engine HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 428 of 1681

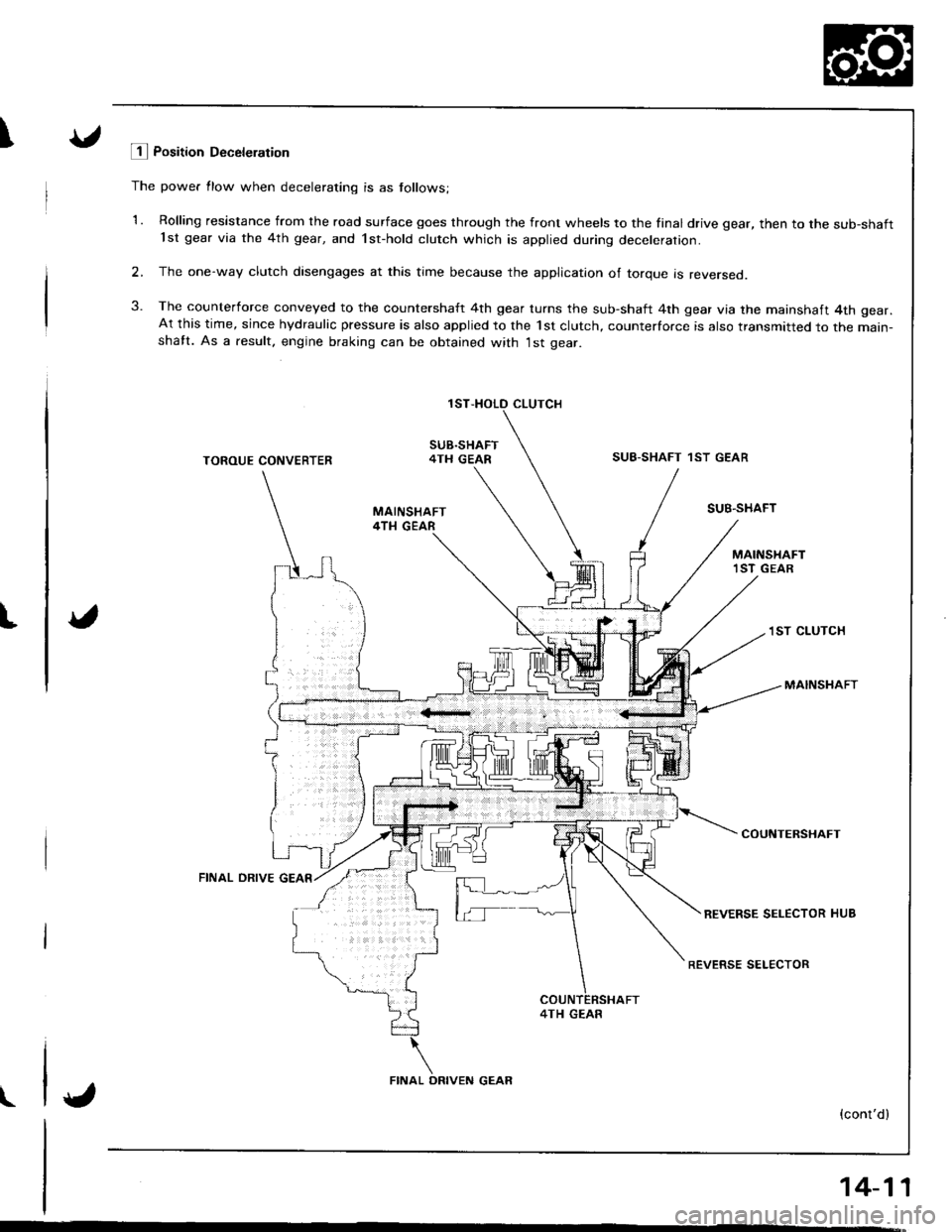

\E Position Deceleration

The power flow when decelerating is as follows;

1. Rolling resistance from the road surface goes through the front wheels to the final drive gear, then to the sub-shaft'lst gear via the 4th gear, and 1st-hold clutch which is applied during decelerarion.

2, The one-way clutch disengages at this time because the application of torque is reversed.

3. The counterforce conveyed to the countershaft 4th gear turns the sub-shaft 4th gear via the mainshaft 4th gear.At this time, since hydraulic pressure is also applied to the 1st clutch, counterforce is also transmitted to the main-shatt. As a.esult. engine braking can be obtained with 1st gear.

CLUTCH

SUB.SHAFT4TH GEARSUB-SHAFT 1ST GEAR

t

TOROUE CONVERTER

FINAL ORIVE

SUB.SHAFT

1ST CLUTCH

MAINSHAFT

COUNTERSHAFT

REVERSE SELECTOR HUB

REVERSE SELECTOR

4TH GEAR

(cont'dl

14-11

\

FINAL ORIVEN GEAR

Page 430 of 1681

I

t

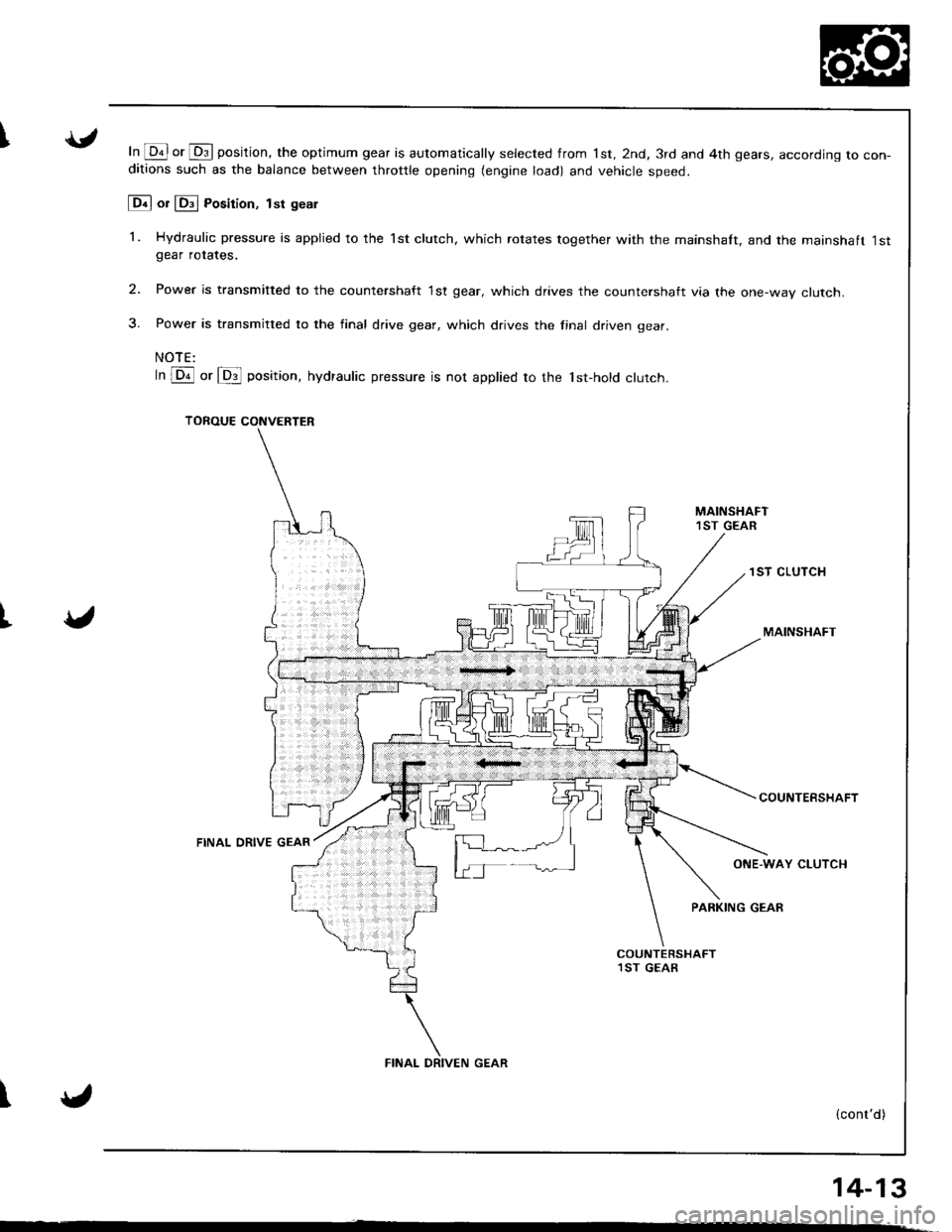

In @ or @ position, the optimum gear is automatically selected from 1st, 2nd, 3rd and 4th gears, accororng ro con-ditions such as the balance between throttle opening (engine load) and vehicle speed.

[Dn] or lDil Posirion, tsr geal

1. Hydraulic pressure is appiied to the 1st clutch, which rotates together with the mainshaft, and the mainshaft 1stgear rotates,

2. Power is transmitted to the countershaft 1st gear, which drives the countershaft via the one-way clutch.

3. Power is transmitted to the final drive gear, which drives the final driven gear.

NOTE:

In lDr'l or lDil position, hydraulic pressure is not applied to the 'tst-hold clutch.

TOROUE CONVERTER

1ST CLUTCH

MAINSHAFT

FINAL ORIVE GEAR

COUNTEBSHAFT

ONE-WAY CLUTCH

PARKING GEAR

\

14_13

,

FINAL DRIVEN GEAR

Page 437 of 1681

Description

Elestronic Control System (cont'd)

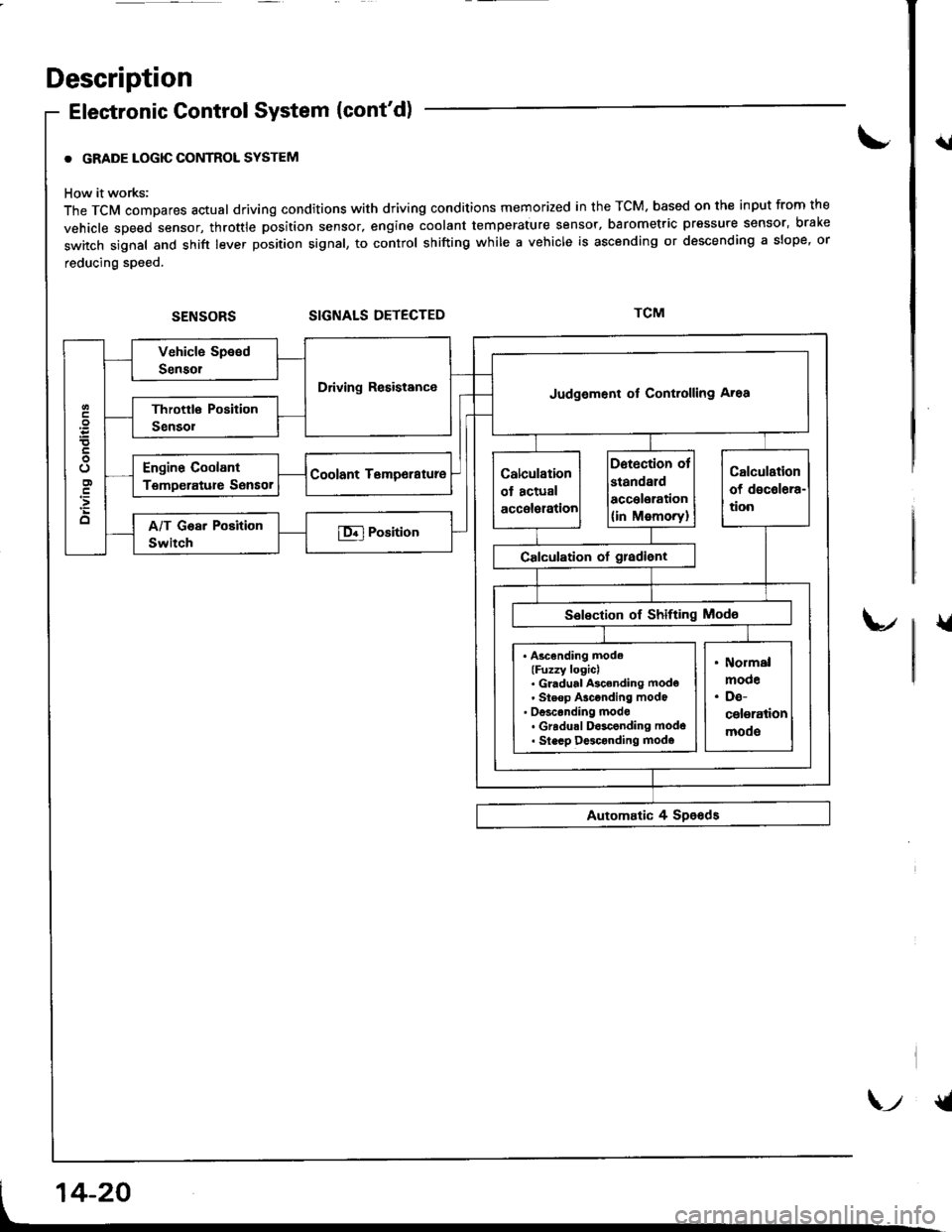

. GRADE LOGIC CONTROL SYSTEM

How it works:

The TCM compares actual driving conditions with driving conditions memorized in the TCM. based on th€ input from the

vehicle speed sensor, throttle position sensor, engine coolant temperature sensor, barometric pressure sensor, bral(e

switch signal and shift lever position signal, to control shifting while a vehicle is ascending or descending a slope, or

reducing speed.

SIGNALS DETECTED

{l

{

Driving ResistanceJudgement of Controlling Aroa

. Ascending mode(Fuzzy logicl. Gl.dual Ascending mode' Steop Asconding mode' oesconding mode. Gradu.l D$conding modo. Slecp D$conding modo

\-t {t

Page 438 of 1681

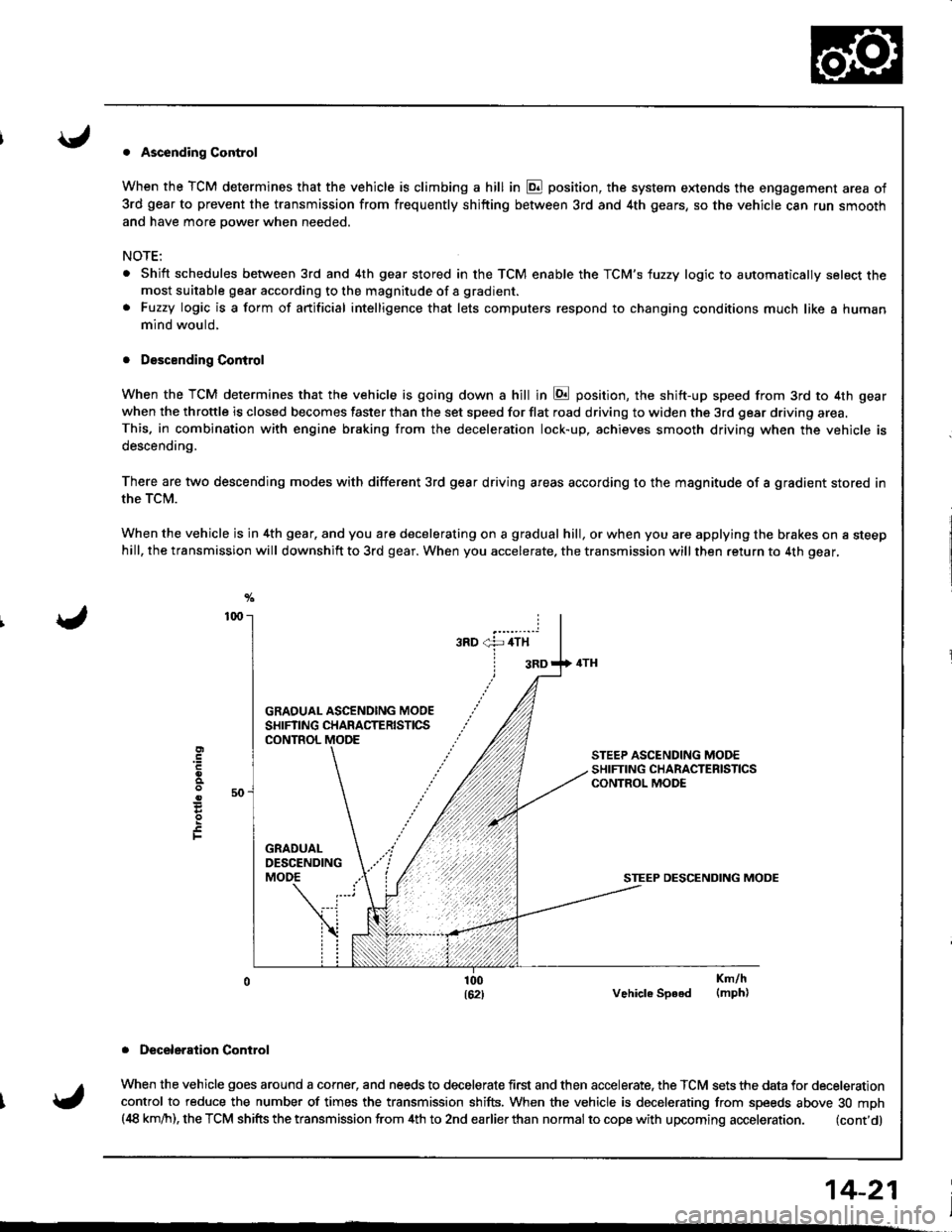

. Ascending Control

When the TCM determines that the vehicle is climbing a hill in E position, the system extends the engagement area of

3rd gear to prevent the transmission from frequently shifting between 3rd and 4th gears, so the vehicle can run smooth

and have more power when needed,

NOTE:

Shift schedules between 3rd and 4th gear stored in the TCM enable the TCM'S fuzzy logic to automatically select themost suitable gear according to the magnitude of a gradient.

Fuzzy logic is a form of artificial intelligence that lets computers respond to changing conditions much like a human

mind would,

. Descending Control

When the TCM determines that the vehicle is going down a hill in E position, the shift-up speed from 3rd to 4th gear

when the throttle is closed becomes faster than the set speed for flat road driving to widen the 3rd gear driving area.This. in combination with engine braking from the deceleration lock-up, achieves smooth driving when the vehicle is

descending,

There are two descending modes with different 3rd gear driving areas according to the magnitude of a gradient stored in

the TCM.

When the vehicle js in 4th gear, and you are decelerating on a gradual hill, or when you are applying the brakes on a steephill, the transmission will downshift to 3rd gear. When you accelerate, the transmission will then return to 4th gear,

GRAOUAL ASCENOING MOOESHIFTING CHARACTERISTICSCONTROL

STEEP DESCENDING MODE

Vehicle Speed

. Deceleraiion Control

When the vehicle goes around a corner, and needs to decelerate first and then accelerate. the TCM sets the data for deceleration

control to reduce the number of times the transmission shifts. When the vehicle is decelerating from speeds above 30 mph(,18 km/h), the TCM shifts the transmission from 4th to 2nd earlierthan normal to cope with upcoming acceleration. (cont'd)

E

F

Km/h(mph)

14-21

Page 440 of 1681

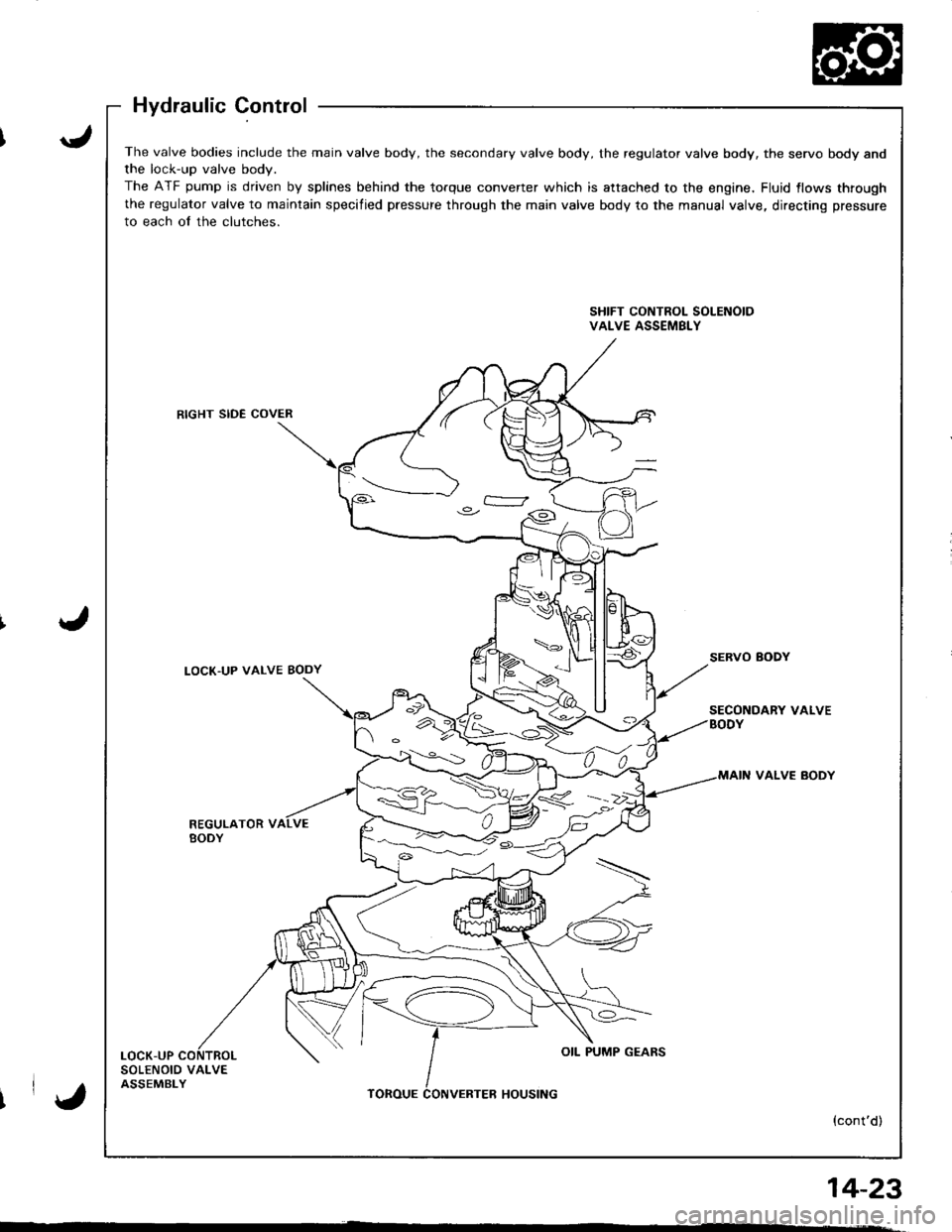

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the servo body andthe lock-up valve bodv.

The ATF pump is driven by splines behind the torque converter which is attached to the engine, Fluid {lows through

the regulator valve to maintain specified pressure through the main valve body to the manual valve, directing pressure

to each of the clutches.

SHIFT CONTROL SOLENOIDVALVE ASSEMBLY

RIGHT SIDE COVER

LOCK'UP VALVE BODYSERVO BODY

SECONDARY VALVEBODY

VALVE BODY

REGULATOR VBODY

LOCK-UPOIL PUMP GEARS

SOLENOID VALVEASSEMBLYTOROUEHOUSING

{cont'd)

%<->--::/ )C)

IrY,

14_23

'

Page 442 of 1681

I

I

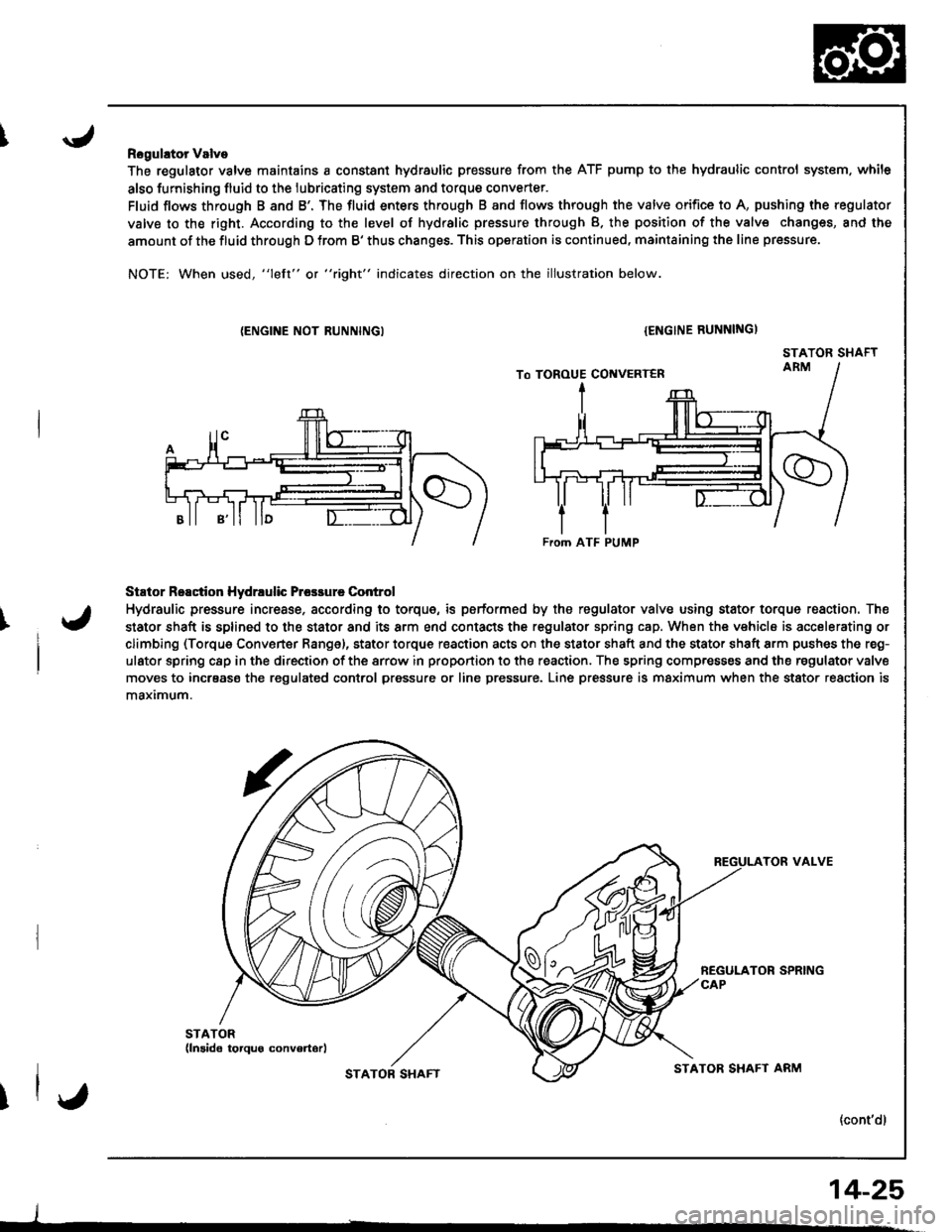

Rogulator Valve

The regulator valve maintains a constant hydraulic pressure from the ATF pump to the hydraulic control system. while

also furnishing fluid to the lubricating system and torque converter.

Fluid flows through B and B'. The fluid enters through B and flows through the valve orifice to A, pushing the regulator

valve to the right. According to the level of hydralic pressure through B. the position of the valv€ changes, and the

amount of the fluid through D from B' thus changes. This operation is continued, maintaining the line pressure.

NOTE: When used, "left" or "right" indicates direction on the illustration below.

{ENGINE NOT RUNNINGI{ENGINE RUNNINGI

STATOR SHAFT

Stator Reactior Hydrrulic Prcsrure Control

Hydraulic pressure incresse, according to torque, is performed by the regulator valve using stator torque reaction. The

stator shaft is splined to the stator and its arm end contacts the regulator spring cap. When the vehicle is accelerating or

climbing (Torque Converter Range), stator torque reaction acts on the stator shaft and the stator shaft arm pushes the reg-

ulator spring c8p in the direction of the srrow in proportion to the reaction. The spring compresses and the regulator valve

moves to incrsase the regulated conlrol pressure or line pressure. Line pressure is maximum when the stator reaction is

maximum.

TOR VALVE

{cont'dl

From ATF PUMP

I

STATOB SHAFTSTATOR SHAFT ARM

14-25

Page 446 of 1681

I

I

I

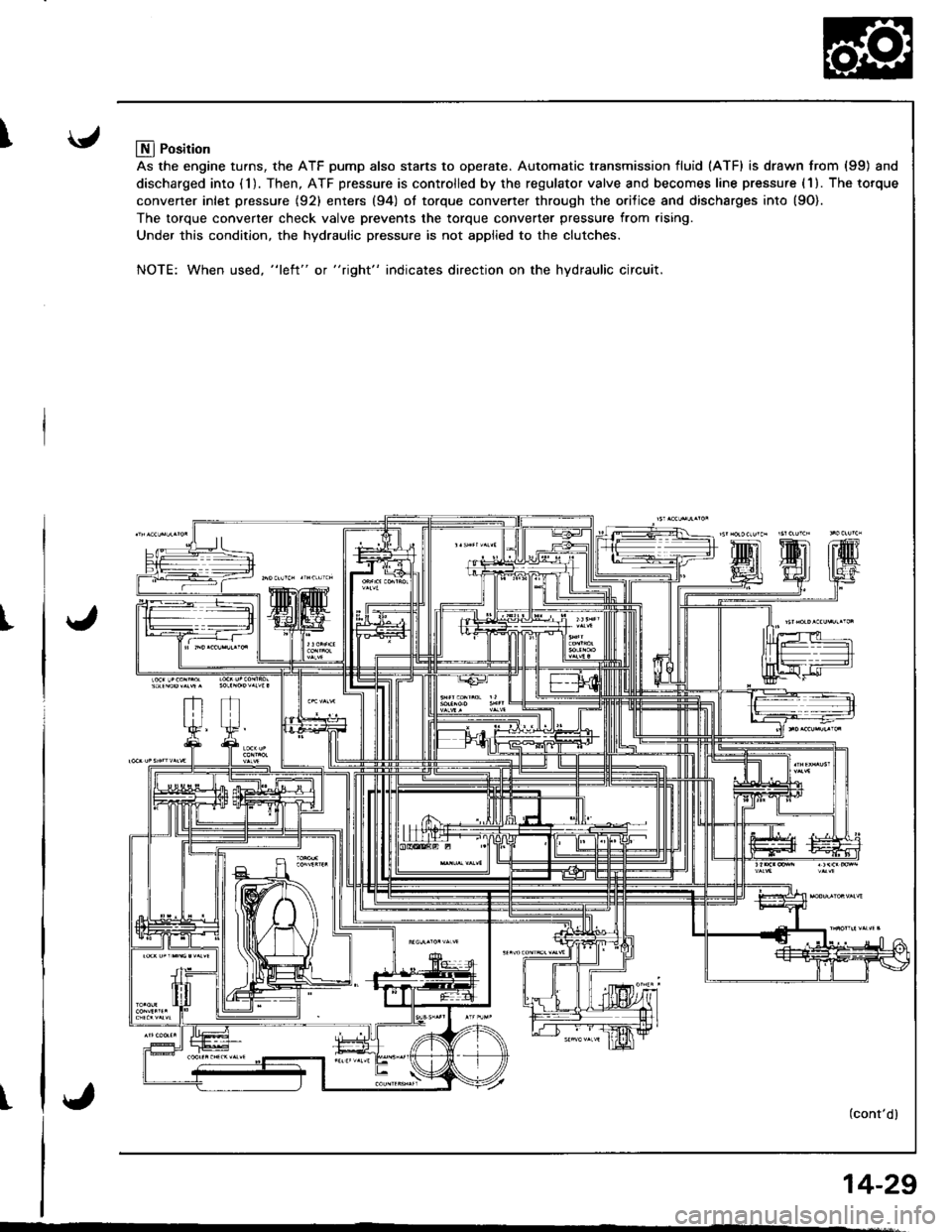

Llfl Position

As the engine turns, the ATF pump also starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and

discharged into (1). Then, ATF pressure is controlled by the regulator valve and becomes line pressure (1). The torque

converter inlet pressure {92} enters (94) ol torque converter through the orilice and discharges into {9O).

The torque converter check valve prevents the torque converter pressure from rising.

Under this condition, the hydraulic pressure is not applied to the clutches.

NOTE: When used, "l€ft" or "right" indicates direction on the hydraulic circuit.

(cont'dl

14-29

Page 449 of 1681

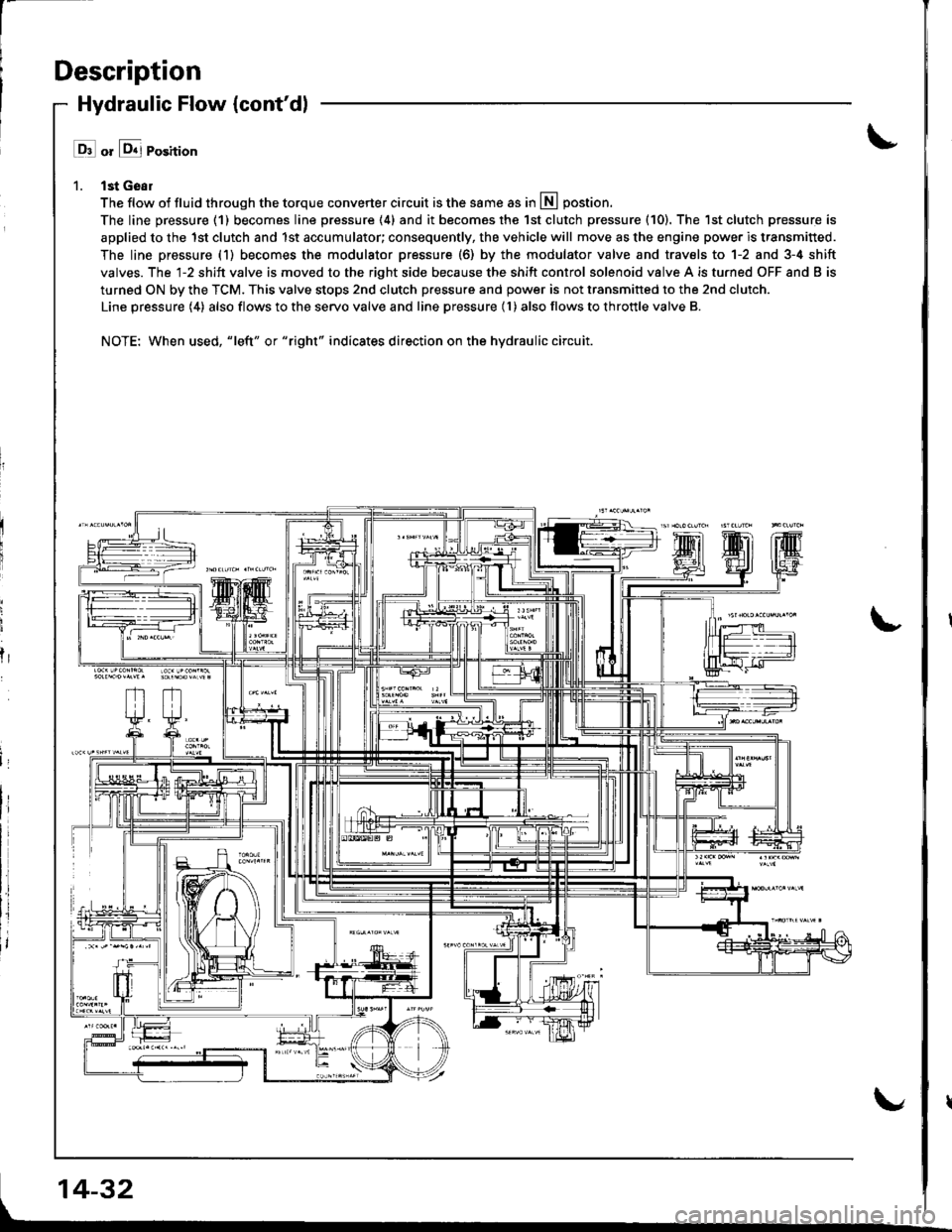

Description

Hydraulic Flow {cont'dl

l ll or &j Position

1. lst Geal

The flow of fluid through the torque converter circuit is the same as in lll postion.

The line pressure (1) becomes line pressure (4) and it becomes the 1st clutch pressure (10). The 1st clutch pressure is

applied to the 1st clutch and 1st accumulator; consequently, the vehicle will move as the engine power is transmitted.

The line pressure (1) becomes the modulator pressure (6) by the modulator valve and travels to 1-2 and 3-4 shift

valves. The l-2 shift valve is moved to the right side because the shift control solenoid valve A is turned OFF and B is

turned ON by the TCM. This valve stops 2nd clutch pressure and power is not transmitted to the 2nd clutch.

Line pressure (4) also flows to the servo valve and line pressure (l ) also flows to throttle valve B.

NOTE: When used, "|eft" or "right" indicates direction on the hydraulic circuit.

fr

14-32

Page 455 of 1681

Description

Lock-up System

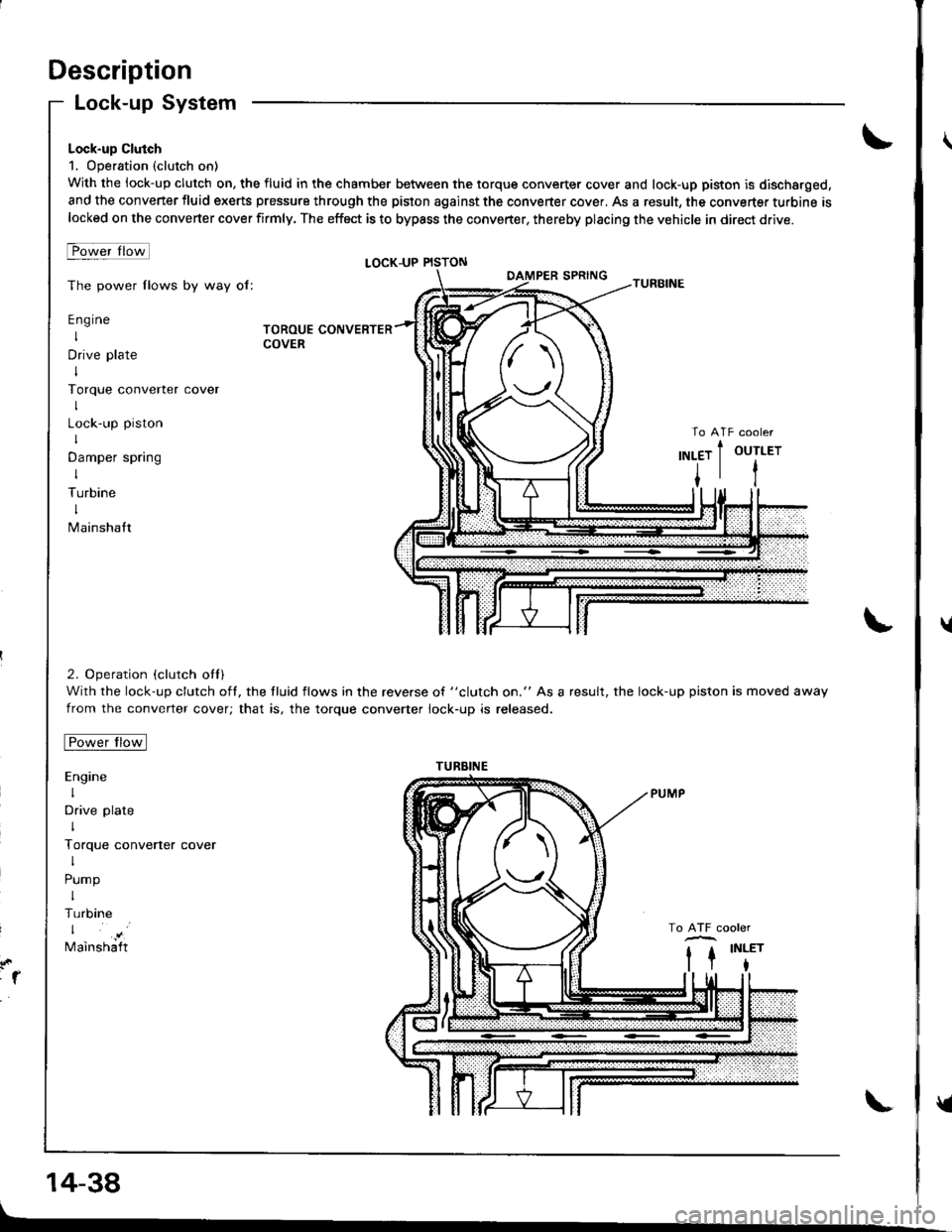

Lock-up Clutch

1. Operation (clutch on)

With the lock-up clutch on, the fluid in the chamber between the torque converter cover and lock-up piston is discharged,

and the converter fluid exerts pressure through the piston against the converter cover, As a result, the converter turbine islocked on the converter cover firmly. The effoct is to bypass the converter, thereby placing the vehicle in direct drive.

t-owerlrotl

The power flows by way of:

Engine

I

Drive plate

I

Torque converter

I

Lock-up piston

I

Damper spring

I

Turbine

I

Mainshatt

2. Operation (clutch otl)

With the lock-up clutch oft, the tluid flows in the reverse of "clutch on." As a result, the lock-up piston is moved away

from the converter cover; that is, the torque converter lock-up is released.

tro-wt rrotl

Engine

I

Drive plate

I

Torque converter cover

I

Pump

I

Turbine

Mainshaft

LOCK-UP PISTON

TOROUE CONVERTERCOVER

:1

14-38

TURBINE

tl

u

v

Page 456 of 1681

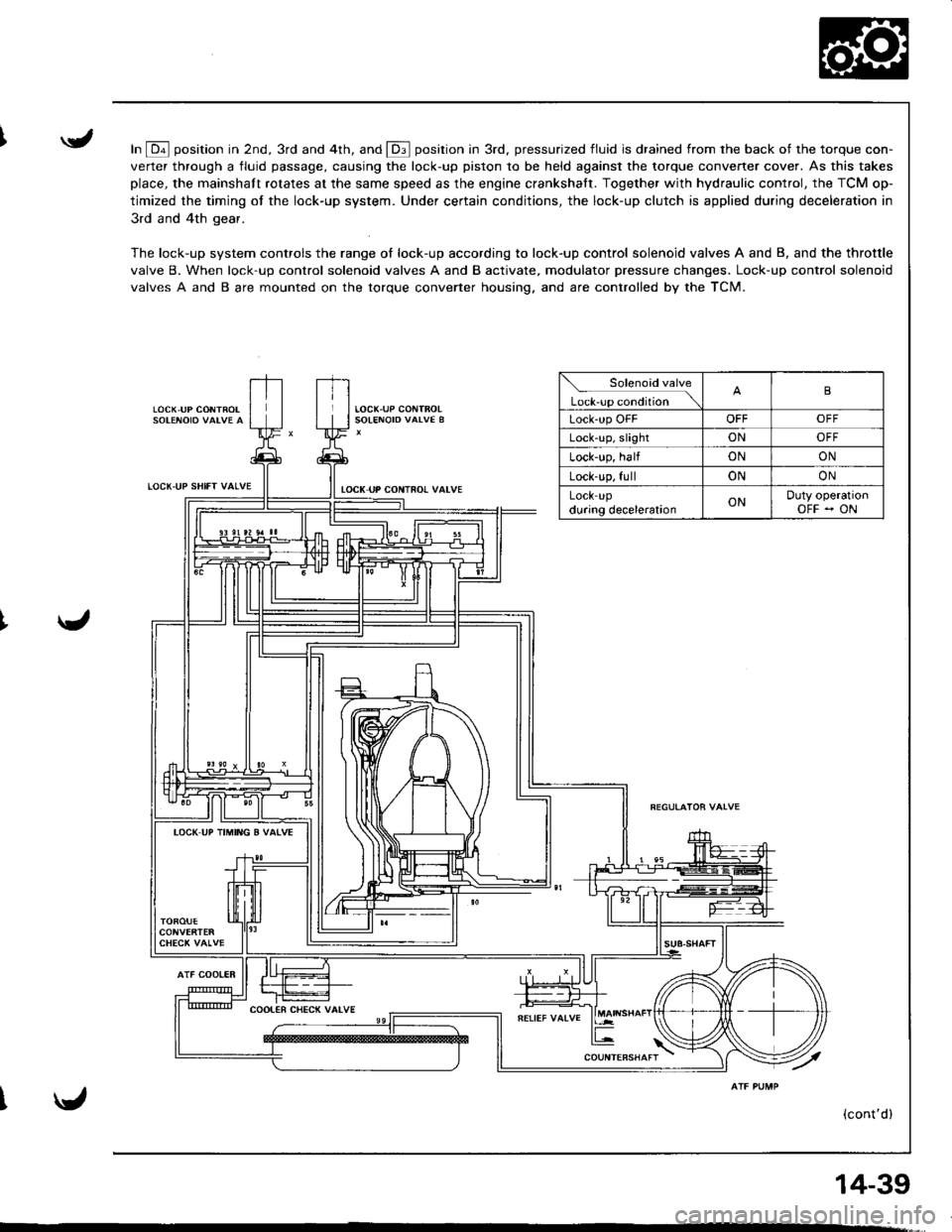

In E position in 2nd, 3rd and 4th, and E position in 3rd, pressurized fluid is drained from rhe back of the torque con-

verter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes

place, the mainshaft rotates at the same speed as the engine crankshatt. Together with hydraulic control, the TCM op-

timized the timing of the lock-up system. Under certain conditions, the lock-up clutch is applied during deceleration in

3rd and 4th gear.

The lock-up system controls the range of lock-up according to lock-up control solenoid valves A and B, and the throttle

valve B. When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid

valves A and B are mounted on the torque converter housing. and are controlled by the TCM.

LOCK,UP CONTROL

LOCT.UP SHIfT VALVE

AlF COOIER

tocK uP coNTno! valvE

Solenoid valve

L*r""r "o.Jtio" \B

Lock'up OFFOFFOFF

Lock-up, slightONOFF

Lock-up, halfONON

Lock-up, fullONON

LOCK-Updu.ing decelerationONDuty operationOFF - ON

IOCK UP TIMING B VATVE

(cont'd)

14-39