engine HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 389 of 1681

4.

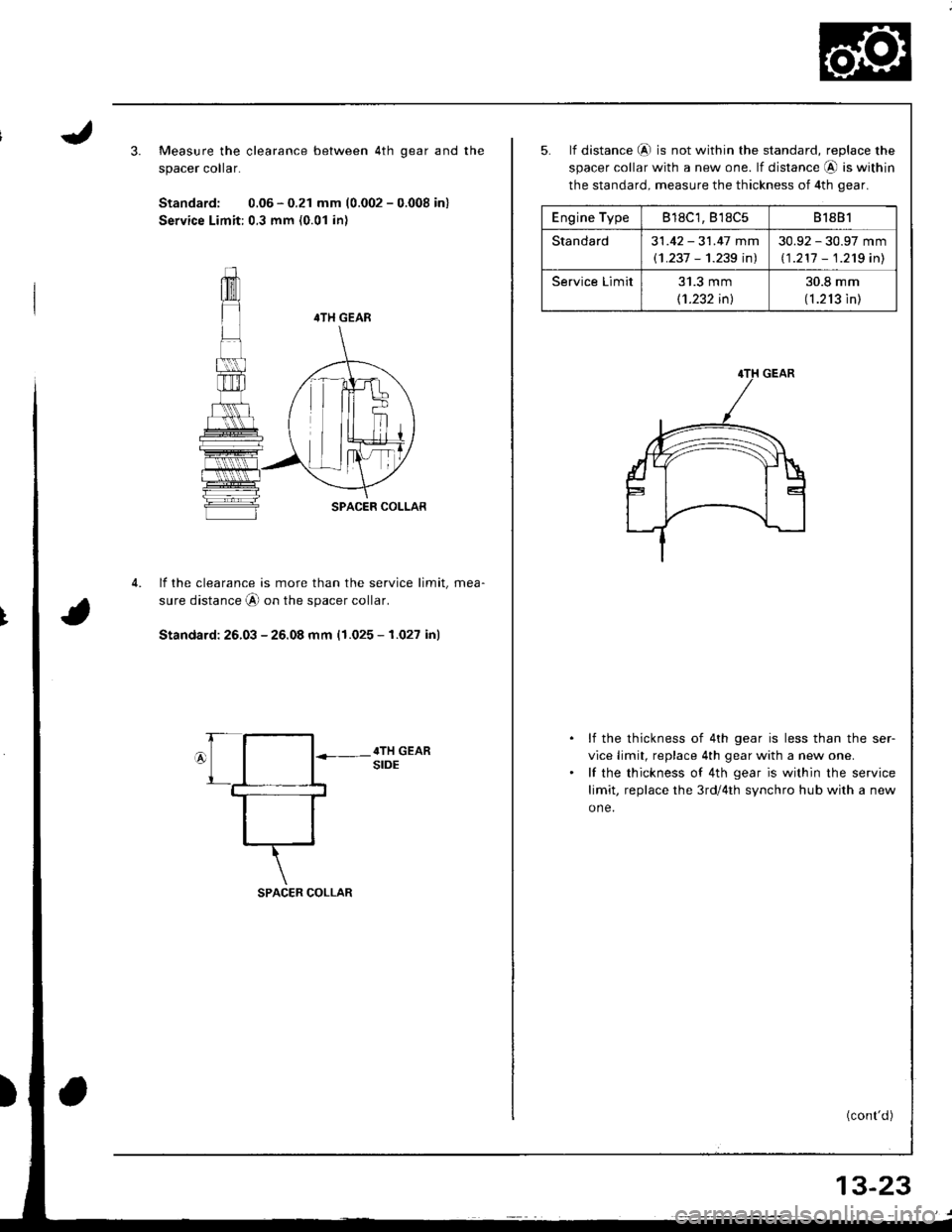

Measure the clearance between 4th qear and the

spacer colar.

Standard: 0.06 - 0.21 mm (0.002 - 0.008 in)

Service Limit:0.3 mm (0.01 in)

4TH GEAR

SPACER COLLAR

lf the clearance is more than the service limit, mea-

sure distance A on the spacer collar.

Standard: 26.03 - 25.08 mm (1.025 - 1.027 in)

SPACER COLLAR

Engine Type818C1, B'�l8C581881

Standard31 .42 - 31.47 mm

(1 .237 - 1.239 inl

30.92 - 30.97 mm

11 .211 - 1.2'tg inl

Service Limit31.3 mm

11.232 inl

30.8 mm

(1.213 in)

5. lf distance @ is not within the standard, replace the

spacer collar with a new one. lf distance @ is within

the standard, measure the thickness of 4th gear.

lf the thickness of 4th gear is less than the ser-

vice limit, replace 4th gear with a new one.

lf the thickness of 4th gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one.

(cont'd)

13-23

Page 393 of 1681

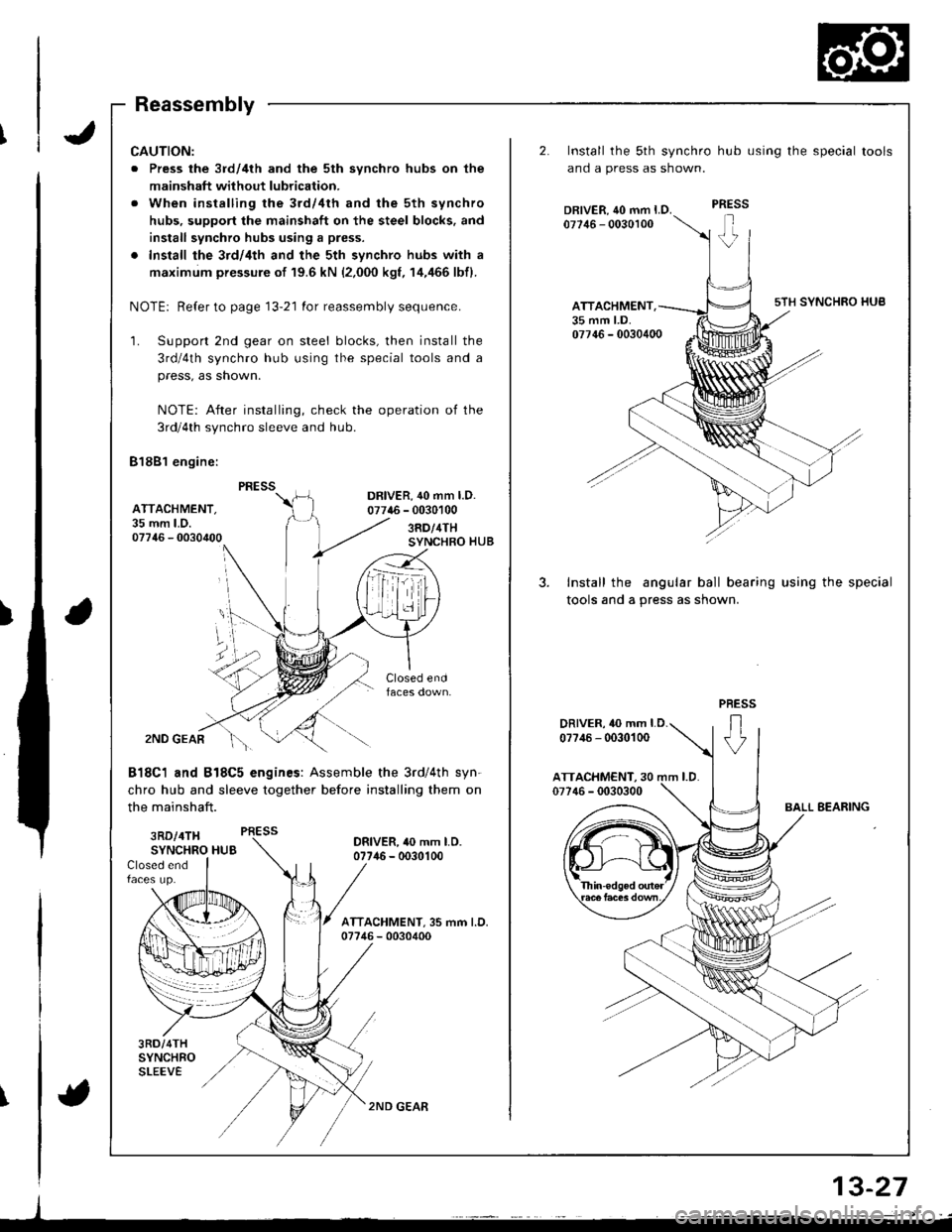

Reassembly

CAUTION:

. Press the 3rd/4th and the 5th synchro hubs on the

mainshaft without lubrication.

. When installing rhe 3rd/4th and the 5th synchro

hubs, support the mainshaft on the steel blocks. and

install synchro hubs using a press.

. Install the 3rd/4th and the 5th synchro hubs with a

maximum pressure of 19.6 kN {2,000 kgf, 14,/166 lbfl.

NOTE: Refer to page 13-21 for reassembly sequence.

'1. Support 2nd gear on steel blocks, then install the

3rd/4th synchro hub using the special tools and a

press, as shown.

NOTE: After installing, check the operation of the

3rd/4th synchro sleeve and hub

81881 engine:

DR|VER,40 mm l.D.07746 - 0030100AITACHMENT.35 mm LD.07746 - 00304003RD/4THSYNCHRO HUB

f

2ND GEAR

818C1 and B18C5 engines: Assemble the 3rd/4th syn-

chro hub and sleeve together before installing them on

the mainshaft.

3RD/4TH PRESS

SYNCHRO HUBORIVER, 40 mm LO.07746 - 0030100Closed endfaces up.

3RD/4THSYNCHROSLEEVE

2ND GEAR

2.

3.

Install the sth synchro hub using the special tools

ano a press as snown.

Install the angular ball bearing using the special

tools and a press as shown.

ATTACHMENT.35 mm LD.

DRIVER, 10 mm LD.

07?,16 - 0030100

J

a

\

13-27

{

Page 395 of 1681

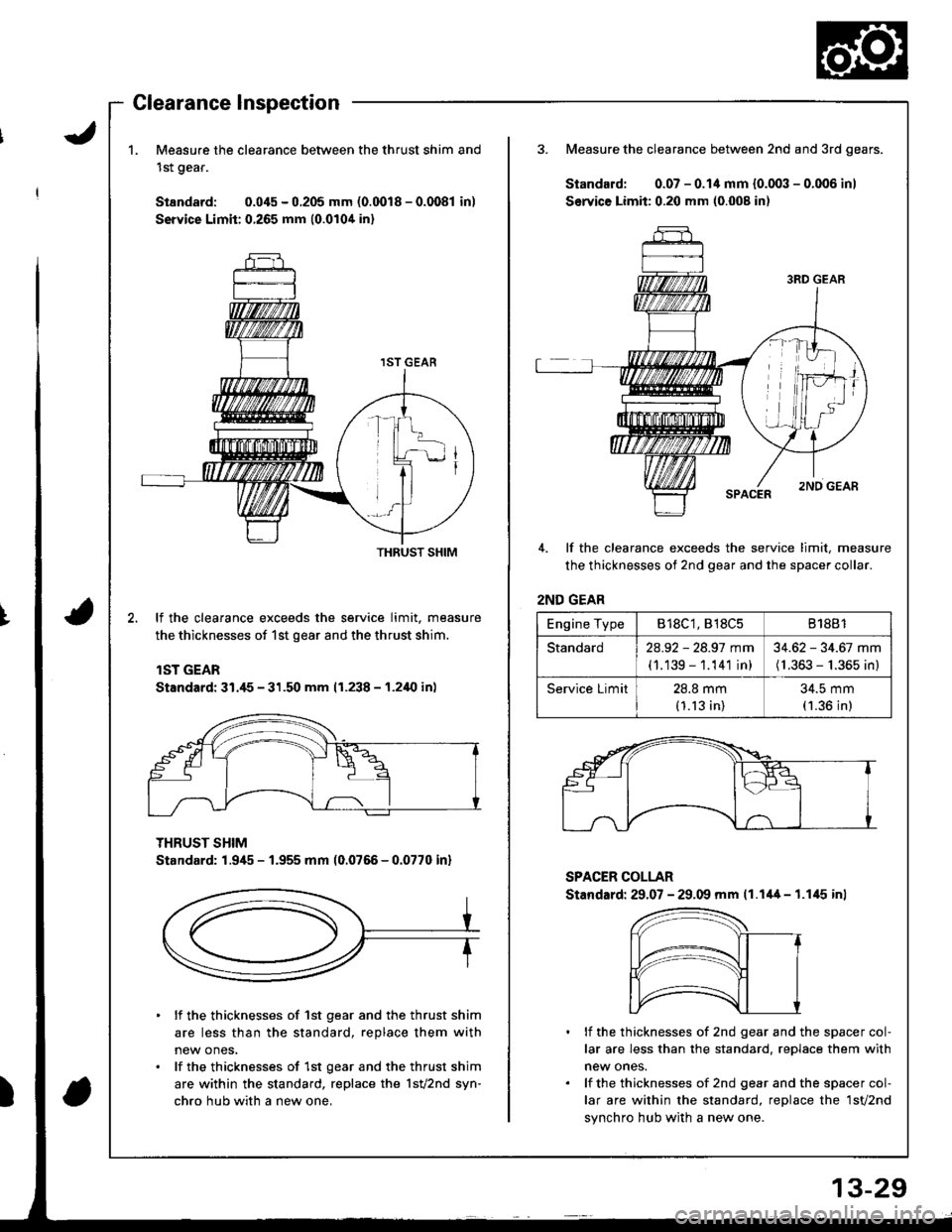

1.Measure the clearance between the thrust shim and

1st gear.

Standard: 0.045 - 0.205 mm (0.0018 - 0.0081 in)

Service Limit:0.265 mm {0.0104 in}

3. Measure the clearance between 2nd and 3rd gears.

Standard: 0.07 - 0.14 mm {0.003 - 0.006 inl

Service Limit: 0.20 mm (0.008 in)

4. lf the clearance exceeds the service limit, measure

the thicknesses of 2nd gear and the spacer collar.

2ND GEAR

lf the clearance exceeds the service limit, measure

the thicknesses of 1st gear and the thrust shim.

lST GEAR

Standard: 31./t5 - 31.50 mm (1.238 - 1.2i10 in)

THRUST SHIM

Standard: 1.945 - 1.955 mm (0.0766 - 0.0770 inl

SPACER COLLAR

Stand.rd: 29.07 - 29.09 mm 11.1'+4 - 1.1,15 inl

lf the thicknesses of 1st gear and the thrust shim

are less than the standard, replace them with

new ones,

lf the thicknesses of 1st gear and the thrust shim

are within the standard, replace the 1sv2nd syn-

chro hub with a new one,

lf the thicknesses of 2nd gear and the spacer col-

lar are less than the standard, reDlace them with

new ones.

lf the thicknesses of 2nd gear and the spacer col-

lar are within the standard, replace the 1sv2nd

synchro hub with a new one.

THRUST SHIM

Engine TypeB18C1, 818C581881

Standard2a.92 - 28.97 mm

(1.139 - 1.141 in)

34.62 - 34.67 mm(1.363 - 1.365 in)

Service Limit28.8 mm(1.13 in)

34.5 mm(1.36 in)

Page 398 of 1681

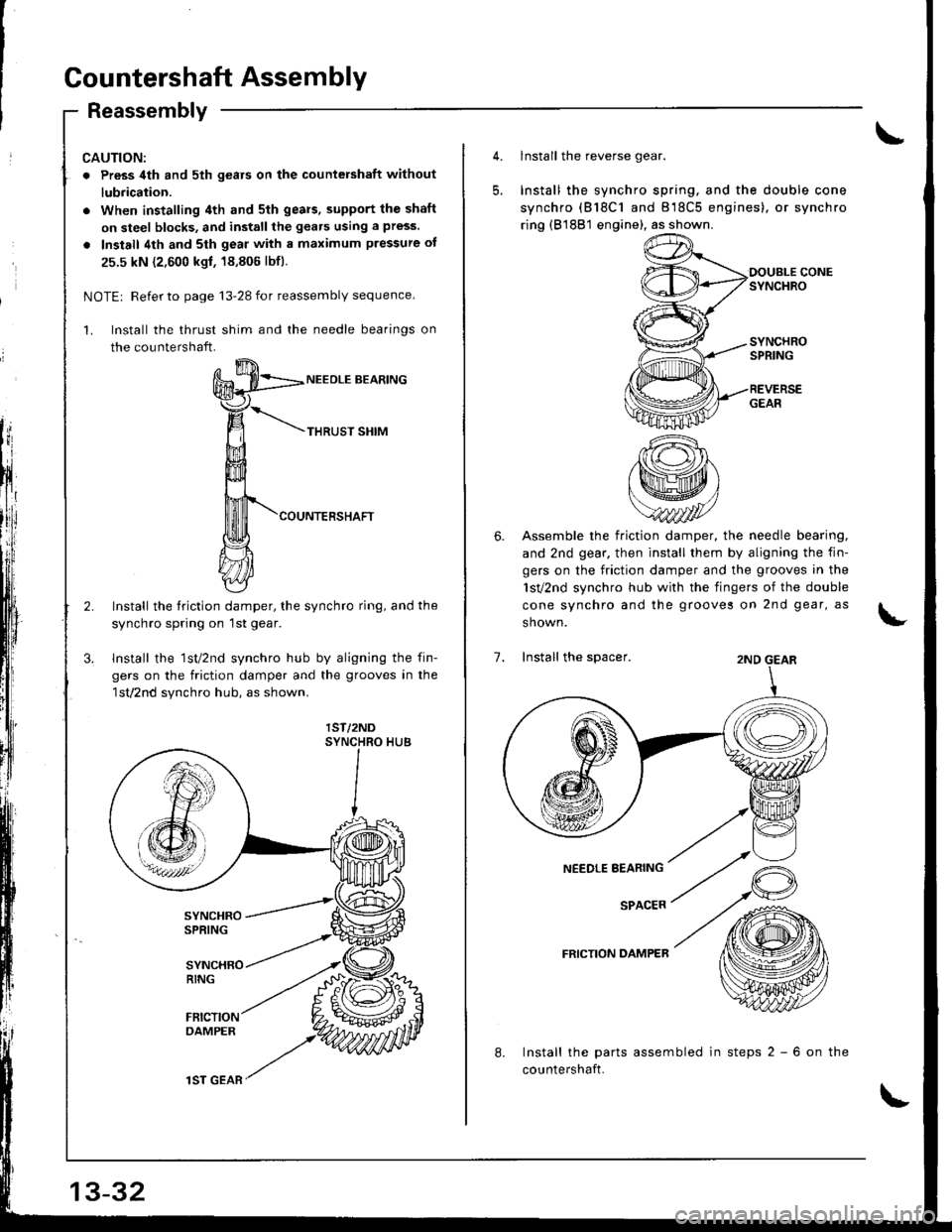

Gountershaft Assembly

Reassembly

CAUTION:

. Press 4th and sth gears on the countershaft without

lubrication.

. When installing 4th and 5th gears, supPort the shaft

on steel blocks, and install the gears using a press.

. Install 4th and sth geal with a maximum pressure of

25.5 kN {2,600 kgf, 18,806 lbfl.

NOTEr Refer to page '13-28 for reassembly sequence

Install the thrust shim and the needle bearings on

the countershaft.

NEEOLE BEARING

THRUST SHIM

COUNTERSHAFT

Install the friction damper, the synchro ring, and the

synchro spring on lst gear.

Install the lst/2nd synchro hub by aligning the fin-

gers on the friction damper and the grooves in the

lst/2nd synchro hub, as shown.

lST/2ND

13-32

1ST GEAR

5.

lnstall the reverse gear.

Install the synchro spring. and the double cone

synchro (818C1 and 818C5 engines). or synchro

ring (81881 engine), as shown.

OOUELE CONESYNCHRO

SYNCHROSPRING

REVERSEGEAR

6. Assemble the friction damper, the needle bearing.

and 2nd gear. then install them by aligning the fin-

gers on the friction damper and the grooves in the

1sv2nd synchro hub with the fingers of the double

cone synchro and the grooves on 2nd gear, as

shown.

7. Install the spacer.2ND GEAR

SPACER

FRICTION DAMPER

8.Install the parts assembled in steps 2 - 6 on the

countershaft.

Page 412 of 1681

I

Transmission Assembly

1.

2.

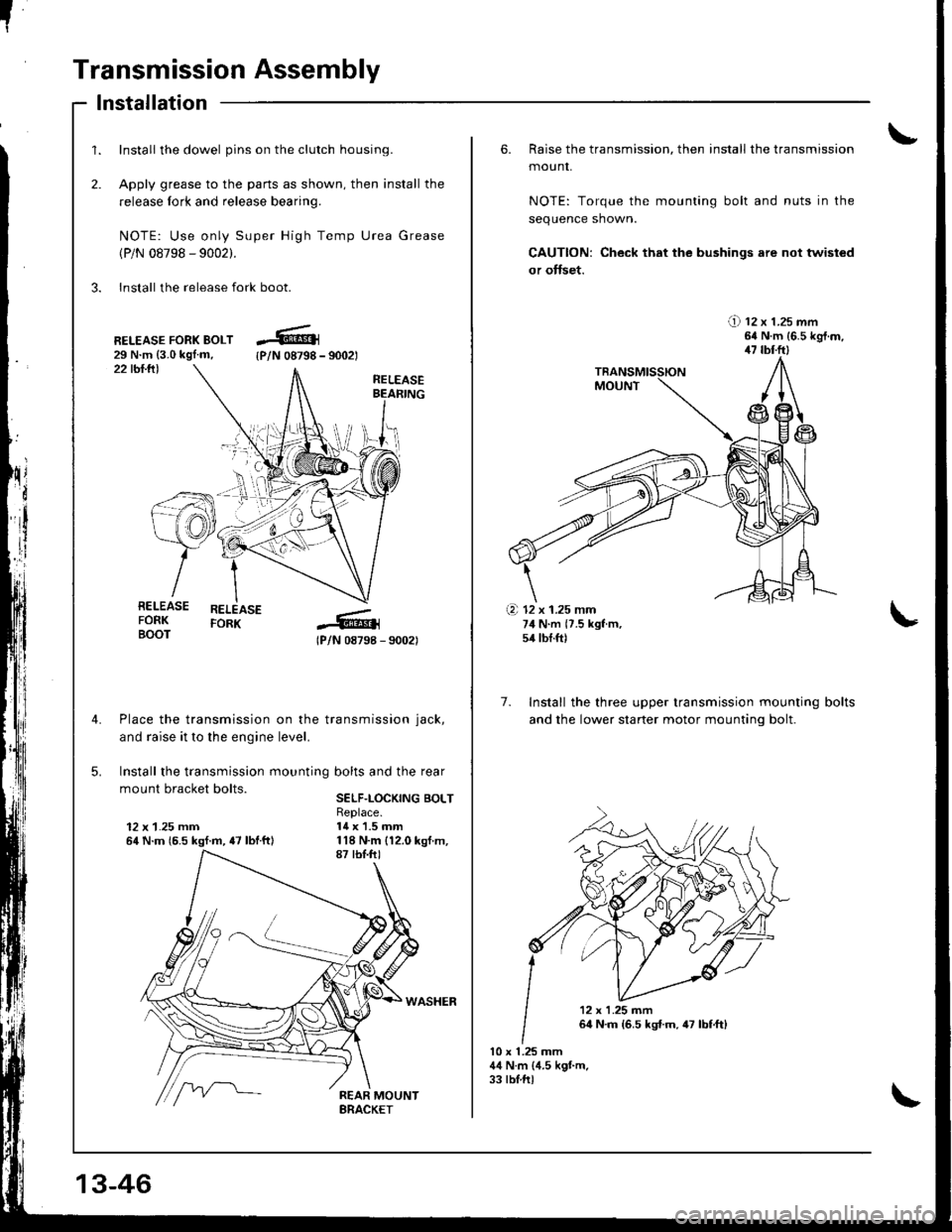

Install the dowel pins on the clutch housing.

Apply grease to the parts as shown, then install the

release fork and release bearing.

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

3. Install the release fork boot.

lnstallation

22 tbl.lll

RELEASE FORK BOLT29 N.m {3.0 kgl.m,{P/N 08798 - 9002t

RELEASEBEAFING

RELEASEFORK

lPlN 08798 - 90021

Place the transmission on the transmission jack,

and raise it to the engine level.

Install the transmission mounting bolts and the rear

mount bracket bolts.SELF.LOCKING BOLT

12 x 1.25 mm64 N.m {6.5 kgf.m, {7 lbtftl

Replace.14 x 1.5 mm

RELEASEFORKBOOT

\i'l-r )i-

.+.i

13-46

6. Raise the transmission, then install the transmission

mounr,

NOTE: Torque the mounting bolt and nuts in the

sequence shown.

CAUTION: Check that the bushings are not twisted

or offset.

!) tz x t.zs mm64 N.m {6.5 kgt.m,47 tbl.ftl

7. Install the three upper transmission mounting

and the lower staner motor mountinq bolt.

bolts

10 x 1.25 mm44 N.m (4.5 kgt m.33 tblftl

(a 12 x 1.25 mm74 N.m {7.5 kgf m,54 tbf.ft)

'12x1.25m�n

64 N.m {6.5 kst.m,47 lbf,ft)

Page 413 of 1681

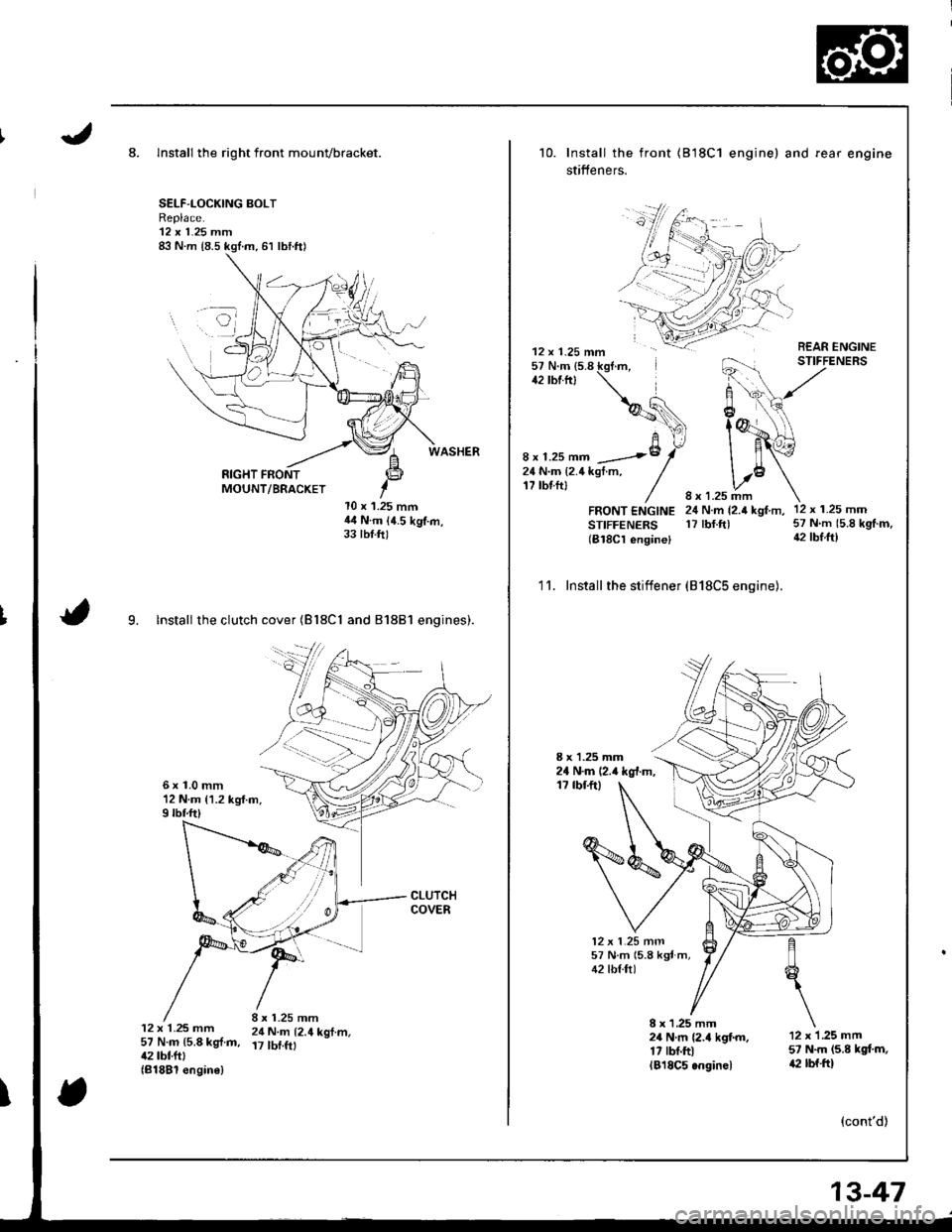

8. Install the right front mounvbracket.

SELF-LOCKING BOLTReplace.'12 x 1.25 mm

RIGHT FRONTMOUNT/BRACKET

l0 x 1.25 mmil4 N.m (4.5 kg'f.m,33 tbt.ft)

9. lnstall the clutch cover (Bl8Cl and 81881 engines).

6x1.0mm12 N.m {1.2 kg{.m,9 rbf.ft)

12 x 1.25 mm 24 N.m t2.4 kof.m.57 N.m {5.8 kg{.m, 17 tbf.ftt42 tbt.ftl(81881 engin€)

10. Install the front

stifteners.

(818C1 engine) and fear engine

REAR ENGINESTIFFENERS

12 x 1.25 mm57 N'm 15.8 kg{.m.42 tbr.ltl

H!\,

f @^\

I B'�{o| \-

1.25 mmN.m {2.4 kgf m,rbf.ftl

12 x 1.25 mm57 N.m (5.8

{2 tbtft}

8 x 1.25 mm -8

24 N.m {2.4 kgt m,17 tbtftl

FRONT ENGINESTIFFENERS(B18Cl engine)

12 x 1.25 mn157 N m (5.8 kgt m,42 tbl.ftl

2111

'11. Install the stiffener (818C5 engine).

8 x 1.25 mm24 N.m (2.4 kg{.m,1? tbf.ftl

8 x 1 ,25 mm24Nm{2.4kgtm.17 rbr.ftllBl8C5.nginel

12 x 1 .25 mm57 N.m (5.8 kgl.m,a2 rbf.ftl

(cont'd)

13-47

Page 414 of 1681

[!

"

Transmission Assembly

Installation (cont'd)

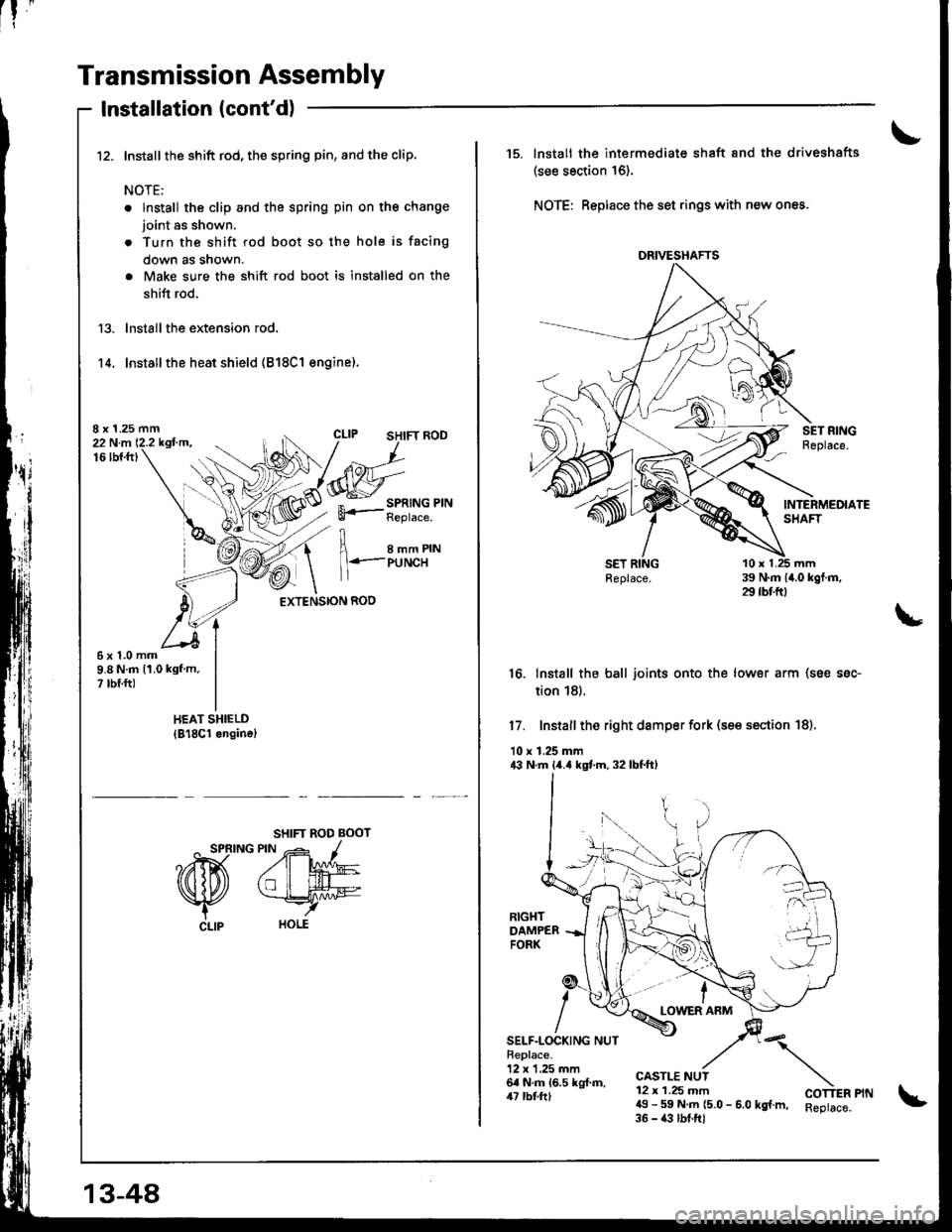

Install the shift rod, the spring pin, and the clip.

NOTE:

. lnstall the clip and the spring pin on the change

joint as shown.

. Turn the shift rod boot so the hole is facing

down as snown.

. Make sure the shift rod boot is installed on the

shift rod.

lnstall the extension rod.

Installthe heat shield (818C1 engine).'t 4.

8 x 1.25 mm22 N.m 12.2 kgfm.16lbt.ft)

I e--erru

1 l+.-PUNCH

EXTENSION ROD

6x1.0mm9.8 N.m 11.0 kgf m,? rbf.ft)

SHIFT ROD BOOT

^ SPRING PIN -- -1

?ffi A'W

Nfu *rry

CLlp HOLE

13-48

DRIVESHAFTS

15. lnstall the intermediate shaft 8nd the driveshafts

(see section 16).

NOTE: Beplace the set rings with new ones.

16. Install the ball joints onto the lower arm (soe ssc-

tion 18).

17. Install the right damper fork (see ssction 18).

10 r 1.25 mm43 N.m lir.a kgt m. 32 lbtftl

LOWER ARM

SELF.LOCKING NUTReplace.12 x 1,25 mm6a N.m 16.5 kg{.ft,/u rbl.tt)

CASTLE NUT12 x 1.25 mm49 - 59 N.m (5.0 - 6.0 kgf.m, Reptace.35 - 43 lbf.ftl

"\

COTTER PIN

Page 415 of 1681

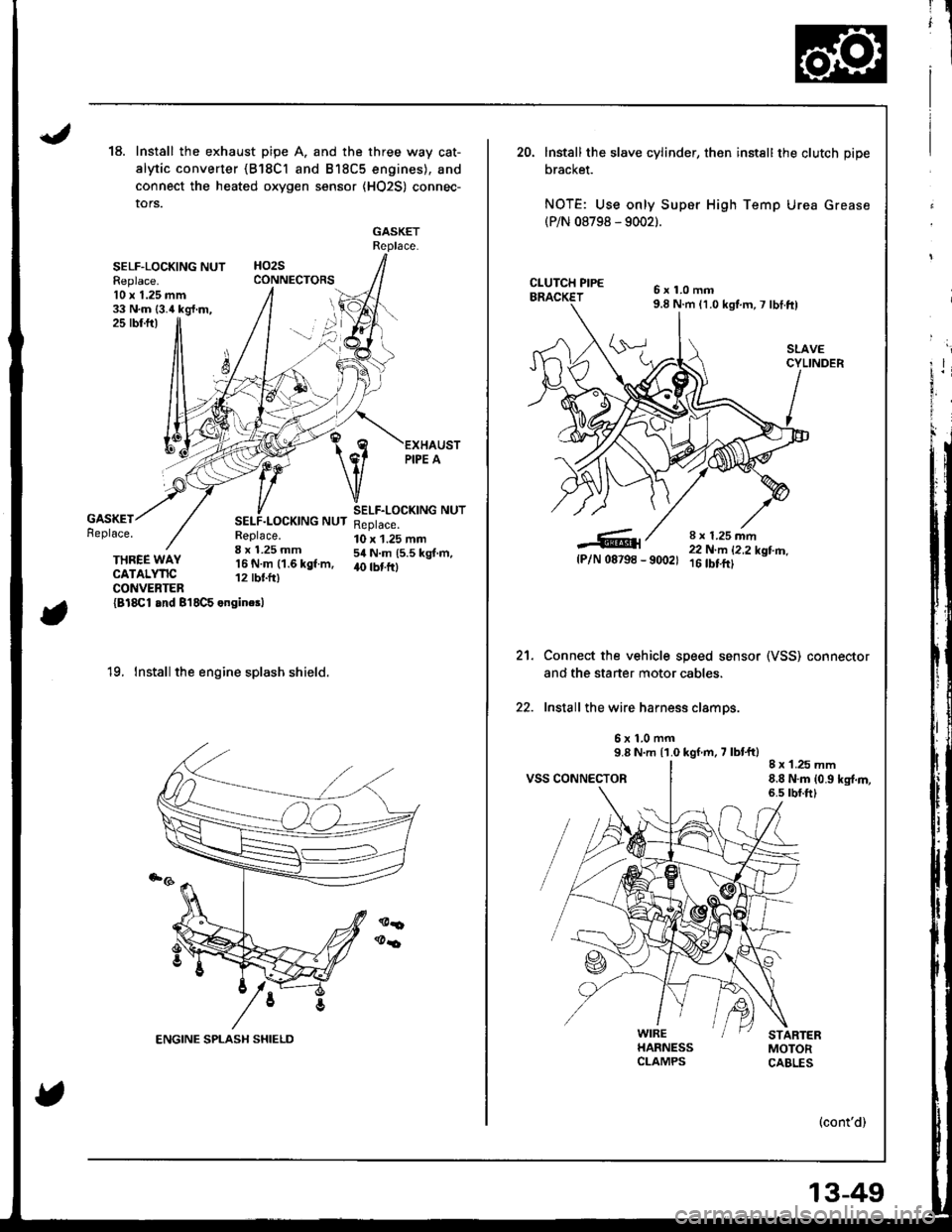

18.Install the exhaust pipe A. and the three way cat-

alytic converter {B18Cl and B18C5 engines), and

connect the heated oxygen sensor {HO2S) connec-

tors.

GASKETReplace.

HO2SCONNECTORSSELF-LOCKING NUTFeplace.10 x 1.25 mm33 N.m {3.4 kg{.m,jj25 rbr.ftl

GASKETReplace.SELF.LOCKING NUTReplace.8 x 1.25 mm'16 N.m (1.6 kgf.m,12 tbtfr)

SELF.LOCKING NUTReplace.10 x 1.25 mm54 N.m (5.5 kgt.m,40 tbt frlTHREE WAYCATALYTICCONVENTER{Bl8Cl and 8'18C5 engincsl

'19. Install the engine splash shield.

20. lnstall the slave cylinder, then instsll the clutch pipe

bracket.

NOTE: Use only Super High Temp Urea Grease(P/N 08798 - 9002).

6x1.0mm9.8 N.m 11.0 kgt m,7 lbI.ft)

SLAVECYLINDER

8 r 1.25 mm22 N.m 12,2 kotm_- 9(x)21 16 tbt.ftt

Connect the vehicle speed sensor (VSS) connestor

and the staner motor cables.

Install the wire harness clamps.

6x1.0mm9.8 N.m {1.0 kgf m, 7 lbt'ft)

VSS CONNECTOR8 x 1.25 mm8.8 N.m {0.9 kg{.m,6.s rbr.ft)

5{P/N 08798

21.

WIREHARNESSCLAMPS

(cont'd)

13-49

Page 420 of 1681

Description

\J

t{

{

14-3

The automatic transmission is a combination of a 3-element torque converter and triple-shalt electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engrne.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in sigle unit. The torque converter is connected to

the engine crankshaft so they turn torether as a unit as the engine turns. Around the outside of the torque convener is a

ring gear which meshes with the starter pinion when the engine is being started. The entire torque converter assembly

serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts; the mainshaft. the countershaft, and the sub shaft. The mainshaft is in-line with

the engine crankshaft.

The mainshaft includes the 1st, and 2ndl4th clutches,and gear for 3rd, 2nd, 4th, reverse, and 1st. (3rd gear is integral with

the mainshaft, while reverse gear is integral with the 4th gear.)

The countershaft includes the 3rd clutch and gears for 3rd,2nd, 4th, reverse, 1st, and parking. Reverse and 4th gears can

be loched to the countershaft at its center,providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the 1st-hold clutch and gears fo 1st and 4th.

The gears on the mainshaft are in constant mesh with those on the countersahft and sub-shaft.When certain combinations

of gears in the transmission are engaged by clutches. power in transmitted from the mainshaft to the countershaft via the

sub-shaft to orovude oil, lo'1. E, E. and E.

Electronic Control

The electronic control svstem consists of the Transmission Control Module (TCM), sensors, and four solenoid valves.

Shilting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the lelt side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the serbvo body, and

the lock-up valve body, through the respective separator plates, They are bolted to the torque converter housing,

The main valve body contains the manual valve, the 1-2 shift valve, the 2-3 shitt valve, the Clutch Pressure Control

lCPC) valve, the 4th exhaust valve, the reliel valve, and the ATF pump gears.

The secondary valve body contains the 4-3 kick-down valve, the 3-2 kick-down valve, the 2-3 orifice control valve, the

3-4 shift valve, the orilice control valve, the modulator valve, and the servo control valve.

The regulator valve body contains the pressure regulator valve, the lock-up control valve, the torque converter check

valve, and the cooler check valve.

The servo body contains the servo valve, which is integrated with shift fork shaft, the throttle valve B, and the accumula-

tors.

The lock-up valve body contains the lock-up shift valve and the lock-up timing B valve, and is bolted to the regulator valve

ooqy.

Fluid from the regulator passes through the manual valve to the various control valves.

Shift Control Mechanism

Input to the TCM from various sensors located throughout the car determines which shift control solenoid valve should

be activated. Activating a shitt control solenoid valve changes modulator pressure, causing a shift valve to move. This

pressurizes a line to one ol the clutches, engaging that clutch and its corresponding gear.

Lock-uD Mechanism

In @ position, in 2nd, 3rd and 4th, and @ position in 3rd, pressurized fluid can be drained lrom the back oI the tor-

que converter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this

takes place, the mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM

optimizes the timing of the lock-up mechanism.

The lock-up valves controlthe range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)

Page 421 of 1681

Description

{cont'd)

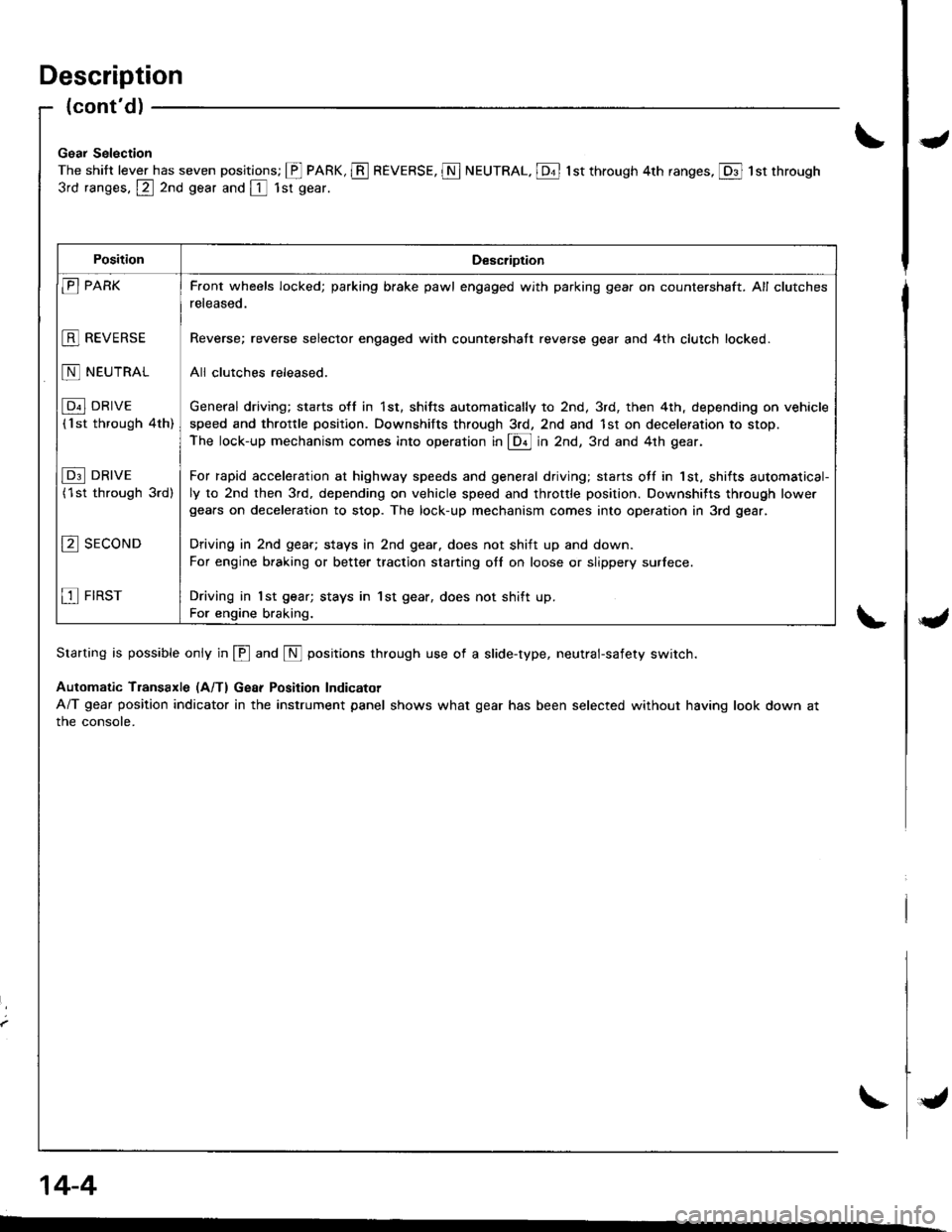

Gsar Selection

The shift lever has seven positions; @ PARK, E REVERSE, N NEUTRAL. [Dt l st through 4th ranges, @ 1st through

3rd ranges, @ 2nd gear and [ 1sr gear.

Starting is possible only in @ and N positions through use of a slide-type, neutral-safety switch.

Automatic Transaxle (A/T) Gear Position Indicator

A/T gear position indicator in the instrument panel shows what gear has been selected without having look down at

the console.

PositionDescription

E PARK

E REVERSE

N NEUTRAL

[p"l DRrvE

('lst through 4th)

I p3l DRrvE

(1st through 3rd)

E sEcoND

E FIRST

F.ont wheels locked; parking brake pawl engaged with parking gear on countershaft. All clutches

released.

Reverse; reverse selector engaged with countershatt reverse gear and 4th clutch locked.

All clulches released.

General driving; sta.ts o{f in 1st, shitts automatically to 2nd, 3rd, then 4th, depending on vehicle

speed and throttle positlon. Downshifts through 3rd, 2nd and 1st on deceleration to stop.

The lock-up mechanism comes into operation in @ in Zna, 3rd and 4th gear.

For rapid acceleration at highway speeds and general driving; starts otf in 1st, shifts automatical-

ly to 2nd then 3rd, depending on vehicle speed and throttle position. Downshifts through lowe.gears on deceleration to stop. The lock-up mechanism comes into operation in 3rd gear.

Driving in 2nd geat; stays in 2nd gear. does not shift up and down.

For engine braking or better traction starting otl on loose or slippery surlece.

Driving in 1st gear; stays in 1st gear, does not shift up.

For engine braking.

14-4

{