abs HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 347 of 1681

lT

Emission Control System

YES

{To page 11-143}

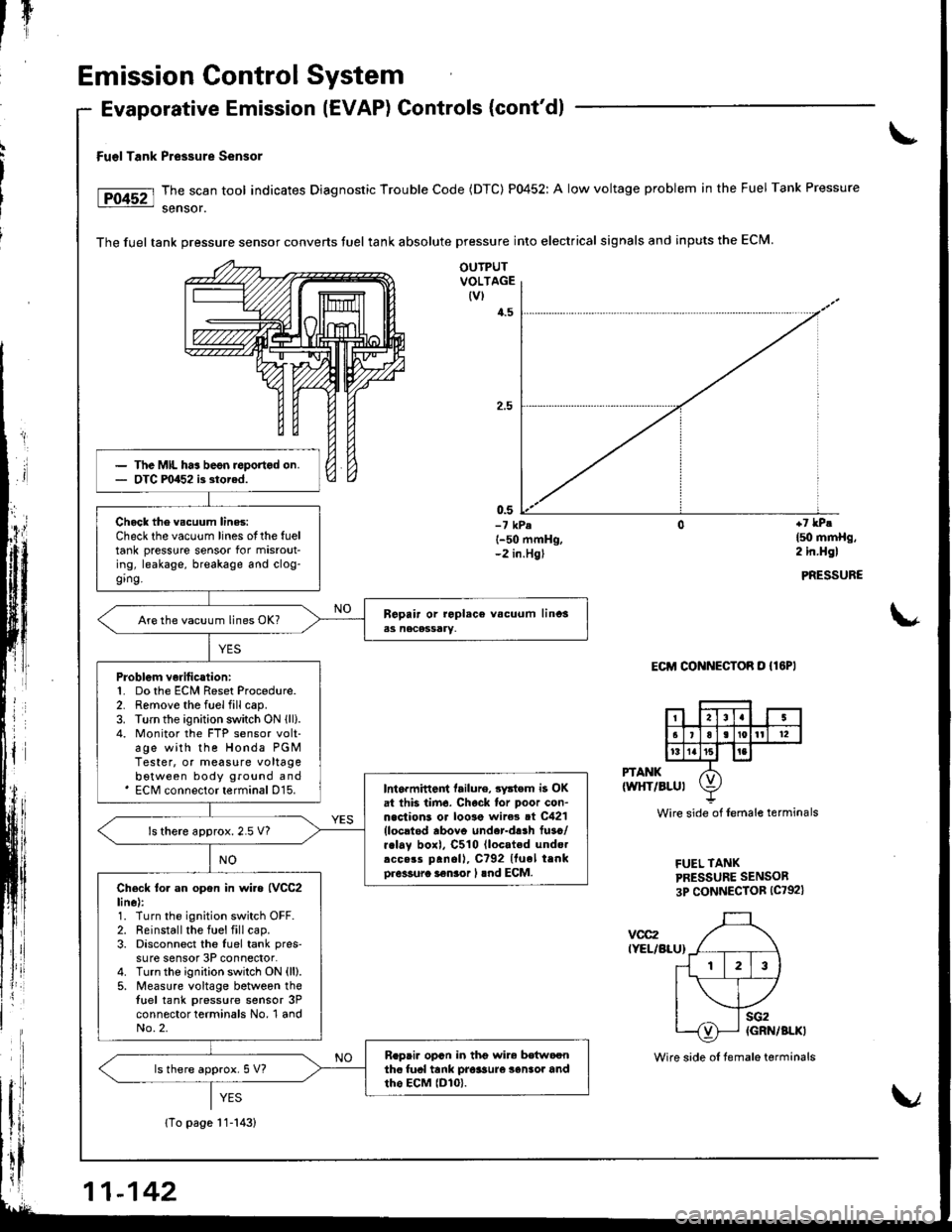

Fu€l Tank Pressure Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensor.

The fuel tank pressure sensor converts tuel tank absolute pressure into electrical signals and inputs the ECM.

Evaporative Emission (EVAP) Controls (cont'dl

OUTPUTVOLTAGE(vl

4.5

0.5-7 kPel-50 mmHg,-2 in.Hgl

+7 lPe

l5o mmHg,2 in.Hgl

PRESSURE

\*

Eclrl CONNECToR o {lEPl

PTANK(wltT/BLul

vcc2IYEL/BLU}

Wire side of lemale terminals

FUEL TANKPRESSURE SENSOR

3P CONNECTOR (C792)

The MIL ha3 beon roportod on.OTC F0452 i3 storad.

Chock the vscuum lines:Check the vacuum lines otthe fueltank pressure sensor for misrout-ing, leakage, breakage and clog-ging.

Are the vacuum lines OK?

Problgm verilication:1. Do the ECM Reset Procedure.2. Remove the fuel fill cap.3. Turn the ignition switch ON lll).4. Monitor the FTP sensor volt-age with the Honda PGMTester, or measure voltagebotween body ground and' ECM connector terminal D15.Int6rmittent tailure, 3ystem i3 OKat thb tirn6. Chock lor poor con-n.clions or loo3e wire3 ot C421{locltod rbovo under-d!.h fuso/r.lay boxl, C510 lloc.ted undo.rcc.rs panoll, C?92 Ituel trnko.6sura i€nior I lnd ECM.

ls there approx.2.5 V?

Check to. an opon in wi.a {VCC2line):1. Turn the ignition switch OFF.2. Reinstall the fuel fill cap.3. Disconnect the luel tank pres'su re sensor 3P connector.4. Turnthe ignition switch ON (ll).

5. Measure voltage between thetuel tank pressure sensor 3Pconnector terminals No, 1 andNo.2.

R.pai. opcn in thg wir6 bdtwoonthc fual tank pro$ure 3enlor andtho EcM lDlo).ls there approx. 5 V?

11-142

Wire side oI temale terminals

Page 532 of 1681

I

t

I

1.

2.

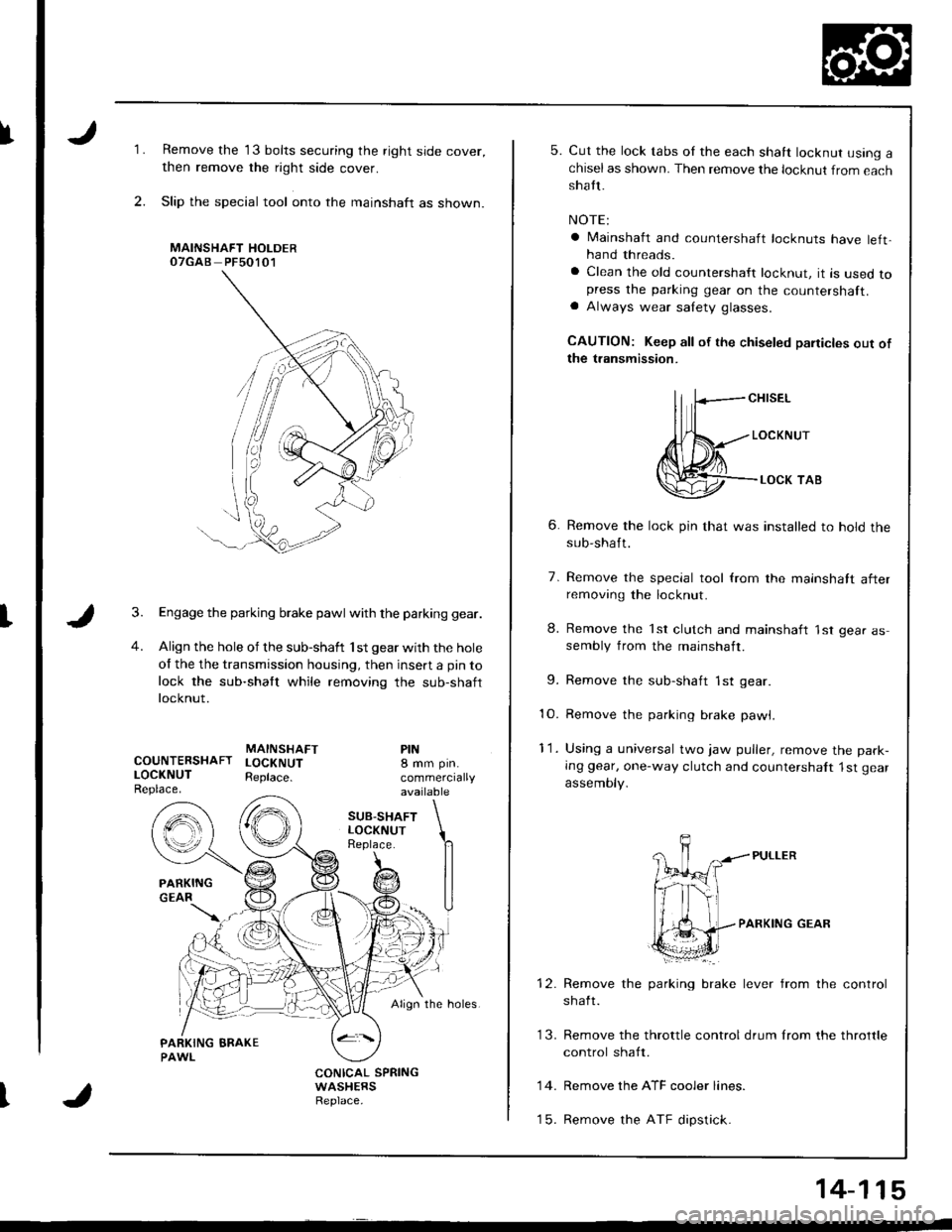

Remove the 13 bolts securing the right side cover,

then remove the right side cover.

Slip the special tool onto the mainshaft as shown.

MAINSHAFT HOLDEROTGAB PFsO1O1

Engage the parking brake pawl with the parking gear.

Align the hole of the sub-shaft 'lst gear with the hole

of the the transmission housing, then insert a pin to

lock the sub-shaft while removing the sub-shaft

locknut.

MAINSHAFTCOUNTERSHAFT LOCKNUTLOCKNUT Reptace.Replace.

PIN8 mm pin.

commerciallyavailable

SUB.SHAFTLOCKNUTReplace.

Align the holes.

CONICAL SPRINGWASHERSReplace.

5. Cut the lock tabs oI the each shaft locknut using achiselas shown. Then remove the locknut from eachshatt.

NOTE:

a lvlainshaft and countershaft locknuts have left,hand threads.

a Clean the old countershaft locknut, it is used topress the parking gear on the countershaft.a Always wear salety glasses.

CAUTION: Keep all of the chiseled paiticles out ofthe transmission.

ll fcH,sEL

Jl{*---,o"*",r

@--.**,o,

6. Remove the lock pin that was installed to hold thesub-shaft.

7. Remove the special tool from the mainshatt afterremoving the locknut.

8. Remove the 'lst clutch and mainshaft 'lst gear assembly from the mainshaft.

9. Remove the sub-shaft 1st gear

10. Remove the parking brake pawl,

11. Using a universal two jaw puller, remove the park-

Ing gear, one-way clutch and countershalt 1st gear

assemoty.

PARKING GEAR

brake lever from the controlRemove the parking

shaft.

Remove the ATF cooler lines.

Remove the ATF dipstick.

13. Remove the throttle control drum lrom the throttle

control shaft.

14.

t5.

14-115

Page 637 of 1681

Driveshafts

Removal lcont'd)

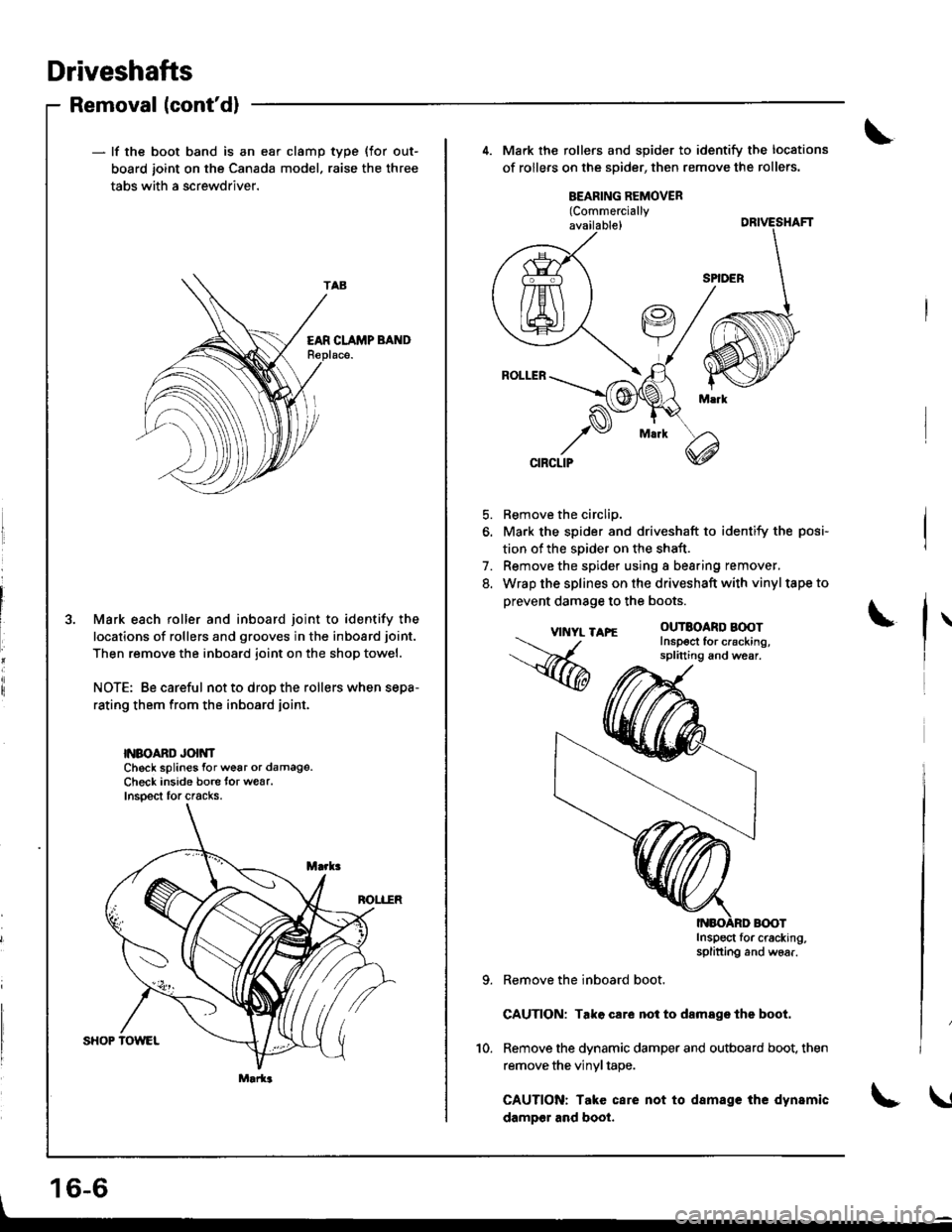

- lf the boot band is an ear clamp

board joint on the Canada mode

tabs with a screwdriver.

type {for out-

raise the three

EAR CLAMP BAND

3. Mark each roller and inboard joint to identify the

locations of rollers and grooves in the inboard joint.

Then remove the inboard joint on the shop towel.

NOTE: Be careful not to drop the rollers when sepa-

rating them from the inboard joint.

NBOAND Jo|NNCheck splines for wear or damage.Check inside bore lor wear.lnsoect for cracks.

Marla

4. Mark the rollers and spider to identify the locations

of rollers on the spider, then remove the rollers.

VI'{YL T

,%

BEARING REMOVER(Commercially

available)

5. Remove the circlip.

6. Mark the spider and driveshaft to identify the posi-

tion of the soider on the shaft.

7. Remove the spider using a bearing remover,

8. Wrap the splines on the driveshaft with vinyltape to

prevent damage to the boots.

APE ouTBoaRD BOOTInsp€ct ror crackrng,splitting and wear.

Inspect for cracking,splitting and woar.

Remove the inboard boot.

GAUTION: Tako care noi to damsge the boot.

Remove the dynamic damper and outboard boot. then

remove the vinyl tape.

CAUTION: Take care not to damage the dynamic

dampor and boot.

10.

16-6

\

Page 644 of 1681

![HONDA INTEGRA 1998 4.G Owners Manual E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion HONDA INTEGRA 1998 4.G Owners Manual E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion](/img/13/6069/w960_6069-643.png)

E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion of the band with a com-

mercially available boot band pincers.

BOOT AAND PINCERS(Commercially available)Oetiker 1098 or equivalent

POSTION

Measure the clearance between the closed ear

portion of the band.

Siandard:0-3 mm (0 - 0.12 in)

lf the band's, clearance is not within the standard,

close the ear portion of the band further.

NOTE:

. Make sure the band does not move.

. Remove any grease remaining in the surround-

ing surfaces.

16-13

Page 679 of 1681

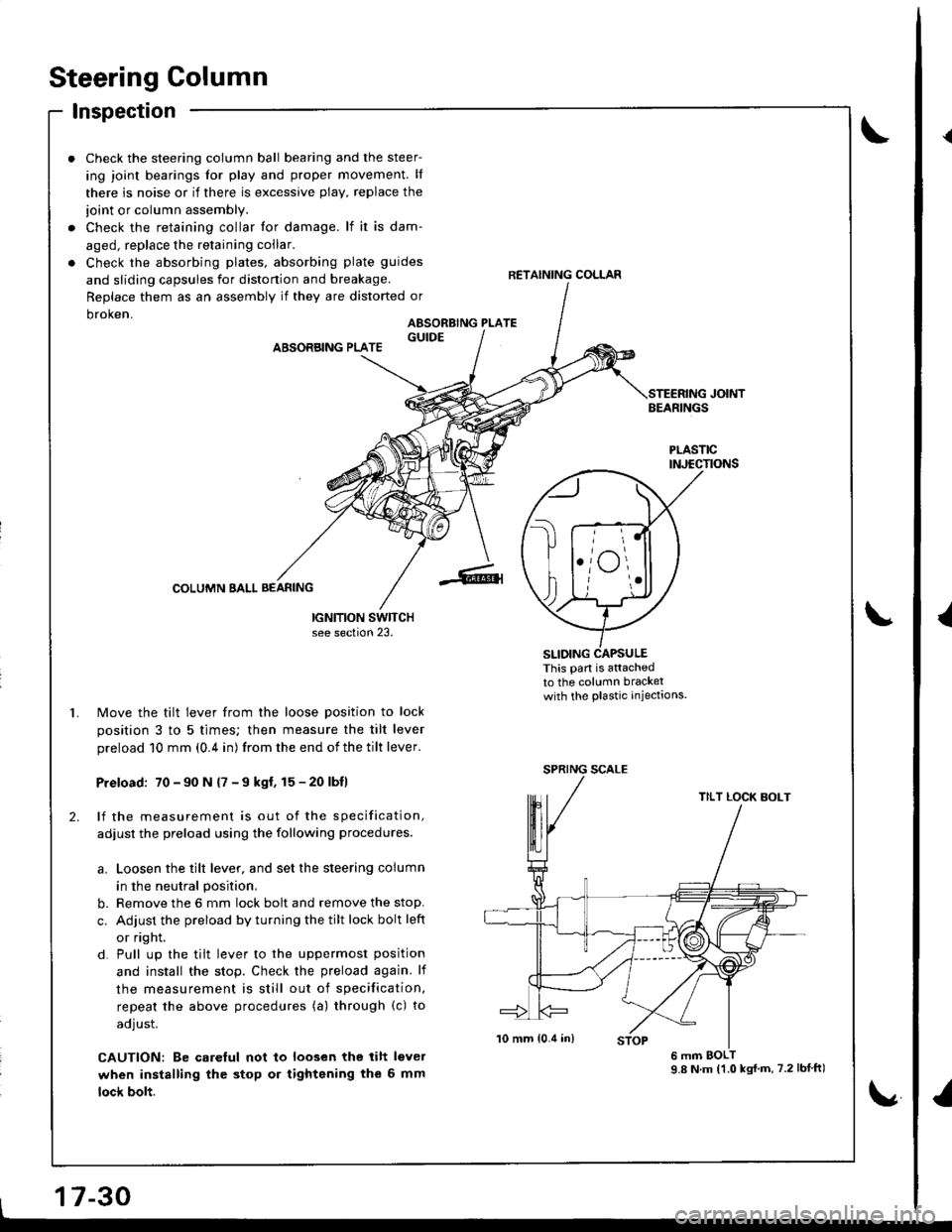

Steering Column

Inspection

Check the steering column ball bearing and the steer-

ing joint bearings for play and proper movement. ll

there is noise or if there is excessive plav, replace the

ioint or column assembly.

Check the retaining collar tor damage. lf ir is dam'

aged, replace the retaining coilar.

Check the absorbing plates, absorbing plate guides

and sliding capsules for distonion and breakage.

Replace them as an assembly if they are distorted or

DroKen.

ABSORBING PLATE

COLUMN SALL BEANING

IGNITION SWITCHsee section 23.

Move the tilt lever from the loose position to lock

position 3 to 5 times; then measure the tilt lever

preload 10 mm (0.4 in) from the end of the tilt lever.

Preload: 70-90 N {7 -9 kgl, 15-20 lbll

lf the measurement is out of the specification,

adjust the preload using the following procedures.

a. Loosen the tilt lever, and set the steering column

in the neutral position,

b. Remove the 6 mm lock bolt and remove the stop.

c. Adjust the preload by turning the tilt lock bolt left

or right.

d. Pull up the tilt lever to the uppermost position

and install the stop. Check the preload again. lf

the measurement is still out of specification,

repeat the above procedures (a) through (c) to

adjust.

CAUTION: Be carelul not to loosen the lilt lsvel

when installing the stop or tightening the 6 mm

lock bolt.

RETAINING COLLAR

AESORBING PLATE

JOINTBEARINGS

PLASTICINJECTIONS

This pan is attachedto the column bracketwith the plastic iniectaons.

t

SPRING SCALE

TILT LOCK BOLT

17-30

9.8 N.m (1.0 kst.m, 7.2 lblft)

t

{

I

Page 707 of 1681

Power Steering Gearbox

Reassembly (cont'dl

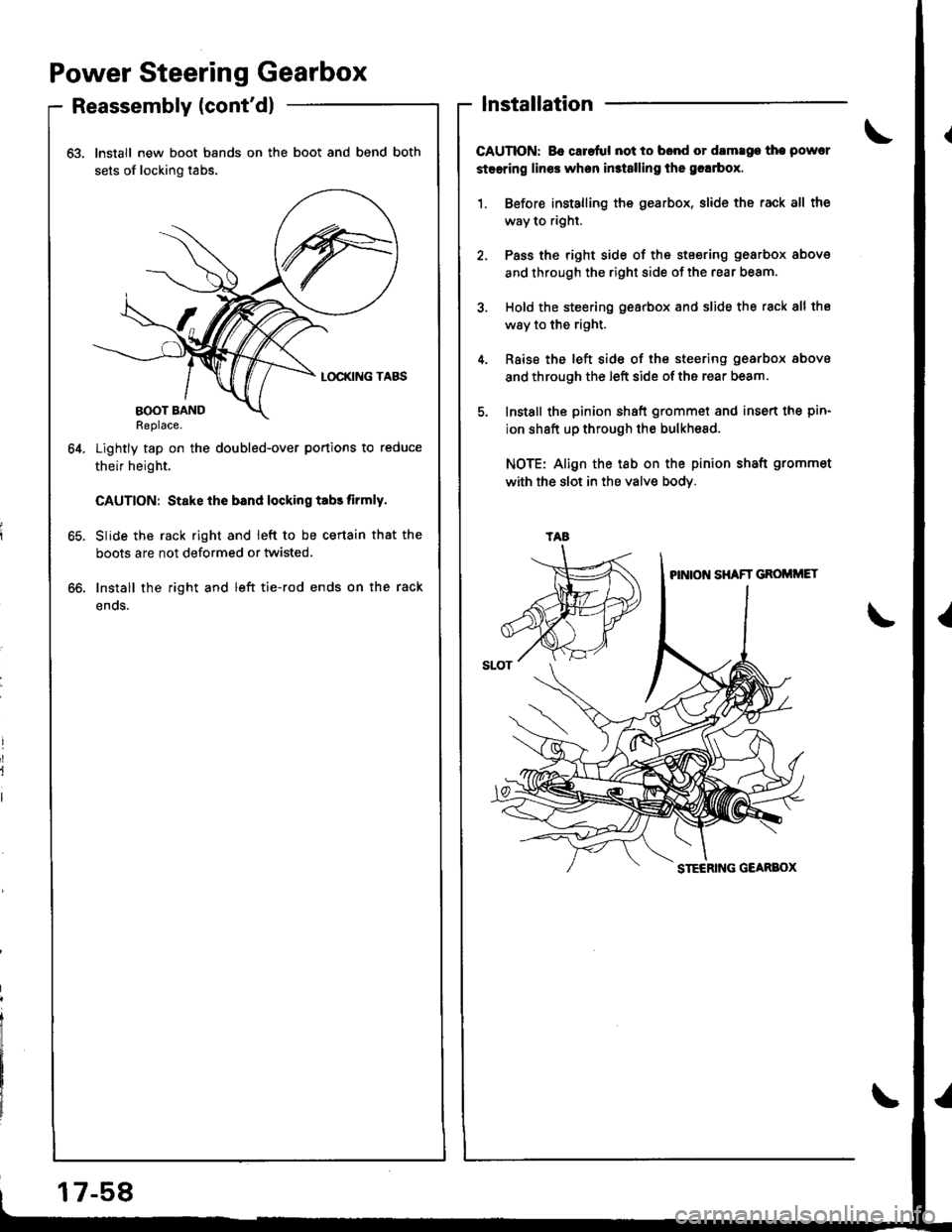

63. Install new boot bands on the boot and bend both

sets of locking tabs.

Lightly tap on the doubled-over portions to reduce

their height.

CAUTION: Stake ihe bsnd locking tabs tirmly.

Slide the rack right and ieft to be certain that the

boots are not deformed or twisted.

Install the right and left tie-rod ends on the rack

enos.

64.

lnstallation

CAUTION: Bo caretul not to bond or damrge the powcr

steering lines when in3t8lling the grlrbox.

1. Before installing the gearbox, slide the rack all the

way to right.

2, Pass the right side of the stsering gearbox above

and through the right side of the rear beam.

3. Hold the steering gearbox and slide the rack 8ll the

way to the right.

4. Rsise the left side of the steering gearbox above

and through the left side of the rear beam.

5. Install the pinion shaft grommet and insert the pin-

ion shaft up through the bulkhesd.

NOTE: Align the tab on the pinion shaft grommet

with the slot in the valve bodY.

oo.

tAa

17-58

Page 721 of 1681

1.

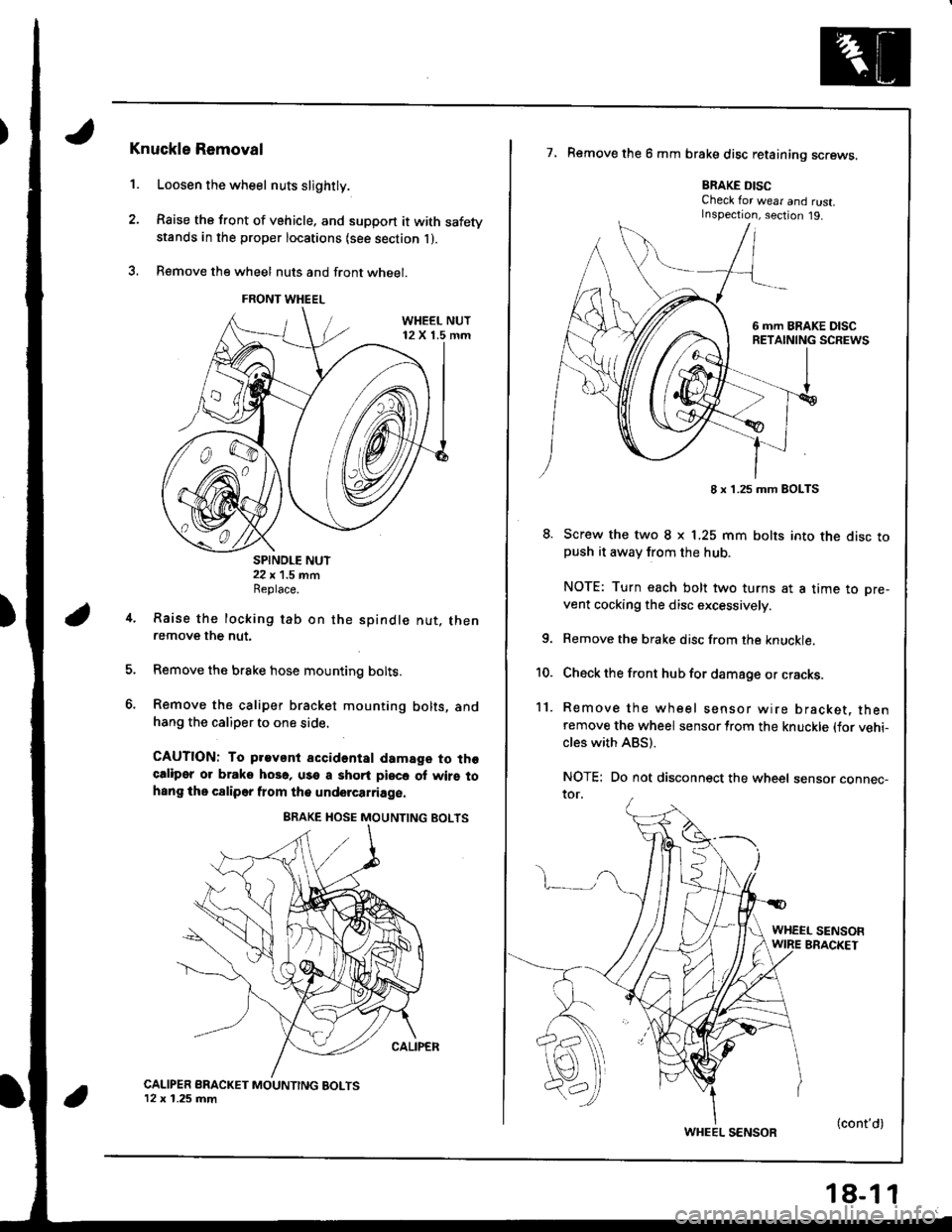

Knuckle Removal

Loosen the wheel nuts slightly.

Raise the front of vehicle. and support it with safetystands in the proper locations {see section l ).

B€move the wheel nuts and front wheel.

SPINDLE NUT22 x 1.5 mmReplace.

Raise the locking tab on the

remove the nut.

spindle nut. then

Remove the brake hose mounting bolts.

Remove the caliper bracket mounting bolts, andhang the caliper to one side.

CAUTION: To pravant accidental damage to thgcaliper or braks hoso, use a shqrt piece of wirs tohsng the c8liper flom the undercarriage.

CALIPER BRACKET MOUNTING BOLTS12 x 1.25 mm

7, Remove the 6 mm brake disc retaining screws.

BRAKE DISCCheck for wear and rust.Inspection, section j9.

8. Screw the two I x L25 mm bolts into the disc topush it awav from the hub.

NOTE: Turn each bolt two turns at a time to pre-

vent cocking the disc excessively.

Remove the brake disc from the knuckle.

Check the front hub for damage or cracks.

Remove the wheel sensor wire bracket, thenremove the wheel sensor lrom the knuckle (for vehi-cles with ABS).

NOTE: Do not disconnect the wheel sensor connec-ror.

4.

6.

10.

11.

WHEEL SENSOFWIRE BRACKET

FRONT WHEEL

8 x 1.25 mm BOLTS

WHEEL SENSOR(cont'd)

Page 726 of 1681

Front Suspension

Knuckle/Hub (cont'd)

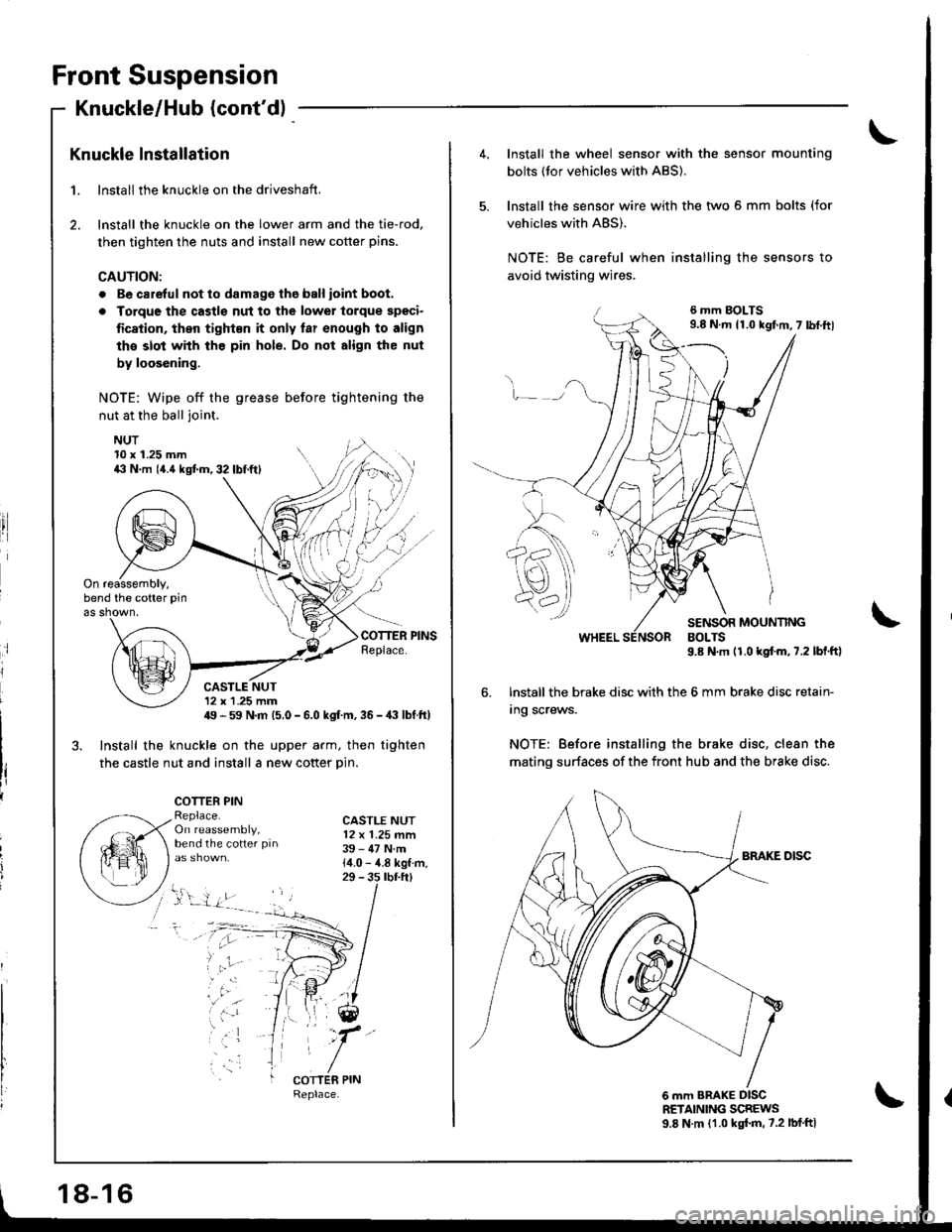

Knuckle lnstallation

1. lnstall the knuckle on the driveshaft.

2. lnstall the knuckle on the lower arm and the tie-rod,

then tighten the nuts and install new cotter pins.

CAUTION:

. Be carelul not to damage tho ball ioint boot.

a Torque the castls nut to the lowel torque spgci-

fication, then tight€n it only far enough to align

the slot with the pin hole. Do not align the nut

by loosening.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

NUT

ri

10 x 1.25 mm4il N.m (4.{ kgtm,32lbf.ftl

On reassembly,bend the cotter pin

as shown.

CASTLE NUT12 x 1 .25 mm49 - 59 N.m (5.0 - 6.0 kgf m, 36 -,|i| lbf ft)

3. Install the knuckle on the upper arm, then tighten

the castle nut and install a new cotter Din.

COTTER PINReplace.On reassembly,bend the cotter pin

CASTLE NUT12 x 1.25 mm39 - 47 N.m{4.0 - 4.8 kgf.m,29 - 3s rbr.ft)

;

, 'ar

COTTER PIN

18-16

4.Install the wheel sensor with the sensor mounting

bolts (tor vehicles with ABS).

lnstall the sensor wire with the two 5 mm bolts (for

vehicles with ABS).

NOTE: Be careful when installing the sensors to

avoid twisting wires.

6 mm BOLTS9.8 N.m 11.0 kgf.m,7 lbf.ftl

v_)

SENSOR MOUNTINGBOLTS9.8 N.m (1.0 kgf.m,7.2 lbl.ftl

6. lnstall the brake disc with the 6 mm brake disc retain-

Ing screws.

NOTE: Before installing the brake disc, clean the

mating surfaces of the front hub and the brake disc.

6 mm BRAKE DISCRETAINING SCREWS9.8 N.m 11.0 kgl.m, 7.2 lbf'ftl

Page 746 of 1681

L

I

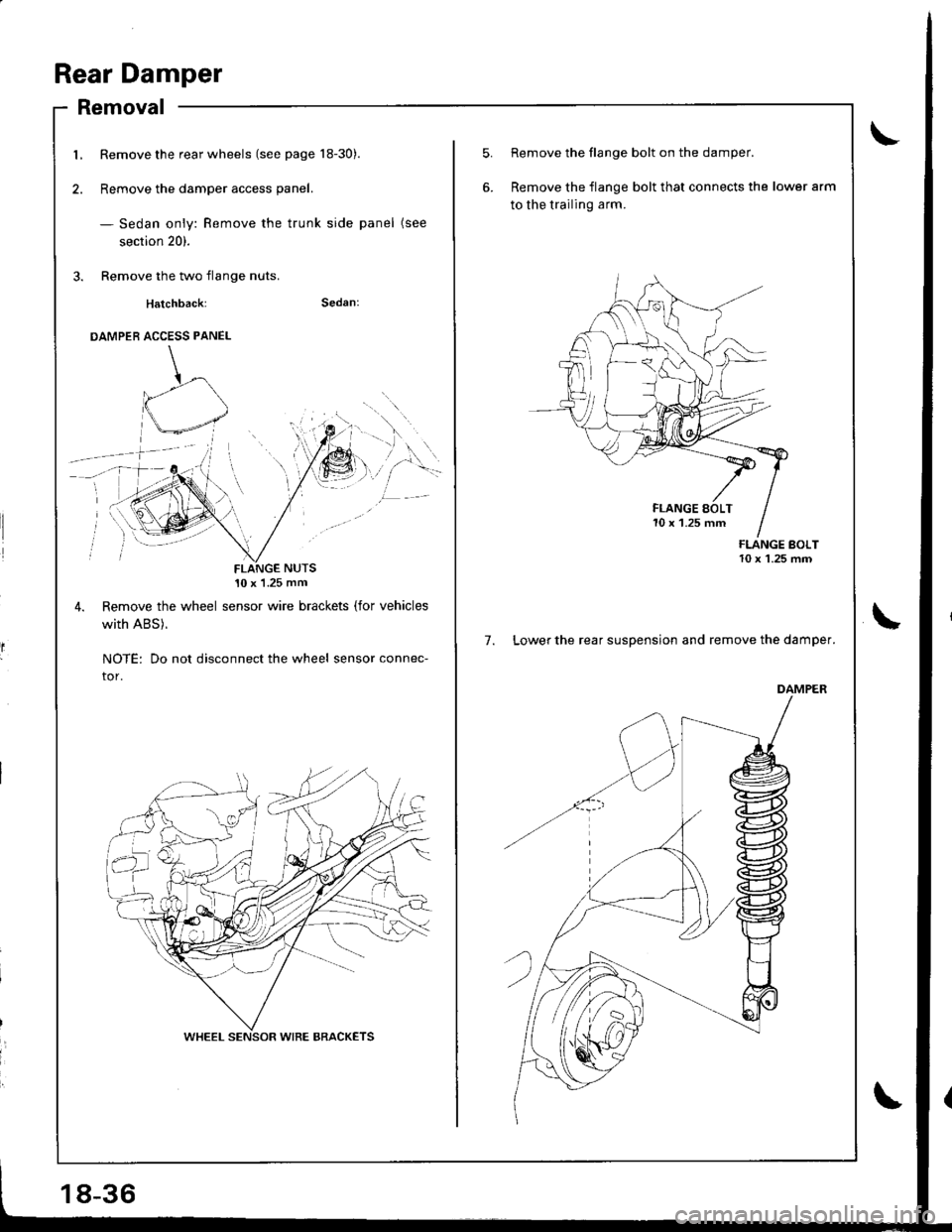

Rear Damper

Removal

Remove the rear wheels (see page 18-30).

Remove the damper access panel.

- Sedan only: Remove the trunk side panel (see

section 20).

Remove the two flange nuts.

Hatchback:

DAMPER ACCESS PANEL

10 x'1.25 mm

Remove the wheel sensor wire brackets (for vehicles

with ABS).

NOTE: Do not disconnect the wheel sensor connec-

tor.

18-36

5.Remove the flange bolt on the damper.

Remove the flange bolt that connects the lower arm

to the trailing arm.

7. Lower the rear suspension and remove the damper.

DAMPER

\

Page 750 of 1681

Rear Damper

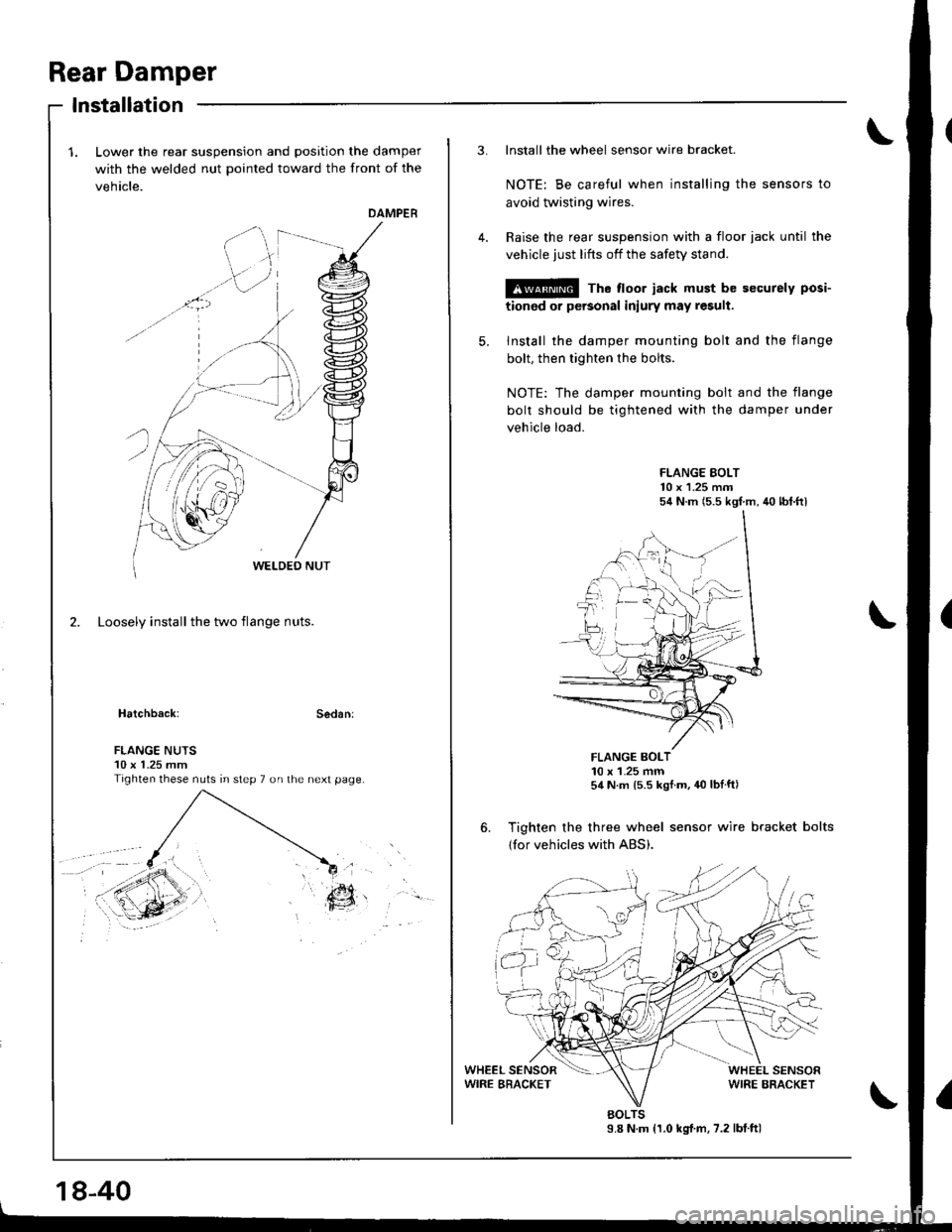

Lower the rear suspension and position the damper

with the welded nut pointed toward the front of the

vehicle.

DAMPER

2. Loosely install the two flange nuts.

Hatchback:Sedan:

lnstallation

. ',.?7,:..r9\,ir '..

EY

FLANGE NUTS10 x 1.25 mmTighten these nuts in step 7 on the next page.

18-40

3. Install the wheel sensor wire bracket.

NOTE: Be careful when installing the sensors to

avoid twisting wires.

Raise the rear suspension with a floor iack until the

vehicle just lifts off the safety stand.

@ The floor jack must be securely posi-

tionod or personal iniury may result.

5. Install the damper mounting bolt and the flange

bolt, then tighten the bolts.

NOTE: The damper mounting bolt and the flange

bolt should be tightened with the damper under

vehicle load.

FLANGE EOLT10 x 1.25 m.n54 N.m (5.5 kgf m, 40 lbt.ftl

FLANGE BOLT10 x 1-25 mm54 N.m ls.s kgf m, 40 lbtft)

6. Tighten the three wheel sensor wire bracket bolts

{for vehicles with ABS).

9.8 N.m {1.0 kg{.m, 7.2 lbtftlBOLTS