check engine Hyundai Matrix 2003 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 255 of 312

DRIVING YOUR HYUNDAI 2- 13

SC200B3-E TOWING ATTACHMENTS It is strongly recommended that only an Hyundai Approved towing attachment is usedto ensure that the loads placed upon the bodystructure are correctly distributed. The use ofa non approved attachment will result in theinvalidation of the vehicle warranty. Hyundaitowing attachments are designed and con-structed to ensure maximum towing perfor-mance and ease of fitment. A range of acces-sories including electrical kits are availablethrough the Hyundai dealer network. It is of the utmost importance that those areas of the vehicle which are subjected to greaterstress during towing are maintained in accor-dance with the recommendations given at theend of this book. In addition, the daily operatingchecks relating to engine oil, transmission oiland tyres must be performed at each refuellingto ensure maximum reliability and safety. The use of a proprietary stabiliser will assist in achieving an inherently stable outfit but whilstthe use of such equipment will improve thecharacteristics of a balanced outfit, it will notcompensate for a badly loaded and thereforeunstable outfit. The tyres and braking equipment fitted to the trailer or caravan must be maintained in ac-cordance with the recommendations of themanufacturer. Special attention should be paidto tyres which deteriorate through time and

WARNING:

It is not recommended that the vehicle be

used for towing until the first 1,000 milesof Running In has been completed. AllHyundai MATRIX models are suited to tow-ing trailers and caravans up to the limitsindicated below. MATRIX models fitted withautomatic transaxle have a transaxle oilcooler and further transaxle cooling shouldnot be required. C190E01FC-EAT

TRAILER AND CARAVAN TOWING

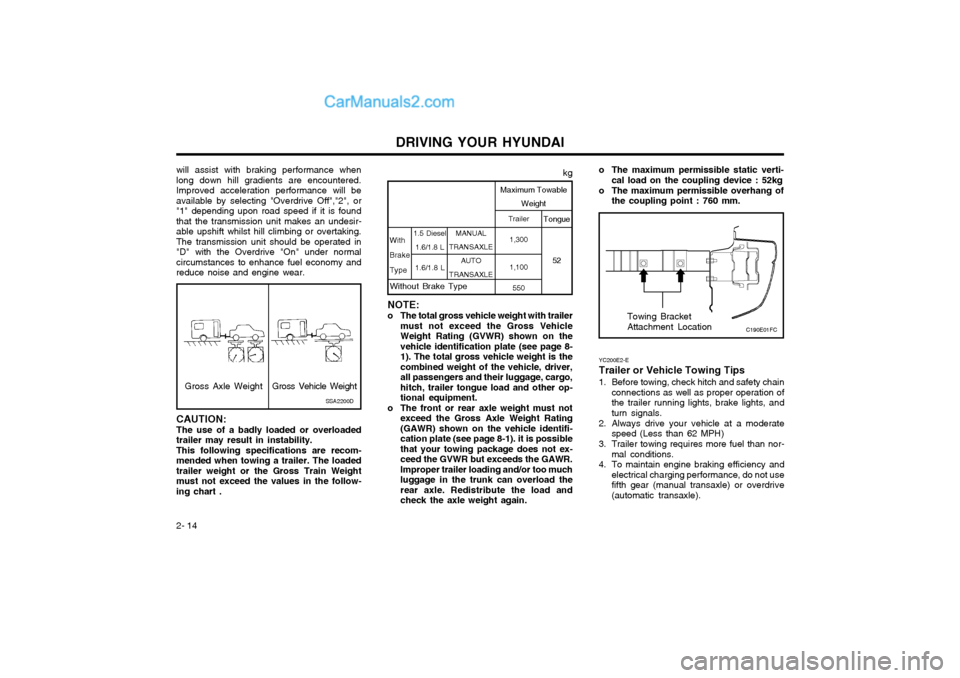

Tongue loadSSA2200B

Total trailer weight

exposure rather than as a result of the dis- tances towed. The inside walls of the tyresshould be inspected along with the outsidewalls for cracking and damage. The trailerwheel nut torque must be checked on a regularbasis, preferably before each towing session.

The trailer hitch and the safety catch mecha-

nism must be maintained in good workingorder. The trailer break away cable or chainshould be inspected for damage and shouldbe attached to the vehicle towing attachmenteach and every time the trailer is hitched tothe vehicle.

Whilst towing, the performance of the vehicle

will be reduced in terms of acceleration, brak-ing and handling due to the increased loadsplaced upon the vehicle. The driver shouldanticipate the change in characteristics andadjust the driving style in keeping with thesechanges. Care should be exercised whencornering and braking to prevent the outfitbecoming uncontrollable by reducing corner-ing speeds and allowing increased brakingdistances.

The driver should exercise care to ensure that

when pulling away from rest particularly onuphill gradients the clutch unit is not subjectedto excessive slippage which will reduce theuseful life of this component. Use of the"Overdrive Off" "2" and "L" positions whendriving vehicles with automatic transmission

Page 256 of 312

DRIVING YOUR HYUNDAI

2- 14 YC200E2-E Trailer or Vehicle Towing Tips

1. Before towing, check hitch and safety chain

connections as well as proper operation of the trailer running lights, brake lights, andturn signals.

2. Always drive your vehicle at a moderate speed (Less than 62 MPH)

3. Trailer towing requires more fuel than nor- mal conditions.

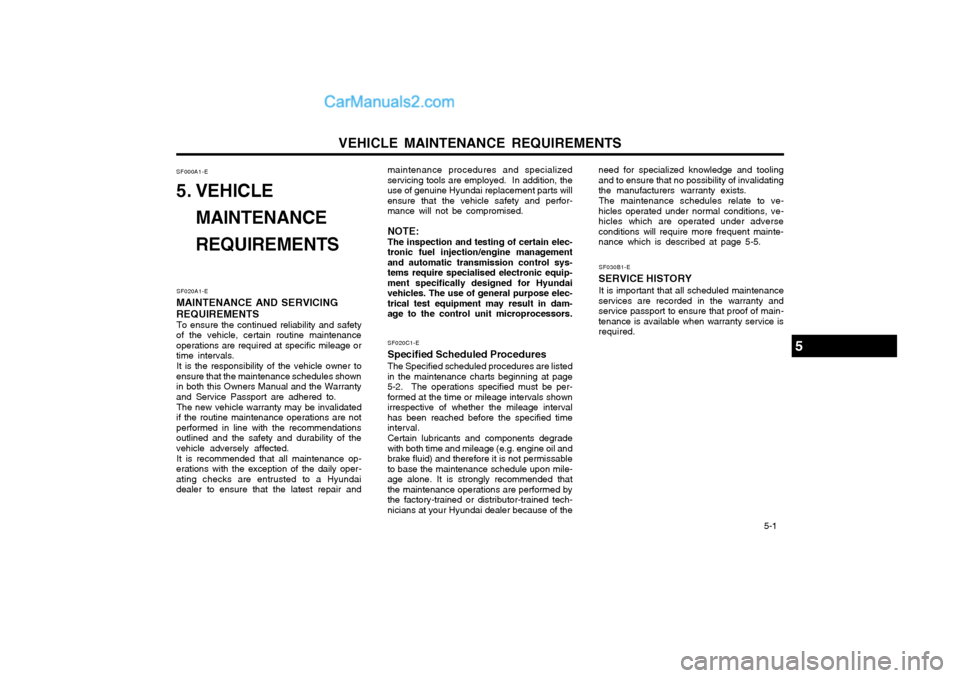

4. To maintain engine braking efficiency and electrical charging performance, do not usefifth gear (manual transaxle) or overdrive(automatic transaxle). Towing Bracket Attachment Location

NOTE:

o The total gross vehicle weight with trailer must not exceed the Gross Vehicle Weight Rating (GVWR) shown on thevehicle identification plate (see page 8-1). The total gross vehicle weight is thecombined weight of the vehicle, driver,all passengers and their luggage, cargo,hitch, trailer tongue load and other op-tional equipment.

o The front or rear axle weight must not exceed the Gross Axle Weight Rating(GAWR) shown on the vehicle identifi-cation plate (see page 8-1). it is possiblethat your towing package does not ex-ceed the GVWR but exceeds the GAWR.Improper trailer loading and/or too muchluggage in the trunk can overload therear axle. Redistribute the load andcheck the axle weight again. MANUAL

TRANSAXLE

AUTO

TRANSAXLE Trailer

1,300 1,100 550 Tongue

52

kg

Maximum Towable Weight

With BrakeType

1.5 Diesel 1.6/1.8 L

1.6/1.8 L

Without Brake Type

o The maximum permissible static verti- cal load on the coupling device : 52kg

o The maximum permissible overhang of the coupling point : 760 mm.

C190E01FC

will assist with braking performance when long down hill gradients are encountered.Improved acceleration performance will beavailable by selecting "Overdrive Off","2", or"1" depending upon road speed if it is foundthat the transmission unit makes an undesir-able upshift whilst hill climbing or overtaking.The transmission unit should be operated in"D" with the Overdrive "On" under normalcircumstances to enhance fuel economy andreduce noise and engine wear.

Gross Axle Weight

CAUTION: The use of a badly loaded or overloaded trailer may result in instability.This following specifications are recom-mended when towing a trailer. The loadedtrailer weight or the Gross Train Weightmust not exceed the values in the follow-ing chart . SSA2200DGross Vehicle Weight

Page 257 of 312

DRIVING YOUR HYUNDAI 2- 15

5. Always secure items in the trailer to pre-

vent load shift while driving.

6. Check the condition and air pressure of all tyres on the trailer and your car. Low tyre pressure can seriously affect the handling.Also check the spare tyre.

7. The vehicle/trailer combination is more af- fected by crosswind and buffeting. When being passed by a large vehicle, keep a constant speed and steer straightahead. If there is too much wind buffetingslow down to get out of the other vehicle'sair turbulence.

8. When parking your car and trailer, espe- cially on a hill, be sure to follow all thenormal precautions. Turn your front wheelinto the curb, set the parking brake firmly,and put the transaxle in 1st or Reverse(manual) or Park (automatic). In addition,place wheel chocks at each of the trailer'styres.

9. If the trailer has electric brakes, start your vehicle and trailer moving, and then applythe trailer brake controller by hand to besure the brakes are working. This lets youcheck your electrical connection at thesame time.

10.During your trip, check occasionally to be sure that the load is secure, and that thelights and any trailer brakes are still work-ing. 11.Avoid jerky starts, sudden acceleration or

sudden stops.

12.Avoid sharp turns and rapid lane changes.

13.Avoid holding the brake pedal down too long or too frequently. This could cause the brakes to overheat, resulting in re-duced braking efficiency.

14.When going down a hill, shift into a lower gear and use the engine braking effect. When ascending a long grade, downshift the transaxle to a lower gear and reducespeed to reduce chances of engine over-loading and/or overheating.

15.If you have to stop while going uphill, do not hold the vehicle in place by pressing onthe accelerator. This can cause the auto-matic transaxle to overheat. Use the park-ing brake or footbrake.

NOTE: When towing check transaxle fluid more frequently. CAUTION: If overheating should occur when towing,(temperature gauge reads near red zone),taking the following action may reduce oreliminate the problem.

1. Turn off the air conditioner.

2. Reduce highway speed.

3. Select a lower gear when going uphill.

4. While in stop and go traffic, place the gear selection in park or neutral and idle the engine at a higher speed.

Page 258 of 312

3-1

IN CASE OF EMERGENCY

SD000A1-E

3. IN CASE OF

EMERGENCY

SD020A1-E

IF THE ENGINE WILL NOT START Seek assistance from the nearest Hyundai dealer with regard to the method of ignition andfuel system diagnosis.

CAUTION:If the engine refuses to start, no attempt

should be made to push or tow start thevehicle. Vehicles with automatic transaxleor fuel injection will not be able to bestarted in this manner since no drive istransmitted through the automatic transaxlewhilst the engine is not running, and in thecase of fuel injected derivatives, the fuelpump will not operate under tow start con-ditions. In addition, if the vehicle isequipped with an exhaust catalyst, dam-age to the catalyst may result if the vehicleis tow started. SD020B1-E

IF THE ENGINE CANNOT BE

CRANKED SD020C1-F

If Engine Turns Over Normally but Does Not Start

SSA3020C

1. Check fuel Level

2. Check all connectors at ignition coil and spark plugs.Replace any that may be disconnected or loose.

3. Check fuel line in the engine room.

4. If engine still refuses to start, call a Hyundai dealer or seek other qualified assistance.

1. If the vehicle is fitted with manual transaxle,

ensure that the clutch pedal is depressed whilst cranking the engine. If the vehicle isfitted with automatic transaxle, ensurethat the transaxle selector is at the "P"or"N" position.

2. Check the battery terminals and connec- tions to ensure that these are clean andalso tight.

3. If the ignition warning lights dim when the engine is cranked and the battery termi-nals have been checked, a dischargedbattery is indicated.

4. Do not attempt to push or tow start the vehicle, refer to "Jump Starting" for infor-mation regarding engine starting when thebattery is discharged. AD020D1-A

If Engine Stalls While Driving

1. Reduce your speed gradually, keeping a straight line. Move cautiously off the road to a safe place.

2. Turn on your emergency flashers.

3. Try starting the engine again. If your ve- hicle will not start, see "IF THE ENGINE WILL NOT START"

3

D010B01FC

Page 259 of 312

IN CASE OF EMERGENCY

3-2

CAUTION:

Personal injury and damage to the vehicle

may occur if jump starting is not per- formed correctly. If any doubt exists as tohow this operation should be performed,seek assistance from qualified personnel. WARNING:

Motor vehicle batteries contain sulphuric

acid and emit hydrogen gas. Protective clothing should be worn and care exer-cised to prevent the acid from coming intocontact with skin or clothing and the ve-hicle. Naked lights should not be permittedin the vicinity of the battery. Care shouldbe exercised to prevent sparks occurringduring connection. If acid accidentallycomes into contact with skin or eyes, theaffected area should immediately be flushed ponents such as the Fuel Injection system

computer and the Automatic Transaxlecomputer. The battery must never be dis-connected whilst the engine is running. SD040A2-E IF THE ENGINE OVERHEATS If the temperature gauge indicates overheat- ing:

1. Pull off the road and stop as soon as it is

safe to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transaxle) and set the parking brake. If the air condition-ing is on, turn it off.

3. If coolant is running out under the car or steam is coming out from under the bonnetstop the engine. Do not open the bonnetuntil the coolant has stopped running orthe steaming has stopped. If there is novisible loss of coolant and no steam, leavethe engine running and check to be surethe engine cooling fan is operating. If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing, check to see that it is tight. If the drive belt seems to besatisfactory, check for coolant leaking fromthe radiator, hoses or under the car. (If theair conditioning had been in use, it isnormal for cold water to be draining fromit).

SD030A1-E JUMP STARTING

with copious amounts of water and medi- cal assistance sought.

1. Ensure that the booster battery is 12 volt type. If the booster battery is installed inanother vehicle, ensure that the two vehi-cles are not touching.

2. Turn off all unnecessary electrical equip- ment in both vehicles.

3. Ensure that the engine of the vehicle pro- viding the jump start is running prior toconnection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the booster battery and theother end to the positive (+) terminal of thedischarged battery.

5. Attach the black jump cable to the nega- tive (-) terminal of the booster battery, andthe other end to a ground point within theengine compartment of the vehicle withthe flat battery. Do not connect to thenegative battery terminal of the flat batterysince sparks may be generated with thesubsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start the engine of thevehicle with the flat battery.

7. Remove jump cables in the reverse order of installation (black cable first).

CAUTION:If the jump cable is incorrectly installed,damage to the vehicle electrical systemmay occur, in particular the electronic com-

HFC4002

Booster battery Discharged battery

Page 260 of 312

3-3

IN CASE OF EMERGENCY

WARNING: While the engine is running, keep hands

and clothing away from moving parts such as the fan and drive belts to preventinjury.

WARNING (Diesel only): Never work on injection system with en-

gine running or within 30 seconds after shutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields.

5. If the water pump drive belt is broken or coolant is leaking out, stop the engine immediately and call the nearest Hyundaidealer for assistance.

WARNING: Do not remove the radiator cap when the

engine is hot since steam and boiling wa- ter may be ejected from the radiator result-ing in burns or scalding. D040A01FC-EAT TEMPORARY SPARE TYREThe following instructions for the temporary spare tyre should be observed:

1. Check inflation pressure as soon as pos-

sible after installing the spare tyre, and adjust to the specified pressure. The tyrepressure should be periodically checkedand maintained at the specified pressurewhile the tyre is stored. 2. The spare tyre should only be used tem-

porarily and should be returned to theluggage compartment as soon as the origi-nal tyre can be repaired or replaced.

3. Continuous use at speeds of over 80 km/h (50 mph) is not recommended.

4. As the temporary spare tyre is specifically designed for your car, it should not beused on any other vehicle.

5. The temporary spare tyre should not be used on any other wheels, nor shouldstandard tyre, snow tyre, wheel covers ortrim rings be used with the temporaryspare wheel. If such use is attempted,damage to these items or other car com-ponents may occur.

6. The temporary spare tyre pressure should be checked once a month while the tyre isstored.

CAUTION:

o Do not use snow chains with your tem- porary spare tyre.

o Do not use more than one temporary spare tyre at a time.

Spare Tyre Pressure

Type Size Inflation Pressure T115/70R(D)15420 kPa (60 psi)6. If the cause of the overheating cannot be

found, wait until the engine temperature has returned to normal. Then, if coolanthas been lost, carefully remove the radia-tor cap and add water to bring the fluid levelin the reservoir up to the base of theradiator fill opening. Fill the coolant expan-sion tank to the halfway mark.

7. Proceed with caution until it is established that the engine is operating normally. If theengine overheats repeatedly, the advice ofa Hyundai dealer should be sought.

CAUTION: Serious loss of coolant indicates there is a leak in the cooling system and thisshould be checked as soon as possibleby a Hyundai dealer.

Page 268 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-1

SF020A1-E

MAINTENANCE AND SERVICING REQUIREMENTS To ensure the continued reliability and safety

of the vehicle, certain routine maintenance operations are required at specific mileage ortime intervals.

It is the responsibility of the vehicle owner to

ensure that the maintenance schedules shownin both this Owners Manual and the Warrantyand Service Passport are adhered to.

The new vehicle warranty may be invalidated

if the routine maintenance operations are notperformed in line with the recommendationsoutlined and the safety and durability of thevehicle adversely affected.

It is recommended that all maintenance op-

erations with the exception of the daily oper-ating checks are entrusted to a Hyundaidealer to ensure that the latest repair and maintenance procedures and specializedservicing tools are employed. In addition, theuse of genuine Hyundai replacement parts willensure that the vehicle safety and perfor-mance will not be compromised. NOTE:

The inspection and testing of certain elec-

tronic fuel injection/engine management and automatic transmission control sys-tems require specialised electronic equip-ment specifically designed for Hyundaivehicles. The use of general purpose elec-trical test equipment may result in dam-age to the control unit microprocessors.

SF000A1-E

5. VEHICLE

MAINTENANCE REQUIREMENTS

SF020C1-E

Specified Scheduled Procedures The Specified scheduled procedures are listed

in the maintenance charts beginning at page 5-2. The operations specified must be per-formed at the time or mileage intervals shownirrespective of whether the mileage intervalhas been reached before the specified timeinterval.

Certain lubricants and components degrade

with both time and mileage (e.g. engine oil andbrake fluid) and therefore it is not permissableto base the maintenance schedule upon mile-age alone. It is strongly recommended thatthe maintenance operations are performed bythe factory-trained or distributor-trained tech-nicians at your Hyundai dealer because of the need for specialized knowledge and toolingand to ensure that no possibility of invalidatingthe manufacturers warranty exists.

The maintenance schedules relate to ve-

hicles operated under normal conditions, ve-hicles which are operated under adverseconditions will require more frequent mainte-nance which is described at page 5-5.

SF030B1-E

SERVICE HISTORY It is important that all scheduled maintenance

services are recorded in the warranty andservice passport to ensure that proof of main-tenance is available when warranty service isrequired.

5

Page 271 of 312

VEHICLE MAINTENANCE REQUIREMENTS

5- 4 F030C01E-EAT

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

GENERAL MAINTENANCE COOLING SYSTEMCOOLANT GASOLINE ENGINEDIESEL ENGINE

ENGINE COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (IN FRONT OF BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

60 72

50 60

4048

I

R R

I I

R I

R R I I II

R

IIIII I

I I IIII I I I I

R I III I I

I

R IIII

R R I I I I

R I III I I

30 36

2024

I

R

I IIII I I II

R IIIIII

I

R IIII

R R I I I I

R I III I I

10 12

I I IIII I I I I

R I III I I

MILES X 1,000 MONTHS

NO. DESCRIPTION

1 2 3 456789

10111213141516171819

Page 273 of 312

VEHICLE MAINTENANCE REQUIREMENTS

5- 6 6ZF060D2-A

o Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and connec- tions for leakage and damage. Replace anydamaged or leaking parts immediately.

WARNING (Diesel only): Never work on injection system with en-gine running or within 30 seconds aftershutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer tothe ECU or wiring harness within theengine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields. 6ZF060E1-A

o Timing belt Replace timimg belt and inspect all associated parts related for damage and deformation.Replace any damaged parts immediately. 6ZF060G1-A

o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in themaintenance schedule. Make sure that a newvapour hose or fuel filler cap is correctlyreplaced. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard andbrittle rubber, cracking, tears, cuts, abra-sions, and excessive swelling indicate dete-rioration. Particular attention should be paid toexamining those hose surfaces nearest tohigh heat sources, such as the exhaustmanifold.Inspect the hose routing to assure that thehoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechani-cal wear. Inspect all hose connections, suchas clamps and couplings, to make sure theyare secure, and that no leaks are present.Hoses should be replaced immediately if thereis any evidence of deterioration or damage.

6ZF060A1-A

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine oil and filter The engine oil and filter should be changed at

the intervals specified in the maintenance schedule. If the car is being driven in severeconditions, more frequent oil and filter changesare required.

6ZF060B1-A

o Drive belts Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation andreplace if necessary. Drive belts should bechecked periodically for proper tension andadjusted as necessary.

6ZF060C1-A

o Fuel filter A clogged filter can limit the speed at which the

vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replace-ment more frequently.

After installing a new filter, run the engine for

several minutes, and check for leaks at theconnections.

Page 274 of 312

VEHICLE MAINTENANCE REQUIREMENTS 5-7

6ZF070D1-A

o Manual transaxle oil Inspect the manual transaxle oil according to

the maintenance schedule. NOTE: If the oil level is low, check for possible

leaks before adding oil. Do not overfill.

6ZF070H1-A

o Rear brake drums and linings/ parking brake

Check the rear brake drums and linings for

scoring, burning, leaking fluid, broken parts, and excessive wear. Inspect the parkingbrake system including the parking brakelever and cables. For detailed service proce-dures, refer to the Shop Manual.

6ZF070J1-A

o Brake pads, calipers and rotors Check the pads for excessive wear, discs for

run out and wear, and calipers for fluid leak-age.

6ZF070K1-A

o Exhaust pipe and muffler Visually inspect the exhaust pipes, mufflerand hangers for cracks, deterioration, or dam-age. Start the engine and listen carefully forany exhaust gas leakage. Tighten connec-tions or replace parts as necessary.

F070E03A-AAT

o Automatic transaxle fluid The fluid level should be in the "HOT" range

of the dipstick, after engine and transaxle areat normal operating temperature. Check theAutomatic Transaxle Fluid level with the en-gine running and the transaxle in neutral, withthe parking brake properly applied. Use DIA-MOND ATF SP- III or SK ATF SP- III when

adding or changing fluid. 6ZF070F1-A

o Brake hoses and lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replaceany deteriorated or damaged parts immediately.

6ZF060H1-A

o Air cleaner filter A Genuine Hyundai air cleaner filter is recom-

mended when filter is replaced.

6ZF060J1-A

o Spark plugs Make sure to install new spark plugs of the

correct heat range.

6ZF070B1-A

o Cooling system Check the cooling system part, such asradiator, coolant reservoir, hoses and con-nections for leakage and damage. Replaceany damaged parts. 6ZF070G2-A

o Brake fluid Check brake fluid level in the brake fluidreservoir. The level should be between "MIN"and "MAX" marks on the side of the reservoir.Use only hydraulic brake fluid conforming toDOT 3 or DOT 4.

6ZF070C1-A

o Engine coolant The coolant should be changed at theintervals specified in the maintenance sched-ule.

F060N01E-AAT

o Valve Clearance Inspect excessive valve noise and/or enginevibration and adjust if necessary. A qualifiedtechnician should perform the operation.

Valve Clearance

Intake valves: 0.0067 ~ 0.0091 in. (0.17 ~ 0.23mm)

Exhaust valves: 0.0098 ~ 0.0122 in. (0.25 ~ 0.31mm)