steering INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1283 of 5621

BR-8

BRAKE PEDAL

Revision: 2006 January2006 M35/M45

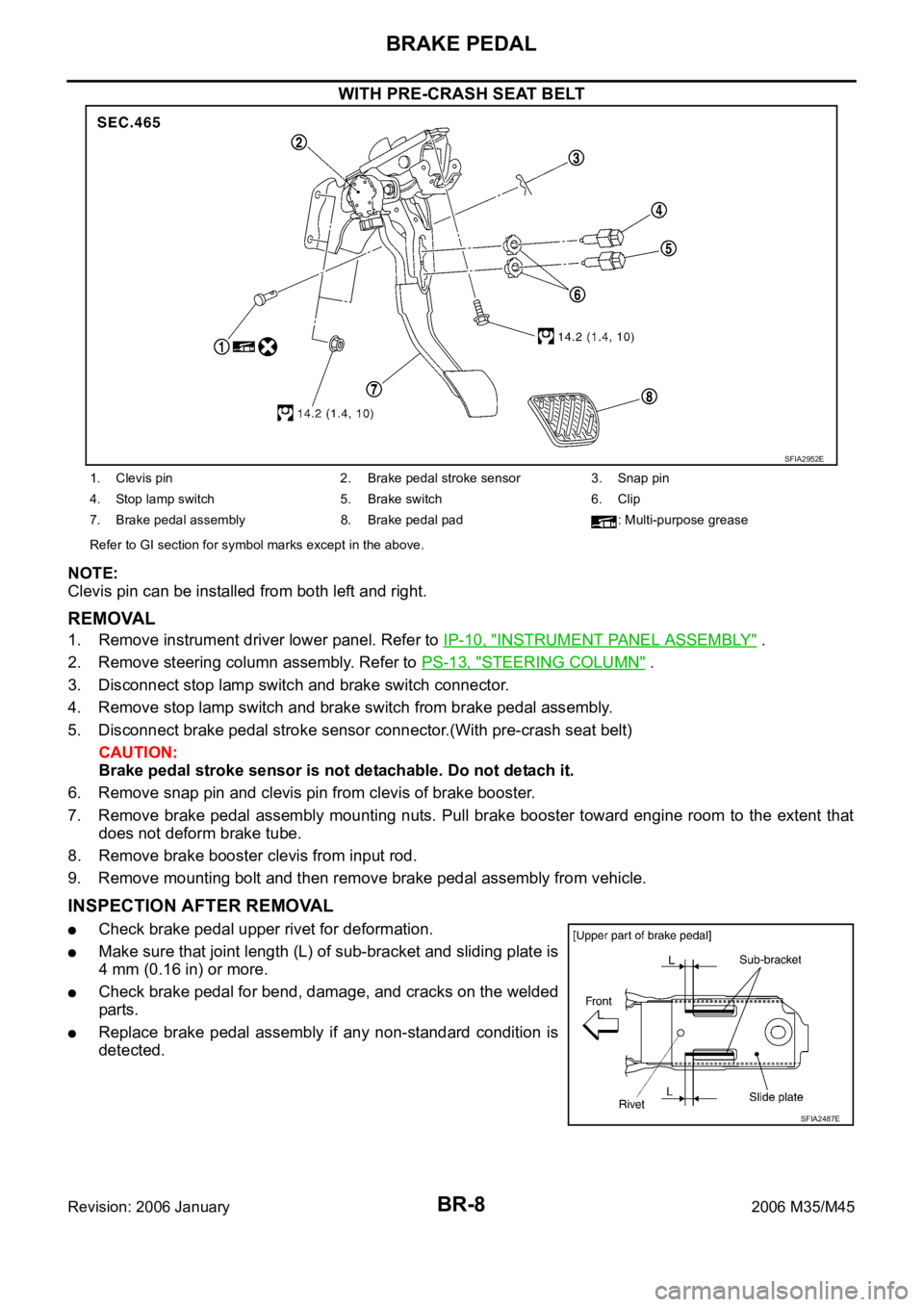

WITH PRE-CRASH SEAT BELT

NOTE:

Clevis pin can be installed from both left and right.

REMOVAL

1. Remove instrument driver lower panel. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove steering column assembly. Refer to PS-13, "

STEERING COLUMN" .

3. Disconnect stop lamp switch and brake switch connector.

4. Remove stop lamp switch and brake switch from brake pedal assembly.

5. Disconnect brake pedal stroke sensor connector.(With pre-crash seat belt)

CAUTION:

Brake pedal stroke sensor is not detachable. Do not detach it.

6. Remove snap pin and clevis pin from clevis of brake booster.

7. Remove brake pedal assembly mounting nuts. Pull brake booster toward engine room to the extent that

does not deform brake tube.

8. Remove brake booster clevis from input rod.

9. Remove mounting bolt and then remove brake pedal assembly from vehicle.

INSPECTION AFTER REMOVAL

Check brake pedal upper rivet for deformation.

Make sure that joint length (L) of sub-bracket and sliding plate is

4 mm (0.16 in) or more.

Check brake pedal for bend, damage, and cracks on the welded

parts.

Replace brake pedal assembly if any non-standard condition is

detected.

SFIA2952E

1. Clevis pin 2. Brake pedal stroke sensor 3. Snap pin

4. Stop lamp switch 5. Brake switch 6. Clip

7. Brake pedal assembly 8. Brake pedal pad : Multi-purpose grease

Refer to GI section for symbol marks except in the above.

SFIA2487E

Page 1288 of 5621

BRAKE TUBE AND HOSE

BR-13

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

CAUTION:

All brake hoses and tubes must be free from excessive bending, twisting and pulling.

Make sure that there is no interference with other parts when turning steering both clockwise and

counterclockwise.

Brake tubes and hoses are an important safety part. Always disassemble the parts and retighten

their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged

part is detected.

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

Cover the open end of brake tubes and hoses when disconnecting to prevent entrance of dirt.

Refill with new brake fluid “DOT 3”.

Never reuse drained brake fluid.

Removal and Installation of Front Brake Tube and Brake Hose NFS000OZ

REMOVAL

1. Drain brake fluid. Refer to BR-10, "Drain and Refill" .

2. Disconnect brake hose from brake tube, using a flare nut wrench.

3. Remove union bolt and remove brake hose from caliper assem-

bly.

4. Remove lock plate and remove brake hose from vehicle.

INSTALLATION

1. Assemble the union bolt and copper washer to the brake hose.

CAUTION:

Do not reuse copper washer.

2. Install brake hose by aligning with the protrusion on brake caliper assembly, and tighten union bolt to the

specified torque. Refer to BR-12, "

Hydraulic Circuit" .

3. Connect brake hose to brake tube, partially tighten flare nut by hand as much as possible, then secure it

to the bracket with lock plate.

4. Using a flare nut torque wrench, tighten flare nut to the specified torque. Refer to BR-12, "

Hydraulic Cir-

cuit" .

5. Refill brake fluid and bleed air. Refer to BR-11, "

Bleeding Brake System" .

Removal and Installation of Rear Brake Tube and Brake Hose NFS000P0

REMOVAL

1. Drain brake fluid. Refer to BR-10, "Drain and Refill" .

2. Disconnect brake hose from brake tube, using a flare nut wrench.

A. With out ICC B. With ICC 1. Front disc brake

2. Master cylinder 3. Brake booster 4. Rear disc brake

5. ABS actuator and electric unit (con-

trol unit)6. Connector 7. Brake hose

8. Brake tube : Flare nut

:18.2 Nꞏm (1.9 kg-m, 13 ft-lb): Flare nut

: 16.2 Nꞏm (1.7 kg-m, 12 ft-lb)

: Union bolt

:18.2 Nꞏm (1.9 kg-m, 13 ft-lb): Connector mounting bolt

: 7.0 Nꞏm (0.7 kg-m, 62 in-lb)

Refer to GI section for symbol marks in the figure.

SFIA2964E

Page 1300 of 5621

FRONT DISC BRAKE

BR-25

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

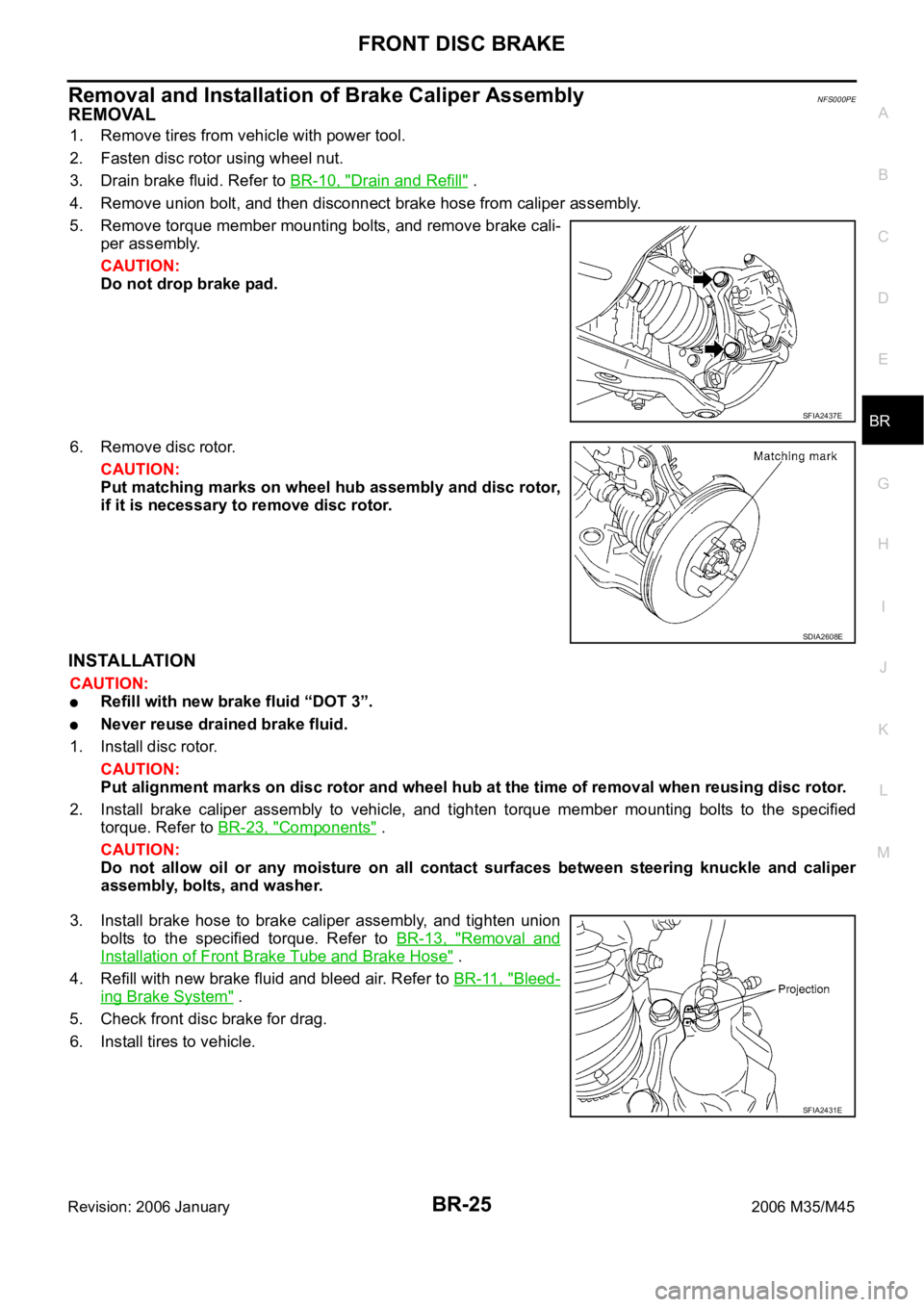

Removal and Installation of Brake Caliper AssemblyNFS000PE

REMOVAL

1. Remove tires from vehicle with power tool.

2. Fasten disc rotor using wheel nut.

3. Drain brake fluid. Refer to BR-10, "

Drain and Refill" .

4. Remove union bolt, and then disconnect brake hose from caliper assembly.

5. Remove torque member mounting bolts, and remove brake cali-

per assembly.

CAUTION:

Do not drop brake pad.

6. Remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor,

if it is necessary to remove disc rotor.

INSTALLATION

CAUTION:

Refill with new brake fluid “DOT 3”.

Never reuse drained brake fluid.

1. Install disc rotor.

CAUTION:

Put alignment marks on disc rotor and wheel hub at the time of removal when reusing disc rotor.

2. Install brake caliper assembly to vehicle, and tighten torque member mounting bolts to the specified

torque. Refer to BR-23, "

Components" .

CAUTION:

Do not allow oil or any moisture on all contact surfaces between steering knuckle and caliper

assembly, bolts, and washer.

3. Install brake hose to brake caliper assembly, and tighten union

bolts to the specified torque. Refer to BR-13, "

Removal and

Installation of Front Brake Tube and Brake Hose" .

4. Refill with new brake fluid and bleed air. Refer to BR-11, "

Bleed-

ing Brake System" .

5. Check front disc brake for drag.

6. Install tires to vehicle.

SFIA2437E

SDIA2608E

SFIA2431E

Page 1302 of 5621

FRONT DISC BRAKE

BR-27

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

ASSEMBLY

1. Apply polyglycol ether based lubricant to piston seal, and install

them to cylinder body.

CAUTION:

Do not reuse piston seal.

2. Apply rubber grease to piston boot. Cover the piston end with

piston boot, and then install cylinder side lip on piston boot

securely into a groove on cylinder body.

CAUTION:

Do not reuse piston boot.

3. Apply brake fluid to piston. Push piston into cylinder body by

hand and push piston boot piston-side lip into the piston groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

4. Install sliding pins and sliding pin boots to torque member.

5. Install torque member to steering knuckle, and tighten mounting bolts to the specified torque. Refer to BR-

23, "Components" .

CAUTION:

Do not allow oil or any moisture on all contact surfaces between steering knuckle and brake cali-

per assembly.

6. Press in piston until pads can be installed, and then install cylinder body to torque member.

7. Tighten sliding pin bolts to the specified torque. Refer to BR-23, "

Components" .

SFIA2399E

SFIA2432E

SFIA2279E

Page 1312 of 5621

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTION BRC

A

B

BRC

Revision: 2006 January2006 M35/M45

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover ..... 3

Precautions for Brake System .................................. 3

Precautions for Brake Control .................................. 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 5

ON-VEHICLE SERVICE ............................................. 6

Adjustment of Steering Angle Sensor Neutral Posi-

tion ........................................................................... 6

SYSTEM DESCRIPTION ............................................ 7

System Diagram ....................................................... 7

Function ................................................................... 7

ABS ....................................................................... 7

EBD ....................................................................... 7

TCS ....................................................................... 7

VDC ....................................................................... 8

ECD ....................................................................... 8

Operation That Is Not "System Error" ...................... 8

ABS ....................................................................... 8

TCS ....................................................................... 8

VDC ....................................................................... 8

Fail-Safe Function .................................................... 8

ABS, EBD SYSTEM .............................................. 8

VDC / TCS ............................................................ 9

Hydraulic Circuit Diagram ........................................ 9

CAN COMMUNICATION .......................................... 10

System Description ................................................ 10

TROUBLE DIAGNOSIS .............................................11

How to Perform Trouble Diagnoses ........................ 11

BASIC CONCEPT ................................................ 11

DIAGNOSIS FLOW CHART ............................... 12

ASKING COMPLAINTS ...................................... 13

EXAMPLE OF DIAGNOSIS WORKSHEET ........ 13

Component Parts Location ..................................... 14

Schematic .............................................................. 15Wiring Diagram — VDC — ..................................... 16

CONSULT-II Functions (ABS) ................................ 22

CONSULT-II MAIN FUNCTION ........................... 22

CONSULT-II BASIC OPERATION PROCEDURE

... 22

Self-Diagnosis .....................................................

... 23

OPERATION PROCEDURE ................................ 23

ERASE MEMORY ............................................... 23

DISPLAY ITEM LIST ........................................... 24

Data Monitor ........................................................... 27

OPERATION PROCEDURE ................................ 27

DISPLAY ITEM LIST ........................................... 27

Active Test .............................................................. 30

OPERATION PROCEDURE ................................ 30

TEST ITEMS ....................................................... 31

For Fast and Accurate Diagnosis ........................... 32

PRECAUTIONS FOR DIAGNOSIS ..................... 32

Basic Inspection ..................................................... 33

BASIC INSPECTION 1: BRAKE FLUID LEVEL,

LEAK INSPECTION AND BRAKE PAD .............. 33

BASIC INSPECTION 2: LOOSENESS OF

POWER SYSTEM TERMINALS AND BATTERY ... 33

BASIC INSPECTION 3: ABS WARNING LAMP,

BRAKE WARNING LAMP, VDC OFF INDICATOR

LAMP AND SLIP INDICATOR LAMP .................. 33

Inspection 1: Wheel Sensor Circuit ........................ 34

Inspection 2: Engine System .................................. 36

Inspection 3: ABS Actuator and Electric Unit (Con-

trol Unit) .................................................................. 36

Inspection 4: ABS Actuator and Electric Unit (Con-

trol Unit) Power Supply and Ground Circuit ............ 37

Inspection 5: ABS Motor and Motor Relay Circuit ... 38

Inspection 6: Solenoid, VDC Change-Over Valve

and Actuator Relay Circuit ...................................... 40

Inspection 7: Pressure Sensor Circuit .................... 41

Inspection 8: Steering Angle Sensor Circuit ........... 41

Inspection 9: Park/Neutral Position (PNP) Switch

Circuit ..................................................................... 43

Inspection 10: Stop Lamp Switch Circuit ................ 44

Inspection 11: Yaw Rate/Side G Sensor Circuit ..... 45

Page 1313 of 5621

BRC-2Revision: 2006 January2006 M35/M45 Inspection 12: Brake Fluid Level Switch Circuit ...... 48

Inspection 13: RAS Control Unit Circuit (With RAS) ... 49

Inspection 14: ICC Sensor Integrated Unit Circuit

(With ICC) ............................................................... 50

Inspection 15: AWD Control Unit Circuit (AWD

Model) ..................................................................... 50

Inspection 16: CAN Communication Circuit ............ 51

Inspection 17: VDC OFF Switch Circuit .................. 51

Inspection 18: Parking Brake Switch Circuit ........... 52

Inspection 19: Warning Lamp and Indicator Lamp

Circuit ..................................................................... 53

Symptom 1 Excessive ABS Function Operation Fre-

quency .................................................................... 53

Symptom 2 Unexpected Pedal Reaction ................ 54

Symptom 3 The Braking Distance Is Long ............. 55

Symptom 4 ABS Function Does Not Operate ........ 55

Symptom 5 Pedal Vibration or ABS Operation

Sound Occurs ......................................................... 55

Symptom 6 Vehicle Jerks During VDC/TCS/ABS

Control .................................................................... 56WHEEL SENSOR ................................................... ... 57

Removal and Installation ......................................... 57

COMPONENT ...................................................... 57

REMOVAL ............................................................ 57

INSTALLATION .................................................... 57

SENSOR ROTOR ...................................................

... 59

Removal and Installation ......................................... 59

REMOVAL ............................................................ 59

INSTALLATION .................................................... 59

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY) ... 60

Removal and Installation ......................................... 60

COMPONENT ...................................................... 60

REMOVAL ............................................................ 60

INSTALLATION .................................................... 61

G-SENSOR ................................................................ 62

Removal and Installation ......................................... 62

REMOVAL ............................................................ 62

INSTALLATION .................................................... 62

STEERING ANGLE SENSOR ................................... 63

Removal and Installation ......................................... 63

REMOVAL ............................................................ 63

INSTALLATION .................................................... 63

Page 1315 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-4

[VDC/TCS/ABS]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Brake ControlNFS000Q1

Just after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operatin INFINITI M35 2006 Factory Service Manual BRC-4

[VDC/TCS/ABS]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Brake ControlNFS000Q1

Just after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operatin](/img/42/57023/w960_57023-1314.png)

BRC-4

[VDC/TCS/ABS]

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Brake ControlNFS000Q1

Just after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operating noise may

be heard from engine compartment. This is normal condition.

When an error is indicated by ABS or another warning lamp, collect all necessary information from cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting

diagnostic servicing. Besides electrical system inspection, check brake booster operation, brake fluid

level, and oil leaks.

If tire size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

ABS might be out of order or malfunctions by putting a radio (wiring inclusive), an antenna and a lead-in

wire near the control unit.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

VDC system may not operate normally or a VDC OFF indicator lamp or SLIP indicator lamp may light.

–When replacing the following parts with parts other than genuine parts or making modifications: Suspen-

sion-related parts (shock absorber, spring, bushing, etc.), tires, wheels (other than specified sizes), brake-

related parts (pad, rotor, caliper, etc.), engine-related parts (muffler, ECM, etc.) and body reinforcement-

related parts (roll bar, tower bar, etc.).

–When driving with worn or deteriorated suspension, tires and brake-related parts.

Page 1317 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to INFINITI M35 2006 Factory Service Manual BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to](/img/42/57023/w960_57023-1316.png)

BRC-6

[VDC/TCS/ABS]

ON-VEHICLE SERVICE

Revision: 2006 January2006 M35/M45

ON-VEHICLE SERVICEPFP:00000

Adjustment of Steering Angle Sensor Neutral PositionNFS000Q4

In case of doing work that applies to the list below, make sure to adjust neutral position of steering angle sen-

sor before running vehicle.

: Required

–: Not required

CAUTION:

To adjust neutral position of steering angle sensor, make sure to use CONSULT-II.

(Adjustment cannot be done without CONSULT-II.)

1. Stop vehicle with front wheels in straight-ahead position.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector on vehicle.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

3. Turn ignition switch ON and touch the CONSULT-II screen in the order of “ABS”, “WORK SUPPORT” and

“ST ANG SEN ADJUSTMENT”.

4. Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle

sensor.

5. After approximately 10 seconds, touch “END”. (After approxi-

mately 60 seconds, it ends automatically.)

6. Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to perform above operation.

7. Run vehicle with front wheels in straight-ahead position, then

stop.

8. Select “DATA MONITOR”, “ECU INPUT SIGNALS”, and “STR ANGLE SIG” on CONSULT-II screen. Then

make sure “STR ANGLE SIG” is within 0

2.5. If value is more than specification, repeat steps 1 to 7.

9. Erase memory of ABS actuator and electric unit (control unit) and ECM. ABS actuator and electric unit

(control unit): Refer to BRC-23, "

ERASE MEMORY" . ECM: Refer to EC-100, "TROUBLE DIAGNOSIS"

(VQ35DE), EC-811, "TROUBLE DIAGNOSIS" (VK45DE).

10. Turn ignition switch OFF.

Situation Adjustment of Steering Angle Sensor Neutral Position

Removing/Installing ABS actuator and electric unit (control unit)

Replacing ABS actuator and electric unit (control unit)

Removing/Installing steering angle sensor

Removing/Installing steering components

Removing/Installing suspension components

Change tires to new ones–

Tire rotation–

Adjusting wheel alignment

SFIA0793E

Page 1318 of 5621

![INFINITI M35 2006 Factory Service Manual SYSTEM DESCRIPTION

BRC-7

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

SYSTEM DESCRIPTIONPFP:00000

System DiagramNFS000Q5

FunctionNFS000Q6

ABS

Anti-Lock Brake System i INFINITI M35 2006 Factory Service Manual SYSTEM DESCRIPTION

BRC-7

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

SYSTEM DESCRIPTIONPFP:00000

System DiagramNFS000Q5

FunctionNFS000Q6

ABS

Anti-Lock Brake System i](/img/42/57023/w960_57023-1317.png)

SYSTEM DESCRIPTION

BRC-7

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

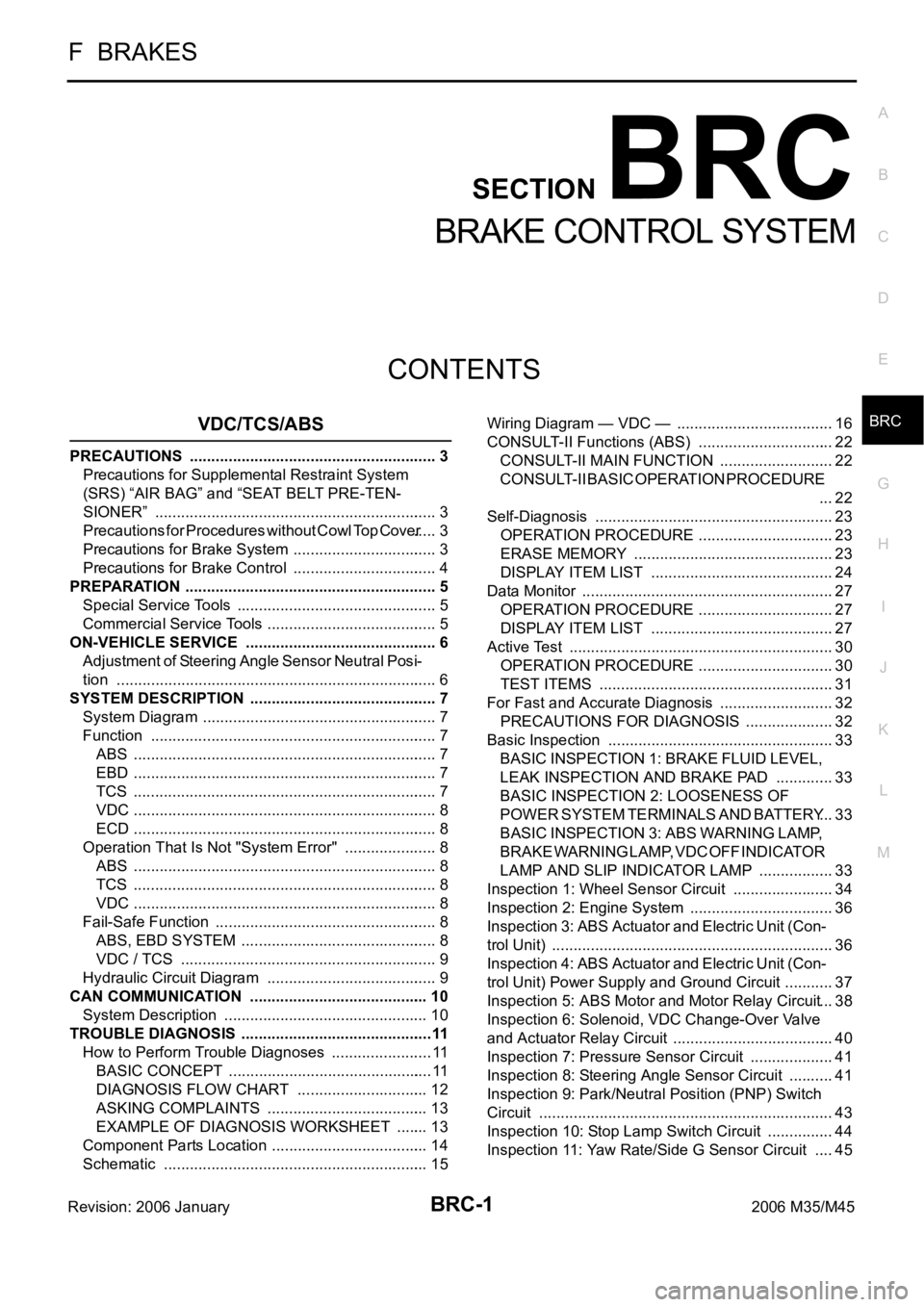

SYSTEM DESCRIPTIONPFP:00000

System DiagramNFS000Q5

FunctionNFS000Q6

ABS

Anti-Lock Brake System is a function that detects wheel revolution while braking, electronically controls

braking force, and prevents wheel locking during sudden braking. It improves handling stability and

maneuverability for avoiding obstacles.

Electrical system diagnosis by CONSULT-II is available.

EBD

Electronic Brake force Distribution is a following function. ABS actuator and electric unit (control unit)

detects subtle slippages between the front and rear wheels during braking. Then it electronically controls

the rear braking force (brake fluid pressure) to reducing and reduces rear wheel slippage. Accordingly it

improves vehicle stability.

Electrical system diagnosis by CONSULT-II is available.

TCS

Traction Control System is a function that electronically controls engine torque, brake fluid pressure and

A/T gear position to ensure the optimum slippage ratio at drive wheels by computing wheel speed signals

1. Electric line 2. Brake hydraulic line 3. ECM

4. TCM 5. Steering angle sensor 6. Warning lamp, indicator lamp

(combination meter)

7. AWD control unit

(AWD model)8. ICC sensor integrated unit

(with ICC)9. RAS control unit

(with RAS)

10. Injector operation signal 11. CAN communication 12. Front RH wheel sensor

13. Front LH wheel sensor 14. Master cylinder 15. ABS actuator and electric unit (con-

trol unit)

16. VDC OFF switch 17. Yaw rate/side G sensor 18. Rear RH wheel sensor

19. Rear LH wheel sensor

SFIA2722J

Page 1319 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-8

[VDC/TCS/ABS]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

from 4 wheel sensors. When ABS actuator and electric unit (control unit) detects a spin at drive wheels

(rear wheels), INFINITI M35 2006 Factory Service Manual BRC-8

[VDC/TCS/ABS]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

from 4 wheel sensors. When ABS actuator and electric unit (control unit) detects a spin at drive wheels

(rear wheels),](/img/42/57023/w960_57023-1318.png)

BRC-8

[VDC/TCS/ABS]

SYSTEM DESCRIPTION

Revision: 2006 January2006 M35/M45

from 4 wheel sensors. When ABS actuator and electric unit (control unit) detects a spin at drive wheels

(rear wheels), it compares wheel speed signals from all 4 wheels. At this time, LH and RH rear brake fluid

pressure are controlled, while fuel being cut to engine and throttle valve being closed to reduce engine

torque by the control unit. Further more, throttle position is continuously controlled to ensure the optimum

engine torque at all times.

During TCS operation, it informs driver of system operation by flashing SLIP indicator lamp.

Electrical system diagnosis by CONSULT-II is available.

VDC

Vehicle Dynamics Control system detects driver's steering operation amount and brake pedal travel from

steering angle sensor and pressure sensor. Using information from yaw rate/side G sensor and wheel

sensor, VDC judges driving condition (conditions of under steer and over steer) to improve vehicle driving

stability by controlling brake application to 4 wheels and engine output.

During VDC operation, it informs driver of system operation by flashing SLIP indicator lamp.

Electrical system diagnosis by CONSULT-II is available.

ECD

Receives deceleration degree commandment value signal from ICC sensor integrated unit, and controls brake

fluid pressure with the motor (built-in ABS actuator and electric unit (control unit)).

Operation That Is Not "System Error" NFS000Q7

ABS

When starting engine or just after starting vehicle, brake pedal may vibrate or the motor operating sound

may be heard from engine room. This is a normal states of the operation check.

During ABS operation, brake pedal lightly vibrates and a mechanical sound may be heard. This is normal.

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel,

or snow-covered (fresh, deep snow) roads.

TCS

Depending on road circumstances, driver may have a sluggish feel. This is normal, because optimum

traction has highest priority under TCS operation.

When vehicle is passing through a road where surface friction varies, downshifting or depressing acceler-

ator pedal fully may activate TCS temporarily.

VDC

During VDC operation, body and brake pedal lightly vibrate and mechanical sounds may be heard. This is

normal.

If vehicle is rotated on turn table, or rolled and rocked on ship, ABS warning lamp, VDC OFF indicator

lamp, and SLIP indicator lamp may turn on. In this case, start engine on normal road again. If ABS warn-

ing lamp, VDC OFF indicator lamp, and SLIP indicator lamp turn off after restart, it is normal.

When starting TCS or VDC under rapid acceleration or hard turn, operating sound by brake pedal is gen-

erated. However, this is not malfunction. This is because TCS and VDC are functioning normally.

VDC may not operate normally or ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp

may turn on when driving special roads with extremely steep slant (banks on circuit road and so on.) How-

ever, it is not malfunction when returning to a normal state after restarting the engine. In that case, be sure

to erase the memory of self-diagnosis. Refer to BRC-23, "

ERASE MEMORY" .

Yaw rate /side G sensor malfunction may occur under hard turn like spin turn, rapid acceleration turn, drift

run, etc., when VDC function is OFF (VDC OFF switch is turned on). It is not malfunction if it is possible to

return to a normal position after restarting engine. Then erase the memory of self-diagnosis. Refer to

BRC-23, "

ERASE MEMORY" .

VDC OFF indicator lamp and SLIP indicator lamp may simultaneously turn on when low tire pressure

warning lamp turns on. This is not a VDC system error but results from characteristic change of tires.

Fail-Safe FunctionNFS000Q8

ABS, EBD SYSTEM

In the event there is a malfunction with the electrical system, the ABS warning lamp, VDC OFF indicator lamp,

and SLIP indicator lamp will turn on when it is the ABS that is malfunctioning, and the brake warning lamp,

ABS warning lamp, VDC OFF indicator lamp, and SLIP indicator lamp will turn on when it is the EBD that is