Panel INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3048 of 5621

REAR PARCEL SHELF FINISHER

EI-43

C

D

E

F

G

H

J

K

L

MA

B

EI

Revision: 2006 January2006 M35/M45

5. Disconnect high-mounted stop lamp harness connector from

front side of rear parcel shelf finisher. (Models with rear window

sunshade)

6. Remove rear parcel shelf finisher mounting clip using a clip clamp remover.

7. Remove the following parts after removing rear parcel shelf finisher.

Rear speaker grille (for woofer)

High-mounted stop lamp

High-mounted stop lamp harness

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Make sure that clips are securely fitted in panel holes on body when installing, and then press them in.

Rear Window SunshadeNIS0024X

REMOVAL AND INSTALLATION

CAUTION:

Be careful not to damage the rear window glass.

Removal

1. Remove rear parcel shelf finisher. Refer to EI-42, "REAR PARCEL SHELF FINISHER" .

2. Disconnect rear window sunshade harness connector.

3. Remove rear window sunshade mounting bolts.

4. Lift up rear window sunshade and pull out locating pin from body side panel hole, and then remove rear

window sunshade.

Installation

Install in the reverse order of removal.

PIIB5130E

Page 3055 of 5621

EI-50

FLOOR TRIM

Revision: 2006 January2006 M35/M45

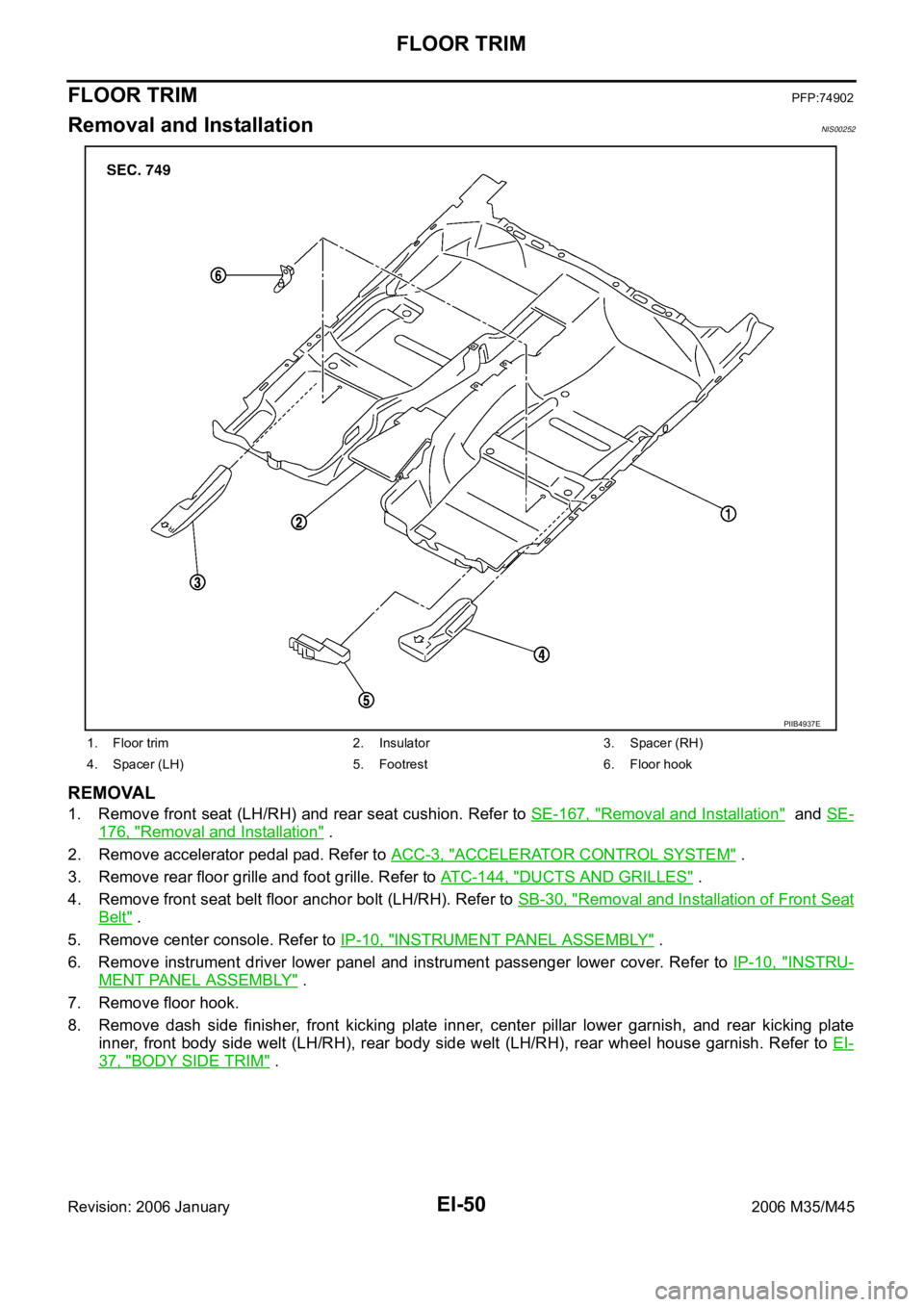

FLOOR TRIMPFP:74902

Removal and InstallationNIS00252

REMOVAL

1. Remove front seat (LH/RH) and rear seat cushion. Refer to SE-167, "Removal and Installation" and SE-

176, "Removal and Installation" .

2. Remove accelerator pedal pad. Refer to ACC-3, "

ACCELERATOR CONTROL SYSTEM" .

3. Remove rear floor grille and foot grille. Refer to ATC-144, "

DUCTS AND GRILLES" .

4. Remove front seat belt floor anchor bolt (LH/RH). Refer to SB-30, "

Removal and Installation of Front Seat

Belt" .

5. Remove center console. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

6. Remove instrument driver lower panel and instrument passenger lower cover. Refer to IP-10, "

INSTRU-

MENT PANEL ASSEMBLY" .

7. Remove floor hook.

8. Remove dash side finisher, front kicking plate inner, center pillar lower garnish, and rear kicking plate

inner, front body side welt (LH/RH), rear body side welt (LH/RH), rear wheel house garnish. Refer to EI-

37, "BODY SIDE TRIM" .

1. Floor trim 2. Insulator 3. Spacer (RH)

4. Spacer (LH) 5. Footrest 6. Floor hook

PIIB4937E

Page 3177 of 5621

![INFINITI M35 2006 Factory Service Manual EM-114

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

REMOVAL

Outline

At first, remove the engine and the transmission assembly with front suspension member from vehicle down-

ward. Then INFINITI M35 2006 Factory Service Manual EM-114

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

REMOVAL

Outline

At first, remove the engine and the transmission assembly with front suspension member from vehicle down-

ward. Then](/img/42/57023/w960_57023-3176.png)

EM-114

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

REMOVAL

Outline

At first, remove the engine and the transmission assembly with front suspension member from vehicle down-

ward. Then separate the engine from transmission.

Preparation

1. Release fuel pressure. Refer to EC-98, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-11, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery cables. Refer to SC-4, "

BATTERY" .

4. Remove the following parts:

Engine room cover (RH and LH); Refer toEM-14, "ENGINE ROOM COVER" .

Engine cover; Refer to EM-19, "INTAKE MANIFOLD COLLECTOR" .

Front road wheel and tires (power tool)

Front and rear engine undercover (power tool)

Cowl top cover (RH); Refer to EI-18, "COWL TOP" .

Air duct and air cleaner case assembly; EM-17, "AIR CLEANER AND AIR DUCT" .

5. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

6. Remove radiator hoses (upper and lower). Refer to CO-14, "

RADIATOR" .

Engine Room LH

1. Disconnect heater hose from vehicle-side, and fit a plug onto hose end to prevent engine coolant leak.

2. Disconnect wire bonding (between vehicle to left bank cylinder head).

3. Disconnect A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to

AT C - 1 5 1 , "

REFRIGERANT LINES" .

4. Disconnect brake booster vacuum hose.

Engine Room RH

1. Disconnect battery positive cable at vehicle side and temporarily fasten it on engine.

2. Disconnect grounding cable.

3. Disconnect fuel feed hose (with damper) and EVAP hose. Refer to EM-45, "

FUEL INJECTOR AND FUEL

TUBE" .

CAUTION:

Fit plugs onto disconnected hoses to prevent fuel leak.

4. Remove reservoir tank of power steering oil pump and piping from vehicle, and temporarily secure them

on engine. Refer to PS-29, "

POWER STEERING OIL PUMP" .

CAUTION:

When temporarily securing, keep the reservoir tank upright to avoid a fluid leak.

Vehicle inside

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "

BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CAUTION:

When pulling out harnesses, take care not to damage harnesses and connectors.

After temporarily securing, cover connectors with vinyl or similar material to protect against for-

eign material adhesion.

Page 3183 of 5621

![INFINITI M35 2006 Factory Service Manual EM-120

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "BODY SIDE

TRIM" and INFINITI M35 2006 Factory Service Manual EM-120

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "BODY SIDE

TRIM" and](/img/42/57023/w960_57023-3182.png)

EM-120

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CAUTION:

When pulling out harnesses, take care not to damage harnesses and connectors.

After temporarily securing, cover connectors with vinyl or similar material to protect against for-

eign material adhesion.

Vehicle Underbody

1. Remove A/T fluid cooler hoses and power steering oil pump oil cooler hoses.

Install plug to avoid leakage of A/T fluid and power steering fluid.

2. Disconnect heated oxygen sensor 2 harness. Refer to EX-3, "

EXHAUST SYSTEM" .

3. Remove three way catalyst and exhaust front tube. Refer to EX-3, "

EXHAUST SYSTEM" .

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to PS-13, "

STEERING COLUMN" .

5. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPELLER SHAFT" .

6. Remove front drive shaft (both side). Refer to FAX-8, "

FRONT DRIVE SHAFT" .

7. Disconnect harness connector from transmission assembly and transfer assembly.

8. Disengage A/T control rod at control device assembly side. Then, temporarily secure it on the transmis-

sion assembly, so that it does not sag. Refer to AT-222, "

SHIFT CONTROL SYSTEM" .

9. Remove rear plate cover from oil pan (upper). Then remove bolts fixing drive plate to torque converter.

Refer to EM-29, "

OIL PAN AND OIL STRAINER" and AT-271, "TRANSMISSION ASSEMBLY" .

10. Remove bolts fixing the transmission assembly to lower rear side of oil pan (upper). Refer to AT- 2 7 1 ,

"TRANSMISSION ASSEMBLY" .

11. Remove front stabilizer at transverse link side. Refer to FSU-18, "

STABILIZER BAR" .

12. Remove lower ends of left and right strut from transverse link. Refer to FSU-23, "

FRONT SUSPENSION

ASSEMBLY" .

13. Separate steering outer sockets from steering knuckle. Refer to PS-18, "

POWER STEERING GEAR" .

14. Remove transverse links mounting bolts at knuckle side. Refer to FSU-31, "

TRANSVERSE LINK" .

Removal Work

1. Use a manual lift table caddy (commercial service tool) or equiv-

alently rigid tool such as a transmission jack. Securely support

bottom of suspension member and transmission.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove rear engine mounting member bolts.

3. Remove front suspension member mounting bolts and nuts. Refer to FSU-23, "

FRONT SUSPENSION

ASSEMBLY" .

4. Carefully lower jack, or raise lift to remove the engine, transmission assembly, transfer, front final drive

assembly and front suspension member. When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with the vehicle.

Make sure that all connection points have been disconnected.

Keep in mind the center of the vehicle gravity changes. If necessary, use jack(s) to support the

vehicle at rear jacking point(s) to prevent it from falling it off the lift.

PBIC0804E

Page 3263 of 5621

![INFINITI M35 2006 Factory Service Manual EM-200

[VK45DE]

ROCKER COVER

Revision: 2006 January2006 M35/M45

b. Remove battery and battery tray. Refer to SC-4, "BATTERY" .

c. Remove grommet (2) from cowl top panel hole (RH).

d. Loosen mo INFINITI M35 2006 Factory Service Manual EM-200

[VK45DE]

ROCKER COVER

Revision: 2006 January2006 M35/M45

b. Remove battery and battery tray. Refer to SC-4, "BATTERY" .

c. Remove grommet (2) from cowl top panel hole (RH).

d. Loosen mo](/img/42/57023/w960_57023-3262.png)

EM-200

[VK45DE]

ROCKER COVER

Revision: 2006 January2006 M35/M45

b. Remove battery and battery tray. Refer to SC-4, "BATTERY" .

c. Remove grommet (2) from cowl top panel hole (RH).

d. Loosen mounting bolts in reverse order as that shown in the fig-

ure.

CAUTION:

Do not hold oil filler neck (right bank) so as not to damage

it.

NOTE:

Loosen No. 10 bolt of right bank from cowl top panel hole using

tool.

8. Remove rocker cover (left bank) as follows:

a. Remove brake master cylinder cover. Refer to EM-173, "

ENGINE ROOM COVER" .

b. Remove two grommets (1) from cowl top panel hole (LH).

c. Loosen mounting bolts in reverse order as that shown in the fig-

ure.

NOTE:

Loosen No. 10 and 12 bolts of the left bank from cowl top panel

hole using tool.

Refer to the following procedure for removal of mounting bolts No. 10 and 12. (For ICC models)

CAUTION:

Do not bend or damage brake piping by tools.

1 : Relay box

: Engine front

PBIC3368E

PBIC0027E

2 : Brake master cylinder

: Engine front

PBIC3452E

PBIC0027E

Page 3264 of 5621

![INFINITI M35 2006 Factory Service Manual ROCKER COVER

EM-201

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

–No. 10 bolt. See the figure and remove them using a 300 mm

expansion bar.

–No. 12 bolt. See the figure an INFINITI M35 2006 Factory Service Manual ROCKER COVER

EM-201

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

–No. 10 bolt. See the figure and remove them using a 300 mm

expansion bar.

–No. 12 bolt. See the figure an](/img/42/57023/w960_57023-3263.png)

ROCKER COVER

EM-201

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

–No. 10 bolt. See the figure and remove them using a 300 mm

expansion bar.

–No. 12 bolt. See the figure and remove them using a 300 mm

expansion bar.

NOTE:

Slide the brake piping frontward to obtain working space.

9. Remove rocker cover gaskets from rocker covers.

10. Use scraper to remove all traces of liquid gasket from cylinder head and camshaft bracket (No. 1 and 6).

CAUTION:

Do not scratch or damage the mating surface when cleaning off oil liquid gasket.

INSTALLATION

1. Apply liquid gasket with tube presser [SST: WS39930000 ( —

)] to joint among rocker cover, cylinder head and camshaft

bracket (No. 1 and 6) as follows:

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

NOTE:

The figure shows an example of left bank side [zoomed in

shows camshaft bracket (No. 1)]. Apply only to camshaft bracket

(No. 1) for right bank side.

a. Refer to the figure “a” to apply liquid gasket to joint part of cam-

shaft bracket (both No. 1 and 6) and cylinder head.

b. Refer to the figure “b” to apply liquid gasket to the figure “a”

squarely.

2. Install new rocker cover gaskets to rocker covers.

3. Install rocker cover.

Check if rocker cover gasket is not dropped from installation groove of rocker cover.

A : Cowl top panel hole

: Engine front

PBIC3367E

A : Cowl top panel hole

: Engine front

PBIC3366E

PBIC2444E

Page 3265 of 5621

![INFINITI M35 2006 Factory Service Manual EM-202

[VK45DE]

ROCKER COVER

Revision: 2006 January2006 M35/M45

4. Tighten mounting bolts in two steps separately in numerical

order as shown in the figure.

CAUTION:

Do not hold oil filler INFINITI M35 2006 Factory Service Manual EM-202

[VK45DE]

ROCKER COVER

Revision: 2006 January2006 M35/M45

4. Tighten mounting bolts in two steps separately in numerical

order as shown in the figure.

CAUTION:

Do not hold oil filler](/img/42/57023/w960_57023-3264.png)

EM-202

[VK45DE]

ROCKER COVER

Revision: 2006 January2006 M35/M45

4. Tighten mounting bolts in two steps separately in numerical

order as shown in the figure.

CAUTION:

Do not hold oil filler neck (right bank) so as not to dam-

age it.

Do not bend or damage brake piping by tools. (ICC mod-

els)

NOTE:

Tighten No. 10 bolt of the right bank and No. 10 and 12 bolts of

the left bank from cowl top panel hole with using tool.

5. Install oil filler cap and oil catcher to rocker cover (right bank), if removed.

6. Install new O-rings and PCV valves to rocker covers (right and left bank), if removed.

7. Install in the reverse order of removal. 1st step : 2.0 Nꞏm (0.2 kg-m, 18 in-lb)

2nd step : 8.3 Nꞏm (0.85 kg-m, 73 in-lb)

PBIC0027E

Page 3308 of 5621

![INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li](/img/42/57023/w960_57023-3307.png)

ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at the rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-42, "Garage Jack and

Safety Stand and 2-Pole Lift" .

REMOVAL

Outline

At first, remove engine, transmission assembly with front suspension member from vehicle downward. Then

separate engine from transmission.

Preparation

1. Release fuel pressure. Refer to EC-809, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-40, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery cables. Refer to SC-4, "

BATTERY" .

4. Remove crankshaft position sensor (POS) from transmission.

CAUTION:

Handle carefully to avoid dropping and shocks.

Do not disassemble.

Do not allow metal powder to adhere to magnetic part at sensor tip.

Do not place sensors in a location where they are exposed to magnetism.

5. Remove the following parts:

Front and rear engine undercover (power tool)

Air duct (inlet), air duct and air cleaner case assembly; Refer to EM-177, "AIR CLEANER AND AIR

DUCT" .

Front road wheels and tires (power tool)

Engine Room LH

1. Disconnect heater hoses, and install plugs to avoid leakage of engine coolant.

2. Disconnect wire bonding from exhaust manifold cover to vehicle.

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

5. Remove A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to AT C -

151, "REFRIGERANT LINES" .

Engine Room RH

1. Disconnect fuel feed hose and EVAP hose. Refer to EM-193, "FUEL INJECTOR AND FUEL TUBE" .

CAUTION:

Fit plugs onto disconnected hose to prevent fuel leak.

2. Disconnect ground cable (between vehicle and right bank cylinder head).

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Disconnect reservoir tank of power steering oil pump from engine, and move it aside for easier work.

CAUTION:

When temporarily securing, keep reservoir tank upright to avoid a fluid leak.

Ve h i c le i n s i d e

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "

BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.

Page 3436 of 5621

![INFINITI M35 2006 Factory Service Manual FRONT SUSPENSION ASSEMBLY

FSU-9

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" INFINITI M35 2006 Factory Service Manual FRONT SUSPENSION ASSEMBLY

FSU-9

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL"](/img/42/57023/w960_57023-3435.png)

FRONT SUSPENSION ASSEMBLY

FSU-9

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

Removal and Installation NES000ID

REMOVAL

1. For VK45DE engine models, disconnect related electric wires and hoses from engine assembly to remove

front suspension member with engine assembly. Refer to EM-244, "

ENGINE ASSEMBLY" .

2. Remove cowl top panel and hood. Refer to EI-18, "

COWL TOP" , EI-17, "HOOD" .

3. For VQ35DE engine models, install engine slinger, and then hoist engine. Refer to EM-113, "

Removal and

Installation (2WD Models)" .

4. Remove tires from vehicle with a power tool.

5. Remove wheel sensor from steering knuckle. Refer to BRC-57, "

WHEEL SENSOR" .

CAUTION:

Do not pull on wheel sensor harness.

6. Remove brake hose bracket. Refer to BR-12, "

BRAKE TUBE AND HOSE" .

7. Remove undercover with a power tool.

8. Remove cotter pin (1), and then loosen the nut.

9. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

10. Remove the mounting nut on the upper side of stabilizer con-

necting rod with a power tool, and then remove stabilizer con-

necting rod from transverse link.

11. Separate steering gear assembly and lower joint. Refer to PS-13, "

STEERING COLUMN" .

12. Remove rack stay. Refer to FSU-8, "

Components" .

13. Remove steering hydraulic piping bracket from front suspension member. Refer to PS-38, "

HYDRAULIC

LINE" .

14. Remove the mounting nut and bolt on the lower side of shock absorber with a power tool, and then

remove shock absorber from transverse link.

15. Remove cotter pin of transverse link and steering knuckle, and then loosen nut.

16. Set jack under front suspension member.

17. Remove transverse link from steering knuckle so as not to damage ball joint boot using the ball joint

remover (suitable tool)

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from suddenly coming off.

18. Remove the mounting nuts of engine mounting insulator. Refer to EM-113, "

ENGINE ASSEMBLY" .

19. Remove the mounting bolts of member bracket, and then remove member bracket from front suspension

member with a power tool. Refer to FSU-8, "

Components" .

20. Remove the mounting nut and bolts of member stay, and then remove member stay from front suspension

member and vehicle with a power tool.

21. Remove the mounting nut of front suspension member with a power tool. Refer to FSU-8, "

Components" .

22. For VQ35DE engine models, gradually lower a jack to remove front suspension assembly from vehicle.

1. Shock absorber mounting bracket 2. Bound bumper 3. Rubber seat

4. Coil spring 5. Shock absorber 6. Upper link

7. Steering knuckle 8. Transverse link 9. Washer

10. Steering stopper bracket 11. Stabilizer connecting rod 12. Stabilizer bar

13. Stabilizer bushing 14. Stabilizer clamp 15. Front suspension member

16. Rack stay 17. Member stay 18. Member bracket

19. Clamp 20. Cotter pin 21. Stopper rubber

SGIA1183E

Page 3453 of 5621

![INFINITI M35 2006 Factory Service Manual FSU-26

[AWD]

FRONT SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

Removal and Installation INFINITI M35 2006 Factory Service Manual FSU-26

[AWD]

FRONT SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

Removal and Installation](/img/42/57023/w960_57023-3452.png)

FSU-26

[AWD]

FRONT SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

Removal and Installation NES000IT

REMOVAL

1. Remove cowl top panel and hood. Refer to EI-18, "COWL TOP" , EI-17, "HOOD" .

2. Install engine slinger, and then hoist engine. Refer to EM-118, "

Removal and Installation (AWD Models)" .

3. Remove tires from vehicle with a power tool.

4. Remove wheel sensor from steering knuckle. Refer to BRC-57, "

WHEEL SENSOR" .

CAUTION:

Do not pull on wheel sensor harness.

5. Remove brake hose bracket. Refer to BR-12, "

BRAKE TUBE AND HOSE" .

6. Remove undercover with a power tool.

7. Remove cotter pin (1), and then loosen the nut.

8. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

9. Remove the mounting nut on the upper side of stabilizer con-

necting rod with a power tool, and then remove stabilizer con-

necting rod from transverse link.

10. Separate steering gear assembly and lower joint. Refer to PS-13, "

STEERING COLUMN" .

11. Remove front cross bar. Refer to FSU-25, "

Components" .

12. Remove steering hydraulic piping bracket from front suspension member. Refer to PS-38, "

HYDRAULIC

LINE" .

13. Remove the mounting nut and bolt on the lower side of shock absorber arm with a power tool, and then

remove shock absorber arm from transverse link.

14. Remove cotter pin of transverse link and steering knuckle, and then loosen nut.

15. Remove transverse link from steering knuckle so as not to damage ball joint boot using the ball joint

remover (suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from suddenly coming off.

16. Set jack under front suspension member.

17. Remove the mounting nuts of engine mounting insulator. Refer to EM-113, "

ENGINE ASSEMBLY" .

18. Remove the mounting bolts of member bracket, and then remove member bracket from front suspension

member with a power tool. Refer to FSU-25, "

Components" .

19. Remove the mounting nuts of front suspension member with a power tool. Refer to FSU-25, "

Compo-

nents" .

20. Gradually lower a jack to remove front suspension assembly from vehicle.

INSTALLATION

Installation is the reverse order of removal. For tightening torque, refer to FSU-25, "Components" .

1. Shock absorber mounting bracket 2. Bound bumper 3. Rubber seat

4. Coil spring 5. Shock absorber 6. Shock absorber arm

7. Upper link 8. Steering knuckle 9. Transverse link

10. Steering stopper bracket 11. Washer 12. Stabilizer connecting rod

13. Stabilizer bar 14. Stabilizer bushing 15. Stabilizer clamp

16. Front suspension member 17. Front cross bar 18. Member bracket

19. Clamp 20. Cotter pin 21. Stopper rubber

SGIA1183E