HONDA INTEGRA 1998 4.G Workshop Manual

INTEGRA 1998 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6069/w960_6069-0.png

HONDA INTEGRA 1998 4.G Workshop Manual

Trending: c503, warranty, wiring diagram, service, wheel bolts, refrigerant type, power steering

Page 191 of 1681

I

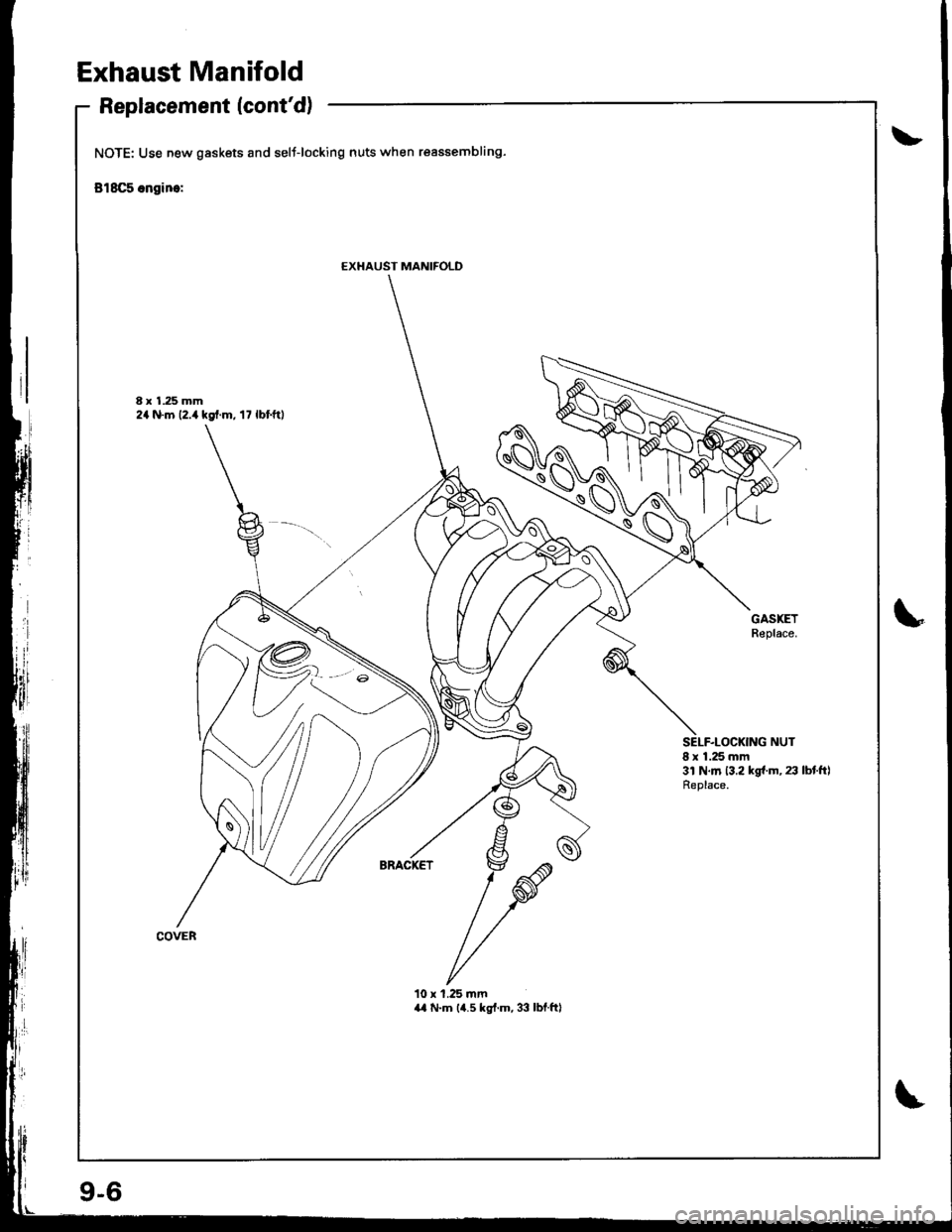

Exhaust Manifold

Replacement (cont'd)

NOTE: Use new gaskets and selt-locking nuts when reassembling-

818C5 ongine:

8 x 1.25 mm2a N.m 12.,r kgf.m, 17 lbf.ftl

GASKETReplace.

8 x 1.25 mm3l N.m 13.2 kgf.m, 23 lbtftlReplace.

10 x 1.25 mma,l N.m (4.5 kg{.m, 33 lbf.ftl

EXHAUST MANIFOLD

\A

9-6

Page 192 of 1681

J

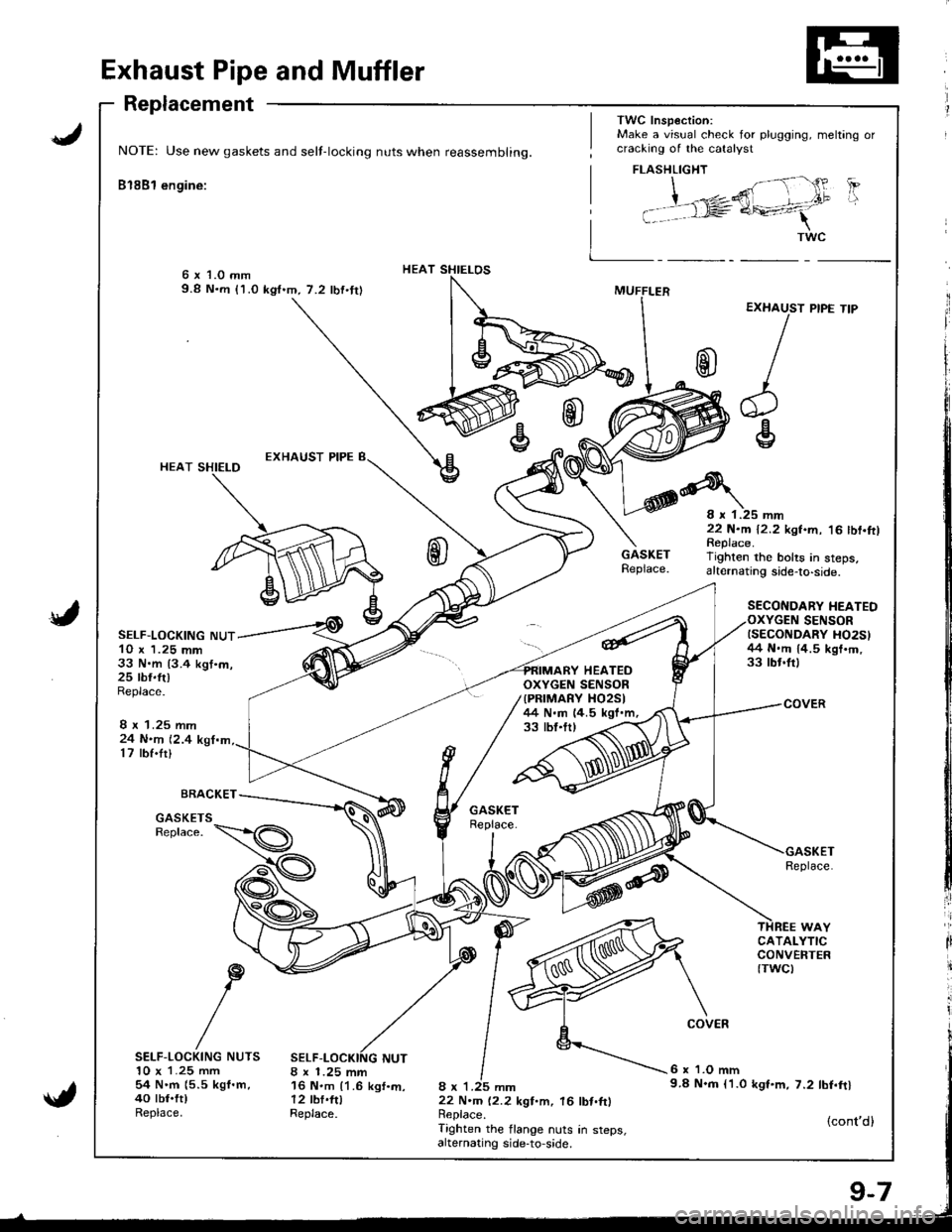

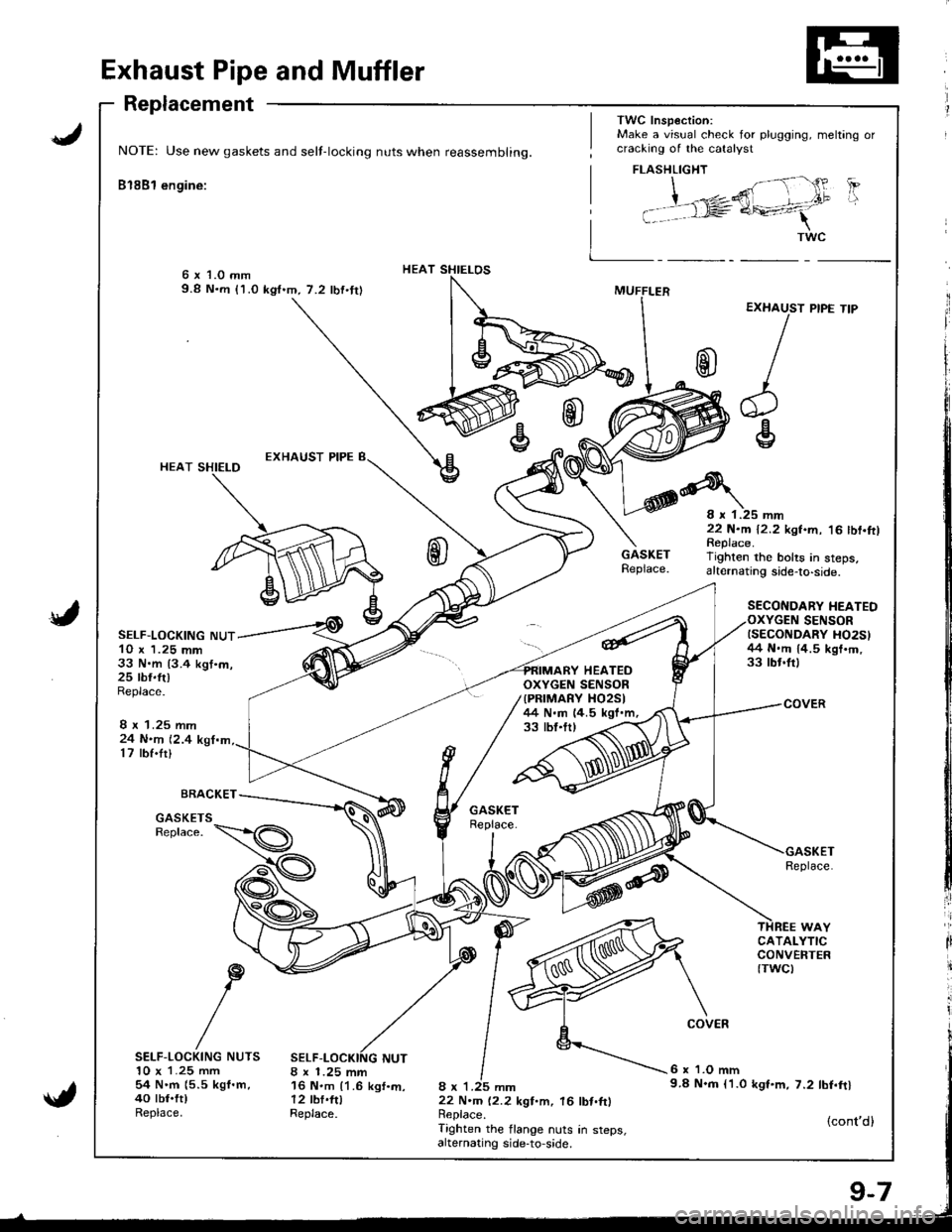

Exhaust Pipe and Muffler

Replacement

NOTE: Use new gaskets and self-locking nuts when reassembling.

Bl8Bl engine:

HEAT SHIELOS6 x 1.0 mm9.8 N.m (1.0 kgf.m,7.2 lbf.tr)

{

HEAT SHIELD

SELF-LOCKING NUT10 x 1.25 mm33 N.m {3.4 kgt.m,25 rbr.ft)Replace.

24 N.n 12.417 rbf.tr)

BRACKET

8 x 1.25 mm16 N.m {1.6 kgf.m,12 tbf.fttReplace.

33 tbt.tr,

8 x 1.25 mm22 N.m 12.2 kgf.m. 16 lbt.ftlReplace.Tighten the flange nuts in steps,alternating side-to,side.

Replace.

6 x 'l.O mm9.8 N.m l'1.0 kgt.m, 7.2 tbf.ftl

{cont'd}

GASKETSReplace.

ir

li

it

SELF-LOCKING NUTS10 x 1.25 mm54 N.m {5.5 kgf.m,40 tbt.ft)Replace.

TWC Insp€ction:Make a visual check for plugging, meltang orcracking of the catalyst

EXHAUST

/

r

cg

HEATEDOXYGEN SENSOR{PRIMARY XO25I/+4 N.m 14.5 kgf.m,

FLASHLIGHT

| ;"1- {' 'PI i ,"*,2ffi - .t"

i t rl= a+-41

I _ _*"

PIPE TIP

8 r 1.25 mm22 N.m 12.2 kgf.m, '16 tbf.ftlReplace.Tighten rhe bolts in steps,altelnating side-to-side.

SECONDARY HEATEDSENSORISECONDARY HO2S}/+4 N.rn 14.5 kgt'm,33 tbr.frl

9-7

Page 193 of 1681

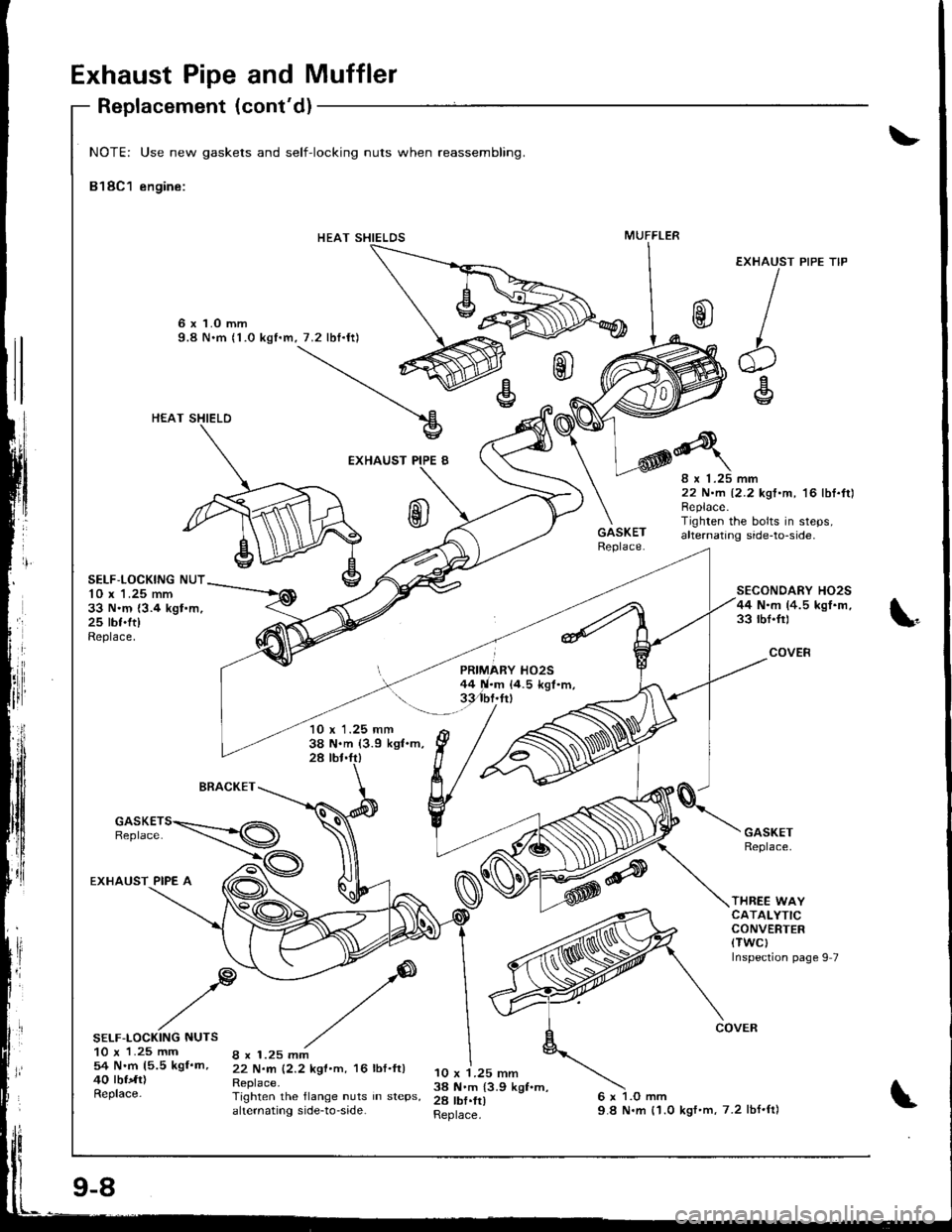

Exhaust Pipe and Muffler

EXHAUST

b

'+l\v

rl

IIrl

NOTE: Use new gaskets and self-locking nuts when reassembling.

818C1 engine:

6 x 1.O mm9.8 N.m (1.0 kgf.m, 7.2 lbf.ft)

HEAT SHIELD

EXHAUST PIPE 8

Replacement (cont'd)

SELF,LOCKING NUT10 x 'l .25 mm33 N.m {3.4 kgt.m,25 tbf.ft)Replace.

PIPE TIP

BRACKET

10 x 1.25 mm38 N.m (3.9 kgl.m,28 tbt.fr)

8 x 1.25 mm22 N.m 12.2 kgt.m, '16 lbI.ft)Replace.Tighren the bolts in steps,alternating side-to-side.

SECONDARY HO2S44 N.m (4.5 kgI.m,33 rbf.fr)

COVER

THREE WAYCATALYTICCONVERTER(TWCI

Inspection page 9 7

EXHAUST PIPE A

SELF-LOCKING NUTS10 x 1.25 mm54 N.m 15.5 kgf.m,40 tbfdr)Replace-

8 x 1.25 mm22 N.rn 12.2 kgf.m, 16 lbf.ft)Replace.Tighten the flange nuts in steps,ahernating side-to-side.

10 x 1.25 mm3a N.m {3.9 kgf.m,28 tbf.fr)Replace.

HEAT SHIELDSMUFFLER

9-8

9.8 N.m {'1.0 kgf'm,7.2 lbf'ft)

Page 194 of 1681

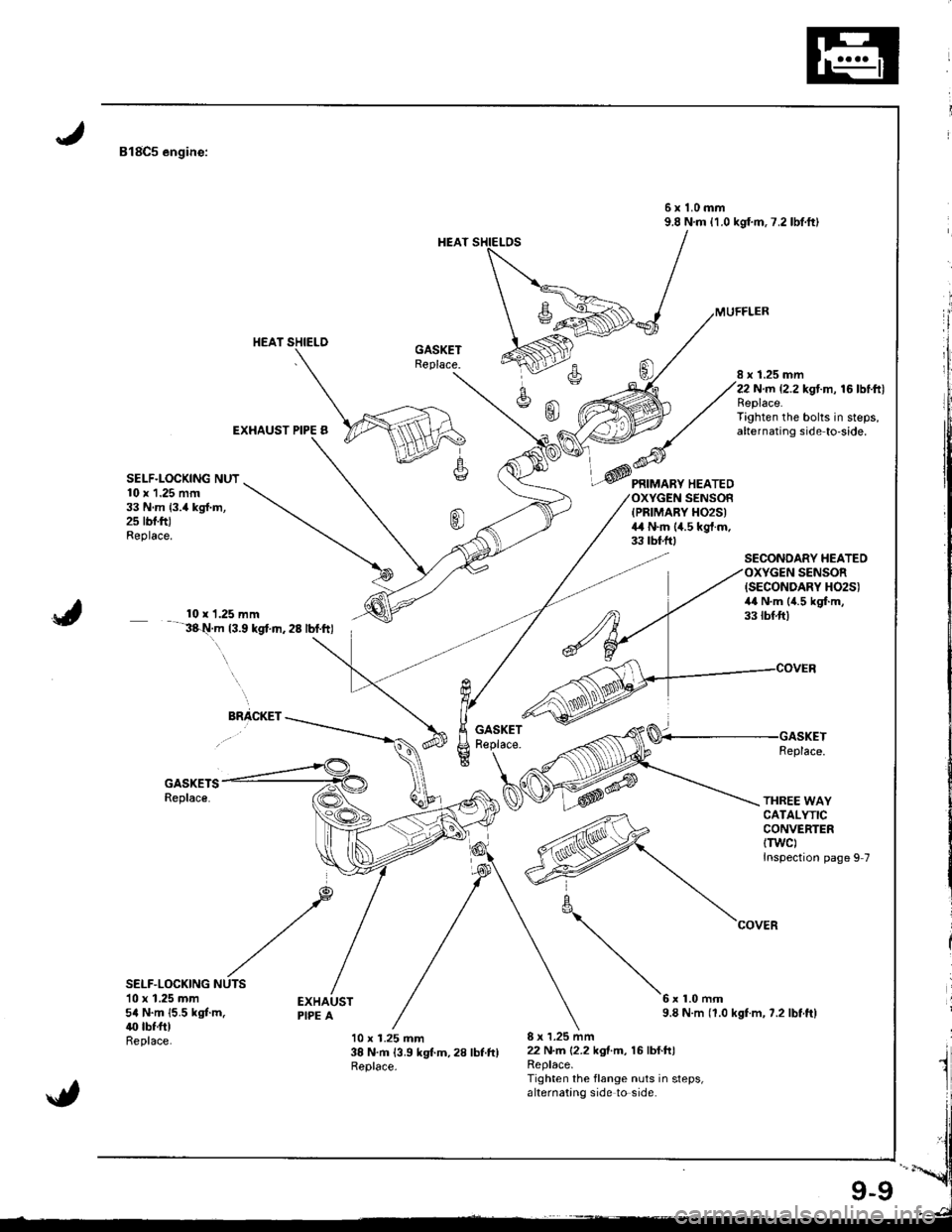

818C5 engine:

6x1.0mm9.8 N.m {1.0 kgf.m.7.2lbtft)

EXHAUST PIPE B

8 x 1.25 mm22 N.rn {2.2 kgt.m, 16 lbtftlReplace.Tighten the bolts in steps,alternating side to'side.

SELF.LOCKING NUT10 x 1.25 mrn33 N.m {3.4 kgl.m,2s rbf.ftJReplace.

PRIMARY HEATEDSENSOFIPRIMARY H02S)4,1 N.m (4.5 kgt.m.33 tbf.ftt

SECONDARY HEATEOSENSOR

J

{SECONDARY H02S)4,0 N.m (4.5 kgf.m,33 tbf.ft)10 x 1.25 mm3&t!.m t3.9 kgt.n.28 lbf.ftl. \

ElacKEr -*_____GASKETReplace-

GASKETSReplace.

Replace.

THREE WAYCATALYTICCONVERTERtTwc)Inspection page 9 7

SELF.LOCKING10 x 1.25 mm5a N.m {5.5 kgt m.40 tbf.ftlReplace.

6x1.0mm9.8 N.m (1.0 kgf.m, ?.2 lbt.ftl

10 x 1.25 mm38 N.m 13.9 kgt m,28 lbt.ftlReplace.

8 x 1.25 mm22 N.m 12.2 kgtm, 16lbf.h)Replace.Tighten the flange nuts in steps,alternating side to side.

_@

\

Page 195 of 1681

Cooling

lllustrated Index ........

Radiator

Replacement ..............

Engine Coolant Refilling and

Bleeding

Cap Testing

Pressure Testing

Thermostat

Replacement ..............

Testing

Water Pump

lllustrated Index .........

Inspection

Replacement ...............

10-2

10-5

10-6

10-8

10-8

10-9

10-9

10-10

10-11

10-11

Page 196 of 1681

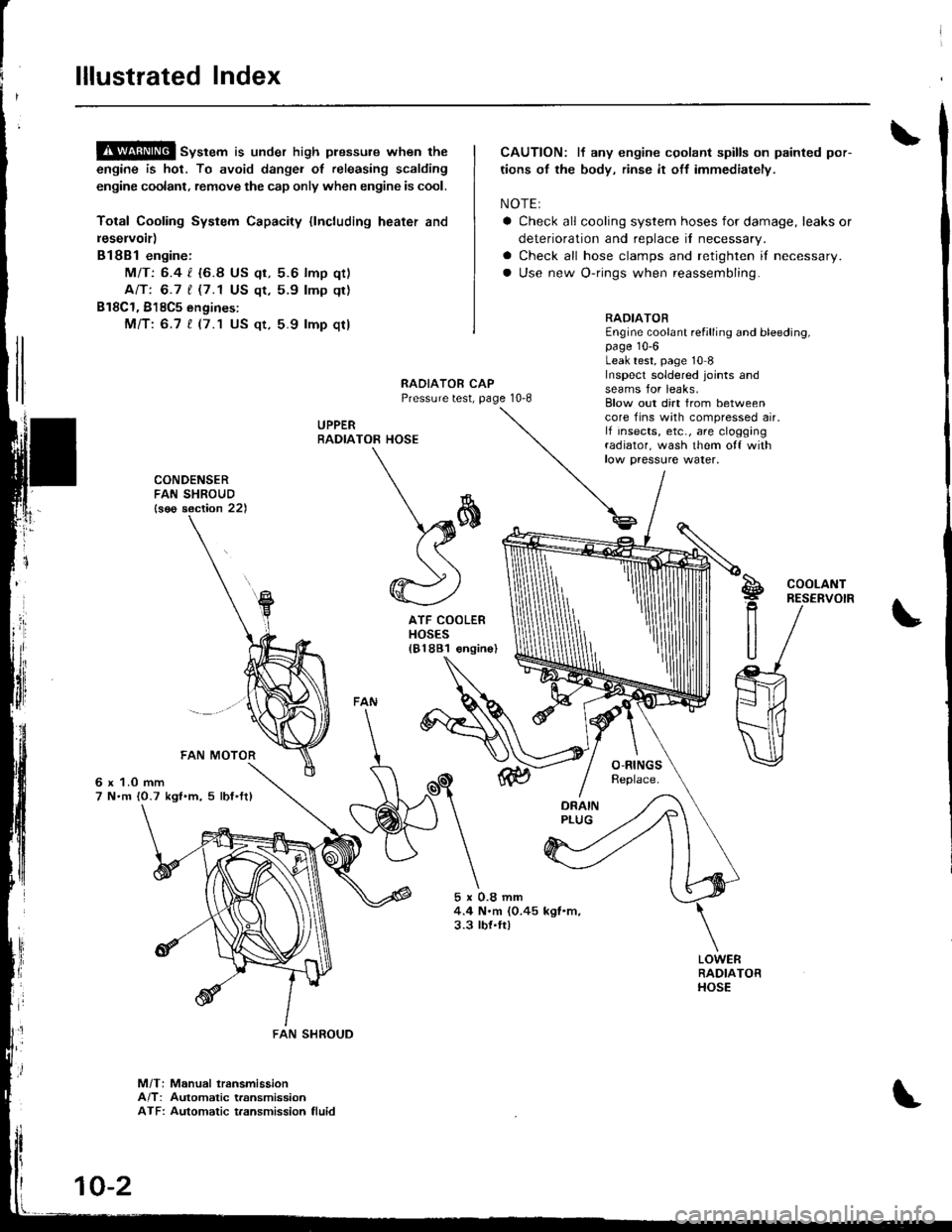

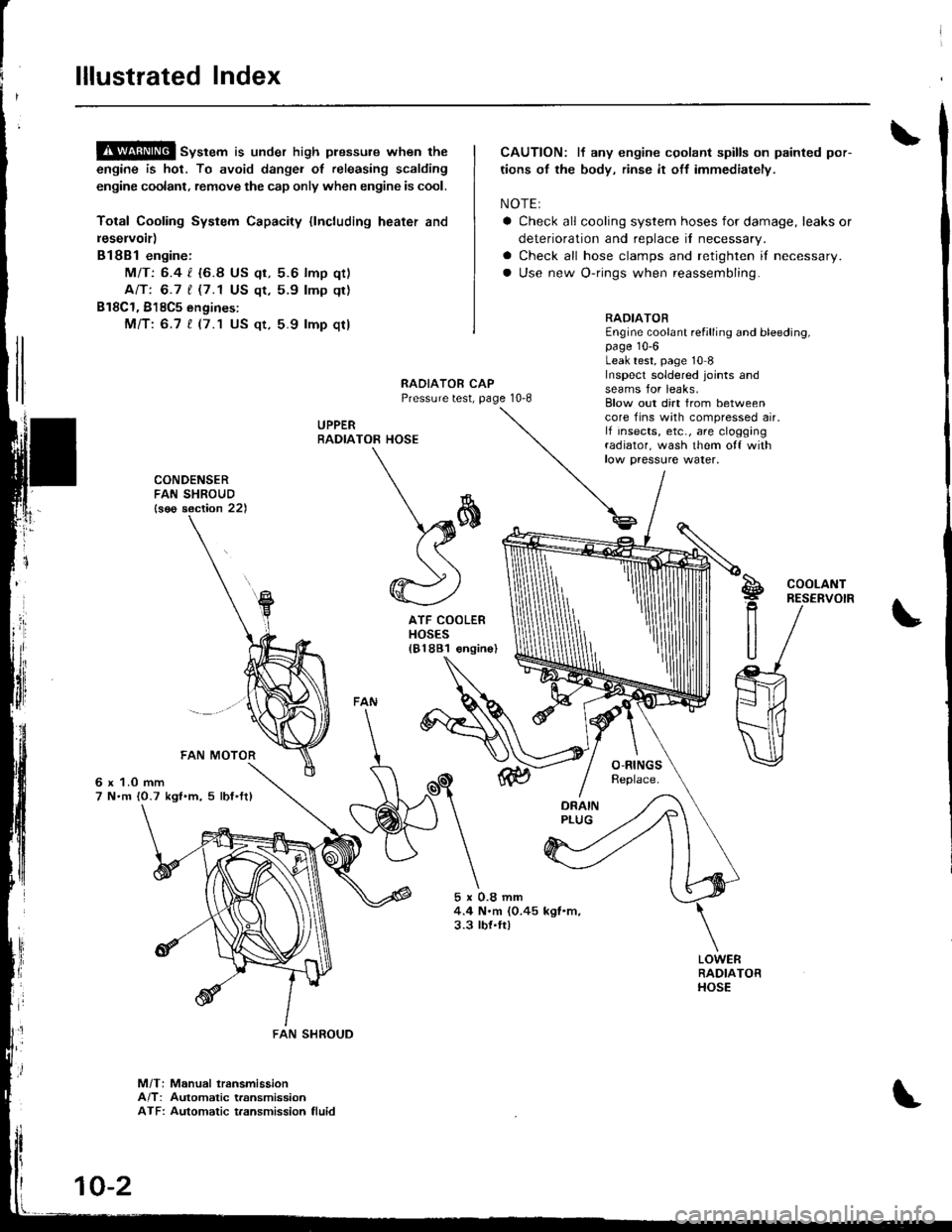

lllustrated Index

!$!!@ sv"t"m is under high plessure when the

engine is hot, To avoid dangei of releasing scalding

engine coolant, remove the cap only when engine is cool.

Total Cooling System Capacity {lncluding heater and

leservoir)

Bl8Bl engine:

MIT: 6.4 l. {6.8 US qt, 5.6 lmp qt)

Ant 6.7 t (7.1 US qt,5.9 lmp qt)

B18C1, 818C5 engines:

Mfi:6.7 t (7.1 US qt, 5.9 lmp qt)

CAUTION: lf any engine cgolant spills on painted por-

tions of the body, rinse it off immediately.

NOTE:

a Check all cooling system hoses for damage, leaks or

deterioration and replace il necessary.

a Check all hose clamps and retighten if necessary.

a Use new O-rings when reassembling.

RADIATOREngine coolant refilling and bleeding,page 10-6Leak test, page 10 8Inspecl soldered joints andseams for leaks,RAOIATOR CAPPressure test, page 10-8

UPPERRADIA

rl

]

CONDENSERFAN SHROUD{s€o section 22)

6 x 1.0 mm7 N.m {0.7 kgl.m, 5 lbf'ftl

5x0.8mm4.4 N.m (0.45 kgl.m,3.3 tbt.ft)

Blow out dirt from betweencore fins with compressed air.lf insects, etc., are cloggingradiator, wash them o{f withlow paessure water,

TOR HOSE

\*

\sffi((

@)

ATF COOLERHOSES181881 €ngin

S!g

R

U

COOLANTRESERVOIR

M/T: Manual lransmissionA/T: Automatic transmissionATF: Automatic t.ansmission fluid

FAN SHROUD

10-2

Page 197 of 1681

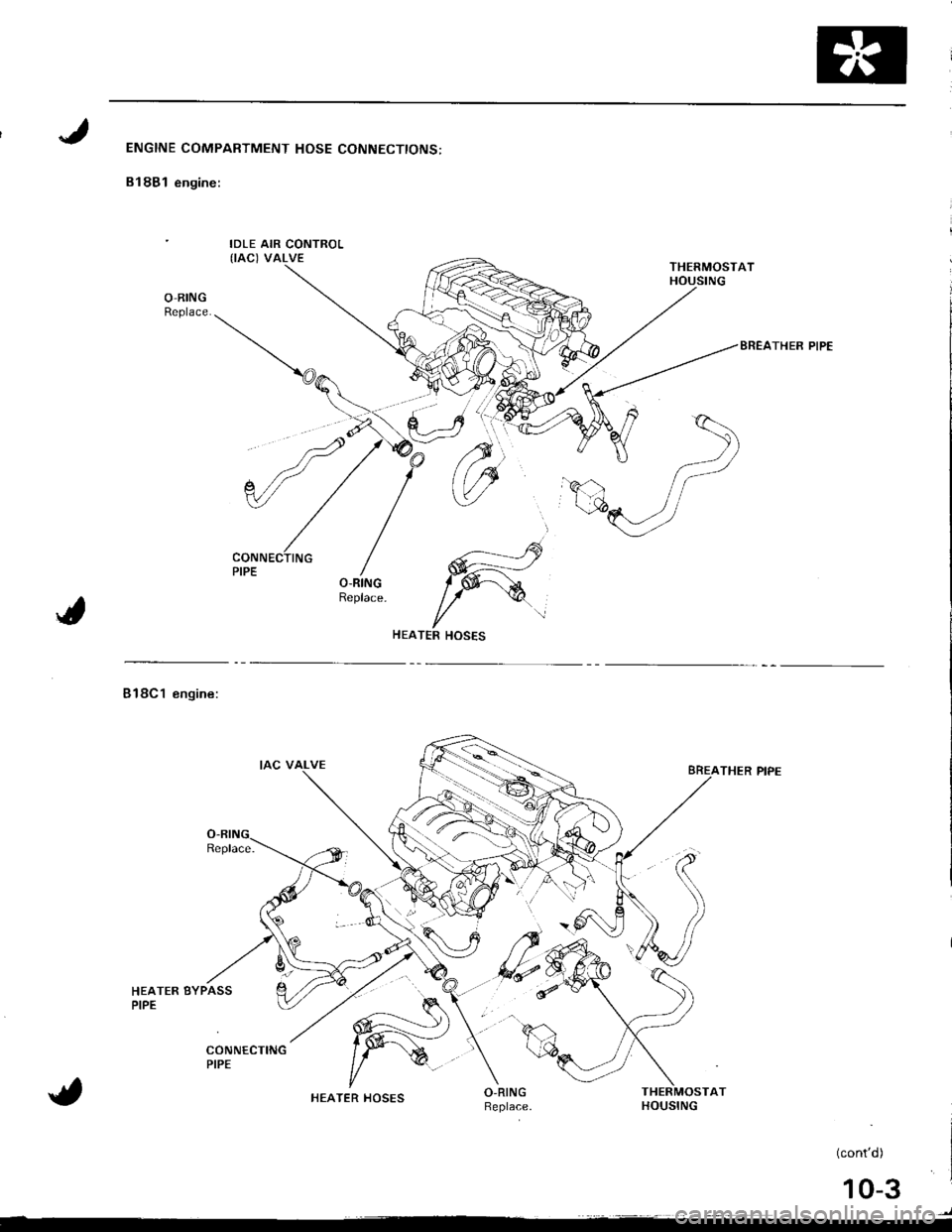

ENGINE COMPARTMENT HOSE CONNECTIONS:

B18B1 engine:

IDLE AIR CONTROL(IAC) VALVE

O-RINGReplace.

BREATHER PIPE

---___...----rs

W

l/TER HOSES

Bl8Cl engine:

HEATER BYPASSPIPE

THER PIPE

AT

(cont'd)

)

HEATER HOSES

10-3

Page 198 of 1681

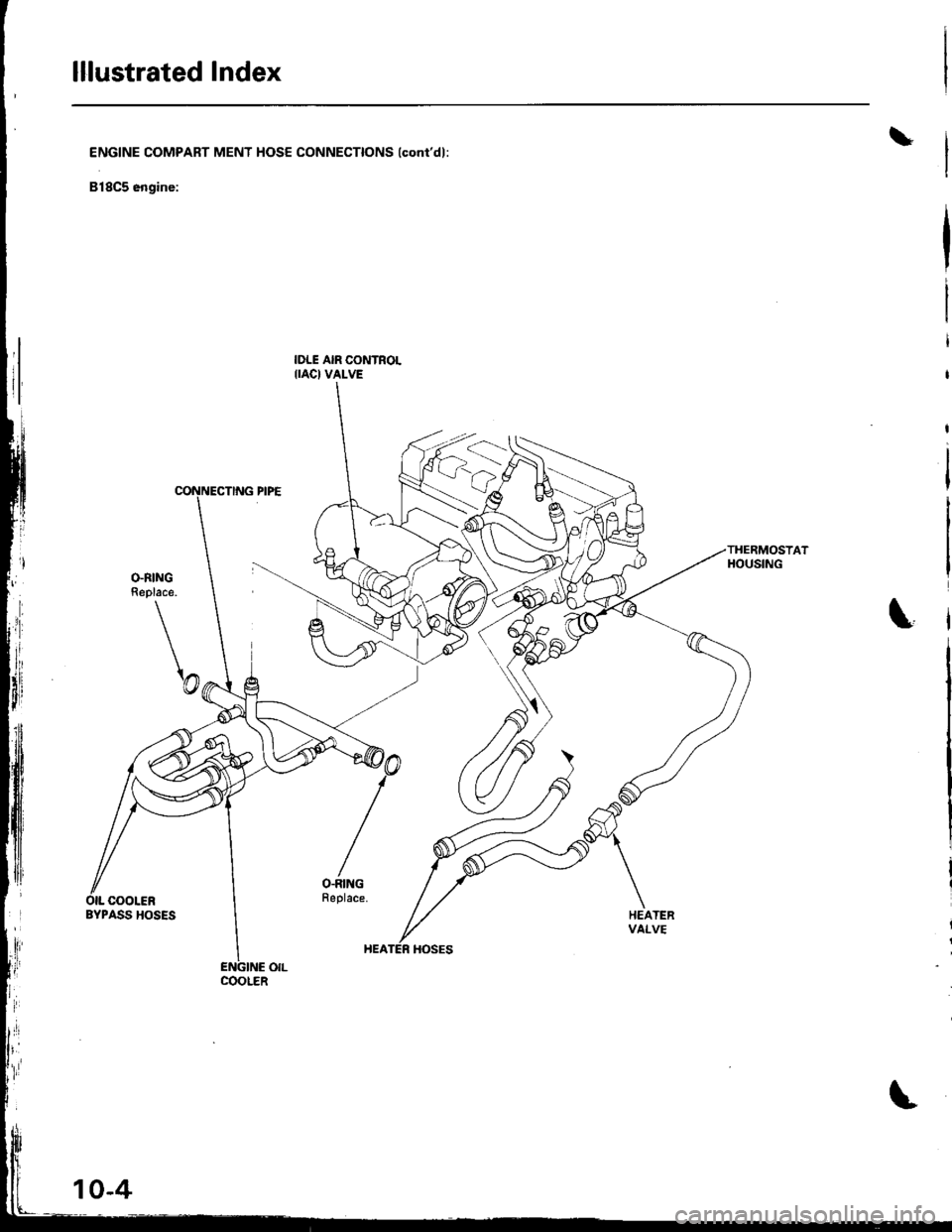

lllustrated Index

\ENGINE COMPART MENT HOSE CONNECTIONS lconi'dl:

818C5 engine:

IDLE AIR CONTROLIIAC} VALVE

THERMOSTATHOUSING

\

\

O.RINGReplace.

\@

/

O-RINGFeplace.OIL COOLERBYPASS HOSESHEATERvAt_vE

COOLER

Page 199 of 1681

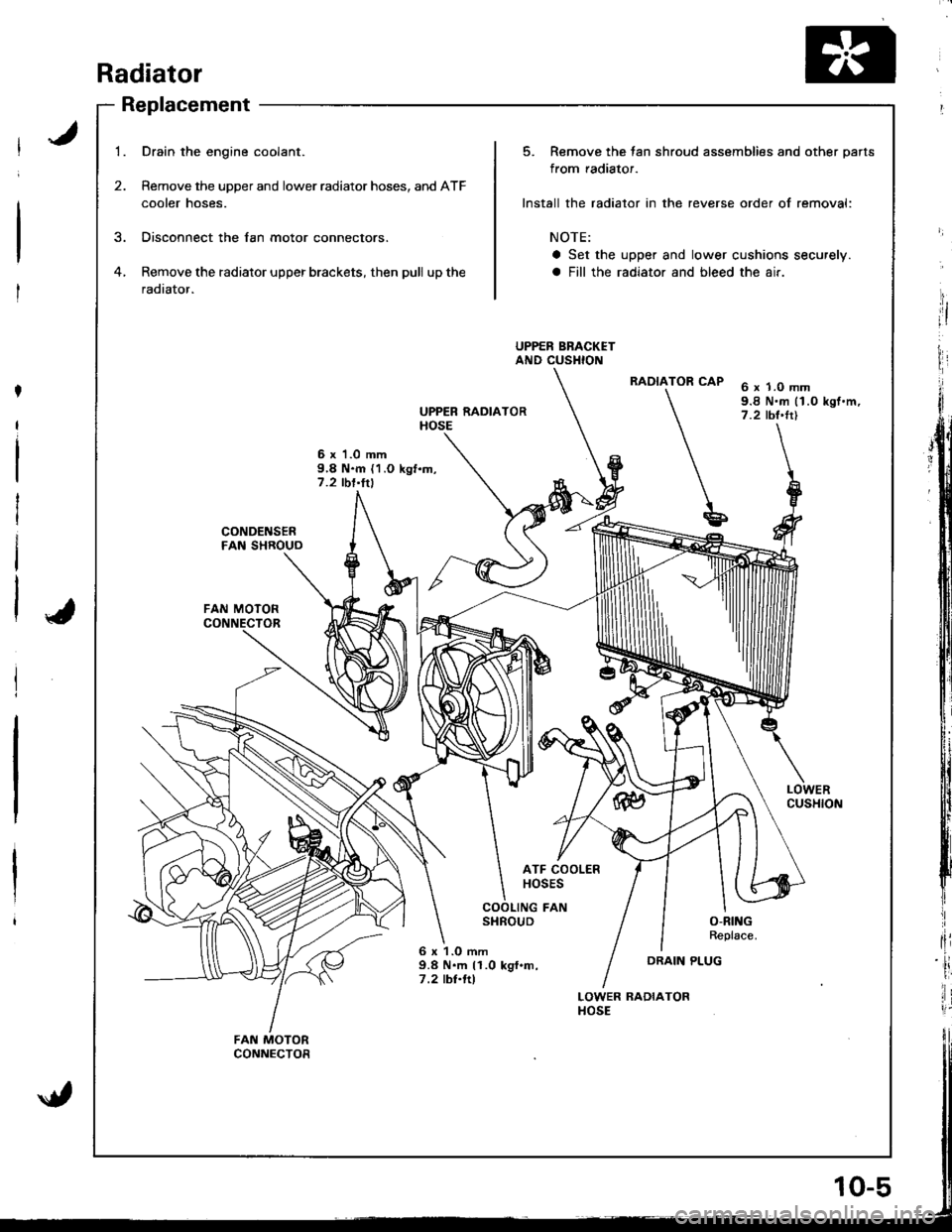

Radiator

Replacement

1.

2.

Drain the engine coolant.

Remove the upper and lower radiator hoses, and ATF

cooler hoses.

Disconnect the lan motor connectors.

Remove the radiator upper brackets, then pull up the

radiator.

6 x 'l .0 mm9,8 N.m {1.O kgf.m,7.2 tbl'ltl

UPPER RADIATORHOSE

6 x 1.0 mm9.8 N.m (1.0 kgf.m,7.2 tbt'trl

LOWERCUSHION

CONDENSERFAN SHROUO

FAN MOTOR

ATF COOLERHOSES

COOLING FANSHROUDO-RINGReplace.

6 x 1.O mm9.8 N.m 11.0 kgf.m,7 .2 tbl.ftl

LOWER RADIATORHOSE

FAN MOTORCONNECTOR

5. Remove the tan shroud assemblies and other parts

from radiator.

Install the radiator in the reverse order of removal:

NOTE:

a Set the upper and lower cushions securely.

a Fill the radiator and bleed the air.

UPPER BRACKETAND CUSHION

RADIATOR CAP

u

DRAIN PLUG

jit

I

HI

I

fli

ii

lir

Page 200 of 1681

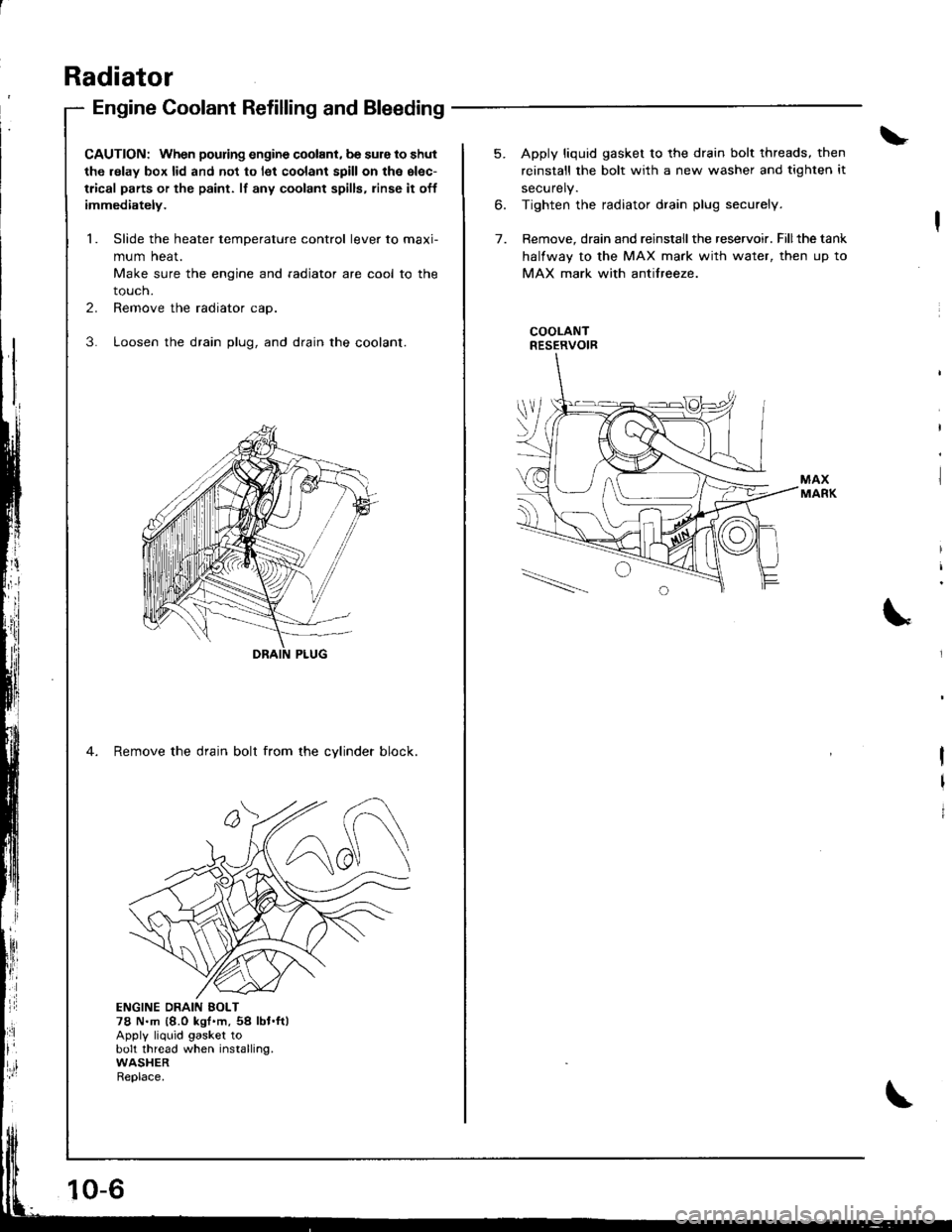

Radiator

Engine Coolant Refilling and Bleeding

CAUTION: When pouring engine coolant, be sure to shut

th6 relay box lid and not to l€t coolant spill on th6 el€c-

trical parts or the paint. lf any coolant spills, rinse it off

immediately.

1. Slide the heater temDerature control lever to maxi-

mum heat.

Make sure the engine and radiator are cool to the

touch.

2. Remove the radiator cap.

3. Loosen the drain plug, and drain the coolant.

4. Remove the drain bolt from the cvlinder block.

ji

Ii'

l:ll

ENGINE DRAIN EOLT78 N.m {8.0 kgt'm,54 lbt.ft)Apply liquid gasket tobolt thread when installing.WASHERReplace.

10-6

5. Apply liquid gasket to the drain bolt threads, then

reinstall the bolt with a new washer and tighten it

securely.

6. Tighten the radiator drain plug securely.

7. Remove, drain and reinstall the reservoir. Fillthe tank

halfway to the MAX mark with water, then up to

MAX mark with antifreeze.

COOLANTRESERVOIR

I

I

I

Trending: timing belt, fuses, transmission oil, parking sensors, sensor, mirror, fuse