main relay HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 211 of 1681

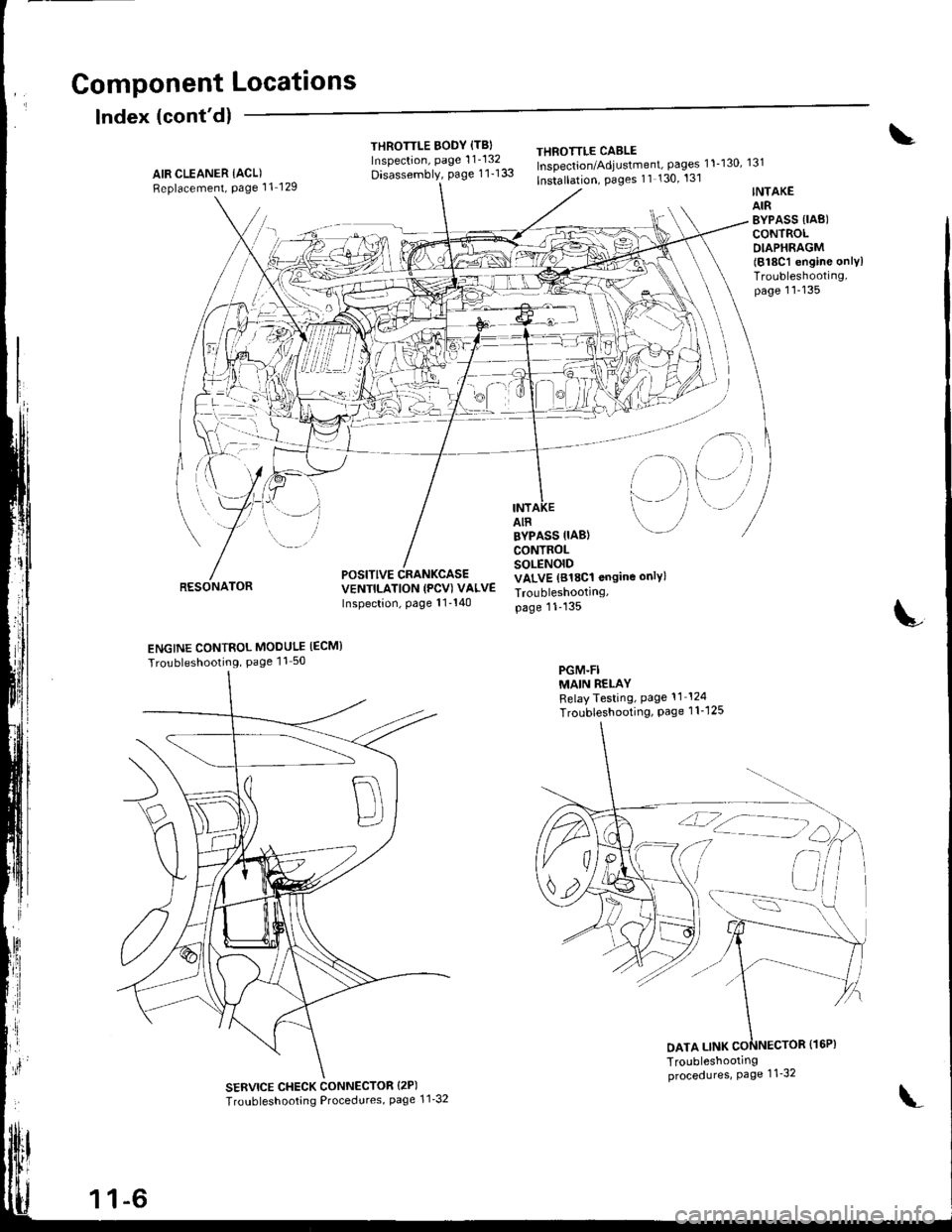

Gomponent Locations

Index (cont'dl

THROTTLE BODY {TBIInspection, page 1 1'132

Disassembly, page 1 1-133

THEOTTLE CABLEInspection/Adjustment, pages 11-130, 131

lnstallation, Pages 11 130' 131AIR CLEANER IACL)Replacement, Page 11 129

RESONATOR

INTAKEAIRBYPASS {IAB)CONTROLDIAPHRAGM(818C1 engine onlylTroubleshooting,page 11-135

i-)

i--- / /

i rl

l'-' i

INTAIR

POSITIVE CRANKCASEVENTILATION (PCV) VALVEInspection, page 11'140

BYPASS IIAB}CONTROLSOLENOIDVALVE (818C1 ongine only)

Troubleshootrng,page 11-135

PGM-FIMAIN RELAYRelayTesting, Page 11 124

Troubleshooting, Page 1 1-1 25

L

ENGINE CONTROL MODULE IECM}

Tro!bleshooting, Page 11 50

SERVICE CHECK CONNECTOR {2P)

Troubleshooting Procedures, page 1 1'32

DATA LINK

1 1-6

\'

Page 227 of 1681

![HONDA INTEGRA 1998 4.G Workshop Manual System Description

System Gonnectors IEngine Compartment]

\

c1G)

c113

c132

cr31 L

UNDER.t{ooDFUSE/RELAYBOX

MAINWIREHARNESS

WIRE HARNESS

11-22 HONDA INTEGRA 1998 4.G Workshop Manual System Description

System Gonnectors IEngine Compartment]

\

c1G)

c113

c132

cr31 L

UNDER.t{ooDFUSE/RELAYBOX

MAINWIREHARNESS

WIRE HARNESS

11-22](/img/13/6069/w960_6069-226.png)

System Description

System Gonnectors IEngine Compartment]

\

c1G)

c113

c132

cr31 L

UNDER.t{ooDFUSE/RELAYBOX

MAINWIREHARNESS

WIRE HARNESS

11-22

Page 231 of 1681

![HONDA INTEGRA 1998 4.G Workshop Manual I

ll

System Description

System Gonnectors [Dash and Floor]

\

ENGINECOMPARTMENTWIREHARNESSPGM.FI MAIN

RELAYOASHBOARD WIREHARNESS

L

.1

:J HONDA INTEGRA 1998 4.G Workshop Manual I

ll

System Description

System Gonnectors [Dash and Floor]

\

ENGINECOMPARTMENTWIREHARNESSPGM.FI MAIN

RELAYOASHBOARD WIREHARNESS

L

.1

:J](/img/13/6069/w960_6069-230.png)

I

ll

System Description

System Gonnectors [Dash and Floor]

\

ENGINECOMPARTMENTWIREHARNESSPGM.FI MAIN

RELAYOASHBOARD WIREHARNESS

L

.1

:J

Page 241 of 1681

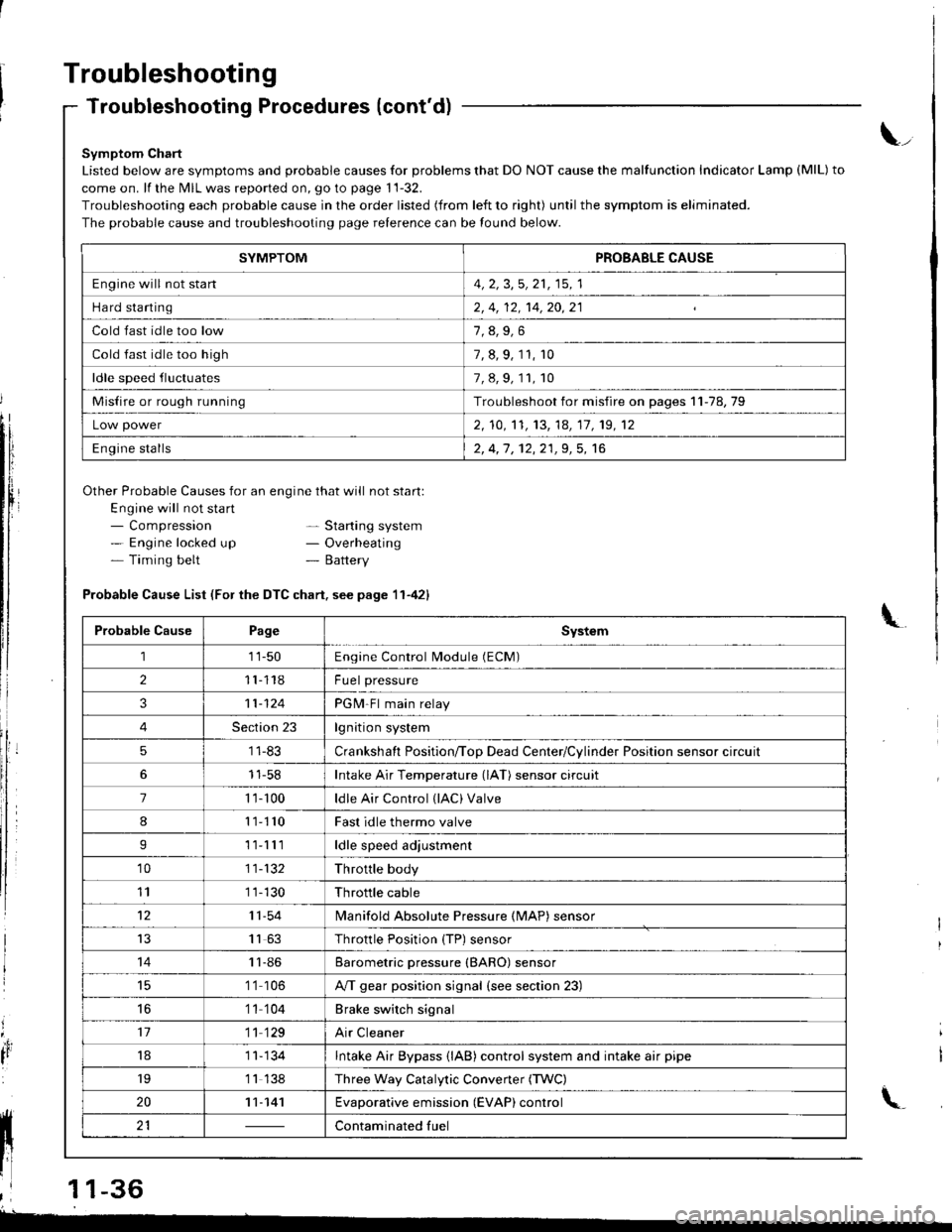

Troubleshooting

Troubleshooting Procedures (cont'd)

Symptom Chart

Listed below are symptoms and probable causes for problems that DO NOT cause the malfunction Indicator Lamp (MlL) to

come on. lf the MIL was reported on, go to page 11-32.

Troubleshooting each probable cause in the order listed (from left to right) until the symptom is eliminated.

The probable cause and troubleshooting page relerence can be found below.

Other Probable Causes for an engine that will not start:

Engine will not sta rt- Compression- Engine locked up- Timing belt

\_

- Starting system- Overheating- Battery

'4,

It

Probable Cause List (For the DTC chart. see page 11-421

Probable CausePageSystem

111-50Engine Control Module (ECM)

211118Fuel pressure

311-124PGM-Fl main relay

4Section 23lgnition system

51 1-83Crankshaft Position/ToD Dead Center/Cylinder Position sensor circuit

11-58Intake Air Temperature (lAT) sensor circuit

71 '�t- 100ldle Air Control (lAC) Valve

811110Fast idle thermo valve

I11lllldle speed adjustment

'1011-132Throttle body

111 1-130Throttle cable

1211-54lvlanifold Absolute Pressure {MAP) sensor

IJ1163Throttle Position {TP) sensor

1411-86Barometric pressure (BARO) sensor

1 '1 106A/T gear position signal {see section 23)

16'1 1 104Brake switch signal

1711 129Air Cleaner

181 1- 134Intake Air Bypass {lAB} control system and intake air pipe

19'1 1 138Three Way Catalytic Convener (TWC)

2011-141Evaporative emission (EVAP) control

21Contaminated fuelll ll 21 | - | cont"-in"t"o tu"

11 l-

I

,l 11-36

-

SYMPTOMPROBABLE CAUSE

Engine will not stan4, 2, 3,5, 21, 15, 1

Hard starting2, 4, 12, 14,20,21

Cold fast idle too low

Cold fast idle too high7, 8, 9, 11, r0

ldle speed fluctuates7,8,9,11,10

Misfire or rough runningTroubleshoot for misfire on pages 11-78,79

Low power2, 10,'t1, 13, 14, 17, 19, 12

Engine stalls2, 4,1 , 12,21,9, 5, 16

Page 253 of 1681

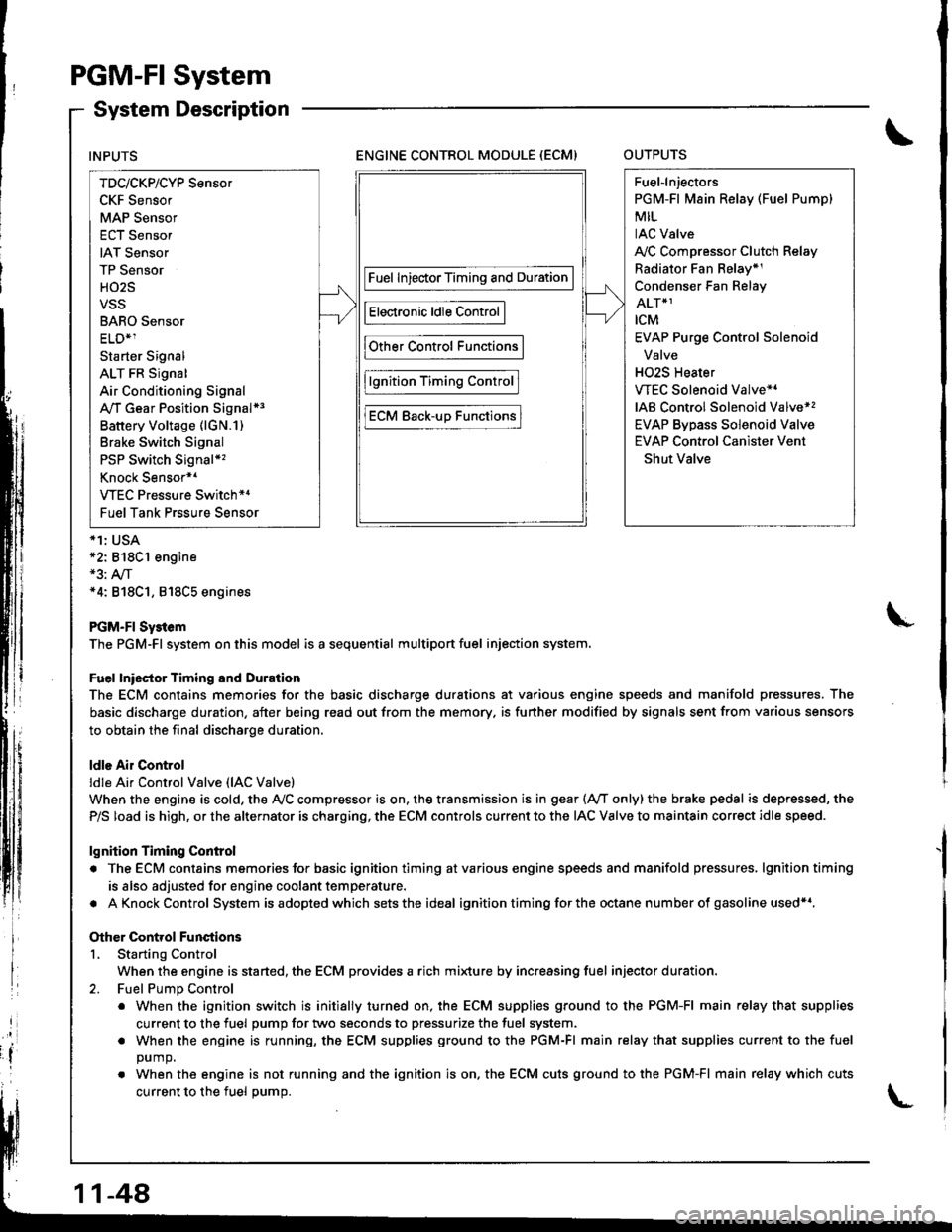

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECM)OUTPUTS

*1: USA*2: 818C1 engine*3: A,/T*4: 818C1, 818C5 engines

PGM-FI Sy3tem

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel lniector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory. is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Ai. Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on. the transmission is in gear (Ay'T only)the brake pedal is depressed, the

P/S load is high, or the alternator is charging, the ECM controls current to the IAC Valve to maintain correct idle speed.

lgnition Timing Control

. The ECM contains memories for basic ignition timing atvarious engine speeds and manifold pressures, lgnitiontiming

is also adjusted for engine coolant temperature.

. AKnockControl System isadoptedwhich sets the ideal ignition timing for the octane n um ber of gasoline used*r,

Other Control Functions

L Starting Control

When the engine is started, the ECM provides a rich mi{ure by increasing fuel injector duration.

2. Fuel PumD Control

. When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel

DUmO.

. When the engine is not running and the ignition is on. the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel oumo.

INPUTS

TDc/CKP/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

HO2S

VSS

BARO Sensor

ELD*1

Starter Signal

ALT FR Signal

Air Conditioning Signal

A,/T Gear Position Signal*3

Battery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal*'�

Knock Sensor*1

VTEC Pressure Switch*4

Fuel Tank Prssure Sensor

Fuel InjectorTiming and Duration

Electronic ldle Control

Other Control Functions

lgnition Timing Control

ECM Back-uD Functions

Fuel-lnjectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

A,/C Compressor Clutch Relay

Radiator Fan Belay*1

Condenser Fan Relay

ALT*1

rcM

EVAP Purge Control Solenoid

Valve

H02S Heater

VTEC Solenoid Valve*'

IAB Control Solenoid Valve*,

EVAP Bypass Solenoid Valve

EVAP Control Canister Vent

Shut Valve

11-48

Page 256 of 1681

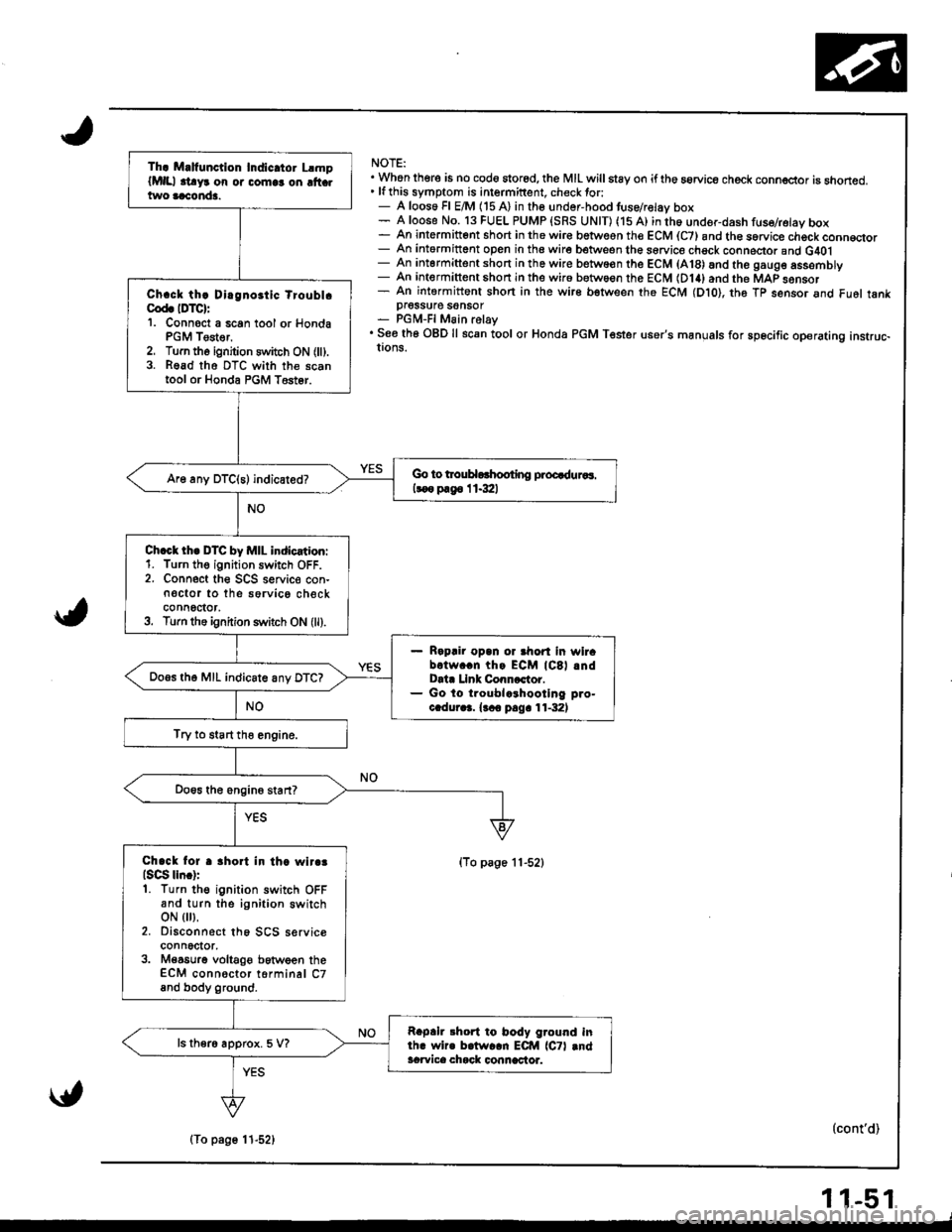

NOTE:. Whon there is no cod6 stored, the MIL willstay on iftho aorvice check conn€ctor is snoned.' lfthis symptom is intermittent. check tor:- A loos6 Fl E/M (15 A) in the undor-hood tuse/relav box- A loose No. 13 FUEL PUMP {SRS UNIT) (15 A) in th6 under-dash fuse/retay box- An intermitt6nt short in the wir€ betwesn the ECM (C7) and th€ sorvice chock conn€qor- An intormittent open in the wire between the sorvice chsck conneclor and G40l- An intermittent short in the wire betwo€n the ECM (A18) and the gaug6 assemDry- An intermittent shon in the wir6 between the ECM (D14) and the MAP sonsor- An intermittent shon in the wire bstween the ECM (Dto), th6 Tp sensor and Fu6l tankpI6SSU16 SOnSOT- PGM-FI Main relay. See th6 OBD ll scan tool or Honda PGM Tester user's manuals for sp6cific operating instruc-!ons.

(To page 11-52)

(cont'd)

Th. M.lfunction Indic.tor LlmplMlll .t!yr on or comlr on ltt .two aaconda.

Ch.ck th! Dirgnoitic tioubl.Cod. IDTC):'1. Connoct a 6can tool or HondaPGM Tester,2. Turn tho ignition switch ON (ll).3. Read tho DTC with the scantool or Honda PGM T6st6r.

Go to trouHorhooting proQduaaa.

koo p.g6 I 1.3:ll

Ch.ct th. DTC by MIL indication:1. Turn th€ ignition switch OFF.2. Connect the SCS seNic€ con-n€ctor to the sorvico checkconnoctor,3. Turn the ignition s1\,itch ON (ll).

Rapair opan or ahort in wirabotw..n thg ECM lCSl .ndData Llnk Conncctor.Go lo troublcrhootlng pro-c.dur.3. {.co pag. 11-32)

Do.s th6 MIL indicate anv DTC?

Try to start tho engine.

Chack lor r 3hort in th. wlr.3lsqg lln.):1. Turn the ignition switch OFFand turn the ignition switchoN { },2. Disconnect th6 SCS serviceconnector,3. M€a6urg voltaOe between theECM connoctor torminal C7and body ground.

Rapah 3hort to body ground inlh. wir. b.lw..n ECM lCTl .ndacwica chack connactor.

ls ther6 approx. 5 V?

\{,

(To page 11-52)

11-51

Page 258 of 1681

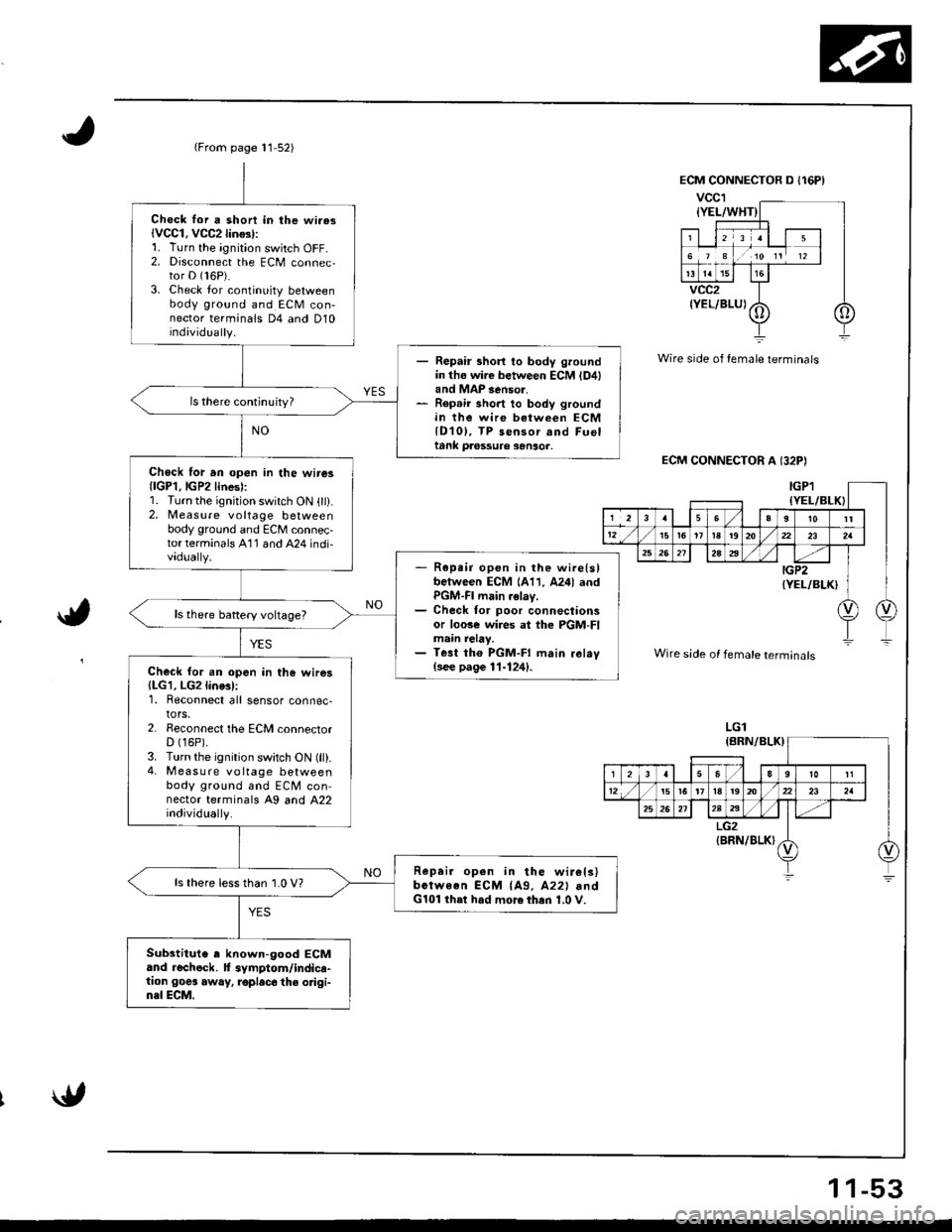

{From page 11 52)

Chock lor a shon in lhe wi.asiVCC1. VCC2lin$l:1. Turn the ignition switch OFF-2. Disconnect the ECM connec,tor D (16P).

3. Check lor continuity betweenbody ground and ECM con-nector terminals D4 and D10individually.

- Repair short to body groundin tho wire between ECM {D4land MAP 3enso..- Rep.ir short to body groundin the wire between ECMlD10l, TP sensor and Fueltank pa6ssure sanso..

Chock lor an op€n in the wire3{lGP1.lGP2lines):1. Turn the ignition switch ON (ll).2, Measure voltage betweenbody ground and ECM connec-torterminals A'11 and A24 indi-vadually.- R6pe;r open in the wire{slbetween ECM 1A11, A24l andPGM-FI main .elay.- Check for poor connectionsor loose wi.es at the PGM-FImain relay.- Test tho PGM-FI main ral.v(see page 11-124).Check for an open in the wires(LG1, LG2line3l:1. Reconnect all sensor connec-tors.2. Reconnect the ECM connectorD (16P).

3. Turn the ignition switch ON (ll).4- M easu re voltage betweenbody ground and ECM connector terminals A9 and A22individually.

Repai. open in the wir€ls)bctween ECM {A9, A22l .ndG101 ihet had more then 1.0 V.

ls there lessthan 1.0 V?

Substitute , known-good ECMand rechock. f symptom/indica-tion goes away, roplac6 the odgi-n3l ECM.

Wire side of female terminals

ECM CONNECTOR A I32P)

a,

Wire side of female terminals

LGl

1 1-53

Page 301 of 1681

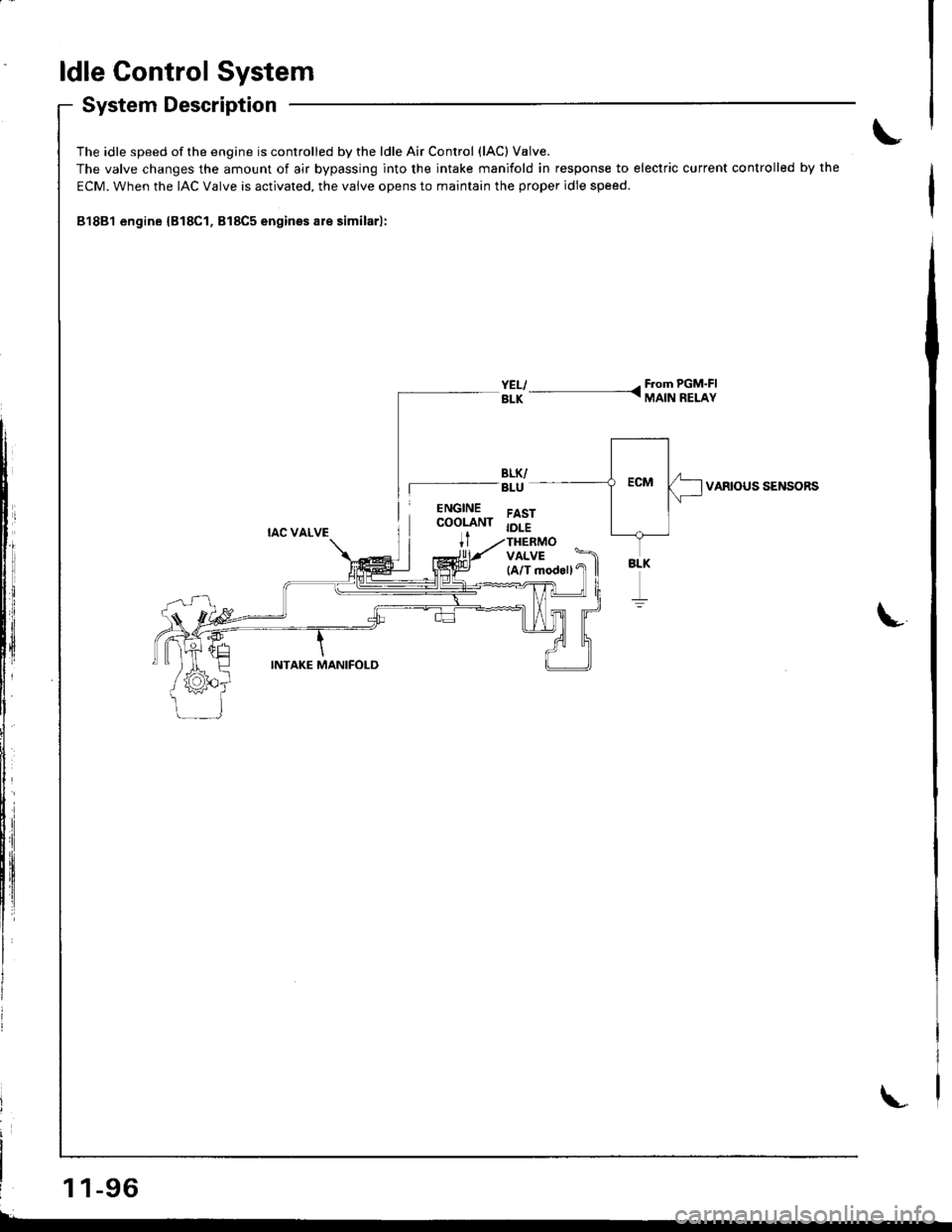

ldle Control System

System Description

The idle speed of the engine is controlled by the ldle Air Control (lAC) V8lve.

The valve changes the amount of air bypassing into the intake manifold in response to electric current controlled by the

ECM. When the IAC Valve is activated. the valve opens to maintain the proper idle speed.

81881 engine {B18Cl, B18C5 engines are similarl:

YELI - F.om PGM'FIBLK - MAIN RELAY

VARIOUS SENSORS

L

1 1-96

Page 310 of 1681

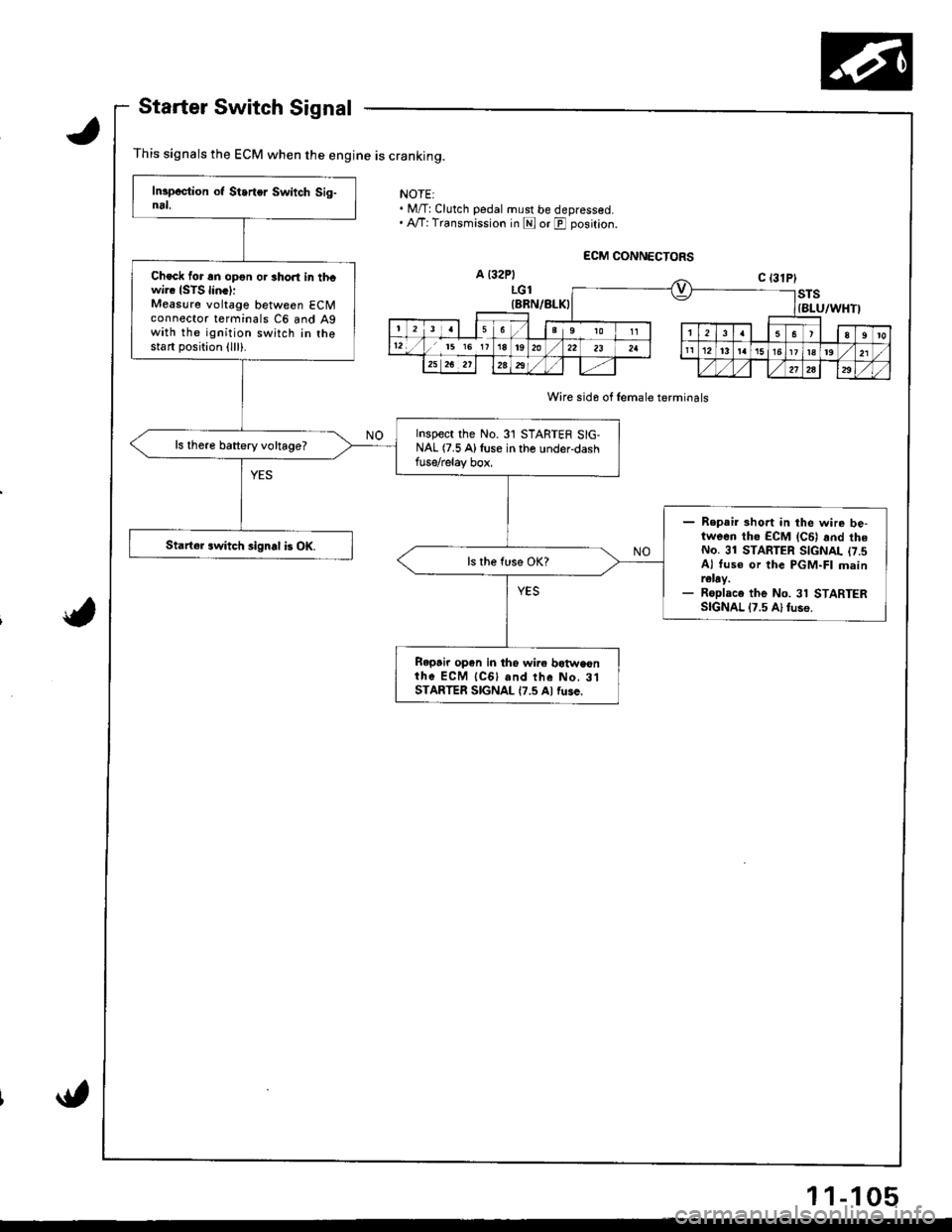

Starter Switch Signal

This signals the ECM when the engine is cranking.

NOTEI. M/T:Clutch pedal must be depressed.. A,/T: Transmission in E or E position.

Wire sida of female terminals

Check for an opon or short in thcwi.. ISTS lin.l:Measure voltage between ECMconnector terminals C6 and Agwith the ignition switch in thostart position (lll).

Inspect the No.31 STARTER SIG-NAL (7.5 Alluse in the under-dashfuse/relay box,

ls there battery voltage?

- Repair 3hort in the wire be-tween tho ECM lc6l rnd theNo. 31 STARTER SIGNAL (7.sAl tus€ or the PGM-FI mainr€lay.- Roplace the No. 31 STARTERSIGNAL 17.5 Al fuso.

Starter switch signal b OK.

Ropair open in tho wire botwaonih6 ECM {CGl and the No, 3lSTARTER SIGNAL {7.5 Al fuse.

11-105

Page 323 of 1681

The fuel supply system co

high pressure fuel pump, t

fuel pressure regulator. f

damper, and fuel delivery i

delivers pressure-regulated

cuts the luel delivery when

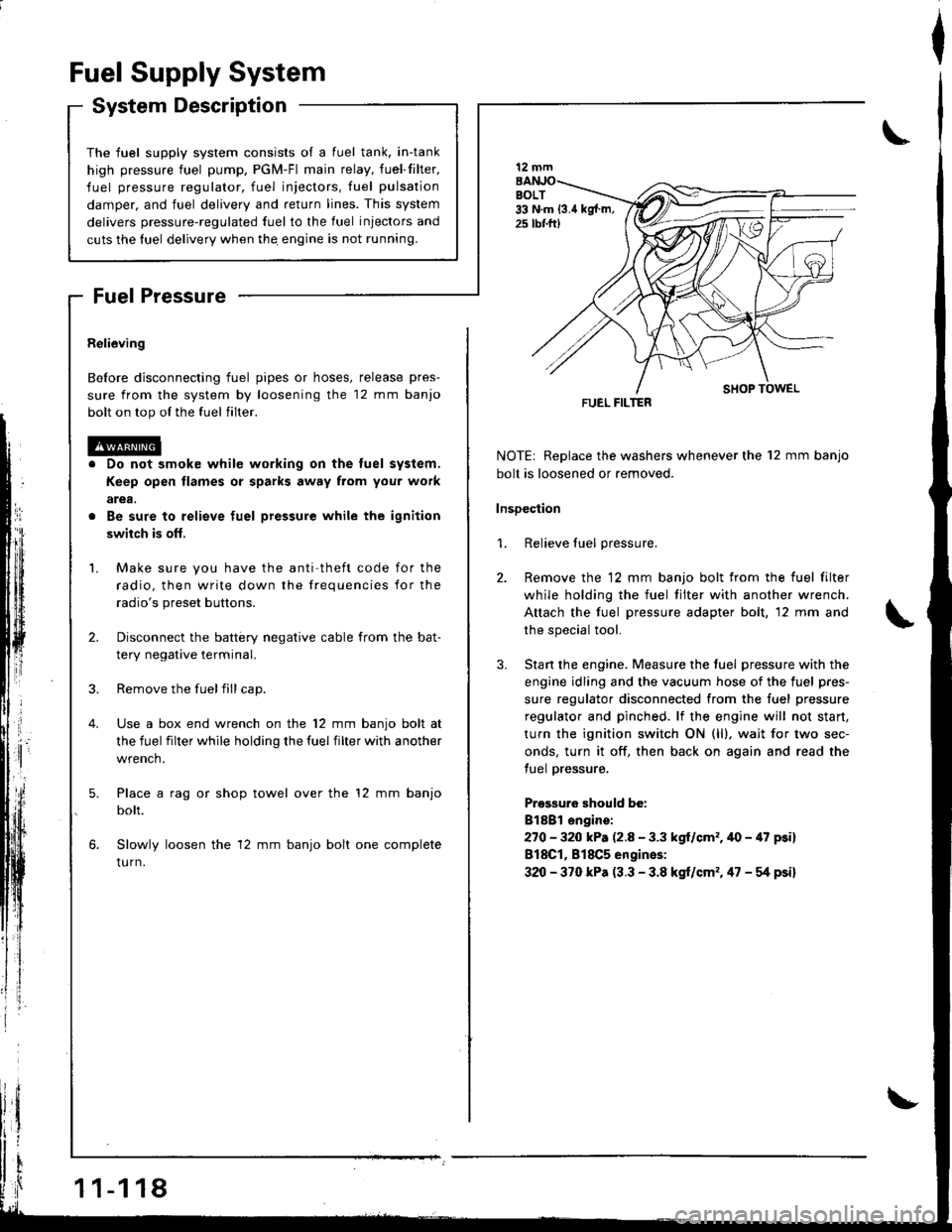

Fuel Supply System

System Description

consists of a fuel tank, in-tank

r, PGM-Fl main relay, fueffilter,

. fuel injectors, fuel pulsation

y and return lines. This system

ed fuel to the fuel injectors and

rn thq engine is not running.

Fuel Pressure

Relieving

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on top ol the fuel filter.

Do not smok€ while working on the tuel system,

Keep open flames or sparks away from you. work

arga.

Be sure to relieve fuel pressure while the ignition

swiich is ofl,

Make sure you have the anti theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

Disconnect the battery negative cable from the bat-

tery negative terminal.

Remove the fuelfill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with another

wrench.

Place a rag or shop towel over the '12 mm banjo

bolt.

Slowly loosen the 12 mm banjo bolt one complete

tu rn.

1 1-1 18

I

NOTE| Replace the washers whenever the 12 mm banjo

bolt is loosened or removed.

lnsDection

1. Relieve fuel pressure.

2. Remove the 12 mm banjo bolt from the fuel filter

while holding the fuel tilter with another wrench.

Attach the fuel pressure adapter bolt, 12 mm and

the special tool.

3. Stan the engine. Measure the tuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch ON (ll), wait for two sec-

onds, turn it off, then back on again and read the

tuel pressure.

Pressuro should be:

Bl8Bl engire:

270 - 320 kP. (2.8 - 3.3 kgl/cm'�.40 - 47 psi)

818C1, 818C5 engines:

320 - 370 kPa (3.3 - 3.8 kgt/cm'�. 47 - g psi)

12 mm

FUEL FILTER