check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1506 of 5621

WARNING CHIME

DI-73

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

4. CHECK BATTERY POWER SUPPLY OF UNIFIED METER AND A/C AMP.

Check battery power supply of unified meter and A/C amp. Refer to DI-35, "

Power Supply and Ground Circuit

Inspection" in unified meter and A/C amp.

OK or NG

OK >> Replace BCM. Refer to BCS-17, "Removal and Installation of BCM" .

NG >> Repair battery power supply circuit of unified meter and A/C amp.

Lighting Switch Signal InspectionNKS003V9

1. CHECK BCM INPUT SIGNAL

1. Select “BCM” on CONSULT-II.

2. With “DATA MONITOR” of “BUZZER”, confirm “TAIL LAMP SW”

when the lighting switch is operated.

OK or NG

OK >> Lighting switch signal is OK. Return to DI-72, "SYMP-

TOM CHART" .

NG >> Check the lighting switch. Refer to LT- 2 3 0 , "

Switch Cir-

cuit Inspection" .

Front Door Switch (Driver Side) Signal InspectionNKS003VA

1. CHECK BCM INPUT SIGNAL

With CONSULT-ll

1. Select “BCM” on CONSULT-II.

2. With “DATA MONITOR” of “BUZZER”, confirm “DOOR SW-DR”

when the driver side door is opened/closed.

Without CONSULT-ll

Check voltage between BCM harness connector and ground.

OK or NG

OK >> Front door switch (driver side) signal is OK. Return to

DI-72, "

SYMPTOM CHART" .

NG >> GO TO 2.“TAIL LAMP SW”

Lighting switch ON (1st position) : ON

Lighting switch OFF : OFF

PKIC0697E

“DOOR SW-DR”

When driver side door is opened : ON

When driver side door is closed : OFF

SEL502W

Terminals

Condition

Voltage

(Approx.) (+)

(–)

BCM

connectorTerminal Driver side door:

M3 62 GroundOpen 0 V

Close 12 V

PKIB7662E

Page 1507 of 5621

DI-74

WARNING CHIME

Revision: 2006 January2006 M35/M45

2. CHECK FRONT DOOR SWITCH (DRIVER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front door switch (driver side)

connector.

3. Check continuity between BCM harness connector (A) and front

door switch (driver side) harness connector (B).

4. Check continuity between BCM harness connector (A) and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK FRONT DOOR SWITCH (DRIVER SIDE)

Check front door switch (driver side). Refer to DI-76, "

FRONT DOOR SWITCH (DRIVER SIDE)" .

OK or NG

OK >> Replace BCM. Refer to BCS-17, "Removal and Installation of BCM" .

NG >> Replace front door switch (driver side).

Seat Belt Buckle Switch Signal InspectionNKS003VB

1. CHECK BCM INPUT SIGNAL

1. Select “BCM” on CONSULT-II.

2. With “DATA MONITOR” of “BUZZER”, confirm “BUCKLE SW”

when the seat belt is fastened/unfastened.

OK or NG

OK >> Seat belt buckle switch signal is OK. Return to DI-72,

"SYMPTOM CHART" .

NG >> GO TO 2.

AB

Continuity

Connector Terminal Connector Terminal

M3 62 B11 2 Yes

A

GroundContinuity

Connector Terminal

M3 62 No

PKIB7663E

“BUCKLE SW”

When seat belt is fastened : OFF

When seat belt is unfastened : ON

SKIA8674E

Page 1508 of 5621

WARNING CHIME

DI-75

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

2. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between unified meter and A/C amp. harness

connector and ground.

OK or NG

OK >> Replace unified meter and A/C amp.

NG >> GO TO 3.

3. CHECK SEAT BELT BUCKLE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector and seat belt

buckle switch (driver side) connector.

3. Check continuity between unified meter and A/C amp. harness

connector (A) and seat belt buckle switch (driver side) harness

connector (B).

4. Check harness continuity between unified meter and A/C amp.

harness connector (A) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4. CHECK SEAT BELT BUCKLE SWITCH (DRIVER SIDE)

Check seat belt buckle switch (driver side). Refer to DI-76, "

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)" .

OK or NG

OK >> Check seat belt buckle switch (driver side) ground circuit.

NG >> Replace seat belt buckle switch (driver side).

Terminals

Condition

Voltage

(Approx.) (+)

(–)

Unified meter and

A/C amp. connectorTerminalSeat belt

(driver side):

M64 9 GroundFasten 12 V

Unfasten 0 V

PKIB7664E

AB

Continuity

Connector Terminal Connector Terminal

M64 9 B203 1 Yes

A

GroundContinuity

Connector Terminal

M64 9 No

PKIB7666E

Page 1509 of 5621

DI-76

WARNING CHIME

Revision: 2006 January2006 M35/M45

Electrical Component InspectionNKS003VC

FRONT DOOR SWITCH (DRIVER SIDE)

Check continuity between terminal 2 and door switch case ground.

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)

Check continuity between terminals 1 and 2.

Terminal Condition Continuity

2Door switch

case groundWhen door switch is released. Yes

When door switch is pushed. No

PKIC0245E

Terminal Condition Continuity

12When seat belt is unfastened. Yes

When seat belt is fastened. No

PKIB7665E

Page 1513 of 5621

DI-80

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

System Diagram

Components Description

NOTE:

*: This indicates in a few seconds for the system check during ignition switch ON.

POWER SUPPLY AND GROUND CIRCUIT

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 12, located in the fuse block (J/B)]

to LDW camera unit terminal 1.

Ground is supplied

to LDW camera unit terminals 6 and 12

through grounds M16 and M70.

Action TestNKS003VH

LDW SYSTEM RUNNING TEST

WAR NING :

Be careful when performing road test.

Understand “Precautions” and “System Description” well before the road test. Refer to DI-78,

"Precautions for Lane Departure Warning (LDW) system" and DI-78, "System Description" .

Function Check

Check the LDW system operation according to the condition that the warning function works. Refer to DI-78,

"LDW SYSTEM OPERATION" .

PKIC0698E

Component Description

LDW camera unitDetects the lane marker by the built-in camera, gives judgement for the warning according to the

result of detection and signals from each unit, and transmits the operation signal to LDW chime and

LDW indicator lamp.

LDW switch

Selects ON/OFF of the system.

Indicates ON/OFF of the signal with LDW system ON indicator.

LDW chime Gives a warning chime according to the direction from LDW camera unit.

LDW indicator lampInstalled in combination meter, and indicates the system condition.

Blinks when LDW system is functioning to alert the driver.

Stays on when LDW system is malfunctioning.*

BCM Transmits turn indicator signal to LDW camera unit with CAN communication signal.

ABS actuator and electric unit

(control unit)Transmits vehicle speed signal to LDW camera unit with CAN communication signal.

TCM Transmits vehicle speed signal to LDW camera unit with CAN communication signal. (For detecting

incorrect speed.)

Page 1514 of 5621

LANE DEPARTURE WARNING SYSTEM

DI-81

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

Camera Aiming AdjustmentNKS003VI

OUTLINE

Adjust the camera aiming every time the LDW camera unit is removed or installed.

CAUTION:

Place the vehicle on the level ground when the camera aiming adjustment is operated.

Follow the CONSULT-II when adjusting the camera aiming. (Camera aiming adjustment cannot be

operated without CONSULT-II.)

PREPARATION

Keep all tires inflated to correct pressures. Adjust the tire pressure to the specified pressure value.

There is no-load in vehicle. Check if coolant, engine oil are filled up to correct level and fuel tank is full.

Shift the gear into “P” position and release the parking brake.

Clean the windshield.

NOTE:

Do not place anything reflective on the upper surface of instrument panel.

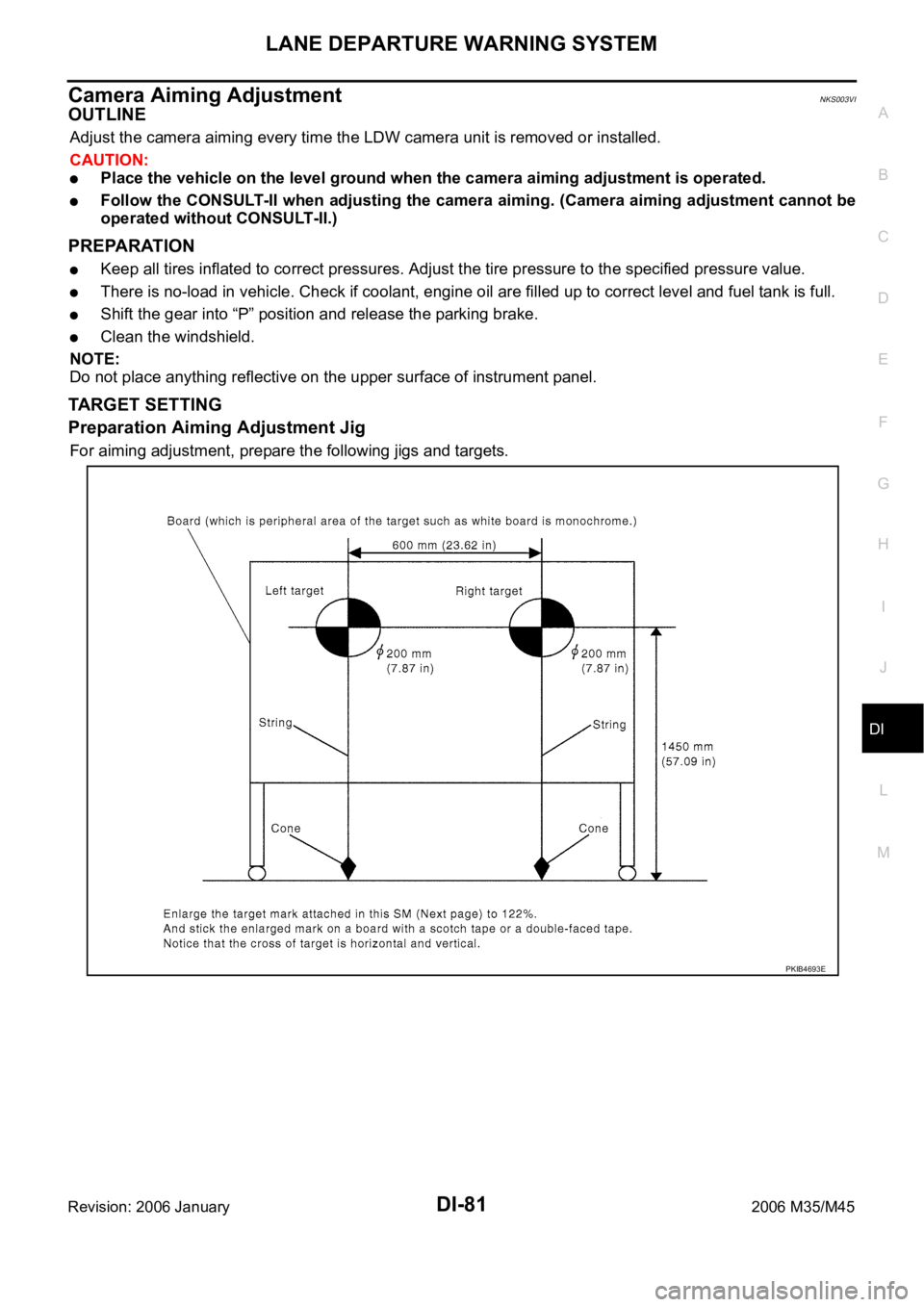

TARGET SETTING

Preparation Aiming Adjustment Jig

For aiming adjustment, prepare the following jigs and targets.

PKIB4693E

Page 1517 of 5621

DI-84

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

7. Mark point at the center of the point “E” and “F”, on the line

“FW”.

CAUTION:

Make sure that “E” through “X” is equal to “F” through “X”.

8. Position the center of the right target to the point of “X”.

VEHICLE HEIGHT CHECK

Measure the wheel arch height. And calculate “Dh”.

NOTE:

“Dh” may be calculated as a minus value.

AIMING ADJUSTMENT

Operation Procedure

CAUTION:

Perform the adjustment under unloaded vehicle condition.

LDW indicator is turned off after the removal/installation, and blinks after replacement.

1. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II CONVERTER to the data link connector, and then turn

ignition switch ON.

2. Start the engine, wait for at least 10 seconds, and touch “START

(NISSAN BASED VHCL)”.

PKIB7668E

Dh [mm] = (Hfl + Hfr) 2 731

where,

Hfl: Front left wheel arch height [mm]

Hfr: Front right wheel arch height [mm]

PKIB7669E

SKIB3794E

BCIA0029E

Page 1519 of 5621

DI-86

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

7. Touch “NEXT”, then a keyboard window is displayed. Input “Dh”,

and then touch “ENTER”.

NOTE:

Check the value “Dh”. Refer to DI-84, "

VEHICLE HEIGHT

CHECK" .

8. Check the regulated value. (Spec.)

NOTE:

Check the value input at step 8.

a. Touch “NEXT” if appropriate.

b. Touch “CHANGE SET” to change “Dh”.

9. Touch “NEXT”.

CAUTION:

Never change “Ht”.

10. Touch “NEXT”.

CAUTION:

Never change “Dt”.

SKIB3147E

SKIB3148E

SKIB3149E

SKIB3173E

Page 1520 of 5621

LANE DEPARTURE WARNING SYSTEM

DI-87

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

11. Touch “START”.

12. Check the display item.

a. When “NORMALLY COMPLETED” is displayed, touch “COM-

PLETION”.

b. Perform the following services when displayed “SUSPENSION”

or “ABNORMALLY COMPLETED”.

NOTE:

Replace camera unit if “suspension” is repeatedly indicated though the above two service is performed.

13. Check if “NORMALLY COMPLETED” is displayed and close the

aiming adjustment procedure by touching “END”.

Check After The Adjustment

1. Perform the LDW camera unit self-diagnosis. Refer to DI-91, "CONSULT-II Function (LDW)" .

2. Test the LDW system operation by running test. Refer to DI-80, "

LDW SYSTEM RUNNING TEST" .

SKIB3150E

SKIB3151E

SKIB3152E

Displays item Service procedure

SUSPENSION00H Routine not activated

Position the target appropriately, and perform the aiming again.

Refer to DI-81, "

Camera Aiming Adjustment" . 10H Writing error

ABNORMALLY COMPLETED —

SKIB3153E

Page 1524 of 5621

LANE DEPARTURE WARNING SYSTEM

DI-91

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

Terminals and Reference Value for LDW Camera UnitNKS003VL

NOTE:

*: Perform “ACTIVE TEST” with CONSULT-II. Refer to DI-94, "

ACTIVE TEST" .

CONSULT-II Function (LDW)NKS003VM

DESCRIPTION

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II BASIC OPERATION

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II CONVERTER to the data link connector, and then turn

ignition switch ON.

Terminal

No.Wire

colorItemCondition

Reference value

(Approx.) Ignition

switchOperation or condition

1 B/R Ignition switch ON or START ON — Battery voltage

3R/WLDW chime ONLDW chimeActivated

*0 V

Not activated 12 V

4 V System ON indicator ON LDW systemON 0 V

OFF 12 V

5 P CAN L — — —

6 B Ground ON — 0 V

8 G/W LDW indicator lamp ON LDW indicator lamp Illuminated

*0 V

Turned OFF 12 V

9 GR LDW switch ON LDW switchPushed 0 V

Released 5 V

10 L CAN H — — —

12 B Ground ON — 0 V

System Diagnosis mode DescriptionReference

page

LDWWORK SUPPORT Displays causes of automatic cancellation of the LDW system.DI-92

SELF-DIAG RESULTS Displays malfunctioning system memorized in LDW camera unit.DI-92

DATA MONITOR Displays real-time input/output data of LDW camera unit.DI-93

CAN DIAG SUPPORT MNTR Displays the results of transmit/receive diagnosis of CAN communication.LAN-7

ACTIVE TEST Enables operation check of electrical loads by sending driving signal to them.DI-94

ECU PART NUMBER Displays part number of LDW camera unit. —

SKIB3794E