engine HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 58 of 1681

Engine Removal/lnstallation

{cont'dl

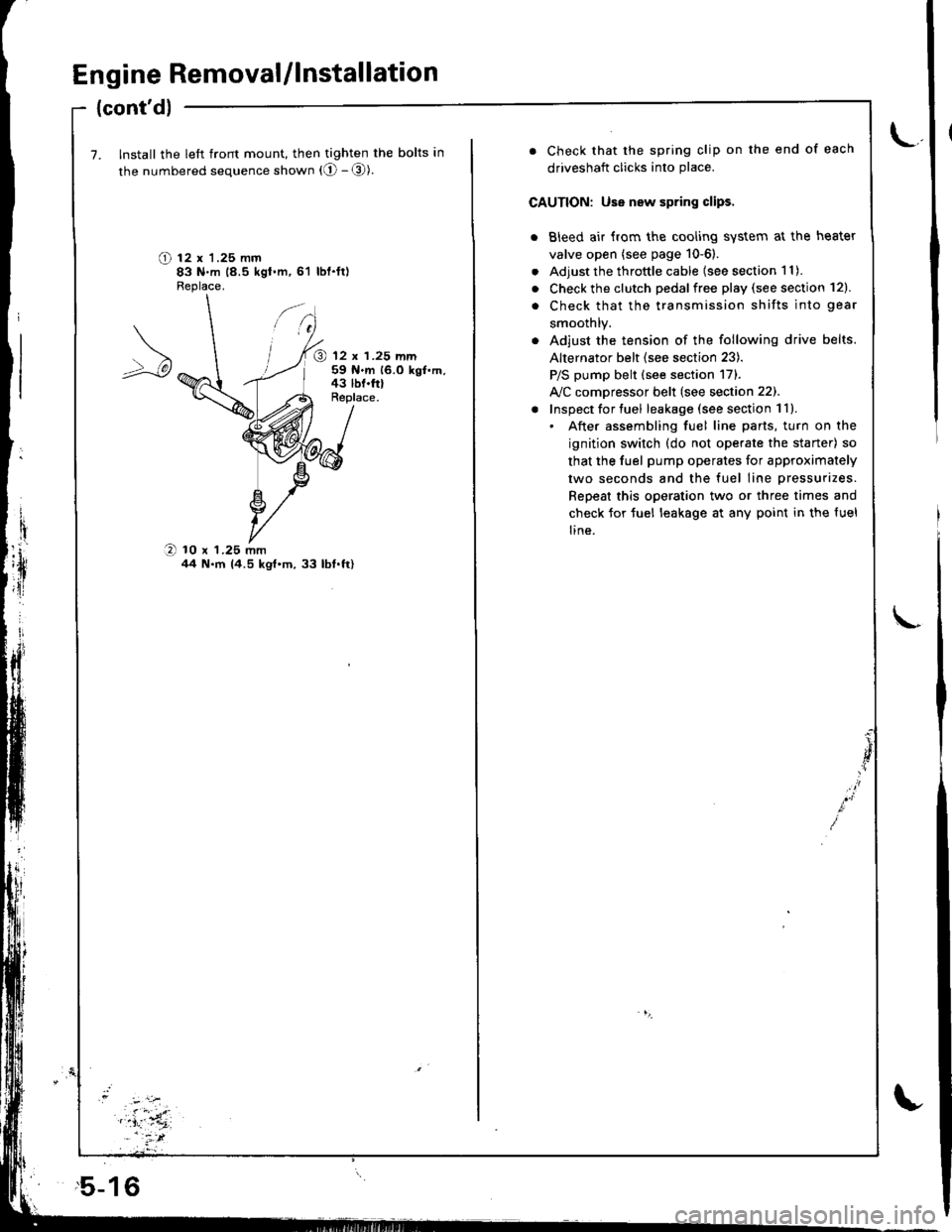

7. Install the left front mount, then tighten the bolts in

the numbered sequence shown (O - @).

O t2 x '1.25 mm83 N.m 18.5 kgt.m,61 lbl.ft)Fleplace.

@ 12 x 1.25 mm59 N.m 16.0 kgf.m,43 lbf.frlReplace.

O 10 x 1.25 mmil4 N.m 14.5 kgt'm,33 lbt.ft)

,5-16

. Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

. Bleed air {rom the cooling system at the heater

valve open (see page 10-6).

. Adjust the throttle cable (see section 1 1).

. Check the clutch pedalfree play (see section 12).

. Check that the transmission shifts into gear

smoothlY.

. Adjust the tension of the following drive belts.

Alternator belt {see section 23).

P/S pump belt (see section 171.

A/C comDressor belt (see section 22).

! Inspect for tuel leakage (see section 1ll.. After assembling fuel line parts, turn on the

ignition switch (do not operate the staner) so

that the fuel pump operates for approximately

two seconds and the fuel line pressurizes.

Repeat this operation two or three times and

check for tuel leakage at any point in the {uel

line.

Page 62 of 1681

I

Mount/Bracket Torque

(cont'dl

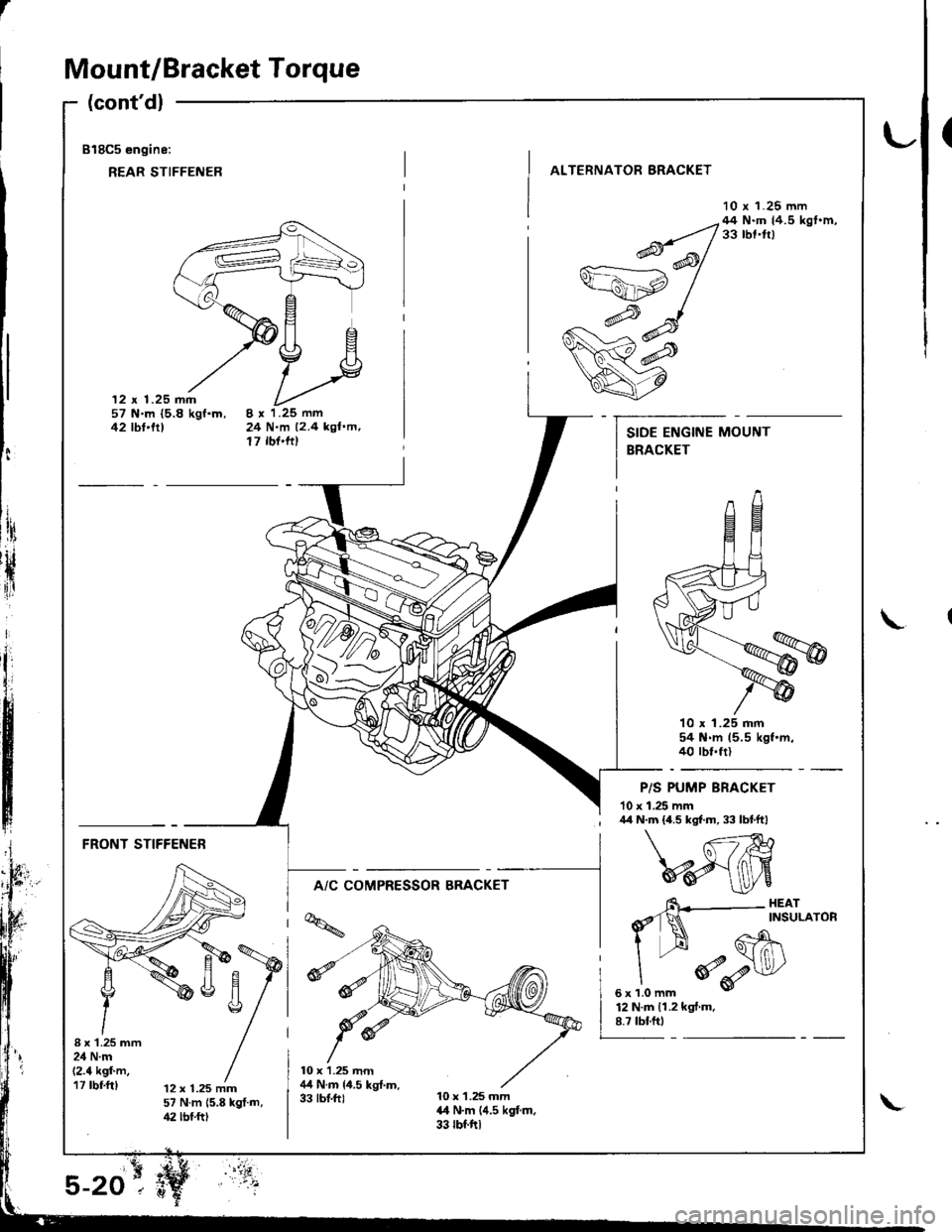

818C5 engine:

REAR STIFFENER

(

ALTERNATOR BRACKET

10 r 1.25 mm

12 x 1.25 mm57 N.m {5.8 kgf.m,42 tbt'trt24 N.m 12.4 kgl.m,17 rbf'ftt

--q;;/44N'mtr.5kst'm'v=ahp /

w#

q7

10 x 1.25 mm54 N.m 15.5 kgf.m.40 rbt.frl

P/S PUMP BRACKET

10 x 1.25 mm

t:

ltri

rH

{ir

I\

; /r/r N.m {4.5 kgf.m, 33 lbtftl

FRONT STIFFENER

A/C COMPRESSOR BRACKET

I x'1.25 mm24 N.m(2.4 kgf'm,17 rbf.ft)12 x 1.25 mm57 N.m 15.8 kgt.m,42 lbf.ftt

6\--- HEAr

d'1N ^rNsuLAroR

I --H Gh\

"

*o-r$l/

sxrlomm v

12 N.m 11.2 kgf.m.8.7 tbf.ftt

Page 70 of 1681

Grankshaft Pulley Bolt

Replacement

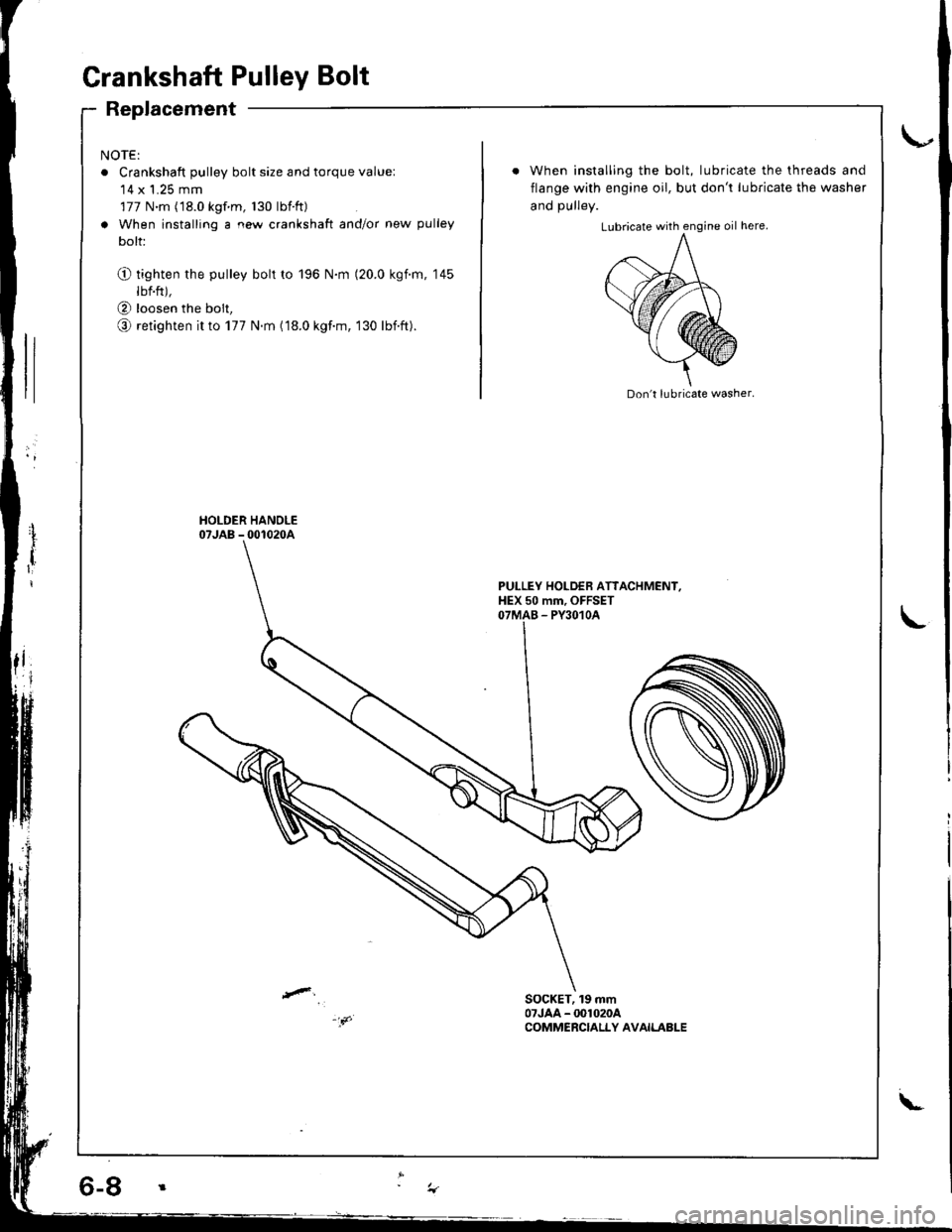

NOTE:

o Crankshaft pulley bolt size and torque value:'14 x 1.25 mm

177 N.m (18.0 kgf m, 130 lbtft)

a When installing a new crankshaft and/or new pulley

bolt:

O tighten the pulley bolt to 196 N.m (20.0 kgim, 145

lbf.ft),

@ loosen the bolt,

o retighten it to 177 N.m (18.0 kgf.m, 130 lbift).

When installing the bolt, lubricate the threads and

flange with engine oil, but don't lubricate the washer

and DUllev.

Don't lubricate washer.

PULLEY HOLDEB ATTACHMENI,HEX 50 mm, OFFSETOTMAB - PY3O1OA

SOCKET, 19 mm07JAA - @1020ACOMMERCIALLY AVAILABLE

\-

Page 78 of 1681

Gylinder Head

lllustrated Index (cont'd)

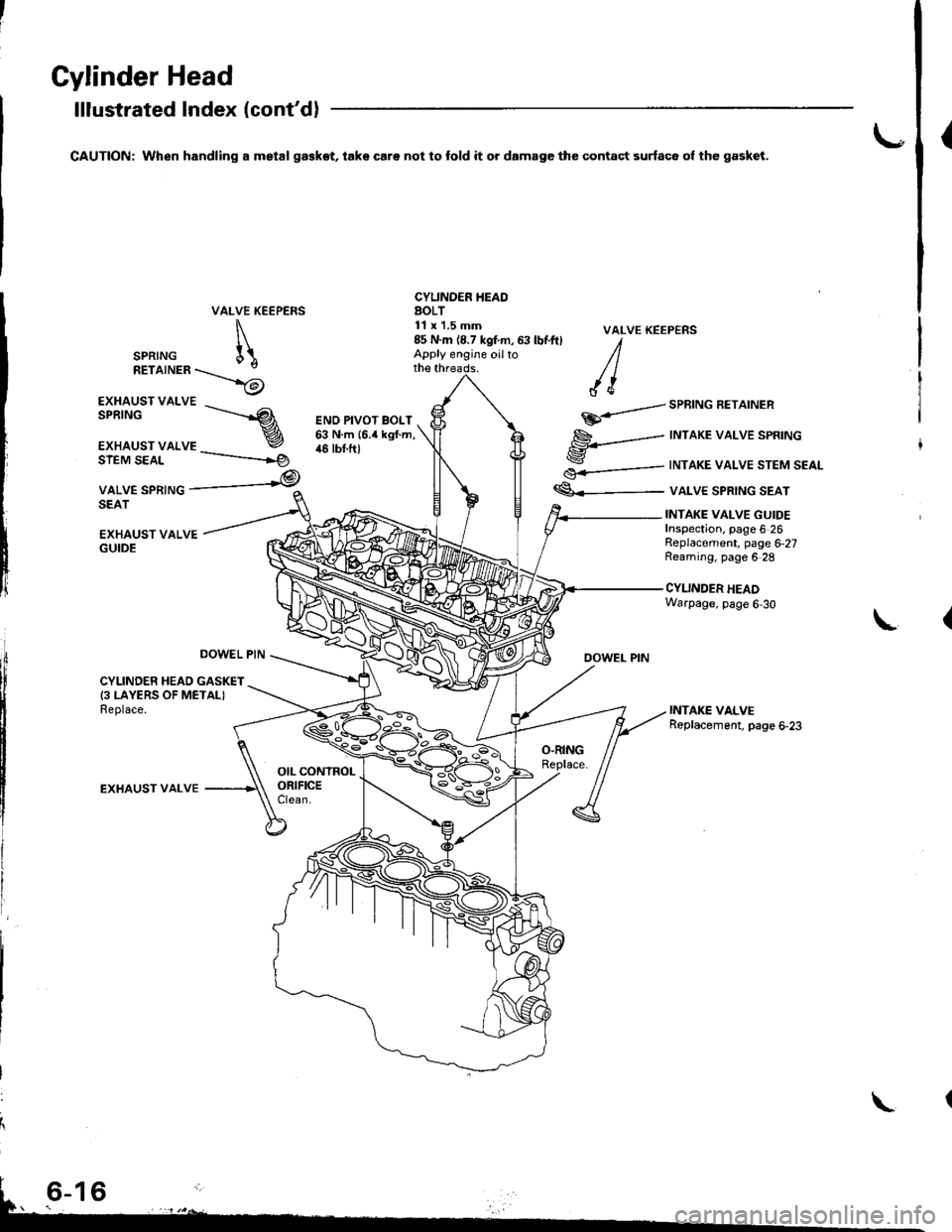

CAUTION: When handling a mstal ga€kot, take care not to fold it o. damage the contact surfac6 ol the gasket.{

VALVE KEEPERS

\

SPRTNG [\RETaTNER\_>6

CYLINDER IIEAOAOLT11 x'1.5 mm

EXHAUST VALVE

EXHAUST VALSPRINGs------.--

r

€.-=---

€<_-

VALVE KEEP€NS

DOWEL PIN

SPRING AEIAINER

INTAKE VALVE SPRING

INTAKE VALVE STEM SEAL

VALVE SPRING SEAT

ENO PIVOT BOLT63 N.m {6.4 kgf.m,46 tbt.ftlSIEM SEAL

VALVE SPRINGSEAT

-----------rg

,@

EXHAUST VALVEGUIDE

INTAKE VALVE GUIDEInspection. page 6 26Replacement, page 6,27Reaming, page 6 28

CYLINDER HEADWarpage, page 6,30

L

DOWEL PIN

CYLINDER HEAD GASKET(3 LAYERS OF METALIReplace.

EXHAUST VALVE

85 N.m (8.7 kgtm, 63 lbf.ft) IApply engine oilto /lthe threads. / |

/ {e

\

Page 80 of 1681

Gylinder Head

Removal (cont'dl

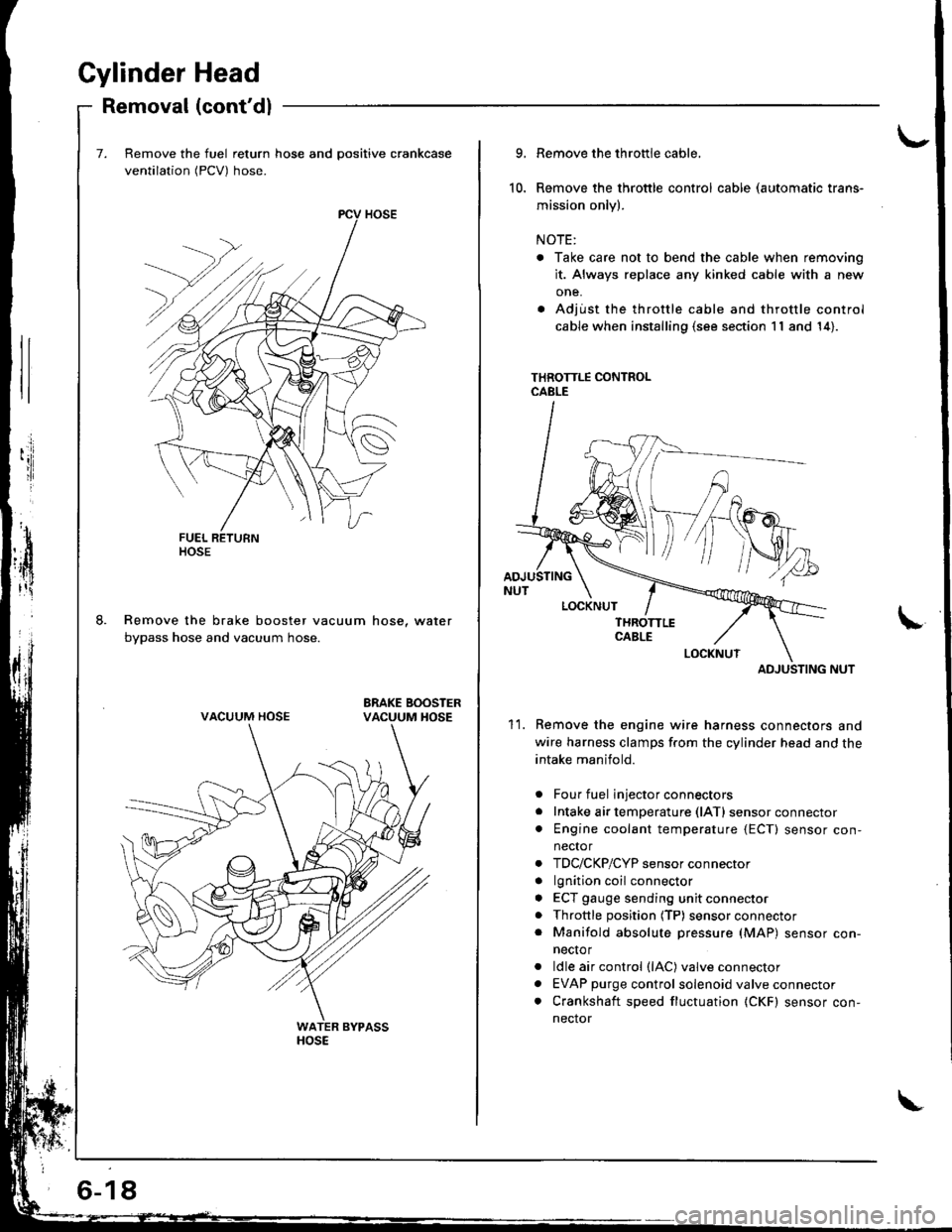

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ltosE

VACUUM HOSE

6-18

10.

9.

11.

Remove the throttle cable,

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (s€e section 11 and 14).

THROTTLE CONTROLCABLE

ADJUSTING NUT

Remove the engine wire harness connectors and

wire harness clamps f.om the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lATl sensor connector

Engine coolant temperature {ECT) sensor con,

nector

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute pressure (MAP) sensor con-

necto r

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

Crankshaft speed fluctuation (CKF) sensor con-

nector

a

a

a

a

a

a

a

a

ADJUSTING

Page 82 of 1681

Gylinder Head

Removallcont'd)

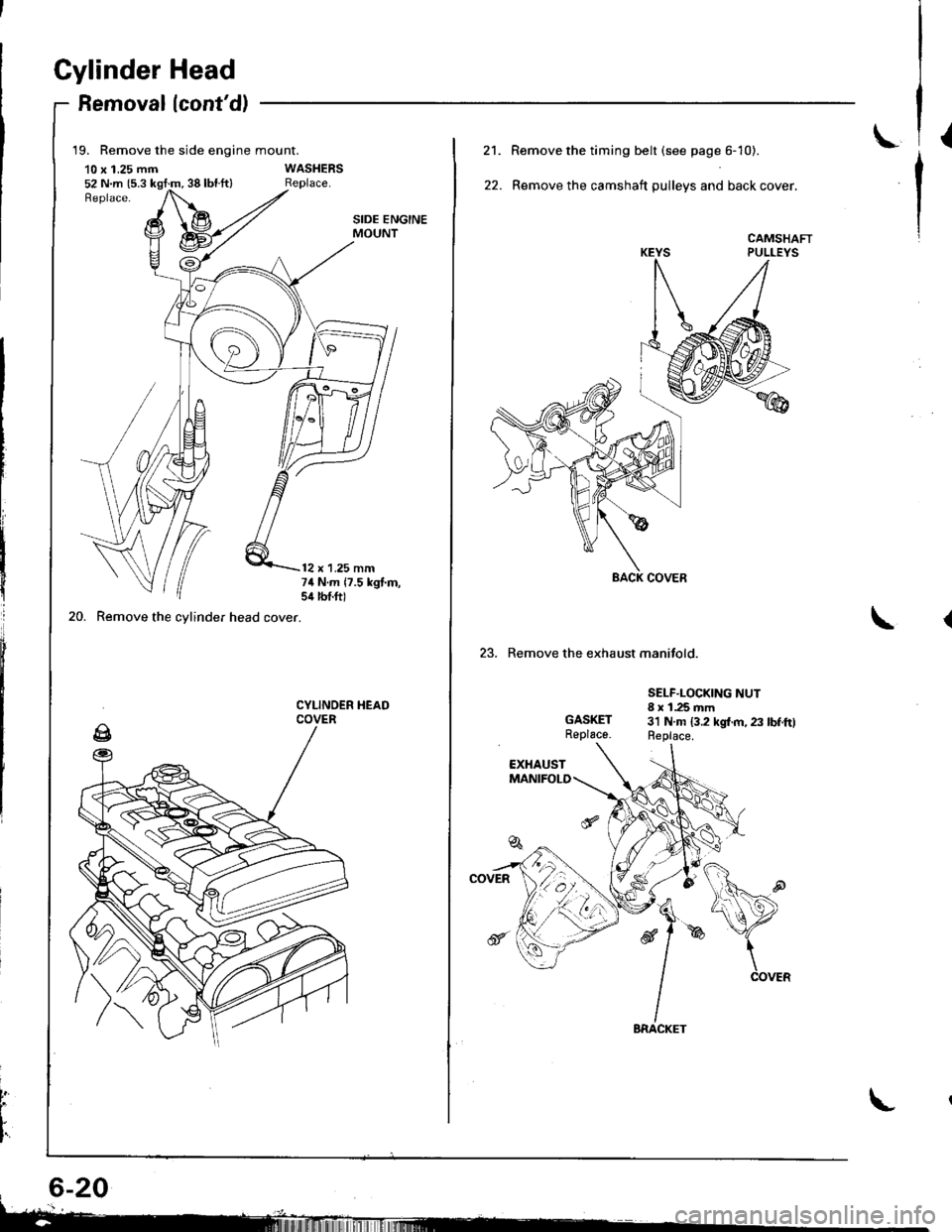

19. Remove the side engine mount.

10 x 1.25 mm52 N.m {5.3 kgt:m, 38 lbl.ft}

20. Remove the cylinder head cover.

SIDE ENGINEMOUNT

12 x 1.25 mm74 N.m 17.5 kgt.m,sil lbtft)

CYLINOER HEADCOVER

t

L

I'

L21.

22.

Remove the timing belt (see page 6- 10).

Remove the camshaft pulleys and back cover.

CAMSHAFTPULLEYS

23. Remove the exhaust manifold.

GASKETReplace.

SELF.LOCKING NUT8 x 1.25 mm3'l N.m 13.2 kgl.m, 23 lbf.ftlReplace.

Page 92 of 1681

Cylinder Head

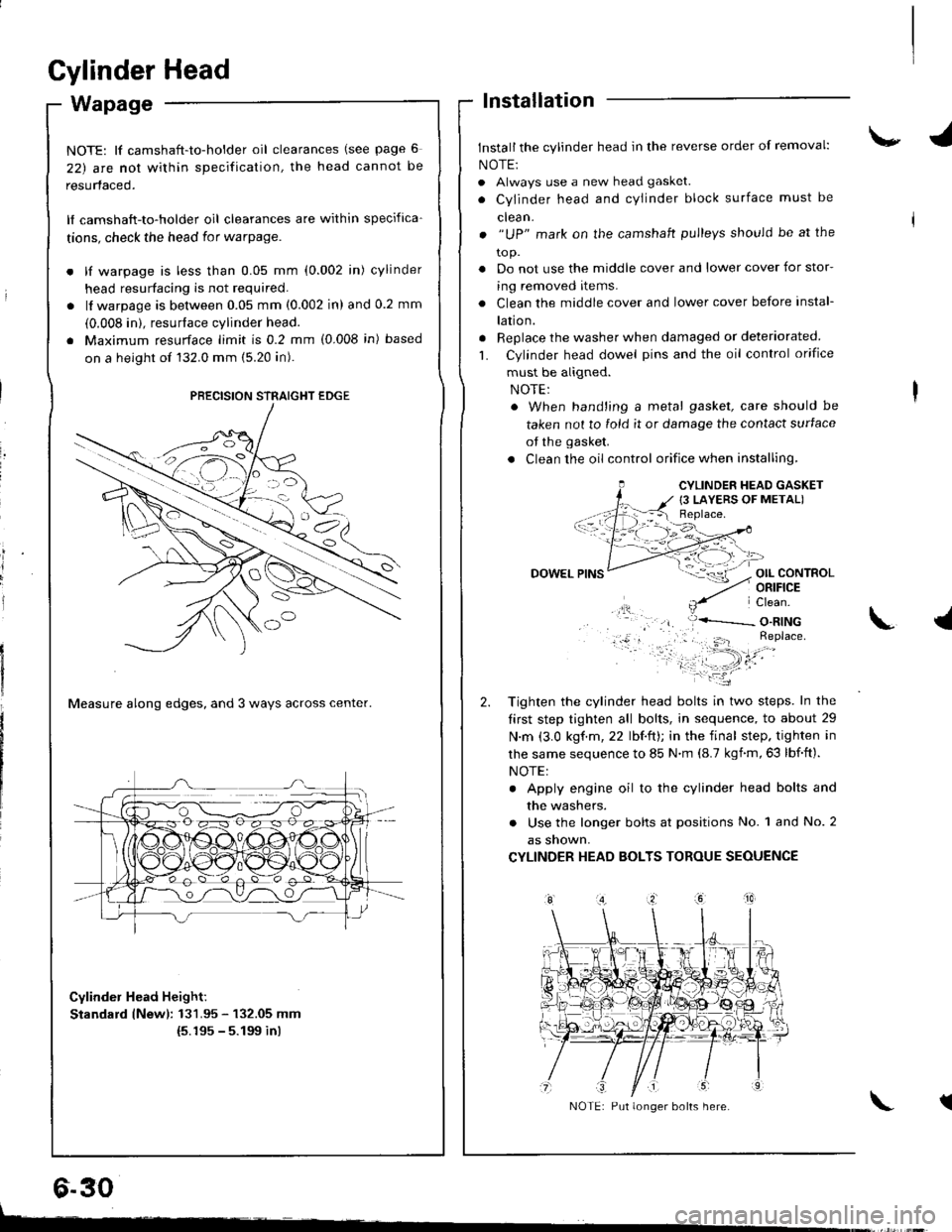

Wapage

NOTE: lf camshaft-to-holder oil clearances (see page 6

22) arc nol within specification, the head cannot be

resurfaced.

lf camshaft-to-holder oil clearances are within specifica-

tions, check the head for warpage.

lf warpage is less than 0.05 mm (0.002 in) cylinder

head resurfacing is not required.

lf warpage is between 0.05 mm (0.002 in) and 0.2 mm

(0.008 in). resurface cylinder head.

Maximum resurface limit is 0.2 mm (0.008 in) based

on a height of 132.0 mm (5.20 in).

Measure along edges, and 3 ways across center.

Cylinder Head Height:

Standard lNewl: 131.95 - 132.05 mm(5.195 - 5.199 inl

lnstallation

Install the cylinder head in the reverse order of removal:

NOTE:

. Always use a new head gasket.

. Cylinder head and cYlinder block surface must be

clean.

. "UP" mark on the camshaft pulleys should be at the

to p.

. Do not use the middle cover and lower cover for stor-

ing removed items.

. Clean the middle cover and lower cover before instal-

lation.

. Replace the washer when damaged or deteriorated

L Cylinder head dowel pins and the oil control orifice

must be aligned.

. When hand'ing a metal gasket, care should be

taken not to fold it or damage the contact surface

of the gasket.

. Clean the oil control orifice when installing,

OIL CONTROLORIFICE

PRECISION STRAIGHT EDGE

6.30

CYLINDER HEAD GASKET

{3 LAYERS OF METAL)

DOWEL

Tighten the cylinder head bolts in two steps. In the

tirst step tighten all bolts, in sequence, to about 29

N.m (3.0 kgf.m,22 lbf.ft); in the final step. tighten in

lhe same sequence to 85 N.m (8.7 kgnm,63 lbf.ft).

NOTE:

. Apply engine oil to the cylinder head bolts and

the washers.

. Use the longer bolts at positions No. 1 and No. 2

as snown,

CYLINDER HEAD BOLTS TOROUE SEOUENCE

\.l

tNOTE: Put longer bolts here.

t-

Page 95 of 1681

15.

16.

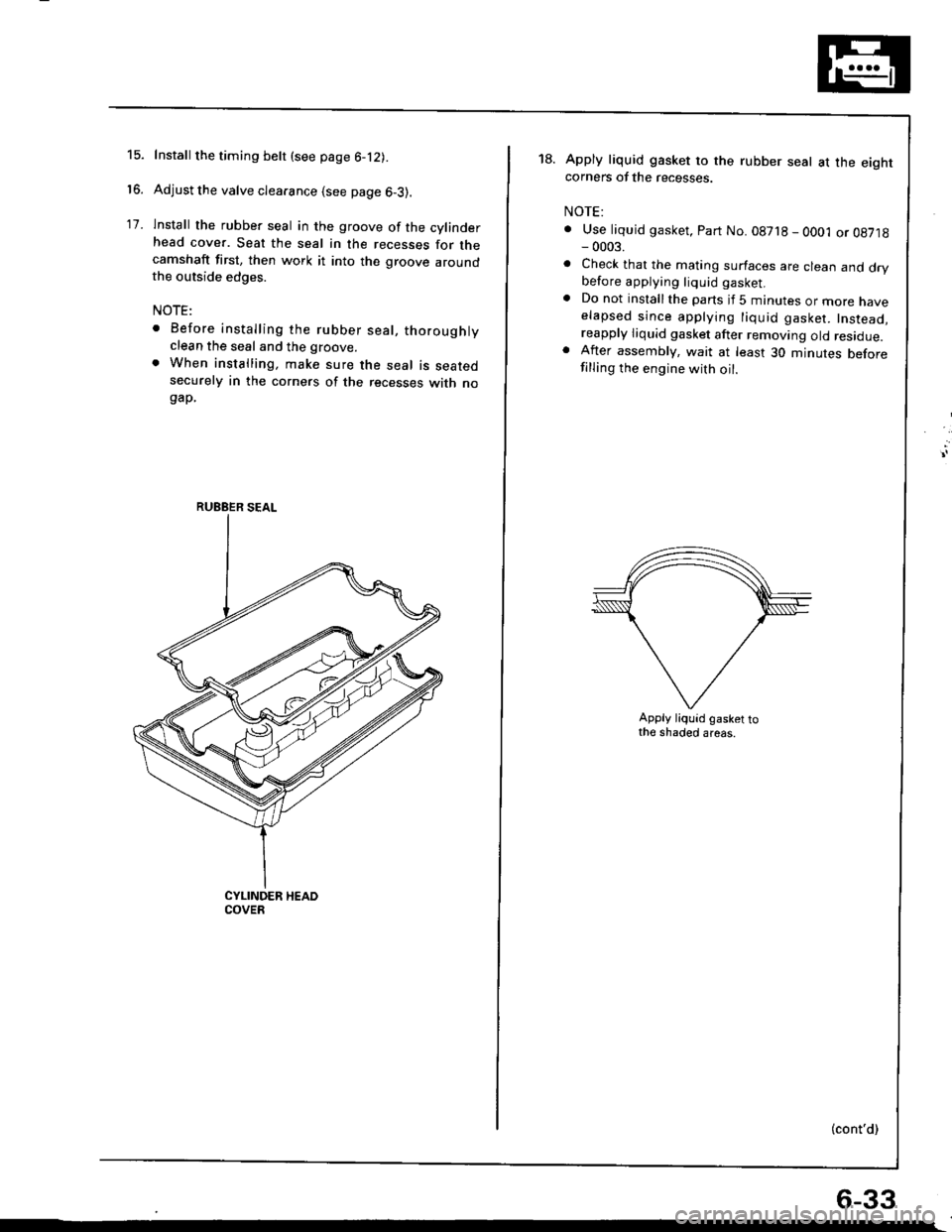

17.

Install the timing belt (see page 6-12).

Adjust the valve clearance (see page 6-3).

lnstall the rubber seal in the groove of the cylinderhead cover. Seat the seal in the recesses for thecamshaft first, then work it into the groove aroundthe outside edges.

NOTE:

. Before installing the rubber seal, thoroughlyclean the seal and the groove.

. When installing, make sure the seal is seatedsecurely in the corners of the recesses with nogap.

RUEBER SEAL

18.Apply liquid gasket to the rubber seal at the eightcorners of the recesses.

NOTE:

. Use liquid gasket, Part No. 08718 - OO01 or 08718- 0003.

. Check that the mating surfaces are clean and drybefore applying liquid gasket.. Do not installthe parts if 5 minutes or more naveelapsed since applying liquid gasket. Instead,reapply liquid gasket after removing old residue.. After assembly, wait at least 30 minutes beforefilling the engine with oil.

Apply liquid gasket tothe shaded areas.

(cont'd)

6-33

Page 147 of 1681

I

lllustrated Index

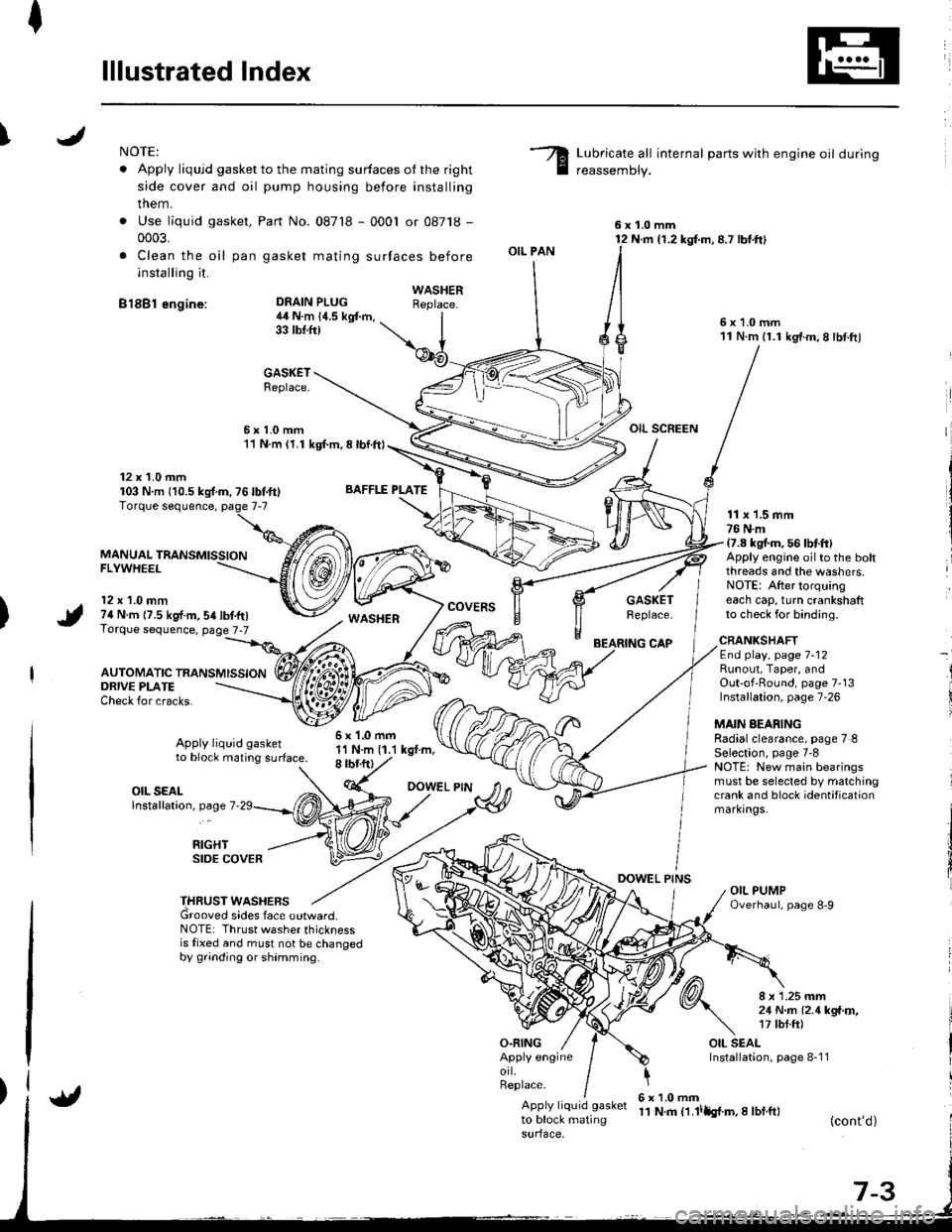

INOTE:

. Apply liqujd gasket to the mating surfaces ot the right

side cover and oil pump housing before installing

them.

. Use liquid gasket,

0003.

. Clea n the oil pan

installing it.

B18Bl engine:

Part No. 087'18 - 0001 or 08718 -

gasket mating surfaces before

Lubricate all internal parts with engine oil during

reassemDly.

6x1.0mm12 N.m {1.2 kg{.m,8.7 lbt.ft}

6x1.0mm11 N.m 11.1 kg'f.m,8 lbt.ftl

OIL SCREEN

DEAIN PLUG4il N.m 14.5 kgt m,33 tbtft)

BAFFLE PLATE

6x1.0mm1'l N.m (1.1 kgt.m,8 rbr.ftl

OIL PAN

O.FING

CAP

DOWEL PINS

WASHERReplace.

GASKETReplace.

6x1.0mm11 N.m (1.1 kgl.m, 8 lbl.ft)

12 x 1.0 mm103 Nm 110.5ks{.m,76lbf.ft}

MANUAL TRANSMISSIONFLYWHEEL

12 x 1.0 mm74 N.m 17.5 kgf.m,54lbf.tr)Torque sequence, page 7-7

AUTOMATIC TRANSMISSION

WASHERcovERsGASKETReplace.

11 x 1.5 mm76 N.m17.8 kgt m, 56 lbtft)Apply engine oilto the boltthreads and the washers.NOTE: After torquingeach cap, turn crankshaftto check for binding.

ORIVE PLATECheck for cracks.

Apply liquid gasketto block mating surface.

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of'Round, page 7-13Installation, page 7-26

MAIN AEARINGRadialclearance, page 7 8Selection, page 7'8NOTE: New main bearingsmust be selected by matchingcrank and block identificationmarkrngs.

I

i

OIL SEALlnstallation, page 7

RIGHTSIDE COVER

THRUST WASHERSGrooved sides face outward.NOTE: Thrust washer thicknessis fixed and must not be changedby grinding or shamming.

8 x 1.25 mm21 N..n l2.1kga'r,�,17 tbf.ft)

OIL SEALInstallation, page 8-1 1Apply engineorl.Replace.

Apply liquid gasket

to block matingsurface,

6x1.0mm11 N.m t1.lilh{.m,I lbf.ft}(cont'd)

Page 149 of 1681

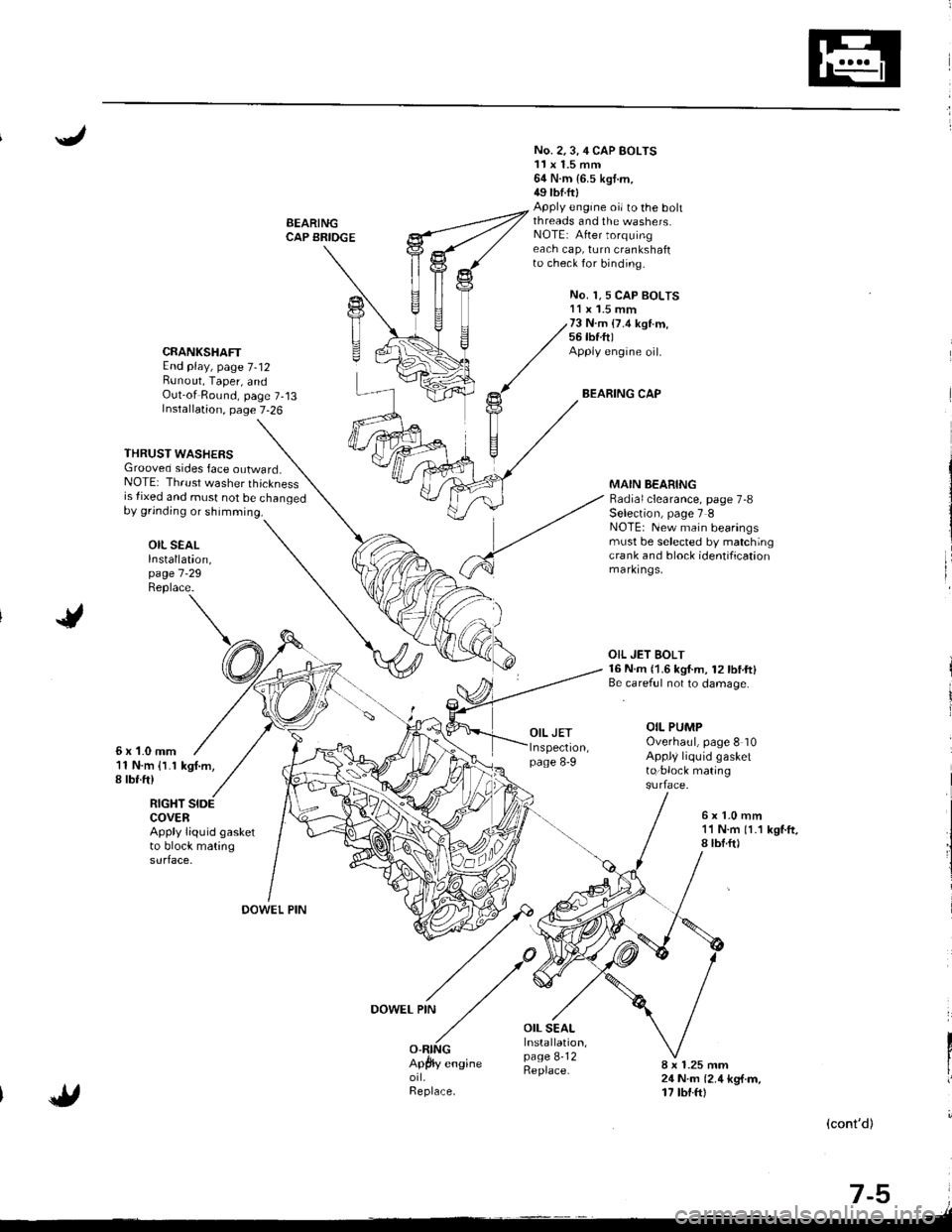

BEARINGCAP BRIOGE

No. 2.3,4 CAP BOLTS11x 1.5 mm64 N.m {6.5 kgt.m,49 tbtftlApply engine oi/ to the bohthreads and the washers.NOTE: After torquingeach cap, turn crankshaftto check for binding.

No. 1,5 CAP BOLTS11 x '1.5 mm73 N.m (7.4 ksl.m,56 tbf.ft)Apply engine oil.

BEARING CAP

CRANKSHAFTEnd play, page 7-12Bunout, Taper, andOut-of Round, page 7-13Installation, page 7-26

THRUST WASHERSGrooved sides face outward_NOTE: Thrust washer thicknessis {ixed and must not be changedby grinding or shimming.

OIL SEALInstallation,page 7 -29

Replace.

MAIN BEARINGRadial clearance, page 7-8Selection, page 7 INOTE: New main bearingsmust be selected by matchingcra nk and block identificationmarkrngs,

6x1-0mm11 N.m {l.1 kgf.m,I rbr.ft)

OIL JET BOLT16 N.m {1.6 kgf.m, 12lbtft}Be.careful not to damage.

OIL PUMPOverhaul, page 8 10Appl/ liquid gasketto:block mating

RIGHT SIDECOVERApply liquid gasketto block matingsurface.

6x1.0mm11 N.m 11.1 kgf.ft,8lbf.ft)

OOWEL PIN

DOWEL PIN

OIL SEALInstallation,page 8-12Replace.8 x 1.25 mm24 N.m {2.4 kg{.m,17 tbt.ftl

(cont'd)

-,tr

t-9 i.lt