check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 895 of 5621

![INFINITI M35 2006 Factory Service Manual AV-274

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK STEERING SWITCH SIGNAL A

1. Turn ignition switch ON.

2. Check voltage between audio unit INFINITI M35 2006 Factory Service Manual AV-274

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK STEERING SWITCH SIGNAL A

1. Turn ignition switch ON.

2. Check voltage between audio unit](/img/42/57023/w960_57023-894.png)

AV-274

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK STEERING SWITCH SIGNAL A

1. Turn ignition switch ON.

2. Check voltage between audio unit harness connector M76 ter-

minals 6 and 15

OK or NG

OK >> Replace steering switch.

NG >> Replace audio unit.

“PTT/TEL”, “BACK”, AND “VOLUME CONTROL” SWITCHES ARE NOT OPERATED

1. CHECK HARNESS

1. Check continuity between spiral cable harness connector (A)

M303 terminal 16 and audio unit harness connector (B) M76 ter-

minal 16.

2. Check continuity between steering switch harness connector (A)

M303 terminal 16 and ground.

OK or NG

OK >> GO TO 2.

NG >> Check spiral cable. If the malfunction is detected, repair

the harness and connector.

2. CHECK STEERING SWITCH SIGNAL B

1. Turn ignition switch ON.

2. Check voltage between audio unit harness connector M76 ter-

minals 16 and 15

OK or NG

OK >> Replace steering switch.

NG >> Replace audio unit.6 – 15 : Approx. 5 V

SKIB4637E

16 – 16 : Continuity should exist.

16 – Ground : Continuity should not exist.

SKIB4638E

16 – 15 : Approx. 5 V

SKIB4639E

Page 896 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

AV-275

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

The Hands-Free Phone Cannot Be UsedNKS004BD

THE VOICE CANNOT BE HEARD

1. CHECK INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

AV-275

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

The Hands-Free Phone Cannot Be UsedNKS004BD

THE VOICE CANNOT BE HEARD

1. CHECK](/img/42/57023/w960_57023-895.png)

TROUBLE DIAGNOSIS

AV-275

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

The Hands-Free Phone Cannot Be UsedNKS004BD

THE VOICE CANNOT BE HEARD

1. CHECK HARNESS AV (NAVI) CONTROL UNIT AND AUDIO UNIT

1. Disconnect AV (NAVI) control unit connector and audio unit connector.

2. Check continuity between AV (NAVI) control unit harness con-

nector (A) M78 terminals 10, 11 and audio unit harness connec-

tor (B) M77 terminals 30, 31.

3. Check continuity between AV (NAVI) control unit harness con-

nector (A) M78 terminals 10, 11 and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair harness or connector.

2. CHECK TEL VOICE SIGNAL

1. Connect AV (NAVI) control unit connector and audio unit connector.

2. Turn ignition switch ON.

3. Check signal between AV (NAVI) control unit harness connector

M78 terminals 10 and 11.

OK or NG

OK >> Replace audio unit.

NG >> Replace AV (NAVI) control unit.

THE VOICE CANNOT BE TRANSMITTED

Refer to AV- 2 7 2 , "THE SCREEN IS SWITCHED BY PRESSING THE STEERING SWITCH" . 10 – 30 : Continuity should exist.

11 – 31 : Continuity should exist.

10, 11 – Ground : Continuity should not exist.

SKIB4640E

10 – 11:When inputting TEL voice

SKIB4641ESKIB3609E

Page 897 of 5621

![INFINITI M35 2006 Factory Service Manual AV-276

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Voice Guidance Is Not HeardNKS004BE

1. CHECK HARNESS BETWEEN AV (NAVI) CONTROL UNIT AND BOSE AMP

1. Disco INFINITI M35 2006 Factory Service Manual AV-276

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Voice Guidance Is Not HeardNKS004BE

1. CHECK HARNESS BETWEEN AV (NAVI) CONTROL UNIT AND BOSE AMP

1. Disco](/img/42/57023/w960_57023-896.png)

AV-276

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Voice Guidance Is Not HeardNKS004BE

1. CHECK HARNESS BETWEEN AV (NAVI) CONTROL UNIT AND BOSE AMP

1. Disconnect AV (NAVI) control unit connector and BOSE amp connector.

2. Check continuity between AV (NAVI) control unit harness con-

nector (A) M78 terminals 12, 14 and BOSE amp harness con-

nector (B) B107 terminals 32, 12.

3. Check continuity between AV (NAVI) control unit harness con-

nector (A) M78 terminals 12, 14 and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair harness or connector.

2. CHECK VOICE GUIDANCE SIGNAL

1. Connect AV (NAVI) control unit connector and BOSE amp connector.

2. Turn ignition switch ON.

3. Push the voice button.

4. Check signal between AV (NAVI) control unit harness connector

M78 terminals 12 and 14.

OK or NG

OK >> Replace AV (NAVI) control unit.

NG >> Replace BOSE amp.12 – 32 : Continuity should exist.

14 – 12 : Continuity should exist.

12, 14 – Ground : Continuity should not exist.

SKIB4644E

12 – 14:

SKIB4645E

SKIB3609E

Page 899 of 5621

![INFINITI M35 2006 Factory Service Manual AV-278

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

MAP DVD-ROM

ROUTE CALCULATION AND VISUAL GUIDANCE

The location of vehicle icon is mis-

aligned from the a INFINITI M35 2006 Factory Service Manual AV-278

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

MAP DVD-ROM

ROUTE CALCULATION AND VISUAL GUIDANCE

The location of vehicle icon is mis-

aligned from the a](/img/42/57023/w960_57023-898.png)

AV-278

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

MAP DVD-ROM

ROUTE CALCULATION AND VISUAL GUIDANCE

The location of vehicle icon is mis-

aligned from the actual position.When using tire chains or replacing the tires, speed

calculations based on the speed sensor may be

incorrect.Drive the vehicle for a while [at approxi-

mately 30km/h (19 MPH) for about 30

minutes] to automatically correct the vehi-

cle icon position.

If this does not correct the vehicle icon

position, contact an INFINITI dealer.

The map data has mistake or is incomplete (the

vehicle icon position is always misaligned in the

same area).Updated road information will be included

in the next version of the map DVD-ROM. Symptom Possible cause Possible solution

Symptom Possible cause Possible solution

The message “Error” appears. Map DVD-ROM is dirty or partially damaged.Check the DVD-ROM and wipe it clean

with a soft cloth.

If there is any damage, replace the DVD-

ROM.

Symptom Possible cause Possible solution

In the auto reroute calculation,

waypoints are not included.Waypoints already passed are not included in the

auto reroute calculation.In case of going to that waypoints again,

edit the route.

Route information is not displayed.Route calculation has not yet been performed.Set the destination and perform route cal-

culation.

The vehicle is not driven on the suggested route. Drive on the suggested route.

Route guidance is set to off. Turn on route guidance.

Route information is not provided for narrow streets

(roads displayed in gray).This is not a malfunction.

The auto reroute calculation (or

detour calculation) suggests the

same route as the one previously

suggested. Route calculation took priority conditions into con-

sideration, but the same route was calculated. This is not a malfunction.

A waypoint cannot be added.Five waypoints are already set on the route, includ-

ing ones that already passed.A maximum of 5 waypoints can be set on

the route. In case of going to 6 or more

waypoints, perform route calculations mul-

tiple times as necessary.

The suggested route is not dis-

played.Roads near the destination cannot be calculated.Reset the destination to a main or ordinary

road, and recalculate the route.

The starting point and destination are too close. Set a more distant destination.

The starting point and destination are too far away.Divide the way by selecting one or two

intermediate destinations, and perform

route calculations multiple times.

There are time restricted roads (by day of week, by

time) near the current vehicle location or destina-

tion.Set “Use Time Restricted Roads” to off.

A part of the route is not displayed.The suggested route includes narrow streets (roads

displayed in gray).This is not a malfunction.

The part of the route already

passed is deleted.A route is managed by sections between way-

points. If you passed the first waypoint, the section

between the starting point and the waypoint is

deleted. (It may not be deleted depending on the

area.)This is not a malfunction.

Page 922 of 5621

BCS-1

BODY CONTROL SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION BCS

A

B

BCS

Revision: 2006 January2006 M35/M45

BODY CONTROL SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

BCM (BODY CONTROL MODULE) ........................... 3

System Description .................................................. 3

BCM FUNCTION ................................................... 3

COMBINATION SWITCH READING FUNCTION ..... 3

CAN COMMUNICATION CONTROL .................... 6

BCM STATUS CONTROL ..................................... 7

SYSTEMS CONTROLLED BY BCM DIRECTLY ..... 8

SYSTEMS CONTROLLED BY BCM AND IPDM

E/R ........................................................................ 8

SYSTEMS CONTROLLED BY BCM AND COM-

BINATION METER ................................................ 8

SYSTEMS CONTROLLED BY BCM AND INTEL-

LIGENT KEY UNIT ................................................ 8SYSTEMS CONTROLLED BY BCM, COMBINA-

TION METER AND IPDM E/R ............................... 8

MAJOR COMPONENTS AND CONTROL SYS-

TEM ....................................................................... 9

CAN Communication Unit ....................................... 10

Schematic ............................................................... 11

CONSULT-II Function (BCM) ................................. 13

CONSULT-II BASIC OPERATION ....................... 13

ITEMS OF EACH PART ...................................... 14

WORK SUPPORT ............................................... 15

CAN DIAG SUPPORT MNTR ............................. 15

CAN Communication Inspection Using CONSULT-

II (Self-Diagnosis) ................................................... 15

Check BCM Power Supply and Ground Circuit ...... 16

Removal and Installation of BCM ........................... 17

REMOVAL ........................................................

... 17

INSTALLATION ................................................... 17

Page 934 of 5621

BCM (BODY CONTROL MODULE)

BCS-13

C

D

E

F

G

H

I

J

L

MA

B

BCS

Revision: 2006 January2006 M35/M45

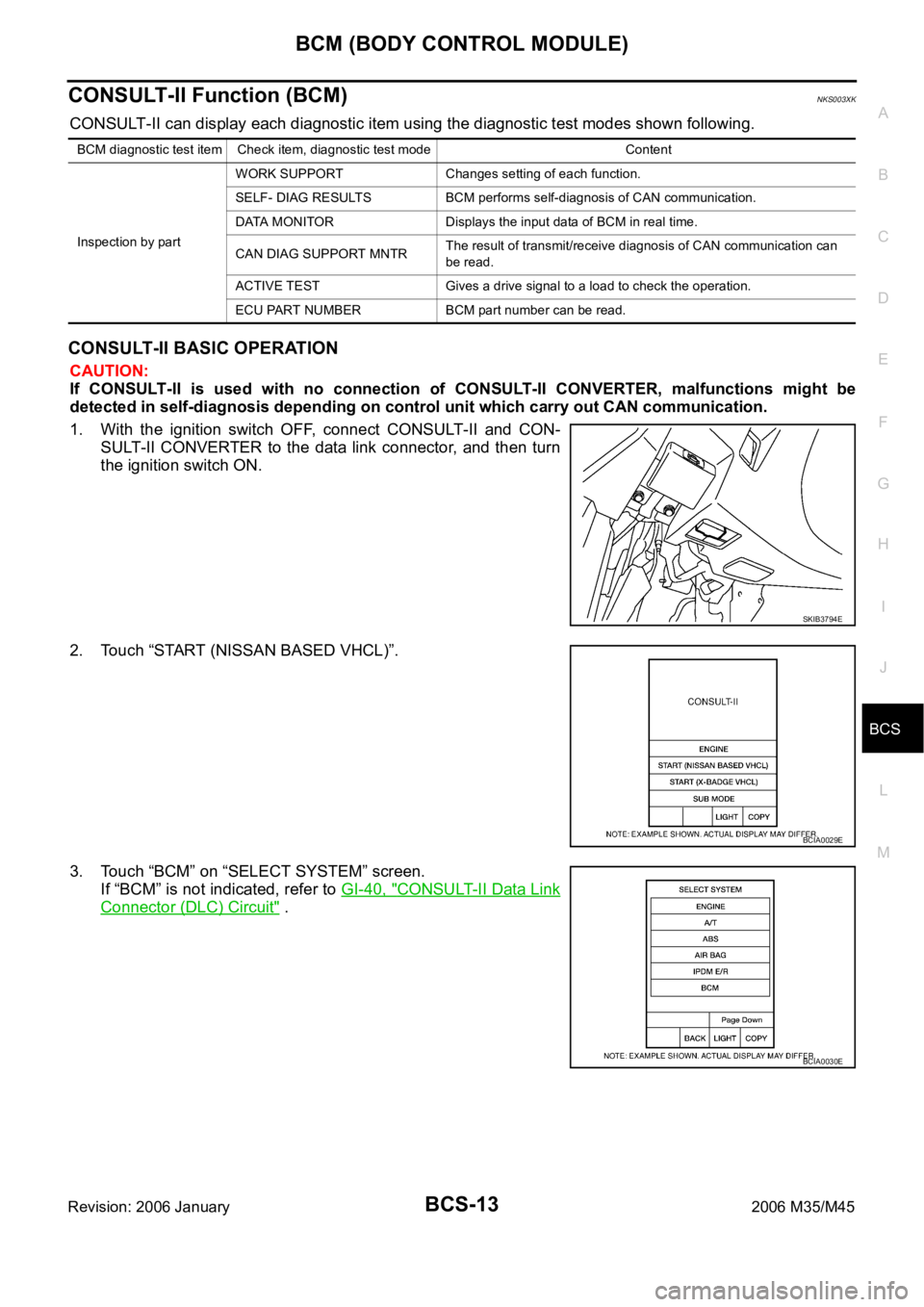

CONSULT-II Function (BCM)NKS003XK

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II BASIC OPERATION

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II CONVERTER to the data link connector, and then turn

the ignition switch ON.

2. Touch “START (NISSAN BASED VHCL)”.

3. Touch “BCM” on “SELECT SYSTEM” screen.

If “BCM” is not indicated, refer to GI-40, "

CONSULT-II Data Link

Connector (DLC) Circuit" .

BCM diagnostic test item Check item, diagnostic test mode Content

Inspection by partWORK SUPPORT Changes setting of each function.

SELF- DIAG RESULTS BCM performs self-diagnosis of CAN communication.

DATA MONITOR Displays the input data of BCM in real time.

CAN DIAG SUPPORT MNTRThe result of transmit/receive diagnosis of CAN communication can

be read.

ACTIVE TEST Gives a drive signal to a load to check the operation.

ECU PART NUMBER BCM part number can be read.

SKIB3794E

BCIA0029E

BCIA0030E

Page 936 of 5621

BCM (BODY CONTROL MODULE)

BCS-15

C

D

E

F

G

H

I

J

L

MA

B

BCS

Revision: 2006 January2006 M35/M45

WORK SUPPORT

Operation Procedure

1. Touch “BCM” on “SELECT TEST ITEM” screen.

2. Touch “WORK SUPPORT” on “SELECT DIAG MODE” screen.

3. Touch “RESET SETTING VALUE” on “SELECT WORK ITEM” screen.

4. Touch “START”.

5. “RESET SETTING VALUE OK?” displayed, and touch “YES”.

6. The setting will be changed and “COMPLETED” will be displayed.

7. Touch “END”.

Display Item List

CAN DIAG SUPPORT MNTR

Refer to LAN-20, "CAN Diagnostic Support Monitor" .

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)NKS003XL

1. CHECK SELF-DIAGNOSTIC RESULT

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Connect to CONSULT-II, and select “BCM” on “SELECT SYSTEM” screen.

2. Select “BCM” on “SELECT DIAG MODE” screen, and select “SELF-DIAG RESULTS”.

3. Check display content in self-diagnostic results.

Contents displayed

No malfunction>>INSPECTION END

Malfunction in CAN communication system>>After printing the monitor items, go to “CAN System”. Refer to

LAN-7, "

Precautions When Using CONSULT-II" .

Item Description

RESET SETTING VALUE Return a value set with WORK SUPPORT of each system to a default value in factory shipment.

CONSULT-II display code Diagnosis item

U1000TRANSMIT DIAG

ECM

IPDM E/R

METER / M&A

I - KEY

Page 937 of 5621

BCS-16

BCM (BODY CONTROL MODULE)

Revision: 2006 January2006 M35/M45

Check BCM Power Supply and Ground CircuitNKS003XM

1. CHECK FUSES

Check for blown fuses.

Refer to LT-13, "Wiring Diagram — H/LAMP —" .

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer to PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open or short between BCM and

fuse.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

OK or NG

OK >> INSPECTION END

NG >> Check harness ground circuit.

Unit Power source Fuse and fusible link No.

BCMBatteryF

18

Ignition switch ON or START position 1

Ignition switch ACC or ON position 6

Terminal Ignition switch position

(+)

(-) OFF ACC ON

BCM

ConnectorTerminal

M111

GroundApprox. 0VBattery

voltageBattery

voltage

38 Approx. 0V Approx. 0VBattery

voltage

M242 Battery

voltageBattery

voltageBattery

voltage

55 Battery

voltageBattery

voltageBattery

voltage

PKIA5204E

Terminal Continuity

BCM

ConnectorTerminal

Ground Yes

M2 52

SKIB5125E

Page 940 of 5621

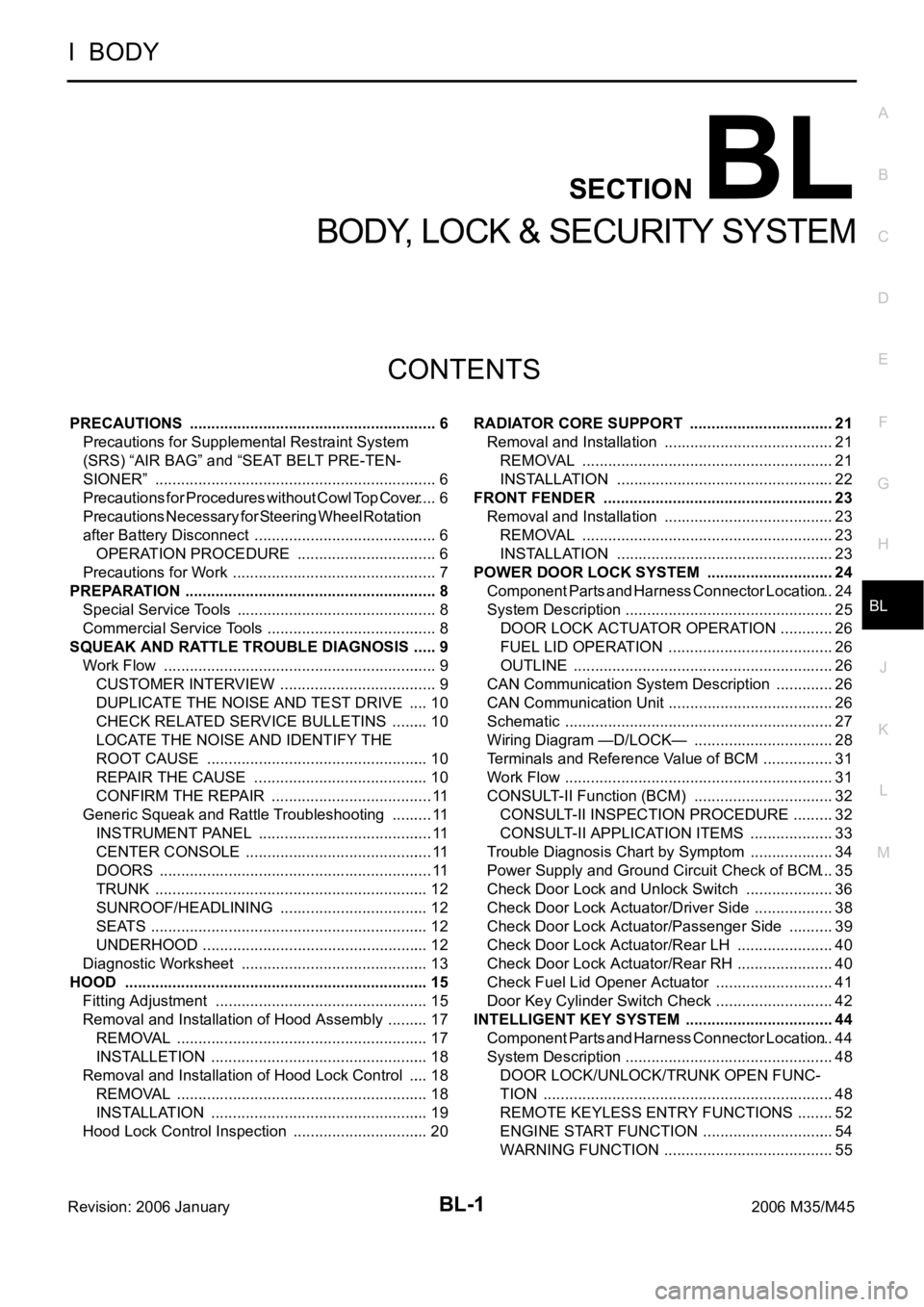

BL-1

BODY, LOCK & SECURITY SYSTEM

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

Revision: 2006 January2006 M35/M45

BODY, LOCK & SECURITY SYSTEM

PRECAUTIONS .......................................................... 6

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 6

Precautions for Procedures without Cowl Top Cover ..... 6

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 6

OPERATION PROCEDURE ................................. 6

Precautions for Work ...........................................

..... 7

PREPARATION ........................................................... 8

Special Service Tools ............................................... 8

Commercial Service Tools ........................................ 8

SQUEAK AND RATTLE TROUBLE DIAGNOSIS ...... 9

Work Flow ................................................................ 9

CUSTOMER INTERVIEW ..................................... 9

DUPLICATE THE NOISE AND TEST DRIVE ..... 10

CHECK RELATED SERVICE BULLETINS ......... 10

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE .................................................... 10

REPAIR THE CAUSE ......................................... 10

CONFIRM THE REPAIR ...................................... 11

Generic Squeak and Rattle Troubleshooting .......... 11

INSTRUMENT PANEL ......................................... 11

CENTER CONSOLE ............................................ 11

DOORS ................................................................ 11

TRUNK ................................................................ 12

SUNROOF/HEADLINING ................................... 12

SEATS ................................................................. 12

UNDERHOOD ..................................................... 12

Diagnostic Worksheet ............................................ 13

HOOD ....................................................................... 15

Fitting Adjustment .................................................. 15

Removal and Installation of Hood Assembly .......... 17

REMOVAL ........................................................

... 17

INSTALLETION ................................................... 18

Removal and Installation of Hood Lock Control ..... 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................... 19

Hood Lock Control Inspection ................................ 20RADIATOR CORE SUPPORT .................................. 21

Removal and Installation ........................................ 21

REMOVAL ........................................................

... 21

INSTALLATION ................................................... 22

FRONT FENDER ................................................... ... 23

Removal and Installation ........................................ 23

REMOVAL ........................................................

... 23

INSTALLATION ................................................... 23

POWER DOOR LOCK SYSTEM .............................. 24

Component Parts and Harness Connector Location ... 24

System Description ................................................. 25

DOOR LOCK ACTUATOR OPERATION ............. 26

FUEL LID OPERATION ....................................... 26

OUTLINE ............................................................. 26

CAN Communication System Description .............. 26

CAN Communication Unit ....................................... 26

Schematic ............................................................... 27

Wiring Diagram —D/LOCK— ................................. 28

Terminals and Reference Value of BCM ................. 31

Work Flow ............................................................... 31

CONSULT-II Function (BCM) ................................. 32

CONSULT-II INSPECTION PROCEDURE .......... 32

CONSULT-II APPLICATION ITEMS .................... 33

Trouble Diagnosis Chart by Symptom .................... 34

Power Supply and Ground Circuit Check of BCM ... 35

Check Door Lock and Unlock Switch ..................... 36

Check Door Lock Actuator/Driver Side ................... 38

Check Door Lock Actuator/Passenger Side ........... 39

Check Door Lock Actuator/Rear LH ....................... 40

Check Door Lock Actuator/Rear RH ....................... 40

Check Fuel Lid Opener Actuator ............................ 41

Door Key Cylinder Switch Check ............................ 42

INTELLIGENT KEY SYSTEM ................................... 44

Component Parts and Harness Connector Location ... 44

System Description ................................................. 48

DOOR LOCK/UNLOCK/TRUNK OPEN FUNC-

TION .................................................................... 48

REMOTE KEYLESS ENTRY FUNCTIONS ......... 52

ENGINE START FUNCTION ............................... 54

WARNING FUNCTION ........................................ 55

Page 941 of 5621

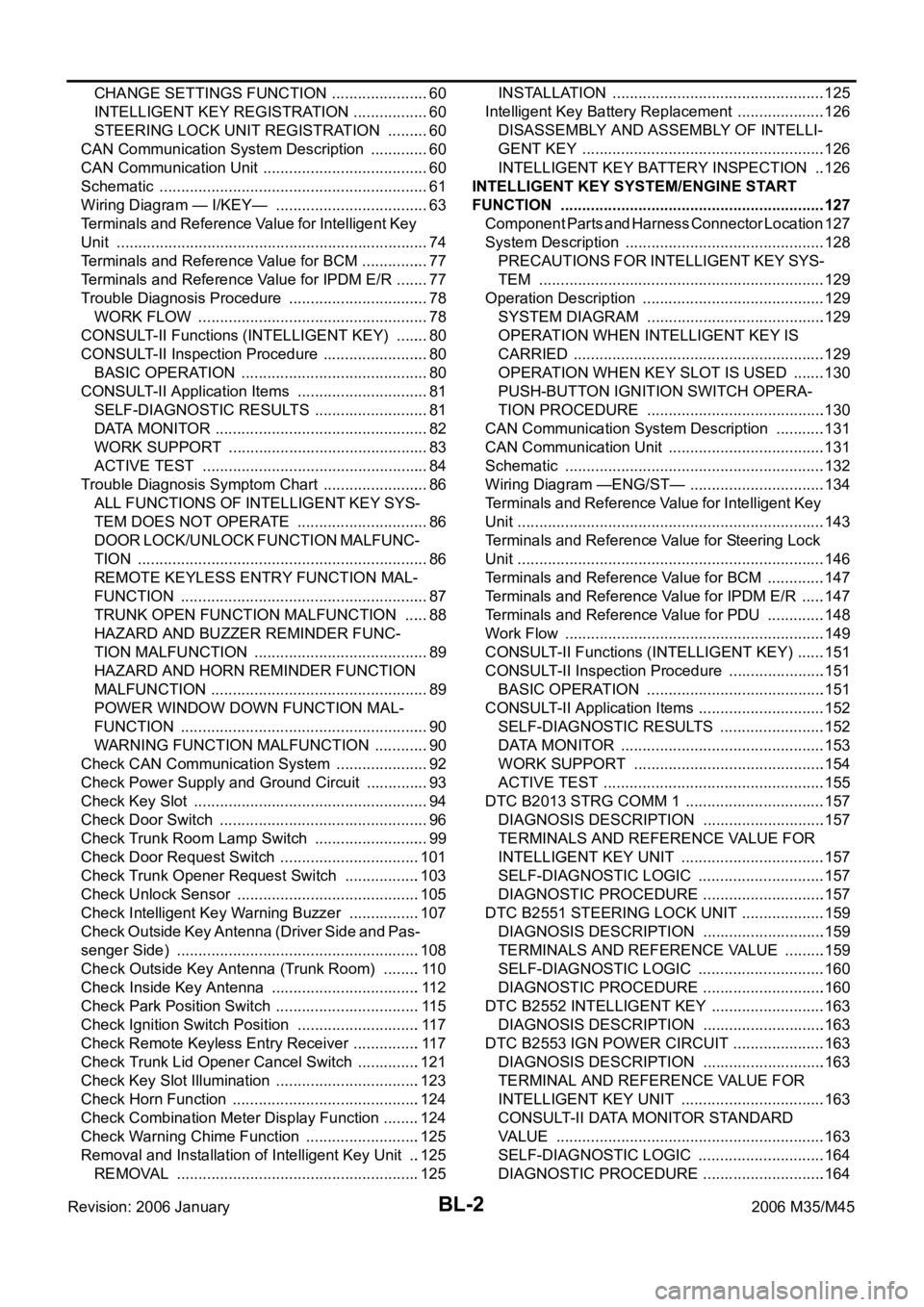

BL-2Revision: 2006 January2006 M35/M45 CHANGE SETTINGS FUNCTION ....................... 60

INTELLIGENT KEY REGISTRATION .................. 60

STEERING LOCK UNIT REGISTRATION .......... 60

CAN Communication System Description .............. 60

CAN Communication Unit ....................................... 60

Schematic ............................................................... 61

Wiring Diagram — I/KEY— .................................... 63

Terminals and Reference Value for Intelligent Key

Unit ......................................................................... 74

Terminals and Reference Value for BCM ................ 77

Terminals and Reference Value for IPDM E/R ........ 77

Trouble Diagnosis Procedure ................................. 78

WORK FLOW ...................................................... 78

CONSULT-II Functions (INTELLIGENT KEY) ........ 80

CONSULT-II Inspection Procedure ......................... 80

BASIC OPERATION ............................................ 80

CONSULT-II Application Items ............................... 81

SELF-DIAGNOSTIC RESULTS ........................... 81

DATA MONITOR .................................................. 82

WORK SUPPORT ............................................... 83

ACTIVE TEST ..................................................... 84

Trouble Diagnosis Symptom Chart ......................... 86

ALL FUNCTIONS OF INTELLIGENT KEY SYS-

TEM DOES NOT OPERATE ............................... 86

DOOR LOCK/UNLOCK FUNCTION MALFUNC-

TION .................................................................... 86

REMOTE KEYLESS ENTRY FUNCTION MAL-

FUNCTION .......................................................... 87

TRUNK OPEN FUNCTION MALFUNCTION ...... 88

HAZARD AND BUZZER REMINDER FUNC-

TION MALFUNCTION ......................................... 89

HAZARD AND HORN REMINDER FUNCTION

MALFUNCTION ................................................... 89

POWER WINDOW DOWN FUNCTION MAL-

FUNCTION .......................................................... 90

WARNING FUNCTION MALFUNCTION ............. 90

Check CAN Communication System ...................... 92

Check Power Supply and Ground Circuit ............... 93

Check Key Slot ....................................................... 94

Check Door Switch ..............................................

... 96

Check Trunk Room Lamp Switch ........................... 99

Check Door Request Switch .................................101

Check Trunk Opener Request Switch ..................103

Check Unlock Sensor ...........................................105

Check Intelligent Key Warning Buzzer .................107

Check Outside Key Antenna (Driver Side and Pas-

senger Side) .........................................................108

Check Outside Key Antenna (Trunk Room) .........110

Check Inside Key Antenna ...................................112

Check Park Position Switch ..................................115

Check Ignition Switch Position .............................117

Check Remote Keyless Entry Receiver ................117

Check Trunk Lid Opener Cancel Switch ...............121

Check Key Slot Illumination ..................................123

Check Horn Function ............................................124

Check Combination Meter Display Function .........124

Check Warning Chime Function ...........................125

Removal and Installation of Intelligent Key Unit ...125

REMOVAL ........................................................

.125INSTALLATION ..................................................125

Intelligent Key Battery Replacement .....................126

DISASSEMBLY AND ASSEMBLY OF INTELLI-

GENT KEY .........................................................126

INTELLIGENT KEY BATTERY INSPECTION ...126

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION ..............................................................127

Component Parts and Harness Connector Location .127

System Description ...............................................128

PRECAUTIONS FOR INTELLIGENT KEY SYS-

TEM ...................................................................129

Operation Description ...........................................129

SYSTEM DIAGRAM ..........................................129

OPERATION WHEN INTELLIGENT KEY IS

CARRIED ...........................................................129

OPERATION WHEN KEY SLOT IS USED ........130

PUSH-BUTTON IGNITION SWITCH OPERA-

TION PROCEDURE ..........................................130

CAN Communication System Description ............131

CAN Communication Unit .....................................131

Schematic .............................................................132

Wiring Diagram —ENG/ST— ................................134

Terminals and Reference Value for Intelligent Key

Unit ........................................................................143

Terminals and Reference Value for Steering Lock

Unit ........................................................................146

Terminals and Reference Value for BCM ..............147

Terminals and Reference Value for IPDM E/R ......147

Terminals and Reference Value for PDU ..............148

Work Flow .............................................................149

CONSULT-II Functions (INTELLIGENT KEY) .......151

CONSULT-II Inspection Procedure .......................151

BASIC OPERATION ..........................................151

CONSULT-II Application Items ..............................152

SELF-DIAGNOSTIC RESULTS .........................152

DATA MONITOR ................................................153

WORK SUPPORT .............................................154

ACTIVE TEST ....................................................155

DTC B2013 STRG COMM 1 .................................157

DIAGNOSIS DESCRIPTION .............................157

TERMINALS AND REFERENCE VALUE FOR

INTELLIGENT KEY UNIT ..................................157

SELF-DIAGNOSTIC LOGIC ..............................157

DIAGNOSTIC PROCEDURE .............................157

DTC B2551 STEERING LOCK UNIT ....................159

DIAGNOSIS DESCRIPTION .............................159

TERMINALS AND REFERENCE VALUE ..........159

SELF-DIAGNOSTIC LOGIC .............................

.160

DIAGNOSTIC PROCEDURE .............................160

DTC B2552 INTELLIGENT KEY ...........................163

DIAGNOSIS DESCRIPTION .............................163

DTC B2553 IGN POWER CIRCUIT ......................163

DIAGNOSIS DESCRIPTION .............................163

TERMINAL AND REFERENCE VALUE FOR

INTELLIGENT KEY UNIT ..................................163

CONSULT-II DATA MONITOR STANDARD

VALUE ...............................................................163

SELF-DIAGNOSTIC LOGIC ..............................164

DIAGNOSTIC PROCEDURE .............................164