ignition HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1200 of 1681

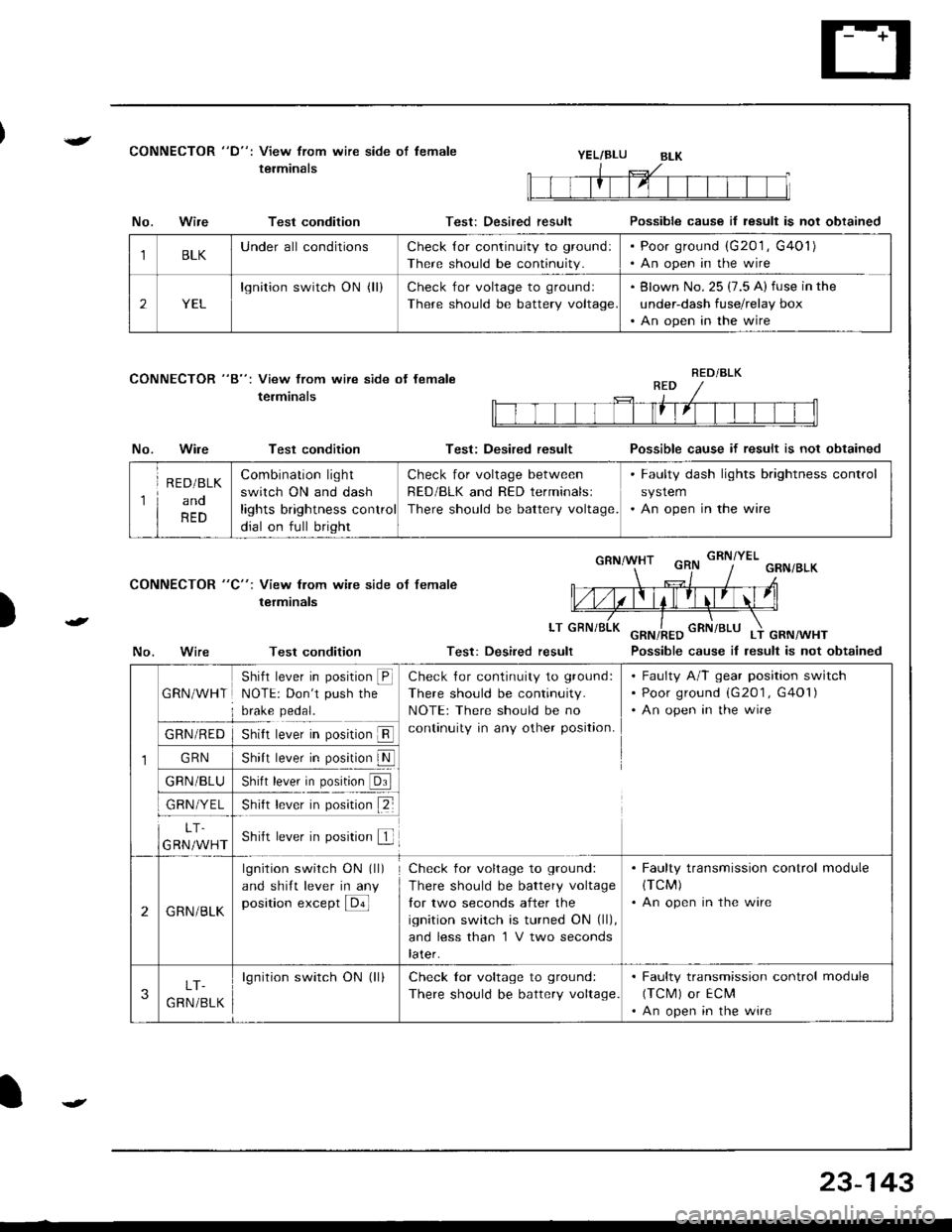

{CONNECTOR "D": View from wire side of lemale

terminalsYEL/BLU

CONNECTOR "8": View from wire side ot female

terminals

No.Wire

No.Wire

Test condition

Test condition

Test condition

Test: Desired result

Test: Desired result

Possible cause il result is not obtained

Possible cause if result is not obtained

Possible cause iI lesult is not obtained

)

CONNECTOR "C": View from wile side ot female

terminals

LT

No.Test: Desired result

1BLKUnderall conditionsCheck {or continuity to ground:

There should be continuity.

Poor ground (G201 , G401)

An open in the wire

2YEL

lgnition switch ON (ll)Check for voltage to groundl

There should be battery voltage

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box

An open in the wire

RED/BLK

1

R E D/BLK

ano

RED

Combination light

switch ON and dash

lights brightness control

dial on full bright

Check for voltage between

RED/BLK and RED terminalsl

There should be battery voltage.

. Faulty dash lights brightness control

system. An open in the wire

1

GRN/WHT

Shifl lever in position @NOTE: Don't push the

brake pedal.

Check {or continuity to ground:

There should be continuity.

NOTE: There should be no

continuity in any other position.

Faulty A/T gear position switch

Poor ground (G201 , G401)

An open in the wire

GRN/RED

GRN

GRN/BLU

GRN/YEL

5nrrI rever In pos[ron ll

shl, b*|' il. p"1,!lN

)nrn rever In posrron url

snt r""-. r p*;ir" tZ-

LT.

GRN/WHTShift lever in position f

2GRN/BLK

lgnition switch ON (ll)

and shift lever in any

position except E

Check for voltage to ground:

There should be battery voltage

lor two seconds after the

ignition switch is turned ON (ll),

and less than 'l V two seconds

later.

. Faulty transmission control module(TCM)

. An open in the wire

3LT-

G RN /BLK

lgnition switch ON (ll)Check lor voltage to ground:

There should be battery voltage.

. Faulty transmission control module

(TCM) or ECM'An open in the wire

23-143

Page 1203 of 1681

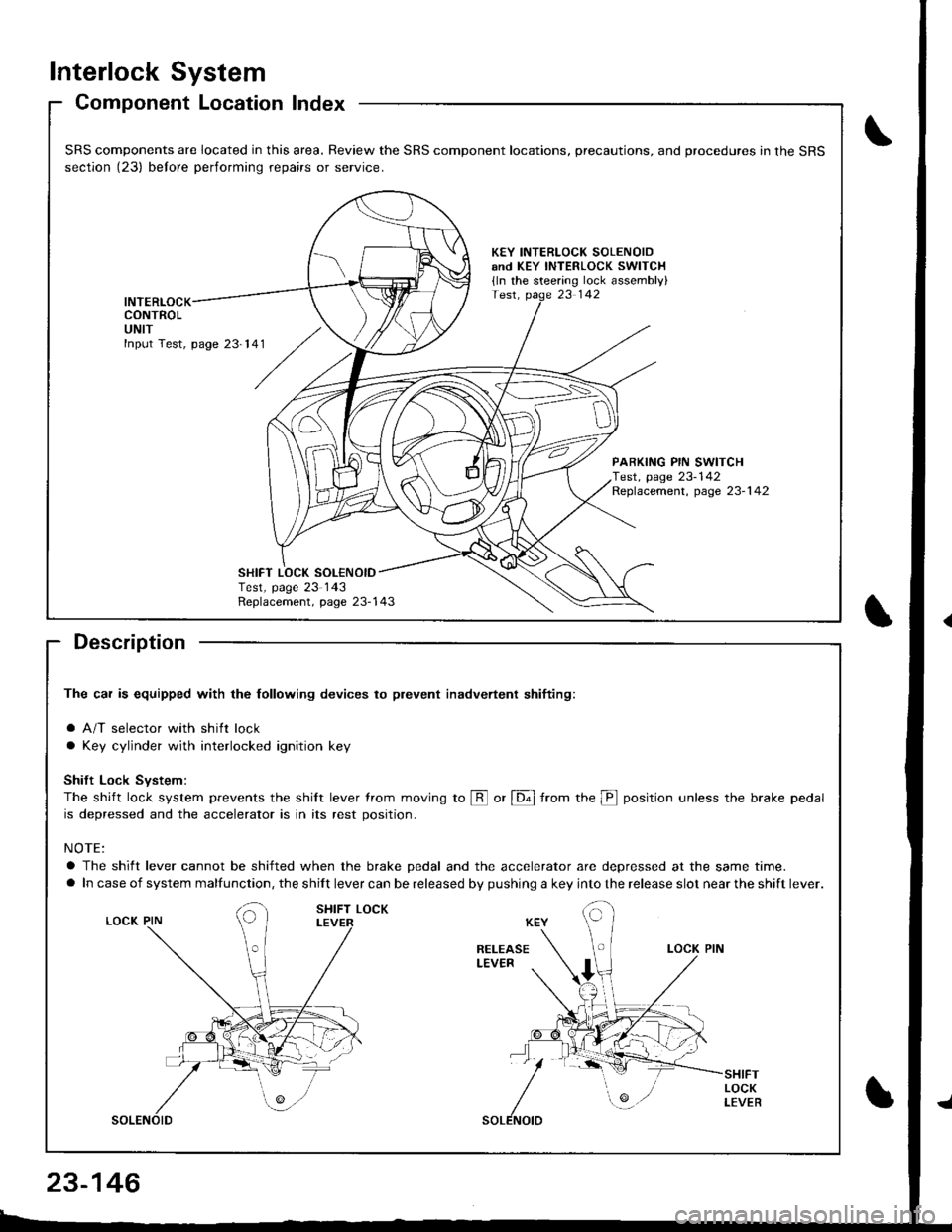

Interlock System

Component Location Index

Description

The car is equipped with the lollowing devices to plevent inadvertent shifiing:

a A/T selector with shift lock

a Key cylinder with interlocked ignition key

Shift Lock Svstem:

The shift lock system prevents the shilt lever trom moving to @ or [6ol from the p position unless the brake pedal

is depressed and the accelerator is in its rest position.

NOTE:

a The shift lever cannot be shifted when the brake pedal and the accelerator are depressed at the same time.

a In case of system malfunction, the shift lever can be released by pushing a key into the release slot near the shift lever.

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (23) belore performing repairs or service.

KEY INTERLOCK SOLENOIDand KEY INTERLOCK swlTCH

{ln the steering lock assembly}

INTERLOCKCONTROLUNIT

PARKING PIN SWITCHTest, page 23-142Replacement, page 23-1 42

Replacement, page 23-143

SHIFT LOCK SOL€NOIDTest, page 23 143

23-146

Page 1204 of 1681

)

t

t

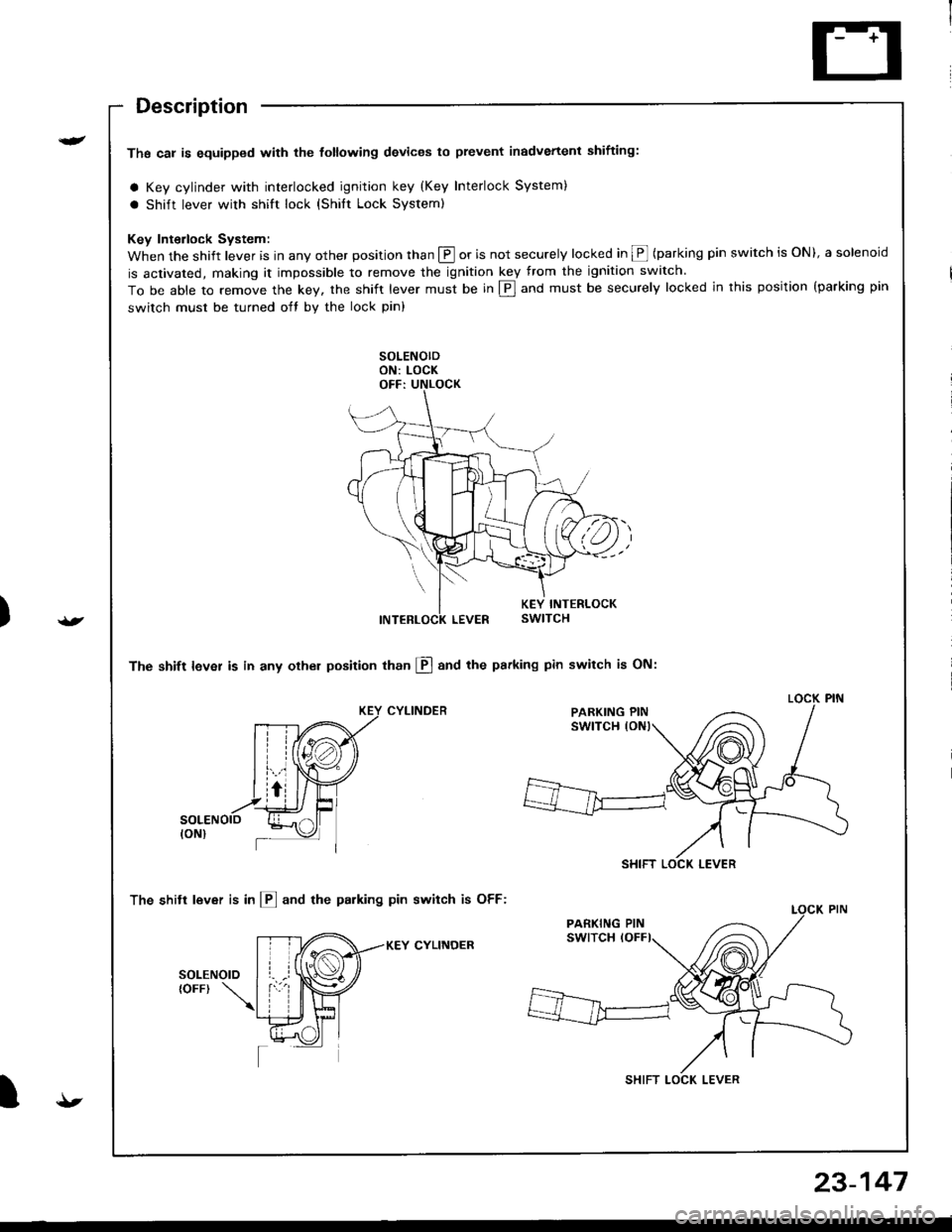

Description

Ths cal is equipped with the tottowing devices to prevent inadvertenl shifting:

a Key cylinder with interlocked ignition key (Key Interlock System)

a shift lever with shift lock (shilt Lock system)

Key Interlock System:

When the shift lever is in any other position than @ or is not securely locked in @ (parking pin switch is ON), a solenoid

is activated, making it impossible to remove the ignition key from the ignition switch.

To be able to remove the key, the shift lever must be in E] and must be securely locked in this position {parking pin

switch must be turned oft by the lock pin)

The shift lever is in any othel position than El and the psrking pin switch is ON:

CYLINDER

The shitt lever is in l!] and the parking pin switch is OFF:

KEY CYLINOER

PARKING PIN

SHIFT LOCK LEVER

SHIFT LOCK LEVER

{t

23-147

Page 1213 of 1681

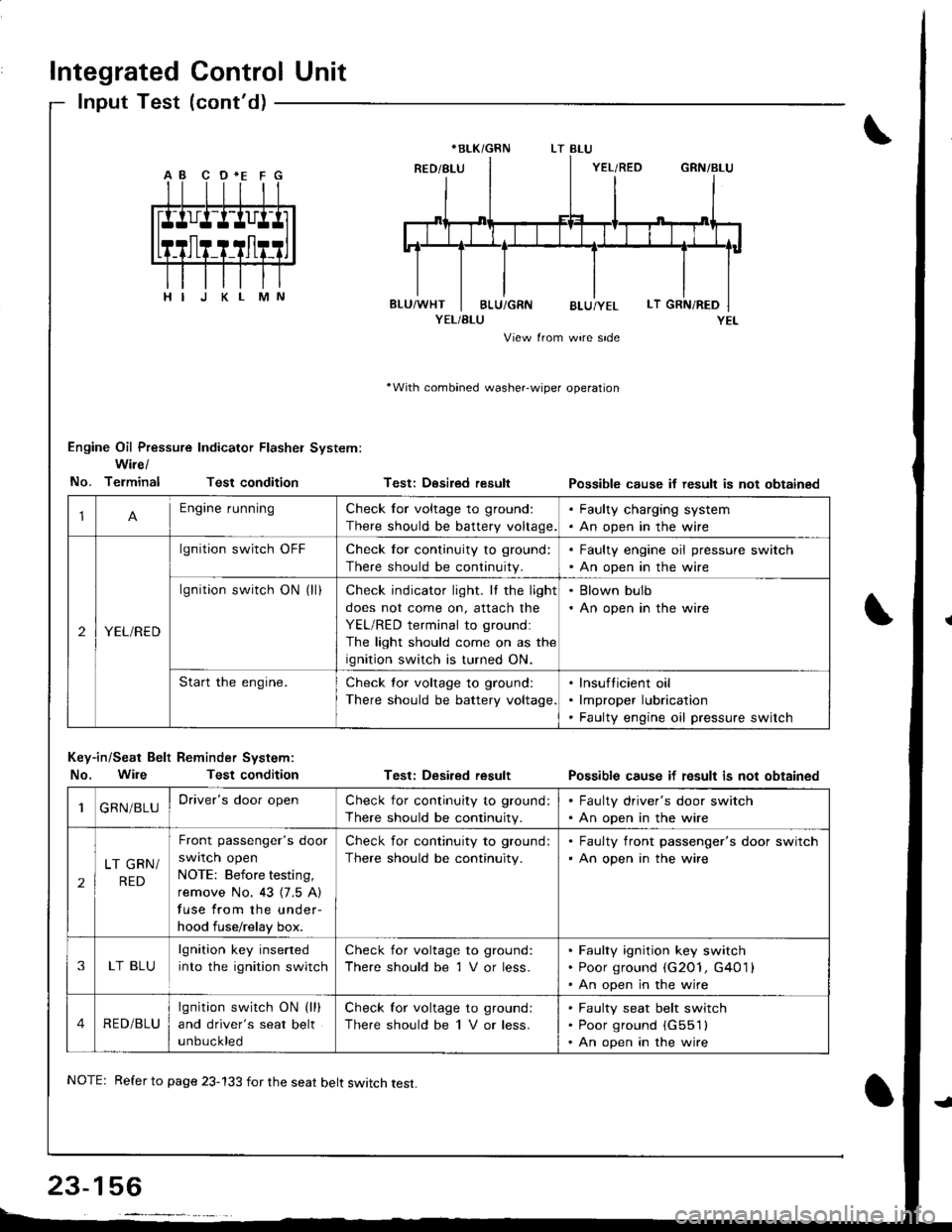

Integrated Control Unit

lnput Test (cont'd)

YEL/BLU

View from wire side

'With combined washer-wiper operation

Engine Oil Pressure Indicator Flasher System:

Wire/

No. TerminalTest condition

Key-in/Seat Belt Reminder System:

No. WileTest condition

Testi Desired result

Test: Desired result

Possible cause if result is not obtainsd

Possible cause if fesult is not obtained

*BLK/GRN

1Engine runningCheck for voltage to ground:

There should be battery voltage.

. Faulty charging system. An open in the wire

2YEL/RED

lgnition switch OFFCheck for continuity to ground:

There should be continuity.

. Faulty engine oil pressure switch. An open in the wire

lgnition switch ON (ll)Check indicator light. It the light

does not come on, attach the

YEL/RED terminal to groundl

The light should come on as the

ignition switch is turned ON.

. Blown bulb. An open in the wire

Start the engine.Check tor voltage to ground:

There should be battery voltage

lnsufticient oil

lmproper lubrication

Faulty engine oil pressure switch

1GRN/BLUDriver's door openCheck for continuity to ground:

There should be continuity.

. Faulty driver's door switch. An open in the wire

2

LT GRN/

RED

Front passenger's door

swrlcn open

NOTE: Before testing,

remove No. 43 {7.5 A)

fuse from the under-

hood fuse/relay box.

Check for continuity to ground:

There should be continuity.

. Faulty front passenger's door switch'An open in the wire

3LT BLU

lgnition key inserted

into the ignition switch

Check for voltage to ground:

There should be 1 V or less.

Faulty ignition key switch

Poor ground (G2O1, G401 l

An open in the wire

4RED/BLU

lgnition switch ON (lll

and driver's seat belt

unbuckled

Check for voltage to ground:

There should be 1 V or less.

Faulty seat belt switch

Poor ground (G551l

An open in the wire

NOTE: Refer to page 23-133 for the seat belt switch test.

Page 1215 of 1681

Key-in ReminderSystem

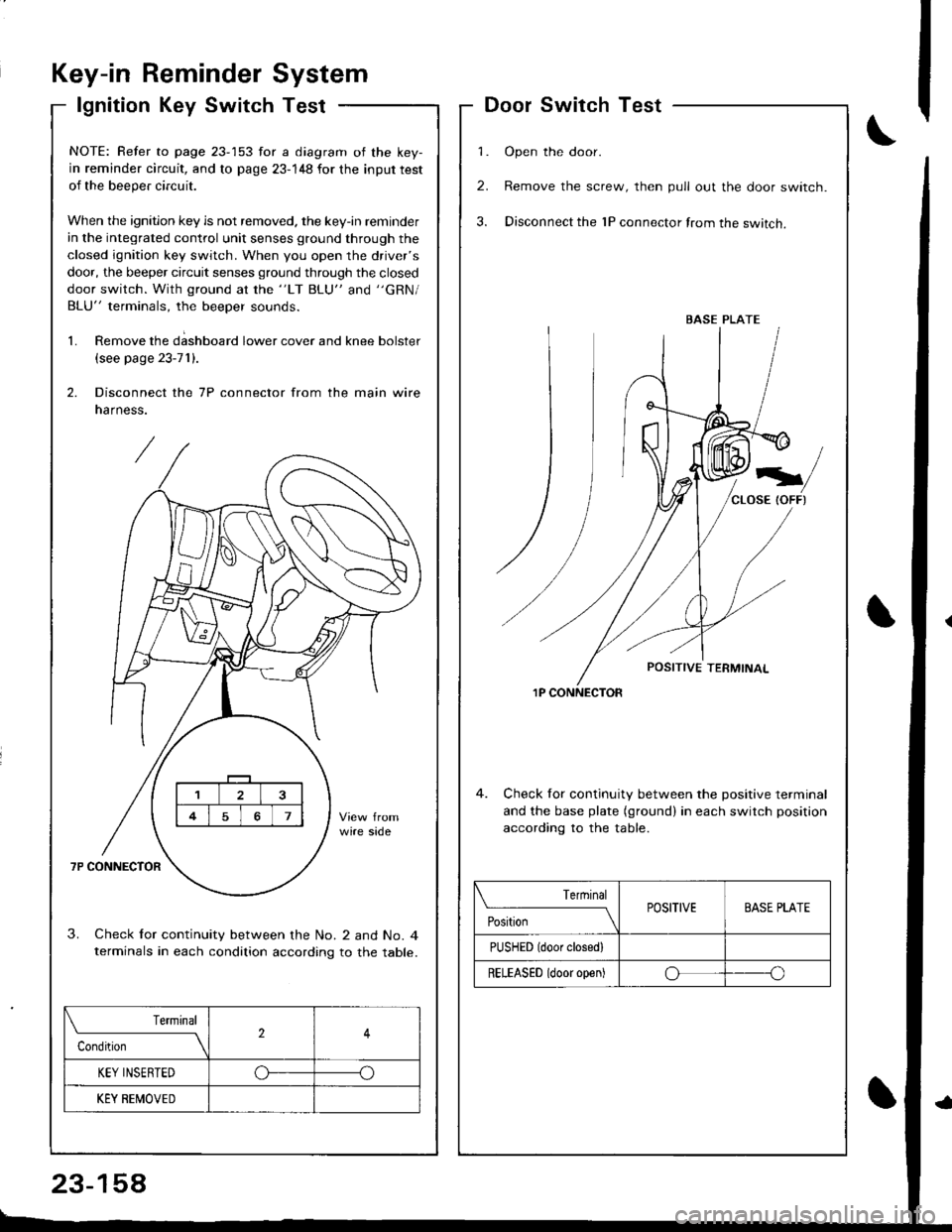

lgnition Key SwitchTest

\f

DoorSwitchTest

1. Open the door.

2. Remove the screw, then pull out the door switch.

3. Disconnect the 1P connector from the switch.

1P CONNECTOR

4. Check for continuity between the positive terminal

and the base plate (ground) in each switch position

accordinq to the table.

BASE PLATE

Terrninal

PositionPOSITIVEBASE PLATE

PUSHED (door closedl

RELEASED (door open)oo

NOTE: Refer to page 23-153 for a diagram of the key-

in reminder circuit, and to page 23-148 for the input test

of the beeper circuit.

When the ignition key is not removed. the key-in reminder

in the integrated control unit senses ground through the

closed ignition key switch. When you open the driver's

door, the beeper circuit senses ground through the closed

door switch. With ground at the "LT BLU" and "GRN/

BLU" terminals, the beeper sounds.

1. Remove the d;shboard lower cover and knee bolster

(see page 23-71).

2. Disconnect the 7P connector from the main wire

narness.

3. Check lor continuity between the No. 2 and No. 4terminals in each condition according to the table.

Terminal

Condition2

KEY INSERTEDo--o

KEY BEMOVED

23-158

Page 1222 of 1681

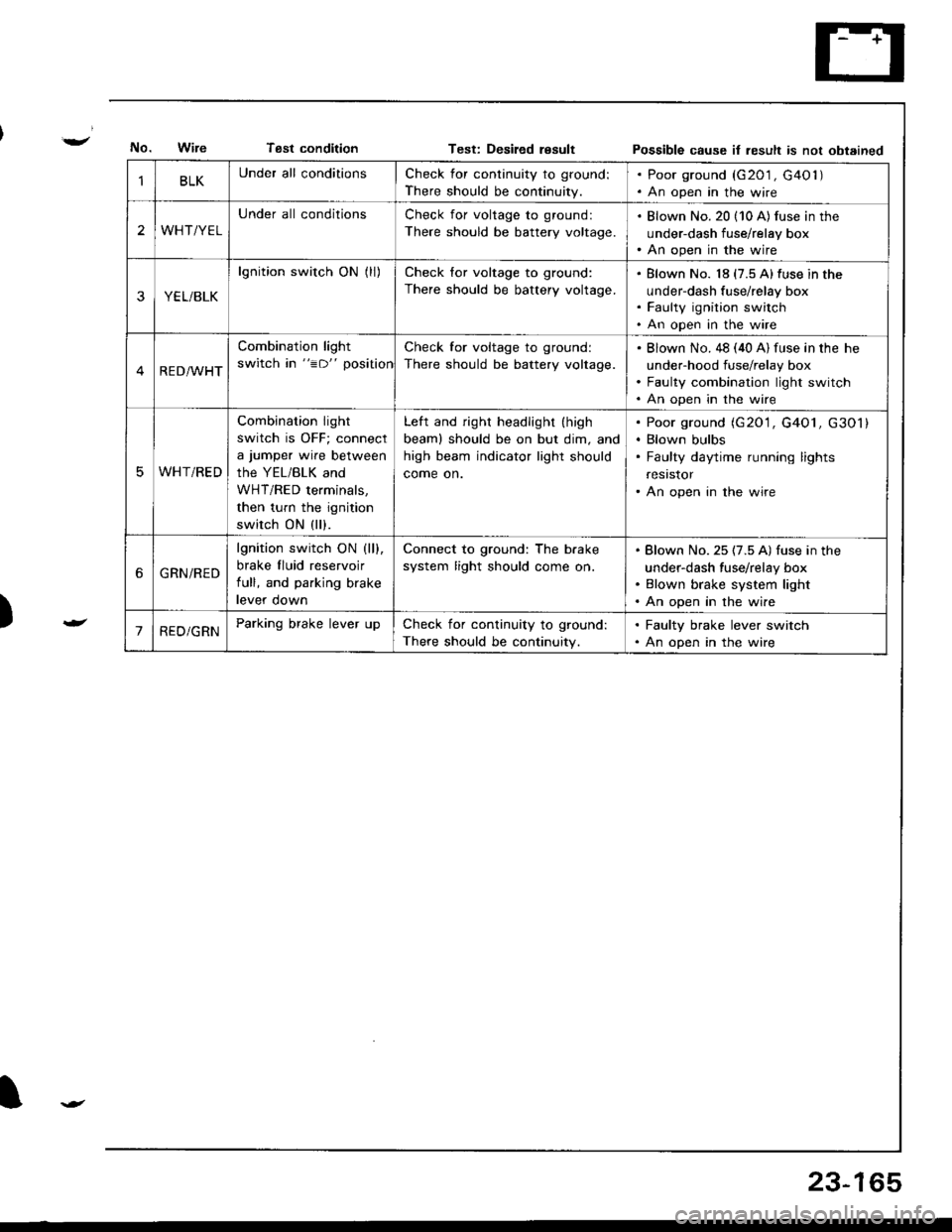

Tsst conditionTest: Desiled resultPossible cause it result is not obtained

)

BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G201 , G40l ). An open in the wire

2WHT/YEL

Under all conditionsCheck for voltage to ground:

There should be battery voltage.

. Blown No. 20 (10 A) fus€ in the

under-dash fuse/relay box. An open in the wire

YEL/BLK

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

Blown No. 18 (7.5 A)fuse in the

under-dash fuse/relay box

Faulty ignition switch

An open in the wire

RED/WHT

Combination light

switch in "=D" position

Check for voltage to ground:

There should be battery voltage.

Blown No. 48 (40 A) fuse in the he

under-hood fuse/relay box

Faulty combination light switch

An open in the wire

WHT/RED

Combination light

switch is OFF; connect

a jumper wire between

the YEL/BLK and

WHT/RED terminals,

then turn the ignition

switch ON (ll).

Left and right headlight (high

beaml should be on but dim, and

high beam indicator light should

come on.

Poor ground (G20'1, G4O1, G301)

Blown bulbs

Faulty daytime running lights

resrstor

An open in the wire

6GRN/RED

lgnition switch ON (ll).

brake fluid reservoir

full, and parking brake

levef oown

Connect to ground: The b.ake

system light should come on.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box

Blown brake system light

An open in the wire

'1RED/GRNParking brake lever upCheck for continuity to ground:

There should be continuity.

. Faulty brake lever switch. An open in the wire

23-165

Page 1244 of 1681

![HONDA INTEGRA 1998 4.G Workshop Manual Back-up Lights

Circuit Diagram

IGNITIONswlTcHUNOER.HOOD FUSEi RELAY BOX

EACK.UPLIGHTswtTcH/ / on lhe \r I ransnBgon I

GRN/BLK

IIJ

TRAILERL]GHT NGCONNECTOR

GRN/BLK

IzA arcx.upI P LIGHTS

f

r:zce21

I HONDA INTEGRA 1998 4.G Workshop Manual Back-up Lights

Circuit Diagram

IGNITIONswlTcHUNOER.HOOD FUSEi RELAY BOX

EACK.UPLIGHTswtTcH/ / on lhe \r I ransnBgon I

GRN/BLK

IIJ

TRAILERL]GHT NGCONNECTOR

GRN/BLK

IzA arcx.upI P LIGHTS

f

r:zce21

I](/img/13/6069/w960_6069-1243.png)

Back-up Lights

Circuit Diagram

IGNITIONswlTcHUNOER.HOOD FUSEi RELAY BOX

EACK.UPLIGHTswtTcH/ / on lhe \r I ransnBgon I

GRN/BLK

IIJ

TRAILERL]GHT NGCONNECTOR

GRN/BLK

IzA arcx.upI P ' LIGHTS

f

r:zce'21

IBLK

II

I

G503

YEL

I

SnoriARr*r.r r*i(3;f;iil're' )V(oN h posirion [E )

l"

IGRN/BLK

23-147

)

I

Page 1245 of 1681

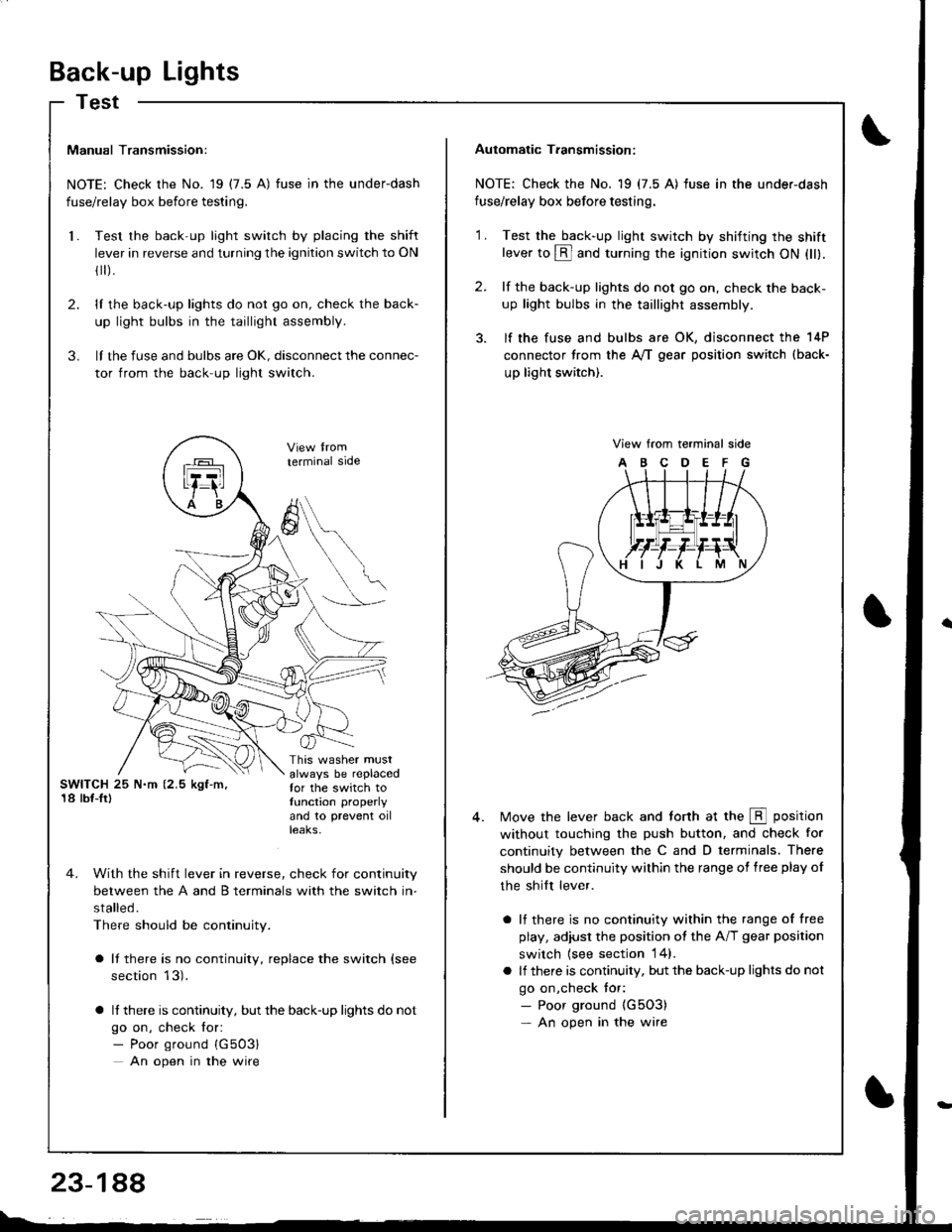

Back-up Lights

Test

Manual Transmission:

NOTE: Check the No. 19 (7.5 A) fuse in the underdash

fuse/relay box before testing.

Test the back-up light switch by placing the shift

lever in reverse and turning the ignition switch to ON

fl r).

lI the back-up lights do not go on, check the back-

up light bulbs in the taillight assembly.

lI the fuse and bulbs are oK, disconnect the connec-

tor from the back-up light switch.

2.

3.

l.

SWITCH 25 N.m (2.5 kgf-m,'18 lbf-Ir)

This washer mustalways be replacedfor the switch totunction properly

and 10 prevent oilteaKs,

terminal side

4. With the shift lever in reverse, check for continuity

between the A and B terminals with the switch in-

stalled.

There should be continuity.

a It there is no continuity, replace the switch (see

section 13).

a lf there is continuity, but the back-up lights do not

go on, check for:- Poor ground {G503}

An open in the wire

A

6

Automatic T.ansmission:

NOTE: Check the No. 19 (7.5 A) fuse in the under-dash

fuse/relay box before testing.

2.

'1 .Test the back-up light swirch by shifting the shiftlever to @ and turning the ignition switch ON (ll).

lf the back-up lights do not go on, check the back-

up light bulbs in the taillight assembly.

lf the fuse and bulbs are OK, disconnect the 14P

connector from the A,/T gear position switch (back-

up light switch).

View from terminal side

ABCDEFG

Move the lever back and torth at the E position

without touching the push button, and check for

continuity between the C and D terminals. There

should be continuity within the range of free play of

the shilt lever.

a lf there is no continuity within the range of free

play, adiusl the position ot the A/T gear position

switch {see section 14}.

a lf there is continuity, but the back-up lights do not

go on,check tor:- Poor ground {G5O3)- An open in the wire

Page 1259 of 1681

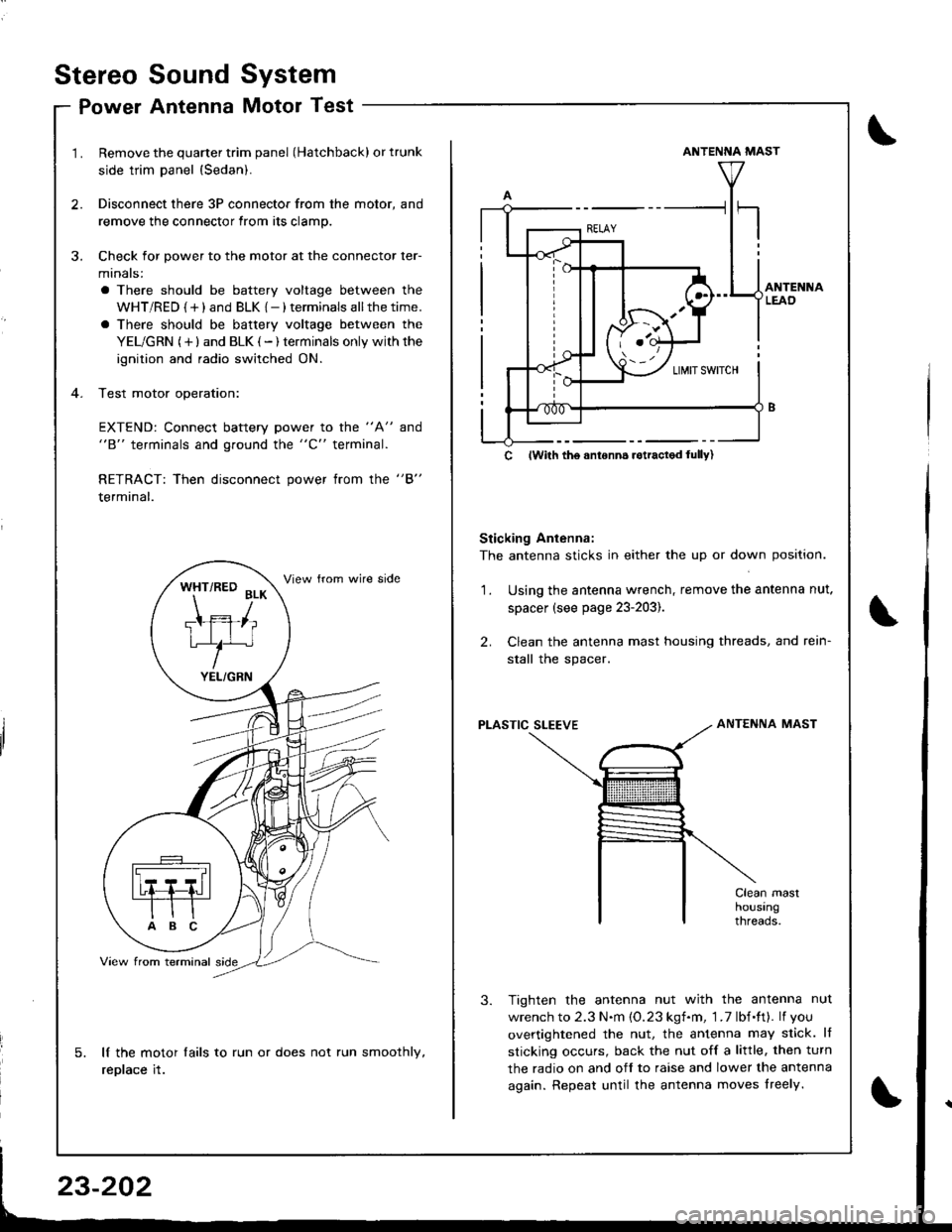

3.

1.

wel

Remove the quarter trim panel (Hatchback) or trunk

side trim panel {Sedan).

Disconnect there 3P connector from the motor, and

remove the connector from its clamp.

Check for power to the motor at the connector ler-

minals:

a There should be battery voltage between the

WHT/RED {+) and BLK {-) terminals allthetime.

a There should be battery voltage between the

YEL/GRN (+) and BLK (-) terminals only withthe

ignition and radio switched ON.

Test motor operation:

EXTEND: Connect battery power to the "A" and"B" terminals and ground the "C" terminal.

RETRACT: Then disconnect power from the "B"

terminal.

lf the motor lails to run or does not run smoothly,

replace it.

WHT/RED BLK

Ttffiliu/^

YEL/GRN

ANTENNA MAST

Sticking Antenna:

The antenna sticks in either the up or down position.

Using the antenna wrench, remove the antenna nut.

spacer (see page 23-203).

Clean the antenna mast housing threads, and rein-

stall the spacer.

2.

1.

PLASTIC SLEEVEANTENNA MAST

Tighten the antenna nut with the antenna nut

wrench to 2.3 N.m {O.23 kgf.m, 1 .7 lbf.ft}. lf you

overtightened the nut, the antenna may slick. lf

sticking occurs, back the nut off a little, then turn

the radio on and off to raise and lower the antenna

again. Repeat until the antenna moves lreely.

c lwith tho anronn6 rotractod lully)

Stereo

Po

Sound

Antenna

System

Motor Test

\

Page 1267 of 1681

Horn

Switch Test (cont'd)

Remove the driver's airbag assembly (refer to the

SRS sub-section in section 23).

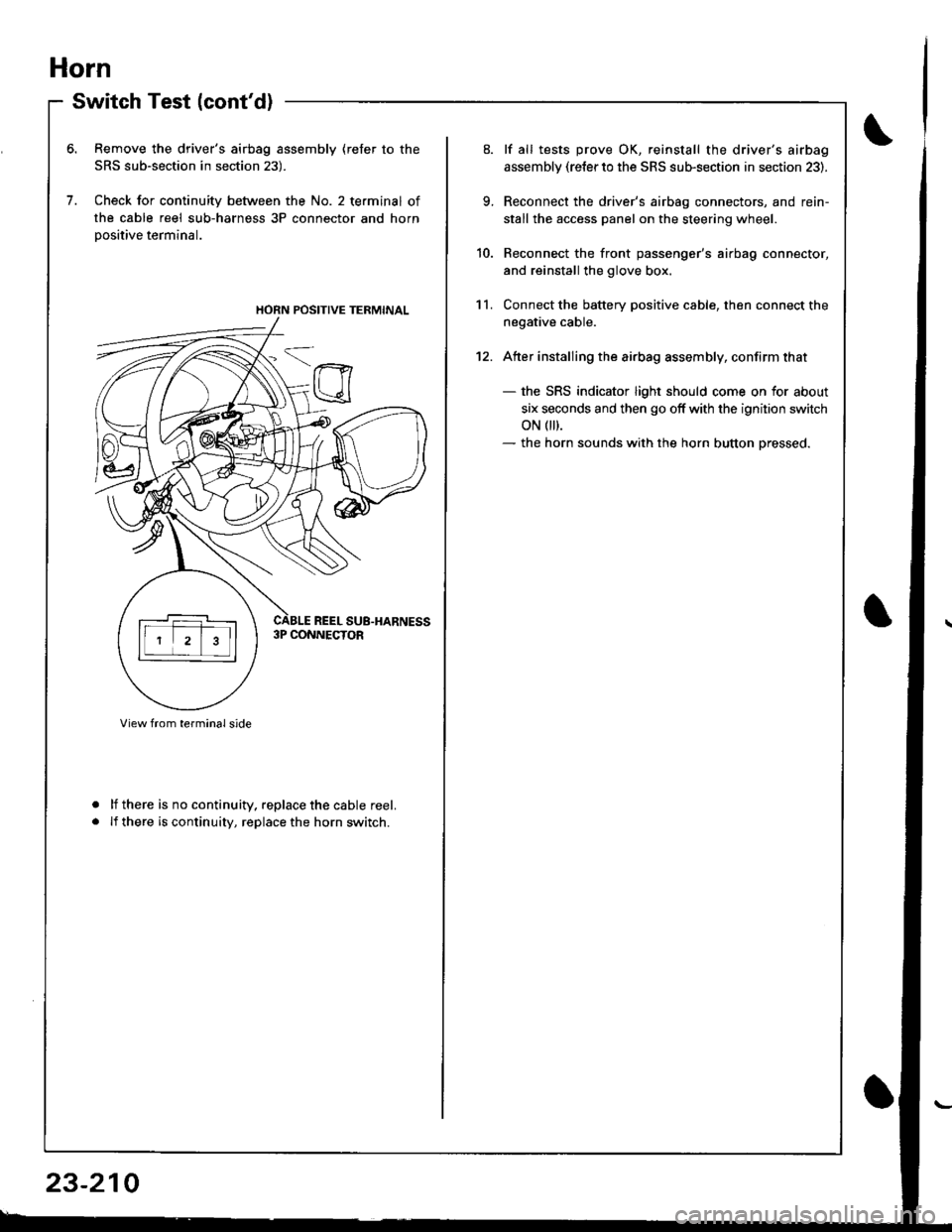

Check for continuity between the No. 2 terminal of

the cable reel sub-harness 3P connector and horn

Dositive terminal.

lf there is no continuity. replace the cable reel.

lf there is continuity, replace the horn switch.

a

a

HORN POSITIVE TERMINAL

23-210

9.

10.

11.

12.

lf all tests prove OK, reinstall the driver's airbag

assembly (re{er to the SRS sub-section in section 23).

Reconnect the driver's airbag connectors, and rein-

stall the access panel on the steering wheel.

Reconnect the front passenger's airbag connector,

and reinstall the glove box.

Connect the battery positive cable, then connect the

negative cable.

Atter installing the airbag assembly, confirm that

- the SRS indicator light should come on for about

six seconds and then go off with the ignition switch

oN 0t).- the horn sounds with the horn button pressed.