HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 171 of 1681

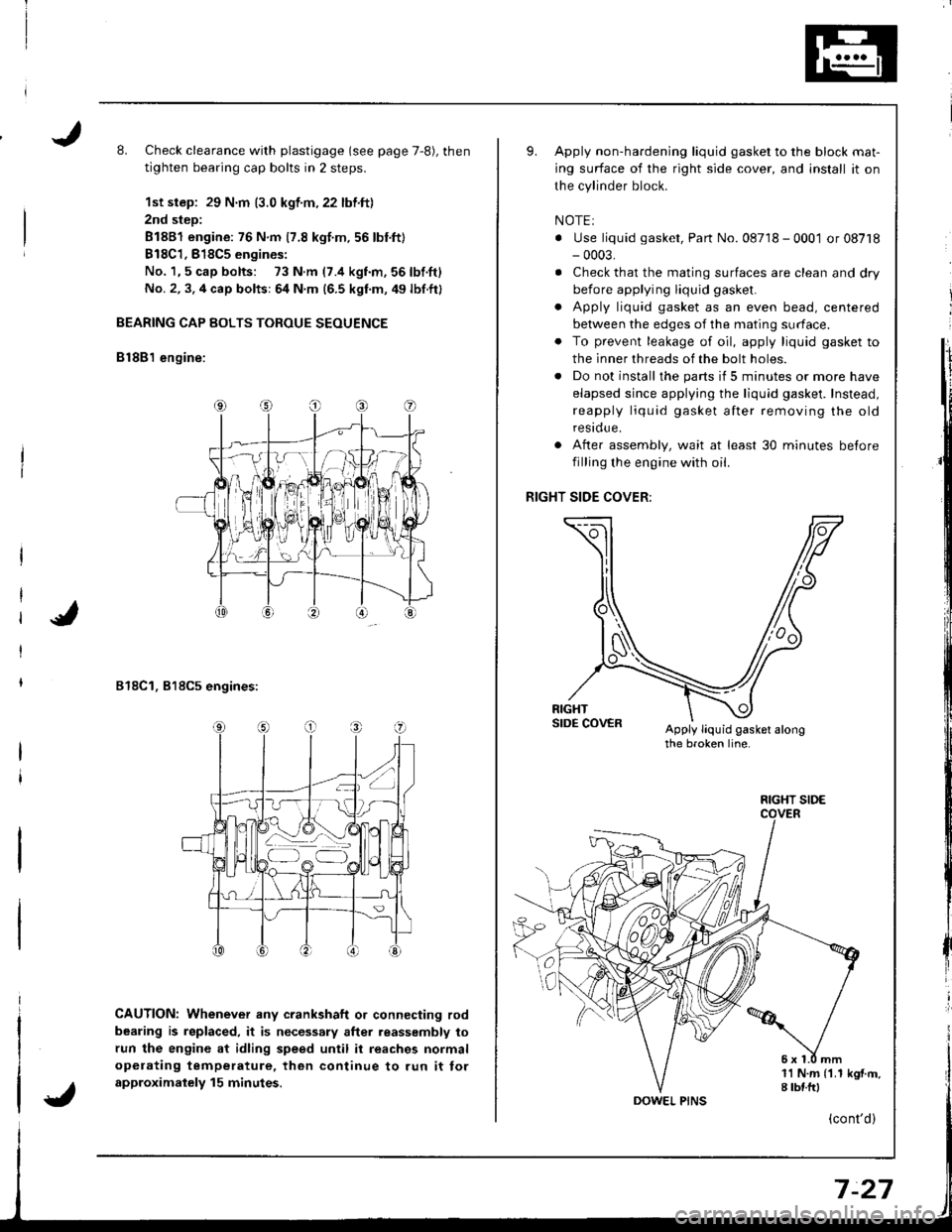

L Check clearance with plastigage (see page 7,8), then

tighten bearing cap bolts in 2 steps.

1st step: 29 N.m (3.0 kgf.m,22 lbf.ft)

2nd step:

81881 engine: 76 N.m 17.8 kgt.m.56 lbnft)

B18C1,818C5 engines:

No. 1,5 cap bolts: 73 N.m (7.4 kgnm,56lbf.ft)

No. 2, 3. 4 cap bolts: 64 N.m (6.5 kgf.m, 49 lbf.ft)

BEARING CAP BOLTS TOROUE SEOUENCE

B lSB'l engine:

818C1, 818C5 engines:

CAUTION: Whenever any crankshaft o. connecting rod

bearing is replaced, it is necessary after reassembly to

run the engine at idling speed until it reaches normal

opelating temperature, then continue to run it tor

approximalely 15 minutes.

Apply non-hardening liquid gasket to the block mat-

ing surface of the right side cover, and install it on

the cylinder block.

NOTEI

. Use liquid gasket, Part No. 08718 - 0001 or 08718- 0003,

. Check that the mating surfaces are clean and dry

before applying liquid gasket.

. Apply liquid gasket as an even bead, centered

between the edges of the mating surface.

. To prevent leakage of oil, apply liquid gasket to

the inner threads of the bolt holes.

. Do not install the parts if 5 minutes or more have

elapsed since applying the liquid gasket. Instead,

reapply liquid gasket after removing the old

residue.

After assembly, wait at least 30 minutes betore

filling the engine with oil.

RIGHT SIDE COVER:

Apply liquid gasket alongthe broken line.

o

a

1l N.m {1.1 kgf.m,I tbf.frl

FIGHT SIDE

(cont'd)

Page 172 of 1681

Crankshaft

Installation (cont'd)

I

I

t

l;I

I

fi,

\

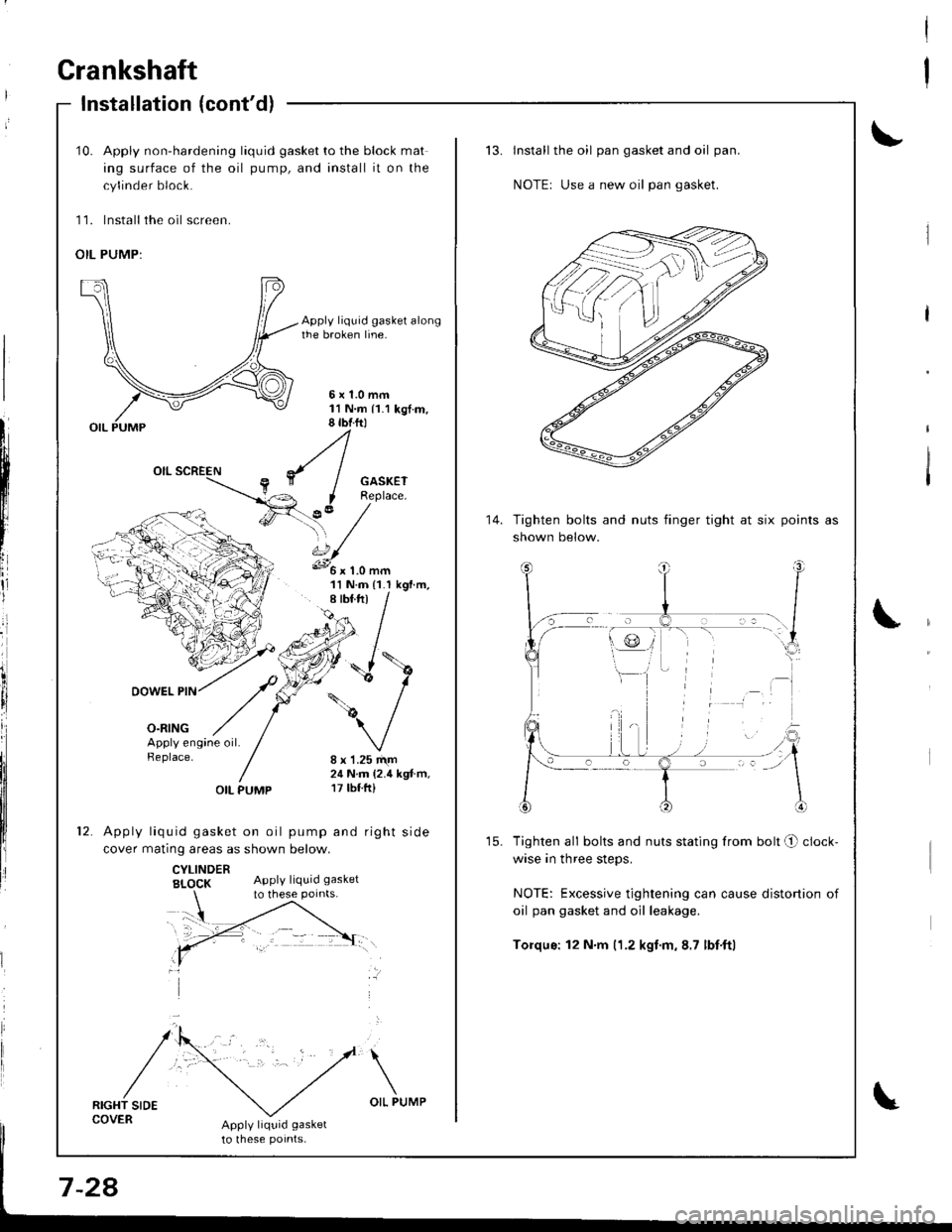

10. Apply non-hardening liquid gasket to the block mat

ing surface of the oil pump, and install it on the

cylinder block.

11. lnstall the oil screen.

OIL PUMP:

Apply liquid gasket alongthe broken line.

5x1.0mm11N.m 11.1 kgt.m,8 tbtftl

GASKETReplace.

?,' /'\, /s.../

11 N.m {1.I kgf.m,

DOWEL PIN

o-ntNG

/\

/

':'

Apply engine oil.Replace.8 x 1.25 r\m24 N.m (2.4 kgt.m,17 tbf.ft)OIL PUMP

Apply liquid gasket on oil pump and right side

cover matinq areas as shown below.

CYLINDERBI_OCK Apply liquid gasket

RIGHT SIDECOVERApply liquid gasket

to lhese potnts-

to these points.

Install the oil pan gasket and oil pan.

NOTEr Use a new oil pan gasket.

Tighten bolts and nuts finger tight at six

shown below.

points as

Tighten all bolts and nuts stating from bolt O clock-

wise in three steps.

NOTE: Excessive tightening can cause distortion of

oil pan gasket and oil leakage.

Torqus: 12 N.m (1.2 kgf.m,8.7 lbf'ftl

14.

Page 173 of 1681

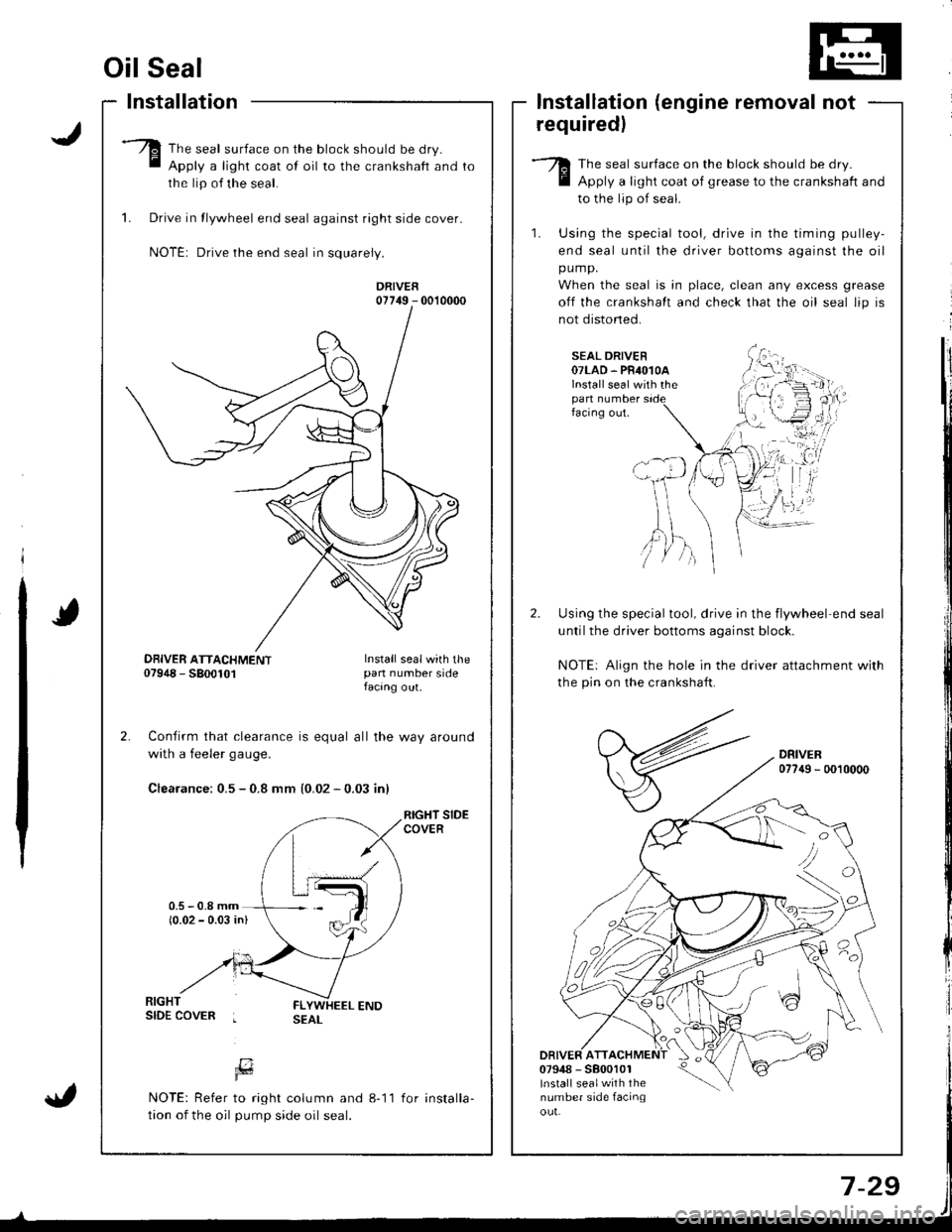

Oil Seal

Installation

The seal surface on the block should be dry.

Apply a light coat of oil to the crankshaft and

the lip of the seal.

1. Drive in tlywheel end seal against right side cover.

NOTE: Drive the end seal in squarely.

DRIVER07749 - 0010000

Confirm that clearance is equal all the way around

with a feeler gaug€.

Clearance: 0.5 - 0.8 mm {0.02 - 0.03 inl

RIGHT SIDECOVER

lnstallation (engine removal not

requiredl

The seal surface on the block should be dry.

Apply a light coat of grease to the crankshaft and

to the lip of seal.

1. Using the special tool, drive in the timing pulley-

end seal until the driver bottoms against the oil

pump.

When the seal is in place, clean any excess grease

off the crankshalt and check that the oil seal lip is

not distoned.

SEAL DRIVER07LAD. PR4O1OAlnstall seal with thepan numberfacing out.

Using the special tool, drive in the flywheel end seal

untilthe driver bottoms aqainst block.

NOTE: Align the hole in the driver attachment with

the pin on the crankshaft.

DRIVER077{9 - 0010000

DRIVER ATT07948 - 5800101lnstall sealwith thenumber side facinqou!.

'tvA,)/ )

DBIVER ATTACHMENT07948 - 5800101Install sealwith thepan number sidefacang out.

[7Fd

NOTE: Refer to right column and 8-11

tion of the oil pump side oil seal.

for installa-

Page 174 of 1681

IJ

Engine Lubrication

Speciaf Tools ........ ........8-2

lllustrated lndex ........ ....8-3

Engine Oil

Inspection ...................... 8-6

Replacement .....,................................. 8-6

Oil Filter

Replacement ....................................... 8-7

Oil Pressure

Testing ......8-9

Oil Jet

Inspection

(818C1,818C5 engines only) ......... 3-9

OilPump

Overhaul .... 8-10

RemovaUlnspection/lnstallation ...... 8-1 1

tr---rl

r-"- i

Page 175 of 1681

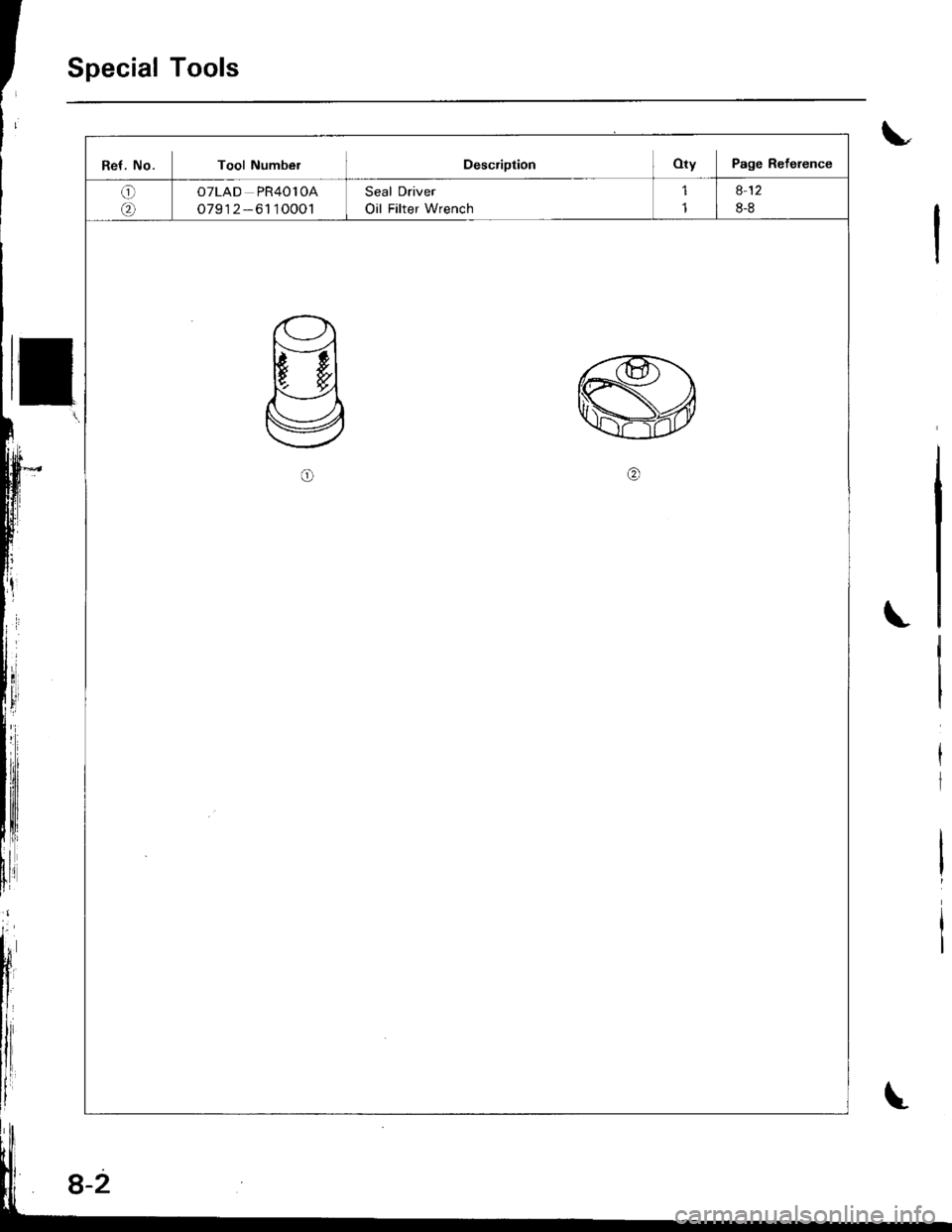

Special Tools

L

Ret. No. Tool NumbelDescriptionOty Page Reference

o

@

OTLAD PR40l OA

o791 2-61 10001

Seal Driver

Oil Filter Wrench

1

1

8-12

8-8

rrl

8-2

Page 176 of 1681

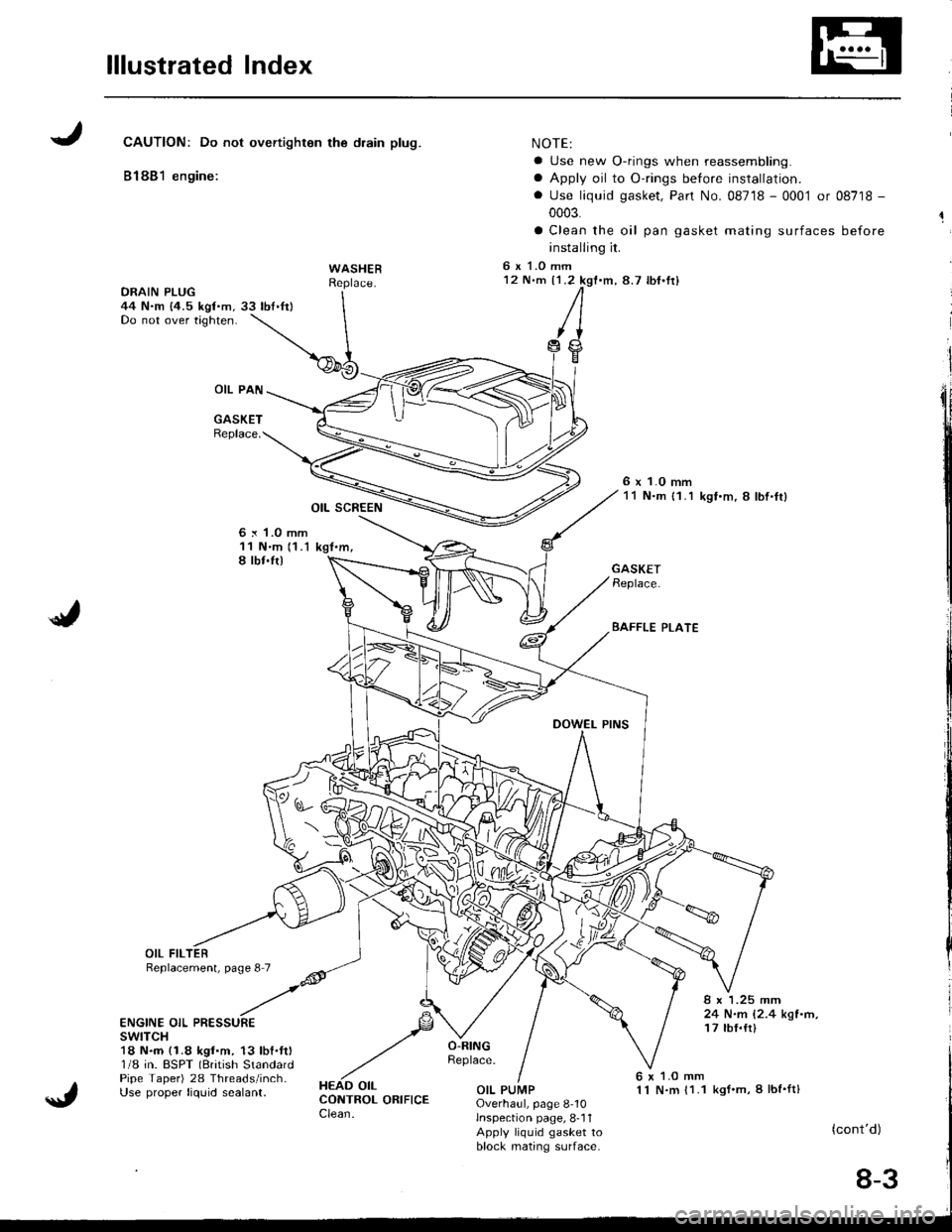

lllustrated Index

JCAUTION: Do not overtighton the drain plug.

81881 engine:

WASHER

OIL PAN

GASKETReplace.

OIL SCREEN

6 x 1.0 mm11 N'm 11.1 kgt.m,I lbt.ft)

NOTE:

a Use new O-rings when reassembling.

a Apply oil to O-rings before installation.

. Use liquid gasket, Pan No. 08718 - 0001 or 08718 -

0003.

a Clean the oil pan gasket mating surfaces before

installing it.

6 x 1.O mm12 N'm {1.2 kgf.m,8.7 lbf'fr)

/I

,trg

6 x 1.0 mm11 N.m {1.1 kgf.m, 8 lbl.ft}

./

GASKETReplace.

BAFFLE PLATE

8 x 1.25 mm24 N.m 12.4 kgl.n,17 tbf.tt)ENGINE OIL PRESSUREswtTcH18 N.m (1.8 kgf.m. 13 lbf.ft)1/8 in. BSPT (British StandardPipe Taper) 28 Threads/inch-Use proper liquid sealant.

6 x 1.O mm1 l N.m {1.1 kgt.m, I lbf'ft}OIL PUMPOverhaul, page 8-10lnspection page, 8-11Apply liquid gasket toblock mating s(]lrface-

(cont'd)

8-3

Page 177 of 1681

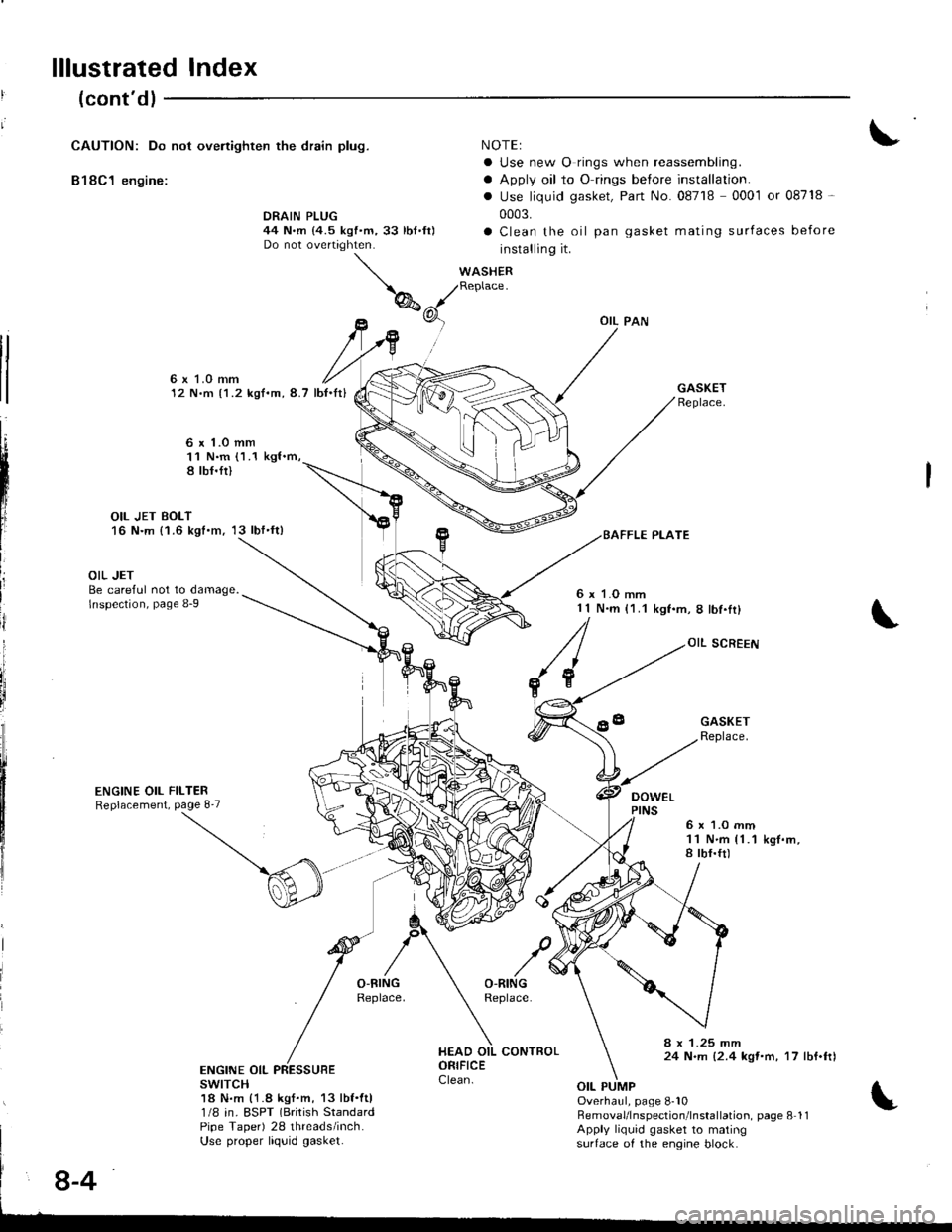

lllustrated Index

(cont'dl

CAUTION: Do not ovenighten the drain plug.

B18C1 engine:

NOTEI

a Use new O rings when reassembling.

a Apply oil to O rings before installation.

. Use liquid gasket, Part No. 08718 0001 or 08718 -

0003.

a Clean the oil pan gasket mating surfaces before

installing it.

WASHERReplace.

DRAIN PLUG44 N.m {4.5 kgf.m,33 lbf.ft)Do not overtighten.

tl

tl

6x LO mm12 N.m {1.2 kgf.m, 8.7 lb{.It}

6 x 1.o mm11 N.m (1.1 kgl.m,8 tbf.fi)

OIL JET BOLT16 N.m {1.6 kgt.m, 13 lbf'ft)

L

III

ij

i

OIL JETBe careful not to damage.lnspection, page 8-9

ENGINE OIL FILTERReplacement, Page 8'7

6 x 1.O mm1 1 N.m (1.1kgf.m,8lbf.Ir)

OIL SCREEN

DOWEL

GASKETReplace.

6x 1.O mm11 N.m {1.1a tbf.ft)k9f.m,

8 x 1.25 mm24 N.m {2.4 kqt'm, 17 lbf.ftlENGINE OIL PRESSUBEswrTcH18 N.m {1.8 kgf.m, 13 lbf.ftl1/8 in. ESPT (Brirish StandardPipe Taper) 28 threads/inch.Use proper liquid gasket.

Overhaul, page 8-10RemovaUlnspection'lnstallation. page 8 11Apply liquid gasket to matingsurtace of the engine block.

8-4

Page 178 of 1681

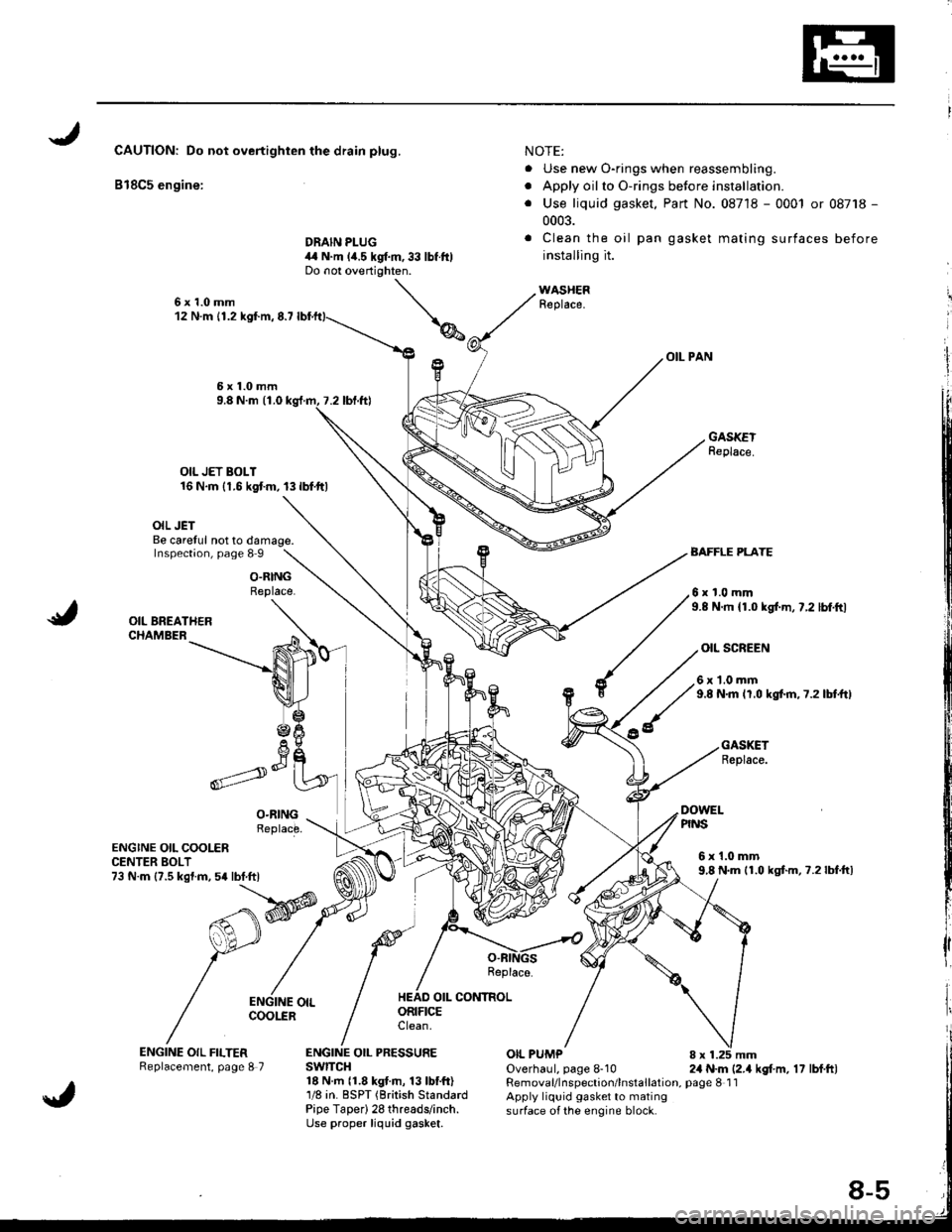

CAUTIONT Do not overtighten the drain plug,

B18C5 engine:

DRAIN PLUG

NOTE:

. Use new O-rings when reassembling.

. Apply oilto O-rings betore installation.

. Use liquid gasket, Part No. 08718 - 0001 or 08718 -

0003.

. Clean the oil pan gasket mating surfaces before

installing it.

WASHERReplace.

OIL PAN

GASKEIReplace.

4,r N.m lia.s kgt m, 33 lbf ftlDo not overtighten.

6x1.0mm12 N.m {1.2 kgI.m,8.7

OIL JET BOLT16 N.m {1.6 kgtm, 13lbf.ttl

\

7.2 tbl.ttl

OIL JETBe carelul not to damage.Inspect;on, page 8 9AAFFLE PLATE

6x1.0mm9.8 N.ft 11.0 kgl.m, 7.2 lbt.ftl

O.RINGReplace.

OIL SCREEN

ENGINE OIL COOLERCENTER BOLT73 N.m {?.5 kgf.m,5a lbt.ftl

ENGINE OIL FILTERReplacement, page I7

Replace.

OIL CONTROL

6x1.0mm9.8 N.m lr.0 kgt ft,7.2lbtftl

GASKETReplace.

8 x 1.25 mm2,1 N.m (2.1 kgt m, 17 lbf.ftl

DOWELPINS

6x1.0mm9,8 N.m 11.0 kgtm,7.2lbf.ftl

ORIFICEClean.

ENGINE OIL PRESSUREswrTcH18 N.m 11.8 kgt.m, 13 lbtft)1/8 in. BSPT (British StandardPipe TaDer) 28 threads/inch.Use proper liquid gasket.

OIL PUMPOverhaul, page 8-10Removal/lnspection/lnstallation, page 8 1 1Apply liquid gasket to matingsurface of the engine block.

Page 179 of 1681

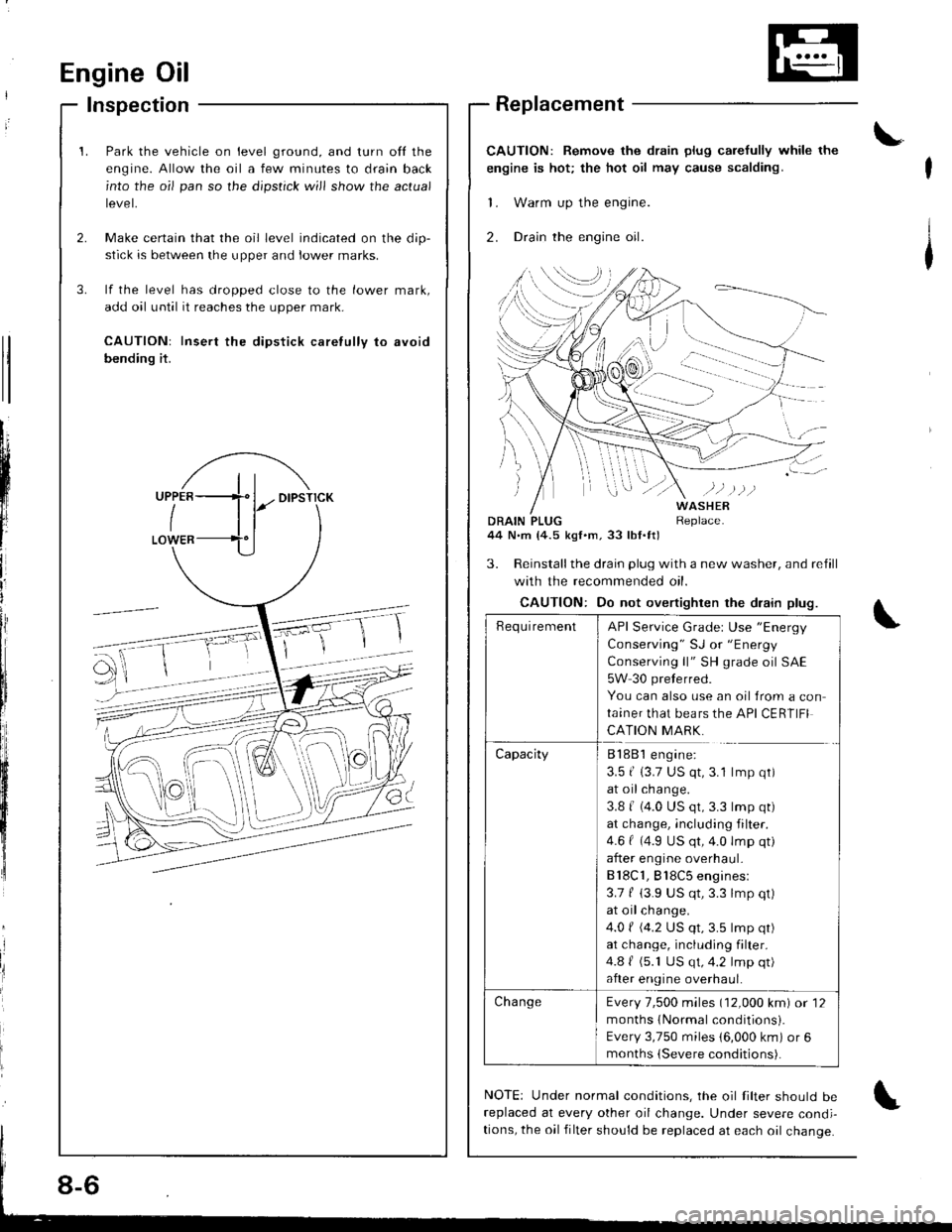

Inspection

Park the vehicle on level ground, and turn ofl the

engine. Allow the oil a few minutes to drain back

into the oil pan so the dipstick will show the actual

tevet,

Make certain that the oil level indicated on the dip-

stick is between the upper and lower marks.

lf the level has dropped close to the lower mark,

add oil until it reaches the upper mark.

CAUTION: Insert the dipstick caretully to avoid

bending it.

Engine Oil

t'

Replacement

CAUTION: Remove the drain plug carefully while the

engine is hot; the hot oil may cause scalding.

'1. Warm up the engine.

2. Drcin the engine oil.

\

tl

tl

tl

Lii

t'l

lr

ii

I

iliIItl

J

DRAIN PLUG44 N.m (4.5 kgl.m,33 lbl.tt)

WASHERReplace.

3. Reinstallthe drain plug with a new washer, and refill

with the recommended oil.

CAUTION: Do not overtighten the drain plug.

NOTE: Under normal conditions, the oil filter should bereplaced at every other oil change. Under severe condi-

tions, the oil filter should be replaced at each oil change.

\

-Ff

_ ,€- @

'@

oE

RequirementAPI Service Grader Use "Energy

Consetuing " SJ or "Energy

Conserving ll" SH grade oil SAE

5W 30 preterred.

You can also use an oil {rom a con

ta,ner that bears the API CERTIFI

CATION MARK.

CapacityB188 l engine:

3.5 | 13.7 US qt,3.1 lmp qt)

at oil change.

3.8 | (4.0 US qt,3.3 lmp qt)

at change, including filter.

4.6 | (4.9 US qt,4.0 lmp qt)

after engine overhaul-

Bl8C1, Bl8C5 engines:

3.7 f (3.9 US qt,3.3 lmp qt)

at oil change.

4.0 ( (4.2 US qt,3.5 lmp qt)

at change, including filter.

4.8 | (5.1 US qt,4.2 lmp qt)

after engine overhaul.

Cha ngeEvery 7,500 miles (12,000 km) or 12

months {Normal conditionsi.

Every 3,750 miles 16,000 km) or 6

months (Severe conditions).

8-6

Page 180 of 1681

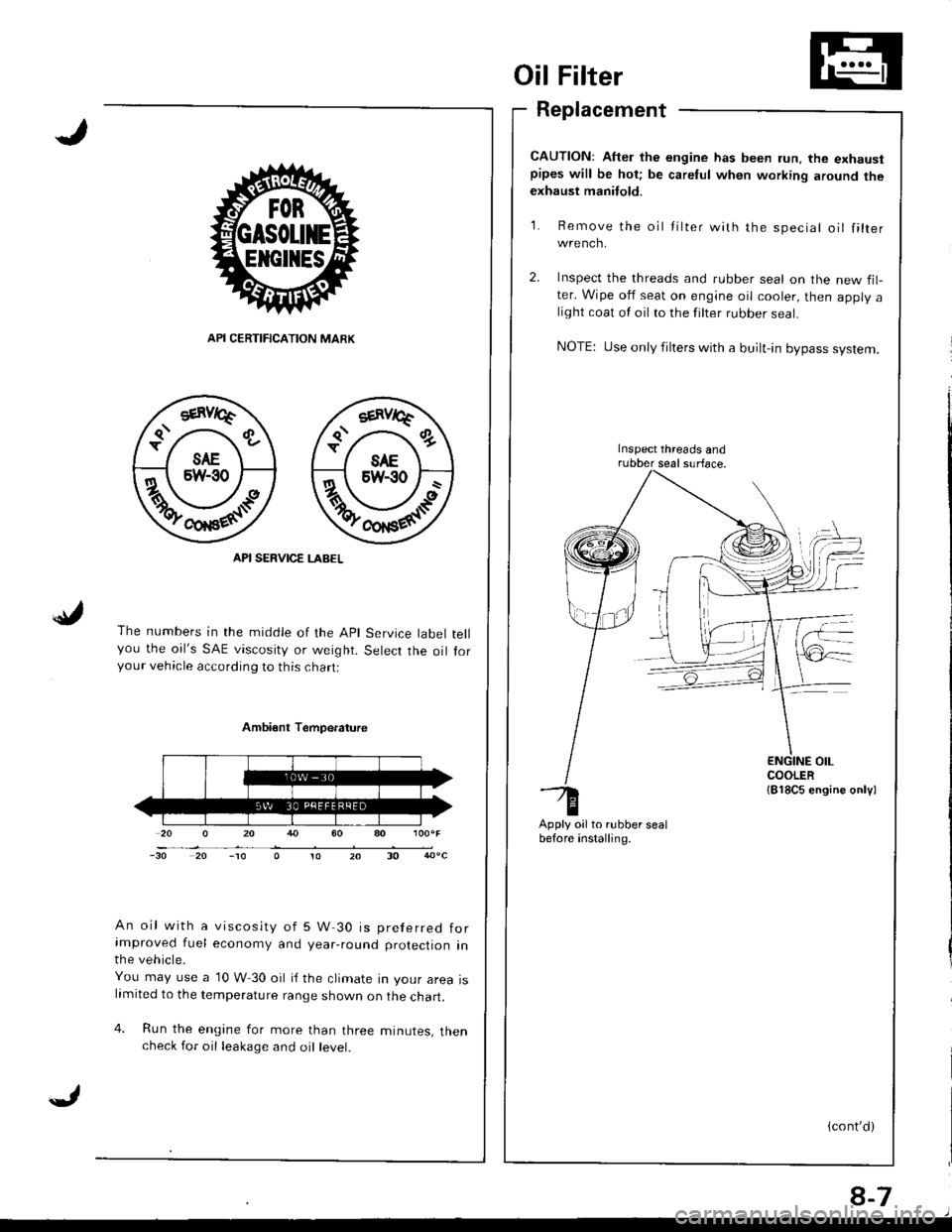

Oil Filter

Replacement

CAUTION: After the engine has been run, the exhaustpipes will be hot; be careful when working around theexhaust manitold.

Re m ove the

wrench.

Iilter with the speciallilter

API CERTIFICATION MARK

API SERVICE LABEL

The numbers in the middle of the Apl Service tabelyou the oil's SAE viscosity or weight. Selecr rhe oilyour vehicle according to this chart:

Inspect the threads and rubber seal on the new fil-ter. Wipe oif seat on engine oil cooler, then apply alight coat ol oil to the filter rubber seal.

NOTE: Use only filters with a built-in bypass system.

Inspect threads andrubber seal surface.

tell

for

Ambi€nt Temperature

An oil with a viscosity of 5 W 30 is preferred forimproved fuel economy and year-round protection inthe vehicle.

You may use a 10 W 30 oil if the climate in your area islimited to the temperature range shown on the chart.

4. Run the engine for more than three minutes, thencheck for oil leakage and oil level.

Apply oilto.ubber sealbefore installing.-to20-30

{cont'd)

8-7