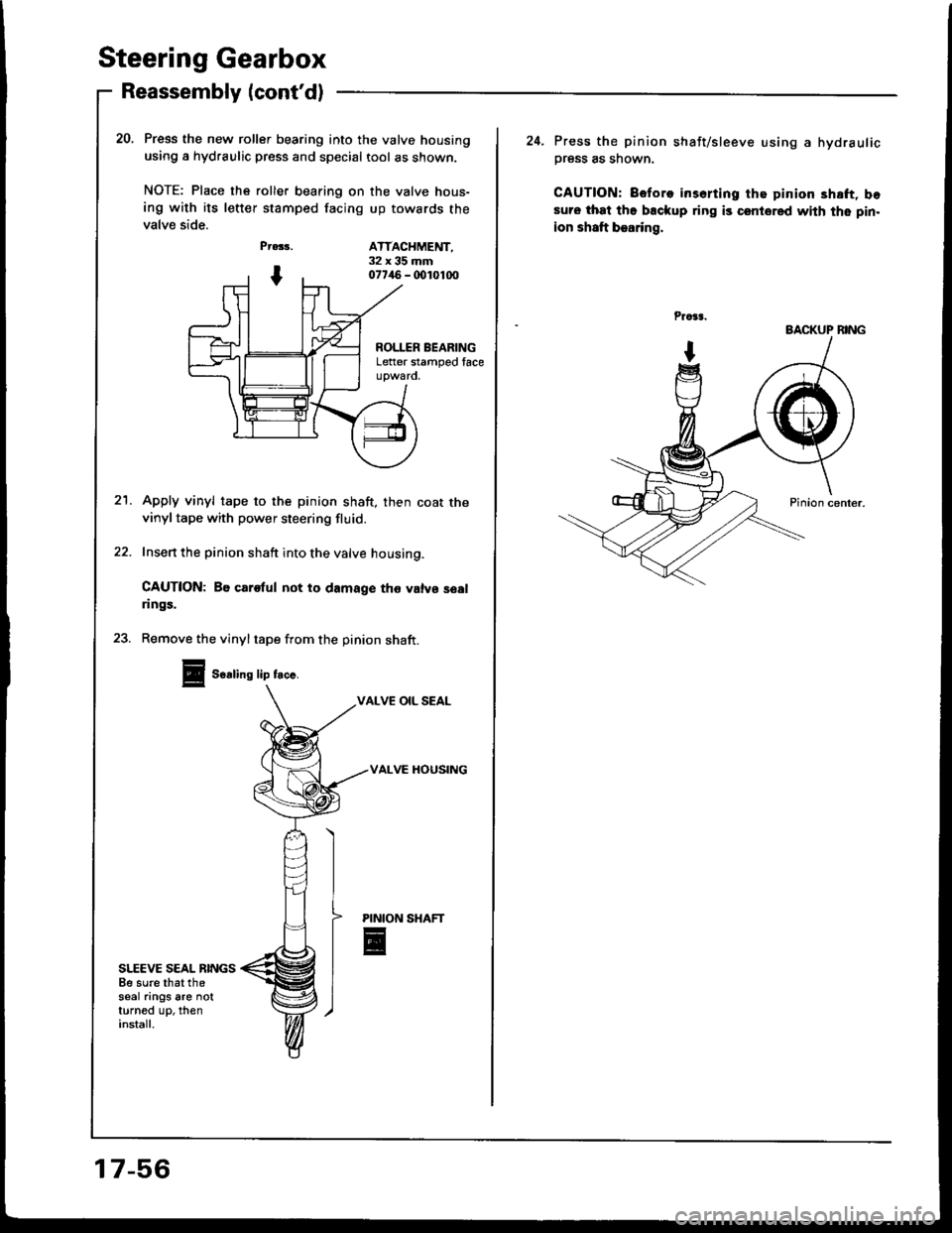

Press the new roller bearing into the valve housing

using a hydraulic press and special tool as shown.

NOTE: Place ths roller bearing on the valve hous-

ing with its letter stamped facing up towards the

valve side.

Pr.33,

I

PINION

E

20.

ATTACHMENT,32x35mm077/aO - (x)1010O

ROLLER BEARINGLetter stamped face

21.Apply vinyl tape to the pinion shaft, then coat thevinyl tape with power steering fluid.

Insert the pinion shaft into the valve housing.

CAUTION: Be carotul not to damage tho valvs soalrings.

23. Remove the vinyltape from the pinion shaft.

Soaling lip frc..

VALVE OIL SEAL

VALVC HOUSING

17-56

24. Press the pinion shaft/sleeve using a hydraulic

Dress as shown.

CAUTION: Before irserting the pinion 3haft, bosuro that the backup ring is csntored with the pin.

ion shaft bearing,

BACKUP BING

Page 668 of 1413

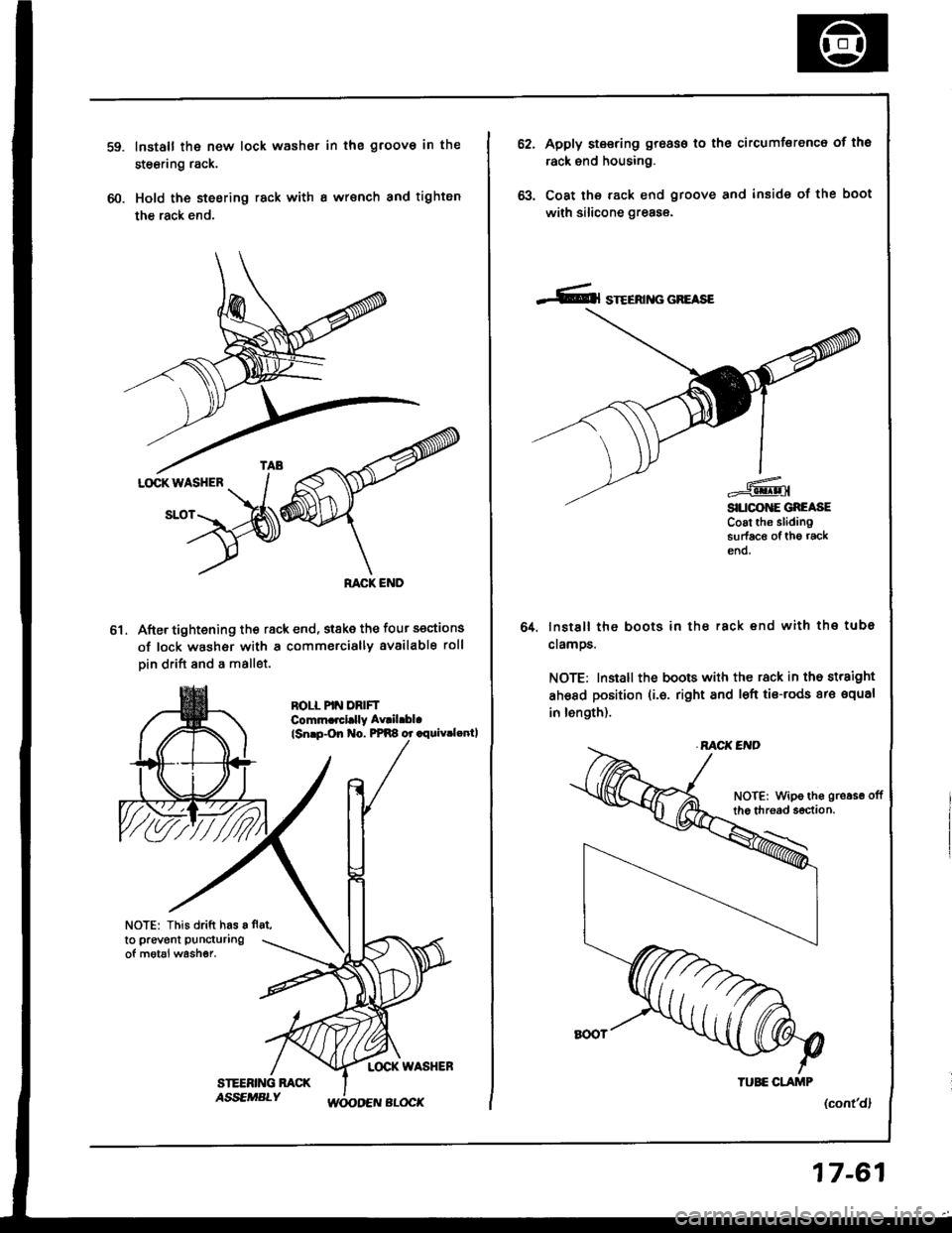

60.

Install the new lock washor in the groov€ in the

steering rack.

Hold the steering rack with I wrsnch and tighten

the rack end.

After tightening th€ rack end, stske the four sections

of lock washer with a commercially available roll

Din drift and a mallet.

ROLL PIN DRIFTComm.rcl.lly Av|il.bl.

lsnrp-On No. PPR8 or .rquiv.lenll

NOTE: This drift has a fl8t,

to prevent puncturing

of motal washer.

ol

62.Apply steering groass to the circumferenc6 of tho

rack end housing.

Coat the rack end groove and inside of the boot

with silicone greas€.

lnstsll the boots in ths rack end with the tube

clamos.

NOTE: Install the boots with the rack in the straight

ahsad position (i.6. right and l€ft tis-rods ar€ squal

in length).

(cont'dl

64.

NOTE: Wipe ths gro.se offthe thread s€ction.

TUEE CLAJTIP

17-61