engine HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 599 of 1681

Differential (818B1 engine)

Special Tools ........ ........ 15-2

Differential

lllustrated Index......... . 15-3

Backfash Inspection .... 15-4

Final Driven Gear Replacement ...... 15-4

Bearing Replacement .................... 1 5-5

Oil Seal Removal ........ 15-5

Side Clearance Adjustment ........... 15-6

Oil Seal Installation .-... 15-8

t

Page 601 of 1681

Differential (81 881 engine)

lllustrated Index

t

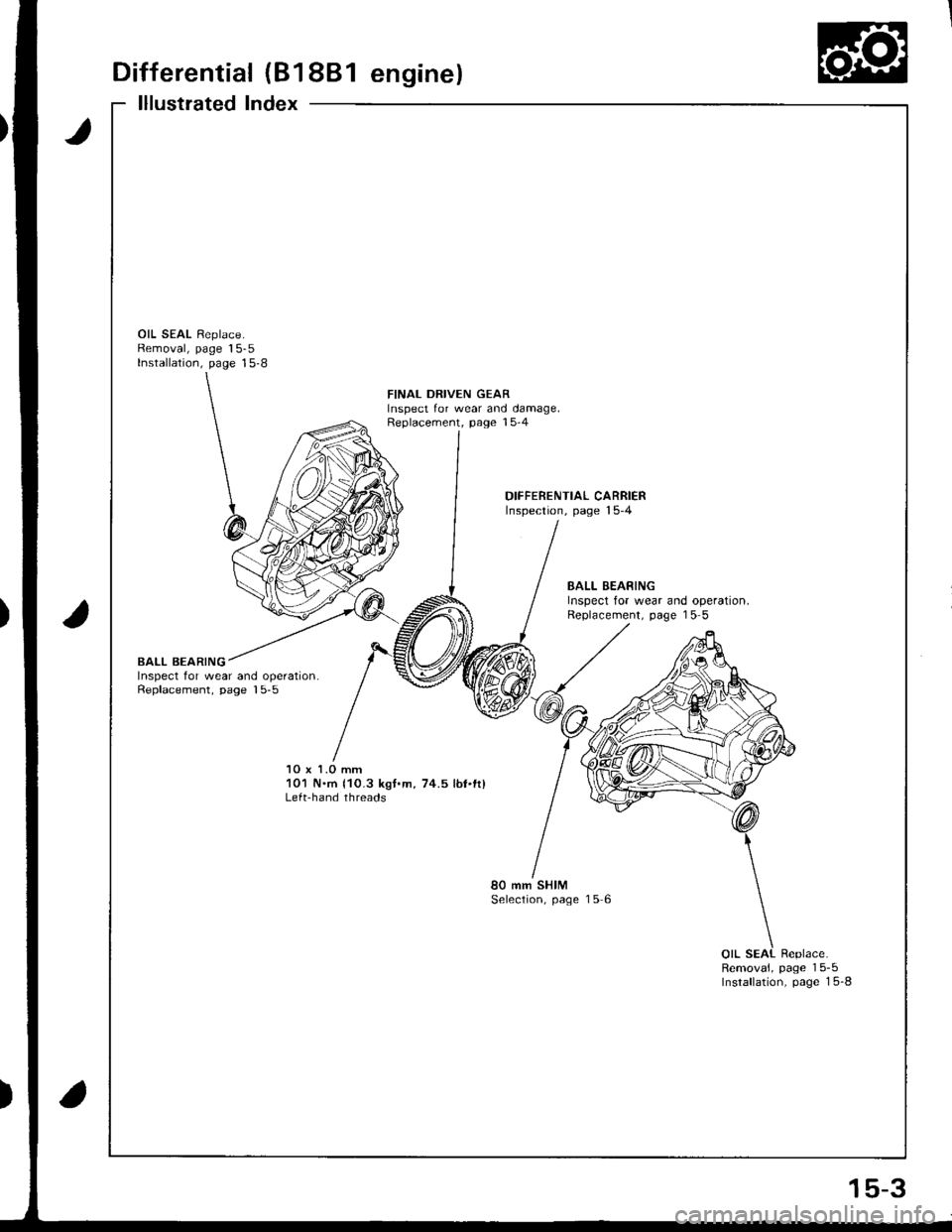

OIL SEAL Replace.Removal, page 15-5Installation, page 15-8

FINAL DRIVEN GEARInspect for wear and damage,Replacement, page 15-4

DIFFEBENTIAL CARRIERInspection, page 15-4

BALL BEARINGInspect for wear and operation.Replacement, page 15 5

BALL BEARINGInspect for wear and operation.Replacement, page 15-5

10 x 1.0 mm101 N'm 110.3 kgt.m, 74.5 lbt'tt)Lefahand threads

80 mm SHIMSelection, page 15 6

Removal, page 15-5Insrallation, page 1 5-8

15-3

Page 602 of 1681

Differential (81881 engine)

Backlash Inspection

Place differential assembly on V-blocks and install

both axles.

N4easure the backlash ot both pinion gears

Standa.d (Newl: O.O5-0.15 mm (O.OO2-0.006 in)

3. It the backlash is not within the standard, replace

the differential carrier.

Final Driven Gear RePlacement

1. Remove the bolts in a crisscross pattern ln several

steps, then remove the linal driven gear trom the

differential carrier.

NOTE: The final driven gear bolts have left-hand

tnreaos.

10 x 1.0 mm101 N'm 110.3 kgf'm, 74.5 lbf'fll

Left-hand threads

FINAL DRIVEN GEAR

OIFFERENTIALCARRIER

Install the final driven gear by tightening the bolts

in a crissc.oss pattern in several steps.

OIAL INDICATOR

Charnfer on inside diameter ottinal driven gear faces carrier.

\

15-4

Page 604 of 1681

Differential (81 8BJ engine)

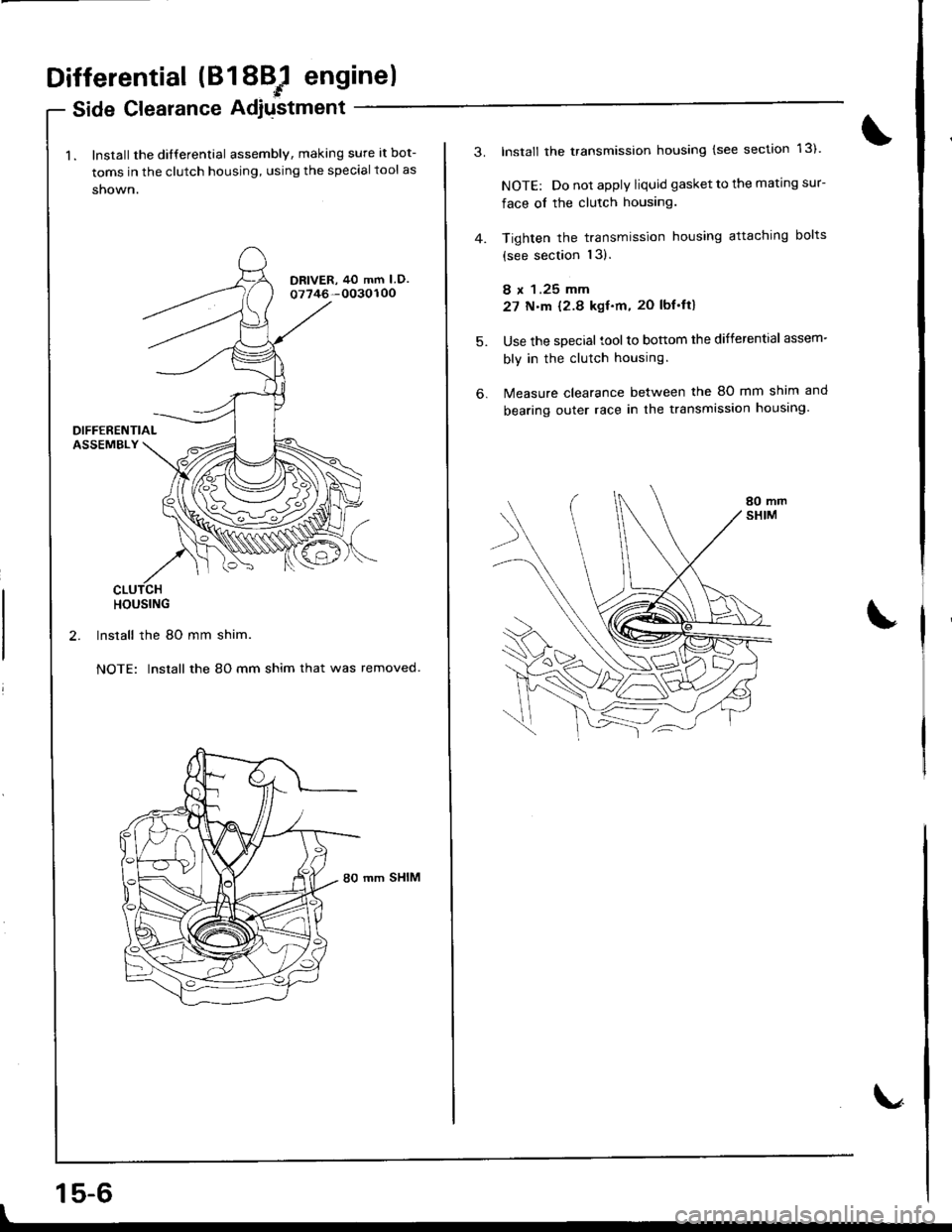

Side Clearance Adjustment

1. lnstall the dilferential assembly, making sure at bot-

toms in the clutch housing, using the special tool as

shown.

DRIVER, 40 mm I D.o7746-0030100

HOUSING

2. Install the 80 mm shim.

NOTE: Insrall the 80 mm shim that was removed.

mm SHIM

15-6

3.Install the transmission housing (see section 13).

NOTE: Do not apply liquid gasket to the mating sur-

face of the clutch housing.

Tighten the transmission housing attaching bolts

{see section l3}.

8 x 1.25 mm

27 N.m {2.8 kgf.m. 20 lbf'ft}

Use the special tool to bottom the differential assem-

bly in the clutch housing.

Measure clearance between the 80 mm shim and

bearing outer race in the transmission housing.

5.

6.

Page 606 of 1681

Differential (81881 engine)

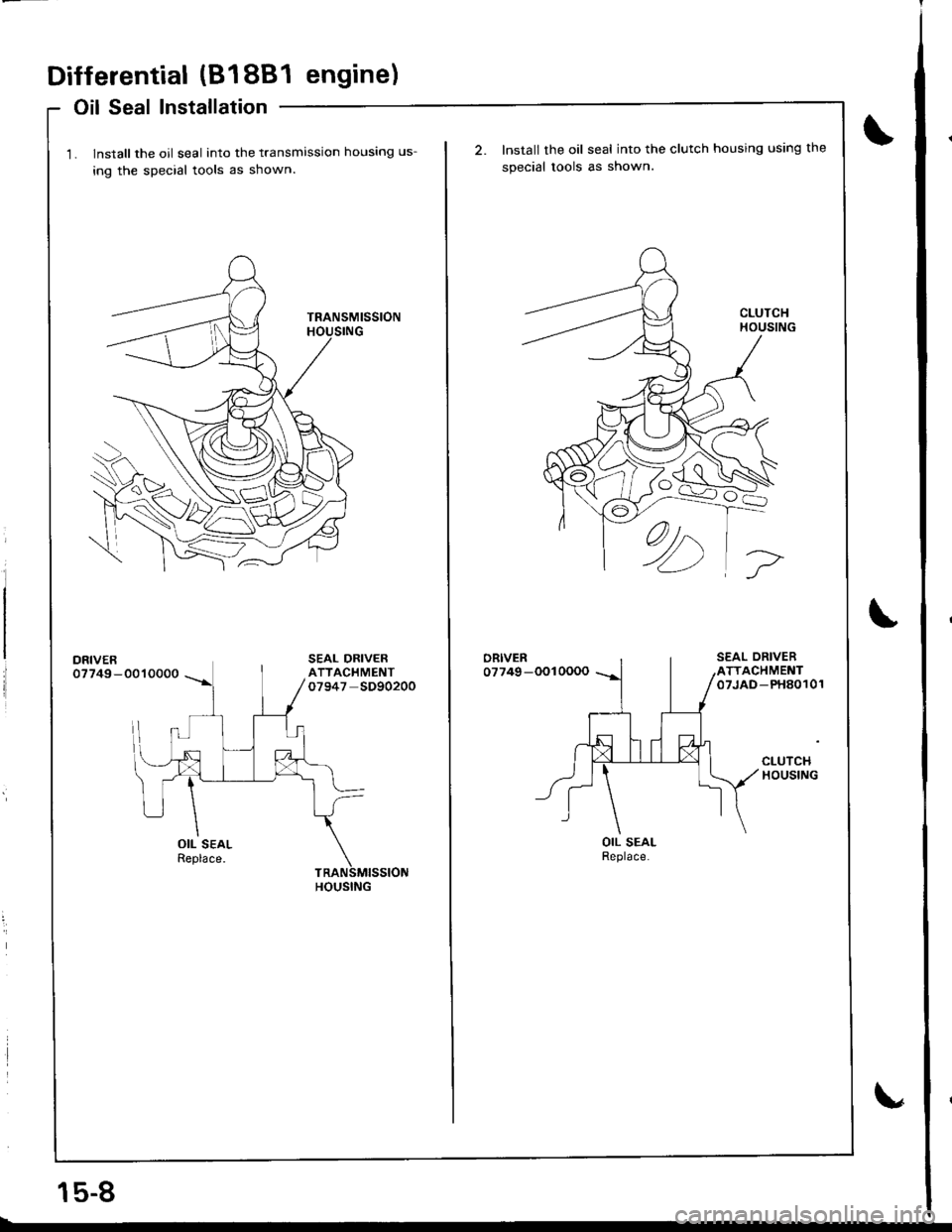

Oil Seal Installation

1. lnstall the oil seal into the transmission housing us-

ing the special tools as shown

DRIVER07749-0010000

OIL SEALReplace.

HOUSING

15-8

Install the oil seal into the clutch housing using the

special tools as shown.

ORIVER07749-OO10000

OIL SEALReplace.

Page 607 of 1681

Differential (818C1 engine)

Special Tools ........ ........ 15-10

Differential

lllustrated Index......... . 15-11

Backfash Inspection .,.. 15-12

Finaf Driven Gear Replacement ...... 15-12

Tapered Roller Bearing Replacement. 15-13

Oil Seal Removal ........ 15-13

Bearing Outer Race Replacement ... 15-14

Tapered Roller Bearing Preload

Adjustment ............. 15-15

Oif Seaf Installation ..... 15-17

Page 609 of 1681

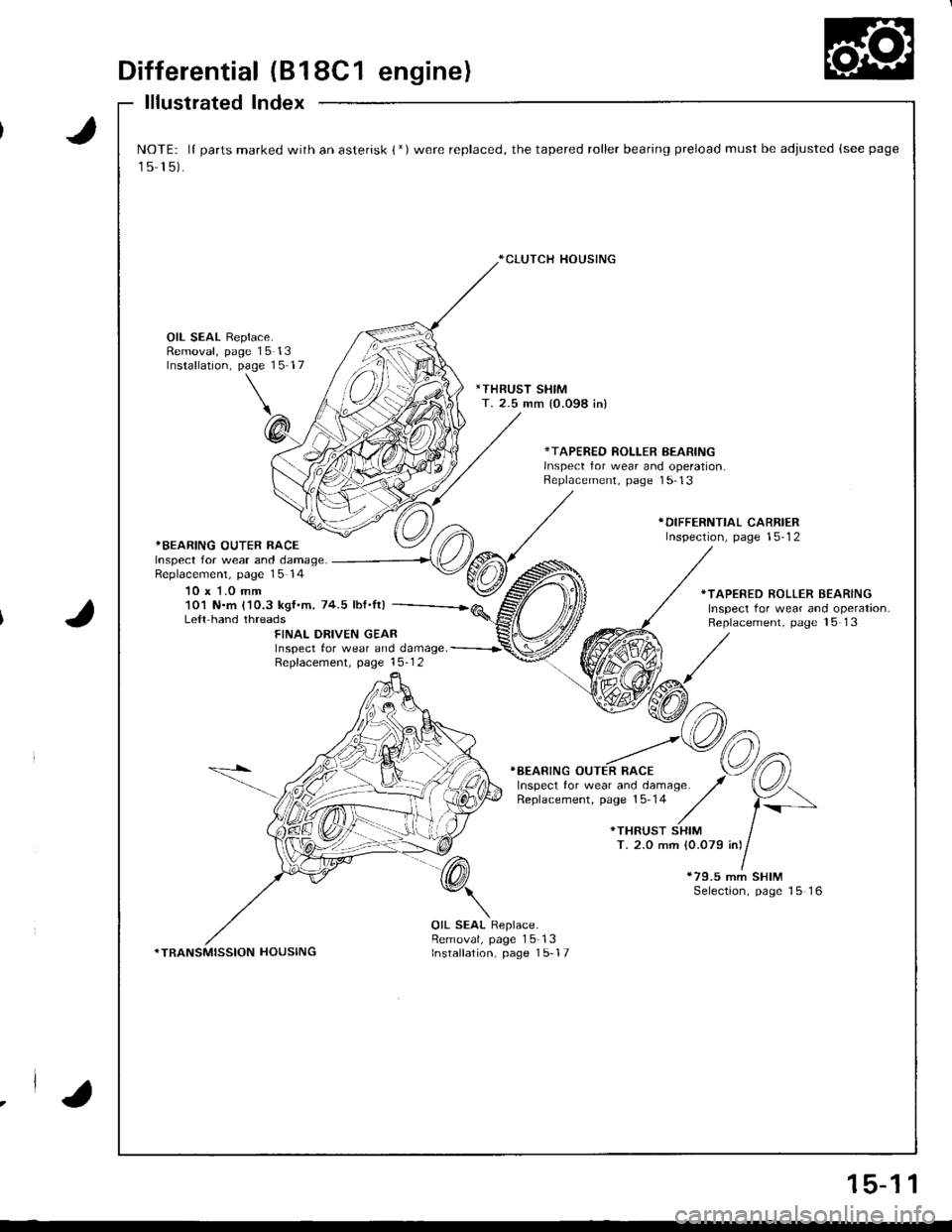

Differential (B18C1 engine)

lllustrated Index

J

J

NOTE: lI parts marked with an asterisk {*)were replaced, the tapered roller bearing preload must be adjusted (see page

15 15).

*CLUTCH HOUSING

OIL SEAL Replace.Removal, page 15 13Installation, page 15 17

*THRUST SHIMT. 2.5 mm {0.098 in)

*TAPERED ROLLER BEARINGlnsDect for wear and ooeration.Replacement, page 1 5-13

*BEARING OUTER RACEInspect for wear and damage.Replacemenl, page 15 14

10 x 1.0 mm

*DIFFERNTIAL CARRIERInspection, page 15-12

101 N.m {'10.3 kgf.m, 74.5 lbf.It)Le{t hand threads

*TAPERED ROLLER BEARINGInspect tor wear and operation.Replacement, page 15 13FINAL DRIVEN GEARInspect tor wear and damage. -----------r'

Repfacement. page 15-1 2

}BEARING OUTER RACE

*79.5 mm SHIMSelection, page 15 16

*TRANSMISSION HOUSING

OIL SEAL Replace.Removal, page 15-13Installation, page 1 5-17

.la

15-1 1

Page 610 of 1681

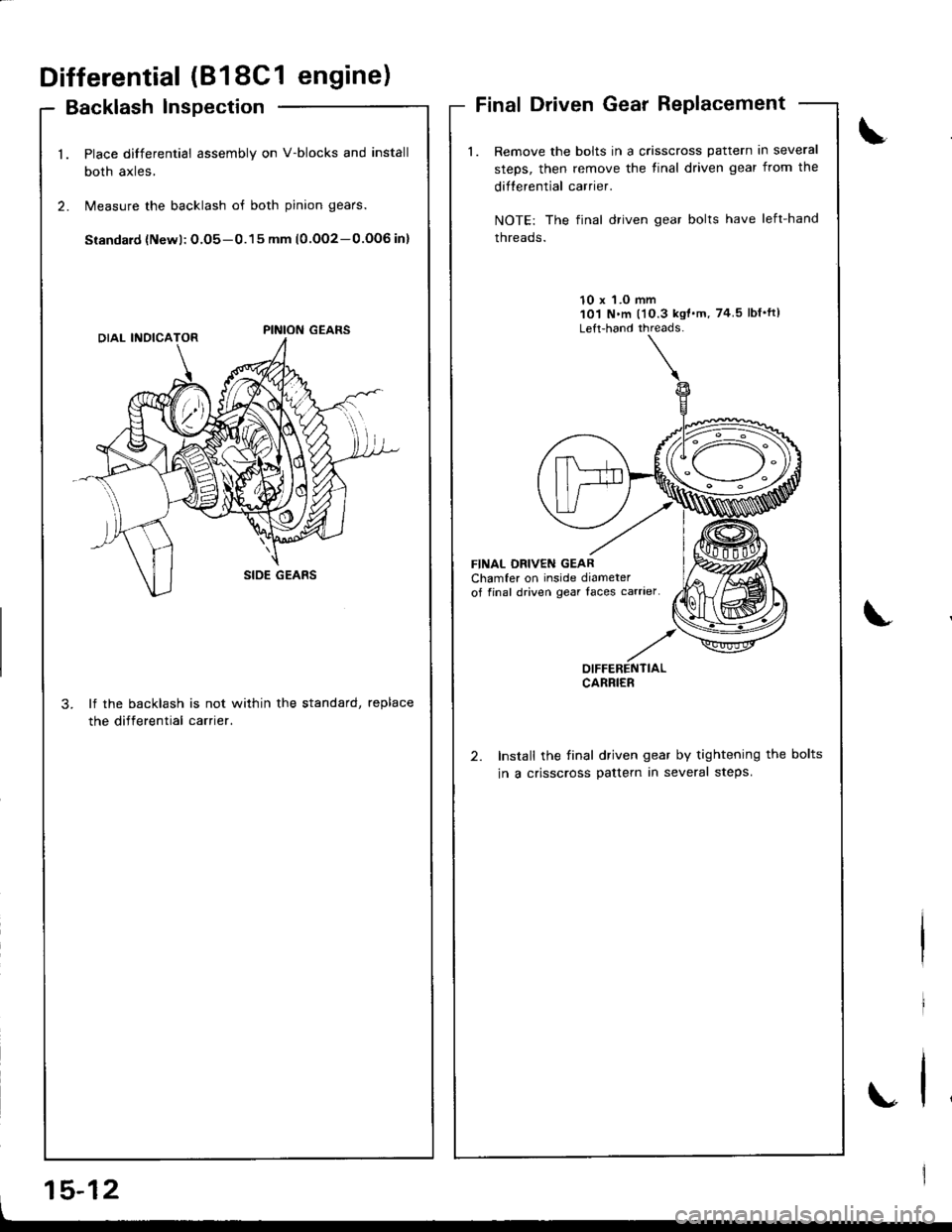

Differential (818C1 engine)

Backlash lnspection

Place differential assembly on V-blocks and install

both axles,

Measure the backlash of both pinion gears.

Siandard {Newl: O.O5-0.15 mm (0.OO2-0.OOG in}

lf the backlash is not within the standard, replace

the differential carrier.

Final Driven Gear Replacement

Remove the bolts in a crisscross pattern in several

steps, then remove the tinal driven gear from the

difterential carrier.

NOTE: The final driven gear bolts have left-hand

threads.

10 x 'l.O mm101 N.m l'10.3 kgt'm, 74 5lbf'ft)

Left-hand threads-

FINAL DBIVEN GEARChamfer on inside diameterof final driven gear Iaces carrier

Install the final driven gear by tightening the bolts

in a crisscross pattern in several steps.

\

.,

OIFFERENTIALCARRIER

I

15-12

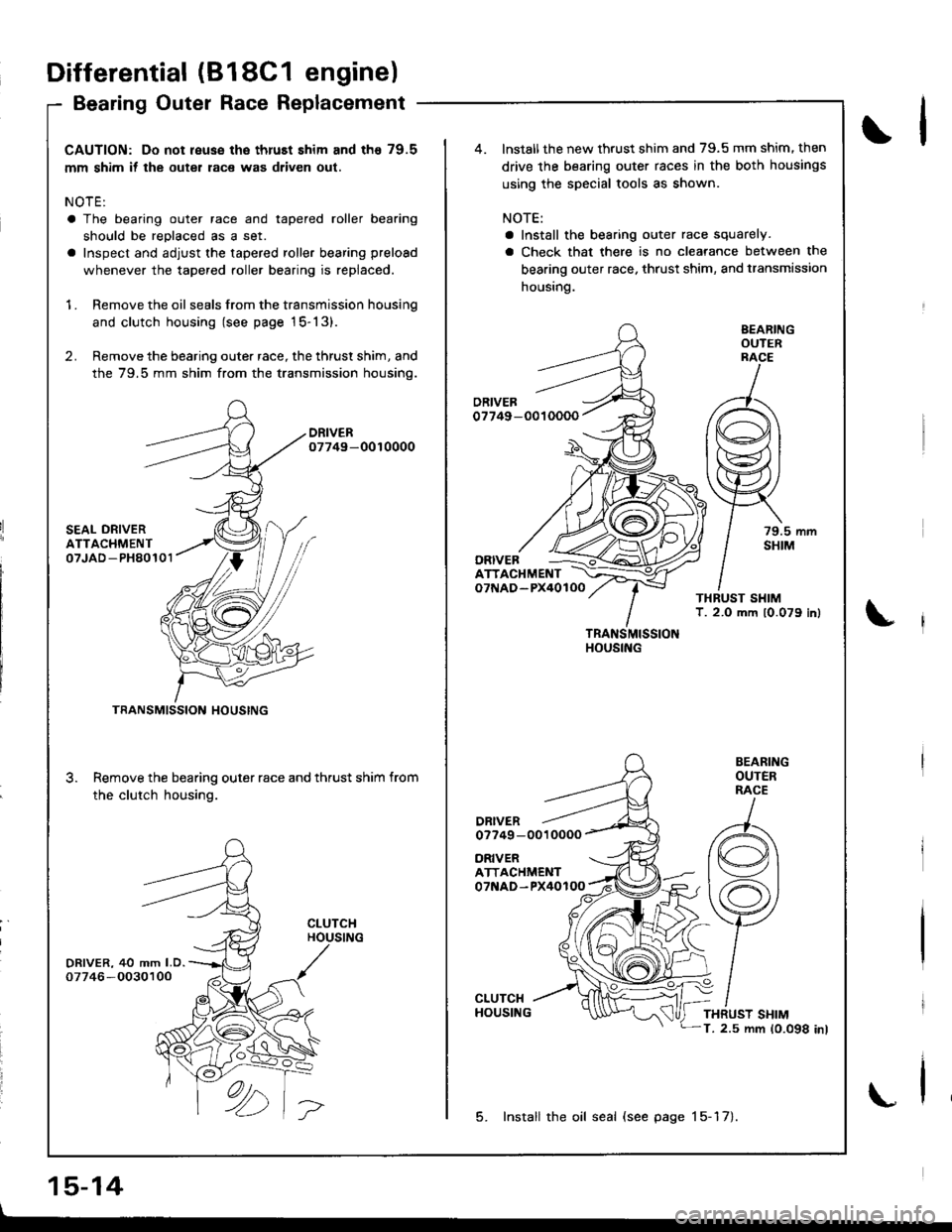

Page 612 of 1681

CAUTION: Do not reuse the thruEt shim and th€ 79.5

mm shim if the outer race was driven out.

NOTE:

a The bearing outer race and tapered roller bearing

should be reDlaced as a set.

a Inspect and adjust the tapered roller bearing preload

whenever the tapered roller bearing is replaced.

1 . Remove the oil seals from the transmission housing

and clutch housing (see page 15-13).

2. Remove the bearing outer race, the thrust shim, and

the 79.5 mm shim from the transmission housino.

DRIVER07749-0010000

SEAL ORIVERATTACHMENT07JAD -PH80101

DRIVER, 40 mm LD.07746 -O030100

3.

TRANSMISSION HOUSING

Remove the bearing outer race and thrust shim from

the clutch housing.

CLUTCHHOUSING

ORIVERATTACHMENT07NAD-PX40100

ATTACHMENTo7f{AD-PX40lOO

DRIVERo7749 -0010000

TRANSMISSIONHOUSING

BEARINGOUTERRACE

79.5 mmSHIM

BEARINGOUTERRACE

THRUST SHIMT. 2.5 mm 10.098 inl

lnstall the new thrust shim and 79.5 mm shim. then

drive the bearing outer races in the both housings

using the special tools as shown.

NOTE:

a Install the bearing outer race squarely.

a Check that there is no clearance between the

bearing outer race. thrust shim, and transmission

housing.

ORIVEB

5. Install the oil seal (see page 15-17).

Differential (818C1 engine)

Bearing Outer Race Replacement

15-14

\l

\

\

Page 614 of 1681

Differential

Ted Roll

(B18C1

er Bearinr

engine)

Preload Adjustment (cont'd)aperelng

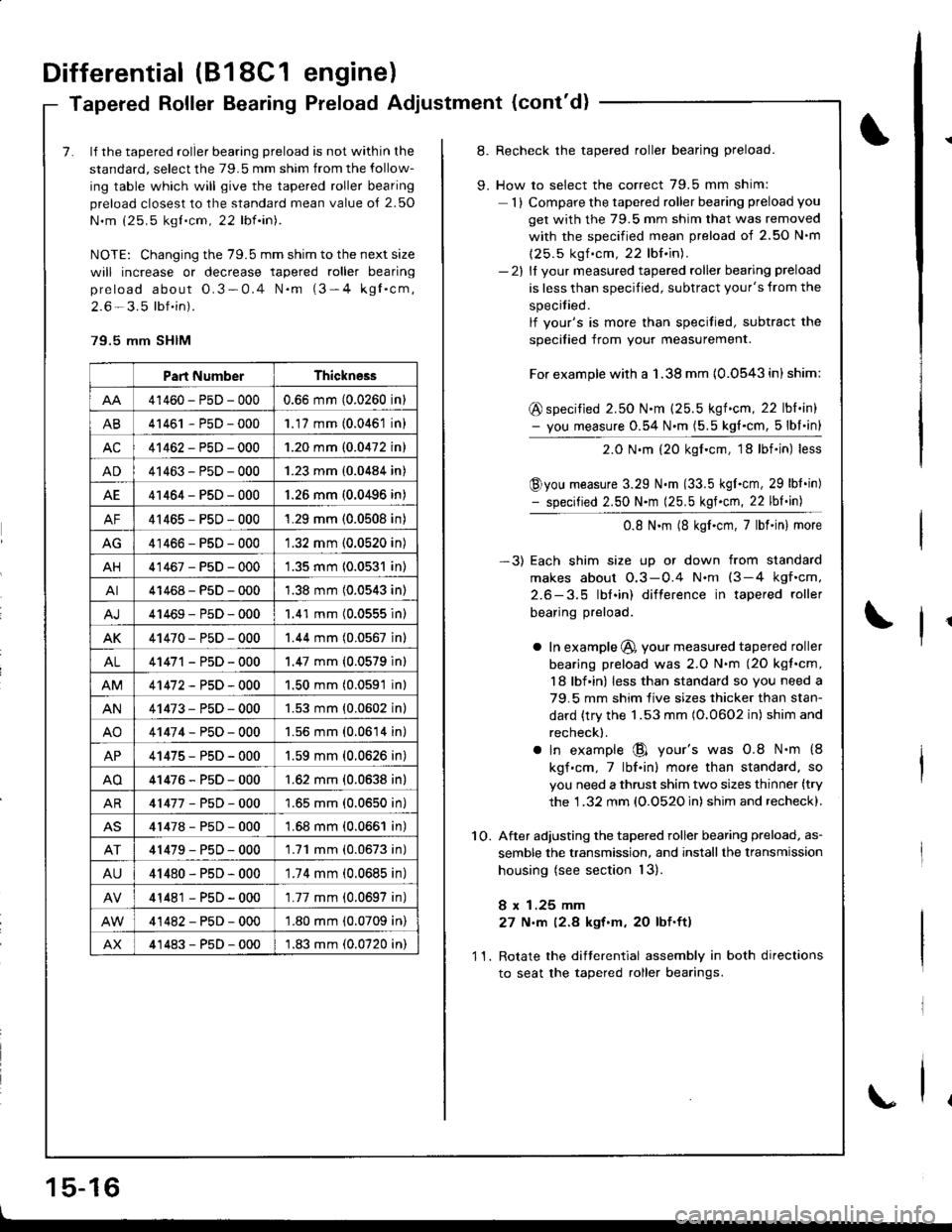

7. lf the tapered roller bearing preload is not within the

standard, select the 79.5 mm shim from the follow-

ing table which will give the tapered roller bearing

preload closest to the standard mean value o{ 2.50

N.m (25.5 kgt.cm, 22 lbf.in).

NOTE: Changing the 79.5 mm shim to the next size

will increase or decrease tapered roller bearing

preload about O.3-0.4 N.m (3-4 kgl.cm,

2.6 - 3.5 lbf.in).

79.5 mm SHIM

Part NumberThickness

41460-PsD-0000.66 mm (0.0260 in)

AB41461 - P5D - 0001.17 mm (0.0461 in)

AC41462-PsD-0001.20 mm (0.0472 in)

AD41463-P5D-0001.23 mm (0.0484 in)

AE41464-PsD-000'1.26 mm (0.0496 in)

AF41465-PsD-0001.29 mm (0.0508 in)

AG41466-PsD-0001.32 mm (0.0520 in)

AH41467-PsD-0001.35 mm 10.0531 in)

AI41468-PsD-0001.38 mm (0.0543 in)

41469-P5D-0001.41 mm (0.0555 inl

AK41470-PsD-0001.44 mm (0.0567 in)

AL41471 - PsD - 000'1.47 mm {0.0579 in}

41472-P5D-0001.50 mm (0.0591 in)

AN41473-PsD-0001.53 mm {0.0602 in}

AO41474-P50-0001.56 mm (0.0614 in)

AP41475-PsD-0001.59 mm (0.0626 in)

AO41476-P5D-000'1.62 mm {0.0638 in}

AR41477-P5D-0001.65 mm (0.0650 in)

41478-P5D-0001.68 mm (0.0661 in)

41479-P50-0001.71 mm (0.0673 in)

AU41480-PsD-0001.74 mm (0.0685 in)

41481 - PsD - 000'1.77 mm (0.0697 in)

41482-PsD-000'1.80 mm (0.0709 in)

AX41483-P5D-0001.83 mm (0.0720 in)

8. Recheck the tapered roller bearing preload.

9. How to select the correct 79.5 mm shim:

1) Compare the tapered roller bearing preload you

get with the 79.5 mm shim that was removed

with the soecified mean Dreload of 2.50 N'm

(25.5 kgf .cm, 22 lbf.in).- 2l ll vour measured tapered roller bearing preload

is less than specified, subtract your's from the

specitied.

lf vour's is more than specitied, subtract the

soecified from vour measurement.

For example with a 1.38 mm {0.0543 in) shim:

@ specified 2.50 N.m (25.5 kgf.cm, 22 lbl.in)- you measure 0.54 N.m (5.5 kg{.cm, 5lbl.in}

2.0 N.m (20 kgf.cm, 18lbf.in) less

@you measure 3.29 N.m (33.5 kgI.cm, 29 lbt.in)- specified 2.50 N.m (25.5 kgf.cm, 22 lbf.in)

0.8 N.m (8 kgf.cm,7lbf.in) more

-3) Each shim size up or down from standard

makes about O.3-0.4 N.nt (3-4 kgf.cm,

2.6-3.5 lbl.in) difterence in tapered roller

bearing preload.

a In example @, your measured tapered roller

bearing preload was 2.O N.m (2O kgt.cm,

18 lbf in) less than standard so you need a

79.5 mm shim live sizes thicker than stan-

dard {try the 1.53 mm (O.0602 in) shim and

recheck).

a ln example @ your's was 0.8 N.m {8

kgf.cm,7lbf.in) more than standard. so

you need a thrust shim two sizes thinner (try

the 1 .32 mm (O.O52O in) shim and recheck).

1O. After adjusting the tapered roller bearing preload, as-

semble the transmission, and installthe lransmission

housing (see section 13).

8 x 1.25 mm

27 N,m (2.8 kgt'm, 20 lbf.ft)

11. Rotate the difterential assembly in both directions

to seat the tapered roller bearings.

1 5-16

\