INFINITI M35 2006 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 531 of 5621

ATC-84

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

SYSTEM DESCRIPTION

Component Parts

Air mix door control system components are:

Unified meter and A/C amp.

Air mix door motor (LCU)

A/C LAN system (PBR built-in mode door motor, upper ventilator door motor, air mix door motor and

intake door motor)

In-vehicle sensor

Ambient sensor

Sunload sensor

Intake sensor

System Operation

The unified meter and A/C amp. receives data from each of the sensors. The unified meter and A/C amp.

sends air mix door, mode door, upper ventilator door and intake door opening angle data to the air mix door

motor LCUs, mode door motor LCUs, upper ventilator door motor LCU and intake door motor LCU.

The air mix door motors, mode door motors, upper ventilator door motor and intake door motor read their

respective signals according to the address signal. Opening angle indication signals received from the unified

meter and A/C amp. and each of the motor position sensors are compared by the LCUs in each door motor

with the existing decision and opening angles. Subsequently, HOT/COLD, DEF/VENT, OPEN/SHUT and FRE/

REC operation is selected. The new selection data are returned to the unified meter and A/C amp.

Air Mix Door Control Specification

RJIA4217E

RJIA1782E

Page 532 of 5621

TROUBLE DIAGNOSIS

ATC-85

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

COMPONENT DESCRIPTION

Air Mix Door Motor

The air mix door motors are attached to the heater & cooling unit

assembly. It rotates so that the air mix door is opened or closed to a

position set by the unified meter and A/C amp. Motor rotation is then

conveyed through a shaft and the air mix door position feedback is

then sent to the unified meter and A/C amp. by PBR built-in air mix

door motor.

DIAGNOSIS PROCEDURE FOR AIR MIX DOOR MOTOR

SYMPTOM: Discharge air temperature does not change.

Perform diagnosis procedure. Refer to AT C - 7 0 , "

DIAGNOSIS PROCEDURE FOR LAN CIRCUIT" .

Air Mix Door Motor PBR CircuitNJS000GR

SYMPTOM:

Discharge air temperature does not change.

PBR circuit is open or shorted.

DIAGNOSIS PROCEDURE FOR AIR MIX DOOR MOTOR PBR

Perform diagnosis procedure. Refer to AT C - 7 0 , "DIAGNOSIS PROCEDURE FOR LAN CIRCUIT" .

RJIA4064E

RJIA4065E

Page 533 of 5621

ATC-86

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Intake Door Motor CircuitNJS000GS

SYMPTOM:

Intake door does not change.

Intake door motor does not operate normally.

INSPECTION FLOW

*1AT C - 5 6 , "FUNCTION CONFIRMA-

TION PROCEDURE", see No. 2 to 6.*2ATC-113, "

Ambient Sensor Circuit"*3AT C - 11 6 , "In-Vehicle Sensor Circuit"

*4AT C - 11 9 , "Sunload Sensor Circuit"*5ATC-83, "Air Mix Door Motor Cir-

cuit"

*6AT C - 5 6 , "FUNCTION CONFIRMA-

TION PROCEDURE", see No. 13.

*7AT C - 7 0 , "

LAN System Circuit"*8ATC-133, "INTAKE DOOR

MOTOR"

*9AT C - 6 4 , "Operational Check"

*10AT C - 4 1 , "SYMPTOM TABLE"*11ATC-122, "Intake Sensor Circuit"

RJIA4066E

Page 534 of 5621

TROUBLE DIAGNOSIS

ATC-87

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

SYSTEM DESCRIPTION

Component Parts

Intake door control system components are:

Unified meter and A/C amp.

Intake door motor (LCU)

A/C LAN system (PBR built-in mode door motor, upper ventilator door motor, air mix door motor and

intake door motor)

In-vehicle sensor

Ambient sensor

Sunload sensor

Intake sensor

System Operation

The intake door control determines intake door position based on the ambient temperature, the intake air tem-

perature and the in-vehicle temperature. When shifting mode position D/F, when the DEF or OFF switches

are pressed, or when A/C switch is OFF, the unified meter and A/C amp. sets the intake door at the FRESH

position.

Intake Door Control Specification

RJIA4214E

RJIA4067E

Page 535 of 5621

ATC-88

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

COMPONENT DESCRIPTION

Intake Door Motor

The intake door motor is attached to the blower unit. It rotates so that

air is drawn from inlets set by the unified meter and A/C amp. Motor

rotation is conveyed to a lever which activates the intake door.

DIAGNOSIS PROCEDURE FOR INTAKE DOOR MOTOR

SYMPTOM: Intake door motor does not operate normally.

Perform diagnosis procedure. Refer to AT C - 7 0 , "

DIAGNOSIS PROCEDURE FOR LAN CIRCUIT" .

RJIA4068E

Page 536 of 5621

TROUBLE DIAGNOSIS

ATC-89

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

Blower Motor CircuitNJS000GT

SYMPTOM: Blower motor operation is malfunctioning.

INSPECTION FLOW

*1ATC-64, "Operational Check"*2ATC-122, "Intake Sensor Circuit"*3ATC-56, "FUNCTION CONFIRMA-

TION PROCEDURE", see No. 2.

*4ATC-56, "

FUNCTION CONFIRMA-

TION PROCEDURE", see No. 6.*5AT C - 5 6 , "

FUNCTION CONFIRMA-

TION PROCEDURE", see No. 13.*6ATC-91, "

DIAGNOSIS PROCE-

DURE FOR BLOWER MOTOR"

*7ATC-41, "SYMPTOM TABLE"*8AT C - 11 3 , "Ambient Sensor Circuit"*9ATC-116, "In-Vehicle Sensor Circuit"

*10ATC-119, "Sunload Sensor Circuit"*11EC-226, "DTC P0117, P0118 ECT

SENSOR" (VQ35DE) or EC-948,

"DTC P0117, P0118 ECT SEN-

SOR" (VK45DE)

RJIA4069E

Page 537 of 5621

ATC-90

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

SYSTEM DESCRIPTION

Component Parts

Fan speed control system components are:

Unified meter and A/C amp.

A/C LAN system (PBR built-in mode door motor, upper ventilator door motor, air mix door motor and

intake door motor)

In-vehicle sensor

Ambient sensor

Sunload sensor

Intake sensor

System Operation

Automatic Mode

In the automatic mode, the blower motor speed is calculated by the unified meter and A/C amp. based on the

input from the PBR, in-vehicle sensor, sunload sensor, intake sensor and ambient sensor.

When the air flow is increased, the duty ratio of the blower fan motor’s drive signal is changed at 8%/sec. to

prevent a sudden increase in air flow.

In addition to manual air flow control and the usual automatic air flow control, starting air flow control, low

water temperature starting control and high passenger compartment temperature starting control are avail-

able.

RJIA4070E

Page 538 of 5621

TROUBLE DIAGNOSIS

ATC-91

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

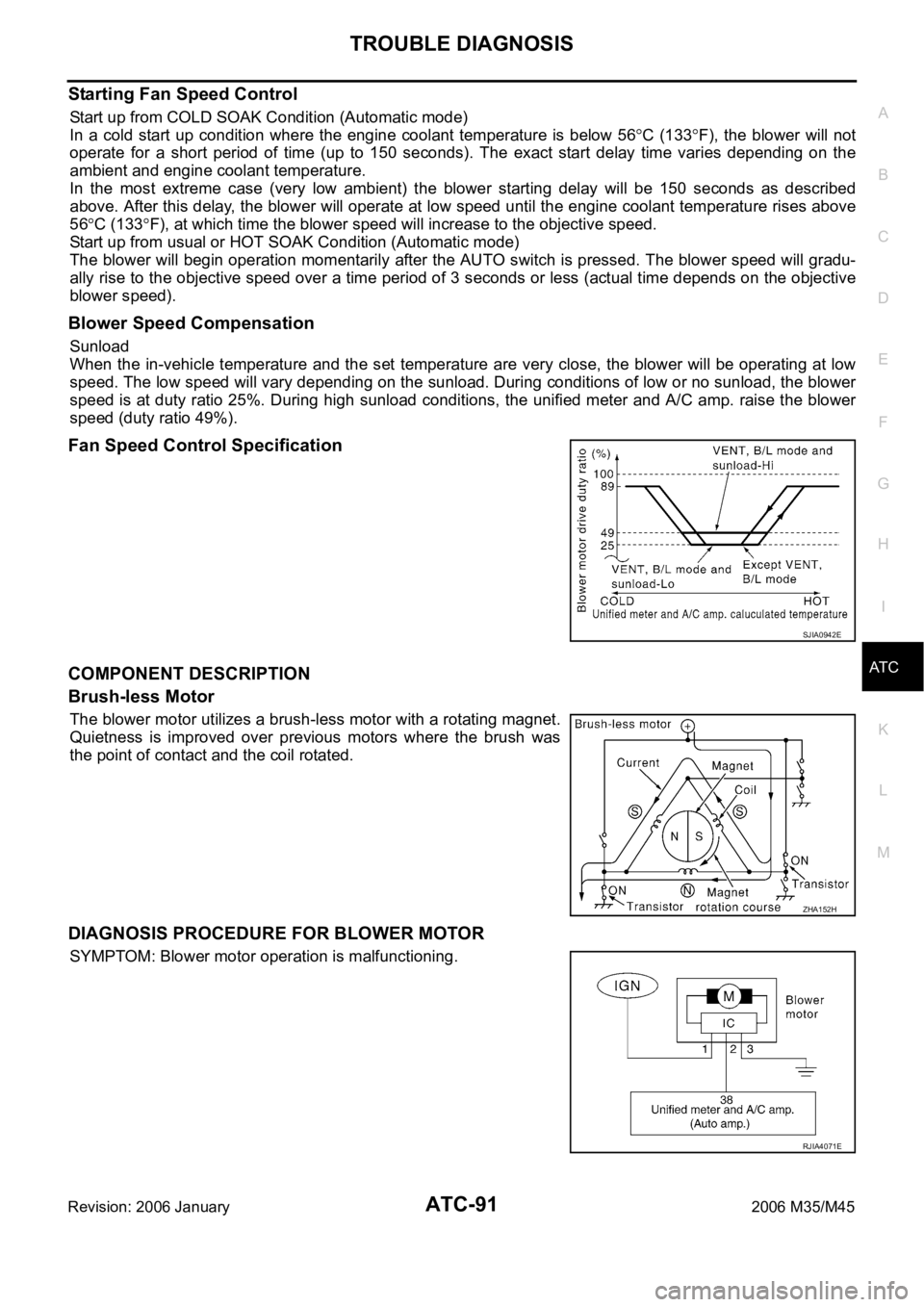

Starting Fan Speed Control

Start up from COLD SOAK Condition (Automatic mode)

In a cold start up condition where the engine coolant temperature is below 56

C (133F), the blower will not

operate for a short period of time (up to 150 seconds). The exact start delay time varies depending on the

ambient and engine coolant temperature.

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at low speed until the engine coolant temperature rises above

56

C (133F), at which time the blower speed will increase to the objective speed.

Start up from usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the AUTO switch is pressed. The blower speed will gradu-

ally rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. During conditions of low or no sunload, the blower

speed is at duty ratio 25%. During high sunload conditions, the unified meter and A/C amp. raise the blower

speed (duty ratio 49%).

Fan Speed Control Specification

COMPONENT DESCRIPTION

Brush-less Motor

The blower motor utilizes a brush-less motor with a rotating magnet.

Quietness is improved over previous motors where the brush was

the point of contact and the coil rotated.

DIAGNOSIS PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning.

SJIA0942E

ZHA152H

RJIA4071E

Page 539 of 5621

ATC-92

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

1. CHECK POWER SUPPLY FOR BLOWER MOTOR

1. Disconnect blower motor connector.

2. Turn ignition switch ON.

3. Check voltage between blower motor harness connector M91

terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> Check power supply circuit and 15A fuses [Nos. 10 and

11, located in the fuse block (J/B)]. Refer to P G - 111 ,

"FUSE BLOCK - JUNCTION BOX (J/B)" .

If fuses are OK, check harness for open circuit. Repair or replace if necessary.

If fuses are NG, check harness for short circuit and replace fuse.

2. CHECK BLOWER MOTOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between blower motor harness connector M91

terminal 3 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK CIRCUIT CONTINUITY BETWEEN BLOWER MOTOR AND UNIFIED METER AND A/C AMP.

1. Disconnect unified meter and A/C amp. connector.

2. Check continuity between blower motor harness connector M91

terminal 2 and unified meter and A/C amp. harness connector

M64 terminal 38.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.1 – Ground : Battery voltage

RJIA1997E

3 – Ground : Continuity should exist.

RJIA4072E

2 – 38 : Continuity should exist.

RJIA4073E

Page 540 of 5621

TROUBLE DIAGNOSIS

ATC-93

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

4. CHECK UNIFIED METER AND A/C AMP. OUTPUT SIGNAL

1. Reconnect blower motor connector and unified meter and A/C

amp. connector.

2. Turn ignition switch ON.

3. Change the fan speed from Lo to Hi, and check the duty ratios

between blower motor harness connector M91 terminal 2 and

ground by using an oscilloscope. Normal terminal 2 drive signal

duty ratios are shown in the table below.

OK or NG

OK >> Replace blower motor after confirming the fan air flow does not change.

NG >> Replace unified meter and A/C amp.

COMPONENT INSPECTION

Blower Motor

Confirm smooth rotation of the blower motor.

Ensure that there are no foreign particles inside the blower unit.

RJIA4074E

RJIA4075E

RJIA4076E