roll HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 31 of 1413

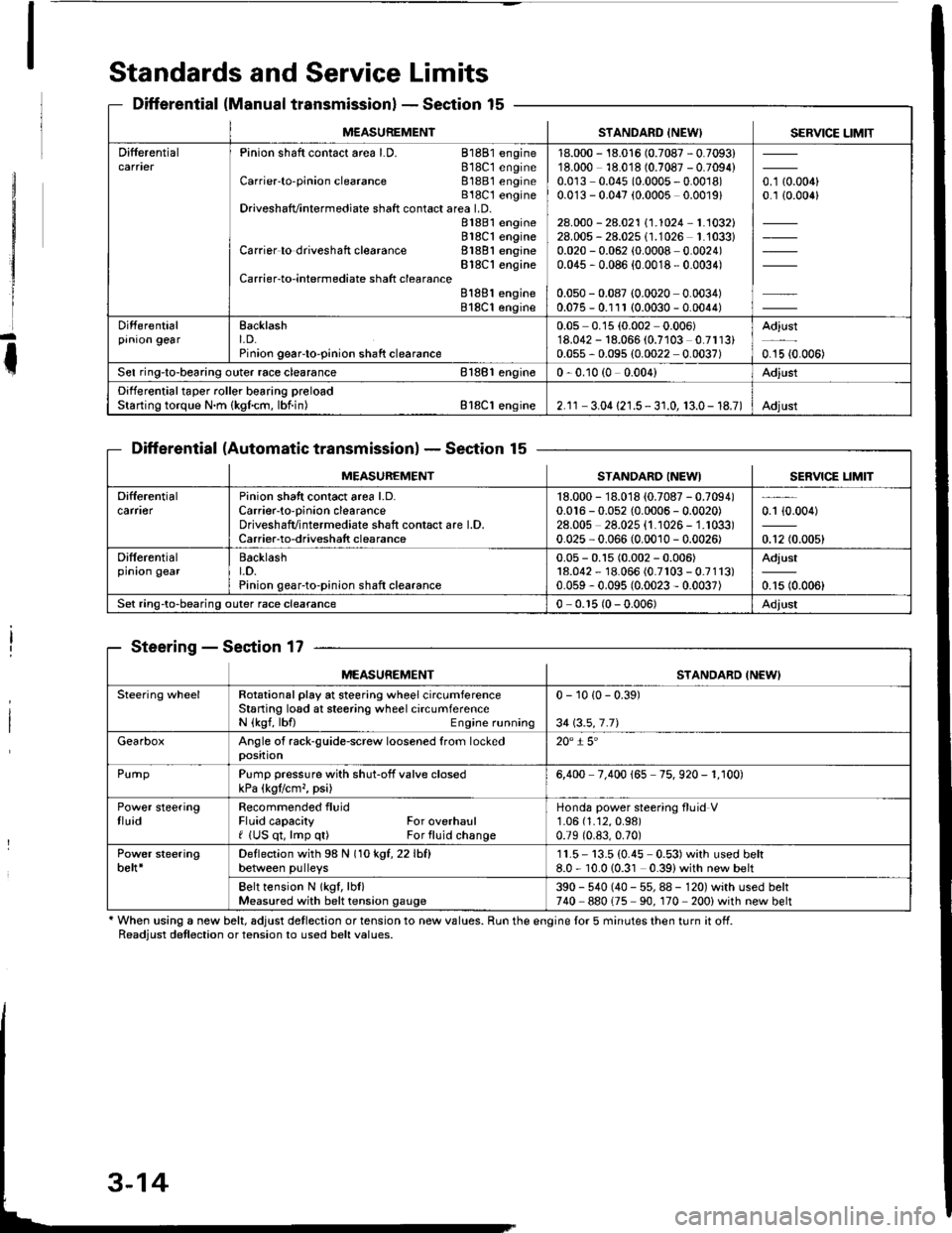

Standards and Service Limits

Differential (Manual transmissionlSection 15

Differential (Automatic transmissionlSection 15

Steering - Section 17

' When using a new belt, adjust detlection or tension to new values. Run the engine lor 5 minutes then turn it off.Readiust detlection or tension to used belt values.

M€ASUREMENTSTANDARD INEW) SERVICE LIMIT

DifferentialPinion shaft contact area LD. 81881 engine818C1 engineCarrier'to-pinion clearance 81881 engineB18C t engineDriveshafvintermediate shaft contact area LD.81881 engine818C1 engineCarrier to driveshaft clearance 81881 engineBlSC'l engineCarrier-to-intermediate shatt clearanceB188l engine818C1 engine

18.000 - 18.016 (0.7087 - 0.7093)18.000 18.018 (0.7087 - 0.7094)0.0r3 0.045 (0.0005 - 0.0018)0.0'13 - 0.047 (0.0005 0.0019)

28.000 - 28.021 \1.1024-1.1032128.005 - 28.025 (1.1026 1.'1033)0.020 - 0.062 (0.0008 0.0024)0.045 , 0.086 {0.0018 - 0.0034)

0.050 - 0.087 (0.0020 0.0034)0.075 - 0.111 (0.0030 - 0.0044)

o. t aron,0.1 {0.006}

Differentialprnron gearEacklasht. D.Pinion geaFto-pinion shaft clearance

0.05 0.15 (0.002 0.006)'18.042 - 18.066 (0.7103 0.7113)0.055 - 0.095 (0.0022 0.0037)

Adjust

0.15 {0.006)

Sel ring-to-bearing outer race clearance 81881 engin€0 - 0.10 (0 0.004)Adjust

Differential taper roller bearing preloadStarting torque N.m {kgfcm, lbf.in) Bl8Cl engine2.1r - 3.04 {21.5 - 3 r.0, 13.0- 18.7)Adjust

MEASUREMENTSTANDARO INEWISERVICE LIM]T

Difterentialcarfl€rPinion shatt contact area l.D.Carrier-to-oinion clearanceDriveshafvintermediate shaft contact are l.D.Carrier-to-driveshatt clearance

18.000 - 18.018 {0.7087 - 0.7094)0.016 - 0.052 {0.0006 - 0.0020)28.00s 28.025 {1.1026 - 1.1033)0.025 - 0.066 (0.0010 - 0.0026)

0.1 {0.004)

0.12 (0.005)

Differentialprnron gearBacklasht.D.Pinion gear-to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.042 - 18.066 (0.7r03 - 0.7113)0.059 - 0.095 (0.0023 - 0.0037)

Adjust

0.15 (0.006)

Set ring-to-bearing outer race clearance0 - 0.r5 (0 - 0.006)Adjust

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning losd at steering wheel circumferenceN {kgf, lbfl Engine running

0 - 10 {0 - 0.39)

34 \3.5,7.71

GearboxAngle of rack-guide-screw loosened from lockedposition20" i 5'

PurnpPump pressure with shut-off valve closedkPa (kgtlcm,, psi)6,400 7.400 165 75. 920 - 1. r00)

Power steeringtluidRecommended fluidFluid capacity For overhaulf (US qt, lmp q0 For fluid change

Honda power steering fluid V1.06 (1.12,0.98)

0.79 (0.83,0.70)

Power steeringbelt*Deflection with 98 N (1okgt,22lhfl

between pulleys11.5- 13.5 (0.45 0.53)with used belt8.0 - 10.010.31 0.39)with new belt

Belt tension N lkgf, lbl)Measured with belt tension gauge390 - 540 (40 - 55, 88 - 120) with used belt740 880175 90. 170 200) with new belt

Page 34 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual Design Specifications

]TEMMETRICENGLISHNOIES

: vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.38 HONDA INTEGRA 1994 4.G Workshop Manual Design Specifications

]TEMMETRICENGLISHNOIES

: vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.38](/img/13/6067/w960_6067-33.png)

Design Specifications

]TEMMETRICENGLISHNOIES

:' vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.380 mm

4.525 mm

'1,710 mm

1,335 mm

1,370 mm

2,570 mm

2,620 mm

't,475/1,470 mm

150 mm

Four (3 DOOR)

172.1in

178.1 in

67.3 in

52.6 in

101.2 in

103.1 in

5|8.1/57.9 in

Five (4 DOOR)

,rerght (usA)cross V€hicle Weight Rating {GVWR)3,680lbs

'le,ght {CANADA)Gross Vehicls Weight Rating {GVWR)1,670 kg

:\GINEType81881 engine

818C1 engine

Cylinder Arrangement

Bore and Stroke

Displacement

Compression Ratio

81881

818C1

81881

B18C I

81881

B 18C1

81881

818C1

engrne

engane

engrne

engine

engine

engine

engine

engine

L!brication Systom

OilPump Displacement

Wster Pump Displacement

FuelRequired

81881

B18C 1

81881

B 18C1

91881

engrne

engrne

engine

engine

engine

818C1 engine

Water-cooled, 4-stroke DOHC

gasoline engine

Watercooled, 4-stroke DOHC

VTEC gasoline engine

Inline 4-cylinder, transverse

81.0 x 89.0 mm

81.0 x 87.2 mm

1,834 cm3 (mf )

1,797 cm3 (m{)

3.19 x 3.50 in

3.19 x 3.43 in

112 cu-in

110 cu-in

9.2:1

10.0 : 1

Eelt driven, OOHC 4 valve per cylinder

Belt driven, DOHC VTEC

4 valve per cylinder

Forced and wet sump, trochoid pump

50, {53 US qt, 44 lmp qt)/minute'l

71 f {75 US qt, 62 lmp qt)/minute"

140 f (148 US qt, 123 lmp qt)/minute*!

140 f (148 US qt. 123 lmp qt)/minute*'

UNLEADED gasoline with 86 Pump

Octane Numb€r or higher

Premium UNLEADED gasoline wilh

91 Pump Octane Number or higher

STARTERTypo

NormalOutput

NominalVoltage

Hour Rating

Direction of Rotation

Weight

Gear reduction

1.4 kW

12V

30 seconds

Clockwise as viewed lrom g6ar end

3.7 k9 | 8.3lbs

CLUTCHClutch Type

Clutch Facing Area

M/TSingle plate dry, diaphragm spring

Torq!e converter

203 cm'� I 31 sq-in

TRANSMISSIONTransmission Type M/T

Primary Reduction

Synchronized 5-speed forward, 1 reverse

Electronically controlled

4-speed automatic. 1 rcverse

Diract 1 : 1

'1: At 6,000 engine

'2: At 7,600 engine

rpm

rpm

(cont'd)

3-17

Page 48 of 1413

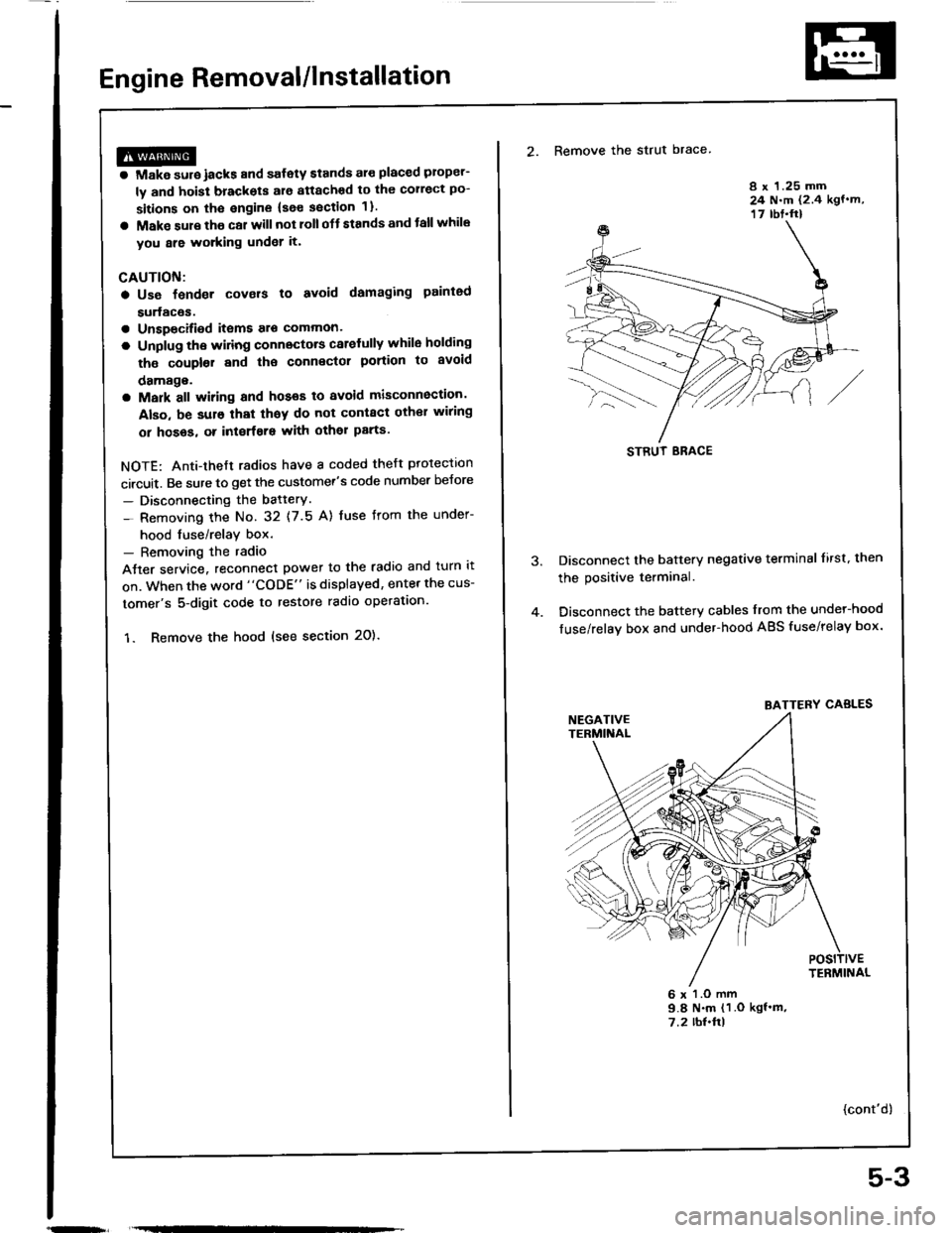

Engine Removal/lnstallation

@a Make sure jacks and safety stands aro placed ploper-

ly and hoisl brackots arg attachod to the correct po-

sitions on tho engine (se€ ssction 1).

a Mak€ sure tho car willnot roll off stands and tallwhile

you are wotking under it'

CAUTION:

a Use fendet covals to avoid damaging painted

sudaces.

r Unspecified itsms alo common

a Unplug tho widng connectots carefully while holding

the couplor and tha connector portion to avoid

oamage.

a Mark all wiring and hoses to avoid misconnection.

Also, be sulo that thsy do not contact other wiring

or hoses, or interfere with oth€l parts.

NOTE: Anti-theft radios have a coded theft ptotection

circuit. Be sure to get the customer's code number beJore

- Disconnecting the batterY.

- Removing the No. 32 (7.5 A) fuse from the under-

hood tuse/relay box.- Removing the radio

Atter service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operataon.

1. Remove the hood (see section 2O).

2. Remove the strut brace

8 x 1.25 mm24 N.m (2.4 kgf.m,17 rbt.ft)

Disconnect the battery negative terminal lirst. then

the positive terminal.

Disconnect the battery cables from the undel-hood

fuse/relay box and under-hood ABS fuse/relay box.

6 x l.O mm9.8 N.m (1 .O kgf'm,7.2 rbl.ftl

{cont'd)

STRUT ERACE

BATTERY CABLES

5-3

Page 54 of 1413

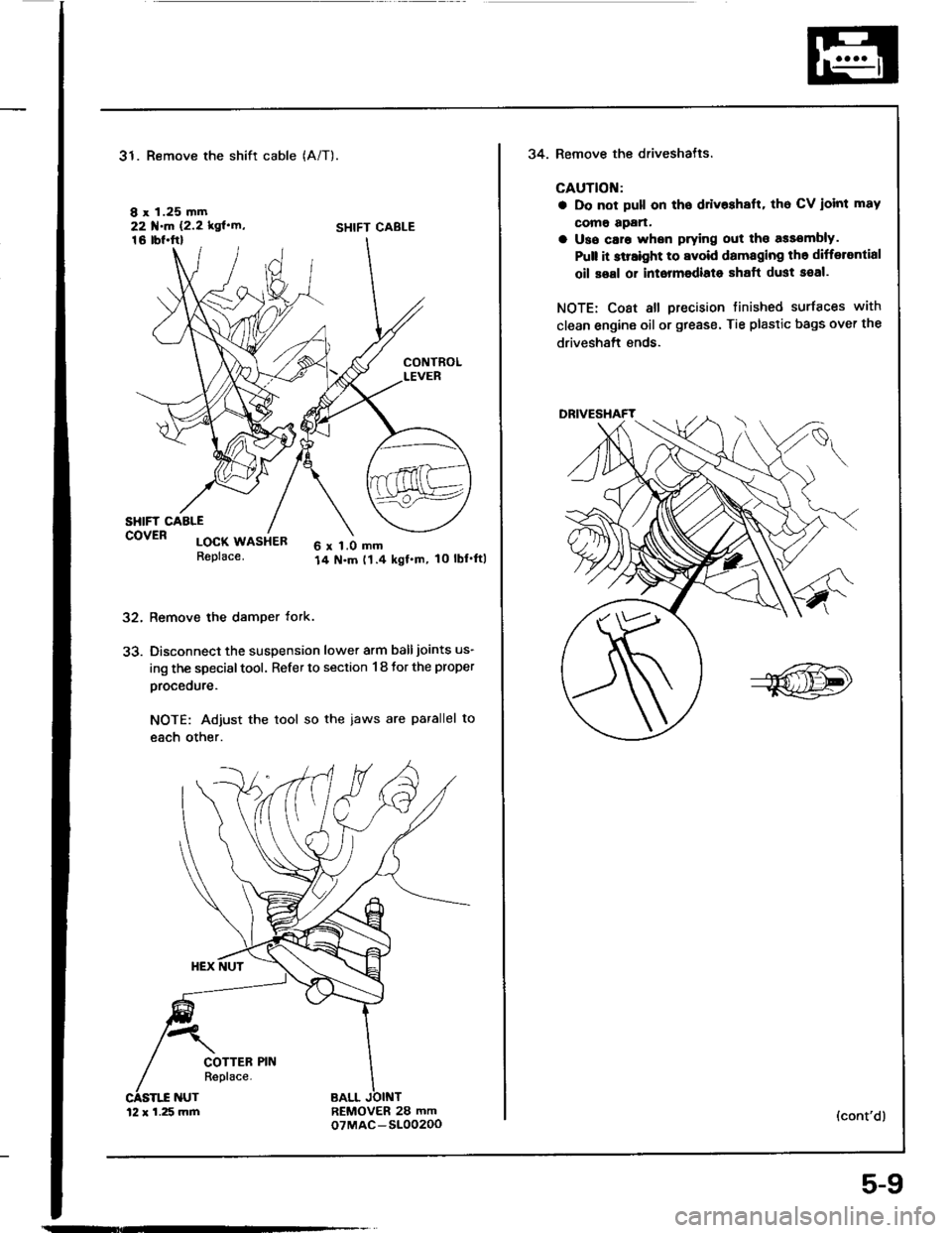

31. Remove the shift cable

I x 1.25 mm22 f.m 12.2 kgl'rn'16 tbl.ftl

(A/T).

SHIFT CABLE

32.

33.

CONTROLLEVER

SHIFT CAALEcovER locx usiea6 x 1.0 mm14 N.m t1.4 kgf.m, 10 lbl'ftlReplace.

Remove the damper tork.

Disconnect the suspension lower arm balljoints us-

ing the special tool. Refer to section 1 8 tor the proper

procedure.

NOTE: Adjust the tool so the iaws are parallel to

each other.

REMOVER 28 mmoTMAC-S10020012 x 1.25 mm

5-9

34. Remove the driveshatls.

CAUTION:

a Do not pull on tho ddv$halt, tho CV ioint mav

como apan.

a Uso caro whsn prying out tho assombly.

Pult it slraight to avoid damaging th6 differantial

oil soal or intormodiato shaft dust seal.

NOTE: Coat all precision tinished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends.

(cont'd)

Page 217 of 1413

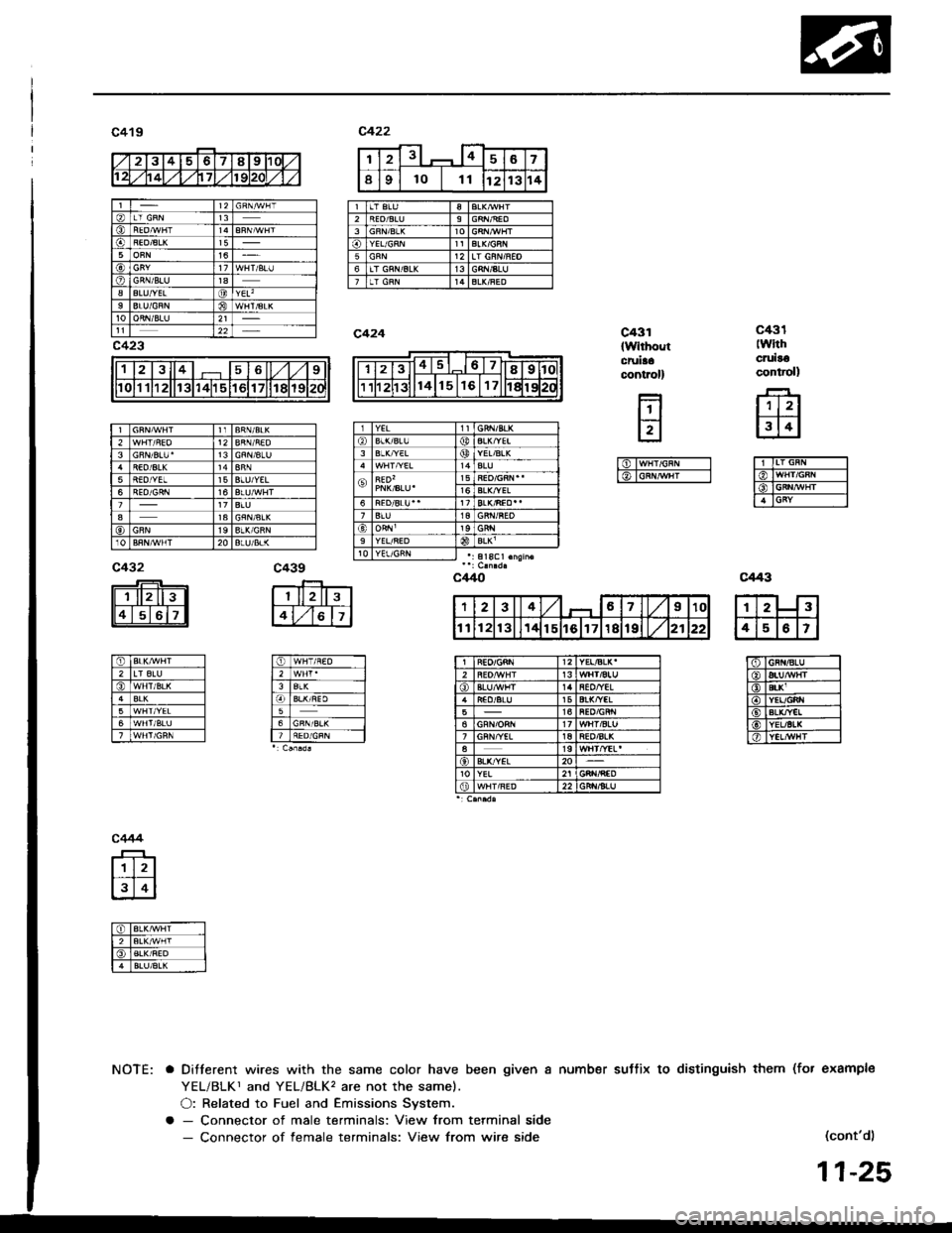

c4't9

234578e nc

5t6 | -

aALUfYELYEL'

c423

c431lwlthcruit€coniroll

| 'lrl

lslnl

fitr G-Fil------lo ln/Hr/68n Ilo lciN,r/vHr Il-IcRY------l

c44il

riTLF-Iffi14l51617l

lO lGRt/8LU ITitfgruffir-----lktlBrKr--I o lYcL/Gnir Ilao laLx./YEL II "] IYEUBL( Iktlterwirr ---

c431(wlthout

crui!acontrol)

-tttI

t3

l6'TwHr/cnN ----'l

1ol cRN^vHr ----l

c439

rfltrrn

I'VCT,1

lETWrr;eo---ffrlwHr. --

l3l8rK II t lBLx,REo It5 |I 6 GRN/BLX If?-TFEpcFN --

c432

ffi

c444

ffir

trtr]

I6TLK^//Hr -l

L ' l!!g!!r llo lsLkrFED I|;TBLU'BLi l]l

NOTE: a Ditterent wires with the same color have been given a number suttix to distinguish them (fot example

YEL/BLKr and YEL/BLK, are not the samel.

O: Related to Fuel and Emissions System.

a - Connector of male terminals: View from terminal side- Connector of female terminals: View from wire side(cont'd)

11-25

12313

5BLU/YEL6

a1a

20

YEL/BLK'2Ht/aluiEO/YIL15516't7

aBL&"/EL20YEL

Page 233 of 1413

3. Fuel Cut-oft Control

a During deceleration with the throttle valve closed, current to the {uel injectors is cut otJ to improve fuel economy

at speeds over tollowing rpm:

. 8188l engine: 91O tpm (Canada model: 1,O50 rpm)

. 818C1 engine: 95O tpm (Canada model: l,O5O rpm)

a Fuel cut-olf action also takes place when engine speed exceeds, 7,O0O rpm {81 8B1 engine), 8,1O0 rpm (B 18Cl

engine), regardless oI the position of the throttle valve, to protect the engine from ovet-revving.

A/C Compressor Clutch Relay

When the ECM receives a domand for cooling trom the air conditioning system, it del8ys the compressor from being

enetgized, and enriches the mixture to assure smooth transition to the A/C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant tempersture is below 163oF {73"C), the ECM supplies a ground to the EVAP pu.ge control

solenoid valve which cuts vacuum to the EVAP purge control diaphragm valve.

Intake Air Bypsss (lAB) Control Sol€noid Valve

When the engine rpm is below 5,750 rpm, the IAB control solenoid valve is activated by a signal from the ECM,

intske air flows through the long intake path, then high torque is delivered. At spaeds highe. than 5,750 rpm, the

solenoid valve is deactivated by the ECM, and intake air flows through the short intake path in order to reduce the

resistance in airflow.

ECM fail-safe/bEck-up Functions

1. Fail-sate Function

When an abnormality occurs in a signal from a sensor, the ECM ignores that signal and assumes a pre-progtammed

value tor that sensor that allows the engine to continue to run.

Back-uD Function

When an abnormalitv occurs in the ECM itself, the fuel iniectors are controlled by a back-up citcuit independent of

the system in order to permit minimal driving.

Self-diagnosis Function IMaltunction Indicator Lamp {MlL)1

Wh6n an abnormality occurs in a signal from a sensor, the ECM supplies ground for the MIL and stores the code

in erasable memory. When the ignition is initially turned on, the ECM supplies ground tor the MIL tor two seconds

to check the MIL bulb condition.

Two Trio Detection Method

To prevent tals€ indications, th€ Two Trip Dstection Method is used for the HO2S and fuel metering-related self-

diagnostic tunctions. When an abnormslity occurs, the ECM stores it in its memo.y. Wh€n the ssme sbnormality

recurs alter the ignition switch is turned OFF and ON ag8in, the ECM informs the driver by lighting the MlL.

However, to ease troubleshooting, this function is canc€ll€d when you short the service check connector. The MIL

will then blink immedistelv when an abnormality occurs.

4.

6.

2

4.

11-41

Page 268 of 1413

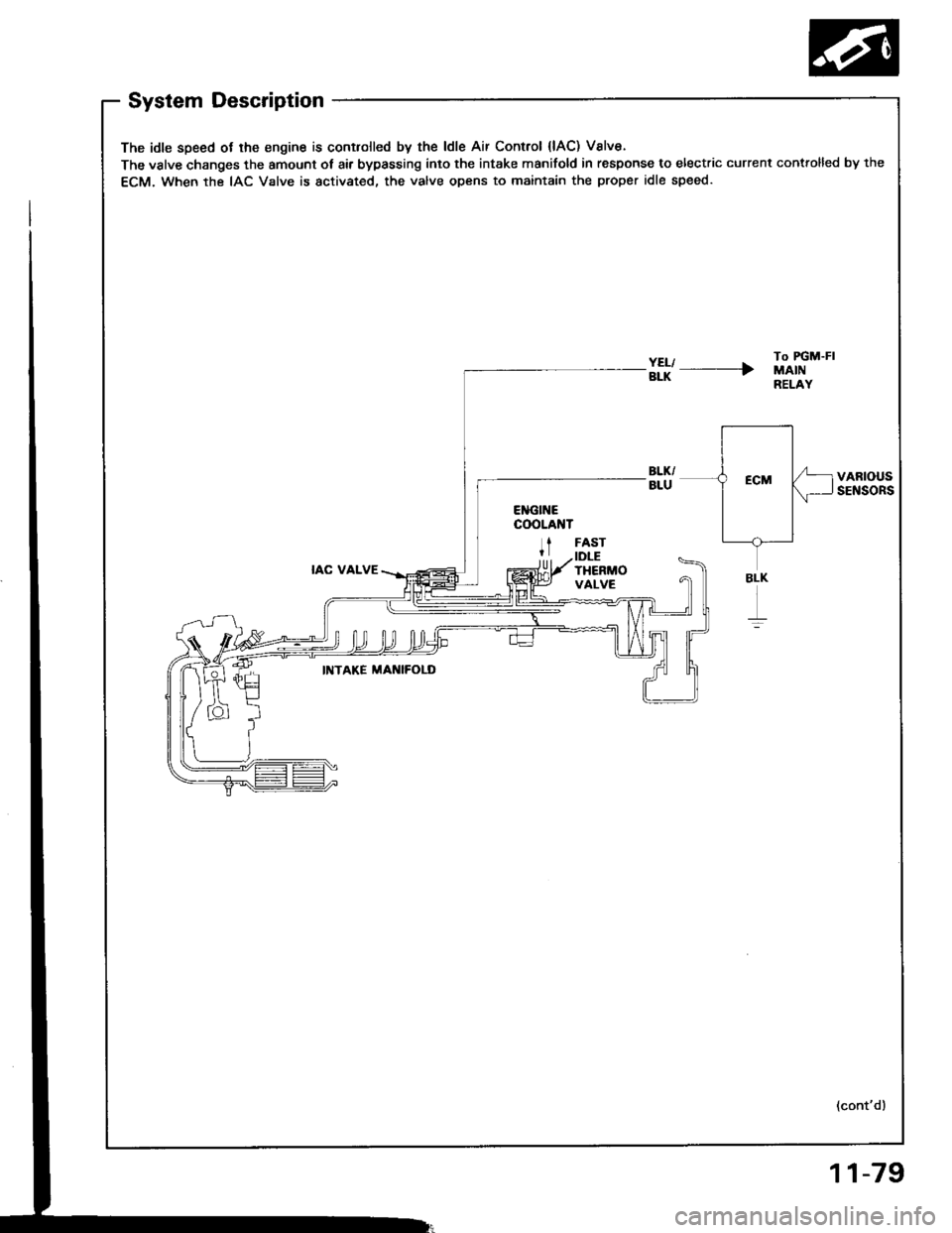

System Description

The idle speed ot lhe engine is controlled by the ldle Air Control {lAC) Valve.

The valve changes the amount ot air bypassing into the intake manifold in response to electric current controlled by the

ECM. When the IAC Valve is activated, the valve opens to maintain the proper idle speed.

#l' ----rTo FGM-FIMAINRELAY

VARIOUSSENSORS

IAC VALVE

FASTIDLETHERMOVALVE

INTAKE MAI{IFOLD

(cont'd)

BLK

r

11-79

Page 269 of 1413

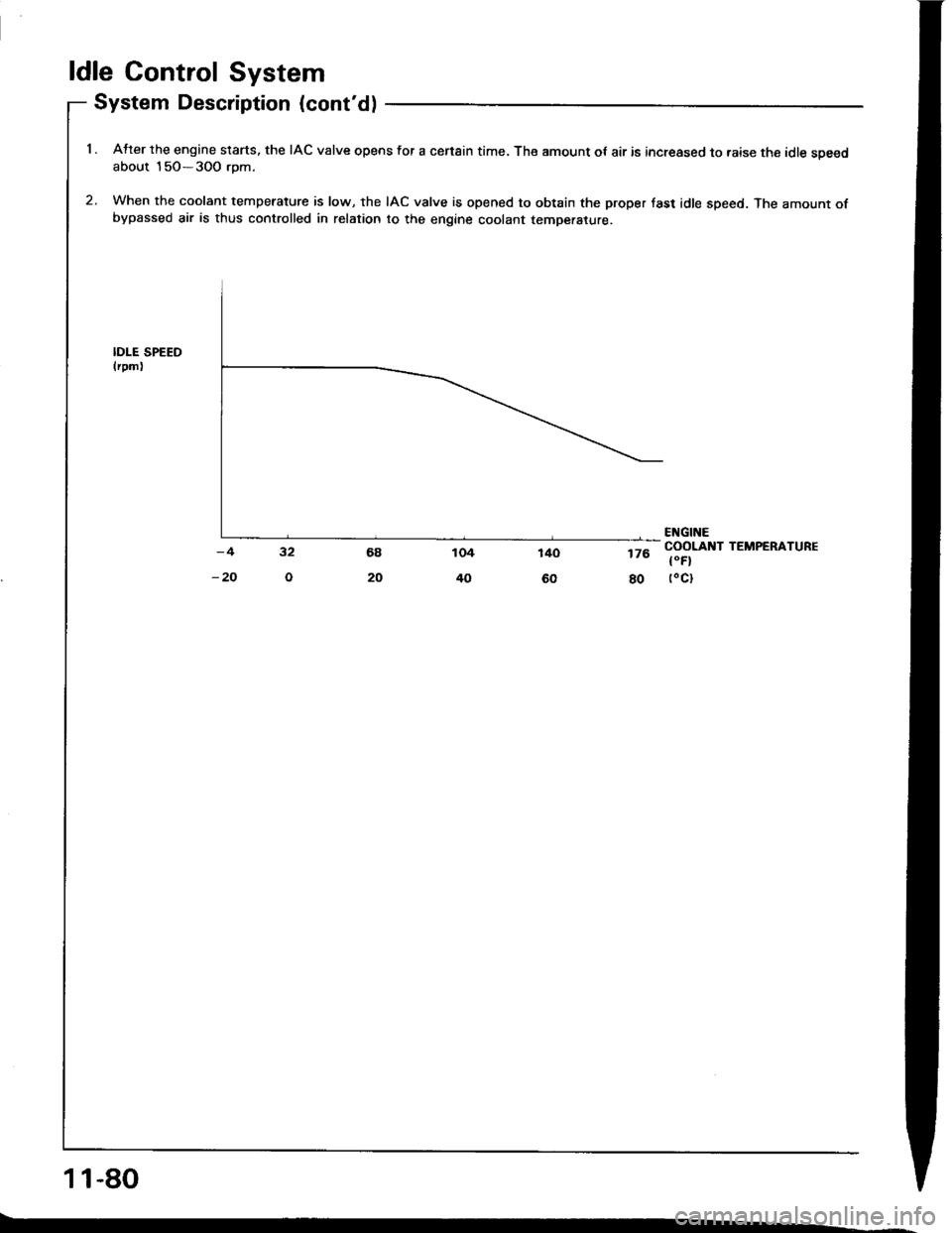

ldle Control System

System Description (cont'd)

1 . Atter the engine slarts. the IAC valve opens for a censin time, The amount ot air is increased to raise the idle soeedabout 15O-3OO rom.

2. When the coolant temperature is low, the IAC valve is opened to obtain the proper fast idle speed. The amount ofbypassed air is thus controlled in relation to the engine coolant temperature.

IDI-E SPEEDlrpm)

176

80

ENGINECOOLANT TEMPERATURE

t"Fl(oct

11-80

Page 283 of 1413

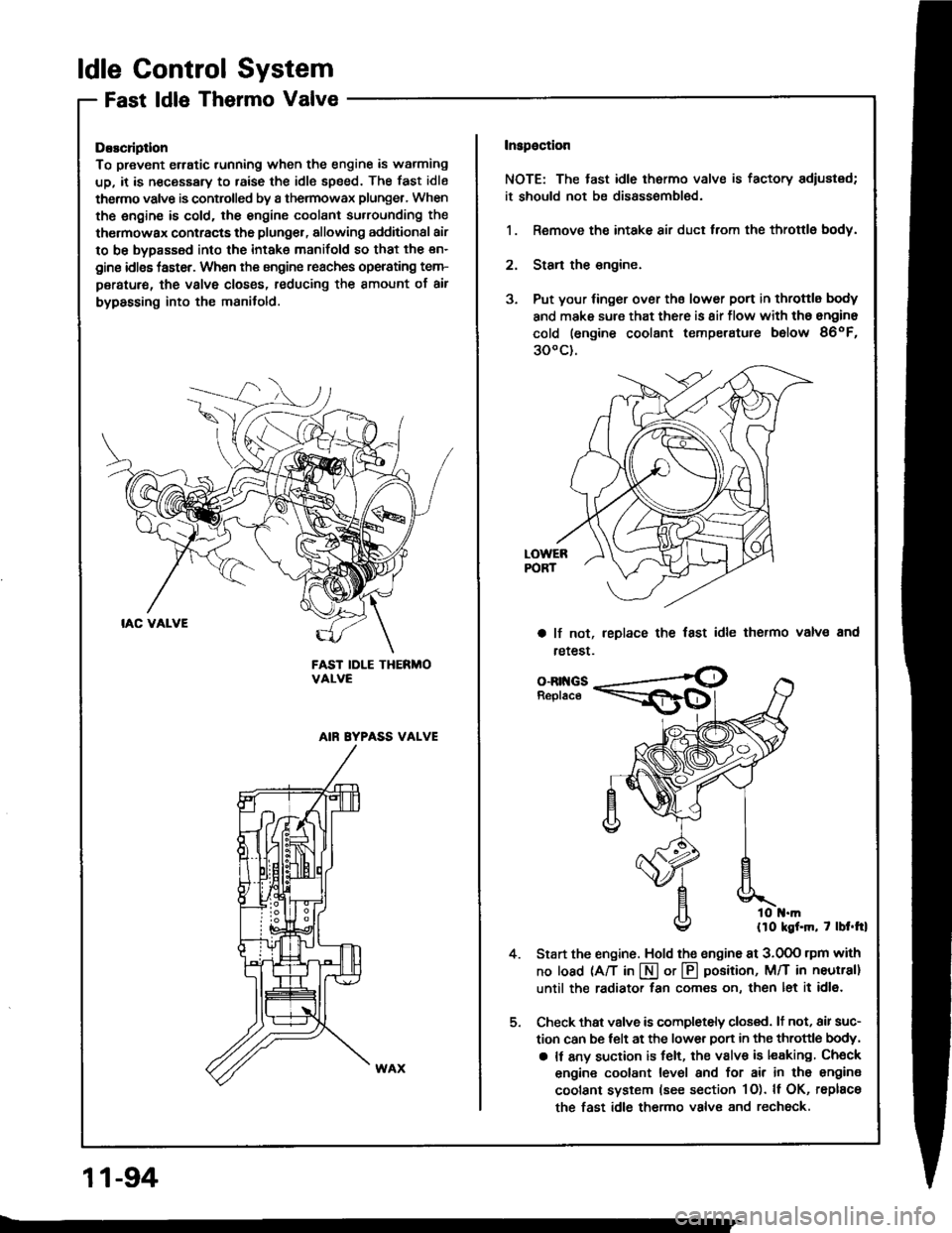

ldle Control System

Fast ldle Thermo Valve

DEscliptlon

To prevent erratic running when the engine is warming

up, it is n€cessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger, When

the engine is cold. the engine coolant su.rounding the

thermowax contracts the plunger, allowing additional air

to be bypassed into the intake manifold so that the en-

gine idlss taster. When the engine reaches operating tem-

peratur€, the valve closss, reducing the amount of air

bypassing into the manifold.

FAST IDLE THERMOVALVE

AIN EYPASS VALVE

Inspaction

NOTE: The tast idle thermo valve is factory adiustsd;

it should not be disassombl€d.

1. Remove the intake air duct from the throttlg body.

2. Stan the engine.

3. Put your finger over ths lower port in throttle body

and make sure that there is 8ir flow with tho engine

cold (engine coolant temperatute below 86oF,

300c).

a lf not,

retest.

leplace the fast idle thermo valvs and

4.

o-Rr{GsReplace

llo kgf.m, 7 lbt.trl

Start the engine. Hold the sngine at 3.0OO rpm with

no load (A/T in I or @ position, M/T in neutral]

until the radiator fan comes on, then let it idl6.

Check thst valve is completely closed. lt not, air suc-

tion can be telt at the lower Don in the throttle body,

a It any suction is felt, the valve is leaking Check

engine coolant level and for air in tho engine

coolant system (see section 1O). ll OK, rsplace

the fast idle thermo valve and rechock.

11-94

Page 324 of 1413

A.

Evaporative Emission (EVAPI Controls

Da.cdptlon

Thg avaporstive omission controls are designed to minimize the smount of fusl vapor escaping to the atmosphero. The

system conaists ot the following compon€nts:

Evlporttly. Emlttbn (EVAPI Control Caniltot

An EVAP control canistor is used lor the temporary storage ot fuel vapor until the fuel vapor can be purged lrom

th€ EVAP control canister into the engin€ and burned.

vlpor hr]gG Cmt]ol Syst m

€VAp control canistgr puroing is accomplished by drawing fresh air through tho EVAP control canister and into a

pon on th6 throttl€ body. Th€ purging vacuum is controllsd by the EVAP purge control diaphragm valve end the

EVAP purge control solenoid valve.

C. Ft|.l Tmk Vlpor Control Systom

When fuel vapor prassure in the fuel tank is higher than the set v8lue of the EVAP two way v8lv6, th€ valve opens

and regulates the flow ol fuel vapor to the EVAP control canister.

(cont'd)

11-135