light HUMMER H3 2010 Owners Manual

[x] Cancel search | Manufacturer: HUMMER, Model Year: 2010, Model line: H3, Model: HUMMER H3 2010Pages: 410, PDF Size: 2.24 MB

Page 293 of 410

Vehicle Care 10-27

Brake Fluid

The brake master cylinder reservoir

is filled with DOT 3 brake fluid as

indicated on the reservoir cap. See

Engine Compartment Overview

on

page 10‑6for the location of the

reservoir. There are only two reasons why the

brake fluid level in the reservoir

might go down:

.The brake fluid level goes down

because of normal brake lining

wear. When new linings are

installed, the fluid level goes

back up.

.A fluid leak in the brake

hydraulic system can also cause

a low fluid level. Have the brake

hydraulic system fixed, since a

leak means that sooner or later

the brakes will not work well.

Do not top off the brake fluid.

Adding fluid does not correct a leak.

If fluid is added when the linings

are worn, there will be too much

fluid when new brake linings are

installed. Add or remove brake fluid,

as necessary, only when work is

done on the brake hydraulic system.

{WARNING

If too much brake fluid is added, it

can spill on the engine and burn,

if the engine is hot enough. You

or others could be burned, and

the vehicle could be damaged.

Add brake fluid only when work is

done on the brake hydraulic

system.

When the brake fluid falls to a low

level, the brake warning light comes

on. See Brake System Warning

Light on page 5‑14.

Page 299 of 410

Vehicle Care 10-33

Headlamp Aiming

The vehicle may have a visual

optical headlamp aiming system.

The aim has been preset at the

factory and should need no further

adjustment.

However, if the vehicle is damaged

in a crash, the headlamp aim may

be affected and adjustment may be

necessary.

If oncoming vehicles flash their high

beams at you, this may also mean

the vertical aim needs to be

adjusted.

It is recommended that the vehicle

is taken to your dealer for service if

the headlamps need to be re-aimed.

It is possible however, to re-aim the

headlamps as described.The vehicle should be:.Placed so the headlamps are

7.6 m (25 ft) from a light colored

wall or other flat surface.

.On a level surface which is level

all the way to a wall.

.Placed so it is at a right angle to

the wall or other flat surface.

.Clear of any snow, ice, or mud

on it.

.Fully assembled, the tires

properly inflated, and all other

work stopped while headlamp

aiming is being performed.

.Normally loaded with the spare

tire in its original location and a

full tank of fuel and one person

or 75 kg (160 lbs) sitting on the

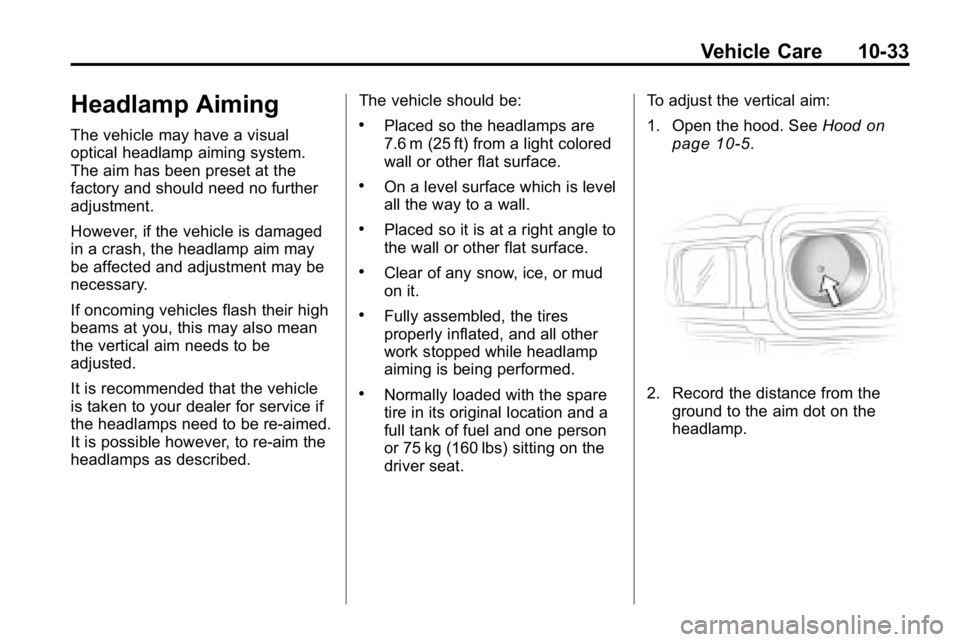

driver seat.To adjust the vertical aim:

1. Open the hood. See

Hood

on

page 10‑5.

2. Record the distance from the ground to the aim dot on the

headlamp.

Page 300 of 410

10-34 Vehicle Care

3. At a wall, measure from theground upward the recorded

distance from Step 2 and

mark it.

4. Draw or tape a horizontal line the width of the vehicle at the

wall where it was marked it

Step 4.

Notice: Do not cover a headlamp

to improve beam cut-off when

aiming. Covering a headlamp may

cause excessive heat build-up

which may cause damage to the

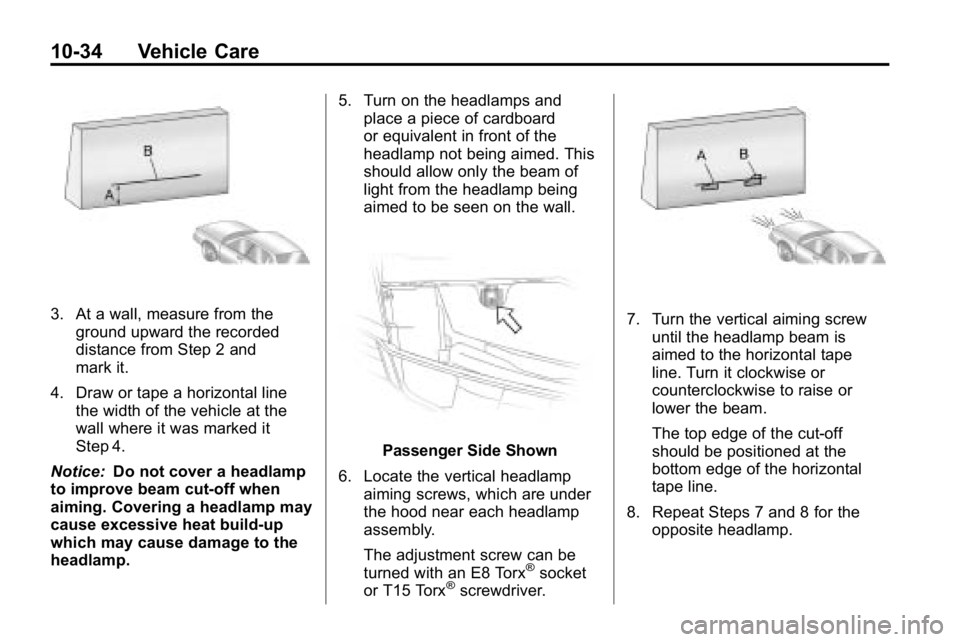

headlamp. 5. Turn on the headlamps and

place a piece of cardboard

or equivalent in front of the

headlamp not being aimed. This

should allow only the beam of

light from the headlamp being

aimed to be seen on the wall.

Passenger Side Shown

6. Locate the vertical headlamp aiming screws, which are under

the hood near each headlamp

assembly.

The adjustment screw can be

turned with an E8 Torx

®socket

or T15 Torx®screwdriver.

7. Turn the vertical aiming screw

until the headlamp beam is

aimed to the horizontal tape

line. Turn it clockwise or

counterclockwise to raise or

lower the beam.

The top edge of the cut-off

should be positioned at the

bottom edge of the horizontal

tape line.

8. Repeat Steps 7 and 8 for the opposite headlamp.

Page 305 of 410

Vehicle Care 10-39

Fuses and Circuit

Breakers

The wiring circuits in your vehicle

are protected from short circuits by

a combination of fuses and circuit

breakers. This greatly reduces the

chance of fires caused by electrical

problems.

Look at the silver-colored band

inside the fuse. If the band is broken

or melted, replace the fuse. Be sure

you replace a bad fuse with a new

one of the identical size and rating.

If you ever have a problem on the

road and do not have a spare fuse,

you can borrow one that has the

same amperage. Just pick some

feature of your vehicle that you can

get along without—like the radio

or cigarette lighter —and use its

fuse, if it is the correct amperage.

Replace it as soon as you can.

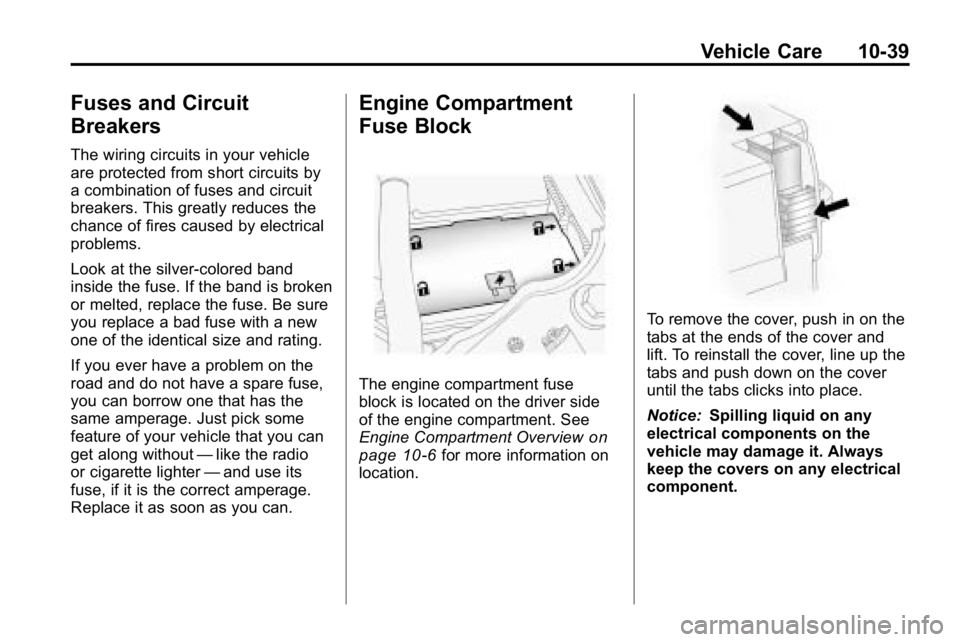

Engine Compartment

Fuse Block

The engine compartment fuse

block is located on the driver side

of the engine compartment. See

Engine Compartment Overview

on

page 10‑6for more information on

location.

To remove the cover, push in on the

tabs at the ends of the cover and

lift. To reinstall the cover, line up the

tabs and push down on the cover

until the tabs clicks into place.

Notice: Spilling liquid on any

electrical components on the

vehicle may damage it. Always

keep the covers on any electrical

component.

Page 308 of 410

10-42 Vehicle Care

FuseUsage

39 Daytime Running

Lamps

40 Passenger Side

Headlamp

41 Driver Side

Headlamp

42 Trailer

Back-Up Lamp

43 Front Park Lamps

44 Air Injection Reactor

(AIR) Solenoid

45 Auxiliary Power 2/

Cigarette Lighter

46 Electronic Throttle

Control

47 Oxygen Sensor

48 Air Conditioning

Clutch

49 Rear Park Lamp

50 Stop Lamp Fuse

Usage

51 Auxiliary Power 1/

Cigarette Lighter

52 StabiliTrak

®,

Antilock Brake

System

53 Power Heated Seat,

Belt Switch

54 Fuel System Control

Module (FSCM)

55 Trailer Parking

Lamps

56 Front Turn Signal,

Hazard Signal,

Courtesy Mirror

57 Power Sunroof

58 Transfer Case

Control Module

Switch

59 Climate Controls

Control Head

60 Back‐Up Lamp

61 Power Seats Fuse Usage

62 Air Injection Reactor

(AIR) Pump

63 Passenger Side

Power Window

64 Antilock Brake

System,

StabiliTrak

®2

Solenoid

67 Antilock Brake

System,

StabiliTrak

®1 Motor

68 Driver Side Power

Window

82 Climate Control Fan

83 Electronic Brake

Controller

84 Trailer B+ Fuse

85 Starter

91 Generator Megafuse

Page 311 of 410

Vehicle Care 10-45

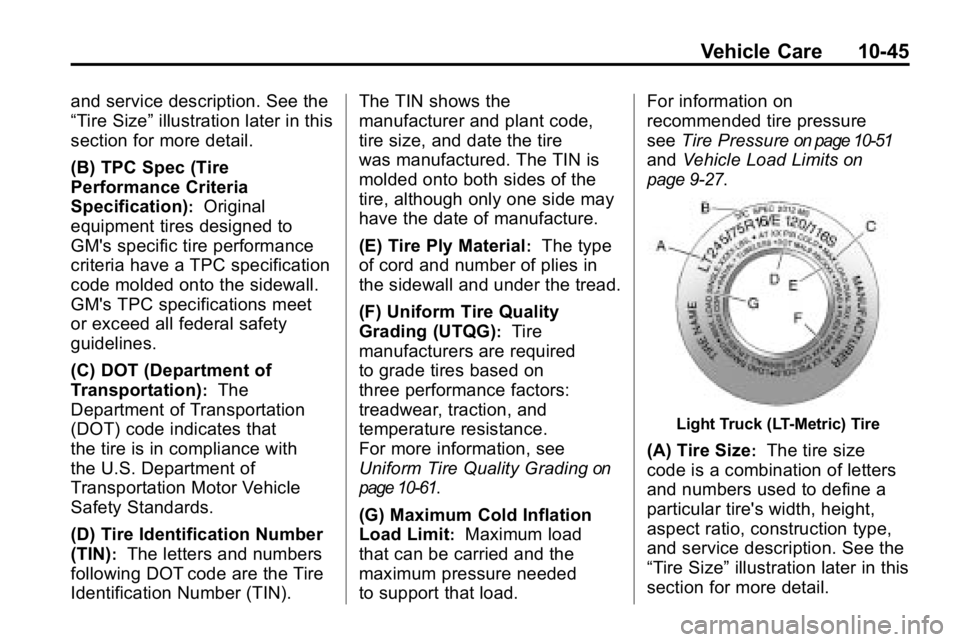

and service description. See the

“Tire Size”illustration later in this

section for more detail.

(B) TPC Spec (Tire

Performance Criteria

Specification)

:Original

equipment tires designed to

GM's specific tire performance

criteria have a TPC specification

code molded onto the sidewall.

GM's TPC specifications meet

or exceed all federal safety

guidelines.

(C) DOT (Department of

Transportation)

:The

Department of Transportation

(DOT) code indicates that

the tire is in compliance with

the U.S. Department of

Transportation Motor Vehicle

Safety Standards.

(D) Tire Identification Number

(TIN)

:The letters and numbers

following DOT code are the Tire

Identification Number (TIN). The TIN shows the

manufacturer and plant code,

tire size, and date the tire

was manufactured. The TIN is

molded onto both sides of the

tire, although only one side may

have the date of manufacture.

(E) Tire Ply Material

:The type

of cord and number of plies in

the sidewall and under the tread.

(F) Uniform Tire Quality

Grading (UTQG)

:Tire

manufacturers are required

to grade tires based on

three performance factors:

treadwear, traction, and

temperature resistance.

For more information, see

Uniform Tire Quality Grading

on

page 10‑61

.

(G) Maximum Cold Inflation

Load Limit

:Maximum load

that can be carried and the

maximum pressure needed

to support that load. For information on

recommended tire pressure

see

Tire Pressure

on page 10‑51

and Vehicle Load Limitson

page 9‑27

.

Light Truck (LT-Metric) Tire

(A) Tire Size:The tire size

code is a combination of letters

and numbers used to define a

particular tire's width, height,

aspect ratio, construction type,

and service description. See the

“Tire Size” illustration later in this

section for more detail.

Page 313 of 410

Vehicle Care 10-47

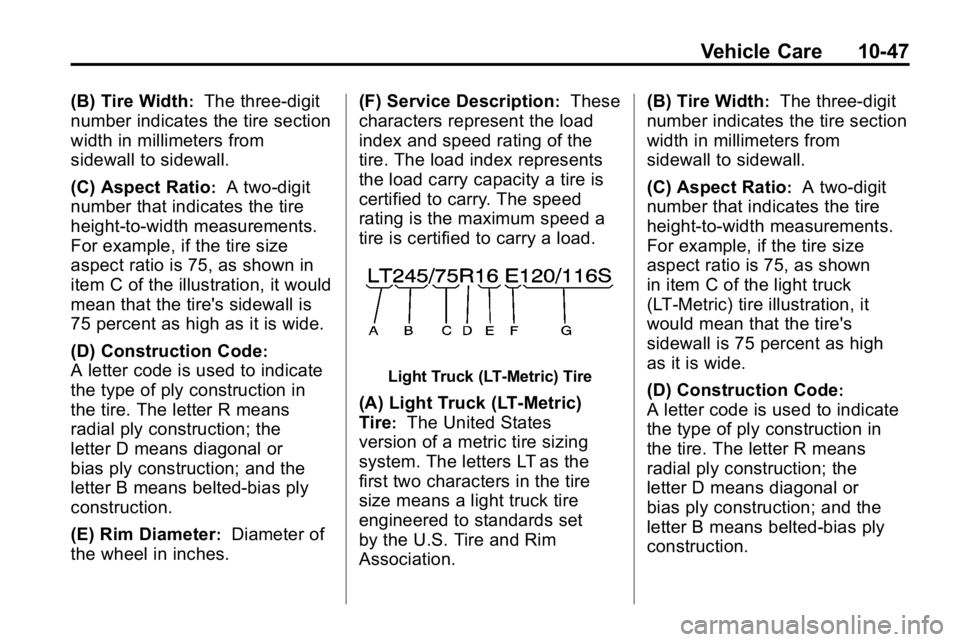

(B) Tire Width:The three‐digit

number indicates the tire section

width in millimeters from

sidewall to sidewall.

(C) Aspect Ratio

:A two‐digit

number that indicates the tire

height‐to‐width measurements.

For example, if the tire size

aspect ratio is 75, as shown in

item C of the illustration, it would

mean that the tire's sidewall is

75 percent as high as it is wide.

(D) Construction Code

:

A letter code is used to indicate

the type of ply construction in

the tire. The letter R means

radial ply construction; the

letter D means diagonal or

bias ply construction; and the

letter B means belted‐bias ply

construction.

(E) Rim Diameter

:Diameter of

the wheel in inches. (F) Service Description

:These

characters represent the load

index and speed rating of the

tire. The load index represents

the load carry capacity a tire is

certified to carry. The speed

rating is the maximum speed a

tire is certified to carry a load.

Light Truck (LT‐Metric) Tire

(A) Light Truck (LT‐Metric)

Tire

:The United States

version of a metric tire sizing

system. The letters LT as the

first two characters in the tire

size means a light truck tire

engineered to standards set

by the U.S. Tire and Rim

Association. (B) Tire Width

:The three‐digit

number indicates the tire section

width in millimeters from

sidewall to sidewall.

(C) Aspect Ratio

:A two‐digit

number that indicates the tire

height‐to‐width measurements.

For example, if the tire size

aspect ratio is 75, as shown

in item C of the light truck

(LT‐Metric) tire illustration, it

would mean that the tire's

sidewall is 75 percent as high

as it is wide.

(D) Construction Code

:

A letter code is used to indicate

the type of ply construction in

the tire. The letter R means

radial ply construction; the

letter D means diagonal or

bias ply construction; and the

letter B means belted‐bias ply

construction.

Page 315 of 410

Vehicle Care 10-49

DOT Markings:A code

molded into the sidewall of a

tire signifying that the tire is

in compliance with the U.S.

Department of Transportation

(DOT) motor vehicle safety

standards. The DOT code

includes the Tire Identification

Number (TIN), an alphanumeric

designator which can also

identify the tire manufacturer,

production plant, brand, and

date of production.

GVWR

:Gross Vehicle Weight

Rating. See Vehicle Load Limits

on page 9‑27.

GAWR FRT

:Gross Axle

Weight Rating for the front axle.

See Vehicle Load Limits

on

page 9‑27

.

GAWR RR

:Gross Axle

Weight Rating for the rear axle.

See Vehicle Load Limits

on

page 9‑27

. Intended Outboard Sidewall

:

The side of an asymmetrical tire,

that must always face outward

when mounted on a vehicle.

Kilopascal (kPa)

:The metric

unit for air pressure.

Light Truck (LT‐Metric) Tire

:

A tire used on light duty trucks

and some multipurpose

passenger vehicles.

Load Index

:An assigned

number ranging from 1 to 279

that corresponds to the load

carrying capacity of a tire.

Maximum Inflation Pressure

:

The maximum air pressure to

which a cold tire can be inflated.

The maximum air pressure is

molded onto the sidewall.

Maximum Load Rating

:The

load rating for a tire at the

maximum permissible inflation

pressure for that tire. Maximum Loaded Vehicle

Weight

:The sum of curb

weight, accessory weight,

vehicle capacity weight, and

production options weight.

Normal Occupant Weight

:The

number of occupants a vehicle

is designed to seat multiplied by

68 kg (150 lbs). See Vehicle

Load Limits

on page 9‑27.

Occupant Distribution

:

Designated seating positions.

Outward Facing Sidewall

:The

side of an asymmetrical tire that

has a particular side that faces

outward when mounted on a

vehicle. The side of the tire that

contains a whitewall, bears

white lettering, or bears

manufacturer, brand, and/or

model name molding that is

higher or deeper than the same

moldings on the other sidewall

of the tire.

Page 316 of 410

10-50 Vehicle Care

Passenger (P-Metric) Tire:

A tire used on passenger cars

and some light duty trucks and

multipurpose vehicles.

Recommended Inflation

Pressure

:Vehicle

manufacturer's recommended

tire inflation pressure as shown

on the tire placard. See Tire

Pressure

on page 10‑51and

Vehicle Load Limits

on

page 9‑27

.

Radial Ply Tire

:A pneumatic

tire in which the ply cords that

extend to the beads are laid at

90 degrees to the centerline of

the tread.

Rim

:A metal support for a tire

and upon which the tire beads

are seated.

Sidewall

:The portion of a tire

between the tread and the bead. Speed Rating

:An

alphanumeric code assigned

to a tire indicating the maximum

speed at which a tire can

operate.

Traction

:The friction between

the tire and the road surface.

The amount of grip provided.

Tread

:The portion of a tire

that comes into contact with

the road.

Treadwear Indicators

:Narrow

bands, sometimes called wear

bars, that show across the tread

of a tire when only 1.6 mm

(1/16 inch) of tread remains.

See When It Is Time for New

Tires

on page 10‑58. UTQGS (Uniform Tire Quality

Grading Standards)

:A tire

information system that provides

consumers with ratings for a

tire's traction, temperature,

and treadwear. Ratings

are determined by tire

manufacturers using

government testing procedures.

The ratings are molded into

the sidewall of the tire. See

Uniform Tire Quality Grading

on

page 10‑61

.

Vehicle Capacity Weight

:

The number of designated

seating positions multiplied by

68 kg (150 lbs) plus the rated

cargo load. See Vehicle Load

Limits

on page 9‑27.

Vehicle Maximum Load on the

Tire

:Load on an individual tire

due to curb weight, accessory

weight, occupant weight, and

cargo weight.

Page 319 of 410

Vehicle Care 10-53

Please note that the TPMS is

not a substitute for proper tire

maintenance, and it is the driver's

responsibility to maintain correct tire

pressure, even if under‐inflation

has not reached the level to trigger

illumination of the TPMS low tire

pressure telltale.

Your vehicle has also been

equipped with a TPMS malfunction

indicator to indicate when the

system is not operating properly.

The TPMS malfunction indicator is

combined with the low tire pressure

telltale. When the system detects a

malfunction, the telltale will flash for

approximately one minute and then

remain continuously illuminated.

This sequence will continue upon

subsequent vehicle start‐ups as

long as the malfunction exists.

When the malfunction indicator

is illuminated, the system may

not be able to detect or signal

low tire pressure as intended.TPMS malfunctions may occur for

a variety of reasons, including the

installation of replacement or

alternate tires or wheels on the

vehicle that prevent the TPMS

from functioning properly. Always

check the TPMS malfunction

telltale after replacing one or more

tires or wheels on your vehicle to

ensure that the replacement or

alternate tires and wheels allow

the TPMS to continue to function

properly.

See

Tire Pressure Monitor

Operation

on page 10‑53for

additional information.

Federal Communications

Commission (FCC) and

Industry Canada

See Radio Frequency Statementon

page 13‑16for information

regarding Part 15 of the Federal

Communications Commission (FCC)

Rules and RSS-210/211 of Industry

Canada.

Tire Pressure Monitor

Operation

This vehicle may have a Tire

Pressure Monitor System (TPMS).

The TPMS is designed to warn the

driver when a low tire pressure

condition exists. TPMS sensors are

mounted onto each tire and wheel

assembly on the vehicle, excluding

the spare tire. The TPMS sensors

monitor the air pressure in the

vehicle's tires and transmit the tire

pressure readings to a receiver

located in the vehicle.

When a low tire pressure

condition is detected, the TPMS

illuminates the low tire pressure

warning light located on the

instrument panel cluster.