service HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1139 of 1681

Staning System

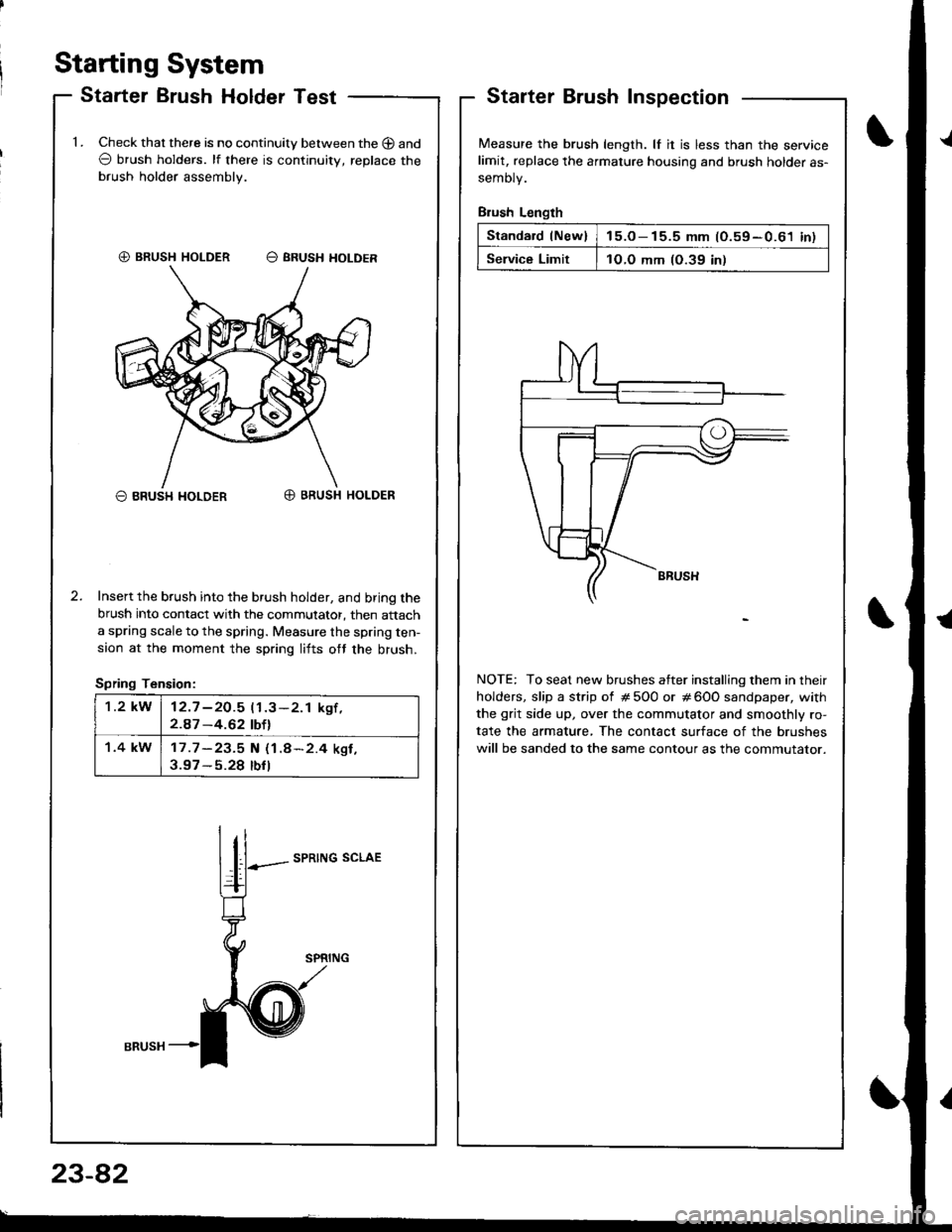

Starter Brush Holder TestStarterInspection

Measure the brush length. lf it is less than the servicelimit, replace the armature housing and brush holder as-

semoty.

Brush Length

Standard lNew)15.o- 15.5 mm (O.59-0.61 inl

Service Limit1O.O mm (O.39 in)

NOTE: To seat new brushes atter installing them in their

holders, slip a strip of # 5O0 or # 600 sandpaper, with

the grit side up, over the commutator and smoothly ro-

tate the armature, The contact surface of the brushes

will be sanded to the same contour as the commutator.

1.Check that there is no continuity between the O and

O brush holders. lf there is continuitv, replace the

brush holder assembly.

O BRUSH I{OLDERO BRUSH HOLDER

Insert the brush into the brush holder, and bring the

brush into contact with the commutator, then attach

a spring scale to the spring. Measure the spring ten-

saon at the moment the spring lifts ott the brush.

Spring Tension:

SPRING SCLAE

€) BRUSH HOLDER O SRUSH HOLDER

1.2 kW12.7 -2O.5 11.3-2.1 kgf ,2.A7 -4.62 tbtl

1.4 kW17 .7 -23.5 N (1.8*2.4 ksf ,3.97 - 5.28 tbfl

I

23-82

Page 1140 of 1681

J

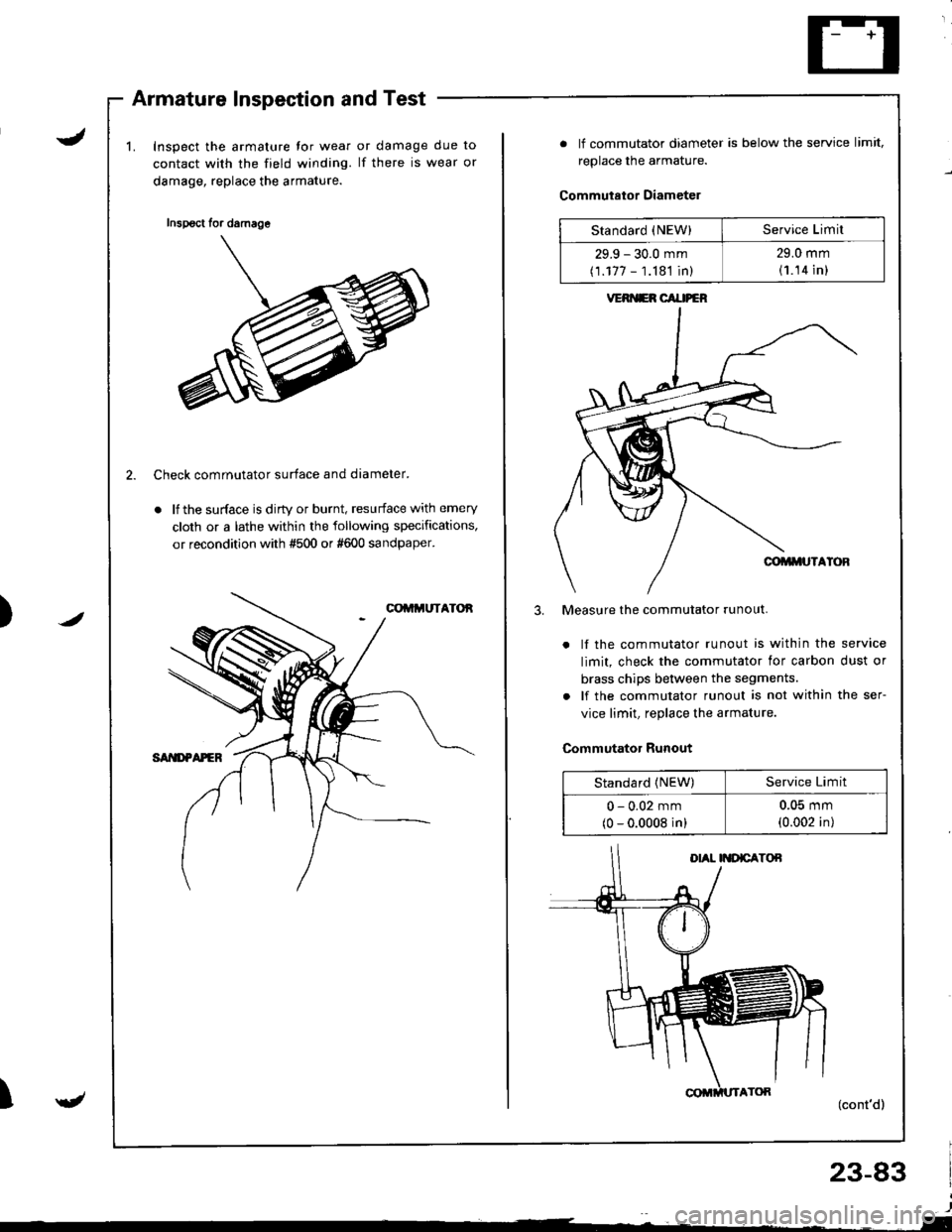

Armature Inspection and Test

Inspect the armature tor wear

contact with the field winding.

damage, replace the armature.

or damage due to

lf there is wear or

/)

2. Check comrnutator surface and diameter.

. lf the surface is dirty or burnt, resurface with emery

cloth or a lathe within the following specifications,

or recondition with #500 or #600 sandpaper.

gt

Inspsct for damage

. lf commutator diameter is below the service limit,

replace the armature.

Commutator Diameter

Measure the commutator runout.

. lf the commutator runout is within the service

limit, check the commutator lor carbon dust or

brass chips between the segments.

. lf the commutator runout is not within the ser-

vice limit, replace the armature.

Commutator Runout

(cont'd)

23-83

Standard (NEW)Service Limil

29.9 - 30.0 mm

(1.177 - 1.181 in)

29.0 mm

(1.14 in l

VERI{ER CAI|PEN

Standard (NEW)Service Limit

0 - 0.02 mm

(0 - 0.0008 in)

u-(J5 mm

(0.002 in)

Page 1141 of 1681

Starting System

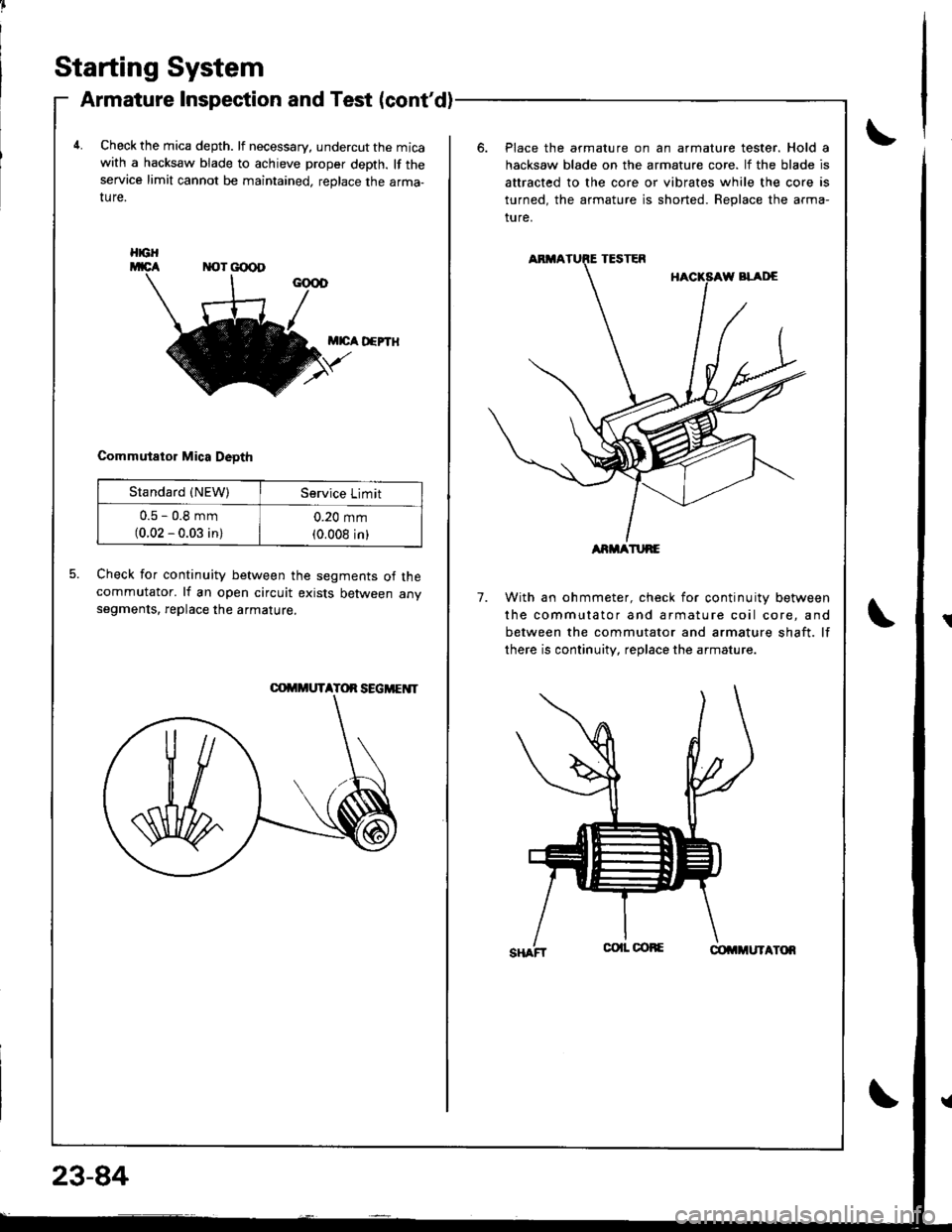

Armature Inspection and Test (cont'd)

4.Check the mica depth. lf necessary, undercut the micawith a hacksaw blade to achieve proper depth. lf theservice limit cannot be maintained, replace the arma-ture.

Place the armature on an armature tester. Hold a

hacksaw blade on the armature core. lf the blade is

attracted to the core or vibrates while the core is

turned, the armature is shorted. Beplace the arma-

ture.

M|cA D€PTH

Commutator Mica Deoth

5.Check for continuity between the segments of thecommutator. lf an open circuit exists between anvsegments, replace the armature.7.With an ohmmeter, check for continuity between

the commutator and armature coil core, and

between the commutator and armature shaft. lf

there is continuity, replace the armature.

HGH

Standard {NEW)Service Limit

u.5 - u,6 mm(0.02 - 0.03 in)

0.20 mm(0.008 inlARMATURE

Page 1145 of 1681

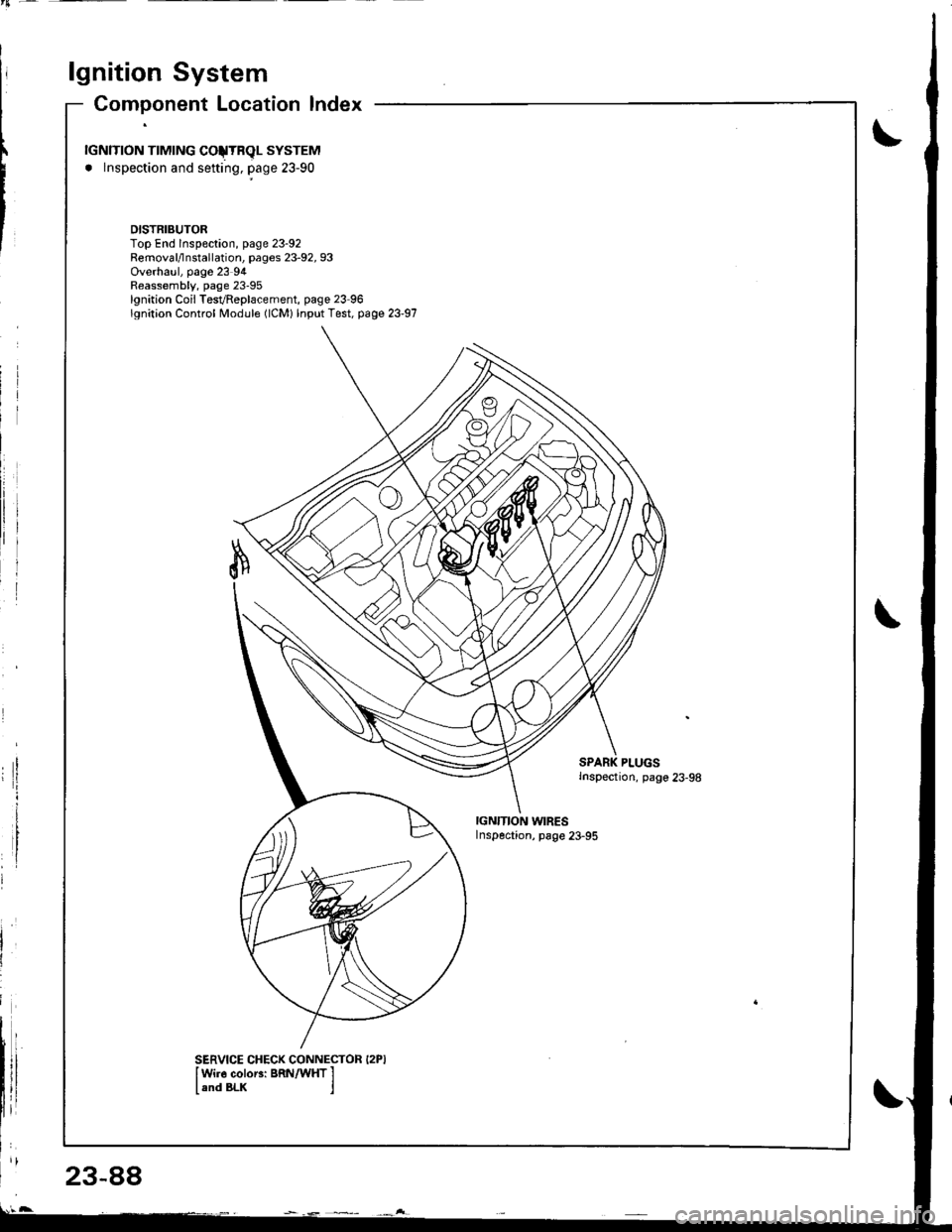

lgnition System

23-88

Component Location lndex

rGNlTroN TTMTNG COJTRqL SYSTEM

. lnspection and sefting, page 23-90

DISTRIBUTORTop End lnspeclion, page 23-92Removal/lnstallation, pages 23-92, 93Overhaul, page 23 94Reassembly, page 23-95lgnition Coil TesvReplacement, page 23 96lgnition Control Module (lCM) lnput Test, page 23-97

PLUGSInspection, pago 23-98

IGN'TION WIRESInspection, page 23-95

SERVICE CHECK CONNECTOR I2PIIWi]6 coloEi BRN/WHT I

land BLK j

Page 1164 of 1681

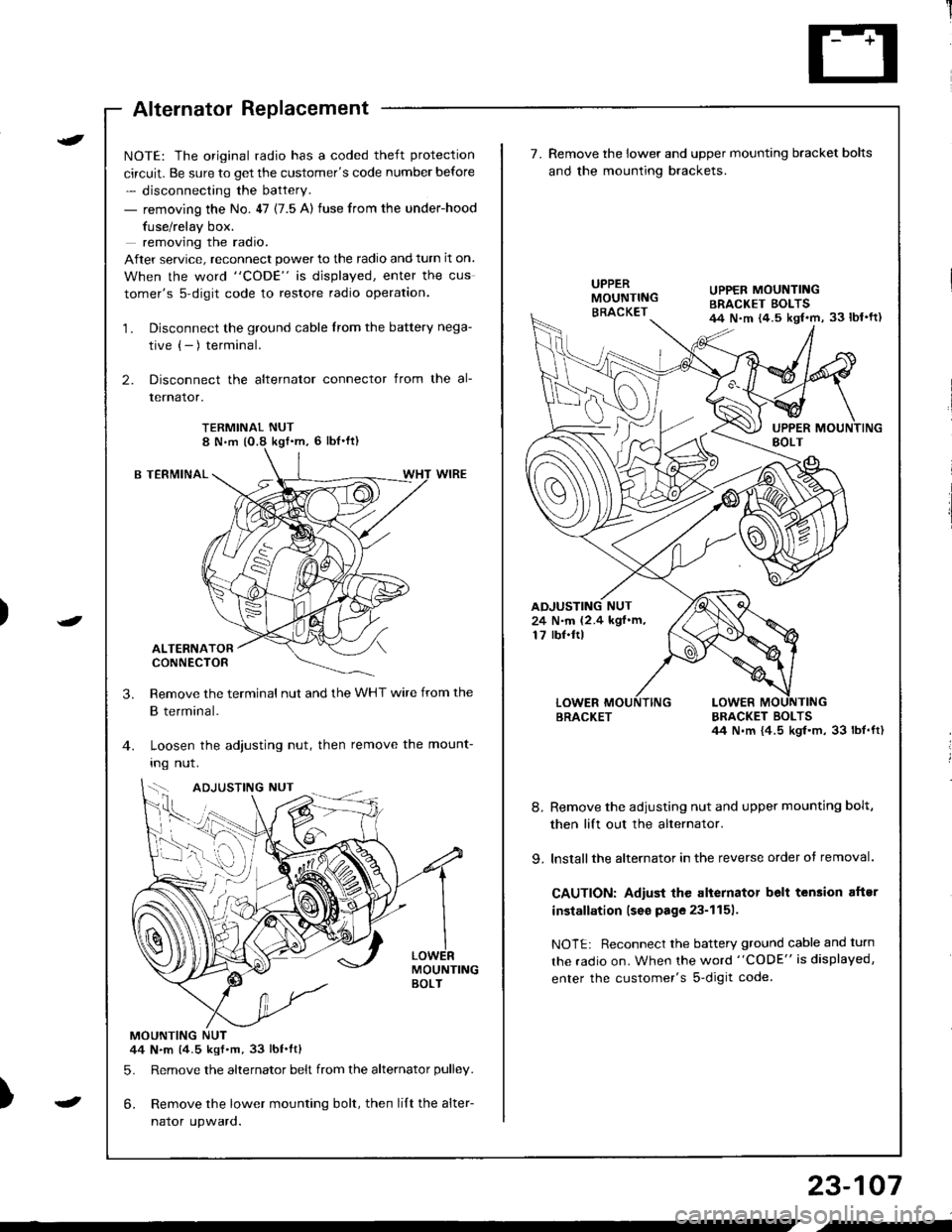

Alternator Replacement

)

t

-

NOTE: The original radio has a coded theft protection

circuit. Be sure to get the customer's code number before

- disconnecting the battery.

- removing the No. 47 (7.5 A) fuse from the under-hood

fuse/relay box.

removing the radio.

After service, reconnect power to the radio and turn it on.

When the word "CODE" is displayed, enter the cus

tomer's s-digit code to restore radio operation.

1. Disconnect the ground cable from the battery nega-

tive (- ) terminal.

2. Disconnect the alternator connector from the al-

lernalor,

TERMINAL NUT8 N,m (O.8 kgf'm, 6 lbl'ft)

B TERMINAL

ALTERNATORCONNECTOR

Remove the terminal nut and the WHT wire from the

B terminal.

Loosen the adjusting nut, then remove the mount-

Ing nut.

MOUNTINGBOLT

MOUNTING NUT44 N.m (4.5 kgf.m.33 lbt.ftl

5. Remove the alternator belt from the alternator pulley.

6. Remove the lower mounting bolt, then lilt the alter-

naror upwaro.

3.

{--,

7.Remove the lower and upper mounting bracket bolts

and the mounting brackets.

BRACKET BOLTSil4 N.m {4.5 kgl.m, 33 lbt.ft)

8. Remove the adiusting nut and upper mounting bolt,

then lift out the alternator.

9. lnstallthe alternator in the reverse order of removal.

CAUTION: Adiust the alternator belt tension aftsr

installation lseo page 23-1151.

NOTE: Reconnect the battery ground cable and turn

the radio on. When the word "CODE" is displayed,

enter the customer's s-digit code.

BRACKET

UPPER MOUNTINGBRACKET EOLTS44 N.m {4.5 kgl.m, 33 lbl'ft)

24 N.m (2.4 kgf.m,17 rbf.ftl

b-h..K

) I

23-107

-

,-

Page 1166 of 1681

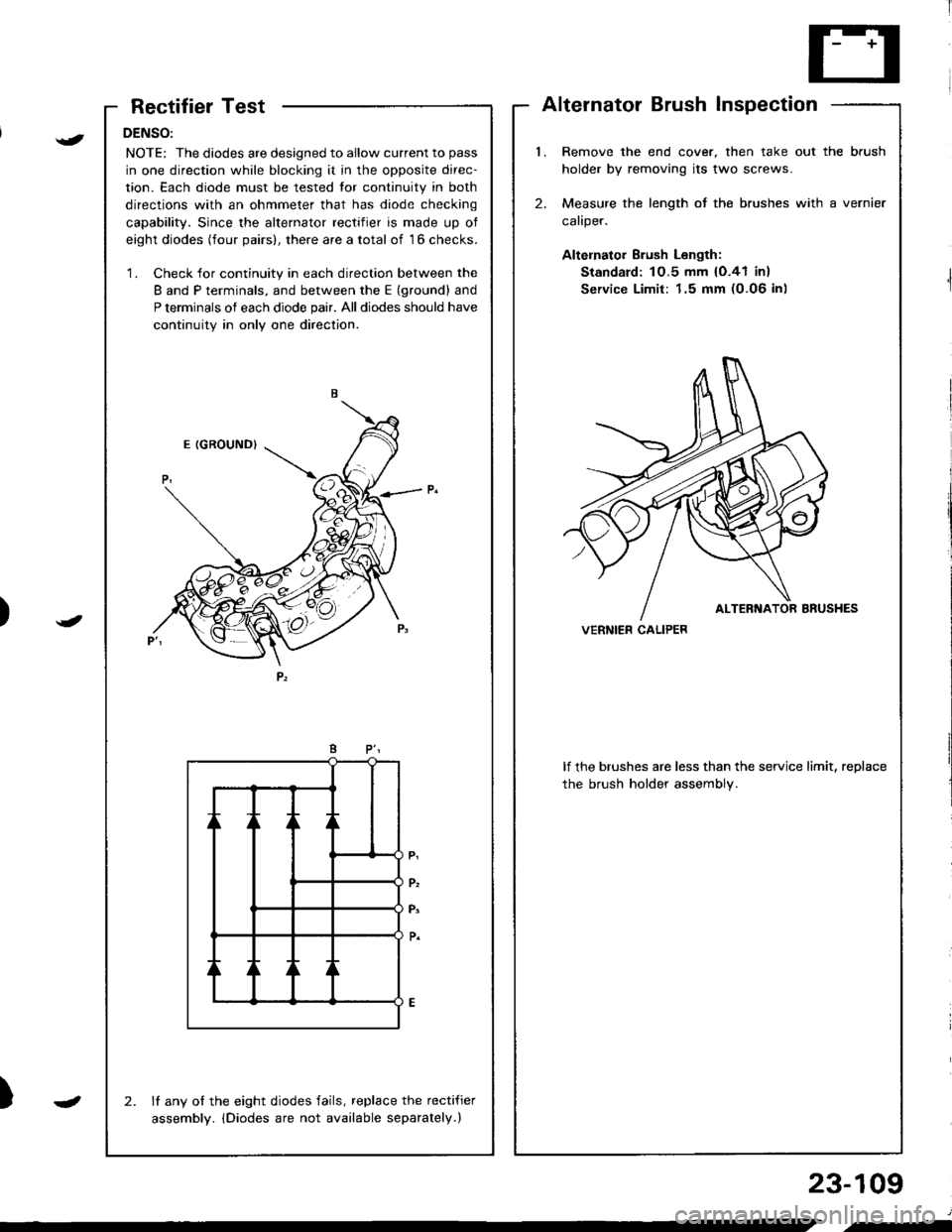

RectifierTest

DENSO:

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc-

tion. Each diode must be tested tor continuity in both

directions with an ohmmeter that has diode checking

capability. Since the alternator rectifier is made up ot

eight diodes (four pairs), there are a total of 16 checks.

'1. Check for continuity in each direction between the

B and P terminals, and between the E (ground) and

P terminals of each diode pair. All diodes should have

continuity in only one direction.

lf any of the eight diodes fails, replace the recti{ier

assembly. iDiodes are not available separately.)

2.

AlternatorBrushInspection

l.Remove the end cover, then take out the brush

holder by removing its two screws.

Measure the length of the brushes with a vernier

caliper.

Altelnator Brush Length:

Standard: 1O.5 mm {O.41 in}

Service Limit: 1.5 mm (0.06 in)

2.

lf the brushes are less than the service limit, replace

the brush holder assembly.

VERNIER CALIPER)

{

J

)

23-109

J

.-

Page 1170 of 1681

i'[

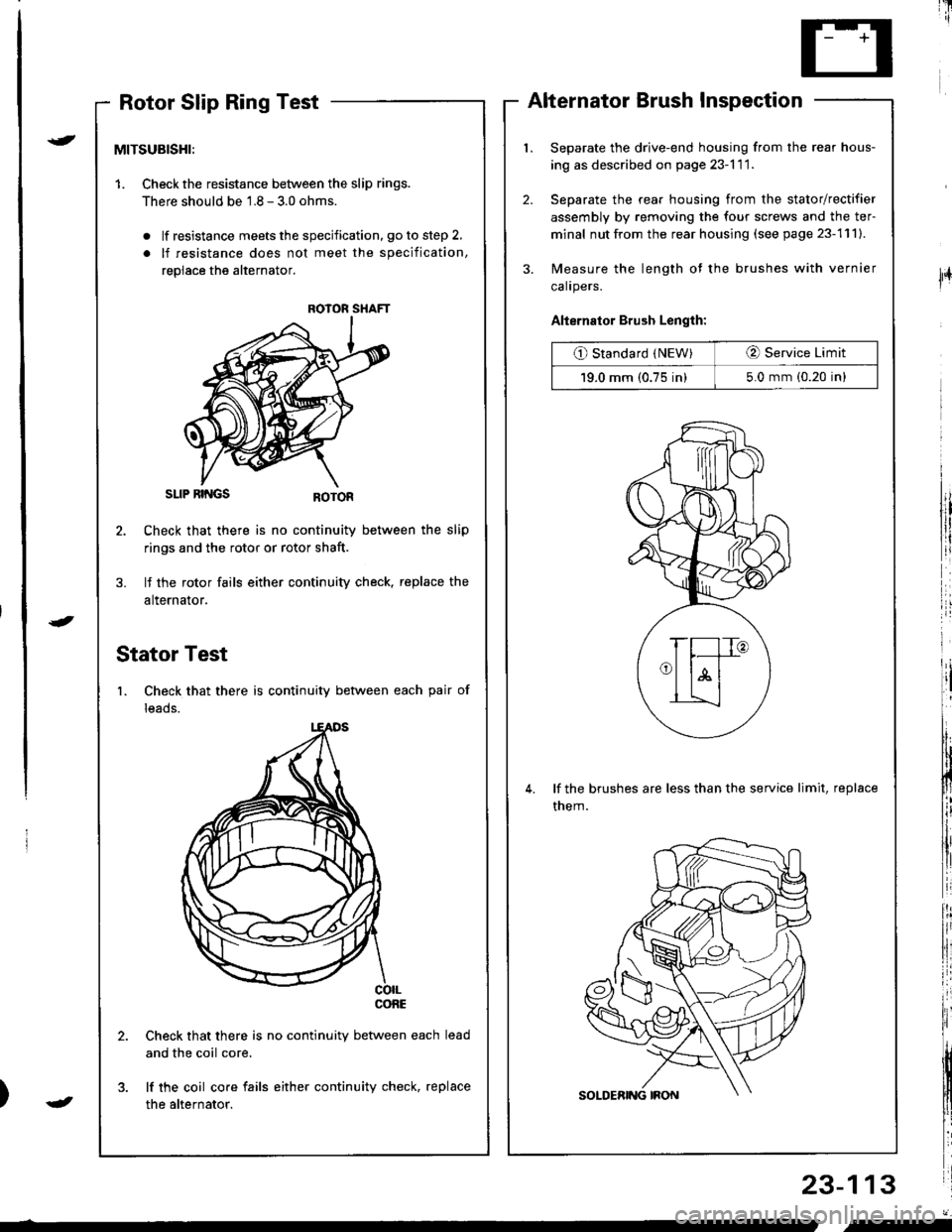

Rotor Slip Ring TestAlternator Brush Inspection

Separate the drive-end housing from the rear hous-

ing as described on page 23-l 1 1.

Separate the rear housing from the stator/rectifier

assembly by removing the four screws and the ter-

minal nut from the rear housing (see page 23-111).

Measure the length of the brushes with vernier

calrpers.

Alternator Brush Length:

O Standard (NEW)O Service Limit

19.0 mm (0.75 in)5.0 mm (0.20 in)

lf the brushes are less than the service limit, replace

them.

23-113

{

J

lFr

MITSUBISHI:

1. Checkthe resistance between the slip rings.

There should be 1.8 - 3.0 ohms.

. lf resistance meets the specification, go to step 2,

. lf resistance does not meet the specification,

replace the alternator.

SLIP RII{GS

Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

lf the rotor fails either continuity check, replace the

alternator.

Stator Test

1. Check that there is continuity between each pair of

leads.

co|LconE

Check that there is no continuity between each

and the coil core.

lf the coil core fails either continuity check, replace

the alternator.

ROIOR SHAFT

J

"-

Page 1203 of 1681

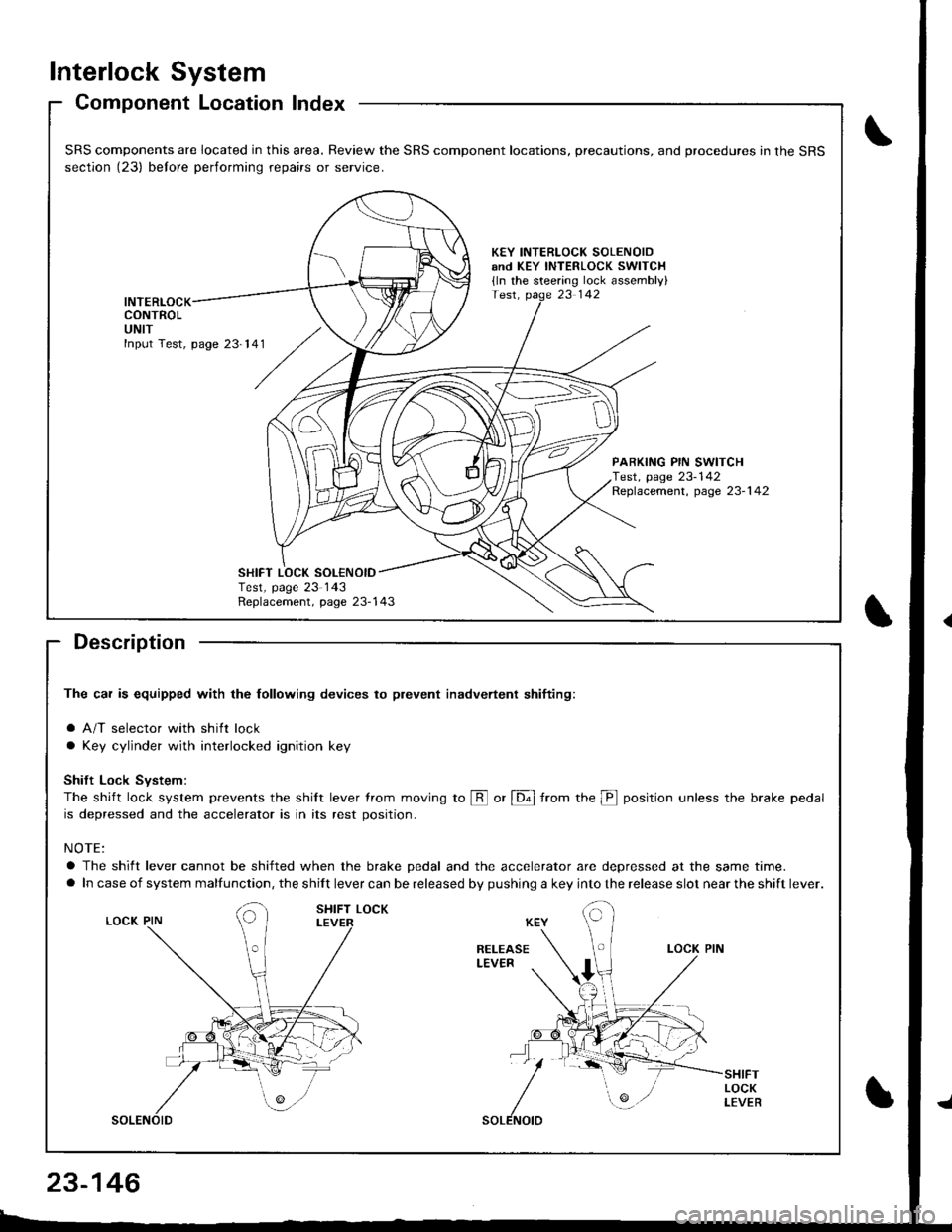

Interlock System

Component Location Index

Description

The car is equipped with the lollowing devices to plevent inadvertent shifiing:

a A/T selector with shift lock

a Key cylinder with interlocked ignition key

Shift Lock Svstem:

The shift lock system prevents the shilt lever trom moving to @ or [6ol from the p position unless the brake pedal

is depressed and the accelerator is in its rest position.

NOTE:

a The shift lever cannot be shifted when the brake pedal and the accelerator are depressed at the same time.

a In case of system malfunction, the shift lever can be released by pushing a key into the release slot near the shift lever.

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (23) belore performing repairs or service.

KEY INTERLOCK SOLENOIDand KEY INTERLOCK swlTCH

{ln the steering lock assembly}

INTERLOCKCONTROLUNIT

PARKING PIN SWITCHTest, page 23-142Replacement, page 23-1 42

Replacement, page 23-143

SHIFT LOCK SOL€NOIDTest, page 23 143

23-146

Page 1253 of 1681

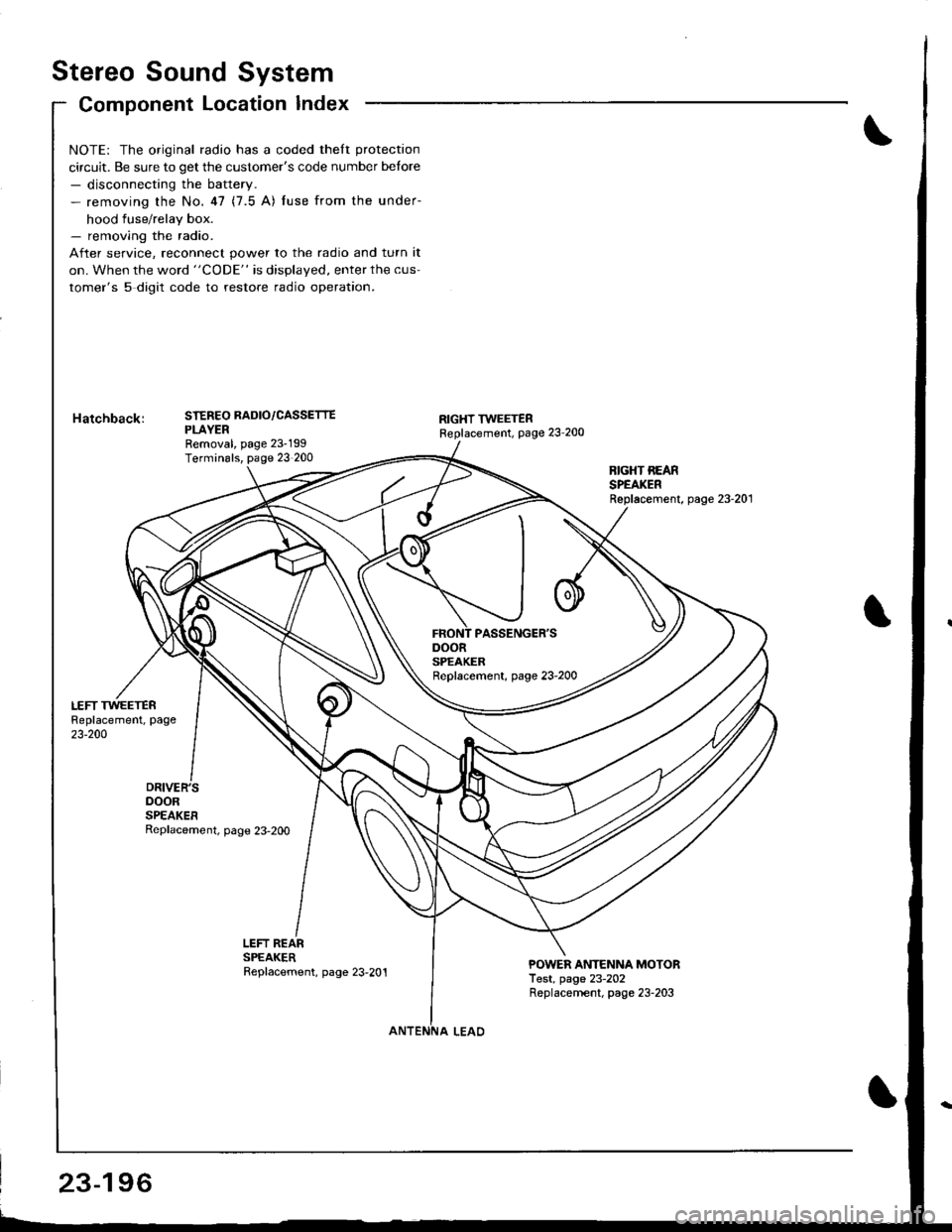

Stereo Sound System

Component Location Index

DOORSPEAKERReplacement, page 23-2OO

NOTE: The original radio has a coded theft protection

circuit. Be sure to get the customer's code number betore- disconnecting the battery.- removing the No.47 (7.5 A) fuse from the under-

hood fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5 digit code to restore radio operation.

STEREO RADIO/CASSETTEPLAYERRemoval, page 23-199Terminals, page 23 200

RIGHT TWEETERReplacement, page 23'200

BIGHT REARSPEAKERReplacement, page 23-201

LEFT REARSPEAKERReplacement, page 23,201POWER ANTENNA MOTORTest, page 23-202Replacernent, page 23-203

23-196

Page 1256 of 1681

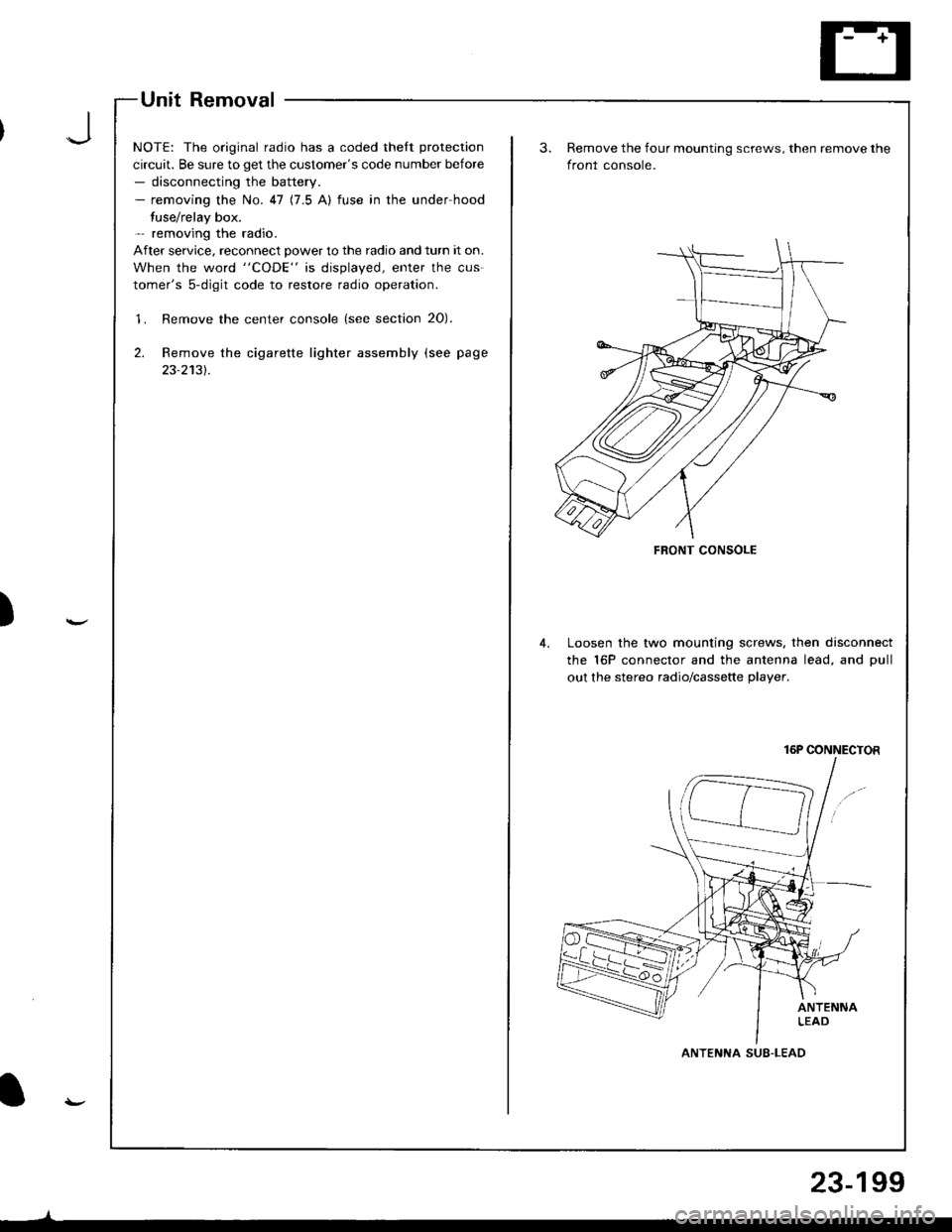

Unit Removal

NOTE: The original radio has a coded thelt protection

circuit. Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 47 (7.5 A) fuse in the under-hood

fuse/relay box.- removing the radio.

After service. reconnect power to the radio and turn it on.

When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

'1. Remove the center console (see section 20).

2. Remove the cigarette lighter assembly (see page

23-2131.

)

FRONT CONSOLE

Remove the four mounting screws, then remove the

front console.

Loosen the two mounting screws. then disconnect

the 16P connector and the antenna lead, and Dull

out the stereo radio/cassette plaver.

16P CONNECTOR

ANTENNA SUB-LEAD

23-199